Abstract

The usage of cellulosic fibers as fillers for thermoplastics has generated great interest due to their numerous advantages and benefits compared to conventional fibers. This article examines a comparative study on the mechanical, thermal, and morphological properties of polypropylene/polyethylene (PP/PE)/cellulose (sugarcane bagasse (SCB) and softwood (SW)) blend composites prepared through melt compounding. The morphology of the obtained PP/PE/SCB and PP/PE/SW blend composites was investigated using scanning electron microscopy (SEM). The X-ray diffraction (XRD) analysis showed reduced crystallinity of the PP/PE blend after fiber interaction. Thermal results showed that the PP/PE/SW blend was more thermally stable compared to the PP/PE/SCB blend. Additionally, the onset temperature of main degradation decreased with th e incorporation of extracted celluloses. Differential scanning calorimetry (DSC) analysis revealed that the introduction of SCB or SW raw fiber and extracted celluloses did not significantly change the melting and crystallization behavior of the PP/PE blend. Dynamic mechanical analysis (DMA) revealed that the storage modulus of the PP/PE/SCB raw and PP/PE/SW raw materials were lower than their corresponding cellulose blend composites across the temperature range studied.

1. Introduction

The use of cellulosic fibers as fillers in thermoplastics has recently attracted scientific interest due to increasing environmental awareness and governmental regulations on sustainable development. These fibers offer numerous benefits and are readily available. They are biodegradable, nontoxic, and environmentally friendly. Additionally, cellulose-based fillers have the potential to significantly enhance the mechanical performance of composites, even when used in low concentrations [1,2,3,4,5]. Polymer blending is a convenient method for formulating novel polymeric materials that possess superior properties compared to individual polymers. Polypropylene (PP) and polyethylene (PE) are among the mostly used thermoplastics due to their excellent characteristics, including processability, high strength, recyclability, and low costs [6,7,8,9]. These thermoplastic polymers find various applications in industries such as including automotive, medical, packaging, construction, and building, among others. Thermoplastic blends offer many desirable intermediate properties, even if they are immiscible to each other. Additionally, the addition of cellulosic fibers impacts the morphology, thermal, and mechanical properties of thermoplastic blends [10,11,12,13]. However, the drawback of these blends is the incompatibility of cellulose fillers with hydrophobic polymer matrices. This incompatibility often results in a weak filler–matrix interface and low interfacial interaction. Cellulosic fillers also have a strong tendency to agglomerate [4]. Many studies have attempted to improve the mechanical properties of PP/PE blends by incorporating various compatibilizers, such as maleic anhydride, and grafted polymers, among others [7]. Gao et al. [14] conducted a study on the mechanical and rheological properties of wood/thermoplastics composites made from PP/PE blends grafted with maleic anhydride. Their findings revealed that grafting with anhydride grafting led to an increase in the tensile and flexural strength of the resulting PP/PE/wood composites, as compared to the nongrafted samples. The introduction of anhydride groups in the PP/PE blend improved the dispersion and interfacial bonding of wood particles within the blend matrix, which was supported by SEM analyses. In another study, Dikobe et al. [15] investigated the thermal and mechanical properties of composites made from a blend of PP, PE, and wood powder (WP). The results showed an improvement in the mechanical properties which was attributed to a stronger interaction between maleic-anhydride-grafted polypropylene (MAPP) and WP. The Young’s modulus and the stress at break increased and decreased, respectively, with an increase in WP content in the composites. Additionally, the introduction of WP increased the thermal stability of the PP/HDPE blend. SEM analysis also revealed enhanced dispersion of WP in the PP/HDPE blend. Hammache et al. [6] also reported similar improvements in mechanical properties, morphology, and thermal stability when investigating the effect of blending thermoplastic starch (TPS) and PP/PE using polyethylene-grafted maleic anhydride (PE-g-MA) in composite blends.

According to Nagamine et al. [12], the compatibility of the fiber with polyolefins can also be achieved through surface modification of cellulose fibers using reactive agents such as polydopamine and octadecylamine, which make the fiber hydrophobic. In their study, the modified cellulose microfibers (CMFs) exhibited improved dispersibility in the PP matrix because of reduced hydrophilicity. Furthermore, increasing the CMF content and surface modification of the CMFs resulted in higher tensile modulus and yield stress. Taufiq et al. [16] developed a wood plastic composite using a blend of recycled PP/PE (rPP/PE) reinforced with kenaf fiber. The results confirmed that the introduction of kenaf fiber improved the flexural strength and modulus, with the maximum improvements observed at weight loading of 30%. Additionally, the results showed that there was reduction in the melting point and degree of crystallinity of r-PP/PE with an increase in kenaf fiber beyond 30% loading. To address the poor performance of PE/PP blends, it is possible to transform them into microfibrillar composites (MFCs) [9]. MFCs are materials comprising a thermoplastic polymer matrix that is reinforced with microfibrils of another thermoplastic polymer. The MFCs have great potential for large-scale application in immiscible recycled polyolefin, and their final properties can be improved by modifying their morphology.

PP and PE are generally incompatible and have a phase separation morphology during their cooling and crystallization processes. According to Siengchin and Dangtungee [13], the crystallization process can have a significant impact on polymer blends’ morphological features, thermal properties, and mechanical properties. The study by Polaskova et al. [11] reported that the addition of PP to PE enhances the polyethylene’s ability to withstand environmental stress cracks and improves the modulus and yield stress of the resulting blend. There have been various studies on PP/PE blend composites in the literature, which have investigated mechanical and morphological properties using different fillers and compatibilizers [17,18,19]. However, to the best of our knowledge, there has never been a systematic comparison of PP/PE/SCB and PP/PE/SW blend composites. This study aims to explore the impact of raw fiber and alkaline-treated cellulose at a lower content (5%) on the properties of PP/PE blend without the use of a compatibilizer.

Moreover, this study aims to establish the potential application of different biomasses to address environmental challenges.

2. Experimental

2.1. Materials

PP was supplied by Sasol Polymers (Johannesburg, South Africa). It has a density of 0.90 g cm−3, a melting point of 165 °C, and a melt flow index (MFI) of 12 g/10 min. Low-density polyethylene (LDPE) was supplied by Sasol Polymers (Johannesburg, South Africa); it has a density of 0.956 g cm−3, a melting point of 136 °C, and an MFI of 2.0 g/10 min. Sodium hydroxide (NaOH) pellets (99.9%) were supplied by Merck (Mumbai, India), and sodium chlorite by Capital lab Suppliers CC (New Germany, South Africa). SCB and SW raw materials were collected from the sugar milling and wood industries, respectively, in Empangeni, South Africa.

2.2. Extraction of Cellulose from SCB and SW

SCB and SW celluloses were extracted from their respective fibers using a method described in the literature [20]. Briefly, the SCB and SW samples were washed and immersed in a water bath at room temperature for 24 h before being dried at 60 °C over-night. Then, the SCB and SW were treated with an alkali solution (2 wt% NaOH) at 100 °C for 4 h. The celluloses were then filtered and washed several times with distilled water until they reached a neutral pH. This process was repeated four times. The same treatment was performed using a 1.7 wt% sodium chlorite solution buffered with acetic acid. Finally, the suspensions were allowed to cool and rinsed with deionized water until they reached neutral pH.

2.3. Sample Composition of SCB and SW

The cellulose and lignin content were analyzed by a reaction with sulfuric acid (H2SO4) according to a standard method recommended in TAPPI-T222 om-88. The hemicellulose content was obtained using the procedure described in TAPPI T19m-54 standards [21].

2.4. Preparation of Blend Composites

The composite blends were prepared according to the ratios indicated in Table 1. The samples were mixed in a Brabender Plastograph internal mixer (Brabender, Duisburg, Germany) at a temperature of 190 °C and a mixing speed of 30 rotations per minute (rpm) for 15 min. Afterwards, the samples were melt-pressed at 200 °C and 100 bar for 3 min, followed by cooling at room temperature for 10 min.

Table 1.

The formulation of PP/PE, PP/PESCB, and PP/PE/SW blend composites (by mass ratio).

3. Characterization

3.1. Fourier-Transform Infrared Spectroscopy (FTIR)

The FTIR spectra were collected by using a Perkin Elmer FTIR spectrometer (Stillwater, GA, USA) in the absorbance mode. The samples were analyzed as synthesized with no prior preparation required. The force was adjusted to 90 gauges for sufficient contact between the surfaces. The samples were scanned over the mid-IR region (450–4000 cm−1).

3.2. X-ray Diffraction (XRD)

Powder X-ray diffraction spectroscopy (Bruker AXS Advance X-Ray diffractometer, Karlshure, Germany) with monochromatic Cu Kα (λ = 1.5406 Å) incident radiation at 40 kV and 40 mA was used to examine the crystal structure of all samples.

The crystallinity index (CI) was determined by using the deconvolution method and peak height method (see Equations (1) and (2)), respectively.

where Aa is the area of the amorphous phase and At is the total area of the diffractogram;

where I002 is the maximum intensity of the 002 peak, and Iam is minimal depression of the amorphous structure.

CI = (1 − Aa/At) × 100 (%)

CI = (I002 − Iam)/Iam × 100

The crystalline sizes of PP composites were obtained by using Scherer’s Equation (3) based on full width at half maximum (FWHM).

where CS = crystalline size, K = constant (0.89), λ = wavelength (0.154 nm), B = FWHM in (radians), and cos θ = 2 θ peak.

CS = Kλ/ßCOSθ

3.3. Thermogravimetric Analysis (TGA)

Thermogravimetric analyses were performed using a TGA analyzer unit (Perkin Elmer) under a flowing nitrogen atmosphere at a flow rate of 20 mL min−1. Approximately 10–15 mg of sample was heated from 30 °C to 700 °C at a heating rate of 10 °C·min−1. The weight loss and rate of weight loss of the sample were continuously recorded as functions of temperature. The analysis only started once isothermal condition had been achieved.

3.4. Differential Scanning Calorimetry (DSC)

The DSC tests were conducted using a DSC analyzer unit (Perkin Elmer) under a flowing nitrogen atmosphere at a flow rate of 20 mL min−1. Approximately 10–15 mg of the sample was heated from room temperature to 200 °C at a heating rate of 10 °C·min−1. The fractional crystallinity was calculated using Equation (2).

where ∆H is the heat of fusion of the sample, w is the weight fraction of blend, and the heats of fusion (∆Hm) for crystalline PP and PE correspond with 209 and 293 Jg−1, respectively [22].

3.5. Scanning Electron Microscopy (SEM)

The surface morphologies of composite blends were analyzed by a SEM analyzer (SEM, model-ZEISS, Jena, Germany) with electrons accelerated at 5 eV. Prior to analysis, samples were coated with gold by means of a sputter-coater for ease of conduction.

3.6. Dynamic Mechanical Analysis (DMA)

The DMA tests were performed in three-point bending mode on a DMA Q800 (DMA, TA Instruments, New Castle, DE, USA) machine using the following parameters: frequency: 1 Hz; temperature range: −70 to 110 °C; heating rate: 5 °C·min−1; force: 1 N.

4. Results

4.1. Sample Compositions of SCB and SW

The sample compositions of SCB and SW are shown in Table 2. It can be observed that both fibers were primarily composed of cellulose, with lignin and hemicellulose present in lesser content. SCB appeared to have a higher hemicellulose content, but lower lignin content compared with SW, with approximately a 20% difference for each. This trend in SCB composition aligns with the previous literature [22,23,24,25]. It is also known that the composition of fibers can vary depending on factors such as the origin of a plant, harvesting period, a domain of the plant, and the aging process [1,3].

Table 2.

Sample compositions of SCB and SW fibers.

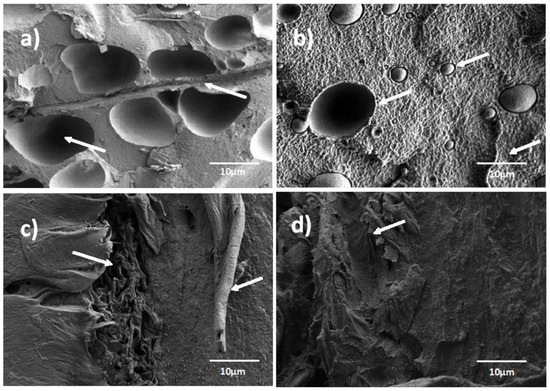

4.2. Scanning Electron Microscopy

Figure 1a–d represent the SEM microstructure of fractured surfaces of PP/PE blend composites containing SCB, SW, and their extracted celluloses. In general, the images show fiber pull-outs and vacant spaces left by the PE phase. Figure 1a (see arrows) contains more vacant spaces than the rest, arguably followed by Figure 1b (see arrows). The phase separation seems suppressed in Figure 1c,d. Loose and hanging fibers are visible in Figure 1c (see arrows), while clear and large pull-outs are seen in Figure 1d (see arrows). Similar observations were reported in other studies that investigated the fracture surfaces of PP/PE/wood-based composites without a compatibilizer [14,15]. The observations were related to poor adhesion between the fiber particles and the matrix blend, which could be the case in the current study. However, the absence of surface separation in this study case of Figure 1c,d may suggest a stronger interaction compared to Figure 1a,b.

Figure 1.

SEM images of (a) PP/PE/SCB untreated 5%, (b) PP/PE/SCB cellulose 5%, (c) PP/PE/SW untreated 5%, and (d) PP/PE/SW cellulose 5% blend composites.

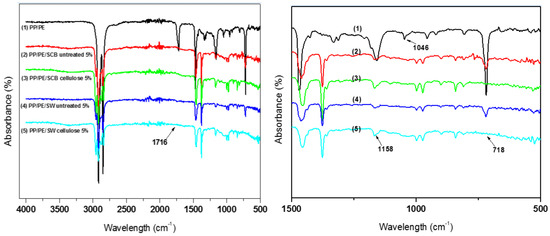

4.3. Fourier-Transform Infrared Spectroscopy

The FTIR spectra of PP/PE, PP/PE/SCB, and PP/PE/SW blend composites are shown in Figure 2. The spectra of PP/PE and all blend composites show main absorbance peaks at around 2915 cm−1, 1716 cm−1, and 1469 cm−1. These peaks are associated with the –CH asymmetric, –CH3 symmetric, and the scissor modes of the –CH stretching of both PP and PE, respectively. Moreover, there are other small peaks at around 1158 cm−1 and 718 cm−1, which are associated with –CH3 symmetric deformation and –CH2 rocking vibration [15,22]. The peak attributed to the hydroxy (–OH) group from fiber materials, as well as intramolecular and intermolecular hydrogen bonds at 3340 cm−1, is more pronounced in the blend containing cellulose [26,27]. This may be due to the stretching and wagging of the groups as cellulose possibly migrates to a more compatible phase. The peaks at 1716 cm−1 and 1046 cm−1 are completely absent with the addition of SCB and SW fiber or cellulose, indicating an interaction between the blend and fibers. Furthermore, the PP/PE blends spectra exhibit –CH2 rocking vibrations around 718 cm−1, which are not present in the cellulose containing blend composites [28]. This disappearance is caused by the decrease in intermolecular hydrogen bonding between the treated fiber and PP/PE.

Figure 2.

FTIR spectra of PP/PE, PP/PE/SCB, and PP/PE/SW blend composites.

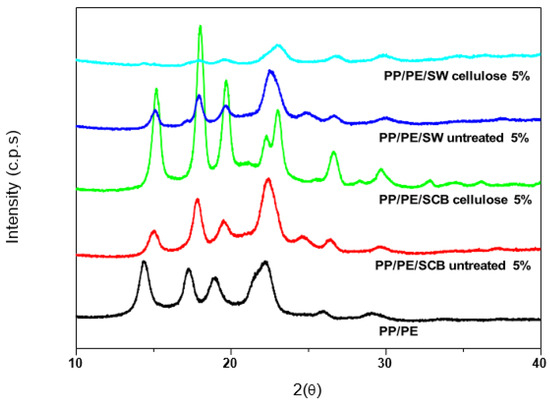

4.4. X-ray Powder Diffraction

The XRD patterns of PP/PE, PP/PE/SCB, and PP/PE/SW blend composites are displayed in Figure 3, and Table 3 summarizes the crystallinity index and size. The PP/PE blend patterns consist of crystalline peaks at 14.38° (110), 17.29° (040), 18.96° (130), and 22.24° (041), which are typical crystal lattices of α PP [29]. Furthermore, there are also peaks at 21.6 (110) and 23.4 (200), which correspond to orthorhombic PE lattices, and halo bump peaks at 26.01° and 29.09° [8,22]. The introduction of both untreated fibers and cellulose generally reduced the intensities of crystalline peaks, except for PP/PE/SCB with 5% cellulose. This is normally attributed to swelling of the amorphous domain due to the defects created by the fiber [16,17]. It is also evident that the introduction of cellulosic fiber did not change the crystalline structure of the PP/PE blend. However, in the case of PP/PE/SCB cellulose 5%, it seems that whatever cellulose derivative formed has favored more of the crystal lattices of PP. These observations are verified by the crystalline sizes, which were shown to increase with disruption of crystalline lattices (Table 3). Moreover, the PP/PE/SW cellulose 5% and PP/PE/SCB cellulose 5% displayed the highest crystallite size and lowest crystallinity compared to their fiber counterparts. The reason might be due to an increase in PP/PE crystalline interplanar distance because of strong cellulose interaction, caused by a decrease in intermolecular hydrogen bonding, as discussed in the FTIR results.

Figure 3.

XRD spectra of PP/PE/SCB and PP/PE/SW blend composites.

Table 3.

Crystallinity index of materials.

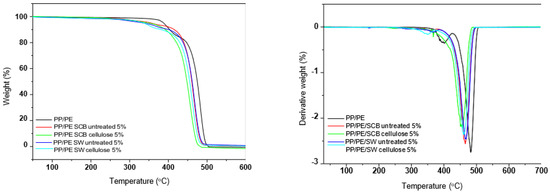

4.5. Thermogravimetric Analysis

Figure 4 presents the TGA and DTG of PP/PE, PP/PE/SCB, and PP/PE/SW blend composites, and their respective degradation temperatures are summarized in Table 4. The PP/PE blend showed two-stage decomposition which is related to the degradation of neat PP and PE, respectively, in the blend [15]. Furthermore, the PP/PE/SCB and PP/PE/SW blend composites displayed two degradation steps. In this case, the first step shifted to lower temperatures compared to the pristine blend. It is known that low thermal stability of fiber/cellulose has the potential to lower the degradation temperatures of polymer composites [2,13]. However, in this study, the fiber seems to have an intermediary degradation temperature with the PP. The thermal decomposition results in Table 4 indicate that all the blend composites are thermally less stable compared to the neat PP/PE blend. None, except poor interfacial interactions, can better explain the observation as seen from SEM images. In fact, cellulose containing blend composites appeared to be the least thermally stable compared to untreated ones. While cellulose derivatives and thermal degradation mechanisms are possible reasons [20], vacant space and poor distribution of fiber, as witnessed in SEM, and resulting crystallinity could also account for the observations. On the contrary, Dikobe et al. [15], in their study, observed an increase in thermal stability with the introduction of WP. They related the improved thermal stability to WP char decomposition, which acted as a barrier that delayed the heat transfer to the polymer matrices. In this study, this is not necessarily the case because the introduction of untreated filler and cellulose appeared to have accelerated the degradation of the PP/PE.

Figure 4.

TGA and DTGA graphs of PP/PE/SCB and PP/PE/SW blend composites.

Table 4.

DTG peaks temperatures of all the investigated samples.

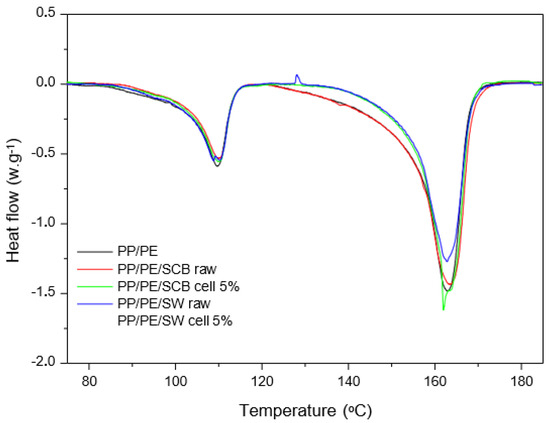

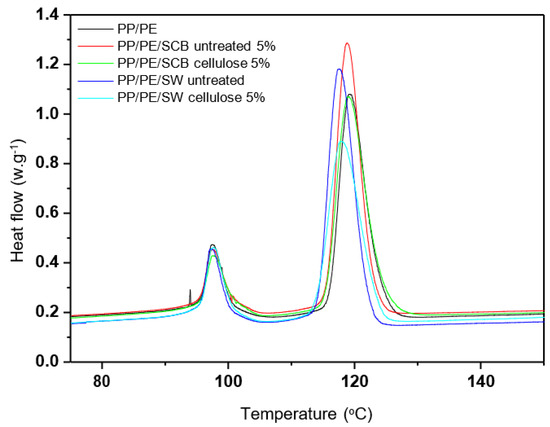

4.6. Differential Scanning Calorimetry

The DSC melting and crystallization curves are shown in Figure 5 and Figure 6, respectively. Table 5 summarizes the results obtained for melting temperature (Tm), crystallization temperature (Tc), heat of fusion (∆H), and crystallinity ratio (Xc). The PP/PE blend clearly displays two well-separated melting peaks for all composites, corresponding to the Tm of LDPE and PP components at low and high temperatures, respectively [17,19]. The DSC data summarized in Table 5 indicate that the introduction of untreated fiber and cellulose does not significantly change the melting and crystallization behavior of both PE and PP. Darweesh et al. [7] also reported minimal changes with variations in the blend compositions in their studies. The slight change to lower temperatures for the melting temperature of PP was correlated to a change in crystal structure. Similar observations were also reported by Khanam et al. [2] who investigated the recycled polymer-based date palm fiber reinforced composites. However, in our case, there is a delayed crystallization for blend composites. According to Dikobe et al. [23], a small variation in the crystallization temperature of the PE influences the fiber to locate in PE, which leads to the crystallization route of the blend composites. The rationale is highly possible in the current study; however, it seems as though the SCB cellulose was dispersed almost homogeneously on both phases since its crystallization appeared to be more stable than that of the blend composites containing SW cellulose. Perhaps it is for that reason that it has shown exceptional crystallinity in XRD. As expected, the melting enthalpy (∆Hm) of PP and PE decreased with the introduction of fiber and cellulose due to the decrease in polymer matrix quantity [25], signaling that lower crystallinity developed for the two components [8]. This decreasing trend of crystallinity was also reported in the XRD investigation. There is also a huge difference in the observed enthalpy (∆Hobs) values and calculated (∆Hcalc) values of PE as compared with PP. This might indicate that the crystallization behavior of PE is probably influenced by the presence of fiber and celluloses in the blend composites.

Figure 5.

DSC melting graphs of PP/PE, PP/PE/SCB, PP/PE/SW blend composites.

Figure 6.

DSC crystallization graphs of PP/PE, PP/PE/SCB, and PP/PE/SW blend composites.

Table 5.

DSC data of PP/PE, PP/PE/SCB, and PP/PE/SW blend composites.

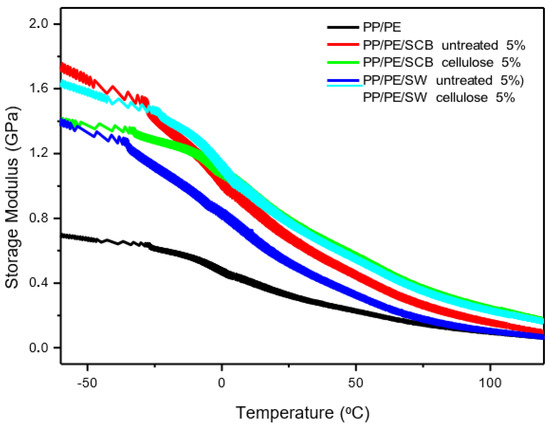

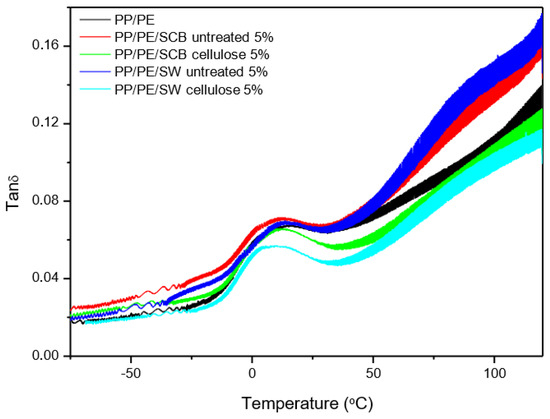

4.7. Dynamic Mechanical Analysis

The storage modulus and Tan δ curves of PP/PE/SCB and PP/PE/SW blend composites are presented in Figure 7 and Figure 8, respectively. In general, the storage modulus decreased with an increase in temperature, with a sharp drop expected around the glass transition temperature (Tg) due to enhanced mobility of the polymer chains [24]. It can be observed that all blend composite materials had a higher storage modulus compared to PP/PE blend. This increase cannot be attributed to a rise in crystallinity, as the DSC results indicated a reduction in crystallinity with the introduction of fibers. Instead, it is likely due to effective stress transfer from the matrix to fibers and interfacial interaction [23]. The storage modulus of the blend composites displayed no general pattern with the introduction of fiber/cellulose at lower temperatures. However, the cellulose blends seemed to have a higher storage modulus around the Tg before the occurrence of viscoelastic deformation of the polymer [25,26].

Figure 7.

Storage modulus graph of PP/PE, PP/PE/SCB, and PP/PE/SW blend composites.

Figure 8.

Tan δ graph of PP/PE, PP/PE/SCB, and PP/PE/SW blend composites.

The tan δ values in Figure 8 increased with a temperature increase before and after the glass transition temperature of the blend. The untreated SCB and SW blend composites appear to have higher tan δ compared to cellulose counterparts, likely due to strong restriction of the mobility of their polymer chains [26]. Furthermore, both the untreated and cellulose introduction did not cause a significant shift in Tg of the blend, except for a small variation and broadening of the peak in blends incorporated with cellulose. The Tg shift in this case might be related to better interfacial interaction between the celluloses and PP/PE blend, as highlighted in the FTIR results. In addition, the broadening of the peak might be due to an increase in the segmental relaxation time of the polymer matrix caused by polymer–filler interaction [23].

5. Conclusions

The effect of sugarcane bagasse, softwood, and their extracted cellulose on the mechanical, thermal, and morphological properties of polypropylene/polyethylene (PP/PE) blends was investigated in this study. TGA results showed that the introduction of cellulosic fibers did not enhance the thermal stability of the PP/PE blend. The cellulose blend composites appeared to be the least thermally stable compared to untreated fibers. The blend composite materials had a higher storage modulus compared to the PP/PE blend, with the PP/PE/SCB untreated blend displaying the highest storage modulus. The current results showed that the mechanical properties of the PP/PE blend could be improved with addition of cellulosic fibers, even at lower filler content. DSC analysis revealed that the introduction of untreated fiber and extracted cellulose did not change the melting and crystallization behavior of the PP/PE blend. The crystallinity index decreased with the introduction of fiber and cellulose, as confirmed by DSC and XRD results. The fractured surfaces of the PP/PE blend showed poor interfacial adhesion between the PP and PE, signaling immiscibility and poor interaction. Moreover, SEM analysis revealed less interaction and poor dispersion of SCB and SW filler with the PP/PE blend. These results show the dependence of morphology on the fabrication method and interfacial interaction. The introduction of a compatibilizer may significantly enhance the interaction between the PP/PE blend and the cellulosic fibers. Lastly, it is evident that the modification of the fabrication method has the potential for large-scale production of immiscible PP/PE blends with improved properties. The surface modification of cellulose fibers with various reactive agents needs to be explored further if the compatibilizers are not utilized.

Author Contributions

Conceptualization, T.E.M.; Investigation, S.M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research work was funded by the National Research Fund (NRF) of South Africa.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to this is a development research in our research group.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bledzki, A.K.; Letman, M.; Viksne, A.; Rence, L. A comparison of compounding processes and wood type for wood fibre-PP composites. Compos. Part A 2005, 36, 789–797. [Google Scholar] [CrossRef]

- Khanam, P.A.; Al-Maadeed, M.A. Improvement of ternary recycled polymer blend reinforced with date palm fibre. Mater. Des. 2014, 60, 532–539. [Google Scholar] [CrossRef]

- Devadiga, D.G.; Bhat, K.S.; Mahesha, G.T.; Sánchez, J. Sugarcane bagasse fiber reinforced composites: Recent advances and applications. Cogent Eng. 2020, 7, 1823159. [Google Scholar] [CrossRef]

- Palange, C.; Johns, M.A.; Scurr, D.J.; Phipps, J.S.; Eichhorn, S.J. The effect of the dispersion of microfibrillated cellulose on the mechanical properties of melt-compounded polypropylene–polyethylene co-polymer. Cellulose 2019, 26, 9645–9659. [Google Scholar] [CrossRef]

- Madhu, S.; Devarajan, Y.; Natrayan, L. Effective utilization of waste sugarcane bagasse filler-reinforced glass fibre epoxy composites on its mechanical properties—waste to sustainable production. Bio-Mass Convers. Biorefin. 2023, 13, 15111–15118. [Google Scholar] [CrossRef]

- Hammache, Y.; Serier, A.; Chaoui, S. The effect of thermoplastic starch on the properties of polypropylene/high density polyethylene blend reinforced by nano-clay. Mater. Res. Express 2020, 7, 025308. [Google Scholar] [CrossRef]

- Darweesh, M.H.; Stoll, B.; El-Taweel, S.H. Compatibilization of polypropylene/high-density polyethylene blends using poly(propylene-co-ethylene). J. Appl. Polym. Sci. 2023, 140, e53687. [Google Scholar] [CrossRef]

- Chiu, F.C.; Yen, H.Z.; Lee, C.E. Characterization of PP/HDPE blend-based nanocomposites using dif ferent maleated polyolefins as compatibilizers. Polym. Test. 2010, 29, 397–406. [Google Scholar] [CrossRef]

- Rosales, C.; Aranburu, N.; Otaegi, I.; Pettarin, V.; Bernal, C.; Müller, A.J.; Guerrica-Echevarría, G. Improving the mechanical performance of LDPE/PP blends through microfibrillation. ACS Appl. Polym. Mater. 2022, 4, 3369–3379. [Google Scholar] [CrossRef]

- Ansari, F.F.; Granda, L.A.; Joffe, R.; Berglund, L.A.; Vilaseca, F. Experimental evaluation of anisotropy in injection molded polypropylene/wood fiber biocomposites. Compos. Part A 2017, 96, 147–154. [Google Scholar] [CrossRef]

- Polaskova, M.; Cermak, R.; Sedlacek, T.; Kalus, J.; Obadal, M.; Saha, P. Extrusion of polyethylene/polypropylene blends with microfibrillar-phase morphology. Polym. Compos. 2010, 31, 1427–1433. [Google Scholar] [CrossRef]

- Nagamine, S.; Mizuno, Y.; Hikima, Y.; Okada, K.; Wang, L.; Ohshima, M. Reinforcement of polypropylene by cellulose microfibers modified with polydopamine and octadecylamine. J. Appl. Polym. Sci. 2021, 138, e49851. [Google Scholar] [CrossRef]

- Siengchin, S.; Dangtungee, R. Polyethylene and polypropylene hybrid composites based on nano sil icon dioxide and different flax structures. J. Thermoplast. Compos. Mater. 2014, 27, 1428–1447. [Google Scholar] [CrossRef]

- Gao, H.; Xie, Y.; Ou, R.; Wang, Q. Grafting effects of polypropylene/polyethylene blends with maleic anhydride on the properties of the resulting wood–plastic composites. Compos. Part A 2012, 43, 150–157. [Google Scholar] [CrossRef]

- Dikobe, D.G.; Luyt, A.S. Thermal and mechanical properties of PP/HDPE/wood powder and MAPP/HDPE/wood powder polymer blend composites. Thermochim. Acta 2017, 654, 40–50. [Google Scholar] [CrossRef]

- Taufiq, M.J.; Mansor, M.R.; Mustafa, Z. Characterisation of wood plastic composite manufactured from kenaf fibre reinforced recycled-unused plastic blend. Compos. Struct. 2018, 189, 510–515. [Google Scholar] [CrossRef]

- Su, B.; Zhou, Y.G.; Wu, H.H. Influence of mechanical properties of polypropylene/low-density polyethylene nanocomposites: Compatibility and crystallization. Nanomater. Nanotechnol. 2017, 7, 1–11. [Google Scholar] [CrossRef]

- Sarker, B.; Dey, K. Effect of incorporation of polypropylene on the physico-mechanical and thermo-mechanical properties of gelatin fiber based linear low density polyethylene bio-foamed composite. J. Thermoplast. Compos. Mater. 2011, 24, 679–694. [Google Scholar] [CrossRef]

- Fang, C.; Nie, L.; Liu, S.; Yu, R.; An, N.; Li, S. Characterization of polypropylene–polyethylene blends made of waste materials with compatibilizer and nano-filler. Compos. Part B 2013, 55, 498–505. [Google Scholar] [CrossRef]

- Mohomane, S.M.; Motaung, T.E.; Revaprasadu, N. Thermal degradation kinetics of sugarcane bagasse and softwood cellulose. Materials 2017, 10, 1246. [Google Scholar] [CrossRef]

- Costa, L.A.D.; Fonêsca, A.F.; Pereira, F.V.; Druzian, J.I. Extraction and characterization of cellulose nanocrystals from corn stover. Cell. Chem. Technol. 2015, 49, 127–133. [Google Scholar]

- Lin, J.H.; Pan, Y.J.; Liu, C.F.; Huang, C.L.; Hsieh, C.T.; Chen, C.K.; Lin, Z.I.; Lou, C.W. Preparation and compatibility evaluation of polypropylene/high density polyethylene polyblends. Materials 2015, 8, 8850–8859. [Google Scholar] [CrossRef] [PubMed]

- Dikobe, D.G.; Luyt, A.S. Comparative study of the morphology and properties of PP/LLDPE/wood powder and MAPP/LLDPE/wood powder polymer blend composites. Express Polym. Lett. 2010, 11, 729–741. [Google Scholar] [CrossRef]

- Moubarik, A.; Grimi, N.; Boussetta, N. Structural and thermal characterization of Moroccan sugar cane bagasse cellulose fibers and their applications as a reinforcing agent in low density polyethylene. Compos. Part B 2013, 52, 233–238. [Google Scholar] [CrossRef]

- El-Fattah, A.A.; El-Demerdash, A.G.M.; Sadik, W.A.A.; Bedir, A. The effect of sugarcane bagasse fiber on the properties of recycled high density polyethylene. J. Compos. Mater. 2015, 49, 3251–3262. [Google Scholar] [CrossRef]

- Zulkifli, N.I.; Samat, N.; Anuar, H.; Zainuddin, N. Mechanical properties and failure modes of recycled polypropylene/microcrystalline cellulose composites. J. Mater. Des. 2015, 69, 114–123. [Google Scholar] [CrossRef]

- Manzato, L.; Rabelo, L.C.A.; de Souza, S.M.; da Silva, C.G.; Sanches, E.A.; Rabelo, D.; Mariuba, L.A.M.; Simonsen, J. New approach for extraction of cellulose from tucuma’s endocarp and its structural characterization. J. Mol. Struct. 2017, 1143, 229–234. [Google Scholar] [CrossRef]

- Shamsuri, A.A.; Azid, M.K.A.; Ariff, A.H.M.; Sudari, A.K. Influence of surface treatment on tensile properties of low-density polyethylene/cellulose woven biocomposites: A preliminary study. Polymers 2014, 6, 2345–2356. [Google Scholar] [CrossRef]

- Spoljaric, S.; Genovese, A.; Shanks, R.A. Polypropylene–microcrystalline cellulose composites with enhanced compatibility and properties. Compos. Part A 2009, 40, 791–799. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).