Abstract

An integrated method, which combines Electronic Speckle Pattern Interferometry, impulse response measurements, finite element method simulations, and psychoacoustic tests, is proposed to evaluate the vibroacoustic behavior of a carbon fiber bouzouki. Three of the carbon fiber instruments are manufactured, and one is qualified via interferometric experimental measurements with reference to a traditional wooden bouzouki, which was evaluated for its sound and playability by the proposed method. Psychoacoustic tests were used to evaluate the sound and playability of the newly qualified carbon fiber bouzouki, which was further modeled by the finite element method and simulated. The simulation results agreed well with the experimental measurements. Furthermore, finite element simulation results of the qualified carbon fiber bouzouki were demonstrated with reference to the traditional wooden bouzouki experimental results, providing new findings crucial for the optimization of the manufacturing and the vibroacoustic behavior of the carbon fiber instrument. The proposed integrated method can be applied to a variety of carbon fiber stringed musical instruments.

1. Introduction

Music and musical instruments have been part of human society for thousands of years. Traditionally, musical instruments are still made of materials such as leather, metal, and wood. String musical instruments are commonly made of wood. Wooden musical instruments are susceptible to factors, such as humidity and temperature, that can affect their overall performance, often in an unpredictable way. The development of new materials has opened the way to the manufacturing of musical instruments from composite materials. One of the first studies in this field was by Haines et al.; [1] concerning a violin with a top plate made of graphite-epoxy. An overview of manufacturing musical instruments using composite materials is reported in [2]. Composite materials are much less prone to environmental effects, such as humidity and temperature. The use of a single material for the development of different parts of the instrument, as opposed to parts made of different types of wood, secures the manufacturing process. Additionally, the construction time and the cost are reduced. The use of wood also has an ecological impact, imposing further limitations, especially when sought-after and rare species of trees are selected. The durability of composite materials is high, allowing them to be used for musical instruments, where high tensions are applied, and at the same time, they are lightweight, thus providing convenience and better playability to the performer. Nowadays, apart from luthiers and scientists, musical instruments of composite materials are also accepted by most performers [3].

Such materials have also been used for the construction of traditional musical instruments, however, to a much-limited extent. Such an instrument is the bouzouki [4], which is a string musical instrument of the wider family of tanbur [5]. The construction of a bouzouki from composite materials is challenging because, apart from the process itself, the final product must be accepted by the players. This acceptance can be achieved if the instrument’s performance is evidently close to that of an established traditional wooden instrument.

In the literature, several authors have studied the vibroacoustic behavior of musical instruments using experimental measurements and numerical simulations. In [6], the vibroacoustic behavior of Persian musical instruments was studied via acoustic radiation measurements and a finite element modal analysis. A review study [7] focused on the vibroacoustic behavior of the violin, covering the nonlinear vibration of the bowed string, the vibration of the instrument body, and the subsequent sound radiation. In [8], the vibroacoustic behavior of an early viola da gamba was studied via Electronic Speckle Pattern Interferometry (ESPI) and finite element analysis (FEA). Vibrational analysis of setar, a Persian long-necked lute, was studied [9] via a combination of the impulse hammer and laser Doppler vibrometer and finite element method (FEM) simulations.

For the complete characterization of musical instruments, we developed an integrated method [10], which combines ESPI [10,11], impulse response [10,11], FEM modeling and simulations [12,13,14,15,16,17,18], and sound perception. Here, we present the application of this integrated method and the corresponding results for the vibroacoustic evaluation of a novel carbon fiber bouzouki and its comparison to the characteristics of a classic wooden bouzouki. A traditional wooden bouzouki, which was used as a reference (W02), was evaluated by performing psychoacoustic tests and ESPI experimental measurements concerning its sound production and playability. Based on the geometrical characteristics and features of the referenced instrument, three carbon fiber bouzouki (C01, 02, and 03) were manufactured with three corresponding top plates of slightly varying characteristics of the carbon fiber directions and layer sequence used, and the bridge and bar materials. The bridge and the two bars of the C01 soundboard were made of spruce wood, following the geometry and the material properties of the wooden referenced bouzouki, as a common part of the comparison studies, while for the cases of C02 and C03, only carbon fibers were used. The three carbon fiber instruments developed were assembled and compared to W02 via ESPI measurements. The vibroacoustic response of C01 was indicated by ESPI, which was also validated by impulse response measurements to agree well with W02. Furthermore, the sound production and playability of C01 were compared to W02 by means of psychoacoustic tests. The qualified carbon fiber bouzouki C01 was further digitized by a laser scanner, and a 3D CAD model was developed based on the point cloud generated. The soundboard of C01 was properly discretized, and a FEM model was developed. The FEM modal simulation results under tuning were validated by ESPI measurements. The FEM model allowed modifications of the C01 carbon fiber bouzouki parameters, such as the carbon material properties and the fiber directions, as well as the geometrical characteristics and the replacement of the wooden bridge and bars with carbon. Therefore, the manufacturing process and the vibroacoustic behavior of the carbon fiber bouzouki may be optimized via the proposed integrated method.

2. Carbon Fiber Bouzouki Manufacturing

The manufacturing of the three-carbon fiber bouzouki was based on the 3D scan of a wooden bouzouki. A 3D CAD surface model of the musical instrument was further developed according to the point cloud generated by a 3D scan. Following the design of the instrument’s parts, the 3D CAD and CAM of the molds of each part were developed for the molding of every carbon fiber part. Based on the G-code produced by CAM, the molds were manufactured by CNC machining. These molds were used for the molding of the carbon fiber bouzouki parts that assembled the musical instrument. The carbon fiber parts were properly machined and surface finish in order to fit perfectly in the global instrument’s assembly and be easily and properly glued. The instrument was completed by placing the keys, fingerboard, saddle, bridge, bars, and strings.

The fabrication of carbon fiber fabric parts is usually conducted by using the mold in the desired form, placing the dry carbon fabrics in it, with the impregnation of the fabrics with resin using a vacuum (infusion), and heating at a specific temperature and for a specific time. The fabrics chosen for manufacture were: (a) 200 gr/m2 Twill, the most well-known and recognizable form of the carbon fiber fabric, which gives high resistance in two directions to the composite and its thickness allows the use of other layers, (b) 300 gr/m2 Ud, which gives strength in only one direction to the composite making it suitable for local reinforcements and its thickness allows for the use of other layers. Three corresponding top plates with slightly varying characteristics were manufactured, and three carbon fiber instruments (C01, 02, and 03) were assembled. The manufacturing of the three top plates was performed using Twill and Ud carbon fiber layers in varying sequences and fiber directions. The bridge and the bars of the soundboard of C01 were made from spruce wood in accordance with the wooden bouzouki for the comparison studies, while the bridge and the bars of C02 and C03 were manufactured by Twill and Ud carbon fiber layers in varying sequences and fiber directions. Figure 1 shows the manufactured carbon fiber four-string bouzouki C01.

Figure 1.

The carbon fiber four-string bouzouki C01.

3. Psychoacoustic Tests

The tests were performed according to the ITU method [19] and according to a study that evaluates musical instruments [20]. Due to the subjectiveness of the process, the participation was anonymous, and the participants belonged to a wide range in terms of their affiliation with music. During the test, each participant was asked to fill in a questionnaire that used the rating scale of the ITU method [19].

This test consisted of two parts. In the first part, five soloists with different years of experience evaluated each instrument focusing on the quality of its sound and playability. Before the tests, the soloists were allowed to rehearse with each instrument for as long as they needed. To maintain the impartiality of the rehearsal, the player was blindfolded. Each of the soloists answered a questionnaire regarding sound and playability. With reference to the sound of the instrument, the categorization was performed in terms of fullness, warmth, brilliance, bass, treble, loudness, attack, and sustain. The questions for playability included the balance behavior, the ease of play, the play response, and the comfort of playing. The second part focused on listening evaluation. Five indicative music parts for bouzouki were recorded by a soloist and were used as input for the listeners. For the second part, a group of 60 participants was formed by 23 music professionals (e.g., players, sound engineers, and music producers) and 37 persons not professionally related to music. Each participant was asked to answer a questionnaire after 15 min of listening to the recorded music samples and to evaluate the sound of the two instruments, using the rating scale of the ITU method, ignoring the correspondence of the music samples to the two bouzoukis.

4. Electronic Speckle Pattern Interferometry

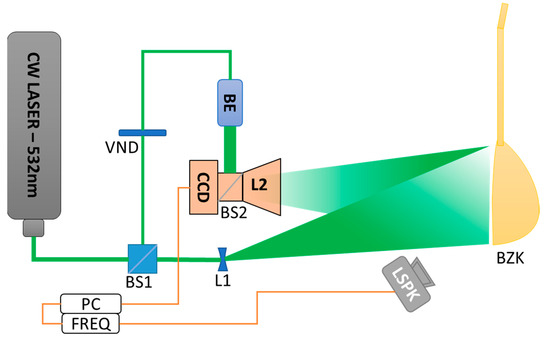

ESPI is a laser-based interferometric technique that measures, among others, the speckle behavior on the top plate surfaces of musical instruments. The ESPI setup is presented in Figure 2. A CW Laser/532nm beam illuminated the top plate of the bouzouki, causing the speckle appearance on the top plate, while an internal beam of the setup was directed to a CCD camera as a reference beam. A loudspeaker driven by a frequency generator excited the bouzouki at specific frequencies. A loudspeaker driven by a frequency generator excited the bouzouki at specific frequencies. The loudspeaker was positioned 60 cm from the instrument. Apart from the excitation at different frequencies, the loudspeaker emitted a sound that was also varied. Two measurement sets at an 80 dB sound pressure level (SPL) and 90 dB SPL were measured. During the measurements, the stability of the SPL was monitored by a digital audio analyzer.

Figure 2.

Schematic of the ESPI setup at the Physical Acoustics and Optoacoustics Laboratory of HMU, with the bouzouki under study and the excitation source. CW Laser Source 532 nm, BS1—Main Beam Splitter, L1—Expanding Lens, VND—Variable Neutral Density Filter, BE—Beam Expander, CCD—Camera, BS2—Secondary Beam Splitter, L2—Objective Camera Lens, BZK—Bouzouki, PC—Computer, FREQ—Frequency Generator, LSPK—Loudspeaker.

The captured images from the camera of the setup were subtracted and processed using specially developed software. The intensity of each sequential image captured from the camera was and , while their subtraction can be given by [10]:

where and are the intensity of each image, is the phase difference between the two beams, with as the the laser wavelength; is the vibration amplitude, is the vibration amplitude difference between the two images, and is the zero order of the Bessel function of the first kind.

The vibrational modes that appeared where the top plate resonated were shaped by the Bessel function term . The dark and white fringes that appeared were equal height curves of the same vibration amplitude, with the bright fringes corresponding to the maxima of .

The resulting images contained both the spatial information of the vibrating surface and the information of its amplitude (perpendicular to the surface). Spatial information corresponds to the extent of the surface coverage by the fringes formed and by the different vibrational modes on the surface of the bouzouki. The amplitude information was extracted after measuring the number of bright fringes and by correlating each fringe to a vibration amplitude through the term . A detailed description may be found in [10].

In the literature, the experimentally measured vibration modes for four-string [21,22] and three-string bouzoukis [21,22,23] with a large vibration amplitude extend to frequencies up to 1500 Hz. For this reason, it was chosen to perform experimental measurements using ESPI interferometry for the frequency range between 40 Hz and 1500 Hz.

5. Impulse Response Measurements

The calculation of the frequency response function (FRF) of the instruments under test was performed by impulse response measurements. The excitation of the instrument was made by an impact hammer (PCB, Model 086E80), and the response was acquired by an accelerometer (PCB, Model TLD352A56). The signals were recorded by a real-time multi-analyzer (OROS, Model OR34). The FRF of acceleration was calculated by the estimator , which is given by:

where is the auto-spectrum of the acceleration and is the cross-spectrum between the force and acceleration signals [24]. The estimator is expressed in dB [re 1 m/(N s2)].

A rectangular grid of measurement points (side length = 3 cm) was created on each instrument, and the roving hammer method was applied. The accelerometer was positioned close to the instrument’s bridge. As it may be assumed, due to the different instrument sizes, the number of measurement points was not equal. The smallest dimensions corresponded to 66 measurement points. After measurements at all points, the average value of the estimator was calculated as:

6. Numerical Modeling and Simulation

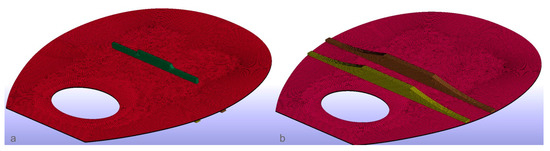

The qualified carbon fiber bouzouki C01 was further digitized by a laser scanner, and a 3D CAD model was developed based on the point cloud generated. The top plate of C01 was properly discretized, and a FEM model was developed. To follow the experimental conditions and measurements, a FEM prestress static analysis and modal analysis were performed using LS-DYNA FEM software [25]. The developed discretized model of the bouzouki soundboard included the bridge at the front and the two bars at the back side, as Figure 3 shows. The total thickness of the manufactured soundboard was 1.25 mm and consisted of four layers (one layer of 0° Twill, then two layers of 0° Ud (unidirectional), and finally, a layer of 0° Twill). The material properties used to simulate the Twill [26] and Ud [27] layers were considered according to the literature values and are presented in Table 1. In the case of modeling wooden parts, the material properties of spruce wood [18] were adopted. Regarding the mesh, an eight-point enhanced strain quadratic solid element was adopted, while a total number of approximately 125,000 elements was considered for the mesh of the model.

Figure 3.

Front (a) and back (b) side view of the bouzouki discretised soundboard.

Table 1.

Elastic properties of 0° Twill, and 0° Ud.

Table 1.

Elastic properties of 0° Twill, and 0° Ud.

| Quantities | Twill | Ud |

|---|---|---|

| Density | 1451 kg m−3 | 1273 kg m−3 |

| Young Modulus (E1) | 59.16 GPa | 10.49 GPa |

| Young Modulus (E2) | 59.16 GPa | 96.66 GPa |

| Young Modulus (E3) | 7.5 GPa | 10.49 GPa |

| Poisson Ration (v12) | 0.04 | 0.1 |

| Poisson Ration (v23) | 0.3 | 0.1 |

| Poisson Ration (v31) | 0.3 | 0.9 |

| Shear Modulus (G12) | 17.5 GPa | 2.16 GPa |

| Shear Modulus (G23) | 2.7 GPa | 2.16 GPa |

| Shear Modulus (G31) | 2.7 GPa | 6.51 GPa |

Regarding the boundary conditions of the top plate, the side of the soundboard that was in contact with the fingerboard and the outer nodes on the edges of the soundboard was considered fixed since this area was in contact and bonded to the full body of the instrument. At the top of the bridge, out-of-plane displacements at four points were constrained in a way that resembled the restrictions provided by the strings [28]. For the prestress static FEM analysis [29], a tension force of 70 N, as was experimentally measured, was considered for each string to simulate the tuning and the same experimental conditions during the measurements. The finite element analysis results of this simulation (stresses and deformed geometry) were considered as the initial data for the subsequent modal FEM analysis performed.

7. Results and Discussion

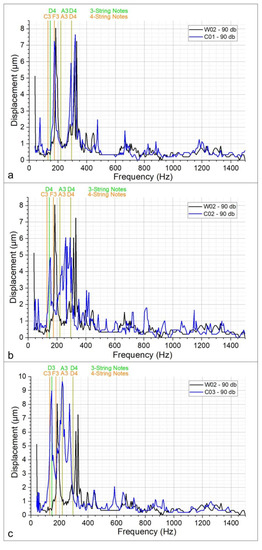

Three carbon fiber bouzoukis were manufactured, and their vibrational behavior was compared to W02 via ESPI measurements. Figure 4 shows the graphs of displacement vs. the frequency of W02 compared to the C01, C02, and C03 bouzouki for 90 dB SPL excitation.

Figure 4.

Displacement vs. frequency of W02 compared to C01 (a), C02 (b), and C03 (c) carbon fiber bouzouki for 90 dB SPL measured by ESPI, including the fundamental string frequencies for 3- and 4-string bouzouki.

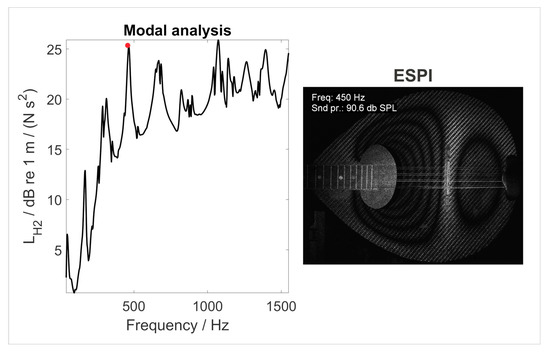

The ESPI experimental results presented were also validated by impulse response measurements. Figure 5 shows the FRF results of the impulse response for the C01 bouzouki in relation to a representative ESPI experimental result. The identification of the mode (1,2) at 450 Hz (red spot) and the corresponding modal shape provided by the ESPI at the same frequency is also demonstrated.

Figure 5.

FRF experimental results (left) and an ESPI representative result (right) for the mode (1,2), at 450 Hz of the carbon fiber bouzouki C01.

The vibration analysis results presented in Figure 4 indicate that the carbon fiber bouzouki C01 behaved acoustodynamically, similar to W02, for many frequencies, while the vibration behavior of the bouzouki C02 and C03 deviated from W02. The vibrational behavior of the C01 and W02 musical instruments was similar for frequencies up to 1000 Hz, and a good agreement was observed for frequencies higher than 1000 Hz. Therefore, C01 was further studied with reference to the W02 bouzouki in terms of the emitted sound and playability via psychoacoustic tests.

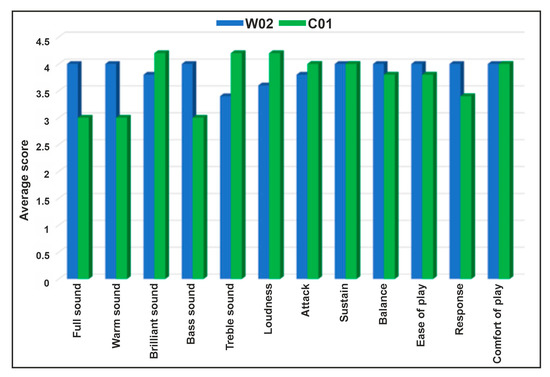

Figure 6 shows the results of the psychoacoustic test performed by the five soloists for the musical instruments W02 and C01. The average score results indicate that the wooden bouzouki excels in full sound, warm sound, bass, balanced behavior, ease of play, and response, while the carbon bouzouki excels in bright sound, treble, loudness, and attack. It should also be mentioned that in the second part of the test, the 60 participants gave an average score of 3.82 for the classic bouzouki and 3.65 for the carbon fiber bouzouki and for all the parameters that characterized the sound behavior of the instruments. The psychoacoustic tests for the reference traditional bouzouki W02 demonstrated that the sound and playability of the wooden instrument were rated slightly better compared to the C01-qualified carbon fiber.

Figure 6.

The average score (5 is the max. value) of W02 and C01, received from the five soloists for the parameters that characterize the sound and playability of the bouzouki.

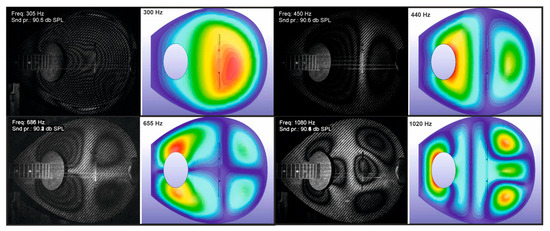

The FEM model of C01 was developed as described in Section 5. The modal FEM simulation results of the resonant frequencies of six vibrational modes compared to the experimental ESPI results are presented in Table 2. The simulation results agreed well with the experimental results, while the maximum deviation was indicated to be less than 6%. This difference could be mainly attributed to the uncertainty of the material properties adopted in the simulations. Figure 7 shows four representative modal shapes obtained by the FEM simulation results in comparison with the ESPI experimental results.

Figure 7.

Experimental ESPI and modal FEM simulation results for the representative modes (1,1), (1,2), (2,2), (3,2).

Table 2.

Resonant frequencies of the vibration modes by the FEM simulation and the ESPI experiment results for C01.

Table 2.

Resonant frequencies of the vibration modes by the FEM simulation and the ESPI experiment results for C01.

| Modes | ESPI Results (Hz) | FEM Results (Hz) |

|---|---|---|

| (1,1) | 305 | 300 |

| (1,2) | 450 | 440 |

| (2,2) | 686 | 655 |

| (2,3) | 880 | 830 |

| (3,2) | 1080 | 1020 |

| (4,3) | 1390 | 1330 |

Aiming to optimize the manufacturing process of the bouzouki by minimizing the time and the production cost, the replacement of the wooden bridge and bars with carbon fiber was studied by FEM. The results of the simulation for the same model and bridge and bars made from Twill carbon fiber (FEM1) are presented in Table 3 with reference to the ESPI W02 traditional bouzouki experimental results. Furthermore, a different number of layers for the soundboard, along with different carbon fiber directions, were also tested. The simulation results of FEM2 in Table 3 correspond to a model where the soundboard has two layers of 0.625 mm thickness, one layer of 0° Ud, and one layer of 90° Ud [19], a carbon fiber bridge of 0° Ud, and two bars of 90° Ud.

Table 3.

Resonant frequencies of the vibration modes of W02 by the ESPI experiment and the FEM1 and 2 simulation results.

A good agreement was observed between the experimental and the FEM2 simulation results, which had a maximum deviation of less than 9%, denoting that the proposed modifications may improve the vibrational behaviour and the emitted sound of the musical instrument.

8. Conclusions

This research work presents the experimental, simulation, and sound perception results of an integrated method that is capable of evaluating the sound and playability of a new carbon fiber bouzouki. The manufactured carbon fiber bouzouki was qualified by ESPI measurements and compared to a traditional wooden bouzouki. A similar vibrational behavior was found between the two musical instruments via ESPI experimental measurements. The psychoacoustic tests for the traditional wooden bouzouki W02, which was used as a reference, demonstrated that the sound and playability of the wooden instrument were slightly better compared to the C01-qualified carbon fiber. C01 was modeled, and the FEM simulation results were compared to the ESPI experimental results along with impulse response measurements, and a good agreement was found.

The FEM simulation models were further used to study the vibrational behavior of C01 by adopting carbon fiber parts (bridge and bars) and varying carbon fiber directions. The simulation results were demonstrated with reference to the W02 ESPI results and provided new findings for the optimization of the manufacturing and vibroacoustic behavior of the carbon fiber instrument.

The proposed integrated method allows for even more investigations and modifications to be performed in the future by means of vibroacoustic behavior improvement and the manufacturing time and cost reduction for a variety of carbon fiber string instruments.

Author Contributions

Methodology, S.B., M.K., Y.O., A.S.-K., S.P. and N.K.; software, M.K., Y.O. and E.K.; investigation, S.B., Y.O., E.K., K.K. and H.P.; resources, I.T., E.I., T.K., M.K. and I.K.; data curation, S.B. and Y.O.; writing—original draft preparation, S.B., E.K., Y.O. and M.K.; manufacturing, I.T., E.I., T.K., M.K. and I.K., writing—review and editing, M.B. and V.D.; supervision V.D., N.A.P., M.B. and M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was co-financed by the European Regional Development Fund of the European Union and Greek National Funds through the Operational Program Competitiveness, Entrepreneurship and Innovation, under the call RESEARCH—CREATE—INNOVATE (project code: T2EDK-01484, project title: Carbon fiber made Bouzouki design).

Data Availability Statement

The data presented in this study are available within the article.

Acknowledgments

This work was supported by computational time granted by the Greek Research & Technology Network (GRNET) in the National HPC facility ARIS-under project ID pr013024-LaMPIOS II.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Haines, D.W.; Chang, N.; Hutchins, C.M. Violin with a graphite-epoxy top plate. J. Acoust. Soc. Am. 1975, 57, S21. [Google Scholar] [CrossRef]

- Bucur, V. Composite materials for musical instruments. In Handbook of Materials for String Musical Instruments, 1st ed.; Springer: Cham, Switzerland, 2016; pp. 845–875. [Google Scholar]

- Scientific American. Available online: https://www.scientificamerican.com/article/carbon-fiber-cellos/ (accessed on 22 February 2023).

- Wikipedia. Available online: https://en.wikipedia.org/wiki/Bouzouki (accessed on 22 February 2023).

- Wikipedia. Available online: https://en.wikipedia.org/wiki/Tanbur (accessed on 22 February 2023).

- Tronchin, L.; Manfren, M.; Vodola, V. Sound Characterization through Intensity of Acoustic Radiation Measurement: A Study of Persian Musical Instruments. Appl. Sci. 2020, 10, 633. [Google Scholar] [CrossRef]

- Woodhouse, J. The acoustics of the violin: A review. Rep. Prog. Phys. 2014, 77, 115901. [Google Scholar] [CrossRef] [PubMed]

- Chatziioannou, V. Reconstruction of an early viola da gamba informed by physical modeling. J. Acoust. Soc. Am. 2019, 145, 3435. [Google Scholar] [CrossRef] [PubMed]

- Mansour, H. Modal analysis of the Setar: A numerical–experimental comparison. J. Vib. Acoust. 2015, 137, 061006–1. [Google Scholar] [CrossRef]

- Bakarezos, E.; Orphanos, Y.; Kaselouris, E.; Dimitriou, V.; Tatarakis, M.; Papadogiannis, N.A. Laser-Based Interferometric Techniques for the Study of Musical Instruments. In Computational Phonogram Archiving. Current Research in Systematic Musicology, 1st ed.; Bader, R., Ed.; Springer: Cham, Switzerland, 2019; Volume 5, pp. 251–268. [Google Scholar]

- Bakarezos, E.; Vathis, V.; Brezas, S.; Orphanos, Y.; Papadogiannis, N.A. Acoustics of the Chelys—An ancient Greek tortoise-shell lyre. Appl. Acoust. 2012, 73, 478–483. [Google Scholar] [CrossRef]

- Kaselouris, E.; Bakarezos, M.; Tatarakis, M.; Papadogiannis, N.A.; Dimitriou, V. A Review of Finite Element Studies in String Musical Instruments. Acoustics 2022, 4, 183–202. [Google Scholar] [CrossRef]

- Kaselouris, E.; Alexandraki, C.; Bakarezos, M.; Tatarakis, M.; Papadogiannis, N.A.; Dimitriou, V. A detailed FEM Study on the Vibro-acoustic Behaviour of Crash and Splash Musical Cymbals. Int. J. Circuits Syst. Signal Process. 2022, 16, 948–955. [Google Scholar] [CrossRef]

- Kaselouris, E.; Paschalidou, S.; Alexandraki, C.; Dimitriou, V. FEM-BEM Vibroacoustic Simulations of Motion Driven Cymbal-Drumstick Interactions. Acoustics 2023, 5, 165–176. [Google Scholar] [CrossRef]

- Gonzalez, S.; Salvi, D.; Baeza, D.; Antonacci, F.; Sarti, A. A data-driven approach to violin making. Sci. Rep. 2021, 11, 9455. [Google Scholar] [CrossRef] [PubMed]

- Bakarezos, M.; Gymnopoulos, S.; Brezas, S.; Orphanos, Y.; Maravelakis, E.; Papadopoulos, C.I.; Tatarakis, M.; Antoniadis, A.; Papadogiannis, N.A. Vibration analysis of the top plates of traditional greek string musical instruments. In Proceedings of the 13th International Congress on Sound and Vibration 2006, ICSV 2006, Vienna, Austria, 2–6 July 2006; Volume 6, pp. 4939–4946. [Google Scholar]

- Stanciu, M.D.; Coşereanu, C.; Dinulică, F.; Bucur, V.T. Effect of wood species on vibration modes of violins plates. Eur. J. Wood Wood Prod. 2020, 78, 785–799. [Google Scholar] [CrossRef]

- Kaselouris, E.; Orphanos, Y.; Bakarezos, M.; Tatarakis, M.; Papadogiannis, N.A.; Dimitriou, V. Influence of the plate thickness and material properties on the violin top plate modes. In INTER-NOISE 2021, Proceedings of the International Congress and Exposition of Noise Control Engineering, Washington, DC, USA, 1–4 August 2021; Institute of Noise Control Engineering: Reston, VA, USA, 2021; Volume 263, pp. 3369–3377. [Google Scholar]

- TU-R BS.1534-1; Method for the Subjective Assessment of Intermediate Quality Level of Coding Systems. International Telecommunication Union: Geneva, Switzerland, 2003.

- Fritz, C.; Dubois, D. Perceptual Evaluation of Musical Instruments State of the Art and Methodology. Acta Acust. United Acust. 2015, 101, 369–381. [Google Scholar] [CrossRef]

- Chartofylakas, L. Acoustic and Sound Analysis of the Instruments of the Bouzouki Family. Master’s Thesis, Department of Music Studies, Ionian University, Corfu, Greece, 2009. [Google Scholar]

- Chartofylakas, L.; Floros, A.; Bakarezos, E.; Papadogiannis, N.A. Acoustic and sound analysis of the instruments of the Bouzouki family. In Proceedings of the 5th Panhellenic Conference Acoustics, Athens, Greece, 4–6 October 2010; pp. 422–428. [Google Scholar]

- Babaris, K. Study of the Use of a New Material for a Bouzouki Soundboard. Diploma Thesis, Department of Product and Systems Design Engineering, University of Aegean, Mytilene, Greece, 2017. [Google Scholar]

- Mc Connell, K.G.; Varoto, P.S. Vibration Testing: Theory and Practice; John Wiley & Sons: New York, NY, USA, 2008. [Google Scholar]

- Hallquist, J.O. LS-DYNA Theory Manual; Livermore Software Technology Corporation: Livermore, CA, USA, 2006. [Google Scholar]

- Arnal, M.I.; Doménech-Ballester, L.; Sánchez-López, F. Manufacturing and Structural Features with Respect to the Modal Behavior of a Carbon Fiber-Reinforced Epoxy Drum Shell. Materials 2019, 12, 4069. [Google Scholar] [CrossRef] [PubMed]

- Plath, N.; Linke, S.; Mores, R. On the angle-dependent vibrational behavior of fiber composite plates and its implications for musical instrument making. J. Acoust. Soc. Am. 2022, 151, 1956–1970. [Google Scholar] [CrossRef] [PubMed]

- Torres, J.A.; Soto, C.A.; Torres-Torres, D. Exploring design variations of the Titian Stradivari violin using a finite element model. J. Acoust. Soc. Am. 2020, 148, 1496–1506. [Google Scholar] [CrossRef] [PubMed]

- Kaselouris, E.; Alexandraki, C.; Orphanos, Y.; Bakarezos, M.; Tatarakis, M.; Papadogiannis, N.A.; Dimitriou, V. Acoustic analysis of impact sound on vibrating circular membranes. In INTER-NOISE 2021, Proceedings of the International Congress and Exposition of Noise Control Engineering, Washington, DC, USA, 1–4 August 2021; Institute of Noise Control Engineering: Reston, VA, USA, 2021; Volume 63, pp. 3378–3385. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).