Abstract

The effect of the two-way injection method during a copper chemical mechanical planarization (CMP) process was investigated. The two-way slurry-injection method has the advantage of not only preventing the degradation of the slurry, but also shortening the process time because the mixing process of the slurry and H2O2 is not required. Compared to the conventional method, the two-way injection method has an equivalent level of less than 9% in material removal rate. In particular, when injecting near the center of the pad, the influence according to the positions and flow rates of the two nozzles is also insignificant, so it deserves to be studied as a slurry-supply method.

1. Introduction

Hydrogen peroxide (H2O2) is one of the widely used chemicals in the semiconductor industry [1]. Because H2O2 has oxidizing properties, it is adopted as an oxidant in cleaning and metal CMP processes [2]. Specifically, in metal CMP, H2O2 acts as a very important factor because it oxidizes the metal film to form an oxidation layer, thereby allowing for polishing with an abrasive [3,4]. However, in many fields, including CMP, problems arise due to decomposition or the generation of H2O2 [5]. In the metal CMP, H2O2 has strong oxidizing power and unstable characteristics, so it can affect the metal CMP slurry [6,7]. In our previous study, as the mixing time of the slurry and H2O2 increased, the material removal rate (MRR) decreased in Cu CMP [8]. H2O2 tends to decompose easily, especially in high-temperature, sunlight, or high pH conditions. Over time, decomposed H2O2 in the slurry can change the pH of the slurry. A change in the pH can change the ionic state of glycine, which acts as a chelating agent. As a result, a decrease in H2O2 concentration decreases the formation of copper oxide or hydroxide, and a decrease in the glycine concentration affects the chelating effect [9]. A change in the pH affects the functional group of glycine [10,11]. These changes in the slurry can occur in a short amount of time depending on the chemical concentration. Therefore, a method is needed to prevent slurry degradation from H2O2 to maintain CMP performance.

In this study, the two-way slurry-injection method is studied without mixing the slurry and H2O2 before the polishing process. The two-way slurry-injection method means that the slurry and H2O2 are separately injected during the CMP process using two nozzles. This means that the H2O2 and slurry are mixed on platen as they are supplied. There are studies on the CMP process with the method of slurry injection using multiple nozzles instead of one nozzle [12,13,14]. These studies aimed to secure the same level of CMP performance while reducing the consumption of the slurry by spraying it with a multinozzle to spread the slurry well throughout the CMP pad. Jha et al. suggested that a slurry-injection system (SIS) from Araca Inc. could realize 40% less consumption of the slurry to achieve the same MRR with improved uniformity. Liao et al. compared the bow wave thickness according to the slurry-injection method (standard pad center area application method and novel slurry-injection system) using an ultraviolet-enhanced fluorescence system, and argued that the multihole injection method is effective in reducing slurry consumption by generating a thicker bow wave. In other studies, a method of supplying one slurry using multiple nozzles was used. In addition, there are many studies focusing on reducing slurry consumption to prevent CMP performance degradation. However, in this study, CMP performance was confirmed when the slurry was supplied through an on-plate mixing method in which the slurry excluding H2O2 and H2O2 was separately supplied. Through this method, the decomposition of H2O2 in the slurry can be minimized to prevent a degradation in CMP performance. The advantage of a two-way injection is that, since H2O2 and slurry are separately injected, degradation caused by mixing before the CMP process can be prevented, and the process of mixing the slurry and H2O2 is unnecessary, which is advantageous in terms of processing time. The CMP performance can be secured through this method. In terms of Cu MRR, the two-way slurry-injection method shows almost the same performance as the general (one-nozzle) method. Therefore, the two-way injection slurry-supply method can be considered an alternative to the general injection method that can prevent slurry degradation.

2. Materials and Methods

2.1. Slurry-Supply System

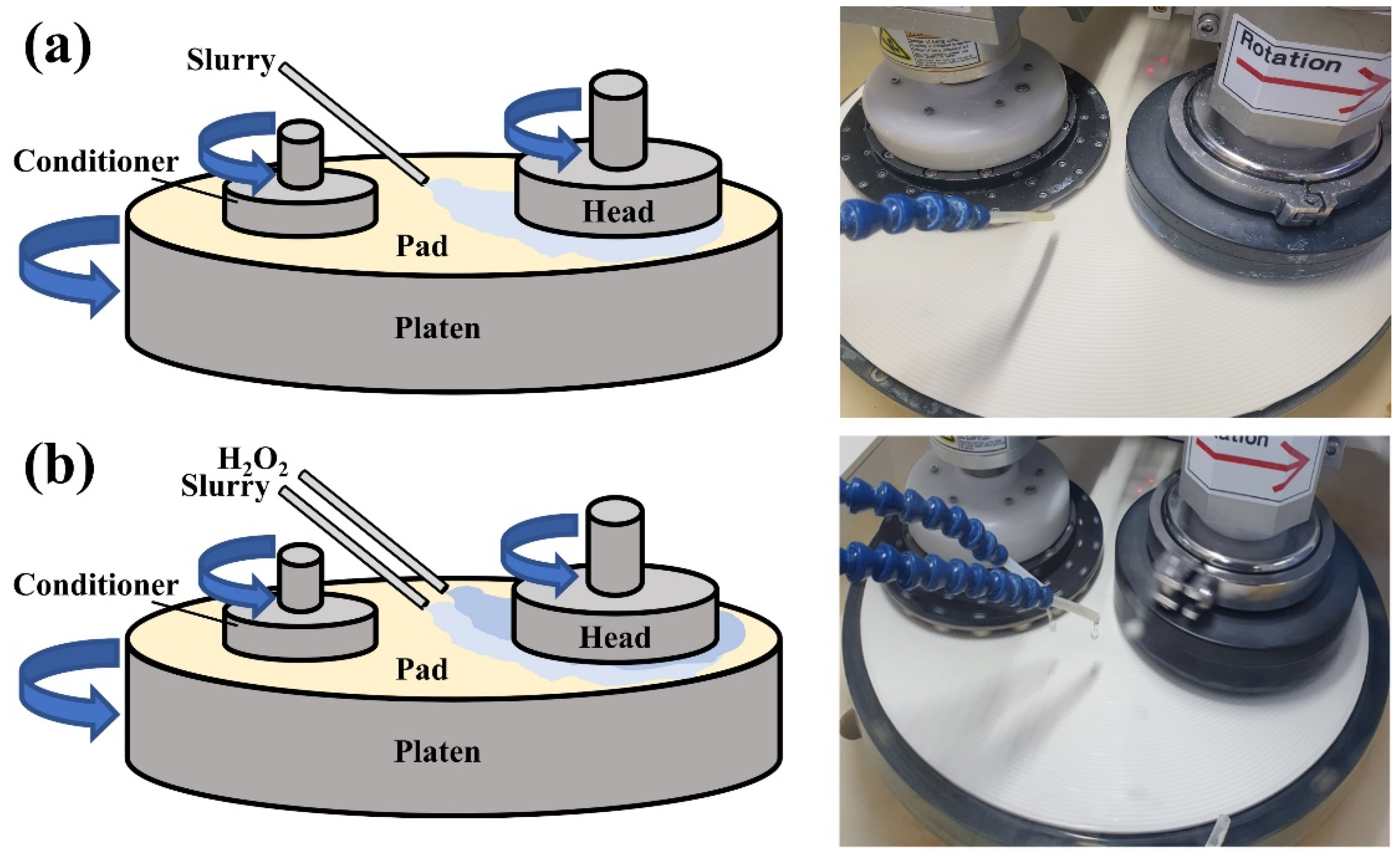

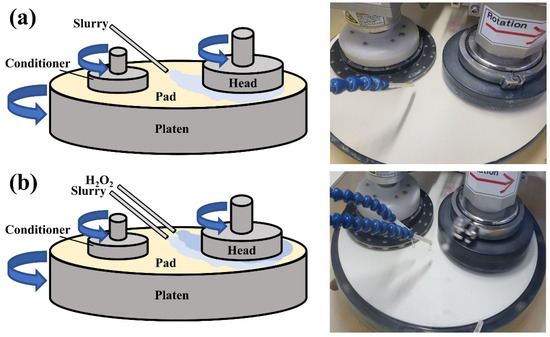

To confirm the effect of the slurry-supply method, the slurry and H2O2 were separately injected from two nozzles. Figure 1. shows a schematic and an image of the general injection method and the two-way injection system. The evaluation was conducted by changing the flow rates of each nozzle for the slurry and H2O2, and the total flow rate injected from the two nozzles was set at 150 mL/min. These results were compared with those of the general slurry-supply method (premixed slurry and H2O2). Since the total amount of additives during the CMP process must be the same, the concentration of additives was slightly varied with the flow rate.

Figure 1.

Images of (a) the general injection method and (b) the two-way injection method.

2.2. Slurry Preparation

In the Cu slurry, about 60 nm colloidal silica (PL-3, Fuso chemical, Osaka, Japan) was used as an abrasive. H2O2, benzotriazole (BTA), glycine, and potassium hydroxide (KOH) were used as oxidants, inhibitors, chelating agents, and pH adjustor, respectively, and all chemicals were purchased from Sigma Aldrich. The abrasive particles and additives were mixed according to a predetermined concentration, and the pH was adjusted to 10. Detailed slurry information is listed in Table S1.

2.3. CMP Evaluation

The Cu coupon wafers (4 × 4 cm2) were polished for 1 min using a polisher (Poli-400, GnP technology, Busan-si, Republic of Korea) with a polyurethane pad (HD-300, SKC, Seoul, Republic of Korea) and pellet-type conditioner (20PPW60EBC0, Saesoldiamond, Ansan-si, Republic of Korea). Three wafers were polished for each condition, and the thickness of Cu was measured using a four-point probe (CMT-SR5000, AIT Co., Ltd., Seoul, Republic of Korea), which is called the sheet resistance measurement. MRRs were calculated by comparing the thickness of the Cu wafers before and after polishing. The slurry-supply method had the same processing conditions except for the flow rate. Down pressure and rotational speed (platen/head) were 3 psi and 93/87 rpm, respectively. The flow rate was 150 mL/min, and in the two-way injection method, the flow rates injected from two nozzles (slurry/H2O2) were divided as follows: 100/50, 75/75, and 50/100 mL/min.

3. Results and Discussion

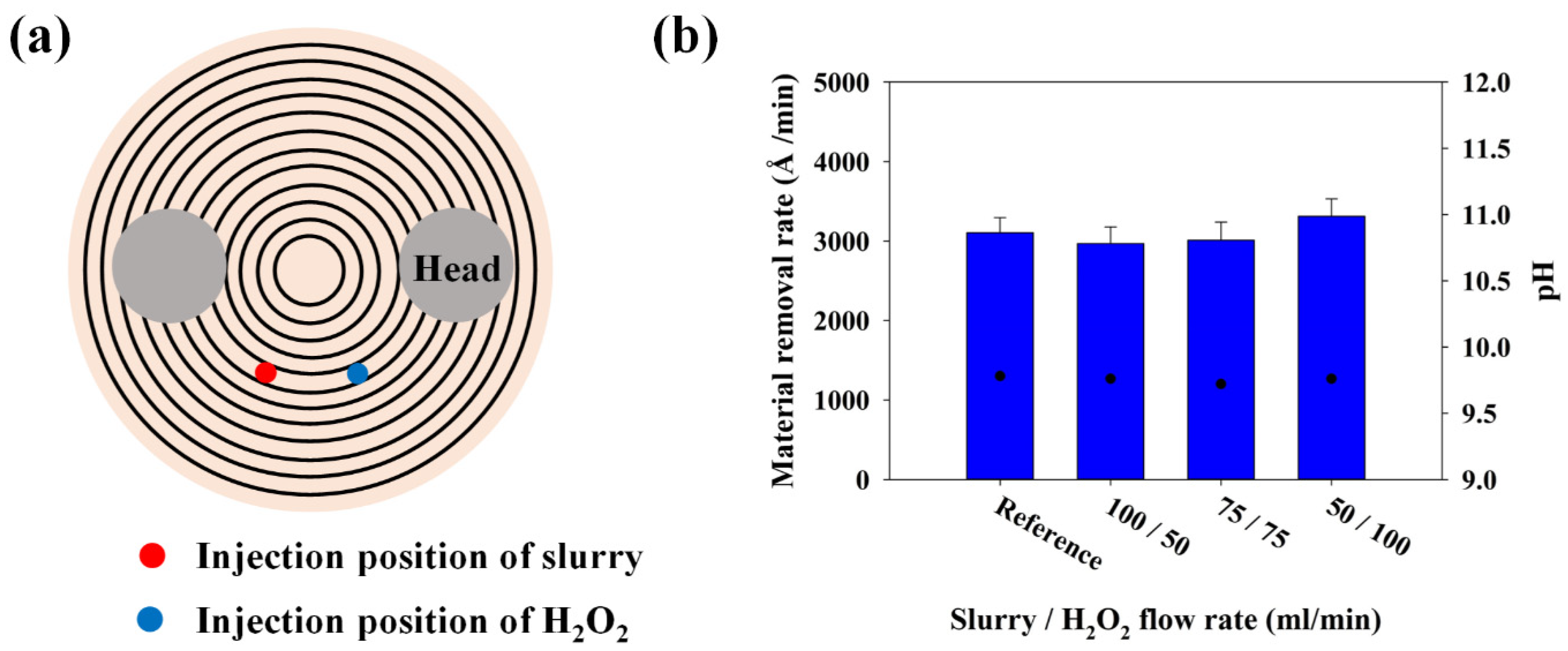

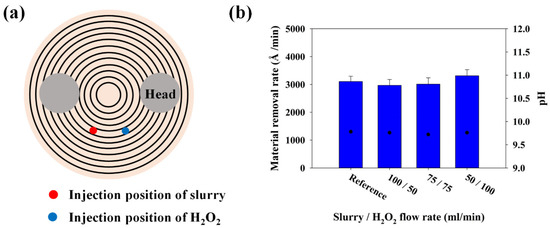

Figure 2 shows the MRRs between the general and the two-way injection method in a slurry-supply system. As shown in Figure 2a, the H2O2 nozzle was placed close to the head, and the slurry nozzle was placed far away from the head due to the mechanism of Cu CMP [4]. This is because, in Cu CMP, after the oxide film on the surface of Cu is formed by the oxidant, the wafer is polished with the abrasive. When H2O2 is first introduced by positioning the H2O2 nozzle close to the head, the oxidation layer is formed by the wafer, and the wafer is then polished by the introduced slurry. These results show that, when using the two-way injection, the MRR was similar to that of the general injection method (indicated by ‘reference’ in the figure). Even when the flow rates of H2O2 and slurry changed in the two-way injection, the MRRs showed similar results. Contrary to the previous experiment, an evaluation was conducted to determine whether the nozzle position affected the MRRs in the two-way injection. Table 1 shows the removal rate numerically for each condition in Figure 2.

Figure 2.

(a) Position of the two way injection;slurry–H2O2 (b) MRR of the reference and the two-way injection with position; slurry–H2O2.

Table 1.

MRR and pH of reference and the two-way injection with position; slurry–H2O2.

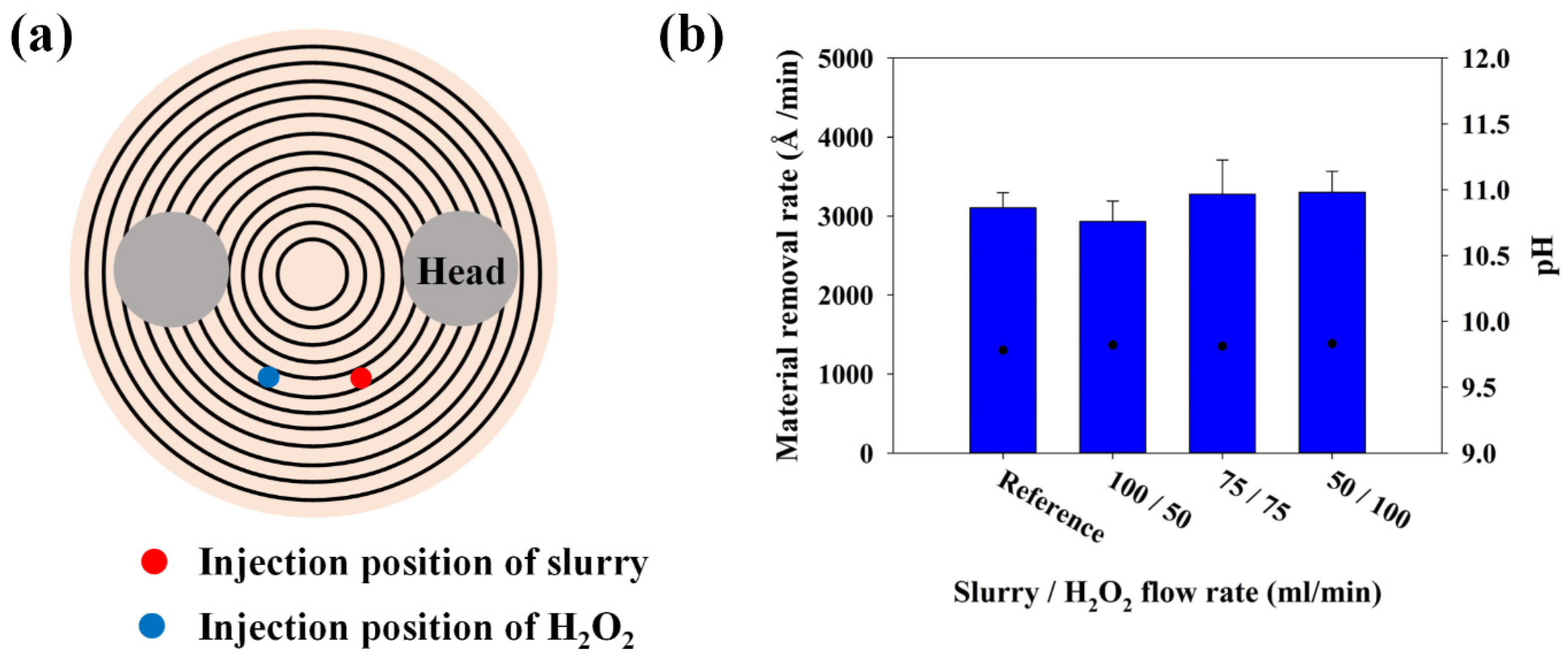

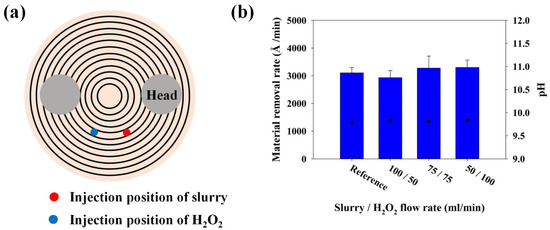

As shown in Figure 3a, the slurry nozzle was close to the head and the H2O2 nozzle was placed farther away. The results of the MRRs when the injecting positions of slurry and H2O2 were reversed are plotted in Figure 3b. The MRRs for Cu remained nearly the same despite the change in the supply position. This means that, even if the slurry and H2O2 were injected without mixing, it did not affect the MRR in Cu CMP. Table 2 shows the removal rate numerically for each condition in Figure 3.

Figure 3.

(a) Position of the two way injection;H2O2-slurry (b) MRR of the reference and the two-way injection with position; H2O2-slurry.

Table 2.

MRR and pH of reference and the two-way injection with position; H2O2–slurry.

In the CMP process, the platen to which the CMP pad was attached rotated, and the slurry was injected onto the pad flows along the grooves in the pad [15]. Therefore, the slurry and H2O2 were injected from the two nozzles, but since the positions of the two nozzles were not far apart, two fluids flowed into the wafer at almost the same time as the pad was rotating, and there was no difference in polishing performance. Many studies on slurry injection have been conducted in the field of CMP process. Wang et al. argued that the MRR decreases as the slurry-injection position goes from the center to the edge of the pad [16]. This is because an increasing amount of slurry is thrown off the pad due to the centrifugal force. Sampurno et al. observed that, the higher the rotational speed was, the more minimal the effect on the slurry-injection position between center of the pad and edge of the wafer carrier [17]. In the two-way slurry-injection method, the slurry and H2O2 were injected near the center of the pad, and the solutions were set to fall into the same circular groove. Therefore, it is possible to minimize the case where the two fluids fall out of the pad due to centrifugal force, and there is no effect on the injection position near the center due to the high rotational speed.

As described above, the flow rate of the slurry and H2O2 was controlled to a total of 150 mL/min, even during the two-way injection, which is the flow rate used in the general method. If the flow rate injected from each nozzle was 150 mL/min, a total flow rate of 300 mL/min was injected, which did not properly deliver the slurry to the wafer, and slurry utilization efficiency decreased [18]. In this case, the use of the two-way injection would be meaningless. Therefore, to compare with the general injection method, the total flow rate injected from the two nozzles had to be 150 mL/min, even in the two-way injection. In addition, to maintain a similar MRRs, the amounts of abrasive particles and additives injected per minute must be the same, so the concentration according to the flow rate is inevitably different, as shown in Table S1. Therefore, despite the difference in flow rates, the same amounts of abrasive particles and additives were injected during the CMP process, resulting in the MRRs being maintained.

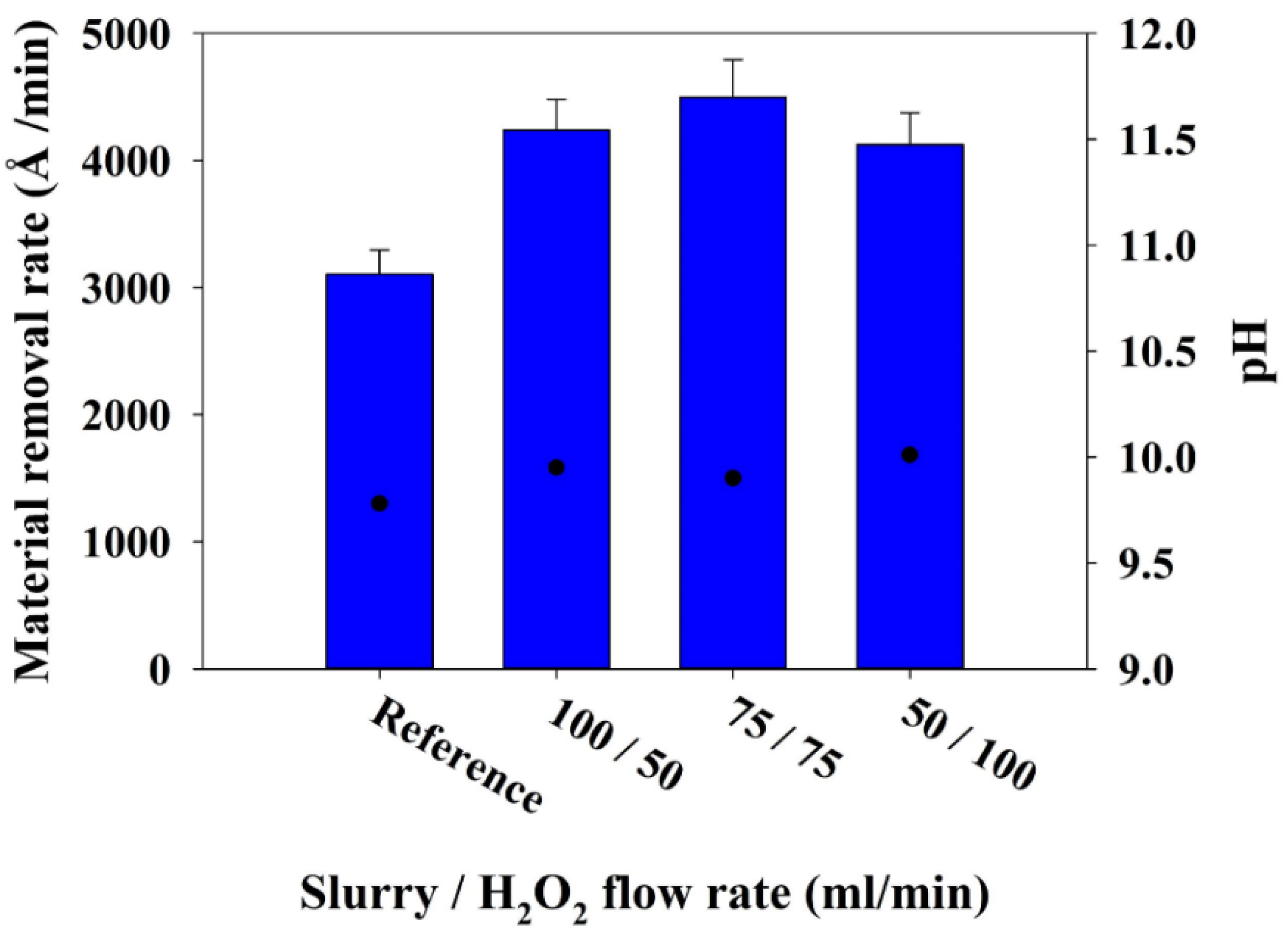

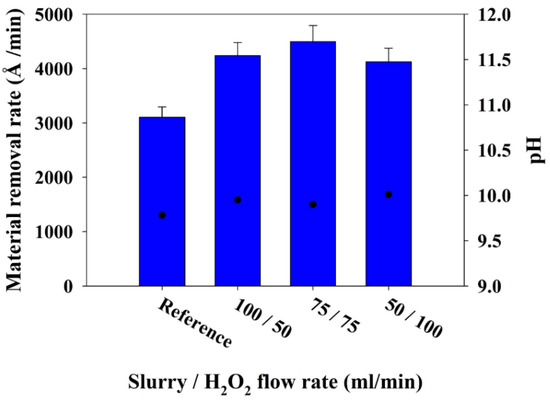

Even if the pH of the slurry is adjusted to 10, H2O2 is acidic, so when mixed with 1.0 wt% H2O2, the pH slightly decreases to about 9.8. This experiments shows quite a similar pH when the samples for each flow rate were mixed in the two-way injection method. In this method, the pH of 1.0 wt % H2O2 was adjusted to 10, and the process and slurry conditions were the same as those in the previous tests. When polishing was performed after adjusting the pH of H2O2 to 10, the MRR was about 1000 Å/min higher than that when the pH was not adjusted, and the result can be seen in Figure 4.

Figure 4.

MRR of the reference and two-way injection; the pH of H2O2 solutions was adjusted to 10.

When the pH of H2O2 was adjusted to 10, the pH when mixed with the slurry was about 10, which is generally 0.2 higher than that without adjusting the pH of H2O2. Therefore, the MRR was as high as 1000 Å/min in the two-way injection method when the pH of H2O2 was 10 because the overall pH increased. As pH increases, glycinate ion increases, and glycine accordingly actively functions as a chelating agent [19]. Therefore, the MRRs of Cu through the chelating effect increases. The results of the MRRs according to the change in the flow rate of the two nozzles had a slight difference, similar to the previous experiment, but it should be considered virtually identical.

4. Conclusions

In this study, the two-way slurry-supply method was investigated as a method to prevent the degradation of the Cu slurry. The two-way injection method showed a similar MRR of Cu polishing as that of the general slurry-supply method. Even if the positions of the two nozzles were changed, it did not significantly affect the MRR. In addition, if the amounts of the abrasive particles and additives injected in 1 min were the same despite the change in the flow rate of the two nozzles, the MRR remained similar. The average MRR difference was about 163.13 Å/min, which is a small difference of about 5%. This means that the process may be performed using a two-way injection without mixing the slurry and H2O2, thereby preventing the degradation of the slurry. The two-way injection method is likely to be applied not only to separately inject the slurry and H2O2 in metal CMP, but also to a mixed abrasive slurry, which has different abrasive types or sizes. In addition, since the two-way injection method is a different study on CMP performance from previous papers related to slurry consumption, it can be suggested as a different method of slurry injection.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/app13063758/s1. Table S1: concentration (wt %) of components with flow rates.

Author Contributions

Conceptualization, T.K., J.K. and C.B.; methodology, D.K.; validation, J.K. and D.K.; investigation, S.O.; writing—original draft preparation, C.B.; writing—review and editing, J.K. and D.K.; supervision, T.K.; project administration, T.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Technology Innovation Program (or Industrial Strategic Technology Development Program) (1415180302, 20020417, Development of aging resistive CMP paddisk and process technology) funded By the Ministry of Trade, Industry & Energy (MOTIE, Republic of Korea).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wu, L.; Chen, K.; Cheng, S.; Lee, B.; Shu, C. Thermal decomposition of hydrogen peroxide in the presence of sulfuric acid. J. Therm. Anal. Calorim. 2008, 93, 115–120. [Google Scholar] [CrossRef]

- Mori, Y.; Uemura, K. Total-reflection X-ray fluorescence analysis for semiconductor process characterization. Spectrochim. Acta Part B At. Spectrosc. 2003, 58, 2085–2092. [Google Scholar] [CrossRef]

- Kondoh, E.; Toyama, M.; Jin, L.; Hamada, S.; Shima, S.; Hiyama, H. Growth kinetics of Cu surface layers in H2O2–BTA aqueous solutions. Jpn. J. Appl. Phys. 2020, 59, SLLF01. [Google Scholar] [CrossRef]

- Yan, C.; Liu, Y.; Zhang, J.; Wang, C.; Zhang, W.; He, P.; Pan, G. Synergistic effect of glycine and BTA on step height reduction efficiency after copper CMP in weakly alkaline slurry. ECS J. Solid State Sci. Technol. 2016, 6, P1. [Google Scholar] [CrossRef]

- Li, R.; Du, Y.; Li, Y.; He, Z.; Dai, L.; Wang, L.; Wu, X.; Zhang, J.; Yi, J. Alloying Strategy for High-Performance Zinc Metal Anodes. ACS Energy Lett. 2022, 8, 457–476. [Google Scholar] [CrossRef]

- Nicoll, W.; Smith, A. Stability of dilute alkaline solutions of hydrogen peroxide. Ind. Eng. Chem. 1955, 47, 2548–2554. [Google Scholar] [CrossRef]

- Hiroki, A.; La Verne, J.A. Decomposition of hydrogen peroxide at water-ceramic oxide interfaces. J. Phys. Chem. B 2005, 109, 3364–3370. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kwak, D.; Park, J.; Kubota, T.; Kim, T. Effects of aging time in hydrogen peroxide-glycine-based Cu CMP slurry. Mater. Sci. Semicond. Process. 2022, 140, 106343. [Google Scholar] [CrossRef]

- Xu, Q.; Chen, L.; Yang, F.; Cao, H. Influence of slurry components on copper CMP performance in alkaline slurry. Microelectron. Eng. 2017, 183, 1–11. [Google Scholar] [CrossRef]

- Aksu, S.; Doyle, F.M. Electrochemistry of copper in aqueous glycine solutions. J. Electrochem. Soc. 2001, 148, B51. [Google Scholar] [CrossRef]

- Silva-Molina, R.; Duarte-Moller, A.; Orrantia-Borunda, E.; Parra-Berumen, R.L.; Álvarez-Ramos, M.E. The role of pH on the second harmonic response of glycine sodium nitrate (GSN). J. Phys. Sci. 2011, 6, 885–890. [Google Scholar]

- Liao, X.; Sampurno, Y.; Zhuang, Y.; Philipossian, A. Effect of slurry application/injection schemes on slurry availability during chemical mechanical planarization (CMP). Electrochem. Solid-State Lett. 2012, 15, H118. [Google Scholar] [CrossRef]

- Jha, A.; Stoll, D.; Tseng, W.T.; Wu, C.; Yang, J.C.; Philipossian, A. Application of Slurry Injection System (SIS) to Advanced Deep-Trench (DT) CMP. In Proceedings of the ICPT 2017, International Conference on Planarization/CMP Technology, Leuven, Belgium, 11–13 October 2017. [Google Scholar]

- Bahr, M.; Sampurno, Y.; Han, R.; Philipossian, A. Slurry injection schemes on the extent of slurry mixing and availability during Chemical Mechanical Planarization. Micromachines 2017, 8, 170. [Google Scholar] [CrossRef]

- Wu, C.; Sampurno, Y.; Liao, X.; Zhuang, Y.; Borucki, L.; Theng, S.; Philipossian, A. Effect of pad groove design on slurry injection scheme during interlayer dielectric chemical mechanical planarization. ECS J. Solid State Sci. Technol. 2015, 4, P272. [Google Scholar] [CrossRef]

- Wang, T.; Zhao, D.; He, Y.; Lu, X. Effect of slurry injection position on material removal in chemical mechanical planarization. Int. J. Adv. Manuf. Technol. 2013, 67, 2903–2908. [Google Scholar] [CrossRef]

- Sampurno, Y.; Borucki, L.; Philipossian, A. Effect of slurry injection position on slurry mixing, friction, removal rate, and temperature in copper cmp. J. Electrochem. Soc. 2005, 152, G841. [Google Scholar] [CrossRef]

- Philipossian, A.; Mitchell, E. Slurry utilization efficiency studies in chemical mechanical planarization. Jpn. J. Appl. Phys. 2003, 42, 7259. [Google Scholar] [CrossRef]

- O’Connor, G.; Lepkova, K.; Eksteen, J.J.; Oraby, E.A. Electrochemical behaviour of copper in alkaline glycine solutions. Hydrometallurgy 2018, 181, 221–229. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).