Abstract

Unsaturated soil is a form of natural soil whose pores are filled by air and water. Different from saturated soil, the microstructure of unsaturated soil consists of three phases, namely, the solid phase (soil particle), vapor phase, and liquid phase. Due to the matric suction of soil pores, the hydraulic and mechanical behaviors of unsaturated soils present a significant dependence on the moisture condition, which usually results in a series of unpredictable risks, including foundation settlement, landslide, and dam collapse. Microbial-induced calcite precipitation (MICP) is a novel and environmentally friendly technology that can improve the water stability of unsaturated soft or expansive soils. This paper reviews the microscopic mechanisms of MICP and its effect on the mechanical properties of unsaturated soils. The MICP process is mainly affected by the concentration of calcium ions and urea, apart from the concentration of bacteria. The moisture-dependent properties were comparatively analyzed through mechanical models and influence factors on the experimental data among various unsaturated soils. It suggests that the variations in resilient modulus and permanent deformation are strongly related to the extent of MICP applied on unsaturated soils. Finally, the problems in the MICP application, environmental challenges, and further research directions are suggested.

1. Introduction

Unsaturated soil is a type of soil consisting mainly of solid particles, a liquid matrix, and pore air. Due to the shrinkage interface between liquid and air, the matrix suction becomes an important structural stress within saturated soil [1]. The mechanical properties of unsaturated soil closely depend on the humidity characteristics [2,3]. The dependence of mechanical behaviors on matric suction or moisture involved in many engineering problems has been reported on in studies of foundation engineering, subgrade engineering, and slope engineering [4,5,6,7,8]. For example, after the soft soil humidifying, the stiffness of the soil subgrades decreased evidently, resulting in the settlement and collapse of the pavement structure. Thus, unsaturated soils should be improved in practice by physical and chemical methods.

The existing soil treatments mainly include dynamic compaction methods and the cement grouting method, but these methods all have certain shortcomings [9,10]. Yao et al. [11] strengthened the collapsible dam foundation by means of the dynamic compaction method, and found that its availability of treatment is limited by construction and geological conditions. The grouting method is often used for soft foundation treatment, but it uses a large amount of cement and its production would increase the quantity of CO2 emissions [12]. More and more attention has been placed on reducing CO2 emissions in the life cycle of engineering practices, with the increasing awareness of people concerned about the environment [13]. These green and low-carbon practices require a novel technology to decouple the dependence of the soil’s treatment by cement. Therefore, the microbial-induced calcite precipitation (MICP) technology has become one of the interest points in geotechnical and geological engineering fields in recent years, since it is an environmentally friendly, noiseless, and low-cost approach for improving the engineering properties of unsaturated soil [14,15].

At present, the cement process of MICP could mainly be classified into four types of bio-mineralization reactions [16], including the urea hydrolysis type [17], ferric reduction type [18], sulfate reduction type [19] and denitrification type [20]. Urea hydrolysis is the most efficient and advantageous way to conduct MICP technology, since it has the advantages of simple operation and is easily controllable [21]. In addition, it can quickly produce calcium carbonate precipitates and has a high microbial survival rate without a special nutrient solution [22]. Studies have been conducted to investigate the improvement of soil mechanical behaviors by urea hydrolysis through macroscopic and microcosmic experiments [23,24]. Martinez et al. [25] applied the MICP grouting method on expansive soil columns and found that the swelling potential and hydrophilicity of expansive soil decreased after the treatment of MICP. Salifu et al. [26] demonstrated that the penetration grouting approach of MICP-solidified fluid can improve the stability of soil slopes, since the generated CaCO3 can fill the volume of the micro-pore structures within soil by 9.9%. Sharma and R. [27] found that the compressive strength of MICP-treated soil was 1.45 to 2.26 times of that of the untreated soil by laboratory tests. Some researchers have reported the effectiveness of MICP treatment on soil mechanical properties, while less considerations and comparisons have been made on the changes of the soil hydraulic properties induced by MICP treatment [28,29,30]. Specially, it is important to investigate the moisture dependence on the stiffness and deformation of unsaturated soil in subgrade construction.

In this paper, the reaction mechanism of microbial-induced calcite precipitation and its influence on the physical and mechanical properties of unsaturated soil are reviewed. Firstly, the reaction mechanism of urea hydrolysis type MICP technology was introduced, considering different influencing factors, including temperature, PH value, nutrient solution concentration, and calcium ion concentration. Secondly, the structural characteristic and the soil water characteristic curve (SWCC) of unsaturated soil and their influence on the physical and mechanical properties of unsaturated soil are introduced in detail. Thirdly, the changes of the soil microstructure before and after mineralization by MICP technology are analyzed and compared from the macro and micro levels. The influence of MICP technology on the permeability of unsaturated soil and SWCC is also discussed. Furthermore, the relationship between the hydraulic and mechanical properties of unsaturated soil is briefly introduced. Finally, it provides the existing problems, environmental challenges, and further research aspects in the application of MICP.

2. Mechanism of Microbial-Induced Calcite Precipitation (MICP)

2.1. Reaction Mechanism of MICP

The MICP is a widely existing bio-mineralization reaction in nature, accompanied by different microbial activities and chemical processes [31]. Different from the mineralization on the geological surface of earth, bio-mineralization refers to the process in which inorganic elements selectively precipitate from the environment to form minerals on a specific organic matrix with the participation of biological cells. This bio driven mineralization reaction mainly occurs in four ways: urea hydrolysis, denitrification, sulfate reduction, and ferric iron reduction [32]. The method of using microorganism-induced denitrification to precipitate calcium carbonate not only has high cultivation cost, but also has low efficiency of generating calcium carbonate [33]. However, it is undeniable that denitrifying bacteria can grow in situ and play a role under anoxic conditions [34]. In the process of microbial-induced sulfate, the sulfate reduction will produce the hydrogen sulfide gas, which is harmful to the environment and human body [35]. In addition, hydrogen sulfide gas also results in accelerating the corrosion of steel bars in structures. For the ferric iron reduction method, the requirements for the oxidation substrate are very high, meaning that it only works when the solubility of the oxidation substrate is low [36]. The urea hydrolysis method is simple and efficient, given that there is no additional reaction condition and no environmental pollution [37]. Because matrixes (urea and CaCl2) have a high solubility in water solution, the MICP process can generate a lot of CaCO3 in a short time [38]. Scholars generally believe that MICP using urea hydrolysis has an enormous potential in soil treatment [39]. In addition, among all biochemical reactions, the reaction of urea hydrolysis is a main technological path to produce ammonium ions and carbonate ions, and its reaction process is relatively simple. Therefore, the reaction mechanism of urea hydrolysis MICP was taken as an example in the following section.

2.2. Reaction Mechanism of Urea Hydrolysis MICP

Chuo et al. [40] found that 17–30% of bacteria collected from Australia can hydrolyze urea rapidly. The Bacillus pasteurii (BP) has a high urease activity within soil and has been widely used in the MICP treatment [41]. During its metabolism, its cell secretes a large amount of urease to produce adenosine triphosphate (ATP), which promotes the catalytic hydrolysis of urea to produce ammonium and carbonate ions. Meanwhile, the PH value in the system increases in this process. Due to the presence of calcium ions, carbonate ions and calcium ions gradually modulate to form CaCO3 precipitation. The reaction equation of urea hydrolysis is shown in Equations (1)–(5) [42].

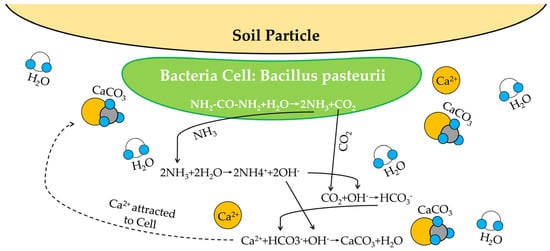

The details of the urea hydrolysis of CaCO3 precipitated by BP are shown in Figure 1. When BP metabolizes to produce urease, it will secrete a metabolite called bail polymer. Due to the existence of the double electric layer structure of the extracellular polymer and its microorganism, the microorganism tends to adsorb on the surface of the sand particles. Because of the negatively charged functional groups such as hydroxyl, amino, amido, and carboxyl, the surface of the microbial cell wall is also negatively charged and constantly attracts calcium ions in the environment, meaning that a large number of calcium ions gather on the cell surface. The carbonate formed after hydrolysis of urea will form CaCO3 precipitation with these calcium ions and envelop the bacteria [43]. From the whole reaction process, it can be found that bacteria mainly play two roles: the core of which is to provide urease, and the other is to provide crystal nuclei for the formation of CaCO3 crystals [44]. The reaction equation of urease bacteria is displayed in Equations (6)–(10) [45].

Figure 1.

Sketch map of microbial-induced carbonate deposition process on particle surface.

2.3. Influencing Factors of MICP Reaction

The essence of MICP technology is to induce microorganisms to generate CaCO3 precipitation between the gaps within soil to achieve the role of bio-cementation and treatment of soil. However, MICP technology will be limited and constrained by many factors in actual operation [46]. The factors that influence the treatment effect of MICP technology contain temperature, PH value, bio-cement concentration, calcium ion concentration, nutrient solution (urea) concentration, and soil particle size [47]. Mortensen et al. [48] showed that the influencing factors were in the order from large to small as temperature, concentration of bio-cementing fluid, nutrient solution concentration, PH value, and calcium ion concentration, respectively, through single factor and orthogonal tests. Sotoudehfar et al. [49] used the optimized orthogonal test method to explore the influence of various parameters in the process of MICP on the curing effect. The results showed that the curing time had the greatest influence on the curing effect, and the bacterial cell concentration, molar concentration ratio of nutrient solution, and the liquid injection flow rate had similar influences on the curing effect.

2.3.1. Temperature and PH Value

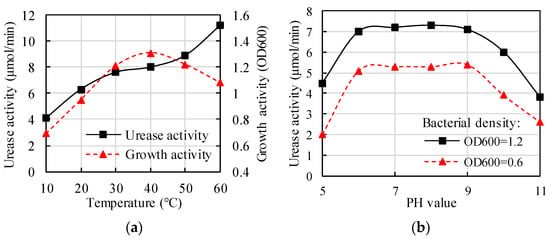

Temperature is the key factor in the success of MICP technology on soil treatment [50]. A change in temperature will affect the growth of bacteria, the activity of microbial enzymes, the biodegradation of bacteria, and the process of binding precipitation, thus affecting the final curing effect. Figure 2a shows the changes of urease and growth activities of BP at different temperatures. An absorbance index at the 600 nm wavelength (OD600) was wildly applied to evaluate the density and growth activity of the BP solution. It found that the growth curve of BP was different when the temperature varied from low to high [51]. It is generally believed that the growth of BP is inhibited at low temperatures, while the urease activity of BP decreases at high temperatures [52,53]. Therefore, the BP should be cultivated under a suitable growth environment (temperature).

Figure 2.

Changes of urease activity influenced by (a) Temperature (b) PH value.

In addition to the temperature, urease activity of BP is an important factor. The decrease in enzyme activity will lead to an insufficient precipitation of CaCO3. Kim et al. [54] found that the suitable temperature for the growth of BP Sarcina was 30 °C, at which the strain propagated rapidly and produced high urease activity. When the temperature was less than 10 °C, the urease activity was almost lost. Furthermore, since the urease activity is affected by temperature, Xiao et al. [55] demonstrated that CaCO3 crystals generated in soil samples had a good homogeneity by grouting at low temperature.

PH value is one of the important influencing factors on microbial life activities. Its influence is mainly reflected in three aspects: First, it affects the biological activity of macromolecular substances (such as proteins and nucleic acids) by changing their charge. Second, it reduces the absorption and utilization of nutrients by microorganisms by changing the charge of cell membrane. Third, it also reduces the utilization effectiveness of nutrients in the living environment of microorganisms and enhances the toxicity of harmful substances [56]. Figure 2b shows the changes of urease activity with the increasing PH value.

2.3.2. Bio-Cementing Liquid Nutrient Solution Concentration

Bio-cementitious fluid plays an important role in microbial soil treatment. Bio-cementing liquid shall be used in the reaction of microbial-induced CaCO3 deposition, which has a direct impact on the treatment effect [57]. From the MICP principle, the increase in calcium ions and urea in the bio-cementing solution will precipitate more CaCO3. In the current research, the bio-cementing fluid generally includes urea and calcium chloride, but the selection of parameters such as bio-concentration, number of rounds, and ratio are different [58]. Cui et al. [59] believed that the bio-concentration of bio-cementing fluid had a significant impact on the treatment effect. Meanwhile, the low bio-concentration was helpful to obtain higher treatment strength, and the size of generated CaCO3 crystal was also large [46]. Cheng and Cord-Ruwisch [60] found that a too low bio-concentration of bio-cement solution will lead to insufficient CaCO3 and will affect the treatment effect.

2.3.3. Nutrient Solution Concentration

Mujah et al. [61] found that changing the nutrient solution can affect the nucleation rate and the size of CaCO3 crystals. Meanwhile, the effect of nutrient solution on different environments was also different. Wong [62] added urea to the culture medium to increase the precipitation rate of CaCO3, which can overcome the inhibition of solidification under low temperature environments. The adding urea does not only increase the urease activity, but also will cause the soil to become alkaline, thus inhibiting the growth of microorganisms [63]. The high urea content causes the uneven distribution of overall precipitation crystals, resulting in the low strength of soil. Zhao [64] found that the concentration of the nutrient solution has an important impact on the shear strength of solidified muddy soil. With the increasing concentration of the nutrient solution, the internal friction angle first increases and then decreases, and the optimal concentration of the corresponding optimal nutrient solution is 1.60 mol/L. Soon et al. [65] found that the bio-cementation effect will reach a peak value with the change in nutrient concentration, according to which the most appropriate nutrient concentration can be obtained. In addition, cells will shrink due to water loss under a high salt environment, thus affecting the physiological and biochemical reaction process of microorganisms. Therefore, the concentration of nutrient solution is very important in the study of microbial solidification of soil. Whiffin et al. [66] found that the activity of bacterial urease decreased significantly, almost linearly, with the increase in calcium ion concentration, indicating that a high concentration of calcium ions have an evident inhibition on urease under this condition.

In conclusion, the output of CaCO3 is positively related to the concentration of nutrient solution within a certain range, but high concentration inhibits the microbial induced CaCO3 generation. At low concentration, the microbial induced CaCO3 is smaller and more evenly distributed in the soil.

2.3.4. Calcium Source and Its Concentration

The BP cells can be regarded as a formation site to produce CaCO3 precipitation [67]. The MICP reaction process in Figure 1 indicated that the carbonate ions generated by the urea decomposition of BP will be continuously transported from the intracellular to the extracellular and meet with calcium ions in the environment. Therefore, the PH value of calcium sources and the concentration of calcium ions affect the rate, quality, and output of CaCO3 crystals produced in the MICP process. Achal and Pan [68] compared the effects of four calcium sources on BP-induced CaCO3 precipitation, and proposed that calcium chloride is a better calcium source in the MICP process, followed by calcium nitrate. Cheng et al. [69] took seawater as the bio-cementing fluid to conduct MICP process, and the results showed that the strength of samples maximized after 200 grouting times, since calcium ion concentration was low in seawater. The Ca2+ concentration is very important for the precipitation and precipitation efficiency of CaCO3 crystals. Okwadha and Li [70] found that high concentrations of urea and CaCl2 (more than 0.5 mol/L) reduces the deposition efficiency of calcium carbonate, and urea and CaCl2 can improve the deposition efficiency of calcium carbonate at low concentrations (0.05–0.25 mol/L). From the current test results, a too low or too high calcium ion concentration cannot have the corresponding calcite yield. The calcium ion concentration should be optimized by laboratory tests to effectively bio-cement the test medium together by MICP calcite.

Based on the above reviews, the MICP technology results from the metabolic processes of bacteria including urease-producing bacteria, sulfate-reducing bacteria, denitrifying bacteria, and oxidizing bacteria. Although the type of bacteria and the reaction mechanism may be different in the MICP application, both the nutrient solution and the calcium source are necessary to generate CaCO3 (calcite). Therefore, the MICP is mainly affected by the concentration of calcium ions and urea.

2.4. Application of MICP in Engineering

The MICP technology comes from the development of microbiology and geotechnical engineering, and is a novel technology with ecologically friendly and sustainable advantages [23]. Now, the technology has achieved good results in engineering applications, including soil treatment, seepage prevention, and cracking repair.

Many scholars have proved that MICP plays a significant role in soil treatment through experimental tests [71,72,73]. For example, compared with untreated expansive soil samples, it found that the swelling rate of soil samples after MICP mixing treatment was significantly reduced [25]. Sharaky et al. [74] found that the unconfined compression resistance of treated clay samples increased nearly three times through the MICP pressure grouting treatment test of clay. Yasuhara et al. [75] used MICP technology to strengthen the sand and premixed method. The so-called premixing method refers to the use of the mixing method and unconfined compressive strength test to make the reaction liquid better contact with the soil. Compared with other methods, the advantage of this method is that it can make CaCO3 uniformly distributed in the soil.

The CaCO3 generated by MICP technology can also fill the pores of the solidified soil and further reduce permeability to achieve the purpose of plugging [76]. A plugging test of MICP was conducted on fly ash modified concrete using giant bacillus [28]. The results suggested that the calcite precipitation between the aggregate and the bio-cement mortar was a primary reason for reducing the permeability of samples.

Liu et al. [77] also demonstrated that as the CaCO3 precipitate is induced by MICP, it plays a role in bio-cementing soil samples, since it fills cracks among soil particles. Wiktor and Jonkers [78] used an energy dispersive spectrometer to observe the status of concrete cracks repaired by MICP, and their results showed that a crack of the width of 0.46 mm was completely healed after 100 days of repair, which was much larger than that of 0.18 mm in the control group. Algaifi et al. [79] found that the MICP has an advantage in the self-healing of cracks in bio-cement slurry by the theoretical model and microscopic test.

In general, the usage of MICP technology can effectively repair cracks, but it is undeniable that the time period for treatment and repair is long. Subsequent research should be carried out to develop a more efficient and faster MICP technology in the material source and reaction processes.

3. Unsaturated Soil

3.1. Characteristic of Unsaturated Soil

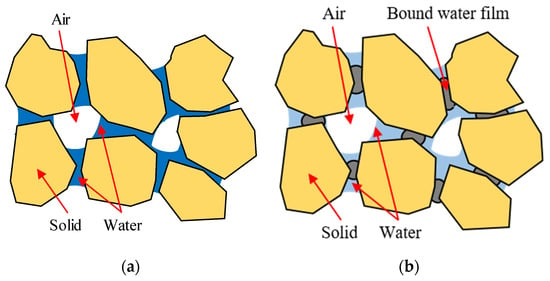

The unsaturated soil exists widely in nature since most of the soil above the groundwater level is in an unsaturated state. Due to the differences in the medium and molding method, the soil has special structure and stress state. There are two types of theory frames to describe mediums in unsaturated soil. Figure 3a considers the unsaturated soil as a three-phase soil, including a solid phase (soil particles and some bio-cementitious substances), a liquid phase (water and aqueous solution), and a gas phase (air and water vapor, etc.). However, with the further study of unsaturated soil mechanics, unsaturated soil is considered as a four phase structure [80]. In addition to the solid, liquid, and gas three-phases, the liquid gas interface is also added as an independent phase. This independent phase can also be called the bound water membrane, as shown in Figure 3b. The nature of the liquid gas interface is not only different from that of water, but also different from that of gas. It is an independent phase. This phase is called the shrink film in surface chemistry. The morphology of the water pores and gas pores of unsaturated soil is closely related to the water content (saturation) of unsaturated soil [81].

Figure 3.

Schematic diagram of mediums in unsaturated soil: (a) solid liquid gas three phase system; (b) four phase diagram.

The unsaturated soil can be divided into four types: fully connected gas phase, partially connected gas phase, internally connected gas phase, and completely closed gas phase. When the gas phase in the pores exists in a fully connected way, the gas permeability has nothing to do with the water content. With the increase in the water content, the effective stress of the soil mass gradually reduces the volume of gas in the pores. A semi closed or closed bubble is formed, and the pore gas exists in a partially connected or internally connected state. At this time, the suction of soil decreases gradually, and the effective stress of soil should consider the influence of pore air pressure and pore bearing pressure, respectively. When the water content in the soil is very high, the gas phase is completely surrounded by liquid, small in volume, and can only flow with the liquid, which can be regarded as a two-phase system with air and water. At this time, the soil mass is basically saturated, the air permeability of the soil is very small, the suction is basically zero, and the effective stress of the soil mass is the same as that of the saturated soil.

Duan et al. [82] pointed out that the shape of unsaturated soil is more complex than that of saturated soil, and this complex medium composition has an important impact on the strength, deformation, and seepage of soil. Given that the structure of water pores and gas pores in unsaturated soil plays a key role in its engineering properties, the effect of the matrix suction and water content on the properties of unsaturated soil should be further studied.

3.2. Soil Water Characteristics of Unsaturated Soil

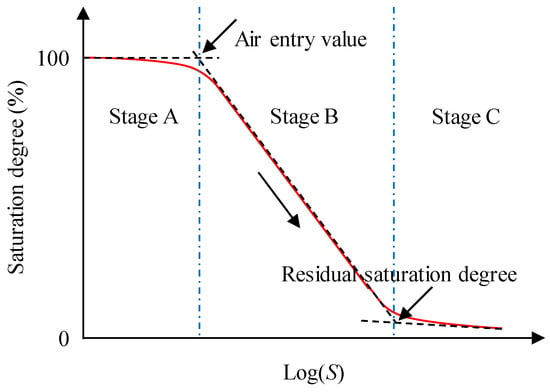

Matrix suction is the main reason why unsaturated soil is different from saturated soil, and it is also a key factor to reflect the mechanical properties of unsaturated soil [83]. The SWCC is a conceptual and interpretative tool to describe the soil water holding capacity when water content changes with suction [84]. SWCC defines the relationship between suction (matric suction), volume water content (θ) or saturation (Sr) of unsaturated soil. A typical SWCC is shown in Figure 4 (determined by the change in water content). The suction state (abscissa of the SWCC) can be expressed by the total suction of the soil water potential. In the high humidity state, the matrix suction (ua − uw) is used, and in the low humidity state, the total suction is used. Since there is little difference between the total suction value and the matrix suction in the low humidity state, the entire SWCC is often expressed by the matrix suction.

Figure 4.

Typical water retention curve.

When the soil changes from a saturated state to a dry state, the distribution of solid, liquid, and gas phases in the soil will also change with the change in stress state. The relationship between these phases has different forms and affects the engineering properties of unsaturated soil. In some cases, the properties may be mainly related to the volume of the separated phase (such as water content), or to the continuity and curvature of the liquid phase (such as permeability coefficient, molecular diffusion), or to the gas phase (such as evaporation coefficient or diffusion coefficient). In other cases, the properties of interphase contact areas that control stress transmission (such as shear strength and volume change) or interphase mass transfer (such as chemical adsorption and volatilization) determine soil properties. The relationship between these phases can be derived from the data of the SWCC, which can then be used to estimate the parameters of unsaturated soil [85].

In the SWCC measure, the saturated water content A can be obtained by tests, while the residual water content B is often difficult to determine, influenced by the instrument precision and soil properties. Therefore, some SWCC models have been proposed to predict the result of the SWCC. The widely used expressions of SWCCs are displayed in Equations (11)–(13).

where ψ is suction; θ is the volume water content; and a, b, q, n, and m are fitting parameters.

3.3. Mechanical Properties of Unsaturated Soil

SWCC is closely related to the strength of unsaturated soil and is an important tool to study the mechanical properties of unsaturated soil. More specifically, SWCC describes the relationship between the thermodynamic potential energy of pore water in soil and the amount of water absorbed by soil system. The SWCC shape of various soils is mainly affected by the properties of soil materials. Fredlund and Xing [86] carried out a large number of tests on different types of unsaturated soils, and showed that the main factors affecting SWCC are mineral composition, pore structure, stress state of soil particles, property of liquid, pore gas, etc.

Many researches have been performed to explore the relationship between water content and mechanical properties of unsaturated soil [87]. The shear strength formula of unsaturated soil can be proposed by Bishop effective stress. It is related to saturation S, which is closely related to SWCC. φb is also closely connected with different sections of SWCC, thus it can χ horn φb to simplify the test measurement and facilitate the engineering application.

Lamborn [88], based on the expanded micromechanical model, proposed the shear strength formula of unsaturated soil as follows:

where τf is the shear strength of unsaturated soil; c′ and φ′ are effective cohesion and effective internal friction angle of saturated soil; (ua − uw) is the matrix suction; (σ − ua) is the net normal stress; and θw is the volume water content.

Vanapalli et al. [89] developed a comment model for predicting the shear strength by SWCC, as shown in Equations (16) and (17).

where Θ is the relative volume water content, Θ = θw/θs; θs is the saturated volume water content; and κ is a fitting parameter.

Garven and Vanapalli [90] introduced the plasticity index Ip into the fitting model of the parameters κ, as follows:

Furthermore, the numerical simulation provides new insights into moisture and stress of unsaturated soil [91]. Liu et al. [92] analyzed the changes of the yield stress with the capillary cohesion between particles by simulating isotropic compression and biaxial shear tests. Jiang et al. [93] proposed two shear strength functions to reflect both the nonlinear characteristics of unsaturated soil and the influence of grain size distribution. Richefeu et al. [94] found that the density of the liquid bond is a decisive parameter for the overall cohesion of wet granular materials. Within the distance of the liquid bridge fracture, even at low water content, the uniform distribution of liquid will lead to the highest cohesion. Scholtès et al. [95] introduced the micromechanics study of unsaturated granular media in the state of the pendulum liquid bridge.

The resilient modulus (MR) of the subgrade is a key parameter to design pavement structures. The MR of unsaturated soil is dependent on the humidity state of subgrades [96]. In the range of low matric suction, the MR increases nonlinearly with the increase in matric suction; however, this trend cannot continue to a higher matric suction range [97]. Ceratti et al. [98] found that the dynamic resilient modulus of red clay increases with the increase in matrix suction when the matrix suction is less than 1 MPa, and the increase in dynamic resilient modulus is not evident when it exceeds this value. This phenomenon may be due to the larger wetted contact area between soil particles and the more significant contribution of matrix suction to soil strength and stiffness when it is in the low matrix suction range. In the higher matrix suction range, the water content is evidently less, and the wetted contact area of soil particles is limited, which limits the effect of matrix suction on the MR.

4. Influence of MICP on Properties of Unsaturated Soil

4.1. Microstructure of MICP Unsaturated Soil

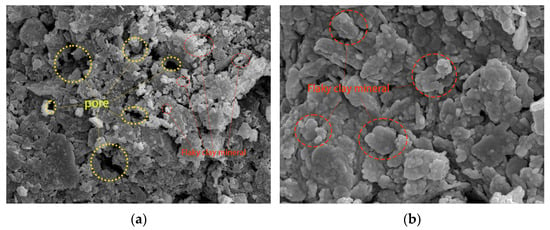

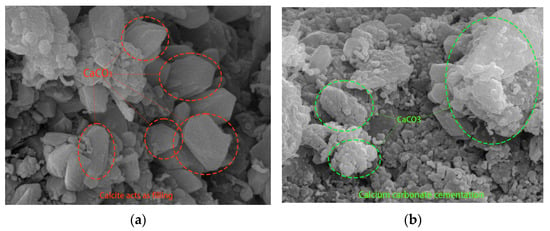

The micro bonding form determines the mechanical properties such as macro strength, to a certain extent. At present, the main ways to study the microstructure of soil are X-ray diffraction analysis and scanning electron microscope (SEM) observation [99]. Xiao et al. [100] carried out SEM analysis to observe the changes in the product morphology and microstructure of MICP soil. Figure 5 presents the microscopic morphology of untreated sand soil using SEM. It shows that there are a few clay minerals attached to the surface of soil particles in the untreated soil, and no evident CaCO3 crystals are found. The SEM results of MICP-treated sand soil are shown in Figure 6. It is evident that a large number of CaCO3 crystals are generated in the shape of parallelepiped calcite, and the size of crystals is 1–10 μm. Cheng et al. [101] explored the relationship between the concentration of the bacteria solution and the concentration of the bio-cement solution in the MICP process from a microscopic perspective. Some of the CaCO3 crystals were dispersed in the soil pores and played the role of filling pores among soil particles. It was proved that the CaCO3 crystal played a role in bio-cementing soil particles.

Figure 5.

Micromorphology of untreated sand soil: (a) pore; (b) flaky clay mineral.

Figure 6.

Micromorphology of sand soil after treatment: (a) filling pore; (b) cementation.

Elmaloglou et al. [102] observed the microscopic morphology of the MICP of the experimental device under different solid particle compositions. It was found that the CaCO3 crystals mainly play the role of encapsulation and can evenly fill the internal pores of soil samples. The permeability of ordinary sand can be reduced by three orders of magnitude due to the CaCO3 in the pores after treatment. Porter et al. [103] investigated the morphology of the sand column after curing with BP and found that CaCO3 played a bio-cementing role in greatly improving the connection strength between sand grains. SEM results show that a layer of white and dense hardened shell formed on the surface of the modified soil sample, and the generated CaCO3 presented a lamellar cleavage [104]. In addition, given that the solubility of CaCO3 is small, the MICP process is very helpful to improve the water stability of soil.

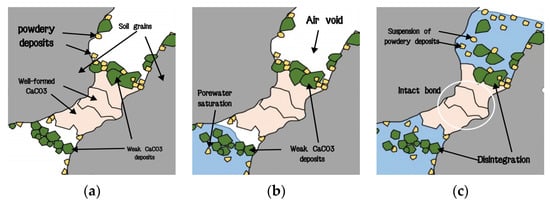

4.2. Permeability of MICP Unsaturated Soil

The CaCO3 crystals deposited in the soil reduced the porosity (or porosity) of the soil. Phillips et al. [105] showed that the permeability of the rock cracks filled with bio-cementation decreased by about four orders of magnitude. The water pressure of the repaired rock cracks was about three times higher than that of original rock cracks. In addition, the field results showed that the permeability of the rock fractures decreased significantly within a few square meters around the injection well [106]. Wang et al. [107] suggested that the CaCO3 precipitation generated divides the large voids in the soil sample into many small voids, which makes the internal distribution of the sample more uniform and reduces the seepage channel in the soil sample. Ferris et al. [108] found that the permeability of the surface decreased by 50% after 45 h, while the soil pores were almost completely blocked after 120 h. They concluded that the permeability coefficient of the soil sample was determined by the content of CaCO3 in the soil sample. Figure 7 shows the schematic diagram of the MICP soil structure during water infiltration. There were three aspects resulting in the permeability decrease in soil: (1) the generated CaCO3 crystals occupied the void space, which was caused by the reduction in porosity; (2) the interspace or pore throat was blocked by crystals; (3) the bioblockage caused by the production amount or related metabolites. Ivanov and Chu [15] found that some CaCO3 precipitations do not contribute to contact bio-cementation, since these carbonates were either randomly crystallized on the soil particles or precipitated on the formed carbonate bridges. In conclusion, the permeability of soil samples was improved by MICP, since pores within soil were blocked by the formation of CaCO3 crystals and the metabolism of microorganisms.

Figure 7.

MICP soil infiltration diagram: (a) MICP soil diagram before wetting, (b) water infiltration into the pores, (c) saturated state.

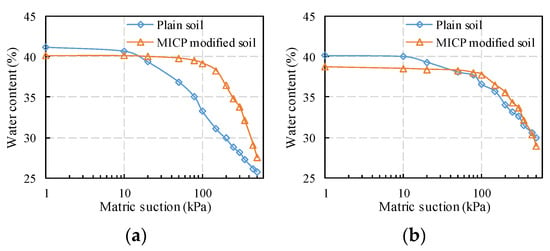

4.3. Water Holding Capacity of MICP Unsaturated Soil

MICP technology mainly changes the water holding capacity of unsaturated soil by generating CaCO3 precipitation to bio-cement soil particle pores [109]. Bo et al. [110] compared the water absorption of soil samples before and after treatment with MICP technology and found that the water absorption of soil samples after treatment is far greater than that of untreated soil. MICP treatment significantly improved the soil water holding capacity and anti-cracking capacity. Figure 8 shows the SWCCs of plain soil, and improved expansive soil are compared under the conditions of compactness of 90% and 95%, respectively. Results show that the pore will become smaller with the increase in compaction degree, thus changing the water holding capacity of soil samples. The SWCC of soil improved by MICP technology changes greatly compared with that of expansive soil before treatment, and the saturated water content of soil improved by MICP technology is higher than that of plain soil. It indicated that the volume of water content of the improved expansive soil changes less under the same matrix suction change, the water holding capacity was stronger, and the water stability was better.

Figure 8.

Comparison of SWCCs between plain soil and MICP improved soil with compactness of (a) 90% and (b) 95%.

4.4. Static Mechanical Behavior of MICP Unsaturated Soil

In the existing research, many scholars have studied the change in soil properties after improvements from various aspects. Wani and Mir [111] investigated the mechanical property of soft soil treated by MICP through unconfined compression tests and found that the strength of MICP soil increased by 3–3.5 times more than that before MICP process. Van Paassen [112] found that the compressive strength of MICP sand was exponential with the amount of CaCO3. Khaleghi and Rowshanzamir [113] finally found that the compressive strength increased by 300 KPa and the permeability decreased significantly after the sand was solidified by MICP. Lian et al. [114] strengthened the sand column by biological grouting. Its unconfined compressive strength reached 1.91 MPa, and the permeability coefficient decreased by three orders of magnitude. Putra et al. [115] added magnesium to optimize the precipitation rate and generation content of CaCO3 precipitation, and the test results showed that the maximum uniaxial compressive strength obtained from the treated sample was 0.6 MPa. Yang et al. [116] found that the improvement of hardness and expansibility of remolded biological treated sand was caused by the particle roughness of CaCO3 coating. Compared with untreated sand, the shear strength was improved. Pakbaz et al. [117] concluded that the shear strength of the samples after MICP treatment increased by 44–86%, since the CaCO3 coating improves the compactness and internal friction angle of the samples.

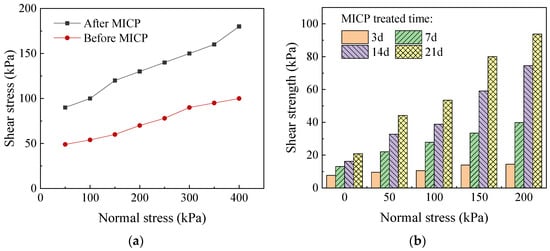

Chittoori et al. [118] demonstrated that the shear strength and unconfined compressive strength of expansive soil had been significantly improved after improvement by the MICP method; the plastic limit water content of expansive soil had increased; the liquid limit water content, plastic index, and expansion rate had decreased; and the microstructure had changed significantly. Therefore, MICP technology is an effective technical means to improve the compressive strength, shear strength, and free expansion rate of unsaturated soil through laboratory tests. Figure 9a is the change in shear stress with the normal stress of soil samples before and after MICP treatment. It shows that the shear strength of expansive soil after MICP treatment has been significantly improved, and the increase in cohesive force of expansive soil samples before and after treatment is far greater than the increase in the internal friction angle. Figure 9b presents the change in shear strength with the curing days of MICP. It can be seen that MICP technology will significantly improve the shear strength of soft soil, and its shear strength will gradually increase with the increase in curing days (3d–21d).

Figure 9.

Curves of shear strength for (a) comparison between MICP-treated and untreated expansive soils; (b) different MICP-treated days.

4.5. Resilient Modulus of MICP Unsaturated Soil

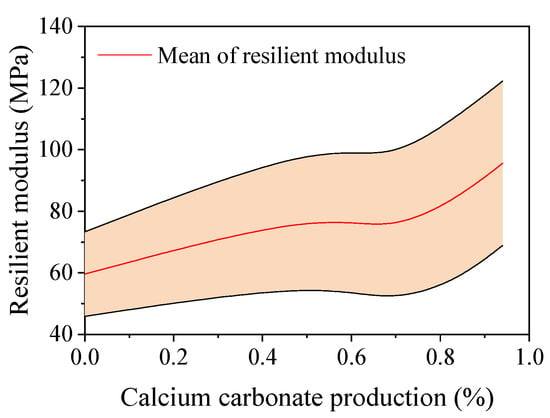

The MR of soil describes the resilient deformation characteristics of soil subgrades under dynamic traffic loads [119]. In the MICP process, CaCO3 precipitation bio-cemented the soil particles and filled the pores between soil particles, leading to the increase in coarse particle content and the decrease in fine particle content in soil. Therefore, with the decrease in fine particle content, the dynamic resilient modulus of improved soil increases. In order to achieve biological stability, Moradi et al. [120] adopted the microbial-induced calcite precipitation (MICP) method. The result shows that the elastic behavior of the treated fine-grained soil was similar to that of coarse grained soil, and the MR of treated soil evidently increased. Bing et al. [121] found that the sensitivity of the MR of the stabilized fine sand to confining pressure decreases when the content of CaCO3 increases. The increase rate of the MR of the saturated stabilized soil is greater than that of the unsaturated stabilized soil. The reason for this structure is due to the improvement of MICP technology. The generated CaCO3 crystals will block and bio-cement the soil particle pores, and the pore volume will decrease with the increase in CaCO3 content. Soil particles can contact closely through CaCO3 crystals, and the MR increases accordingly. Figure 10 shows the relationship between dynamic MR and CaCO3 output. It can be seen from the figure that the output of CaCO3 is closely related to the dynamic MR. The minimum value of dynamic MR increases by about 50% at most, and the maximum value increases by about 66.8%.

Figure 10.

Dynamic resilient modulus with different CaCO3 production.

After microbial improvement, it can be found that there is evident CaCO3 precipitation between soil particles. CaCO3 deposits on the surface of soil particles, forming bio-cement points and connecting soil particles. These bio-cements can be bio-cemented into larger aggregates, which enhances the connection ability between soil particles and improves the stability of soil particles. Therefore, the structural strength of the soil sample is improved, and the physical and mechanical properties of the soil sample are improved.

The comment model for predicting MR is shown in Equation (19) [122]. The dynamic resilient modulus of subgrade soil is affected by factors such as soil type, soil physical properties, stress state, and humidity state.

where MR is the dynamic resilient modulus (MPa); Pa is the atmospheric pressure, and the reference value is 101.3 kPa; τoct is octahedral shear stress; and k1, k2, and k3 are all model parameters, which meets k1 ≥ 0, k2 ≥ 0, k3 ≤ 0.

Combined with the research on the mechanical properties of MICP improved soil [123], the influence of soil type, water content, thousand density, and plasticity index on the dynamic resilient modulus of improved soil was analyzed. Previous studies found that the model parameters (k1, k2, k3) decreased with the increase in water content. With the decrease in plasticity index, model parameter k1 decreases and k2 and k3 increase. Similarly, k3 ≤ 0, and the influence of the plasticity index on k1 and k3 is different from that on k2 [123]. Therefore, after improving by MICP method, the hydrophilicity of soil is weakened, and the variation range of water content is reduced. The plasticity index of soil is significantly reduced after improvement by the MICP method. Evidently, compared with the unmodified soil, the dynamic resilient modulus of the improved soil increases.

5. Conclusions and Suggestions

Microbial-induced calcite precipitation (MICP) is an emerging technology in recent years, which is widely applied in geotechnical and environmental engineering. This study reviews the microcosmic mechanism of MICP technology including the metabolic reactions of bacteria and changes of soil microstructures. Compared with temperatures and PH values, the nutrient solution concentrations and calcium ion concentrations are the main factors influencing the MICP process, since they are necessary for the survival of bacteria and CaCO3 formation. MICP technology can improve the water stability of soft soil, since the soil particles will be covered by a layer of white and dense hardened shell of CaCO3 after treatment, and the water solubility of CaCO3 is very small. Meanwhile, the permeability of soil samples decreases after the MICP process, given that pores within soil are also filled by CaCO3 crystals. These phenomena result in the improvement of the mechanical properties of unsaturated soils. The shear strength of soft soil increases with the MICP curing times. Due to the bio-cementation process of soil particles, the structural strength of the soil sample is improved. Based on the prediction model of resilient modulus, since the fitting parameters increase when the water content decreases, the dynamic resilient modulus of the MICP-treated soil is larger than that of the untreated soil.

As far as the progress of MICP technology mentioned above, there are still some problems that need to be solved urgently.

- (1)

- The current research focuses on the improvement in mechanical properties of sand soil treated by MICP, but long-term water stability is lacking attention. In addition, the effect of the MICP process on the acid resistance, frost resistance, erosion resistance, and the other durability’s of unsaturated soil should be further studied.

- (2)

- The diversity and complexities of actual environmental conditions requires the MICP technology to have a corresponding adaptability. Therefore, an environmental adaptability study should be performed for the application of MICP technology.

- (3)

- Although MICP is more environmentally friendly than other treatment approaches of soil, there are still some harmful products emitted to the environment, for example, the ammonia produced by urea hydrolysis. Thus, subsequent research should be conducted in a more environmentally friendly direction or to find suitable methods to reduce the impact of the generated waste on the environment.

- (4)

- In the existing literature, the methods of using MICP technology mainly include mixing, grouting, and soaking. However, both mixing and soaking are limited by construction conditions in engineering practice. Thus, further research work can be attempted in the field test section to find a better way to apply the MICP technology.

Author Contributions

Conceptualization, J.L.; methodology, W.B.; software, W.B.; validation, Z.L.; formal analysis, Y.Y.; investigation, W.B. and Z.L.; resources, J.L.; data curation, W.B. and Y.Y.; writing—original draft preparation, J.L., W.B., and Z.L.; writing—review and editing, J.L. and Y.Y.; visualization, Z.L.; supervision, J.L.; project administration, J.L.; funding acquisition, Y.Y. and J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 52208426; Special Financial Aid to the Post-Doctorate Research Project of Chongqing, grant number 2021XM1012; Open Fund of Key Laboratory of Special Environment Road Engineering of Hunan Province (Changsha University of Science and Technology), grant number kfj210501; the Key Research and Development Program of Hunan Province, grant number 2021SK2050; the Science and Technology Project of the Department of Transportation of Jiangxi Province, grant number 2022H0024.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rao, S.M.; Revanasiddappa, K. Role of microfabric in matrix suction of residual soils. Eng. Geol. 2005, 80, 60–70. [Google Scholar]

- Lu, N.; Likos, W.J. Suction Stress Characteristic Curve for Unsaturated Soil. J. Geotech. Geoenviron. Eng. 2006, 132, 131–142. [Google Scholar]

- Zhang, Q.; Cui, Y.; Cao, Z.; Cai, Y.; Gu, C.; Wang, J. Experimental investigation into the shakedown state of unsaturated road base aggregate at various fine contents and matric suctions. Eng. Geol. 2022, 306, 106744. [Google Scholar]

- Rahardjo, H.; Kim, Y.; Satyanaga, A. Role of unsaturated soil mechanics in geotechnical engineering. Int. J. Geo-Eng. 2019, 10, 8. [Google Scholar] [CrossRef]

- Li, S.; Qin, C.; Chian, S.C.; Zhang, W. Another look at the stability of unsaturated soil slopes considering nonuniformity and nonlinearity. Comput. Geotech. 2022, 148, 104743. [Google Scholar]

- Wu, L.; Cheng, P.; Zhou, J.; Li, S. Analytical solution of rainfall infiltration for vegetated slope in unsaturated soils considering hydro-mechanical effects. Catena 2022, 217, 106472. [Google Scholar]

- Feng, R.; Fourtakas, G.; Rogers, B.D.; Lombardi, D. Two-phase fully-coupled smoothed particle hydrodynamics (SPH) model for unsaturated soils and its application to rainfall-induced slope collapse. Comput. Geotech. 2022, 151, 104964. [Google Scholar]

- Chen, J.; Alonso, E.E.; Gu, C.; Cao, Z.; Cai, Y. Long term cyclic behavior of unsaturated granular soils. Transp. Geotech. 2018, 17, 48–55. [Google Scholar]

- Green, R.A.; Mitchell, J.K. Energy-based evaluation and remediation of liquefiable soils. In Geotechnical Engineering for Transportation Projects; American Society of Civil Engineers: Los Angeles, CA, USA, 2004; pp. 1961–1970. [Google Scholar]

- Li, J.; Qian, J.; He, C. Experimental analysis of cement-treated red sandstone coarse-grained soil and its microstructural evolution. Case Stud. Constr. Mater. 2022, 17, e01535. [Google Scholar]

- Yao, Z.; Zhou, C.; Lin, Q.; Yao, K.; Satchithananthan, U.; Lee, F.H.; Tang, A.M.; Jiang, H.; Pan, Y.; Wang, S. Effect of dynamic compaction by multi-point tamping on the densification of sandy soil. Comput. Geotech. 2022, 151, 104949. [Google Scholar]

- Jiang, H.; Qiu, X. Performance assessment of a newly developed and highly stable grouting material for a completely weathered granite dam foundation. Constr. Build. Mater. 2021, 299, 123956. [Google Scholar]

- Alaloul, W.S.; Altaf, M.; Musarat, M.A.; Faisal Javed, M.; Mosavi, A. Systematic review of life cycle assessment and life cycle cost analysis for pavement and a case study. Sustainability 2021, 13, 4377. [Google Scholar]

- Mitchell, J.K.; Santamarina, J.C. Biological considerations in geotechnical engineering. J. Geotech. Geoenviron. Eng. 2005, 131, 1222–1233. [Google Scholar]

- Ivanov, V.; Chu, J. Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev. Environ. Sci. Bio/Technol. 2008, 7, 139–153. [Google Scholar]

- Qian, X.; Fang, C.; Huang, M.; Achal, V. Characterization of fungal-mediated carbonate precipitation in the biomineralization of chromate and lead from an aqueous solution and soil. J. Clean. Prod. 2017, 164, 198–208. [Google Scholar]

- Liu, B.; Zhu, C.; Tang, C.-S.; Xie, Y.-H.; Yin, L.-Y.; Cheng, Q.; Shi, B. Bio-remediation of desiccation cracking in clayey soils through microbially induced calcite precipitation (MICP). Eng. Geol. 2020, 264, 105389. [Google Scholar]

- Achal, V.; Mukherjee, A.; Goyal, S.; Reddy, M. Corrosion prevention of reinforced concrete with microbial calcite precipitation. ACI Mater. J. 2012, 109, 157–164. [Google Scholar]

- Warthmann, R.; van Lith, Y.; Vasconcelos, C.; McKenzie, J.A.; Karpoff, A.M. Bacterially induced dolomite precipitation in anoxic culture experiments. Geology 2000, 28, 1091–1094. [Google Scholar]

- Van Paassen, L.A.; Daza, C.M.; Staal, M.; Sorokin, D.Y.; van der Zon, W.; van Loosdrecht, M.C. Potential soil reinforcement by biological denitrification. Ecol. Eng. 2010, 36, 168–175. [Google Scholar]

- Bhutange, S.P.; Latkar, M. Microbially induced calcium carbonate precipitation in construction materials. J. Mater. Civ. Eng. 2020, 32, 03120001. [Google Scholar]

- Carmona, J.P.S.F.; Oliveira, P.J.V.; Lemos, L.J.L. Biostabilization of a Sandy Soil Using Enzymatic Calcium Carbonate Precipitation. Procedia Eng. 2016, 143, 1301–1308. [Google Scholar]

- Mujah, D.; Shahin, M.A.; Cheng, L. State-of-the-Art Review of Biocementation by Microbially Induced Calcite Precipitation (MICP) for Soil Stabilization. Geomicrobiol. J. 2017, 34, 524–537. [Google Scholar]

- Chen, F.; Deng, C.; Song, W.; Zhang, D.; Misned, F.A.A.; Mortuza, M.G.; Gadd, G.M.; Pan, X. Biostabilization of Desert Sands Using Bacterially Induced Calcite Precipitation. Geomicrobiol. J. 2016, 33, 243–249. [Google Scholar]

- Martinez, B.C.; DeJong, J.T.; Ginn, T.R.; Montoya, B.M.; Barkouki, T.H.; Hunt, C.; Tanyu, B.; Major, D. Experimental Optimization of Microbial-Induced Carbonate Precipitation for Soil Improvement. J. Geotech. Geoenviron. Eng. 2013, 139, 587–598. [Google Scholar]

- Salifu, E.; MacLachlan, E.; Iyer, K.R.; Knapp, C.W.; Tarantino, A. Application of microbially induced calcite precipitation in erosion mitigation and stabilisation of sandy soil foreshore slopes: A preliminary investigation. Eng. Geol. 2016, 201, 96–105. [Google Scholar]

- Sharma, A.; Ramkrishnan, R. Study on effect of Microbial Induced Calcite Precipitates on strength of fine grained soils. Perspect. Sci. 2016, 8, 198–202. [Google Scholar]

- Achal, V.; Pan, X.; Özyurt, N. Improved strength and durability of fly ash-amended concrete by microbial calcite precipitation. Ecol. Eng. 2011, 37, 554–559. [Google Scholar]

- Fang, C.; Kumari, D.; Zhu, X.; Achal, V. Role of fungal-mediated mineralization in biocementation of sand and its improved compressive strength. Int. Biodeterior. Biodegrad. 2018, 133, 216–220. [Google Scholar]

- Mitchell, A.C.; Dideriksen, K.; Spangler, L.H.; Cunningham, A.B.; Gerlach, R. Microbially enhanced carbon capture and storage by mineral-trapping and solubility-trapping. Environ. Sci. Technol. 2010, 44, 5270–5276. [Google Scholar]

- Umar, M.; Kassim, K.A.; Chiet, K.T.P. Biological process of soil improvement in civil engineering: A review. J. Rock Mech. Geotech. Eng. 2016, 8, 767–774. [Google Scholar]

- Patil, M.; Dalal, P.H.; Shreedhar, S.; Dave, T.N.; Iyer, K.K.R. Biostabilization techniques and applications in Civil Engineering: State-of-the-Art. Constr. Build. Mater. 2021, 309, 125098. [Google Scholar]

- Erşan, Y.Ç.; De Belie, N.; Boon, N. Microbially induced CaCO3 precipitation through denitrification: An optimization study in minimal nutrient environment. Biochem. Eng. J. 2015, 101, 108–118. [Google Scholar]

- Pham, V.P.; Nakano, A.; Van Der Star, W.R.; Heimovaara, T.J.; Van Paassen, L.A. Applying MICP by denitrification in soils: A process analysis. Environ. Geotech. 2016, 5, 79–93. [Google Scholar]

- Hamed Khodadadi, T.; Kavazanjian, E.; van Paassen, L.; DeJong, J. Bio-grout materials: A review. Grouting 2017, 2017, 1–12. [Google Scholar]

- Tsai, C.-P.; Ye, J.-H.; Ko, C.-H.; Lin, Y.-R. An Experimental Investigation of Microbial-Induced Carbonate Precipitation on Mitigating Beach Erosion. Sustainability 2022, 14, 2513. [Google Scholar]

- Hammes, F. Key roles of pH and calcium metabolism in microbial carbonate precipitation. Rev. Environ. Sci. Biotechnol. 2002, 1, 3–7. [Google Scholar]

- Achal, V.; Mukherjee, A.; Sudhakara Reddy, M. Microbial Concrete way to enhance the durability of building structures. Cell 2011, 2, 2. [Google Scholar]

- Naveed, M.; Duan, J.; Uddin, S.; Suleman, M.; Hui, Y.; Li, H. Application of microbially induced calcium carbonate precipitation with urea hydrolysis to improve the mechanical properties of soil. Ecol. Eng. 2020, 153, 105885. [Google Scholar]

- Chuo, S.C.; Mohamed, S.F.; Mohd Setapar, S.H.; Ahmad, A.; Jawaid, M.; Wani, W.A.; Yaqoob, A.A.; Mohamad Ibrahim, M.N. Insights into the current trends in the utilization of bacteria for microbially induced calcium carbonate precipitation. Materials 2020, 13, 4993. [Google Scholar]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2008, 36, 197–210. [Google Scholar]

- Cheng, L.; Cord-Ruwisch, R.; Shahin, M.A. Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can. Geotech. J. 2013, 50, 81–90. [Google Scholar]

- Konhauser, K.O. Introduction to Geomicrobiology; Blackwell Publishing Company: Malden, MA, USA, 2009. [Google Scholar]

- Achal, V.; Pan, X.; Zhang, D. Remediation of copper-contaminated soil by Kocuria flava CR1, based on microbially induced calcite precipitation. Ecol. Eng. 2011, 37, 1601–1605. [Google Scholar]

- Meng, C.; Huihui, X.; Suying, L. Review on Research Progress of MICP Technology. J. Phys. Conf. Ser. 2022, 2185, 012054. [Google Scholar]

- Qabany, A.A.; Soga, K.; Santamarina, C. Factors Affecting Efficiency of Microbially Induced Calcite Precipitation. J. Geotech. Geoenviron. Eng. 2012, 138, 992–1001. [Google Scholar]

- DeJong, J.T.; Soga, K.; Banwart, S.A.; Whalley, W.R.; Ginn, T.R.; Nelson, D.C.; Mortensen, B.M.; Martinez, B.C.; Barkouki, T. Soil engineering in vivo: Harnessing natural biogeochemical systems for sustainable, multi-functional engineering solutions. J. R. Soc. Interface 2011, 8, 1–15. [Google Scholar]

- Mortensen, B.; Haber, M.; DeJong, J.; Caslake, L.; Nelson, D. Effects of environmental factors on microbial induced calcium carbonate precipitation. J. Appl. Microbiol. 2011, 111, 338–349. [Google Scholar]

- Sotoudehfar, A.R.; Sadeghi, M.M.; Mokhtari, E.; Shafiei, F. Assessment of the Parameters Influencing Microbial Calcite Precipitation in Injection Experiments Using Taguchi Methodology. Geomicrobiol. J. 2016, 33, 163–172. [Google Scholar]

- Mitchell, A.C.; Ferris, F.G. The coprecipitation of Sr into calcite precipitates induced by bacterial ureolysis in artificial groundwater: Temperature and kinetic dependence. Geochim. Cosmochim. Acta 2005, 69, 4199–4210. [Google Scholar]

- Sun, X.; Miao, L.; Tong, T.; Wang, C. Study of the effect of temperature on microbially induced carbonate precipitation. Acta Geotech. 2019, 14, 627–638. [Google Scholar]

- Yang, Y.; Chu, J.; Xiao, Y.; Liu, H.; Cheng, L. Seepage control in sand using bioslurry. Constr. Build. Mater. 2019, 212, 342–349. [Google Scholar]

- Martinez, B.; Barkouki, T.; DeJong, J.; Ginn, T. Upscaling microbial induced calcite precipitation in 0.5 m columns: Experimental and modeling results. In Geo-Frontiers 2011: Advances in Geotechnical Engineering; American Society of Civil Engineers: Los Angeles, CA, USA, 2011; pp. 4049–4059. [Google Scholar]

- Kim, G.; Kim, J.; Youn, H. Effect of Temperature, pH, and Reaction Duration on Microbially Induced Calcite Precipitation. Appl. Sci. 2018, 8, 1277. [Google Scholar]

- Xiao, Y.; Wang, Y.; Wang, S.; Evans, T.M.; Stuedlein, A.W.; Chu, J.; Zhao, C.; Wu, H.; Liu, H. Homogeneity and mechanical behaviors of sands improved by a temperature-controlled one-phase MICP method. Acta Geotech. 2021, 16, 1417–1427. [Google Scholar]

- Brock, T.D.; Madigan, M.T.; Martinko, J.M.; Parker, J. Brock Biology of Microorganisms; Prentice-Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Gomez, M.G.; Martinez, B.C.; DeJong, J.T.; Hunt, C.E.; deVlaming, L.A.; Major, D.W.; Dworatzek, S.M. Field-scale bio-cementation tests to improve sands. Proc. Inst. Civ. Eng.-Ground Improv. 2015, 168, 206–216. [Google Scholar]

- Nemati, M.; Voordouw, G. Modification of porous media permeability, using calcium carbonate produced enzymatically in situ. Enzym. Microb. Technol. 2003, 33, 635–642. [Google Scholar]

- Cui, M.-J.; Zheng, J.-J.; Zhang, R.-J.; Lai, H.-J.; Zhang, J. Influence of cementation level on the strength behaviour of bio-cemented sand. Acta Geotech. 2017, 12, 971–986. [Google Scholar]

- Cheng, L.; Cord-Ruwisch, R. In situ soil cementation with ureolytic bacteria by surface percolation. Ecol. Eng. 2012, 42, 64–72. [Google Scholar]

- Mujah, D.; Cheng, L.; Shahin, M.A. Microstructural and Geomechanical Study on Biocemented Sand for Optimization of MICP Process. J. Mater. Civ. Eng. 2019, 31, 04019025. [Google Scholar]

- Wong, L.S. Microbial cementation of ureolytic bacteria from the genus Bacillus : A review of the bacterial application on cement-based materials for cleaner production. J. Clean. Prod. 2015, 93, 5–17. [Google Scholar]

- Wen, K.; Li, Y.; Liu, S.; Bu, C.; Li, L. Evaluation of MICP treatment through EC and pH tests in urea hydrolysis process. Environ. Geotech. 2019, 8, 274–281. [Google Scholar]

- Zhao, Q. Experimental Study on Soil Improvement Using Microbial Induced Calcite Precipitation (MICP). Ph.D. Thesis, China University of Geosciences, Wuhan, China, 2014. [Google Scholar]

- Soon, N.W.; Lee, L.M.; Khun, T.C.; Ling, H.S. Factors affecting improvement in engineering properties of residual soil through microbial-induced calcite precipitation. J. Geotech. Geoenviron. Eng. 2014, 140, 04014006. [Google Scholar]

- Whiffin, V.S.; Paassen, L.A.v.; Harkes, M.P. Microbial Carbonate Precipitation as a Soil Improvement Technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar]

- Ferris, F.; Fyfe, W.; Beveridge, T. Bacteria as nucleation sites for authigenic minerals in a metal-contaminated lake sediment. Chem. Geol. 1987, 63, 225–232. [Google Scholar]

- Achal, V.; Pan, X. Influence of calcium sources on microbially induced calcium carbonate precipitation by Bacillus sp. CR2. Appl. Biochem. Biotechnol. 2014, 173, 307–317. [Google Scholar]

- Cheng, L.; Shahin, M.; Cord-Ruwisch, R. Bio-cementation of sandy soil using microbially induced carbonate precipitation for marine environments. Géotechnique 2014, 64, 1010–1013. [Google Scholar]

- Okwadha, G.D.O.; Li, J. Optimum conditions for microbial carbonate precipitation. Chemosphere 2010, 81, 1143–1148. [Google Scholar]

- Chahal, N.; Rajor, A.; Siddique, R. Calcium carbonate precipitation by different bacterial strains. Afr. J. Biotechnol. 2011, 10, 8359–8372. [Google Scholar]

- Shanahan, C.; Montoya, B. Strengthening coastal sand dunes using microbial-induced calcite precipitation. In Proceedings of the Geo-Congress 2014: Geo-Characterization and Modeling for Sustainability, Atlanta, GA, USA, 23–26 February 2014; pp. 1683–1692. [Google Scholar]

- Montoya, B.M.; DeJong, J.T. Stress-Strain Behavior of Sands Cemented by Microbially Induced Calcite Precipitation. J. Geotech. Geoenviron. Eng. 2015, 141, 04015019. [Google Scholar]

- Sharaky, A.M.; Mohamed, N.S.; Elmashad, M.E.; Shredah, N.M. Application of microbial biocementation to improve the physico-mechanical properties of sandy soil. Constr. Build. Mater. 2018, 190, 861–869. [Google Scholar]

- Yasuhara, H.; Neupane, D.; Hayashi, K.; Okamura, M. Experiments and predictions of physical properties of sand cemented by enzymatically-induced carbonate precipitation. Soils Found. 2012, 52, 539–549. [Google Scholar]

- Sun, X.; Miao, L.; Wang, C. Experimental study on calcium carbonate precipitates induced by Bacillus megaterium. In Proceedings of the China-Europe conference on Geotechnical Engineering, Vienna, Austria, 13–16 August 2016; pp. 834–837. [Google Scholar]

- Liu, S.; Wen, K.; Armwood, C.; Bu, C.; Li, C.; Amini, F.; Li, L. Enhancement of MICP-treated sandy soils against environmental deterioration. J. Mater. Civ. Eng. 2019, 31, 04019294. [Google Scholar]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar]

- Algaifi, H.A.; Bakar, S.A.; Sam, A.R.M.; Abidin, A.R.Z.; Shahir, S.; AL-Towayti, W.A.H. Numerical modeling for crack self-healing concrete by microbial calcium carbonate. Constr. Build. Mater. 2018, 189, 816–824. [Google Scholar]

- Seltacho, S.; Sriboonlue, V.; Suwanang, N.; Wiriyakitnateekul, W.; Hammecker, C. Quantification and Modeling of Water Flow in Sandy Soils in Northeast Thailand; CRC Press: London, UK, 2013. [Google Scholar]

- Karube, D.; Kawai, K. The role of pore water in the mechanical behavior of unsaturated soils. Geotech. Geol. Eng. 2001, 19, 211–241. [Google Scholar]

- Duan, X.; Zeng, L.; Sun, X. Generalized stress framework for unsaturated soil: Demonstration and discussion. Acta Geotech. 2019, 14, 1459–1481. [Google Scholar]

- Yao, Y.; Li, J.; Xiao, Z.; Xiao, H. Soil-Water characteristics and creep deformation of unsaturated expansive subgrade soil: Experimental test and simulation. Front. Earth Sci. 2021, 9, 1141. [Google Scholar]

- Vanapalli, S.; Fredlund, D.; Pufahl, D. Influence of soil structure and stress history on the soil-water characteristics of a compacted till. Géotechnique 2001, 51, 573–576. [Google Scholar]

- Yao, Y.; Ni, J.; Li, J. Stress-dependent water retention of granite residual soil and its implications for ground settlement. Comput. Geotech. 2021, 129, 103835. [Google Scholar]

- Fredlund, D.G.; Xing, A. Equations for the soil-water characteristic curve. Can. Geotech. J. 1994, 31, 521–532. [Google Scholar]

- Yao, Y.; Li, J.; Ni, J.; Liang, C.; Zhang, A. Effects of gravel content and shape on shear behaviour of soil-rock mixture: Experiment and DEM modelling. Comput. Geotech. 2022, 141, 104476. [Google Scholar]

- Lamborn, M.J. A Micromechanical Approach to Modeling Partly Saturated Soils; Texas A&M University: College Station, TX, USA, 1986. [Google Scholar]

- Vanapalli, S.; Fredlund, D.; Pufahl, D.; Clifton, A. Model for the prediction of shear strength with respect to soil suction. Can. Geotech. J. 1996, 33, 379–392. [Google Scholar]

- Garven, E.; Vanapalli, S. Evaluation of empirical procedures for predicting the shear strength of unsaturated soils. In Proceedings of the Fourth International Conference on Unsaturated Soils, Carefree, AZ, USA, 2–6 April 2006; pp. 2570–2592. [Google Scholar]

- Li, J.; Zhang, J.; Yang, X.; Zhang, A.; Yu, M. Monte Carlo simulations of deformation behaviour of unbound granular materials based on a real aggregate library. Int. J. Pavement Eng. 2023, 24, 2165650. [Google Scholar] [CrossRef]

- Liu, S.H.; Sun, D.A.; Wang, Y. Numerical study of soil collapse behavior by discrete element modelling. Comput. Geotech. 2003, 30, 399–408. [Google Scholar]

- Jiang, M.; Leroueil, S.; Konrad, J. Insight into shear strength functions of unsaturated granulates by DEM analyses. Comput. Geotech. 2004, 31, 473–489. [Google Scholar]

- Richefeu, V.; Youssoufi, M.S.E.; Peyroux, R.; Radjaï, F. A model of capillary cohesion for numerical simulations of 3D polydisperse granular media. Int. J. Numer. Anal. Methods Geomech. 2008, 32, 1365–1383. [Google Scholar]

- Scholtès, L.; Hicher, P.Y.; Nicot, F.; Chareyre, B.; Darve, F. On the capillary stress tensor in wet granular materials. Int. J. Numer. Anal. Methods Geomech. 2009, 33, 1289–1313. [Google Scholar]

- Peng, J.; Zhang, J.; Li, J.; Yao, Y.; Zhang, A. Modeling humidity and stress-dependent subgrade soils in flexible pavements. Comput. Geotech. 2020, 120, 103413. [Google Scholar]

- Yao, Y.; Zheng, J.; Zhang, J.; Peng, J.; Li, J. Model for predicting resilient modulus of unsaturated subgrade soils in south China. KSCE J. Civ. Eng. 2018, 22, 2089–2098. [Google Scholar]

- Ceratti, A.J.; Gehling, W.Y.Y.; Núñez, W.P. Seasonal Variations of a Subgrade Soil Resilient Modulus in Southern Brazil. Transp. Res. Rec. 2004, 1874, 165–173. [Google Scholar]

- Martínez-Nistal, A.; Veniale, F.; Setti, M.; Cotecchia, F. A scanning electron microscopy image processing method for quantifying fabric orientation of clay geomaterials. Appl. Clay Sci. 1999, 14, 235–243. [Google Scholar]

- Xiao, Y.; Zhao, C.; Sun, Y.; Wang, S.; Wu, H.; Chen, H.; Liu, H. Compression behavior of MICP-treated sand with various gradations. Acta Geotech. 2021, 16, 1391–1400. [Google Scholar]

- Cheng, L.; Qian, C.; Wang, R.; Wang, J. Study on the mechanism of calcium carbonate formation induced by carbonate-mineralization microbe. Acta Chim. Sin. 2007, 65, 2133–2138. [Google Scholar]

- Elmaloglou, A.; Terzis, D.; De Anna, P.; Laloui, L. Microfluidic study in a meter-long reactive path reveals how the medium’s structural heterogeneity shapes MICP-induced biocementation. Sci. Rep. 2022, 12, 1–16. [Google Scholar]

- Porter, H.; Dhami, N.K.; Mukherjee, A. Synergistic chemical and microbial cementation for stabilization of aggregates. Cem. Concr. Compos. 2017, 83, 160–170. [Google Scholar]

- De Muynck, W.; Debrouwer, D.; De Belie, N.; Verstraete, W. Bacterial carbonate precipitation improves the durability of cementitious materials. Cem. Concr. Res. 2008, 38, 1005–1014. [Google Scholar]

- Phillips, A.J.; Lauchnor, E.G.; Eldring, J.; Esposito, R.A.; Mitchell, A.C.; Gerlach, R.; Cunningham, A.B.; Spangler, L.H. Potential CO2 leakage reduction through biofilm-induced calcium carbonate precipitation. Environ. Sci. Technol. 2013, 47, 142–149. [Google Scholar]

- Cuthbert, M.O.; McMillan, L.A.; Handley-Sidhu, S.; Riley, M.S.; Tobler, D.J.; Phoenix, V.R. A field and modeling study of fractured rock permeability reduction using microbially induced calcite precipitation. Environ. Sci. Technol. 2013, 47, 13637–13643. [Google Scholar]

- Wang, J.; Long, Y.; Zhao, Y.; Pan, W.; Qu, J.; Yang, T.; Huang, X.; Liu, X.; Xu, N. Laboratory Experiment on Formation of MICP Horizontal Seepage-Reducing Body in Confined Aquifer for Deep Excavation. Appl. Sci. 2023, 13, 104. [Google Scholar]

- Ferris, F.; Stehmeier, L.; Kantzas, A.; Mourits, F. Bacteriogenic mineral plugging. J. Can. Pet. Technol. 1997, 36, PETSOC-97-09-07. [Google Scholar]

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. Effect of wetting and drying cycles on the durability of bio-cemented soil of expressway slope. Int. J. Environ. Sci. Technol. 2022, 19, 2309–2322. [Google Scholar]

- Bo, L.; ChaoSheng, T.; XiaoHua, P.; Cheng, Z.; YaoJia, C.; JinJian, X.; Bin, S. Potential Drought Mitigation Through Microbial Induced Calcite Precipitation-MICP. Water Resour. Res. 2021, 57, e2020WR029434. [Google Scholar]

- Wani, K.M.N.S.; Mir, B.A. Effect of Microbial Stabilization on the Unconfined Compressive Strength and Bearing Capacity of Weak Soils. Transp. Infrastruct. Geotechnol. 2021, 8, 59–87. [Google Scholar]

- Van Paassen, L.A. Biogrout, Ground Improvement by Microbial Induced Carbonate Precipitation; Delft University of Technology: Delft, The Netherlands, 2009. [Google Scholar]

- Khaleghi, M.; Rowshanzamir, M.A. Biologic improvement of a sandy soil using single and mixed cultures: A comparison study. Soil Tillage Res. 2019, 186, 112–119. [Google Scholar]

- Lian, J.; Xu, H.; He, X.; Yan, Y.; Fu, D.; Yan, S.; Qi, H. Biogrouting of hydraulic fill fine sands for reclamation projects. Mar. Georesources Geotechnol. 2018, 37, 212–222. [Google Scholar]

- Putra, H.; Yasuhara, H.; Kinoshita, N.; Neupane, D.; Lu, C.-W. Effect of Magnesium as Substitute Material in Enzyme-Mediated Calcite Precipitation for Soil-Improvement Technique. Front. Bioeng. Biotechnol. 2016, 4, 37. [Google Scholar]

- Yang, X.; Xiang, H.; Musharraf, Z.; Guoliang, M.; Chang, Z. Review of Strength Improvements of Biocemented Soils. Int. J. Geomech. 2022, 22, 03122001. [Google Scholar]

- Pakbaz, M.S.; Behzadipour, H.; Ghezelbash, G.R. Evaluation of Shear Strength Parameters of Sandy Soils upon Microbial Treatment. Geomicrobiol. J. 2018, 35, 721–726. [Google Scholar]

- Chittoori, B.C.; Burbank, M.; Islam, M.T. Evaluating the effectiveness of soil-native bacteria in precipitating calcite to stabilize expansive soils. In IFCEE 2018; American Society of Civil Engineers: Los Angeles, CA, USA, 2018; pp. 59–68. [Google Scholar]

- Li, J.; Zhang, J.; Zhang, A.; Peng, J. Evaluation on deformation behavior of granular base material during repeated load triaxial testing by discrete-element method. Int. J. Geomech. 2022, 22, 04022210. [Google Scholar]

- Moradi, G.; Shafaghatian, S.; Katebi, H. Effect of Chemical and Biological Stabilization on the Resilient Modulus of Clay Subgrade Soil. Int. J. Pavement Res. Technol. 2022, 15, 415–432. [Google Scholar]

- Bing, Y.; Hui, L.; Haozhen, L.; Nailing, G.; Guibao, M.; Hengji, Z. Experimental investigation on the mechanical and hydraulic properties of urease stabilized fine sand for fully permeable pavement. Int. J. Transp. Sci. Technol. 2020, 11, 60–71. [Google Scholar]

- Program, N.C.H.R. Guide for mechanistic-empirical design of new and rehabilitated pavement structures. In Proceedings of the 2004 Annual Conference of the Transportation Association of Canada, Quebec City, QC, Canada, 19–22 September 2004. [Google Scholar]

- Zhang, J.; Peng, J.; Zeng, L.; Li, J.; Li, F. Rapid estimation of resilient modulus of subgrade soils using performance-related soil properties. Int. J. Pavement Eng. 2021, 22, 732–739. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).