Abstract

The permeability characteristics of tailings directly affect the position of the infiltration line of the tailings dam, which is the most critical factor affecting tailings dam failures. In order to fully analyze the essence of its permeability characteristics, computed tomography (CT) technology is used to analyze the structure of different types of tailings from a microscopic perspective and carry out microscopic seepage simulation. The results showed the following findings: (1) The porosity of viscous tailings ranges from 25 to 35%, the distribution of surface porosity along the height is relatively uniform, and the distribution is shown as having a certain discrete nature with the increase in particle size. (2) Compared with silty and sandy tailings, the surface of viscous tailings is smoother and more round, and the shape factor can reach 0.95; (3) The data gap between the simulation and the measurements by CT scanning technology is less than 10%, and the estimation of the permeability characteristics is feasible, with good applicability in the simulation of tailings seepage. (4) In the microscopic pore throat structure, the permeability characteristics of the tailings are more affected by the radius of the throat than the pore radius, and the exponential function relationship between the permeability coefficient and the porosity satisfies a high correlation. In this paper, the relationship between the microstructure and permeability characteristics of tailings is analyzed by CT technology; the permeability is simulated and calculated, and a permeability coefficient prediction model for tailings is proposed in combination with the experiment, which can provide a new idea and method for the study of the permeability characteristics of tailings.

1. Introduction

There are very rich mineral resources in China, with billions of tons of tailings discharged every year, and the amount of waste tailings remaining after beneficiation is even greater [1]. The treatment of tailings often takes the form of damming and storing on the surface, which have the advantages of being low cost and simple treatments, and can also realize the resource utilization of tailings. In the long-term operation of tailings ponds, a major problem is the safety and stability of the dam, prone to failure due to seepage damage to the tailings ponds [2]. A large number of studies and engineering practices at home and abroad show that the location of the seepage infiltration line of the dam body is the most critical influencing factor for seepage failure in a tailings dam, and the most critical internal factor affecting the location of the infiltration line is undoubtedly the permeability characteristics of the dam tailings.

Mei Haifeng [3] analyzed the factors influencing the seepage characteristics of tailings dams and the changes in infiltration lines in different dry beach lengths and different upstream and downstream slope ratios in actual engineering based on the basic theory of seepage. Wang Qiang [4] used ANSYS to simulate the seepage field of tailings dams, and concluded that the initial dam permeability coefficient had the greatest influence on the change in infiltration line. Yin Guangzhi et al. [5] took the coarse and fine tailings sands from two mines in Yunnan Province as test materials, compared and studied the seepage laws of coarse and fine tailings sands during dam construction, and found that the damming infiltration line of fine tailings was higher than that of coarse tailings. Although a large number of scholars have analyzed the seepage mechanism, most of them relied on laboratory experiments or numerical simulations, and there are few studies on the relationship between the particle structure and permeability characteristics of the tailings material itself.

The tailings are the grinding beneficiation waste, in the form of silty and fine sand, and their particle properties determine the permeability characteristics of the dam body; if the mechanical characteristics of the fine-grained tailings are poor, it is difficult to consolidate the actual project, which brings difficulties to the fine-grained dam. With the development of beneficiation technology, fine-grained damming and high-pile damming will become the main development directions, so it is necessary to study the structural characteristics and permeability characteristics of tailings particles. As an important parameter to characterize permeability characteristics, the permeability coefficient is a key parameter in the field of geotechnical engineering, and a large number of scholars at home and abroad have carried out a great deal of research. Yang Xi et al. [6] carried out an indoor variable head test on iron tailings, and established a calculation formula for the permeability coefficient of iron tailings from multiple perspectives such as gradation and particle size. Yang Bing [7] studied the effects of average particle size and the inhomogeneity coefficient of sand on the permeability coefficient by using the constant head test, and found that the permeability coefficient tended to be stable when the inhomogeneity coefficient of sand increased to 11. Kozeny–Carman [8,9] proposed an empirical formula for the permeability coefficient of Corson–Kármán specifically for sandy soils, and considered density to be the key parameter affecting the permeability coefficient of soil. Mesri et al. [10] proposed a K = BeA permeability model for cohesive soils based on the formula of the permeability coefficient of sandy soils, where e is the porosity ratio, and A and B are the proportional parameters proposed by different cohesive soils for the Kozeny–Carman formula. Although many scholars have carried out research on the permeability coefficient, most of the research objects are a single type of soil, and the tailings are a kind of sand–silt–clay mixed soil structure in the accumulation process of actual engineering, so it is necessary to study the prediction model of the tailings permeability coefficient with different particle sizes.

In general, the previous studies mainly focused on the discussion of the macroscopic mechanical properties of tailings, but the structural characteristics and permeability characteristics of tailings from a microscopic perspective were rarely studied. The microscopic pore structure and particle morphology of tailings can well characterize their physical properties, which are of great significance for the microscopic analysis of tailings materials [11]. In recent years, with the advancement and innovation of image processing technology (DIP), X-ray computed tomography (X-ray CT) has been widely used in the field of material microscopy; it can be used to perform 3D imaging and nondestructively analyze the microscopic features of objects [12]. This technology has been widely used in the study of rock and soil, but the study of the microstructure and permeability characteristics of tailings has rarely been reported.

In this paper, the Zeiss Xradia 410 Versa (Oberkochen, Germany) high-performance micron CT scanner was used to scan tailings samples with different particle sizes, and the microscopic information of the tailings was obtained to characterize the morphological characteristics of the grains. Based on the pore throat model of the tailings, a microscopic seepage simulation was carried out in combination with the indoor variable head test, and a feasible permeability coefficient model based on different particle size tailings was proposed, which provided a new method for the study of the permeability characteristics of tailings, and at the same time, provided a new perspective for the study of permeability characteristics of other types of soil.

2. Specimen Preparation and CT Image Acquisition

The accumulation of a tailings dam is composed of sandy, silty and viscous tailings, and the permeability characteristics of tailings with different particle sizes are quite different. The permeability coefficient of coarse-grained tailings is often about 10−4 cm/s, while the permeability coefficient of fine-grained tailings is very small, generally more than 10−6 cm/s−10−7 cm/s, and some are even less than 10−7 cm/s, with a difference of 2–3 orders of magnitude. Therefore, the accurate description of the microstructure and the permeability characteristics of tailings with different particle sizes can provide a new idea for the study of seepage failure in tailings dams by combining CT test and laboratory permeability tests.

2.1. Specimen Preparation

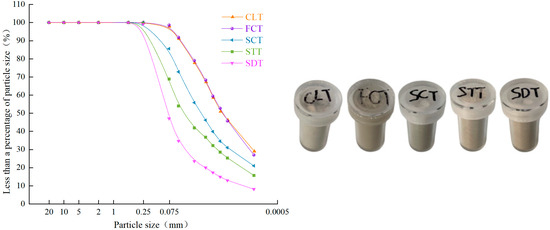

In this paper, cylindrical glass tubes with a diameter of 9 mm and a height of 30 mm that meet the requirements of the CT testing machine were used to collect tailings samples with different particle sizes. Clay tailings are abbreviated as CLT, clay tailings in iron ore are abbreviated as FCT, silty-clayey tailings are abbreviated as SCT, silty tailings are abbreviated as STT, and sandy tailings are abbreviated as SDT. In the following paper, different types of tailings samples are discussed by abbreviation. The porosity of the sample was measured by mercury intrusion test; the sample was saturated with vacuum to make its saturation greater than 95%, and then the permeability coefficient was measured by the indoor variable head test. The basic physical parameters of each sample are shown in Table 1, and the gradation curve between the sample and the particle is shown in Figure 1.

Table 1.

Basic physical characteristics of tailings samples.

Figure 1.

Tailings samples and particle gradation curves.

2.2. Introduction to Micro-Ct Equipment and CT Image Acquisition

The experiment uses the Zeiss Xradia 410 Versa high-performance micron CT scanner produced by Carl Zeiss in German city of Oberkochen., which includes a high-precision sample stage, a closed X-ray source, a Macro-70 (0.4×) detector, a 4×, 20× detector (objective lens), an automatic detector lens turntable, and a computer workstation. The tailings samples were scanned, and 1014 micron-level high-precision CT images were obtained for each sample in 16-bit Tiff format, each slice was 1024 × 1024 pixels, and the distance between adjacent slices was a two-dimensional pixel unit. The main parameters of the instrument are shown in Table 2.

Table 2.

The main parameters of the instrument.

2.3. CT Image Processing and 3D Reconstruction

In the detection process of CT scanned objects, it can be seen from the Lambert–Beer law [13] theorem that the attenuation of the intensity of X-rays when passing through a homogeneous object can be expressed by Equation (1), and the decay law of energy intensity when X-rays penetrate the detected object is shown in Figure 2:

where I0 is the incident X-ray intensity, I1 is the attenuated ray intensity, μ is the absorption density of the object per unit mass, and L is the projection thickness of the detected object.

I1 = I0 exp(−µL)

Figure 2.

The attenuation of energy as X-rays penetrate the object being inspected.

The processing of digital images consists of two parts: pre-processing and threshold segmentation. The purpose of pre-processing is to eliminate the noise part of the experimental process and retain some small details in the original image, so as to improve the clarity of image restoration. Threshold segmentation is based on the fact that different phases will correspond to different gray value ranges, so as to divide their corresponding voxel sets to obtain different regions, and these regions have the same properties inside, so as to extract the part we need. The brightness difference method and binarization are used to output all the data within the selected threshold range as 1, and the rest of the data are output as 0. As shown in Figure 3, the binarized black and white image data and the corresponding 3D model can be obtained, in which the black dots are pores and the white is the matrix.

Figure 3.

Binarized comparison chart: (a) original grayscale map (b) binary processing effect (c) original grayscale 3D model (d) binary 3D model.

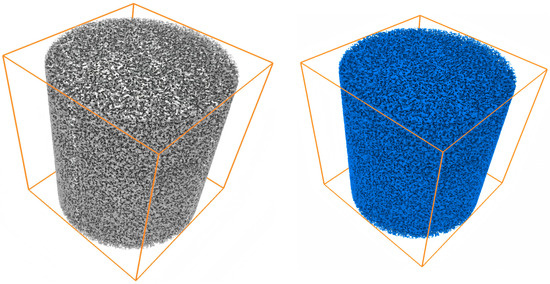

The binary image after digital image processing was imported into the AVIZO-2022 software to reconstruct the image to realize the three-dimensional visual characterization of the tailings sample. Because the upper and lower ends are closely attached to the acrylic material during scanning, there are areas at the ends that are too bright or too dark for 3D representation, so in order to better reconstruct the image, only the middle part of the slice with better imaging is reconstructed in 3D. Figure 4 shows the three-dimensional visualization space stacking reconstruction model of a CLT specimen reconstruction.

Figure 4.

Three-dimensional visualization of tailings accumulation reconstruction model.

2.4. Three-Dimensional Rendering Model

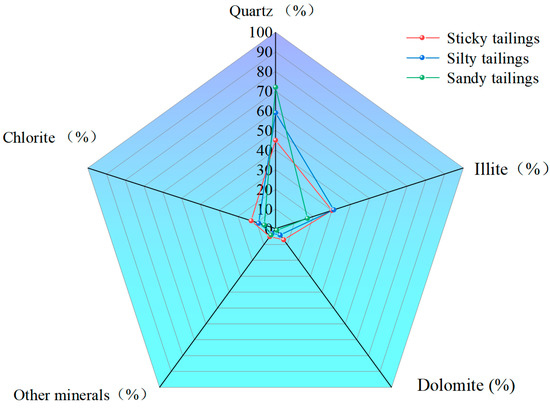

The gray value of the same substance has a large range and is not a single value, and the key to threshold segmentation lies in how to accurately find a suitable threshold. The gray value of the pixel is repeatedly compared with the selected threshold, so as to distinguish the target area into different parts. In order to avoid errors in quantitative analysis due to improper selection of thresholds, the optimal threshold was determined by referring to the porosity ratio obtained from the experiment. In the original 2D CT grayscale image, the black ones are pores, the highlighted white material is minerals, and the rest of the gray ones are soil-like matrices. In order to render the tailings model more clearly, the mineral composition contained in it was tested. XRD diffraction tests were performed on three different types of tailings using the D8 Advance X-ray diffractometer (Bruker AG, Berlin, Germany), and the mineral composition was mainly composed of quartz, chlorite, dolomite, illite, and trace amounts of other components, such as calcite, metallic minerals, etc. The test results can be seen in Table 3, which is plotted as a five-dimensional radar distribution map, as shown in Figure 5.

Table 3.

Results of X-ray diffraction test of tailings.

Figure 5.

Radar map of mineral component content distribution of tailings.

As can be seen from Figure 5, the highest mineral content in tailings is quartz, and a three-dimensional rendering model of the tailings was established on this basis, as shown in Figure 6. Figure 6 illustrates in detail the process of tailings from 2D grayscale (Figure 6a) to color rendering (Figure 6b) and then 3D reconfiguration into a model (Figure 6c) and the meaning of the different colors (Figure 6d). Clay, quartz, and pores are rendered green, red, and blue, respectively.

Figure 6.

Rendering process diagram of 3D reconstruction of tailings (a) 2D grayscale (b) 2D rendering (c) 3D rendering (d) 3D models.

3. Microscopic Characterization of Tailings Particles

3.1. Pore Extraction

According to the microstructure of tailings, the thresholds of materials corresponding to different gray values were selected and divided in the original image, and the interactive threshold segmentation was used to extract the black pores with low brightness in the gray image. However, due to the presence of mineral components and the high overall brightness of the high-density components after scanning, the brightness of the internal pore structure is slightly high, which is close to the brightness of the high-density components, so it is difficult to directly extract the pores by the brightness difference method alone. Therefore, the “Top-hat Threshold” was used to extract the details in the image, and the results obtained by the two were combined with the “or image” command to obtain a more accurate pore structure. The pore extraction process is shown in Figure 7.

Figure 7.

(a) Grayscale graph, (b) threshold segmentation, (c) local segmentation, (d) the two are jointly identified, (e) the two are combined to extract the pores.

The volume of pore and soil particles was VP and VS, respectively, and the overall porosity ωp was calculated by Equation (2), and the results are shown in Table 4.

Table 4.

Porosity of each specimen.

3.2. Layer-by-Layer Porosity

The layer-by-layer change in surface porosity along the height of the sample can reflect the specific distribution of pores in the tailings sample to a certain extent. The layer-by-layer porosity analysis of the tailings samples was carried out, and the spatial distribution curve of the porosity of the slice along the height of the sample was plotted, as shown in Figure 8.

Figure 8.

Profile of porosity along height.

It can be seen from Figure 8 that the apparent porosity of CLT, FCT and SCT was between 20 and 30%, and the distribution along the height was relatively uniform, which was very close to the overall porosity. The porosity of STT slices was mainly concentrated in the range of 30–35%, and the porosity of each layer gradually decreased along the height; the porosity of SDT slices was mainly concentrated in the range of 40–50%, showing a trend of first increasing and then decreasing. It can be seen that the porosity range of the slice can reflect the overall porosity to a certain extent, and it has a certain discrete nature with the increase in tailing particle size.

3.3. Microstructure Characterization

In the two-dimensional characterization of microscopic particles, Barrett [14] believes that there are three independent properties, namely, the description of the overall contour (roundness) of the particle, the description of the smoothness of the edges and corners of the particle (convexity), and the description of the surface texture (roughness) of the particle. The characterization of tailings’ particle morphology is the key to the characterization of the tailings’ microstructure, and its roundness can be described by the form factor FS. The form factor is the ratio of the perimeter of the particle boundary to the circumference of a circle of the same area as the particle, which will directly affect the accumulation characteristics of the tailings, change the porosity and permeability path of the tailings, and most importantly, it is closely related to the shear strength of the tailings. It can be calculated according to Equation (3) [15].

where P is the perimeter of the particle; r is the equivalent radius.

According to Equation (3), the shape factor of the circle is 1.0, and it can be seen that the closer the shape factor value is to 1, the closer the particle is to a circle, and the roundness reflects the degree to which the overall contour of the particle is close to a circle. Taking the CLT sample as an example, the histogram of its frequency distribution and the trend change plot are shown in Figure 9.

Figure 9.

Shape factor distribution and trend change chart. (a) Distribution histogram; (b) change in shape factor of tailings.

As can be seen from Figure 9, the shape factor of the tailings particles is mainly distributed between 0.8 and 1.1, and the particles in this interval are more than 90%. It can be seen that the two-dimensional morphology of particles is mainly approximate to an ellipse. A comprehensive comparison of viscous tailings, silty tailings and sandy tailings shows that the circularity will decrease slightly with the increase in tailings particle size, but the overall situation is relatively stable, with the value ranging from 0.7 to 1.1, and the average value is maintained around 0.875. The parameters for characterizing the morphological size of the particles are shown in Table 5, and the particles are analyzed and calculated according to the parameters listed in the table. A schematic diagram of the structure of the characterization of physical parameters is shown in Figure 10.

Table 5.

Basic size parameters of particle morphology.

Figure 10.

Basic parameters of particle morphology.

The convexity (C) can describe the degree of depression of the projection surface profile of the particle, and the closer this value is to 1, the fewer the edges and depressions in the particle, and the smoother the surface, which can be calculated by Equation (4) [16].

The convexities of CLT, FCT, SCT, STT and SDT were 0.861, 0.877, 0.927, 0.859 and 0.851, respectively. It can be seen that the tailings samples had fewer edges and corners, and the surface was relatively smooth.

The surface roughness R can be defined in terms of Equation (5): the ratio of the particle boundary perimeter P1 to the particle circumference P2 [17]:

R can be described by the fractal dimension, a two-dimensional fractal dimension is a number greater than 1 and strictly less than 2; the higher the fractal dimension, the rougher the surface. On the basis of the Hausdorff dimension, the box counting method is widely used in the calculation of fractal dimensions because of its simple method and small error, and the fractional dimension is called the box dimension [18], which is defined in Equation (6) as follows:

where D is the dimension of the box, is the size of the covered unit, and is the number of covered elements.

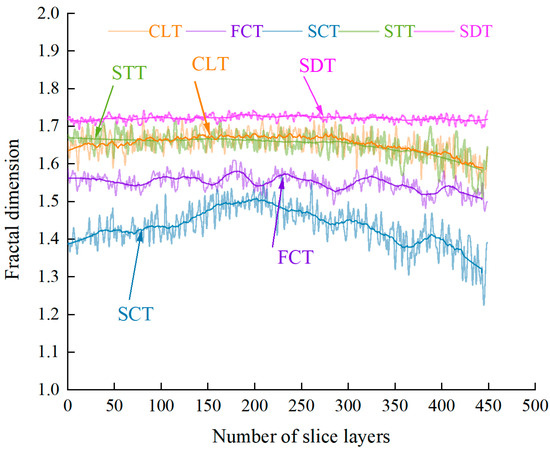

The fractal dimension of the image was calculated by using the fractal dimension function of AVIZO, and the result was plotted as shown in Figure 11.

Figure 11.

Fractal dimensions of tailings sample.

It can be seen from Figure 11 that the fractal dimensions of CLT, FCT and SCT clay tailings particles were between 1.2 and 1.7; they fluctuate greatly with the number of slice layers, and STT and SDT fluctuate around 1.7 without obvious change. The results show that the smaller the particle size, the smoother the surface, and the lower the surface fluctuation in the clay particles.

3.4. Three-Dimensional Pore Throat Model and Parameter Analysis

At present, the most widely used method for extracting 3D pore throat models is the “maximum sphere method”, which is simple, stable, and can accurately preserve the distribution and connectivity features of pore throats [19]. The largest ball method is used to simplify the hole throat to obtain a model composed of a large number of balls and sticks, which is called the “ball stick model”. The model includes pores and throats, and finding out the relationship between the two can provide further understanding of the microscopic characteristics inside the specimen. The pore-network modeling analysis module was used to calculate the maximum spherical model in AVIZO, and the pore–throat model of the tailings sample was established, as shown in Figure 12, where the sphere represents the connected pores in the soil sample and the cylinder represents the throat between the pores.

Figure 12.

Model of tailing specimens and balls.

The number, radius, coordination number, and number, radius, and length of the roar are the key parameters of the model, which all restrict the permeability of tailings. Pore coordination refers to the number of roaring channels connected to the pores, which is a key parameter to reflect the connectivity of the pore throat-network model. In general, it is believed that the larger the average coordination number, the stronger the connectivity between the pores, and the greater the permeability, as shown in Figure 13.

Figure 13.

Coordination distribution chart.

From Figure 13, it can be seen that the number of coordination pores of CLT, FCT and SCT is small and all of them are distributed in the range of 0–15, while the number of STT and SDT is greater and mainly distributed in the range of 5–25.

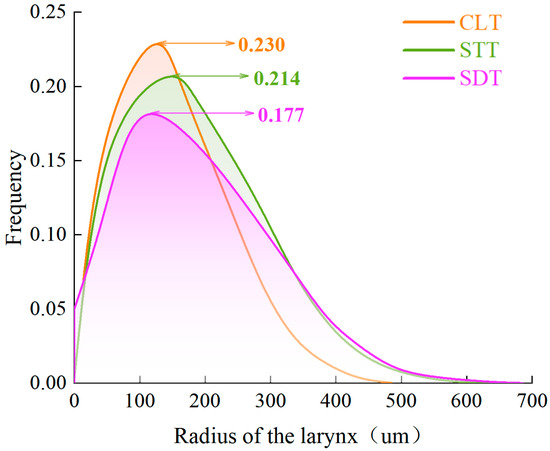

The permeability characteristics of the tailings samples are closely related to the distribution of the throat radius, and when the radius distribution of the throat is concentrated and the frequency value at the peak is high, it can be inferred that its permeability is poor. When the radius distribution of the larynx is dispersed and the frequency at the peak is low, it can be inferred that its permeability is good [20]. The probability distribution of the throat radius of three tailings samples with the representative throat numbers of CLT, STT and SDT is plotted as shown in Figure 14.

Figure 14.

Laryngeal radius frequency distribution.

As can be seen from Figure 14, the probability distribution of the laryngeal radius tends to be normally distributed, and the peak frequency and concentration of the radius distribution decrease from CLT to STT and then to SDT, and the permeability should tend to increase, which is in line with conventional thinking.

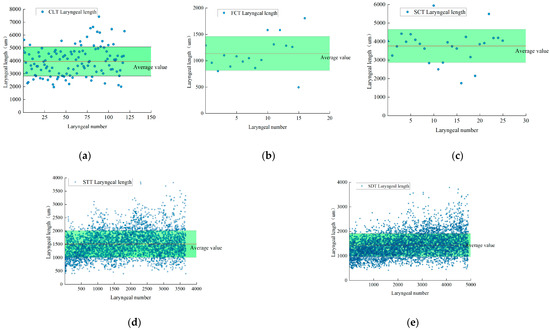

The length and distribution of the throat is an important feature of the flow capacity, and when the throat radius is similar, the longer the throat, the greater the number of pores connected, the better the connectivity, and the corresponding permeability. The scatter plot of the throat length distribution of the tailing samples is shown in Figure 15.

Figure 15.

Scatter plot of throat length distribution of samples. (a) CLT; (b) FCT; (c) SCT; (d) STT; (e) SDT.

As can be seen from the scatter plot of Figure 15, the length of the roar of the SDT and STT specimens is widely distributed; a large number of roars are distributed from 500 to 3000 μm, and the frequency distribution is very uniform. However, the number of roars of CLT, FCT and SCT samples was relatively small, and the length of CLT and SCT roars was longer, distributed between 2000 and 6000 μm; the longest roar of CLT reached 7500 μm, while FCT was generally shorter, distributed between 500 and 1500 μm.

The pore–throat ratio is one of the key structural parameters of the tailings pore–throat model and is defined as the ratio of the pore radius to the average of the throat radius to which it is attached. With the decrease in the pore–throat ratio, the development of pore space becomes more balanced, and the permeability will also be improved. The probability distribution of the pore–throat ratio of the tailings samples was summarized into a single figure, as shown in Figure 16.

Figure 16.

Frequency distribution of pore–throat ratio.

As can be seen from Figure 16, the peak value of STT and SDT pore–throat ratio is about 3, the peak value of FCT, SCT and CLT is about 4, the peak value of the pore–throat ratio of the sample from FCT→SCT→CLT→STT→SDT should gradually decrease, and the permeability characteristics should be gradually enhanced.

5. Conclusions

The main conclusions of the paper are as follows:

- (1)

- The data between the CT test results and the measured results are less than 10%, which give good applicability in the study of the permeability characteristics of tailings.

- (2)

- The porosity of viscous tailings ranges from 25 to 35%, the surface porosity of the distribution along the height is similar, and the distribution becomes more uniform with the increase in particle size.

- (3)

- Based on the various microstructure characteristics of tailings, it can be seen that, compared with sand tailings and silty tailings, the viscous tailings have fewer edges and corners, a smoother surface, a geometric shape closer to a circle, a convexity greater than 0.85, a fractal dimension as low as 1.2, and a shape factor of 0.95.

- (4)

- According to the correlation analysis results of the microscopic parameters of tailings, the porosity, the number of pores and the number of throats are the three key factors affecting the permeability characteristics. The exponential relationship between the porosity n and the permeability coefficient K (×10−6 cm·s−1) satisfies: K = 2.64e0.07n−13.60, R2 = 0.9998.

- (5)

- The effective porosity is the main factor that affects the permeability of tailings. This is in line with common sense.

Author Contributions

Conceptualization, Q.L., C.M. and C.Z.; data analysis, Q.L and C.M.; methodology, Q.L.; software, Q.L.; supervision, Y.G. and T.Z.; writing—original draft preparation, Q.L.; writing—review and editing, Q.L. and Y.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the National Key Research and Development Program of China (NO.2021YFC3001305; NO.2021YFC3001303; NO.2023YFC3012201); and funded by China Coal Technology Group Special key projects of scientific and technological innovation and entrepreneurship funds (NO.2022-ZD002).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the author.

Acknowledgments

The authors acknowledge all the participants and administrators in this study.

Conflicts of Interest

Author Tong Zhou was employed by the company Wushan Copper Mine, Jiangxi Copper Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Xu, B. Study on The Variation Law of Tailing Sand Strength under Freeze-thaw Cycles. Master’s Thesis, Liaoning Technical University, Fuxin, China, 2022. [Google Scholar]

- Zeng, S.; Ji, K.; Li, J.; Wang, P. Numerical Simulation of the Influence of Structural Features of Tailings on its Permeability. Met. Mine 2017, 1, 43–46. [Google Scholar]

- Mei, H. The Study of Seepage Theory and It’s Application in Tailings Dam Engingeering under Consolidation. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2007. [Google Scholar]

- Wang, Q.; Lu, B.; Wang, S.; Zhou, W.; Xiao, J. Finite Element Analysis for Seepage Field in Tailing Dam by ANSYS. Mod. Min. 2009, 25, 27–30. [Google Scholar]

- Yin, G.; Jing, X.; Wei, Z.; Li, X. Study of Model Test of Seepage Characteristic and Field Measurement of Coarse and Fine Tailing Dam. Chin. J. Rock Mech. Eng. 2010, 29, 3710–3718. [Google Scholar]

- Yang, X.; Zhang, Y.; Gan, D.; Jia, Y. Experimental Study on Permeability Characteristics of Undisturbed Iron Tailing. Adv. Eng. Sci. 2020, 52, 110–117. [Google Scholar]

- Yang, B.; Liu, Y.; Wan, F.; Yang, T.; Feng, J.; Zhao, X.; Zheng, D. Experimental Study on Influence of Particle-Size Distribution on Permeability Coefficient of San. J. Southwest Jiaotong Univ. 2016, 51, 855–861. [Google Scholar]

- Kozeny, J. Ueber kapillare Leitung des Wassers im Boden. Sitzungsberichte Der Akad. Der Wiss. Wien 1927, 136, 271–306. [Google Scholar]

- Carman, P.C. Permeability of saturated sands, soils and clays. J. Agric. Sci. 1939, 29, 262–273. [Google Scholar] [CrossRef]

- Mesri, G.; Olson, R.E. Mechanisms controlling the permeability of clays. Clays Clay Miner. 1971, 19, 151–158. [Google Scholar] [CrossRef]

- Li, D.; Wang, H.; Zhang, C.; Chen, Q. Study on meso-structure characteristics of tailings based on CT scanning. Eng. J. Wuhan Univ. 2020, 53, 574–582. [Google Scholar]

- Zhang, P.; Lee, Y.; Zhang, J. A review of high-resolution X-ray computed tomography applied to petroleum geology and a case study. Micron 2019, 124, 102702. [Google Scholar] [CrossRef]

- Li, Z. Study on the macro-fine structure and mechanical properties of the whole tailings layered cemented backfill. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2023. [Google Scholar]

- Barrett, P.J. The shape of rock particles, a critical review. Sedimentology 1980, 27, 291–303. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, C.; Li, Q.; Yu, Y.; Ma, C.; Duan, Z. Disaster mechanism and prevention methods of large-scale high tailings dam. Rock Soil Mech. 2021, 42, 1–17. [Google Scholar]

- Yang, Y.; Wei, Z.; Chen, Y.; Ren, B. Study on the shapes of tailings particles based on microscopy and image processing technologies. Chin. J. Rock Mech. Eng. 2017, 36, 3689–3695. [Google Scholar]

- Hu, X.; Gao, S.; Zhang, X.; Wang, W.; Zhong, H.; Zhou, H. A rock thin section analysis system based on continuous extinction characteristic. Earth Sci. Front. 2021, 28, 296–304. [Google Scholar]

- Wu, S. Effect of Particle Size on Physico-Mechanical Properties of Tailings and Dam Stability Study. Ph.D Thesis, Chongqing University, Chongqing, China, 2017. [Google Scholar]

- Sheng, J.; Yang, C.; Xu, L.; Ding, X.; Yang, X.; Li, G. Application of Digital Core Technology in the Study of Microscopic Seepage Characteristics of Tight Reservoirs. J. Xi’an Shiyou Univ. 2018, 33, 83–89. [Google Scholar]

- Li, Z. Research on pore structure parameters of sandstone based on CT data. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2023. [Google Scholar]

- Wang, Q. Study on characteristics of waterproof material in underground engineering based on micro scanning technology. Ph.D Thesis, Southwest Jiaotong University, Chengdu, China, 2017. [Google Scholar]

- Ministry of Housing and Urban-Rural, Development of the People’s Republic of China. Standards for Geotechnical Test Methods; State Administration for Market Regulation of the People’s Republic of China: Beijing, China, 2019. [Google Scholar]

- Wei, B.; Xie, N. Unified representation and properties of generalized Grey relational analysis models. Syst. Eng.-Theory Pract. 2019, 39, 226–235. [Google Scholar]

- Xu, L.; Zhang, W.; Liang, X.; Xiao, R.; Cao, J. The Grey correlation degree analysis of pore structure parameters of Geotechnical medium. J. Nanjing Univ. 2018, 54, 1105–1113. [Google Scholar]

- Dong, Y.; Duan, Z. A new method for determining the grey correlation resolution coefficient. J. Xi’an Univ. Archit. Technol. 2008, 4, 589–592. [Google Scholar]

- Wei, T.; Fan, W.; Yuan, W.; Wei, Y.N.; Yu, B. Three-dimensional pore network characterization of loess and paleosol stratigraphy from South Jingyang Plateau. Environ. Earth Sci. 2019, 78, 1–15. [Google Scholar] [CrossRef]

- Zhao, J.; He, X.; Lai, Q.; Yu, B.; Wu, Z. A Model of Permeability Prediction for Carbonate Rocks Based on Digital Cores. Prog. Geophys. 2024, 1–12. Available online: http://link.cnki.net/urlid/11.2982.P.20240611.1524.064 (accessed on 15 December 2024).

- An, R.; Kong, L.; Zhang, X.; Li, C. Effects of dry-wet cycles on three-dimensional pore structure and permeability characteristics of granite residual soil using X-ray micro computed tomography. J. Rock Mech. Geotech. Eng. 2022, 14, 851–860. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).