Abstract

Data were obtained on the copolymerization of ethylene with α-olefins over supported titanium–magnesium catalysts (TMC) prepared on the same magnesium dichloride support but differing in the composition and oxidation state of titanium. The copolymerization kinetics of ethylene with 1-hexene over TMC of different compositions were studied. Data on the composition of the produced ethylene–1-hexene copolymers, their molecular weight distribution, thermophysical characteristics, and branching distribution were presented. The constants of ethylene–1-hexene copolymerization over catalysts with different compositions were calculated. The TMC containing only Ti(II) compounds as the active component exhibited increased copolymerizing ability compared to the conventional TiCl4/MgCl2 catalyst containing Ti(III) compounds as the active component. In addition, TMC with Ti(II) as an active component produces copolymers with a more uniform branching distribution. It was shown that the TMC containing isolated Ti(II) ions could be used to produce X-ray amorphous ethylene-propylene elastomers with a high yield.

1. Introduction

At present, an essential amount of polyethylene (PE) in the world is produced with the use of highly active Ziegler-Natta catalysts, which contain titanium chlorides deposited on the MgCl2-containing support (supported titanium–magnesium catalysts, TMC), in combination with organoaluminum co-catalysts (OAC) [1,2,3]. The majority of produced PE grades, for example, pipe and film grades of high-density polyethylene (HDPE) and also linear low-density polyethylene (LLDPE), are copolymers of ethylene with α-olefins. In particular, LLDPE contains up to 5 mol.% of α-olefin. The physico-mechanical and rheological properties of the produced copolymers depend on the type and content of the comonomer and its distribution in the obtained polymer [4,5,6,7]. Naturally, the ability of the comonomer to efficiently and uniformly insert itself into the polymer chains is determined primarily by the characteristics of the catalyst active sites and by the polymerization conditions [8,9,10,11,12].

It is known that conventional multisite Ziegler-Natta catalysts, particularly the TMC, produce copolymers with broad molecular weight distribution (MWD) and non-uniform molecular weight distribution of the comonomer [8,9,10,11,12,13]. Supposedly [14,15], the formation of copolymers with the indicated properties may be caused by the non-uniformity of the TMC active sites with respect to the oxidation state of titanium.

According to our data [16,17,18], the oxidation state of titanium in a titanium–magnesium catalyst exerts virtually no effect on the molecular weight characteristics of the produced homopolyethylene. However, the literature provides virtually no data concerning the effect of the titanium oxidation state in TMC on the copolymerization ability of such catalysts or the compositional heterogeneity of the obtained ethylene–α-olefin copolymers. Refs. [16,19] demonstrate that the composition of TMC, in particular the titanium oxidation state in the active component, affects the efficiency of comonomer insertion into the polymer chain during polymerization of ethylene with 1-hexene. Note that the authors of refs. [16] and [19] reached opposite conclusions on the copolymerization ability of the Ti(II)-based catalyst. In ref. [16], where the TMC active component was represented by the divalent titanium complex η6-BenzeneTiAl2Cl8 (the TiCl2 compound bound with two AlCl3 molecules), an increased copolymerization ability was observed in the polymerization of ethylene with 1-hexene as compared to the standard TMC (TiCl4/MgCl2). In ref. [19], the TMC containing only titanium(II) chloride (TiCl2) showed a decreased copolymerization ability in comparison with the TiCl4-based TMC. Most likely, the reactivity of the catalyst active site is affected not only by the oxidation state of Tin+ (the electronic state of titanium) but also by its coordination environment.

In this study, we investigated the copolymerization kinetics of ethylene with 1-hexene and propylene over four modifications of TMC, in which the active component was represented by titanium compounds in different oxidation states (Ti(II), Ti(III), or Ti(IV)) and in different coordination environments. Data were obtained on the copolymerization ability of these catalysts, their molecular weight characteristics, and the compositional heterogeneity of the produced copolymers.

2. Materials and Methods

Titanium tetrachloride (TiCl4) was used without additional purification. The divalent titanium complex with the composition [η6-BenzeneTiCl2·2AlCl3] was synthesized according to the Fisher–Hafner method [20,21] by the reduction of TiCl4 with aluminum in the presence of AlCl3 in a benzene medium. The obtained complex was made in a solution using a procedure reported in ref. [22]: 1 g of a solid titanium-benzene complex was dissolved in 100 mL of benzene containing AlEt3 at a concentration of 1 mmol/L for 2 h at a temperature of 70 °C. ESR spectra of the initial complexes are characterized by the virtually complete absence of Ti(III) ions. The soluble TiCl3∙nDBE complex was synthesized according to [23] by the reduction of titanium tetrachloride with hydrogen at room temperature in a 1,2-dichloroethane medium in the presence of a carbon-supported palladium catalyst and dibutyl ether (DBE). The ESR spectrum of the obtained TiCl3∙nDBE complex contains the signal typical for Ti(III) ions. Therewith, the concentration of isolated paramagnetic ions was 12% of the total titanium amount. After the addition of pyridine (Py/Ti = 50 (mol)), which destructs the associates of titanium compounds with the formation of soluble TiCl3∙nPy adducts, an isotropic ESR signal from Ti(III) was observed. The intensity of this signal corresponded to the total content of titanium.

The highly dispersed MgCl2-containing support was prepared according to ref. [24] via the interaction of the organomagnesium compound Mg3Ph4Cl2·nDBE dissolved in chlorobenzene with a mixture of Si(OEt)4 and PhSiCl3, at the molar ratios of Si(OEt)4/Mg = 0.25 and PhSiCl3/Mg = 0.75. Dibutyl ether, which was used to synthesize the MgCl2 support, was removed by treating the support with diethyl aluminum chloride (DEAC) at a molar ratio of Al/Mg = 1.5 and repeated washing of the support with heptane.

The catalysts were synthesized by depositing the calculated amount of titanium compound (1.5 wt.% titanium of the support weight) on the MgCl2 support in heptane at 20 °C.

To synthesize the TMC-1 catalyst, a solution of the Ti(II) complex ([η6-BenzeneTiCl2·2AlCl3]) was used. The TMC-1-2 catalyst was obtained by treating the TMC-1 catalyst with chloropentafluorobenzene (C6F5Cl) in a toluene solution for a day at a molar ratio of C6F5Cl/Ti = 20 for the oxidation of Ti(II) to Ti(III). The catalyst was then washed with heptane to remove an excess of C6F5Cl. The interaction of TMC-1 with C6F5Cl leads to the oxidation of Ti(II) to Ti(III), which is indicated by the appearance of an intense signal in the ESR spectrum, which is typical of isolated paramagnetic Ti(III) ions. The concentration of Ti(III) ions in the produced TMC-1-2 catalyst corresponds to the titanium content in the initial TMC-1 catalyst.

The TMC-2 catalyst was synthesized by depositing a solution of the TiCl3 nDBE complex in 1,2-dichloroethane on the MgCl2 support.

The TMC-3 catalyst was obtained by treating the magnesium dichloride support with TiCl4 in heptane at 20 °C.

After holding the reaction mixture at 60 °C for 1 h, all the catalysts were washed with heptane three times.

The polymerization of ethylene or copolymerization of ethylene with α-olefin (1-hexene) was carried out in a 1 L stainless steel reactor. The reactor was equipped with a jacket to maintain the polymerization temperature. It was also equipped with a magnetically coupled stirrer with a controlled stirring speed. A constant ethylene pressure in the reactor was maintained using an automatic feeder of ethylene. The polymerization conditions were as follows: heptane (0.25–0.3 L); polymerization temperature was 80 °C; ethylene pressure was 2 bars; hydrogen pressure was 0.25 bars; TIBA (triisobutylaluminum) was used as a co-catalyst (4.0–4.8 mmol L–1). In some experiments, 1-hexene (5–20 mL) was charged into the reactor at the beginning of the polymerization. The amount of TMC-1 catalyst injected into the polymerization reactor was 8 mg; TMC-1-2 catalyst, 6.1 mg; TMC-2 catalyst, 10.7 mg; and TMC-3 catalyst, 6.7 mg.

The synthesis of X-ray amorphous ethylene-propylene copolymers (EPC) was performed in the same polymerization reactor at a temperature of 70 °C and a pressure of 3 bars for the ethylene-propylene mixture. The propylene content in an autoclave before the experiments was equal to 64.5 mol.%, whereas the propylene content in the feed mixture was 32–33 mol.%. The reaction time was 60 min. TIBA was used as a co-catalyst (4.8 mmol L–1).

The content of titanium in the catalysts was determined by AES-ICP using an Optima 4300 DV spectrometer (PerkinElmer, Waltham, MA, USA).

MWD measurements were carried out using a high-temperature gel permeation chromatography (GPC) PL 220 system (Angilent Technologies, Inc., Santa Clara, CA, USA) equipped with RI and DV detectors in 1,2,4-trichlorobenzene at a flow rate of 1 mL·min–1 and a temperature of 160 °C. The polymers were analyzed on a set of Olexis columns. The instrument was calibrated using polyethylene and polystyrene standards with a narrow MWD.

Copolymer fractionation into narrow fractions was carried out on a PolymerChar PREP mc2 fractionation instrument (PolymerChar, Valencia, Spain) [8]. The branching content in the initial copolymer and separate fractions were measured by IR spectroscopy on a Shimadzu FTIR 8400S spectrometer (Shimadzu Corp, Kyoto, Japan) (the absorption band is at 1378 cm–1) or by NMR spectroscopy on a Bruker MSL-400 spectrometer (Bruker Physic-AG Corporation, Karlsruhe, Germany) [25,26]. Therewith, the number of terminal methyl groups calculated from the Mn value was subtracted from the total number of methyl groups.

The melting temperature (Tm) and crystallinity (Xc) were determined on a DSC 204 F1 (Netzsch) instrument (Netzsch, Selb, Germany) according to ASTM D3418-82 and ASTM D3417-83 procedures in an argon atmosphere. The melting temperature and enthalpy (ΔH) were measured from the data of the second melting.

3. Results and Discussion

3.1. The Oxidation State of Titanium in the Active Component of Ti-Mg Catalysts of Different Composition According to ESR Data

The same MgCl2 support was prepared according to ref. [24] (the mean particle size of 6–7 µm, Ssp = 176 m2/g) was used to synthesize a series of highly active supported TMCs of different compositions. The TMC-1 catalyst was prepared by depositing on MgCl2 a compound with the composition [η6-BenzeneTiAl2Cl8]. This catalyst contains only monomeric Ti(II) ions bound with two aluminum chloride molecules [18]. The TMC-1-2 catalyst was obtained by treating the TMC-1 catalyst with chloropentafluorobenzene; its active component is represented by monomeric compounds of Ti(III) ([η6-BenzeneTiAl2Cl8]/MgCl2/C6F5Cl). TMC containing mostly the associated Ti(III) compounds (60–90%) after the interaction with AlR3 (TMC-2 and TMC-3 catalysts) were prepared as the reference catalysts. TMC-2 catalyst was prepared by depositing the TiCl3·nDBE soluble complex on the MgCl2 support, and the TMC-3 catalyst was prepared by depositing the TiCl4 on the MgCl2 support.

Our earlier data [18] on the content of titanium in different valent states and in different coordination environments in the catalysts synthesized using different titanium compounds, which were employed in this study, are listed in Table 1.

Table 1.

Content of titanium in different oxidation states and different environments in TMC synthesized using titanium compounds of different compositions.

One can see in Table 1 that the TMC-1 catalyst (exp. 1), which was synthesized using a complex with the composition [η6-BenzeneTiCl2·2AlCl3], contains only the isolated Ti(II) ions. These data were obtained after the treatment of TMC-1 with water or chloropentafluorobenzene, leading to the oxidation of Ti(II) ions in the catalyst to Ti(III) ions, which were identified by ESR [18]. It should be noted that additional evidence indicating the presence of divalent titanium in TMC-1 is the result of ethylene polymerization in the absence of an organoaluminium co-catalyst on this catalyst (the activity of 146 kg PE/(gTi × h) at 80 °C and 4 bar C2H4). The literature data [27,28] allow the conclusion that, among Ti-containing catalytic systems, only the catalysts based on divalent titanium can perform ethylene polymerization without an organoaluminium co-catalyst.

The TMC-1-2 catalyst obtained by the interaction of TMC-1 with chloropentafluorobenzene contains only the mononuclear compounds of trivalent titanium (isolated Ti(III) ions) (Table 1, exp. 2). The interaction of this catalyst with aluminum trialkyl (TIBA/Ti = 15 mol/mol) does not change the valent state of titanium (Table 1, exp. 2-1). The isolated state of titanium ions in these two catalysts may be caused by the composition of the initial titanium complex [η6-Benzene TiCl2·2AlCl3], namely, by the presence of two AlCl3 groups, which hinder the mutual interaction of titanium ions on the magnesium chloride surface.

According to ESR data, the TMC-2 catalyst with the composition TiCl3/MgCl2, which was prepared by depositing the TiCl3∙nDBE complex on MgCl2, contains 35% of isolated Ti(III) ions and 65% of Ti(III) as associates of Ti(III) titanium ions, which are observed in the ESR spectrum after treating the catalyst with pyridine [18]. After the interaction of this catalyst with TIBA at 298 K (Al/Ti = 15 mol/mol), a small part of the associated titanium ions (~5–10%) is reduced to the divalent state (Table 1, exp. 3-1).

The TMC-3 catalyst with the composition TiCl4/MgCl2 after the interaction with TIBA (Al/Ti = 15 mol/mol, 298 K) contains a wide set of titanium compounds with different oxidation states of titanium ions and coordination states of Ti(III) ions (Table 1, exp. 4-1). Therewith, the major part of trivalent titanium (ca. 70%) is present as TiCl3 associates, which are observed in the ESR spectrum only after treatment of the catalyst with pyridine [18].

According to our data obtained in the study of the above-listed catalysts in the homopolymerization of ethylene [18], differences in the oxidation state of titanium ions and their coordination state (isolated or associated Ti(II) and Ti(III) ions) in the active component of catalysts exert virtually no effect on the molecular weight and polydispersity (Mw/Mn) of the produced homopolyethylenes.

3.2. Copolymerization of Ethylene with α-Olefins over Ti-Mg Catalysts Containing Titanium Compounds in Different Oxidation States and Different Coordination Environments

3.2.1. Copolymerization of Ethylene with 1-Hexene

Data obtained on the homopolymerization of ethylene and copolymerization of ethylene (C2) with 1-hexene (C6), using TMC of different compositions are presented in Table 2 and Figure 1. To maintain a close concentration of 1-hexene in the reaction medium, the copolymerization experiments were carried out under conditions where the conversion of 1-hexene at the end of the experiment did not exceed 20%. So, the polymerization time was limited to the production of no more than 20 g of the copolymer.

Table 2.

Data on the copolymerization of ethylene with 1-hexene over Ti-Mg catalysts containing titanium compounds in different oxidation states as the active component.

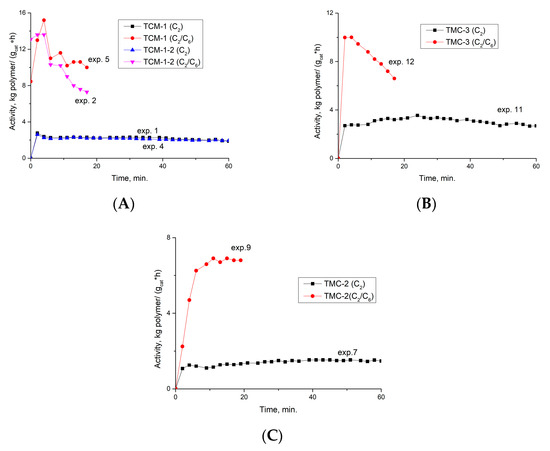

Figure 1.

Kinetic curves of ethylene homopolymerization and ethylene–1-hexene copolymerization over TMC with different compositions of the active component ((A)—TMC-1 and TMC-1-2; (B)—TMC-3; (C)—TMC-2) (the numbering of kinetic curves corresponds to the numbering of experiments in Table 2).

To estimate the copolymerization ability of various TMCs, copolymerization constants (r1) were calculated from the dependence of the content of the comonomer (1-hexene) in the polymer on the molar ratio of monomers in the reaction medium (heptane) using Equation (1):

(α-olefin/C2H4) (polymer) = 1/r1 ([α-olefin]/[C2H4] (heptane)

According to Table 2, all the tested TMCs have close levels of the average activity in the homopolymerization of ethylene (1.4–3.0 kg PE/(g cat × h)). The maximum activity was observed for TMC-3, which contains TiCl4 as the active component. The TMC-2 catalyst has a lower activity (1.4 kg/(g cat × h)). The decreased activity of this catalyst may be caused by the presence of dibutyl ether in it.

The TMC-1 and TMC-1-2 catalysts, which contain only the isolated monomeric compounds of Ti(II) and Ti(III), have close activity and similar forms of kinetic curves, which are characterized by high initial activity and a minor decrease during polymerization (Figure 1A). In the case of TMC-2 and TMC-3 catalysts containing titanium chlorides in different oxidation states (TiCl3 and TiCl4) as the active component, the activity changes slightly with the polymerization time (Figure 1B,C).

In the case of ethylene–1-hexene copolymerization over TMC-1, TMC-1-2, and TMC-3 catalysts (Figure 1A,B), a high initial activity followed by a considerable decrease in polymerization rate was observed. In the case of copolymerization over TMC-2, the activity sharply increases in the initial period (10 min) until a stable level is achieved (Figure 1C). It was supposed [29,30,31] that the increase in activity of different catalysts in the copolymerization of ethylene with α-olefin relative to the homopolymerization of ethylene may be associated with the higher concentration of monomers on the surface of catalysts. This effect was explained by an increase in the portion of amorphous material in the produced copolymers in comparison with homopolyethylene, which has a higher crystallinity. As seen in Table 2, indeed, all the copolymers of ethylene with 1-hexene have a lower crystallinity (26–47%) with respect to PE (60–66%) and a lower melting point of the crystalline part.

The gel permeation chromatographic analysis of the C2/C6 copolymer samples produced on different TMC under similar polymerization conditions revealed that the polymers have close molecular weights (Mw = 170–230 × 103) and MWD (Mw/Mn = 4.1–4.4) (Table 2, exps. 5, 9, and 12). An increase in the concentration of 1-hexene in the reaction medium leads to a decrease in the molecular weight (Mw drops from 170–230 to 100–140 kg/mol) of copolymers obtained over all the TMC. As was shown in refs. [32,33], α-olefin is an efficient polymer chain transfer agent during the copolymerization of ethylene with α-olefins (propylene, 1-hexene) over TMC.

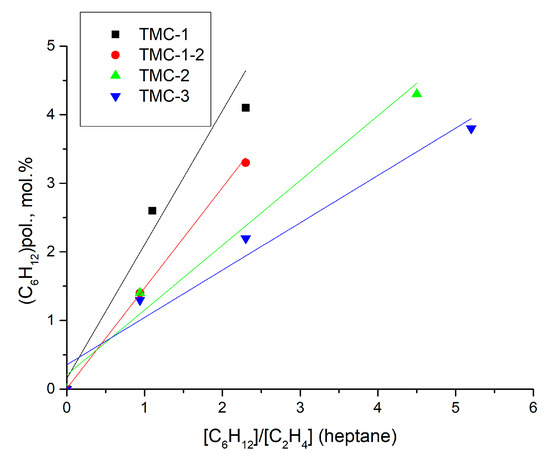

Figure 2 displays the dependences of 1-hexene content in copolymers obtained over TMC of different compositions on the [C6H12]/[C2H4] ratio in the reaction medium (heptane).

Figure 2.

The content of 1-hexene in C2/C6 copolymers obtained on TMC of different compositions versus the [C6H12]/[C2H4] ratio in the reaction medium (heptane) (for polymerization conditions and the catalyst’s number, see Table 2).

According to the data presented in Figure 2 and Table 2, which corresponds to the inverse r1 value, the copolymerization ability changes in the following series of catalysts: TMC-1 > TMC-1-2 > TMC-2 > TMC-3.

Thus, the highest copolymerization ability (r1 = 49) was observed for the TMC-1 catalyst, which contains isolated monomeric compounds of Ti(II) as the active component. The copolymerization ability of this catalyst exceeds that of TMC-2 and TMC-3 by a factor of 2–3 (r1 = 99 and 130, respectively). The intermediate copolymerization ability (r1 = 68) was exhibited by the TMC-1-2 catalyst, which contains isolated monomeric Ti(III) compounds obtained by the oxidation of Ti(II) compounds in the TMC-1 catalyst.

It is known that one of the main factors affecting the properties of copolymers is the distribution of comonomer units in the polymer chain (in the fractions of copolymers with different molecular weights). To analyze the compositional heterogeneity of copolymers obtained on different catalysts and, respectively, the heterogeneity of active sites of these catalysts in the copolymerization of ethylene with 1-hexene, copolymers with a close content of 1-hexene (17–21 Bu/1000C) were separated into fractions with a narrow molecular weight distribution.

Data on the content of comonomers in the fractions of copolymers produced on catalysts of different compositions are listed in Table 3 and presented in Figure 3.

Table 3.

Data on the molecular weight characteristics of individual fractions and the content of branchings in these fractions for copolymers produced over TMC-1, TMC-1-2, TMC-2, and TMC-3 catalysts.

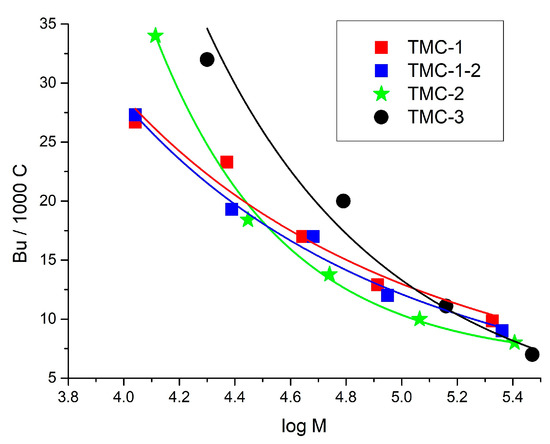

Figure 3.

The content of butyl branching in the fractions of copolymers produced on the catalysts of different compositions.

According to Table 3 and Figure 3, the copolymer produced over TMC-3 has the most non-uniform distribution of comonomer over the polymer fractions with different molecular weights (the amount of 1-hexene in F1 and F4 fractions differs by a factor of 4.7). The most uniform distribution of comonomers is observed for the copolymer obtained on the TMC-1 catalyst, which has the maximum copolymerization ability in the studied series of catalysts (Figure 3).

3.2.2. Copolymerization of Ethylene with Propylene

Data on the ethylene-propylene copolymerization and properties of the polymers produced over TMC-1, TMC-1-2, and TMC-3 catalysts (activity of the catalysts, molecular weight characteristics, and propylene content in copolymers) are listed in Table 4. In this case, copolymerization was performed at an increased content of propylene in the reaction medium (C3/C2 ≈ 0.5 mol/mol) under conditions ensuring the formation of copolymers with a high content of methyl branchings, which are necessary for the production of ethylene-propylene elastomers. These experiments were carried out with TMC-1 and TMC-1-2 catalysts having an increased copolymerization ability and the TMC-3 catalyst having a decreased copolymerization ability in the copolymerization of ethylene with 1-hexene (Table 3).

Table 4.

Data on the copolymerization of ethylene with propylene, composition, and molecular weight characteristics of copolymers obtained over catalysts of different compositions.

One can see in Table 4 that all the TMCs have a close activity toward the copolymerization of ethylene with propylene under the conditions used for the production of ethylene-propylene elastomers. The produced EPCs have close molecular weights and increased polydispersity (Mw/Mn = 8.3–11.6) as compared to ethylene–1-hexene copolymers, for which Mw/Mn = 4.0–5.0. According to differential scanning calorimetry data, the produced ethylene-propylene copolymers have only small crystallinity regions at ca. 100 °C and are virtually X-ray amorphous; their crystallinity is below 0.5% in terms of ethylene crystallinity.

The content of propylene in EPC (Table 4) decreases in the following TMC series: TMC-1 > TMC-1-2 > TMC-3.

Thus, similar to the copolymerization of ethylene with 1-hexene, the TMC-1 catalyst containing the monomeric Ti(II) compound has a higher copolymerization ability in the copolymerization of ethylene with propylene as compared to TMC-1-2 and TMC-3 and makes it possible to obtain the ethylene-propylene elastomer with the required content of propylene (40–50 mol.%).

Supposedly, the enhanced copolymerization ability of the TMC-1 catalyst in the copolymerization of ethylene with 1-hexene and propylene may be related to the formation of the active component in this catalyst as the AlCl3·TiCl2·AlCl3 structure, in which the active site is probably more accessible for coordination and insertion of comonomers having methyl (propylene) or butyl branchings (1-hexene) near the double bond.

4. Conclusions

Data on the ethylene-1-hexene copolymerization kinetics of four modifications of supported titanium–magnesium catalysts have been obtained. These catalysts contain titanium chloride compounds with different oxidation states and coordination states of titanium ions. It was found that catalysts with the active component represented by mononuclear Ti(II) compounds having the TiCl2·2AlCl3 composition (the TMC-1 catalyst) and mononuclear compounds of Ti(III) having the TiCl3·2AlCl3 composition (the TMC-1-2 catalyst) possess a higher copolymerizing ability compared to conventional catalysts containing associates of Ti(III) ions (the (TiCl3)2) structure as the active component (the TMC-2 and TMC-3 catalysts). The TMC-1 catalyst was shown to produce the ethylene–1-hexene copolymer with a more uniform branching distribution as compared to the TMC-3 catalyst. It was found that the TMC-1 catalyst allows for the high yield of the X-ray amorphous ethylene-propylene copolymer with a propylene content of 42 mol.%. The increased copolymerizing ability of the TMC-1 catalyst in the copolymerization of ethylene with 1-hexene and propylene may be determined by the formation of the active component with the AlCl3 TiCl2·AlCl3 structure.

Author Contributions

Conceptualization, T.B.M. and V.A.Z.; methodology, M.A.M.; validation, T.B.M., V.A.Z. and M.A.M.; formal analysis, M.A.M. and T.B.M.; investigation, P.G. and T.B.M.; resources, M.A.M.; data curation, V.A.Z.; writing—original draft preparation, T.B.M.; writing—review and editing, T.B.M., V.A.Z. and M.A.M.; supervision, V.A.Z.; project administration, M.A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the MINISTRY OF SCIENCE AND HIGHER EDUCATION OF THE RUSSIAN FEDERATION (project AAAA21-121011490008-3).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All needed data are in the manuscript. No additional data are required.

Acknowledgments

The authors thank Marina Nikolaeva, Marina Vanina, and Anastasiya Manyakhina for the analysis of molecular weight characteristics of PE.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nowlin, T.E. Business and technology of the global polyethylene industry. In An In-Depth Look at the History, Technology, Catalysts, and Modern Commercial Manufacture of Polyethylene and Its Products; WILEY Scrivener Publishing: Beverly, MA, USA, 2014; p. 403. ISBN 978-1-118-94598-8. [Google Scholar]

- Sauter, D.; Taoufik, M.; Boisson, C. Polyolefins, a success story. Polymers 2017, 9, 185. [Google Scholar] [CrossRef] [PubMed]

- Plastics Europe: Plastics—The Facts 2020. Available online: https://plasticseurope.org/de/wp-content/uploads/sites/3/2021/11/Plastics_the_facts-WEB-2020 version Jun21_final.pdf (accessed on 27 June 2022).

- Bialek, N.; Czaja, K. The effect of the comonomer on the copolymerization of ethylene with long chain α-olefins using Ziegler–Natta catalysts supported on MgCl2 (THF)2. Polymer 2000, 41, 7899. [Google Scholar] [CrossRef]

- Alizadeh, A.; Richardson, L.; Xu, J.; McCartney, S.; Marand, H.; Cheung, Y.W.; Chum, S. Influence of structural and topological constraints on the crystallization and melting behavior of polymers. 1. Ethylene/1-octene copolymers. Macromolecules 1999, 32, 622. [Google Scholar] [CrossRef]

- Soares, J.B.P. An overview of important microstructural distributions for polyolefin analysis. Macromol. Symp. 2007, 257, 1–12. [Google Scholar] [CrossRef]

- Wahner, U.M.; Tincul, I.; Joubert, D.J.; Sadiku, E.R.; Forlini, F.; Losio, S.; Tritto, I.; Sacchi, M.C. 13C NMR study of copolymers of propene with higher 1-olefins with new microstructures by ansa-zirconocene catalysts. Macromol. Chem. Phys. 2003, 204, 1738–1746. [Google Scholar]

- Matsko, M.A.; Echevskaya, L.G.; Zakharov, V.A.; Nikolaeva, M.I.; Mikenas, T.B.; Vanina, M.P. Study of multi-site nature of supported Ziegler-Natta catalysts in ethylene-1-hexene copolymerization. Macromol. Symp. 2009, 282, 157. [Google Scholar] [CrossRef]

- Cho, H.S.; Chung, J.S.J.; Han, J.H.; Ko, Y.G.; Lee, W.Y. Polymerization of ethylene and ethylene/1-hexene over Ziegler–Natta/metallocene hybrid catalysts supported on MgCl2 prepared by a recrystallization method. J. Appl. Polym. Sci. 1998, 70, 1707–1715. [Google Scholar] [CrossRef]

- Aigner, P.; Averina, E.; Garoff, T.; Paulik, C. Effects of alterations to Ziegler–Natta catalysts on kinetics and comonomer (1-butene) incorporation. Macromol. React. Eng. 2017, 11, 1700009. [Google Scholar] [CrossRef]

- Cöpperl, L.; Pernusch, D.; Schwarz, J.; Paulik, C. Impact of polymerization process parametrs on improved comonomer incorporation behavior in Ziegler-Natta catalysis. Macromol. React. Eng. 2022, 16, 2100042. [Google Scholar] [CrossRef]

- Masoori, M.; Rashedi, R.; Sepahi, A.; Jandaghian, M.H.; Nikzinat, E.; Houshmandmoayed, S. Structure–Performance Relationship(SPR) of Ziegler Natta catalysts (TiCl4/MgCl2 based) in ethylene/1 butene and ethylene/1 hexene copolymerization. J. Polym. Res. 2022, 29, 317. [Google Scholar] [CrossRef]

- Alghyamah, A.A.; Soares, J.B.P. Simultaneous deconvolution of the bivariate distribution of molecular weight and chemical composition of polyolefins made with Ziegler-Natta catalysts. Macromol. Rapid. Commun. 2009, 30, 384–393. [Google Scholar] [CrossRef]

- Zucchini, U.; Cecchin, G. Control of molecular-weight distribution in polyolefins synthesized with Ziegler-Natta catalytic systems. Adv. Pol. Sci. 1983, 51, 109. [Google Scholar]

- Mori, H.; Hasebe, K.; Terano, M. Variation in oxidation state of titanium species on MgCl2-supported Ziegler catalyst and its correlation with kinetic behavior for propylene polymerization. Polymer 1999, 40, 1389–1394. [Google Scholar] [CrossRef]

- Mikenas, T.B.; Tregubov, A.A.; Zakharov, V.A.; Echevskaya, L.G.; Matsko, M.A. Titanium-magnesium catalysts for olefin polymerization- effect of titanium oxidation state on catalyst performance. Polymery 2008, 53, 353–357. [Google Scholar] [CrossRef]

- Zakharov, V.A.; Echevskaya, L.G.; Mikenas, T.B.; Matsko, M.A.; Tregubov, A.A.; Vanina, M.P.; Nikolaeva, M.I. Supported Ziegler-Natta catalysts for ethylene slurry polymerization and control of molecular weight distribution of polyethylene. Chin. J. Polym. Sci. 2008, 26, 553–559. [Google Scholar] [CrossRef]

- Tregubov, A.A.; Zakharov, V.A.; Mikenas, T.B. Supported titanium-magnesium catalysts for ethylene polymerization: A comparative study of catalysts containing isolated and clustered titanium ions in different oxidation states. J. Polym. Sci. Part A 2009, 47, 6362–6372. [Google Scholar] [CrossRef]

- Senso, N.; Praserthdam, P.; Jongsomjit, B.; Taniike, T.; Terano, M. Effect of Ti oxidation on ethylene, 1-hexene comomomer polymerization by MgCl2-supported Ziegler-Natta catalysts. Polym. Bull. 2011, 67, 1979–1989. [Google Scholar] [CrossRef]

- Fisher, E.O.; Hafner, W.Z. Di-benzol-chrom über aromatenkomplexe von metallen I. Naturforsch 1955, 10b, 665–668. [Google Scholar] [CrossRef]

- Albizzati, E.; Giannini, U.; Balbontin, G.; Camurati, I.; Chadwick, J.C.; Dall’Occo, T.; Dubitsky, Y.; Galimberti, M.; Morini, G.; Maldotti, A. Propylene polymerization with catalysts containing divalent titanium. J. Polym. Sci. Part A 1997, 35, 2645–2652. [Google Scholar] [CrossRef]

- Fowles, G.W.A.; Hoodless, R.A. The reaction of titanium halides with tertiary amines. J. Chem. Soc. 1963, 1, 33. [Google Scholar] [CrossRef]

- Makino, K.; Tsuda, K.; Takaki, M. Preparation of a soluble TiCl3 catalyst for copolymerization of ethylene with propene—A new reduction method of TiCl4 with hydrogen. Macromol. Chem. Rapid. Commun. 1990, 11, 223–227. [Google Scholar] [CrossRef]

- Mikenas, T.B.; Nikitin, V.E.; Zakharov, V.A.; Mozgunova, N.V. The Method of Preparation of the Catalyst and the Process of Polymerization of Ethylene Using This Catalyst. RF Patent 2320410C1, 27 March 2008. [Google Scholar]

- Randall, J.C. Methylene sequence distributions and number average sequence lengths in ethylene-propylene copolymers. Macromolecule 1978, 11, 33–36. [Google Scholar] [CrossRef]

- Echevskaya, L.G.; Zakharov, V.A.; Golovin, A.V.; Mikenas, T.B. Molecular structure of polyethylene produced with supported vanadium-magnesium catalyst. Macromol. Chem. Phys. 1999, 200, 1434. [Google Scholar] [CrossRef]

- Werber, F.X.; Benning, C.J.; Wszolek, W.R.; Ashby, G.E. Crystalline titanium dichloride—An active catalyst in ethylene polymerization. I. Catalyst activation. J. Polym. Sci. Part A 1968, 6, 743–754. [Google Scholar] [CrossRef]

- Bukatov, G.D.; Zakharov, V.A.; Ermakov, Y.I. On the nature of active centers during polymerization of ethylene on titanium dichloride. Kinetika I Kataliz 1971, 12, 743. [Google Scholar]

- Gul’tseva, N.M.; Ushakova, T.M.; Aladyshev, A.M.; Raspopov, L.N.; Meshkova, I.N. Influence of the nature of monomers on the activity of supported titanium catalysts in the α-olefin polymerization. Polym. Bull. 1992, 9, 639–646. [Google Scholar] [CrossRef]

- Jaber, A.; Fink, G. Active centers concentration in ethylene homo- and copolymerization with 1-hexene using the highly active TiCl4/MgH2-AlEt3 catalyst system. J. Mol. Catal. A Chem. 1995, 97, 135–141. [Google Scholar] [CrossRef]

- Sukulova, V.V.; Barabanov, A.A.; Matsko, M.A.; Zakharov, V.A.; Mikenas, T.B. Kinetic features of ethylene copolymerization with 1-hexene over titanium-magnesium Ziegler-Natta catalysts: Effect of comonomer on the number of active centers and the propagation rate constant. J. Catal. 2019, 369, 276–282. [Google Scholar] [CrossRef]

- Garoff, T.; Mannonen, L.; Vaananen, M.; Eriksson, V.; Kallio, K.; Waldvogel, P. Chemical composition distribution study in ethylene/1-hexene copolymerization to produce LLDPE material using MgCl2- TiCl4-based Ziegler-Natta catalysts. J. Appl. Polym. Sci. 2010, 115, 826–836. [Google Scholar] [CrossRef]

- Nikolaeva, M.I.; Matsko, M.A.; Mikenas, T.B.; Echevskaya, L.G.; Zakharov, V.A. Copolymerization of ethylene with a-olefins over supported titanium–magnesium catalysts. II. Comonomer as a chain transfer agent. J. Appl. Polym. Sci. 2012, 125, 2042–2049. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).