Abstract

The coal mining industry in Pakistan faces recurring fatal accidents due to data scarcity, lack of research, and technology adoption. This paper reviews the current status of coal mining, the ongoing energy crisis, the utilization of indigenous coal resources, and the prevailing safety challenges. By comparing coal mining safety standards in Pakistan with global benchmarks, this study proposes advanced mining technologies to improve productivity and safety. This study emphasizes the importance of investigating the underlying factors causing mining accidents in order to devise effective strategies to mitigate them. The lack of relevant data and the reluctance to adopt technology in the industry are identified as major obstacles to improving safety conditions. The proposed strategies for overcoming safety issues include improving data collection and analysis, increasing research efforts, and promoting the adoption of advanced technology. Thus, this paper highlights the urgent need to address safety concerns in Pakistan’s coal mining industry to avoid further loss of lives and resources.

1. Introduction

Pakistan stands seventh among the top countries in terms of coal potential [1]. Though the total coal reserves amount to about 185 billion tons, this sector lacks adequate development due to financial resources and technical constraints in the past several years [2]. Coal in Pakistan varies from lignite to sub-bituminous and bituminous. The country has one of the most abundant lignite reserves in Asia, with nearly 97% of the lignite-bearing varieties [3]. The total coal production amounted to about 4 million tons in 2018 [4], and about 10 million tons were produced in 2022 after the development of Block-II in the Thar coalfield. However, to meet the energy demands in Pakistan, an additional million tons of coal are imported each year [5]. Pakistan’s mining sector is among the most neglected sectors of the country and still awaits to be granted the status of industry [6]. In Pakistan, there is an immense potential for coal resources for power generation, but, unfortunately, no proper attention has been paid to the proper utilization and socioeconomic development of this particular sector by the concerned authorities and the government [7]. Pakistan’s total annual production is still very low (compared to that of neighbors such as China, India, and Bangladesh) to meet the general needs of the country. At present, the country is facing a significant energy crisis, especially electricity, which is a basic need for household and industrial use. In Pakistan, the domestic and commercial sectors are facing long power outages of about 8 to 12 h daily due to the deficiency of power generation capacity [8,9]. In Pakistan, coal contributed about 10% to its energy sector in 2011–2012. The cement and brick kiln industries were the main consumers of coal, consuming 60% and 40% of coal, respectively [10]. Therefore, coal has a substantial share in the economic growth of the country, but the coal mining work conditions are considered to be the most hazardous.

Pakistan’s coal mining sector suffers from a significant lack of publicly accessible literature and systematic data collection, as well as inadequate reporting practices. This scarcity of information restricts the ability to perform a comprehensive analysis and may contribute to a less nuanced understanding of the market’s behavior. Thus, data scarcity related to mining accidents results in recurring fatalities and injuries, affecting lives, the economy, and time, making the applied coal mining methods more complex and less sustainable. Since the last decade, Pakistan’s mining sector has been the most affected industry in terms of occupational safety. There has been a surge in fatal accidents, resulting in the deaths of approximately 414 coal miners (2010 to 2019) [11]. These accidents include suffocation, gas explosions, roof falling, etc., with roof falling being the major contributor to the fatalities [12]. Similarly, in 2020, about 100 coal miners were killed in 72 accidents in the Balochistan province alone [13]. According to the survey conducted by the Pakistan Central Mines Labor Federation, there are 100 to 200 fatalities every year. In addition, more than 318 miners have been killed while working in different coal mines in Balochistan in the last eight years [14]. Shahani et al. (2020) conducted a study comparing the fatality rate in coal mines in Pakistan with that of China and India. According to their findings, the fatality rate in Pakistan was found to be significantly higher than that of the compared countries [15]. These findings can be used to enhance safety and save lives in the mining industry. Data scarcity refers to the fact that there is little or no data available relevant to a certain phenomenon. Without specific data, it is difficult for researchers to understand any subject matter. Resultantly, data scarcity creates significant socioeconomic and sustainability problems for the country. Data scarcity results in a lack of research, where researchers are left with little to no basis for understanding the origins of the problem. Research is one of the most essential factors in understanding the subject matter well and overcoming it by providing effective strategies accordingly; so, without any basic or relevant data, one cannot accomplish this task. The availability of data can help not only to understand the subject matter but also to handle it consequently. However, the lack of relevant data and the inaccessibility of the available data and online databases by the concerned authorities lead to a major gap in the research on the coal mining sector in Pakistan. Whatever few or incomplete data are available from newspapers and reports cannot help to overcome the safety issues faced, especially in the underground coal mines of Pakistan. Thus, the mining industry has been facing huge losses in terms of safety and consequent productivity. Lack of technology and the will to adopt technology are additional issues for the mining industry. The mining industry around the world has mostly shifted to the latest mining technologies to extract mineral deposits in a very safe and efficient manner, but Pakistan is among the few countries in Asia that still use primitive mining technologies, which not only compromise safety but also make mining operations more expensive and complex.

Several studies have been conducted by different research scholars in terms of mining safety [1,2,16,17,18]. Sherin et al.’s (2021) study aims to identify common hazards leading to accidents in surface mines in Pakistan, propose preventive measures, and employ fault tree analysis to outline accident causation paths. The study identifies human errors, unsafe procedures, equipment deficiencies, and law violations as significant causes [19]. However, only managerial direction was emphasized in the studies, rather than addressing the latest redesign of mining methods in the country’s mines.

This study addresses significant gaps in existing research concerning Pakistan’s coal mining sector. It critically examines crucial factors such as the current status of coal mining, the energy crisis, the utilization of indigenous coal resources, the power demand, and the prevailing health and safety scenario. A prominent challenge identified is the lack of comprehensive nationwide data and follow-up studies.

This study aims to contribute practical insights by conducting a comparative analysis of coal mining safety in Pakistan with global standards. Furthermore, it proposes potential mining technologies aimed at improving coal productivity while minimizing resource loss in the country.

2. Search Strategy

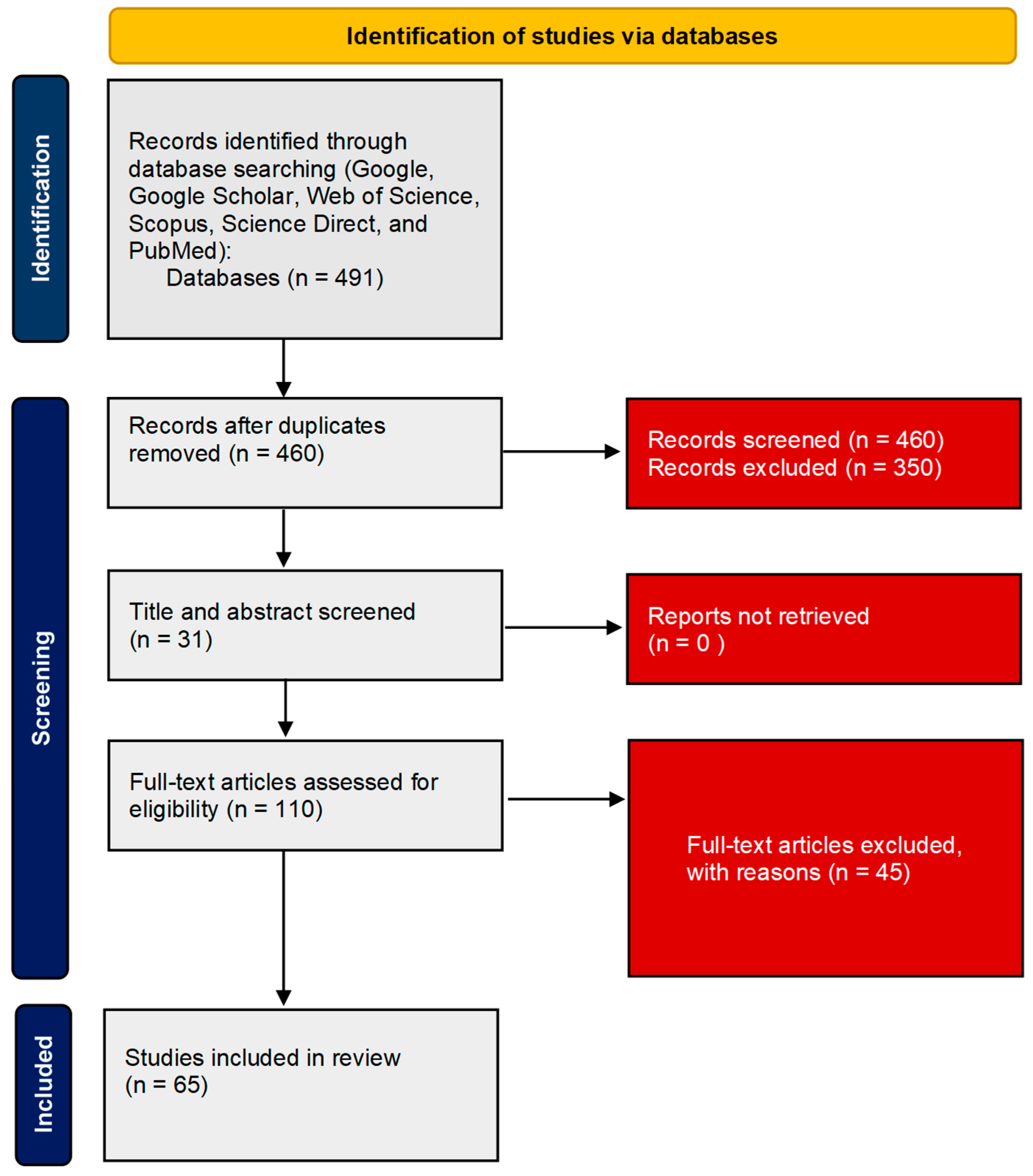

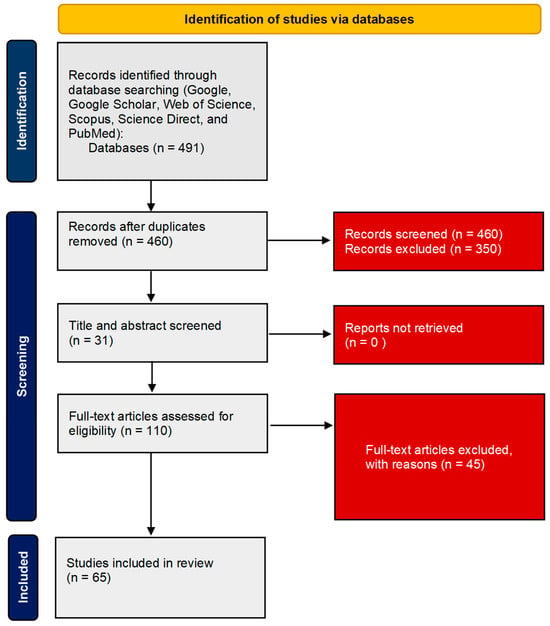

A comprehensive search of databases spanning from 2000 to 2024 was conducted. The studies included in this review, focusing on coal mining safety, were sourced from Google, Google Scholar, Web of Science, Scopus, Science Direct, and PubMed. The search terms used included coal mining safety, safety issues, energy crisis, indigenous coal resources, power consumption, coal mine fatal accidents, safety measures, artificial intelligence, human error in mining, human behavior, and mining safety in Pakistan and the world. A total of 65 articles from 2000 to 2024 were thoroughly reviewed. Figure 1 presents the preferred reporting items for systematic reviews and meta-analyses (PRISMA) diagram, illustrating the screening process findings.

Figure 1.

PRISMA diagram.

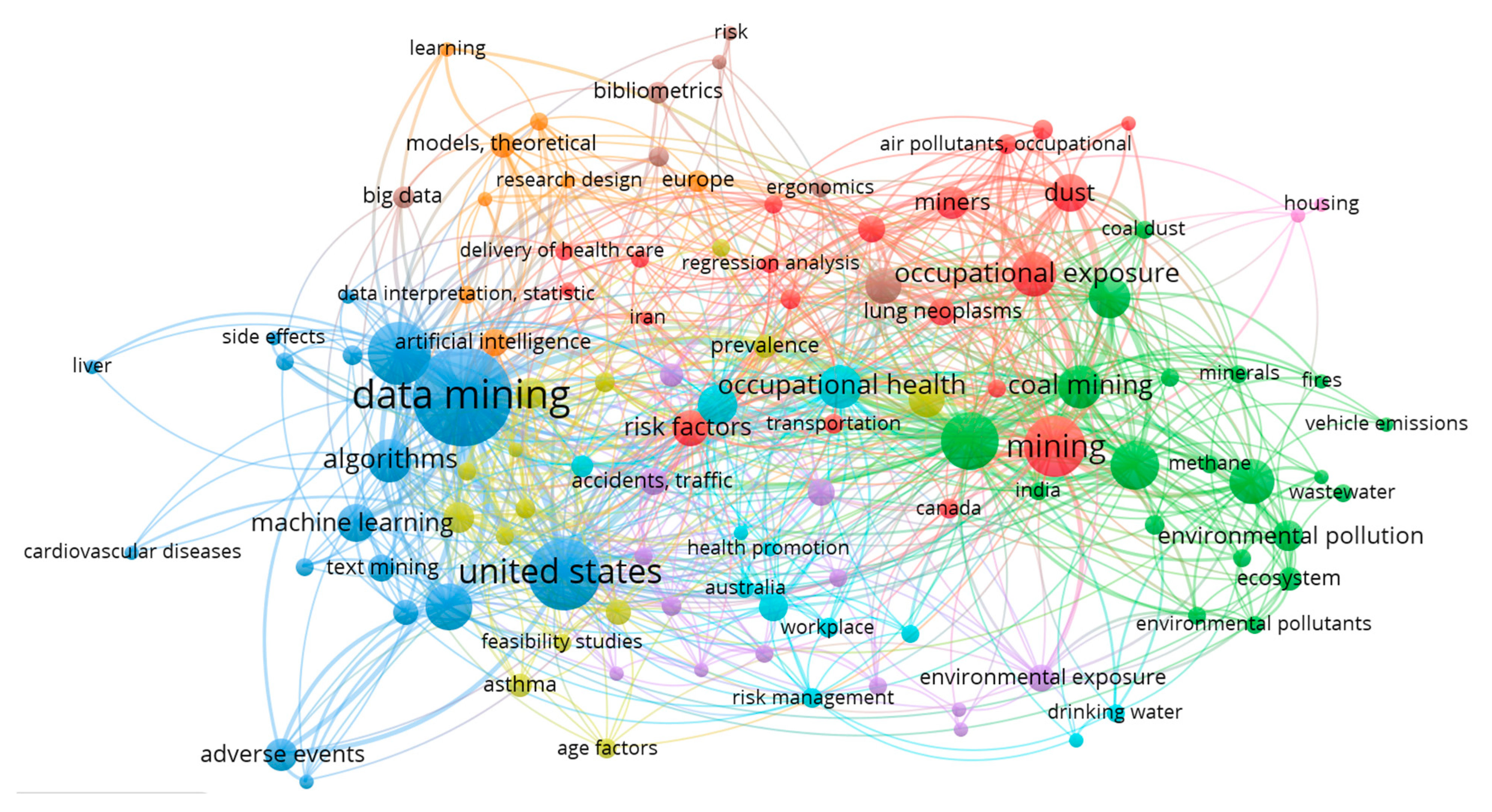

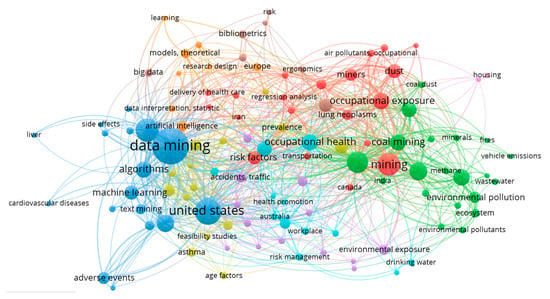

To identify the most significant keywords in the coal mining safety field, this research conducted a co-occurrence analysis of popular keywords that frequently appear together in the same article. The ‘full counting’ method was used to evaluate the author’s keywords listed below the abstract, assigning equal weight to each co-occurrence link. Using the VOSviewer software 1.6.20, 2412 keywords were identified across 491 publications. Figure 2 illustrates the 110 keywords that exhibit the highest co-occurrence frequency, considering a minimum threshold of three occurrences. In this figure, each keyword is represented by a node, and the size of the node corresponds to the number of articles in which those keywords are featured. Larger nodes indicate that the associated keywords are more prevalent in the literature. The lines connecting the nodes vary in thickness; thicker lines signify a greater frequency of co-occurrences, highlighting pairs of keywords that often appear together in the same articles. This visualization enables us to discern relationships between concepts more clearly. In the network diagram, shorter distances between nodes indicate stronger associations. The closeness of nodes represents how frequently two keywords co-occur in the articles. Additionally, the colors of the node denote that the keywords belong to the same clusters. This clustering provides insight into the interconnectedness of various topics within the literature, revealing important trends and areas of focus in the research landscape.

Figure 2.

Co-occurrence of authors’ keywords network in the field of coal mine safety.

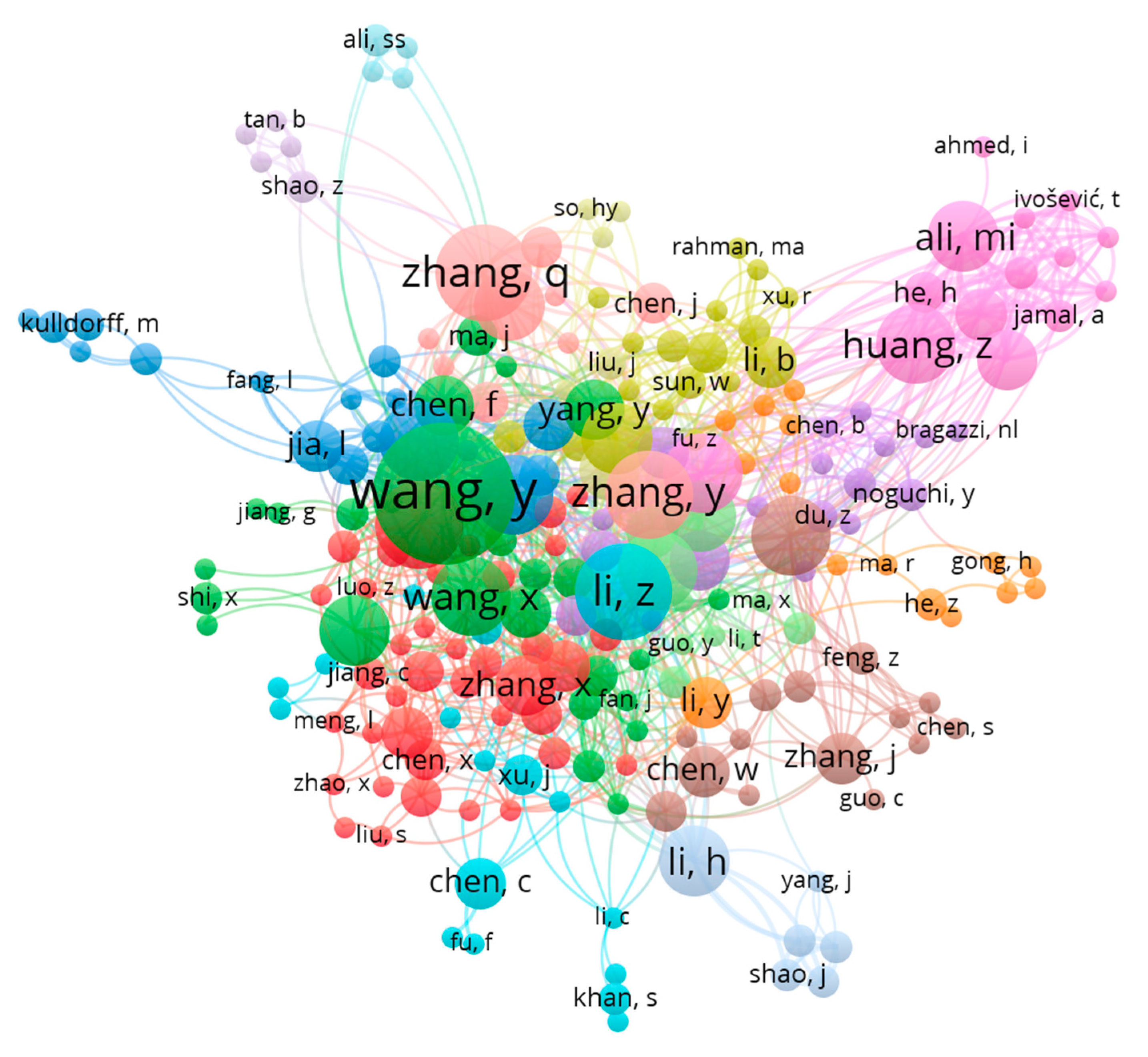

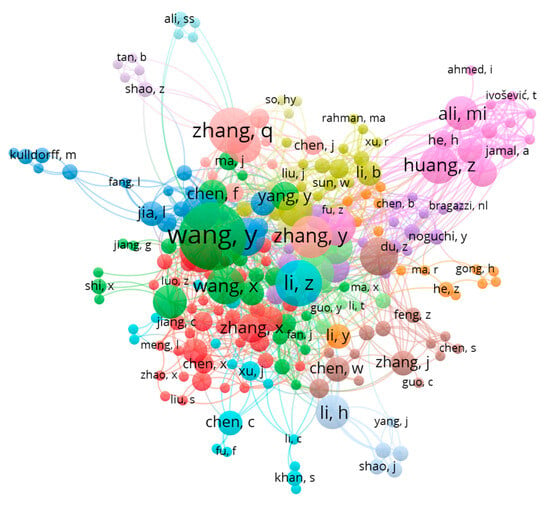

Figure 3 presents a co-occurrence network graph that visually represents the relationships among authors and keywords extracted from the publications. This figure displays the 220 authors with the highest co-occurrence frequency, considering a minimum of two documents per author. Out of the 2189 authors, 267 meet this threshold. Nodes correspond to authors and keywords, with their sizes proportional to their frequencies. The connections between nodes indicate co-occurrences in the publications, with thicker lines denoting stronger relationships. Different colors are used to highlight clusters of authors and keywords that frequently appear together. Central nodes such as ‘Wang, y’ and ‘Li, z’ highlight influential authors and their associated keywords, while peripheral nodes indicate less frequent associations. This visualization effectively depicts key authors, prominent research topics, and the overall intellectual structure of the field. Understanding these collaboration networks is essential for recognizing influential researchers and research groups driving innovation. Furthermore, by mapping out these relationships, the diagram serves as a strategic tool for identifying potential future collaborators or untapped areas for interdisciplinary partnerships. Such insights can help shape future research directions, ensuring that knowledge is not developed in isolation but through a broad, collective effort that maximizes impact and efficiency. For researchers looking to expand their collaborative networks or institutions aiming to foster strategic partnerships, this type of analysis is invaluable.

Figure 3.

Co-occurrence network illustrating relationships among authors and keywords.

3. Energy Dilemma: Coal Resources and Power Demand

Mining safety, mining techniques, and the increased utilization of coal resources in Pakistan are critical in addressing the country’s energy crisis. Given the ongoing energy crisis and the availability of indigenous coal resources in Pakistan, it is crucial to focus on improving coal mining safety to ensure sustainable and efficient power generation. Energy is the lifeline for the progress of any nation; however, progress cannot be made and sustained without an adequate energy supply. Pakistan has been facing an acute crisis of energy for decades. There are multiple causes of the energy crisis in Pakistan, with the lack of domestic coal utilization being one of them. Increasing demand and consumption of energy are adding to the substantial escalation in power scarcity since electricity is considered a basic need for utilization in the industrial and domestic sectors.

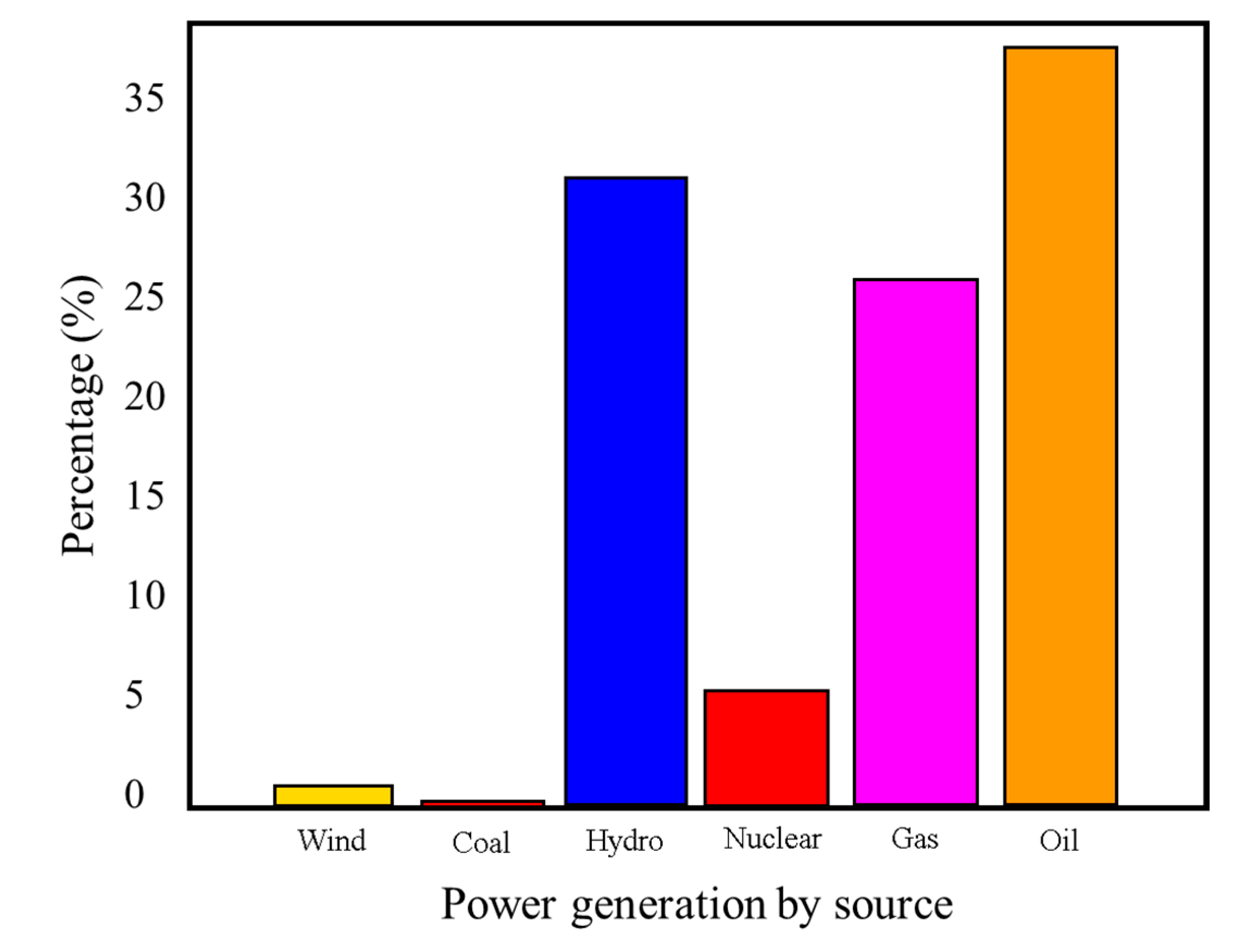

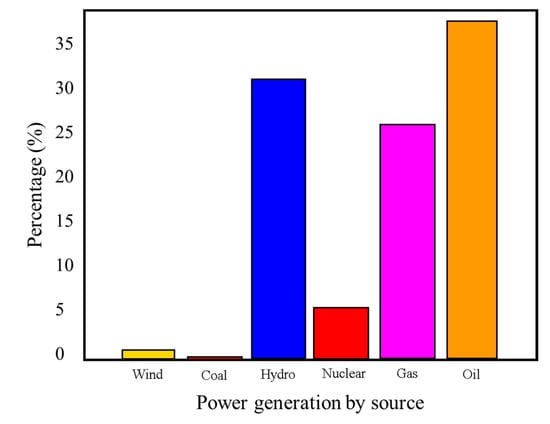

Mining safety is crucial for the sustainable development of coal resources. Unsafe conditions, often worsened by outdated methods and inadequate safety regulations, lead to accidents that cause both human and economic losses while also disrupting coal production. Without prioritizing safety, scaling up coal extraction to meet growing energy demands becomes impossible. Implementing proper safety protocols and modernizing equipment will not only protect workers but also enhance the productivity and efficiency of coal mines. As mentioned earlier, in Pakistan, both the domestic and commercial sectors experience significant power outages lasting approximately 8 to 12 h every day. These outages are a result of insufficient power generation capacity in the country. Coal is a cheap source of energy, and Pakistan possesses a substantial quantity of it. Nevertheless, little attention has been paid to the development of the coal mining sector by the government for the appropriate utilization of coal. Table 1 highlights the total coal resources in Pakistan [20]. Figure 4 shows that coal contributed only 0.14% of power generation in 2013–2014, which is considerably little compared to the massive coal reserves in the country. Hence, the proper utilization of coal may boost the economy by reducing the energy crisis in Pakistan [21]. According to 2015 statistical data from the International Energy Agency (IEA), in Pakistan, hydropower (30.7%) and oil (37.2%) are the key sources of power generation, followed by natural gas (25.7%), nuclear energy (5.5%), wind energy (0.8%), and coal (0.14%).

Table 1.

Total coal resources in Pakistan.

Figure 4.

Key power generation sources in Pakistan.

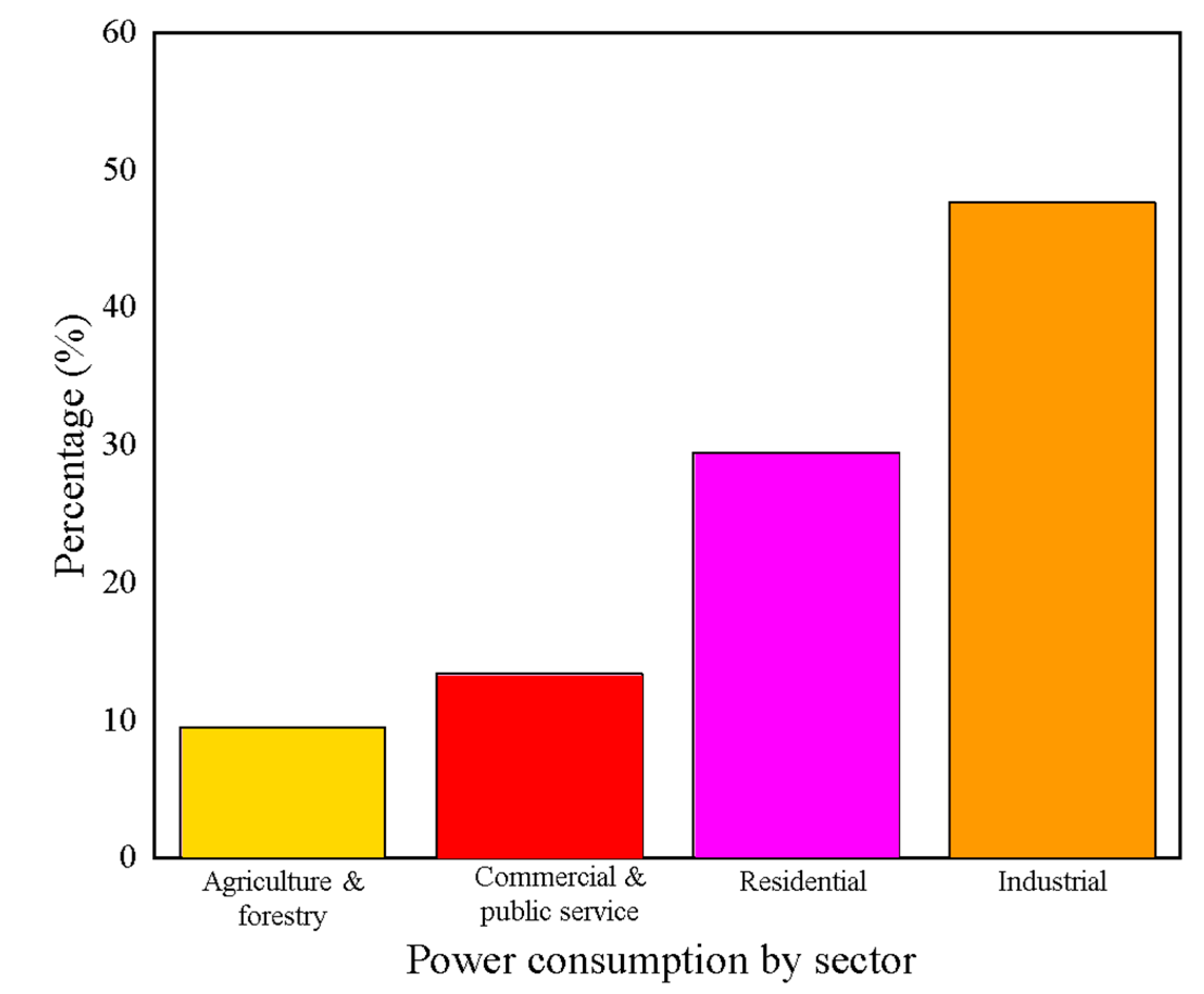

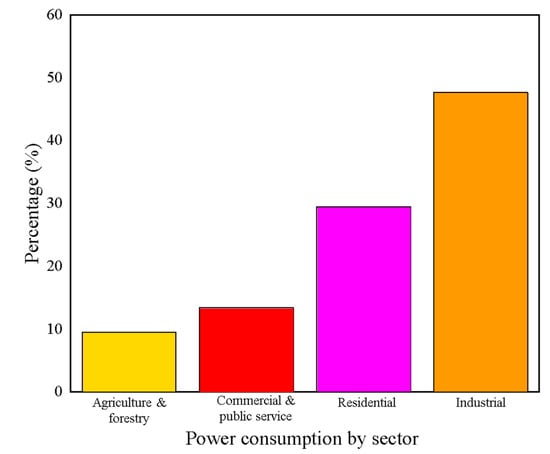

In Pakistan, the main power consumers are the industrial, commercial, agricultural, and residential sectors, and the demand is expected to grow exponentially over the next 30 years [22,23,24,25]. Figure 5 presents the total power consumed by different sectors in Pakistan, such as the industrial, commercial and public service, agriculture and forestry, and residential sectors, which consumed 47.72%, 13.38%, 9.47%, and 29.43%, respectively.

Figure 5.

Sector-wise power consumption in Pakistan.

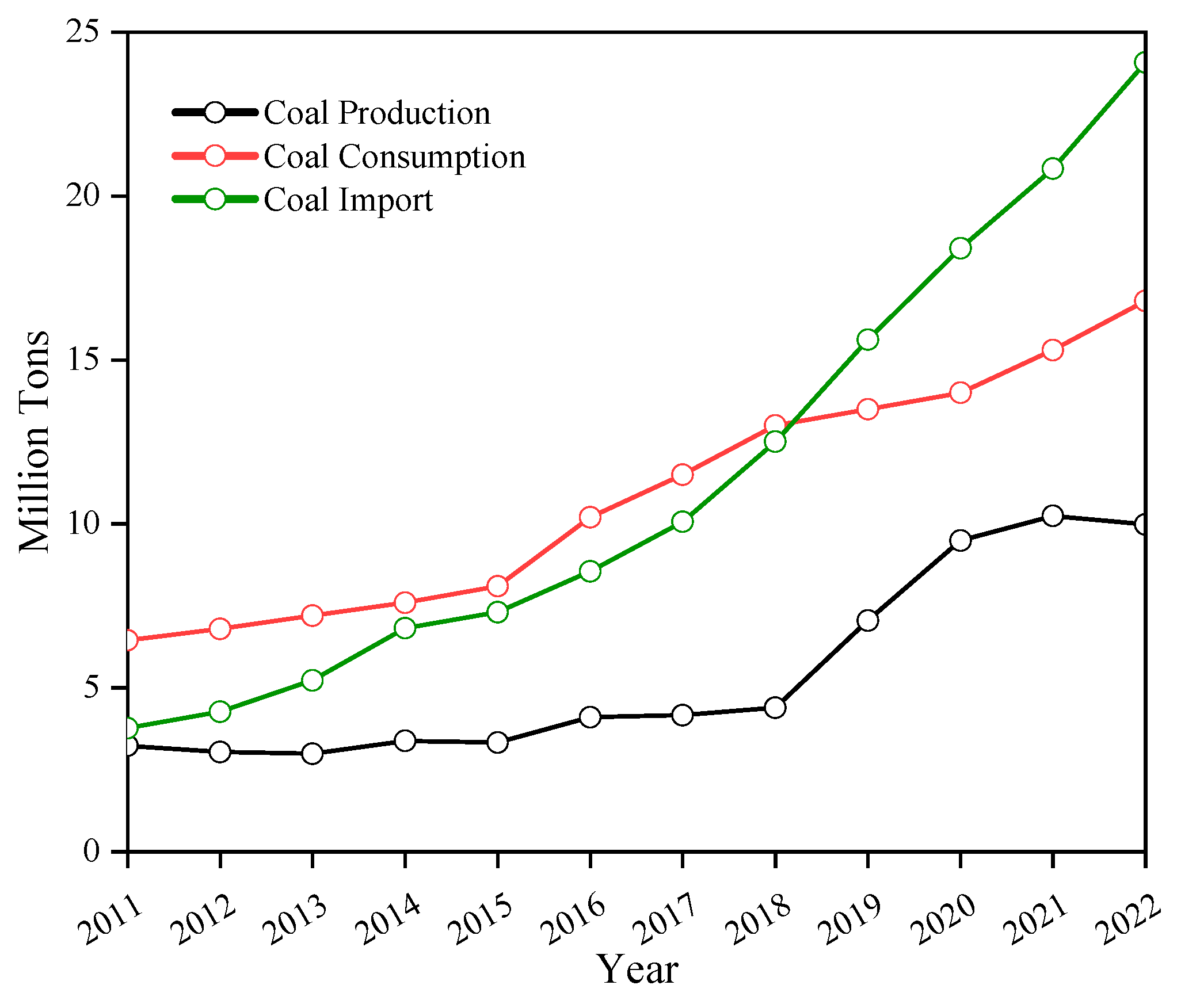

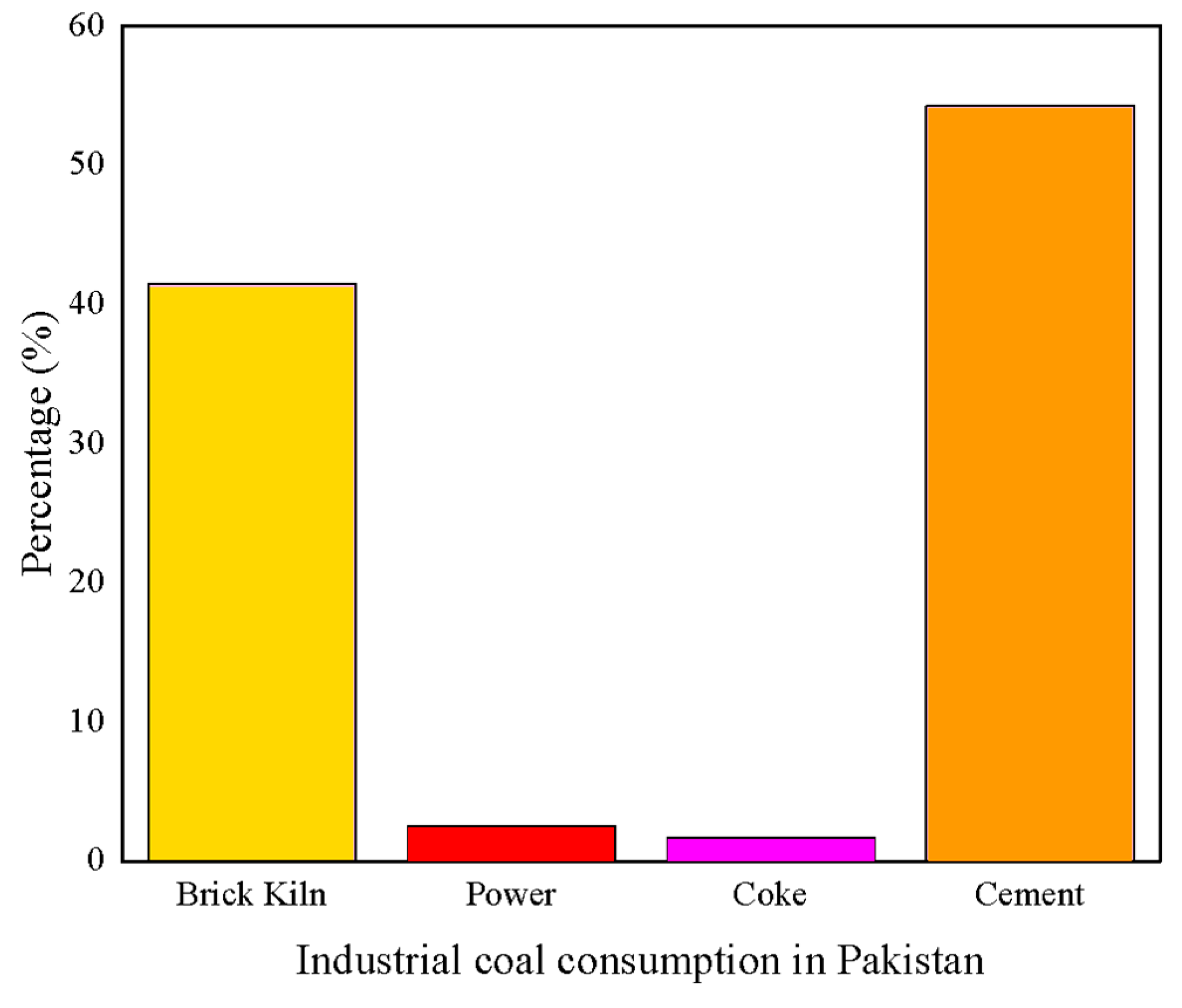

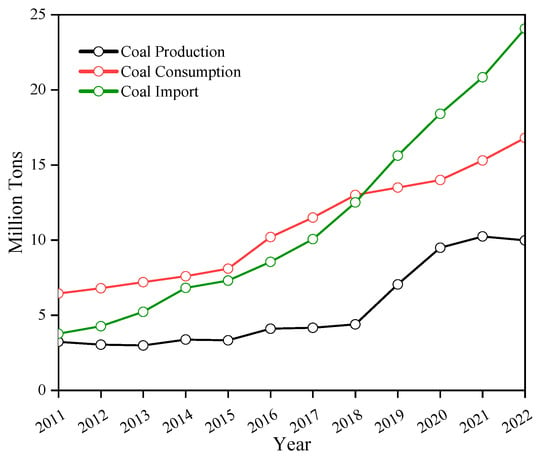

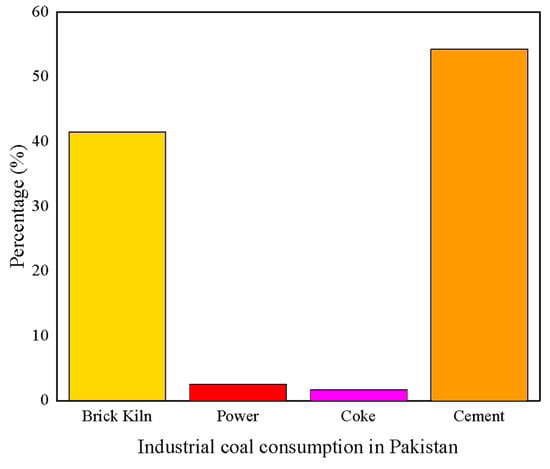

The country is currently faced with three main issues, i.e., (1) a gap in coal supply and demand, (2) the import of coal, and (3) expensive energy. The solution to these issues lies in utilizing the indigenous coal resources of the country. In 2022, Pakistan’s total annual coal production reached approximately 10 million tons. Despite this, the country’s energy needs necessitated the import of around 24 million tons of coal, as illustrated in Figure 6 (data source: [5,26,27,28]). This significant reliance on imports underscores the growing demand for coal to meet the nation’s energy requirements. Keeping in view that the demand for coal is too high and is increasing every year, the supply is still significantly low. As discussed earlier, coal is an economical source of energy, and its adequate utilization could replace the expensive sources of energy for different industrial purposes like power generation after the cement brick kiln industries. In Figure 7 (modified after [29]), it can be seen that the top consumers of coal are the cement and brick kiln sectors, with 54.30% and 41.50%, respectively. Next, the remaining amount of coal is consumed by coke and power generation, with 1.70% and 2.50%, respectively. According to the Worldometer estimation [30], the total consumption of national coal is 0.3%; however, 99.7% of proven coal reserves are still untapped due to a lack of modern technology, financial constraints, and lack of awareness regarding its appropriate development.

Figure 6.

Coal production, consumption, and import from 2011 to 2022 in Pakistan.

Figure 7.

Industrial coal consumption in Pakistan.

To conclude, Pakistan is facing a severe scarcity of energy due to a lack of indigenous coal consumption and a lack of political consensus on energy issues. It is time for the government, stakeholders, and other related organizations to play their roles in addressing the energy crisis in the country. Moreover, the proper implementation of recommendations may tackle the crisis and play an important role in socioeconomic and sustainable development.

The interrelationship between mining safety, modern techniques, and coal resource utilization is crucial for meeting a country’s energy demand. By improving safety protocols and adopting advanced mining methods, coal production can be significantly enhanced, thereby closing the gap between coal supply and demand while reducing the need for costly imports. This will profoundly impact the country’s energy landscape and contribute to economic growth.

4. Current Health and Safety Scenario

Coal mining is considered a highly hazardous occupation due to its susceptibility to high rates of accidents and fatalities [18,31]. In Pakistan, the primary mining methods employed are room-and-pillar and longwall mining. “The coal mining sector in Pakistan shows promise, with an average growth rate of 2–3% per annum. The country hosts over 5000 operational mines and 50,000 small mining enterprises (SMEs), providing direct employment to approximately 300,000 workers” [32]. Some of the deepest coal mines in Pakistan reach depths of nearly 1000 m [33,34,35]. To understand the current state of coal safety and the underlying safety problems, Jiskani et al. proposed a novel mine safety model aimed at promoting sustainable mining practices in Pakistan [36]. Building on this foundation, Jiskani et al. emphasized the systematic improvement in mine safety by addressing critical factors. The study sequentially outlines these factors and proposes a methodological approach applicable to prioritizing efforts, analyzing indicators, and recommending suitable management strategies [37]. Janjuhah et al. highlighted the importance of comprehensive hazard assessments in mines, particularly advocating for decision matrix risk assessments (DMRAs) to develop effective mitigation strategies. This approach is crucial for enhancing safety and minimizing environmental impact in underground mining operations, particularly those in Pakistani coal mines [38]. Rehman et al. investigated the reporting practices of fatal accidents in coal mines in Punjab, Pakistan, proposing measures to elevate safety standards [39]. Ayaz et al. examined health issues among underground coal miners in Balochistan, Pakistan, stemming from working conditions and contamination concerns [40]. In the realm of risk management, Jiskani et al. utilized an enhanced Z-number-based fuzzy fault tree method to evaluate health and safety risks in surface mines, aiming to bolster risk management practices [41]. They also introduced a mining decision-making system aligned with Industry 4.0 standards and climate neutrality goals [42]. Raza et al. employed the analytical hierarchy process (AHP) and fuzzy TOPSIS methods to assess and rank risks in surface mining operations across Pakistan, contributing to effective risk prioritization [43].

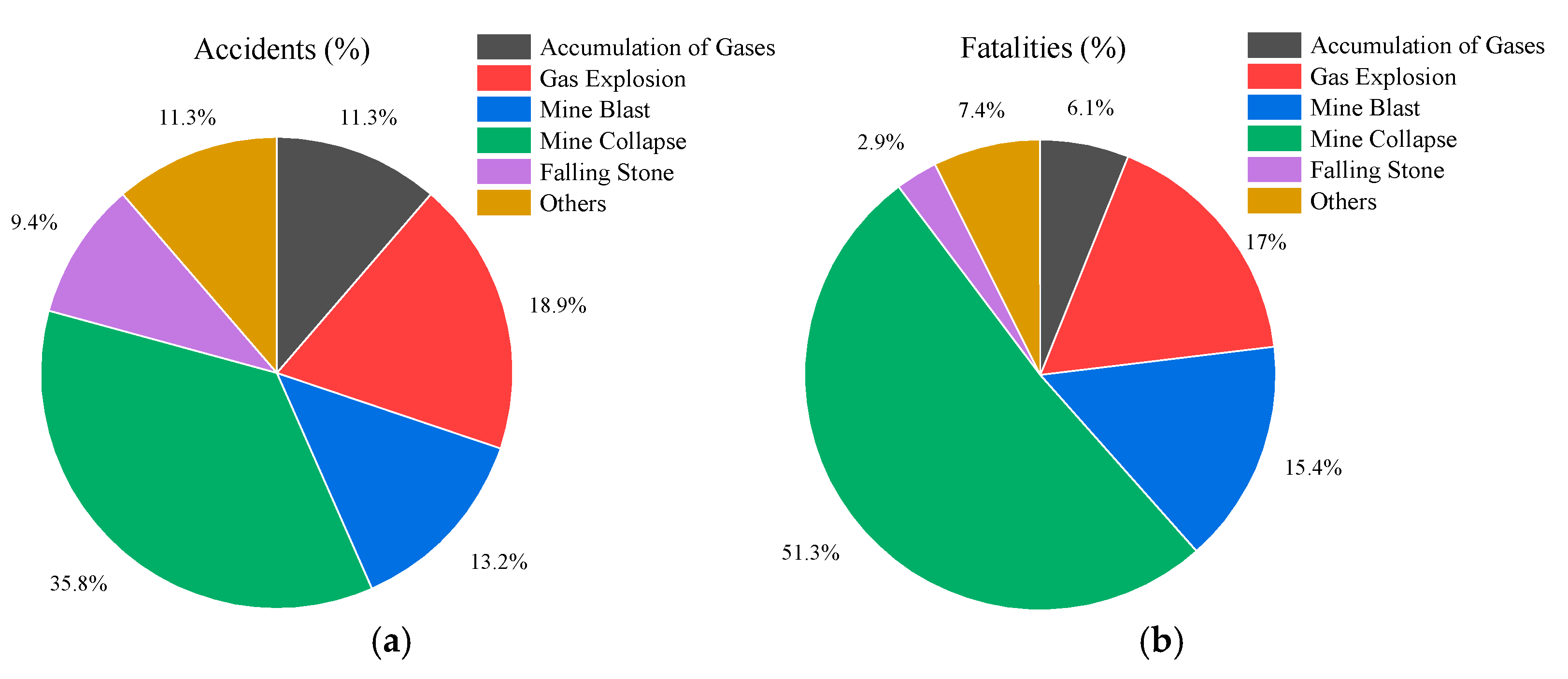

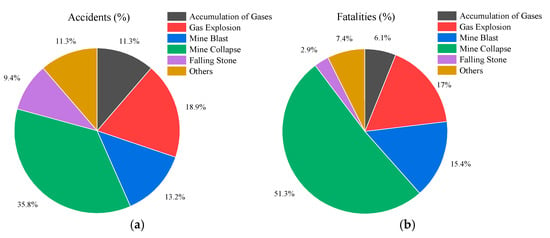

Furthermore, a statistical analysis of coal mine accidents and fatalities in Pakistan was conducted on data from 2010 to 2018 [15]. Table 2 shows that from 2010 to 2018, a total of 53 accidents resulted in 312 deaths in underground coal mines in Pakistan. Based on Table 2, compared to other territories in Pakistan, major fatal accidents occurred in Balochistan (28 accidents, 219 fatalities) and Khyber Pakhtunkhwa (19 accidents, 77 fatalities) out of a total of 53 accidents and 312 fatalities. An average of six accidents resulted in 35 fatalities each year. In Figure 8, it can be seen that mine collapses accounted for about 36% of the accidents and 51% of the fatalities out of the 53 accidents and 312 fatalities. Gas explosions followed with about 19% of the accidents and 17% of the fatalities, with mine blasts ranking third with 13% of the accidents and 16% of the fatalities. In addition, the accumulation of gases accounted for 11% of the accidents and 6% of the fatalities, falling stones accounted for 10% of the accidents and 3% of the fatalities, and other causes accounted for 10% of the accidents and 7% of the fatalities. The analysis concluded that one key element that culminated in accidents was the negligence and violation of effective safety measures by the administration. Moreover, the fatalities in Pakistan’s mining sector are primarily caused by mine collapse, mine blast, and gas explosion. These disasters highlight the insufficient attention given to implementing strict safety measures by the government of Pakistan and the mine safety authorities. It is crucial to address these issues to make the workplace less hazardous for the workforce, especially in the Balochistan and Khyber Pakhtunkhwa provinces. It must be noted that the available data addressed only the number and apparent causes of the accidents and the consequent casualties. No data addressing the underlying causes leading to these accidents are available.

Table 2.

Province-wise distribution of accidents and fatalities from 2010 to 2018.

Figure 8.

Cause-wise distribution of (a) accidents and (b) fatalities from 2010 to 2018.

5. Comparison of Coal Mining Safety Between Pakistan and the World

A comparison of Pakistan’s coal mining safety regulations with global standards reveals several significant challenges, particularly in safety training, emergency response, ventilation systems, and technological advancements. It is clear that since the inception of Pakistan, its coal extraction technologies have not improved and have remained primitive and outdated, unsuited for productive and safe mining. Coal is mined and handled manually with labor work and animal efforts, except for a few mines. Roofs are poorly and inadequately supported by wooden props, which is not acceptable and often leads to lower productivity and increased safety issues, with an increasing number of coal miners’ fatalities. Presently, Pakistan, although it is a coal-rich country, faces a huge energy crisis, in part resulting from little attention being paid to domestic coal sector development; instead, coal is imported. These deficiencies substantially increase the risk of accidents and health hazards in Pakistani coal mines. Table 3 highlights the current global state of coal mining safety, where continuous improvements in operations have been made to mitigate safety issues. In contrast, Pakistan’s mining sector remains outdated, with limited potential for coal production and numerous safety problems, resulting in a high incidence of miner fatalities and injuries.

Table 3.

Current global state of coal mining safety.

Worldwide, coal mining operations have seen a decline in fatal accidents due to rapid technological advancements and significant financial investments. However, Pakistan currently lacks adequate safety precautions in its coal mines. This analysis aims to compare the state of mining in Pakistan with global practices, emphasizing the urgent need for Pakistan to adopt international safety standards. By doing so, Pakistan can not only prevent further loss of miners’ lives but also enhance coal production to meet the country’s energy needs and contribute to its overall well-being.

Keeping in view the overall scenario, a comparison between Pakistan’s coal mining safety and that of the world highlights the need for significant improvements. By examining the current state of mining in Pakistan and learning from other countries’ practices, this study proposes the following potential mining strategies to enhance coal mining safety and productivity in Pakistan, as shown in Table 4.

Table 4.

Safety challenges, consequences, and preventive measures to enhance coal mining safety in Pakistan.

In addition, the increasing focus on environmental sustainability is affecting every sector, including coal mining. In the context of Pakistan, it is important to assess how the coal mining sector is adapting to these changes. This includes investigating new regulations aimed at reducing environmental impact, the market’s rising demand for eco-friendly practices, and how these shifts are influencing investment risks and daily operations in the industry. By understanding these factors, we can better examine how coal mining in Pakistan is evolving to meet the growing global emphasis on sustainable practices.

These strategies emphasize the need for modernizing coal mining practices in Pakistan to enhance productivity and safety. By addressing the outlined safety challenges through targeted preventive measures, the coal mining sector in Pakistan can achieve significant improvements in operational efficiency and worker safety.

6. Conclusions

Coal is considered to be one of the most abundant and economical energy sources around the globe. It can play an integral part in national development. As Pakistan is facing an extensive energy crisis, coal can be used to generate electricity. However, mines in Pakistan have a hazardous work environment due to the primitive mining methods and lack of skilled workforce; as a result, mine collapse, mine blast, and gas explosion are the major sources of fatalities due to the little attention paid to the implementation of safety measures that must be ensured by the government of Pakistan and the mining safety authorities to bring down the hazard level in the workplace for coal miners, especially in the Balochistan and Khyber Pakhtunkhwa provinces. In conclusion, this paper introduces critical challenges in Pakistan’s coal mining sector, including the energy crisis, the utilization of indigenous coal resources, and power demand. It highlights the detrimental effects of data scarcity, lack of research, and technology adoption as factors leading to the recurring and severe safety threats in underground coal mines. Furthermore, this study conducts a comparative analysis of coal mining safety between Pakistan and the world and proposes practical strategies to address safety concerns within the country’s coal mining industry. It emphasizes the utilization of domestic coal resources as a means to foster socioeconomic development in a low-GDP country like Pakistan. These strategies aim to maximize the benefits for the nation’s overall growth and progress.

Funding

This study was funded by the Guizhou Provincial Education Department’s “Hundred Schools Thousands of Enterprises Science and Technology Research List” Project ([2024]013) and Qiankehezhongyindi ([2024]039).

Data Availability Statement

Not applicable.

Acknowledgments

Our sincere thanks go to the anonymous reviewers for their valuable comments and suggestions.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shahani, N.M.; Wan, Z.; Ali, M.; Ullah, B. Detection and monitoring of underground coal mine gases at Lakhra Coal Mines, Pakistan. In Proceedings of the 35th Annual International Pittsburgh Conference, Zuzhou, China, 15–18 October 2018; pp. 1–8. [Google Scholar]

- Jiskani, I.M.; Ullah, B.; Shah, K.S.; Bacha, S.; Shahani, N.M.; Ali, M.; Maqbool, A.; Qureshi, A.R. Overcoming mine safety crisis in Pakistan: An appraisal. Process Saf. Prog. 2019, 38, e12041. [Google Scholar] [CrossRef]

- Ullah, M.F.; Mahmood, K.; Akram, M.S. Coal mining trends and future prospects: A case study of Eastern Salt Range, Punjab, Pakistan. J. Himal. Earth Sci. 2018, 51, 87. [Google Scholar]

- CEIC. Pakistan Coal Production. Available online: https://www.ceicdata.com/en/indicator/pakistan/coal-production#:~:text=Production%20in%202022%3F-,Pakistan%20Coal%20Production%20was%20reported%20at%209.900%20Tonne%20mn%20in,table%20below%20for%20more%20data (accessed on 7 July 2024).

- The Global Economy. Pakistan: Coal Imports. 2022. Available online: https://www.theglobaleconomy.com/Pakistan/coal_imports/ (accessed on 7 July 2024).

- Businerss Recorder. Mining Sector Likely to Get Status of Industry. Available online: https://www.brecorder.com/news/40188393 (accessed on 7 July 2024).

- Rauf, O.; Wang, S.; Yuan, P.; Tan, J. An overview of energy status and development in Pakistan. Renew. Sustain. Energy Rev. 2015, 48, 892–931. [Google Scholar] [CrossRef]

- Mirjat, N.H.; Uqaili, M.A.; Harijan, K.; Valasai, G.D.; Shaikh, F.; Waris, M. A review of energy and power planning and policies of Pakistan. Renew. Sustain. Energy Rev. 2017, 79, 110–127. [Google Scholar] [CrossRef]

- Latif, A.; Ramzan, N. A review of renewable energy resources in Pakistan. J. Glob. Innov. Agric. Soc. Sci. 2014, 2, 127–132. [Google Scholar] [CrossRef]

- Malkani, M.S. A review of coal and water resources of Pakistan. J. Sci. Technol. Dev. 2012, 31, 202–218. [Google Scholar]

- IndustriAll Global Union. 27 Coalminers Killed in Pakistan So Far in 2019. 2019. Available online: https://www.industriall-union.org/27-coalminers-killed-in-pakistan-so-far-in-2019 (accessed on 7 July 2024).

- Naveed, M.A.; Ali, A. Health and safety information behaviour of coal miners in Pakistan. Libri 2021, 71, 29–40. [Google Scholar] [CrossRef]

- Aljazeera. Seven Killed in Southwest Pakistan Coal Mining Disaster. 2021. Available online: https://www.aljazeera.com/news/2021/3/16/seven-killed-in-southwest-pakistan-coal-mining-disaster (accessed on 7 July 2024).

- Business and Human Rights Resource Centre. Pakistan: Over 318 Workers Killed in Last Eight Years in Coal Mines in Balochistan. 2018. Available online: https://www.business-humanrights.org/de/neuste-meldungen/pakistan-over-318-workers-killed-in-last-eight-years-in-coal-mines-in-balochistan/ (accessed on 5 July 2024).

- Shahani, N.M.; Sajid, M.J.; Zheng, X.; Brohi, M.A.; Jiskani, I.M.; Ul Hassan, F.; Qureshi, A.R. Statistical analysis of fatalities in underground coal mines in Pakistan. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–16. [Google Scholar] [CrossRef]

- Shahani, N.M.; Sajid, M.J.; Brohi, M.A.; Qureshi, A.R.; Shahani, L.B.; Bacha, S.; Ullah, B. An empirical analysis of fatal accidents in the coal mines of Pakistan. In Proceedings of the International Conference on Energy, Resources, Environment and Sustainable Development, Xuzhou, China, 31 May–3 June 2019; pp. 726–733. [Google Scholar]

- Shahani, N.M.; Sajid, M.J.; Zheng, X.; Jiskani, I.M.; Brohi, M.A.; Ali, M.; Ullah, B.; Qureshi, A.R. Fault tree analysis and prevention strategies for gas explosion in underground coal mines of Pakistan. Min. Miner. Depos. 2019, 13, 121–128. [Google Scholar] [CrossRef]

- Shahani, N.M.; Sajid, M.J.; Jiskani, I.M.; Ullah, B.; Qureshi, A.R. Comparative analysis of coal Miner’s fatalities by fuzzy logic. J. Min. Environ. 2021, 12, 77–87. [Google Scholar]

- Sherin, S.; Rehman, Z.; Hussain, S.; Mohammad, N.; Raza, S. Hazards identification and risk analysis in surface mines of Pakistan using fault tree analysis technique. Min. Miner. Depos. 2021, 15, 119–126. [Google Scholar] [CrossRef]

- Coal mining in Pakistan. 2023. Available online: https://en.wikipedia.org/wiki/Coal_mining_in_Pakistan#cite_note-2 (accessed on 7 July 2024).

- Shakeel, S.R.; Takala, J.; Shakeel, W. Renewable energy sources in power generation in Pakistan. Renew. Sustain. Energy Rev. 2016, 64, 421–434. [Google Scholar] [CrossRef]

- Aftab, S. Pakistan’s energy crisis: Causes, consequences and possible remedies. Expert Anal. Nor. 2014, 1–6. Available online: https://www.files.ethz.ch/isn/177484/ade59fba5daf67a11a1c217434abf440.pdf (accessed on 7 July 2024).

- Anwar, J. Analysis of energy security, environmental emission and fuel import costs under energy import reduction targets: A case of Pakistan. Renew. Sustain. Energy Rev. 2016, 65, 1065–1078. [Google Scholar] [CrossRef]

- Omer, A.M. Sustainable Energy Development, the Role of Renewables and Global Warming. J. Sustain. Dev. Stud. 2012, 1, 1–67. [Google Scholar]

- Farooq, M.; Shakoor, A. Severe energy crises and solar thermal energy as a viable option for Pakistan. J. Renew. Sustain. Energy 2013, 5, 013104. [Google Scholar] [CrossRef]

- CEIC. Pakistan Coal Production. 2022. Available online: https://www.ceicdata.com/en/indicator/pakistan/coal-production (accessed on 7 July 2024).

- CEIC. Pakistan Coal Consumption: Total. 2018. Available online: https://www.ceicdata.com/en/pakistan/energy-consumption-and-supplies-annual/coal-consumption-total (accessed on 7 July 2024).

- The Nation. Power Sector Remains Biggest Consumer of Coal in Pakistan. 2023. Available online: https://www.nation.com.pk/01-Jul-2023/power-sector-remains-biggest-consumer-of-coal-in-pakistan (accessed on 7 July 2024).

- Bilal, A.S. Country Report of Pakistan. In Proceedings of the JICA Training on Energy Policy, Tokyo, Japan, 26 June–23 July 2016. [Google Scholar]

- Pakistan Coal. 2016. Available online: https://www.worldometers.info/coal/pakistan-coal/ (accessed on 7 July 2024).

- Sajid, M.J.; Shahani, N.; Ali, M. Calculating inter-sectoral carbon flows of a mining sector via hypothetical extraction method. J. Min. Environ. 2019, 10, 853–867. [Google Scholar]

- Shah, S.A.H. Strategy for Mineral Sector Development in Pakistan; Ministry of Planning: Islamabad, Pakistan, 2018; pp. 1–24.

- Department of the Interior, U.S. Geological Survey. Available online: https://pubs.usgs.gov/of/1988/0251/report.pdf (accessed on 7 July 2024).

- Qureshi, A.A.; Kakar, D.M.; Akram, M.A.; Khattak, N.U.; Tufail, M.; Mehmood, K.; Jamil, K.; Khan, H.A. Radon concentrations in coal mines of Baluchistan, Pakistan. J. Environ. Radioact. 2000, 48, 203–209. [Google Scholar] [CrossRef]

- Pakistan Mineral Development Corporation. Available online: https://www.pmdc.gov.pk/ (accessed on 7 July 2024).

- Jiskani, I.M.; Cai, Q.; Zhou, W.; Chang, Z.; Chalgri, S.R.; Manda, E.; Lu, X. Distinctive model of mine safety for sustainable mining in Pakistan. Min. Metall. Explor. 2020, 37, 1023–1037. [Google Scholar] [CrossRef]

- Jiskani, I.M.; Han, S.; Rehman, A.U.; Shahani, N.M.; Tariq, M.; Brohi, M.A. An integrated entropy weight and grey clustering method–based evaluation to improve safety in mines. Min. Metall. Explor. 2021, 38, 1773–1787. [Google Scholar] [CrossRef]

- Janjuhah, H.T.; Ishfaque, M.; Mehmood, M.I.; Kontakiotis, G.; Shahzad, S.M.; Zarkogiannis, S.D. Integrated underground mining hazard assessment, management, environmental monitoring, and policy control in Pakistan. Sustainability 2021, 13, 13505. [Google Scholar] [CrossRef]

- Rehman, A.U.; Emad, M.Z.; Khan, M.U.; Saleem, M.A.; Saki, S.A. Investigation and analysis of fatal accident reporting practices in the Punjab province of Pakistan and remedial measures. Resour. Policy 2021, 73, 102186. [Google Scholar] [CrossRef]

- Ayaz, M.; Jehan, N.; Nakonieczny, J.; Mentel, U. Health costs of environmental pollution faced by underground coal miners: Evidence from Balochistan, Pakistan. Resour. Policy 2022, 76, 102536. [Google Scholar] [CrossRef]

- Jiskani, I.M.; Yasli, F.; Hosseini, S.; Rehman, A.U.; Uddin, S. Improved Z-number based fuzzy fault tree approach to analyze health and safety risks in surface mines. Resour. Policy 2022, 76, 102591. [Google Scholar] [CrossRef]

- Jiskani, I.M.; Zhou, W.; Hosseini, S.; Wang, Z. Mining 4.0 and climate neutrality: A unified and reliable decision system for safe, intelligent, and green & climate-smart mining. J. Clean. Prod. 2023, 410, 137313. [Google Scholar]

- Javaid, A.; Siddique, M.A.; Reshi, A.A.; Rustam, F.; Lee, E.; Rupapara, V. Coal mining accident causes classification using voting-based hybrid classifier (VHC). J. Ambient Intell. Humaniz. Comput. 2023, 14, 13211–13221. [Google Scholar] [CrossRef]

- Yang, L.; Birhane, G.E.; Zhu, J.; Geng, J. Mining employees safety and the application of information technology in coal mining. Front. Public Health 2021, 9, 709987. [Google Scholar] [CrossRef]

- Dursun, A.E. Fatal Accident Analysis and Hazard Identification in Turkish Coal-Extracting Industry Using Analytic Hierarchy Process. Min. Metall. Explor. 2024, 41, 149–172. [Google Scholar] [CrossRef]

- Kumar, P.P.; Paul, P.S.; Ananda, M. Development of LoRa Communication System for Effective Transmission of Data from Underground Coal Mines. Processes 2023, 11, 1691. [Google Scholar] [CrossRef]

- Rahimdel, M.J.; Aryafar, A.; Vaziri, S. Fuzzy FMEA for the safety risk analysis of underground coal mining (a case study in Iran). Min. Technol. 2022, 131, 104–114. [Google Scholar] [CrossRef]

- Margolis, K.A. Underground coal mining injury: A look at how age and experience relate to days lost from work following an injury. Saf. Sci. 2010, 48, 417–421. [Google Scholar] [CrossRef]

- Connolly, E.; Orsmond, D. The Mining Industry: From Bust to Boom|Conference–2011. 2011. Available online: https://www.rba.gov.au/publications/confs/2011/connolly-orsmond.html (accessed on 9 July 2024).

- Liu, Q.; Meng, X.; Hassall, M.; Li, X. Accident-causing mechanism in coal mines based on hazards and polarized management. Saf. Sci. 2016, 85, 276–281. [Google Scholar] [CrossRef]

- Liu, Q.; Peng, Y.; Li, Z.; Zhao, P.; Qiu, Z. Hazard identification methodology for underground coal mine risk management-Root-State Hazard Identification. Resour. Policy 2021, 72, 102052. [Google Scholar] [CrossRef]

- Liu, Q.; Dou, F.; Meng, X. Building risk precontrol management systems for safety in China’s underground coal mines. Resour. Policy 2021, 74, 101631. [Google Scholar] [CrossRef]

- Bhattacherjee, A.; Kunar, B.M.; Baumann, M. Associations between occupational factors and occupational injury and the interplay of personal factors in Indian and French coal miners. In The 34th International Conference of Safety in Mines Research Institutes (34th ICSMRI); Macmillan Publishers India Ltd.: New Delhi, India, 2011; pp. 481–493. [Google Scholar]

- Bhattacherjee, A.; Kunar, B.M.; Baumann, M.; Chau, N.; Lorhandicap Group. The role of occupational activities and work environment in occupational injury and interplay of personal factors in various age groups among Indian and French coalminers. Int. J. Occup. Med. Environ. Health 2013, 26, 910–929. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Li, X.; Meng, X. Effectiveness research on the multi-player evolutionary game of coal-mine safety regulation in China based on system dynamics. Saf. Sci. 2019, 111, 224–233. [Google Scholar] [CrossRef]

- Spanidis, P.M.; Pavloudakis, F.; Roumpos, C. The Knowledge Management Landscape in the Greek Coal Mining Industry. Min. Metall. Explor. 2024, 41, 819–841. [Google Scholar] [CrossRef]

- Reason, J. Managing the Risks of Organizational Accidents; Routledge: London, UK, 2016. [Google Scholar]

- Esmaeilzadeh, A.; Shaffiee Haghshenas, S.; Mikaeil, R.; Guido, G.; Shirani Faradonbeh, R.; Abbasi Azghan, R.; Jafarpour, A.; Taghizadeh, S. Risk Assessment in Quarries using Failure Modes and Effects Analysis Method (Case study: West-Azerbaijan Mines). J. Min. Environ. 2022, 13, 715–725. [Google Scholar]

- Sanmiquel, L.; Rossell, J.M.; Bascompta, M.; Vintró, C.; Yousefian, M. Data mining of accidents in Spanish underground mines in the period 2003–2021 caused by a collision with a moving object. Heliyon 2024, 10, e24716. [Google Scholar] [CrossRef]

- Yu, H.; Zahidi, I.; Chow, M.F. Vegetation as an ecological indicator in assessing environmental restoration in mining areas. iScience 2023, 26, 107667. [Google Scholar] [CrossRef]

- De Dianous, V.; Fievez, C. ARAMIS project: A more explicit demonstration of risk control through the use of bow–tie diagrams and the evaluation of safety barrier performance. J. Hazard. Mater. 2006, 130, 220–233. [Google Scholar] [CrossRef] [PubMed]

- Chevreau, F.R.; Wybo, J.L.; Cauchois, D. Organizing learning processes on risks by using the bow-tie representation. J. Hazard. Mater. 2006, 130, 276–283. [Google Scholar] [CrossRef] [PubMed]

- Chau, N.; Wild, P.; Dehaene, D.; Benamghar, L.; Mur, J.M.; Touron, C. Roles of age, length of service and job in work-related injury: A prospective study of 446 120 person-years in railway workers. Occup. Environ. Med. 2010, 67, 147–153. [Google Scholar] [CrossRef] [PubMed]

- Ukey, N.; Yang, Z.; Li, B.; Zhang, G.; Hu, Y.; Zhang, W. Survey on exact knn queries over high-dimensional data space. Sensors 2023, 23, 629. [Google Scholar] [CrossRef]

- Sharma, M.; Maity, T. Review on machine learning-based underground coal mines gas hazard identification and estimation techniques. Arch. Comput. Methods Eng. 2024, 31, 371–388. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).