Abstract

This study investigated the impact of incorporating Cissus quadrangularis (CQ) powder into Yanggaeng, a traditional Korean food, focusing on its functional properties. This study examined the proximate composition, physicochemical characteristics, antioxidant capabilities, sensory attributes, and consumer preferences of Yanggaeng when treated with different levels (CON [0%], CQ2 [2%], CQ4 [4%], and CQ6 [6%]) of CQ powder. Yanggaeng with CQ powder exhibited a significantly reduced pH, and among the CQ additive groups the highest °Brix value was observed in CQ2. The water holding capacity (WHC) decreased after adding CQ powder. The color properties of Yanggaeng with CQ powder, including L*, a*, and b*, were measured. L* values dose-dependently decreased as the amount of CQ powder increased. Conversely, a* values increased significantly with CQ powder addition compared with CON, and b* values were highest in CQ2. Similarly, the browning index (BI) increased in the CQ powder treatment groups compared with CON. The antioxidative properties of Yanggaeng with CQ powder were evaluated by measuring the total phenolic content (TPC), total flavonoid content (TFC), 1,1-diphenyl-1-picrylhydrazyl (DPPH) and 6-hydroxy-2,5,7,8-tetramethylchroman-2-carboxylic acid (ABTS) radical scavenging activities, and ferric reducing antioxidant power (FRAP). The antioxidant capacity dose-dependently increased with higher levels of CQ powder added. Regarding the texture profile of Yanggaeng, compared with the control group, adding CQ powder caused decreased hardness, gumminess, and chewiness. In consumer preference evaluations, CQ2 showed similarities to CON in all aspects (color, scent, flavor, sweetness, taste, chewiness, overall acceptance, and purchase intention). Therefore, incorporating CQ powder, a natural and edible antioxidative ingredient, into Yanggaeng may be acceptable to consumers despite significant changes in its physicochemical properties.

1. Introduction

Yanggaeng is a traditional Korean confectionery categorized as a “hangwa” or Korean sweet treat. It is crafted from boiled sweet bean or red bean paste combined with ingredients such as agar powder and sugar [1]. Natural food coloring reagents and sugar are added, and the mixture is heated and concentrated before being molded into its final shape. Yanggaeng is known for its sweet taste and smooth texture, making it appealing to individuals of all ages [2]. Additionally, Yanggaeng has a substantial shelf life, making it a favored snack choice for travel and outings [3]. Particularly, the main ingredient in Yanggaeng, the sweet bean paste, contains essential amino acids such as glutamic and aspartic acids [4], as well as phytochemicals such as phytoestrogens and isoflavones [5].

In recent years, following economic development, consumers have increasingly considered the functional properties of food alongside taste, color, and aroma when making food choices [6,7]. This has led to growing interest in traditional food preparation methods incorporating bioactive compounds [8]. Furthermore, considering that Yanggaeng is a highly popular sweet among Korean sweet products but, conversely, Yanggaeng is also rich in sugar and poor in nutrition density, such technological solutions should be sought to increase its quality and nutritional value [9]. Therefore, research on Yanggaeng production, which includes various natural ingredients with physiological benefits, has become more active. For example, studies have reported adding ingredients such as barley sprouts [10], black ginger [11], finger root powder [12], tomatoes [3], mugwort powder [13], aronia juice [1], Enteromorpha prolifera [14], Hallabong orange [15], green tea powder [16], and paprika [17] to enhance the nutrition density and physiological properties of Yanggaeng.

Cissus quadrangularis (CQ), a plant native to parts of Africa and Asia, has a long history of use in traditional medicine for treating various conditions such as bone fractures [18], joint pain [19], and inflammation [20]. Studies have shown that CQ extract effectively reduces pain and improves joint function in patients with osteoarthritis [21]. Additionally, CQ exposure has demonstrated its effectiveness in reducing inflammation and oxidative stress in individuals with metabolic syndrome [22]. Furthermore, CQ prevents weight gain clinically by reducing waist circumference and inducing circular adiponectin [23], probably attenuating adipogenesis and lipolysis in vitro [24]. Currently, CQ supplements are available in various forms, such as capsules, powders, and tinctures [25]. However, it is noteworthy that the complete spectrum of potential advantages that CQ offers, particularly its use as a readily available food component, remains inadequately investigated in scientific research.

Therefore, in this study, we aimed to investigate the potential of harnessing CQ, known for its exceptional components and functional properties, in the food industry. The effects of incorporating CQ powder as a functional food additive at different concentrations on its physicochemical characteristics and antioxidant capabilities were assessed. Furthermore, sensory assessments were conducted among consumers to determine the viability of CQ as a novel dessert choice.

2. Materials and Methods

2.1. Ingredients of Yanggaeng

CQ powder was supplied by Nuon (Bucheon, Republic of Korea). The main ingredients used for creating Yanggaeng included white bean (Phaseolus vulgaris L.) paste (containing 61.7% of white bean and others (white sugar, salt, and starch); Daedoo Food, Seoul, Republic of Korea), white sugar (Cheiljedang, Seoul, Republic of Korea), and agar powder (Thehadam, Goseong, Republic of Korea).

2.2. Recipe for Yanggaeng

The recipe of Yanggaeng was established based on previous research, and the ratios are presented in Table 1. To prepare the CQ powder, various weight ratios (0%, 2%, 4%, and 6%) were added to the white bean paste of the control (CON) group, which had been determined through several preliminary experiments. The agar powder was soaked in distilled water for 10 min, then heated at 80 °C for 2 min. Subsequently, CQ powder, agar powder, and sugar were incorporated and heated while stirring for 10 min until foam formed and the mixture thickened. This mixture was then poured into a mold, cooled at 4 °C, and used as a sample for this experiment.

Table 1.

Formulation of Yanggaeng with treated C. quadrangularis powder.

2.3. Proximate Composition of Yanggeang

The proximate composition of Yanggaeng was assessed according to the AOAC (2005) standard method [26]. Moisture content was determined using the atmospheric pressure drying method at 105 °C, crude protein was analyzed using the Kjeldahl method with a conversion factor of 6.25 for protein (Method No. 978.04), crude fat was assessed using the Soxhlet extraction method (Method No. 930.10), and crude ash content was measured at 550 °C. Carbohydrate content was calculated as the value obtained by subtracting moisture content, crude protein, crude fat, and crude ash content from 100.

2.4. pH, °Brix, and Water Holding Capacity of Yanggeang

To determine the pH and °Brix of the Yanggaeng, 3 g of the sample was dissolved in 30 mL distilled water for extraction. Subsequently, the supernatant was centrifuged at 2000× g for 10 min. pH was measured using a pH meter (Orion Star A211, Thermo Fisher Scientific Korea Co., Ltd., Seoul, Republic of Korea), and the °Brix was measured using a °Brix meter (Hanna Instruments, Woonsocket, RI, USA). The water holding capacity (WHC) of the Yanggaeng was determined using a modified Lee’s method [27]. Approximately 0.5 g of the sample was placed in a 1.5 mL tube and centrifuged at 2000× g for 15 min. WHC was calculated using the following formula based on the weight of the tube after removing the sample.

WHC = {sample weight − (dry weight − tube weight)/sample weight} × 100

2.5. Hunter’s Color Properties of Yanggaeng

The colorimetric values of Yanggaeng were determined using a colorimetric parameter (LC100, Tintometer Limited, Amesbury, England). The L* (lightness), a* (redness), and b* (yellowness) parameters were measured from the Yanggaeng’s surface. The browning index (BI) was calculated using the method introduced by Bal et al. [28].

BI = (z − 0.31)/0.17 × 100

z = (a* + 1.75L*)/5.645L* + a* − 3.012b*

2.6. Total Polyphenol Content and Total Flavonoid Content of Yanggaeng

To assess the antioxidative properties of Yanggaeng, 2.5 g of the sample was dissolved in 50 mL of 99.5% ethyl alcohol (Samchun Chemical, Pyeongtaek, Republic of Korea) and centrifuged at 2000× g for 10 min. The total polyphenol content (TPC) was determined as described by Lupu et al. [29], whereas the total flavonoid content (TFC) was determined using Asma Cherbal’s method [30]. These values were expressed in milligrams of gallic acid equivalent (GAE) per gram and milligrams of quercetin (QE) equivalent, respectively.

2.7. Antioxidant Capacities of Yanggaeng

The antioxidant capacities against DPPH radical scavenging activities, ABTS radical scavenging activities, and FRAP were assessed. Ethanol extracts of Yanggaeng were prepared before evaluating their antioxidant capacities. DPPH and ABTS radical scavenging activities were determined using the previously described methods [31,32], respectively. FRAP was conducted according to the procedure outlined in a previous report [33].

2.8. Texture Profile Analysis of Yanggaeng

To conduct mechanical texture analysis on Yanggaeng, texture profile analysis (TPA) was performed using a texture analyzer (TA-XT2, Stable Micro Systems Co., Haslemere, UK) and assessed through a peer-reviewed approach established by Baek et al. [34]. The measured parameters included hardness, adhesiveness, resilience, cohesion, springiness, gumminess, and chewiness. Samples were prepared with dimensions of 25 × 25 × 25 mm3, and a 20 mm diameter probe (TA-11ss) was used. The pretest speed was set at 5 mm/s, the distance at 6 mm, and the time at 5 s. Texture measurements were taken five times, and the average value was calculated for comparison.

2.9. Consumer Preferences of Yanggaeng

Consumer preferences for Yanggaeng were assessed using a 9-point hedonic scale (1: dislike extremely, 9: like extremely). We evaluated 50 Dankook University students and staff members who provided feedback on color, scent, flavor, sweetness, taste, chewiness, overall acceptance, and purchase intention. The experimental procedures for measuring consumers’ preferences were approved by the Institutional Review Board of Dankook University (DKU-2022-03-201-001).

2.10. Statistical Analysis

The experimental data were ranked and analyzed using analysis of variance (ANOVA) followed by Duncan’s multiple range test. They were conducted with SPSS 26.0 (Statistical Package for Social Science, IBM Corp., Armonk, NY, USA).

3. Results

3.1. Proximate Compositions of Yanggaeng

Table 2 shows the proximate compositions (moisture, crude ash, crude fat, crude protein, and carbohydrate) of Yanggaeng. The moisture, crude ash, and carbohydrate content did not alter among experimental Yanggaeng regardless of CQ treatment. The crude fat content of Yanggaeng decreased with increased CQ powder concentration, whereas the protein content increased with increased CQ powder concentration compared with the CON group. In a previous study, the biochemical content of CQ powder was reported as follows: moisture 9.24%, crude protein 25.64%, crude fat 3.33%, crude ash 19.39%, and carbohydrate 42.66% [35]. Therefore, CQ powder was found to be rich in carbohydrates, crude protein, and crude ash. However, CQ powder is not a source rich of fat; therefore, increasing the quantity of CQ may result in relatively lower fat contents. It is suggested that the varying results may be attributed to the inclusion of additional ingredients, such as white bean paste or sugar, in Yanggaeng with CQ powder, resulting in different outcomes.

Table 2.

Proximate compositions of Yanggaeng with treated C. quadrangularis powder.

3.2. pH, °Brix, and Water Holding Capacity (WHC) of Yanggaeng

Table 3 shows the summary of the physicochemical properties of Yanggaeng. With an increased amount of CQ powder, the pH of Yanggaeng was dose-dependently reduced, resulting in acidification. The pH in the CON group was 6.97, whereas it declined to 6.65, 6.46, and 6.29 in CQ2, CQ4, and CQ6, respectively. This declined pH due to increased CQ powder levels may be attributed to the inherent characteristics of CQ, which contains various organic acids, such as citric, gallic, and tartaric acids [36].

Table 3.

pH, °Brix, and water holding capacity of Yanggaeng with treated C. quadrangularis powder.

The °Brix value of Yanggaeng reached its peak in CQ2 (2.8), whereas CQ6 exhibited the lowest value (2.1). Water holding capacity (WHC) is a critical property in gel formation in food products [37]. A higher WHC allows for better absorption and retention of moisture, thus improving gel-forming abilities and producing firmer, more stable gels [38]. In the case of Yanggaeng, WHC decreased compared with CON. The reduced WHC due to the CQ powder addition may suggest that external factors, such as external forces or temperature fluctuations (e.g., freezing and thawing), could be influential, potentially affecting the loss of water from the gel.

3.3. Hunter’s Color Properties of Yanggaeng

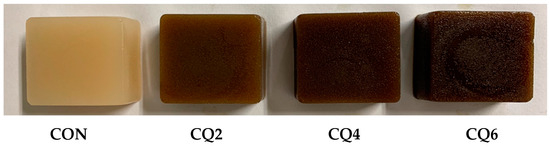

Figure 1 and Table 4 shows the colorimetric properties of Yanggaeng. The L* values, indicating the brightness of the subject Yanggaeng’s color, were highest for the CON (45.73). However, as the amount of CQ powder increased, the L* values decreased for CQ2, CQ4, and CQ6 to 21.3, 13.73, and 9.73, respectively. Contrastingly, the a* parameter, responsible for the red or green color, had the lowest value for the CON (−0.60). The CQ added Yanggaeng exhibited an increase, with CQ2, CQ4, and CQ6 having values of 5.53, 5.37, and 4.67, respectively. Notably, the b* parameter, describing the presence of blue or yellow color, significantly increased with the addition of CQ powder, with CQ2 having the highest value (14.10).

Figure 1.

Appearance of Yanggaeng treated with C. quadrangularis powder.

Table 4.

Hunter’s color properties of Yanggaeng with treated C. quadrangularis powder.

Furthermore, the brightness index (BI) was calculated using the acquired L*, a*, and b* values, and it was higher in Yanggaeng than in CON. During the drying process of CQ, the color typically shifts from green to brown or yellowish [39]. Moreover, the color alterations observed during the drying process of CQ in Setthawat’s research mirror these transformations, indicating possible compositional changes during drying. This is likely due to interactions among the diverse chemical components present in CQ and the transformations that occur throughout the drying process [40].

3.4. Total Polyphenol Content and Total Flavonoid Content of Yanggaeng

CQ contains a significant quantity of phenolic compounds and flavonoids, which are closely linked to antioxidant properties. The phenolic compounds include tannins, alkaloids, resveratrol, and quadrangularin [41,42]. Furthermore, flavonoids, including catechin, quercetin, quercitrin, and kaempferol, are reportedly present in CQ as innate phenolic components [43]. Table 5 provides data on the total phenolic content (TPC) and total flavonoid content (TFC) in Yanggaeng. The TPC consistently increased as the CQ powder was incorporated into Yanggaeng. In the CON group, the TPC was measured at 16.96 mg GAE/g. However, the TPC values exhibited continuous growth in samples with CQ powder additions, measuring 30.20, 39.87, and 44.19, respectively.

Table 5.

Total polyphenol content and total flavonoid content of Yanggaeng with treated C. quadrangularis powder.

Additionally, TFC in the CON group was measured at 0.01 mg QE/g. However, in samples where CQ powder was incorporated, specifically CQ2, CQ4, and CQ6, the TFC dose-dependently increased, reaching values of 8.11, 17.06, and 24.78 mg QE, respectively. As mentioned earlier, it is hypothesized that the phenolic compounds and flavonoid constituents present in CQ influence the dose-dependent changes in TPC and TFC in Yanggaeng with CQ addition.

3.5. Antioxidant Capacities of Yanggaeng

DPPH and ABTS radical scavenging activities are expressed as percentages of free radical inhibition and are summarized in Table 6. Including CQ powder in Yanggaeng, dose-dependently increased the overall radical scavenging activities. Specifically, the DPPH radical scavenging activities were measured at 13.61% in CON but increased to 25.89%, 32.03%, and 52.96% in CQ2, CQ4, and CQ6, respectively. Similarly, the ABTS radical scavenging activities also significantly increased. In the CON, it was 12.06% but it increased to 15.34%, 23.73%, and 27.53% in CQ2, CQ4, and CQ6, respectively.

Table 6.

Antioxidant capacities of Yanggaeng with treated C. quadrangularis powder.

The overall increased radical scavenging capacity is likely closely associated with TPC and TFC in the CQ powder, as previously reported in peer-reviewed publications [36]. Phenols and flavonoids can interact with free radicals, inhibiting oxidative processes and neutralizing radicals, ultimately preventing cellular damage. CQ exhibits potent radical-scavenging abilities against DPPH and ABTS radicals as well as hydroxyl radicals, nitric oxide, and superoxide radicals.

Furthermore, the FRAP assay demonstrated a dose-dependent enhancement with increasing amounts of CQ powder. In the control, FRAP was not detectable, whereas in the CQ2, CQ4, and CQ6 samples, FRAP was gradually increased to 92.00, 252.00, and 285.38, respectively. This indicates an increasing reduction capability with higher CQ concentrations. FRAP exhibits a close correlation with TPC and TFC as well as ABTS radical scavenging activity. Our findings suggest that phenolic compounds contribute to both oxidative inhibition and radical scavenging capability [44].

3.6. Texture Profile Analysis of Yanggaeng

Texture profile analysis (TPA) of Yanggaeng was conducted to measure various parameters, including hardness, adhesiveness, resilience, cohesion, springiness, gumminess, and chewiness, relating to the amount of added CQ powder. Table 7 shows the TPA results.

Table 7.

Texture profile analysis of Yanggaeng with treated C. quadrangularis powder.

Hardness significantly decreased in the CQ powder-added groups, specifically CQ4 and CQ6, with values of 1687.78 and 1634.30, respectively, compared with the CON group. This reduced hardness follows a similar trend observed in studies in which natural additives, including tomato powder [3], black ginger [11], and fermented garlic paste [45] in Yanggaeng, were incorporated. Cohesion of Yanggaeng significantly decreased in CQ6, with a value of 0.27, compared to CON. The decrease in cohesion observed in CQ6 may be linked to a decrease in WHC (Table 3).

Gumminess gradually decreased following CQ addition (CQ2 (544.74, statistically identical with the CON), CQ4 (464.77), and CQ6 (433.47)) compared with the control group, with a value of 574.78. Except for CQ2, chewiness significantly decreased in CQ4 and CQ6, with values of 475.54 and 460.74, respectively, compared with the CON. Therefore, CQ powder incorporation was found to reduce the hardness, gumminess, and chewiness of Yanggaeng. Similar trends of decreasing gumminess and chewiness were observed in studies involving the addition of dried persimmon [46] and green tea to Yanggaeng [16].

The reduced hardness, gumminess, and chewiness can be attributed to the reduced content of white bean paste and the low sugar content of the CQ powder. However, further research considering other factors, such as the cooking method and the combination of other ingredients in Yanggaeng, would be informative. Such a decrease in hardness may be advantageous, especially for older adults with impaired chewing ability. Interestingly, resilience and cohesion exhibited an insignificant decrease in CQ2, CQ4, and CQ6 compared with the CON. This suggests that other ingredients and not CQ addition in Yanggaeng could influence these characteristics.

3.7. Consumer Preferences of Yanggaeng

Table 8 shows the sensory evaluation of Yanggaeng. To assess consumer preferences for Yanggaeng, a questionnaire using a 9-point hedonic scale was distributed to individuals from the general public who had no prior training in the subject matter. The questionnaire evaluated the sensory attributes of Yanggaeng with varying amounts of CQ powder, including color, scent, flavor, sweetness, taste, chewiness, overall acceptance, and purchase intention.

Table 8.

Consumers’ preferences for Yanggaeng with treated C. quadrangularis powder.

Generally, CQ2 and CQ4 elicited similar preferences compared with CON. The Yanggaeng’s color was considered more favorable in CQ2 and CQ4 compared with other samples, insignificantly differing from CON. Similarly, CQ powder addition insignificantly influenced the scent and flavor in CQ2 and CQ4. However, in CQ6, sweetness and taste decreased, which could be attributed to the increased acidity caused by the higher CQ powder content. Interestingly, chewiness decreased from CQ4 onward, which could be attributed to the texture difference caused by CQ powder addition. This caused decreased hardness, gumminess, and chewiness according to TPA, possibly affecting the preference for Yanggaeng’s texture.

Overall preference and purchase intention of Yanggaeng were insignificantly different compared with the CON, except for CQ6, indicating that CQ powder addition has good consumer acceptance. In this study, the sensory attributes were consistent with those reported in a study by Karadbhajne et al. [47]. In their study, dried CQ extract was added to cookies and biscuits, and consumers preferred the products up to the lowest CQ concentration. However, when the CQ concentration was increased, the product’s sensory acceptability decreased. This decreased acceptability was attributed to the bitter taste and darker color contributed by higher CQ concentrations [48]. Therefore, in this study, the decreased purchase intention of CQ6 may be attributed to the excessive addition of CQ in Yanggaeng, which altered the physical and sensory characteristics.

In summary, the survey results regarding consumer preferences (color, scent, flavor, sweetness, taste, chewiness, overall acceptance, and purchase intention) found that CQ2 received statistically identical scores compared to the CON. Therefore, for potential Yanggaeng product development, an addition of up to 2% of CQ would be acceptable. In the case of CQ4, it also received nearly identical responses compared to the CON or CQ2; however, CQ4 exhibited a lower score for chewiness than the conventional Yanggaeng. As for CQ6, all the indices for consumer preferences were significantly diminished.

4. Conclusions

The primary objective of this study was to investigate whether the addition of CQ in Yanggaeng could enhance the physicochemical characteristics to align with consumer preferences. The secondary aim in this study was to determine the maximum concentration of CQ addition to Yanggaeng that elicited responses identical to those of the conventional Yanggaeng prototype, labeled as CON. To answer our research question, in this study, the physicochemical properties, antioxidant activity, and sensory attributes of Yanggaeng enriched with CQ powder were investigated. CQ powder addition gradually decreased the pH of Yanggaeng, resulting in acidification. Additionally, CQ powder significantly affected the °Brix value and WHC, thereby altering the characteristics of Yanggaeng compared with the control (CON).

In terms of colorimetric properties, CQ powder addition reduced the L* and a* values of Yanggaeng while increasing the b* value and BI. Moreover, CQ powder addition caused proportional increases in TPC and TFC, accompanied by enhanced antioxidant activities, including DPPH radical scavenging, ABTS radical scavenging, and FRAP, indicating an increased capacity to donate electrons.

Furthermore, CQ powder incorporation resulted in reduced hardness, gumminess, and chewiness compared with CON, affecting the textural properties of Yanggaeng. Regarding consumer preferences, CQ2 and CON received statistically similar scores across various aspects, including color, scent, flavor, sweetness, taste, chewiness, overall acceptance, and purchase intention. In conclusion, CQ2 exhibited a preference similar to that of the commercially available conventional Yanggaeng (CON). This study sets the foundation for the development of food products incorporating Yanggaeng, a traditional Korean delicacy.

Author Contributions

Conceptualization, I.K. and J.-H.H.; methodology, H.J. and J.L.; software, H.J., J.L., S.W., Y.K., I.K. and J.-H.H.; validation, H.J., J.L., M.D., I.K. and J.-H.H.; formal analysis, H.J., J.L., S.W. and Y.K.; investigation, I.K. and J.-H.H.; resources, J.-H.H.; data curation, H.J., J.L., S.W., Y.K., M.D., I.K. and J.-H.H.; writing—original draft preparation, H.J., J.L., S.W., Y.K., M.D., I.K. and J.-H.H.; writing—review and editing, H.J., J.L., S.W., Y.K., M.D., I.K. and J.-H.H.; visualization, H.J., J.L. and J.-H.H.; supervision, J.-H.H.; project administration, I.K. and J.-H.H.; funding acquisition, I.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Institutional Review Board of Dankook University (protocol code DKU-2022-03-201-001 approved on 11 May 2022).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Acknowledgments

All authors deeply appreciate all the contributions of Jihye Lee.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hwang, E.-S.; Lee, Y.-J. Quality Characteristics and Antioxidant Activities of Yanggaeng with Aronia Juice. J. Korean Soc. Food Sci. Nutr. 2013, 42, 1220–1226. [Google Scholar] [CrossRef]

- Han, E.-J.; Kim, J.-M. Quality Characteristics of Yanggaeng Prepared with Different Amounts of Ginger Powder. J. East. Asian Soc. Dietary Life 2011, 21, 360–366. [Google Scholar]

- Kim, K.-H.; Kim, Y.S.; Koh, J.-H.; Hong, M.-S.; Yook, H.-S. Quality Characteristics of Yanggaeng Added with Tomato Powder. J. Korean Soc. Food Sci. Nutr. 2014, 43, 1042–1047. [Google Scholar] [CrossRef]

- Koh, K.J.; Shin, D.B.; Lee, Y.C. Physicochemical Properties of Aqueous Extracts in Small Red Bean, Mung Bean and Black Soybean. Korean J. Food Sci. Technol. 1997, 29, 854–859. [Google Scholar]

- Zhou, T.; Meng, C.; He, P. Soy Isoflavones and Their Effects on Xenobiotic Metabolism. Curr. Drug Metab. 2019, 20, 46–53. [Google Scholar] [CrossRef]

- Wang, Q.J.; Mielby, L.A.; Junge, J.Y.; Bertelsen, A.S.; Kidmose, U.; Spence, C.; Byrne, D.V. The Role of Intrinsic and Extrinsic Sensory Factors in Sweetness Perception of Food and Beverages: A Review. Foods 2019, 8, 211. [Google Scholar] [CrossRef]

- Eertmans, A.; Baeyens, F.; Van den Bergh, O. Food Likes and Their Relative Importance in Human Eating Behavior: Review and Preliminary Suggestions for Health Promotion. Health Educ. Res. 2001, 16, 443–456. [Google Scholar] [CrossRef]

- Dias, M.I.; Ferreira, I.C.; Barreiro, M.F. Microencapsulation of Bioactives for Food Applications. Food Funct. 2015, 6, 1035–1052. [Google Scholar] [CrossRef]

- Chae, R.; Im, S.Y.; Lee, C.J. Quality Characteristics of Yanggaeng Supplemented with Monk Fruit Powder. Korean J. Food Sci. Technol. 2022, 54, 518–523. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Yook, H.-S. Quality Characteristics and Antioxidant Activity of Yanggaeng Made with Barley Sprout Powder. J. Korean Soc. Food Sci. Nutr. 2022, 51, 1178–1184. [Google Scholar] [CrossRef]

- Kwon, G.-H.; Kim, M.H.; Han, Y.S. Quality Characteristics and Antioxidant Activity of Yanggaeng Added with Black Ginger (Kaempferia parviflora). J. Korean Soc. Food Sci. Nutr. 2021, 50, 715–724. [Google Scholar] [CrossRef]

- Hasegawa, H.; Chung, N.-Y.; Shin, M.-H. Quality Evaluation of Yanggaeng added with Finger root Powder. Foodserv. Ind. J. 2021, 17, 219–229. [Google Scholar]

- Choi, I.K.; Lee, J.H. Quality Characteristics of Yanggaeng Incorporated with Mugwort Powder. J. Korean Soc. Food Sci. Nutr. 2013, 42, 313–317. [Google Scholar] [CrossRef]

- Kim, S.j.; Lim, D.H.; Kim, M.R. Physicochemical Properties and Antioxidant Activities Evaluation of Allulose Yanggaeng Containing Enteromorpha prolifera. J. Korean Soc. Food Sci. Nutr. 2019, 48, 977–986. [Google Scholar] [CrossRef]

- Kim, H.E.; Lim, J.A.; Lee, J.H. Quality Characteristics and Antioxidant Properties of Yanggaeng Supplemented with Hallabong Powder. J. Korean Soc. Food Sci. Nutr. 2015, 44, 1918–1922. [Google Scholar] [CrossRef]

- Choi, E.-J.; Kim, S.-I.; Kim, S.-H. Quality Characteristics of Yanggaeng by the Addition of Green Tea Powder. J. East. Asian Soc. Dietary Life 2010, 20, 415–422. [Google Scholar]

- Park, L.Y.; Woo, D.I.; Lee, S.W.; Kang, H.M.; Lee, S.H. Quality Characteristics of Yanggaeng Added with Different Forms and Concentrations of Fresh Paprika. J. Korean Soc. Food Sci. Nutr. 2014, 43, 729–734. [Google Scholar] [CrossRef][Green Version]

- Azam, Z.; Sapra, L.; Baghel, K.; Sinha, N.; Gupta, R.K.; Soni, C.; Saini, C.; Mishra, P.K.; Srivastava, R.K. Cissus quadrangularis (Hadjod) Inhibits RANKL-Induced Osteoclastogenesis and Augments Bone Health in an Estrogen-Deficient Preclinical Model of Osteoporosis Via Modulating the Host Osteoimmune System. Cells 2023, 12, 216. [Google Scholar] [CrossRef]

- Lakshmanan, D.K.; Ravichandran, G.; Elangovan, A.; Thilagar, S. Fortification of Raw Rice and Rice Flour Using Cissus quadrangularis L. (veldt grape) Stem Powder to Overcome Osteoporosis and Its Associated Skeletal Complication through Staple Diet. J. Food Biochem. 2021, 45, e13918. [Google Scholar] [CrossRef]

- Syed, A.A.; Shafiq, M.; Reza, M.I.; Bharati, P.; Husain, A.; Singh, P.; Hanif, K.; Gayen, J.R. Ethanolic Extract of Cissus quadrangularis Improves Vasoreactivity by Modulation of eNOS Expression and Oxidative Stress in Spontaneously Hypertensive Rats. Clin. Exp. Hypertens. 2022, 44, 63–71. [Google Scholar] [CrossRef]

- Bloomer, R.J.; Farney, T.M.; McCarthy, C.G.; Lee, S.-R. Cissus quadrangularis Reduces Joint Pain in Exercise-Trained Men: A Pilot Study. Phys. Sportsmed. 2013, 41, 29–35. [Google Scholar] [CrossRef]

- Lekshmi, R.K.; Rajesh, R.; Mini, S. Ethyl Acetate Fraction of Cissus quadrangularis Stem Ameliorates Hyperglycaemia-mediated Oxidative Stress and Suppresses Inflammatory Response in Nicotinamide/streptozotocin Induced Type 2 Diabetic rats. Phytomedicine 2015, 22, 952–960. [Google Scholar] [CrossRef] [PubMed]

- Toor, R.H.; Khan, Z.N.; Tariq, M.; Tassaduq, R.; Gardner, Q.A.; Zaman, W.; Lian, J.B.; Stein, J.L.; Stein, G.S.; Shakoori, A.R. Bioactivity-Guided Isolation and Identification of Anti-adipogenic Constituents from the n-Butanol Fraction of Cissus quadrangularis. Critical reviews in eukaryotic gene expression. Crit. Rev. Eukaryot. Gene Expr. 2020, 30, 519–541. [Google Scholar] [CrossRef] [PubMed]

- Chatree, S.; Sitticharoon, C.; Maikaew, P.; Pongwattanapakin, K.; Keadkraichaiwat, I.; Churintaraphan, M.; Sripong, C.; Sririwichitchai, R.; Tapechum, S. Cissus Quadrangularis Enhances UCP1 mRNA, Endicative of White Adipocyte Browning and Decreases Central Obesity in Humans in a Randomized Trial. Sci. Rep. 2021, 11, 2008. [Google Scholar] [CrossRef]

- Brahmkshatriya, H.R.; Shah, K.A.; Ananthkumar, G.B.; Brahmkshatriya, M.H. Clinical Evaluation of Cissus quadrangularis as Osteogenic Agent in Maxillofacial Fracture: A pilot study. Ayu 2015, 36, 169–173. [Google Scholar] [PubMed]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis of AOAC International; Association of Official Analytical Chemists: Maryland, MD, USA, 2005. [Google Scholar]

- Lee, J.-J.; Choi, J.; Ha, J.-H. Physicochemical and Storage Characteristics of Pork Tteokgalbi Treated with Boesenbergia pandurata (Roxb.) Powder. Appl. Sci. 2022, 12, 2425. [Google Scholar] [CrossRef]

- Bal, L.M.; Kar, A.; Satya, S.; Naik, S.N. Kinetics of Colour Change of Bamboo Shoot Slices during Microwave Drying. Int. J. Food Sci. Technol. 2011, 46, 827–833. [Google Scholar] [CrossRef]

- Lupu, M.I.; Canja, C.M.; Padureanu, V.; Boieriu, A.; Maier, A.; Badarau, C.; Padureanu, C.; Croitoru, C.; Alexa, E.; Poiana, M.-A. Insights on the Potential of Carob Powder (Ceratonia siliqua L.) to Improve the Physico-Chemical, Biochemical and Nutritional Properties of Wheat Durum Pasta. Appl. Sci. 2023, 13, 3788. [Google Scholar] [CrossRef]

- Cherbal, A.; Bouabdallah, M.; Benhalla, M.; Hireche, S.; Desdous, R. Phytochemical Screening, Phenolic Content, and Anti-Inflammatory Effect of Foeniculum vulgare Seed Extract. Prev. Nutr. Food Sci. 2023, 28, 141–148. [Google Scholar] [CrossRef]

- Seleshe, S.; Ameer, A.; Kang, S.N. Exploration of the Antioxidant Chemical Constituents and Antioxidant Performance of Various Solvent Extracts of Eighteen Plants. Prev. Nutr. Food Sci. 2022, 27, 212–222. [Google Scholar] [CrossRef]

- Kim, S.Y. Chemical Composition and Antioxidant Activity of Crude Polysaccharide from Citron (Citrus junos Sieb. Ex TANAKA) Seed. Prev. Nutr. Food Sci. 2018, 23, 335–340. [Google Scholar] [CrossRef] [PubMed]

- Jang, H.; Lee, J.; Kim, M.; Kim, I.; Ha, J.-H. Physicochemical Characteristics and Sensory Attributes of Yanggaeng Treated with Corni fructus Powder: A Pilot Study. Appl. Sci. 2023, 13, 2839. [Google Scholar] [CrossRef]

- Baek, J.J.; Ryu, S.I.; Paik, K. Quality Characteristics of Citrus Peel Jelly. Prev. Nutr. Food Sci. 2023, 28, 79–82. [Google Scholar] [CrossRef] [PubMed]

- TP, C.S.K.; Nisha, A.R. Proximate and Phytochemical Analysis of Methanolic Extract of Cissus quadrangularis. Int. J. Fauna Biol. 2023, 8, 50–55. [Google Scholar] [CrossRef]

- Kaur, J.; Dhiman, V.; Bhadada, S.; Katare, O.; Ghoshal, G. LC/MS Guided Identification of Metabolites of Different Extracts of Cissus quadrangularis. Food Chem. 2022, 1, 100084. [Google Scholar] [CrossRef]

- Mao, R.; Tang, J.; Swanson, B.G. Water Holding Capacity and Microstructure of Gellan Gels. Carbohydr. Polym. 2001, 46, 365–371. [Google Scholar] [CrossRef]

- Urbonaite, V.; Kaaij, S.; Jongh, H.H.J.; Scholten, E.; Ako, K.; Linden, E.; Pouvreau, L. Relation Between Gel Stiffness and Water Holding for Coarse and Finestranded Protein Gels. Food Hydrocoll. 2016, 56, 334–343. [Google Scholar] [CrossRef]

- Thanimkarn, S.; Cheevitsopon, E.; Jongyingcharoen, J.S. Drying Characteristics and Quality Evaluation in Convective Drying of Cissus quadrangularis Linn. Matec. Web Conf. 2018, 192, 03041. [Google Scholar] [CrossRef][Green Version]

- Thanimkarn, S.; Cheevitsopon, E.; Jongyingcharoen, J.S. Effects of Vibration, Vacuum, and Material Thickness on Infrared Drying of Cissus quadrangularis Linn. Heliyon 2019, 5, e01999. [Google Scholar] [CrossRef]

- Avula, B.; Bae, J.-Y.; Zhao, J.; Wang, Y.-H.; Wang, M.; Zhang, Z.; Ali, Z.; Chittiboyina, A.G.; Khan, I.A. Quantitative Determination and Characterization of Polyphenols from Cissus quadrangularis L. and Dietary Supplements using UHPLC-PDA-MS, LC-QToF and HPTLC. J. Pharm. Biomed. Anal. 2021, 199, 114036. [Google Scholar] [CrossRef]

- Muhamad, M.; Sze, W.A.; Zulkifli, N.S.; Sharaniza, A.-R. Qualitative Analysis on the Phytochemical Compounds and Total Phenolic Content of Cissus hastata (Semperai) Leaf Extract. Int. J. Plant Biol. 2022, 14, 53–62. [Google Scholar] [CrossRef]

- Jain, V.; Shaikh, M.S. Simultaneous RP-HPLC Analysis of Quercetin and Kaempferol in Different Plant Parts of Cissus quadrangularis. Int. J. Pharm. Pharm. Sci. 2016, 8, 138–142. [Google Scholar]

- Platzer, M.; Kiese, S.; Tybussek, T.; Herfellner, T.; Schneider, F.; Schweiggert, W.U.; Eisner, P. Radical Scavenging Mechanisms of Phenolic Compounds: A Quantitative Structure-Property Relationship (QSPR) Study. Front. Nutr. 2022, 9, 882458. [Google Scholar] [CrossRef] [PubMed]

- Park, C.-H.; Kim, K.-H.; Kim, N.-Y.; Kim, S.-H.; Yook, H.-S. Antioxidative Capacity and Quality Characteristics of Yanggaeng with Fermented Aged Black Giant Garlic (Allium ampeloprasum L. var. ampeloprasum auct.) Paste. Korean J. Food Nutr. 2014, 27, 1014–1021. [Google Scholar] [CrossRef][Green Version]

- Bong, J.-H.; Kim, J.-Y.; Choi, S.-K. Quality Characteristics of Yanggaeng Containing Various Amounts of Dried Persimmon. J. East. Asian Soc. Dietary Life 2014, 24, 664–671. [Google Scholar] [CrossRef]

- Karadbhajne, S.V.; Kumbhare, V.; Bombaywala, M.A. Application of Cissus quadrangularis Linn. (Hadjor) in Nutraceutical Food (Bakery) Products. Int. J. Chemtech Res. 2014, 6, 2263–2270. [Google Scholar]

- Kelbore, T.; Yilma, B.; Srinivasan, B. Value Addition of Cissus quadrangularis Stem Powder in Ethiopian flat bread: Injera and Its Effect on Nutritional Composition, Sensory Attributes and Microbial Load. J. Food Sci. Technol. 2022, 59, 1450–1459. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).