1. Introduction

According to the United Nations Economic Commission for Europe (UNECE) online workshop [

1], vehicle technical defects can relate to 8 to 15% of death accidents in high income countries. In middle income countries the number can be even higher, at 15 to 25%.

Vehicle inspection service stations offer periodical vehicle safety inspections (PTI) to prevent traffic accidents resulting from vehicle malfunction. PTI’s significance has been highlighted in [

2]. During PTI, vehicles are assessed for compliance with national safety regulations and, in several countries, emission inspections are conducted in conjunction with safety inspections to ensure compliance with emission regulations. The significance of road-worthiness inspections extends beyond verifying the vehicle’s proper functioning to include environmental considerations. In the European Union, two forms of evaluation are performed: on-the-spot roadside inspections and periodic checks that necessitate vehicle owners taking their cars to an inspection service station

It is difficult to quantify exactly how much road safety in Europe has improved as a result of periodic technical inspections. PTIs are just one of many factors that can influence road safety and it is difficult to isolate the specific impact of PTIs on road safety trends. Taneerananon et al. in [

3] conducted a study on traffic accidents in Thailand and the correlation between vehicle defects and these incidents. The study findings indicate that implementing adequate vehicle inspections could potentially serve as an efficient approach to decrease road accidents. On the other hand, Hoagland and Woolley proposed an opposing view in the paper [

4], stating that advancements in modern vehicle technology and reliability have reduced the necessity for effective vehicle inspections. This conclusion yielded from examining the impact of removing vehicle inspections in New Jersey and observing no notable rise in accidents caused by vehicle defects.

That being said, there is evidence that PTIs can help to improve road safety by identifying and correcting problems with a vehicle that could potentially cause accidents. For example, a PTI might identify worn brakes or faulty lighting, which could be repaired before they become a safety hazard. Previous reports have shown a wide variation in the proportion of road crashes caused by vehicle defects. In developed countries, this percentage has been estimated to range from 3% to 19% [

5,

6], while in developing countries, it was reported to be as high as 27% [

3]. The primary basis for the implementation of PTI programs in many countries is the relationship between technical defects in vehicles and road crashes. By detecting such defects, PTIs can help ensure roadworthiness and prevent crashes [

6,

7,

8,

9]. Studies [

10,

11] provide further evidence of the positive influence of Periodic Technical Inspections (PTI) on road safety. It explores the relationship between PTI for vehicles and traffic accidents caused by technical defects in Slovakia. The aim was to evaluate the effectiveness of PTI in enhancing road safety by analyzing statistical data on accidents resulting from vehicle technical defects and PTI records.

The study revealed two significant findings. Firstly, as the PTI validity period approaches its end, the probability of accidents caused by technical defects increases. Secondly, an increase in the number of vehicles assessed at PTI stations as temporarily roadworthy or not roadworthy corresponds to a decrease in accidents caused by vehicle technical defects. These findings demonstrate that PTI has a measurable impact on reducing accidents caused by vehicle technical defects, thus contributing positively to road safety and justifying its implementation.

Instead of questioning the PTI systems, it is recommended that national authorities implement more stringent measures to enhance PTI performance, particularly at the EU level. This may include the mandatory accreditation of PTI under ISO 17020, which has been proven to enhance the quality of PTI activities. Additionally, attention should be given to inspections of PTI. The example of the Slovak Republic is cited, where the introduction of camera monitoring effectively controls the work of inspectors. As a result, the rate of temporary roadworthiness and non-worthiness assessments significantly increased, leading to a reduction in accidents caused by vehicle technical defects. PTIs can also help to reduce emissions from vehicles, which can have positive impacts on air quality and public health, especially in urban areas [

12]. According to several studies [

13,

14,

15,

16,

17], measuring PN (particle number) during PTI (periodic technical inspection) can be a significant factor in reducing particle emissions and improving air quality. In general, according to [

18,

19], road safety in Europe has improved significantly over the past decades due to a combination of factors including improved vehicle safety technologies, changes in traffic laws and enforcement, and improvements in road infrastructure. It is likely that PTIs have contributed to this improvement in road safety to some degree, although it is difficult to quantify the specific impact of PTIs on road safety trends. According to reports by the National Highway Traffic Safety Administration in the USA, the risk of road crashes associated with driving a vehicle manufactured before 2000 is 71% higher than for vehicles manufactured in 2010 and later [

20].

The European Union, previously known as the European Community or European Economic Community, has conducted periodical technical vehicle inspections since the late 1970s through directive 77/143/EEC ([

21]). As of April 2014, all member states of the European Union are required to conduct periodic safety and emission inspections for most types of motor vehicles according to the EU directive 2014/45 ([

22]). Although the specific process for PTI varies among EU countries, inspections generally include the following checks:

Technical inspections, as per EU directive [

23], are concerned with the vehicle’s condition and maintenance, focusing on the following aspects:

- -

Axles, brakes, wheels, tyres, and wheel alignment;

- -

Frame/body, including vehicle identification (such as chassis number and licence plates);

- -

Exhaust system, with attention to environmental factors such as noise and exhaust emissions;

- -

Steering;

- -

Lighting and electrical systems, as well as electrical equipment;

- -

Windows, mirrors, and visibility;

- -

Accessories;

- -

Pedals, seats, and seat belts;

- -

Electronic safety systems.

The tools, devices, and processes used by the inspectors during the inspection process can differ between countries.

1.1. OBD Reading

OBD (On-Board Diagnostics) is an integrated self-diagnostics system incorporated within vehicles. The OBD-II socket, a 16-pin connector, is typically located near the driver’s wheel, under the dashboard. The inception of OBD can be traced back to California, where the CARB (California Air Resources Board) implemented strict regulations and raised awareness regarding emissions control [

24]. CARB mandated the use of OBD in all cars manufactured after 1991 to monitor and regulate the emission of harmful gases [

25]. OBD-II plays a crucial role in the automotive industry by enabling the logging of various essential parameters of vehicles. It encompasses the analysis and diagnostics of small vehicle systems as well as facilitates comprehensive fleet management and route optimization [

25].

OBD-II (On-Board Diagnostics version 2) is a protocol used for identifying, diagnosing, and reporting the health and condition of a vehicle’s engine to the user. It operates on the CAN (Controller Area Network) protocol, allowing the vehicle to connect with scanning tools and external hardware known as OBD scanners. These scanners can be connected to PCs or laptops to extract information from the vehicle’s onboard computer, providing parameters such as driving speeds, engine speeds, coolant levels, coolant temperature, emission control, engine idle time, and other vital engine information [

24].

CAN is a Vehicle Bus Standard designed to facilitate communication between various modules within the vehicle. It enables interaction and coordination among microcontrollers and components, eliminating the need for a dedicated host computer. OBD scanners retrieve CAN data and convert it into a format that is easily understood through presentation and application layers. Look-up tables are used to decipher the received data. OBD functions as the higher layer, handling presentation and application aspects, while the CAN Bus serves as the communication layer, dealing with data transmission and physical layer issues [

24].

A wide range of OBD readers can be found in the market, spanning from as low as EUR 10 to several thousand euros in price. The most affordable devices typically utilize the ELM 327 chip [

26] or its clones and offer limited functionality, providing only basic diagnostic capabilities. These support only SAE J1850 PWM (41.6 kbit/s), SAE J1850 VPW (10.4 kbit/s), ISO 9141-2 (5 baud init, 10.4 kbit/s), ISO 14230-4 KWP (5 baud init, 10.4 kbit/s), ISO 14230-4 KWP (fast init, 10.4 kbit/s), ISO 15765-4 CAN (11 bit ID, 500 kbit/s), ISO 15765-4 CAN (29 bit ID, 500 kbit/s), ISO 15765-4 CAN (11 bit ID, 250 kbit/s), ISO 15765-4 CAN (29 bit ID, 250 kbit/s), SAE J1939 (250 kbit/s), and SAE J1939 (500 kbit/s) and that makes these unsuitable for heavy duty vehicles. One of the advantages is that there are many mobile/PC apps supporting these low end OBD readers.

Advanced, high-end OBD devices such as [

27,

28,

29], catering to professionals, are available at a considerable cost, often ranging in the several thousands of euros. These devices are designed to support a wide range of OBD II protocols, ensuring compatibility with most vehicles. Additionally, they often offer proprietary OBD services specifically tailored for advanced diagnostics in repair shops. Alongside the hardware, these devices typically include the necessary software products required for comprehensive vehicle analysis and troubleshooting.

In addition to the low-end and high-end options, there are also mid-range OBD readers available on the market. These devices offer additional functionalities and incorporate sophisticated IoT capabilities. For instance, products such as [

30] provide real-time fleet monitoring capabilities, enabling users to track and manage a fleet of vehicles effectively. This trend highlights the direction in which OBD technology is evolving, moving towards connected OBD solutions that leverage connectivity and advanced features for enhanced vehicle monitoring and management [

31].

1.2. PTIs in EU Countries

As per the [

32] report, Luxembourg holds the highest record of passenger cars per thousand residents. In Luxembourg, all registered motor vehicles, trailers, and articulated lorries are required to undergo regular technical inspections. The prescribed intervals for these inspections for automobiles are as follows: the first periodic inspection occurs four years after the vehicle has been put into service and the second periodic inspection takes place six years after the vehicle has been put into service. Subsequently, inspections are required annually. Technical inspections relate to the condition and maintenance of the vehicle and, in particular, to: vehicle identification (chassis number, licence plates), environmental nuisances (noise, exhaust emissions), the braking mechanisms, lights and reflectors, the electrical equipment, axles, wheels, tires and suspension, the chassis and its accessories, seat belts, steering, and visibility [

33].

Italy has the second largest number of passenger cars per thousand inhabitants [

32]. All vehicles must undergo a regular inspection at official test centers. This inspection is to ensure the car is legal and roadworthy with safe emissions. According to Article 80 of the Italian Highway Code (Codice della Strada), vehicles must be submitted to a compulsory test for roadworthiness within four years after their first registration and then every alternate year thereafter. This includes passenger cars and transport vehicles, as well as mopeds and motorcycles from 50cc upwards. The tests focus on: brakes, tires, lights, steering, suspension, wheel alignment, transmission, windscreen and wipers, chassis, seat belts, and horn [

34].

Finland has the third largest number of passenger cars per thousand inhabitants [

32]. The vehicles are inspected within three years after their first registration, then within two years after and then every alternate year thereafter. This includes all passenger cars, vans, trucks, ATVs and for trailers with maximum structural weight of more than 750 kg. The tests focus on: brakes, suspension, emission, and a diesel test [

35].

Nevertheless, the largest number of passenger cars in use in the EU is in Germany (more than 48 million according to [

36]). All registered vehicles must be periodically tested for safety on the road and adherence to traffic safety regulations. The tests focus on: brakes, wheels, tyres, frame/body, exhaust system, steering, lighting/electrical systems, windows/mirrors, accessories, pedals, seats, seat belts, and electronic safety systems. Passenger cars have to be inspected within three years of their first registration and then every two years thereafter [

37].

There are many countries using some kind of mobile/PC application in the PTI process. However, as far as we know, only in Germany, Croatia, Spain, Slovakia, and Belgium are safety-relevant OBD DTCs readings being performed during PTI checks. In the largest market, Germany, a special device named an HU adapter is used to obtain these data [

38].

Starting from January 1st, 2019, Croatia has implemented OBD (On-Board Diagnostics) testing methods. Vehicles belonging to emission classes Euro 3 and newer are required to have an OBD connection. The OBD scanning collects various data including the MIL status, readiness-code status, number of Diagnostic Trouble Codes (DTCs), coolant temperature, and engine speed. In addition to the OBD test, vehicles of all Euro classes are also subjected to the classic tailpipe test. Self-developed OBD bluetooth devices have been utilized in the process; for more details see, e.g., [

39]. In Spain, an OBD reader [

40] has been used at a number of PTI stations. In general, the OBD readers mentioned above are designed to offer a solution, which includes both the hardware device and the accompanying software. However, these closed solutions make it hard to replace the vendor of the reader devices or the software provider. In Belgium, the modified version of the presented app has been utilized from the end of May 2023 with the same kind of OBD readers as in Slovakia.

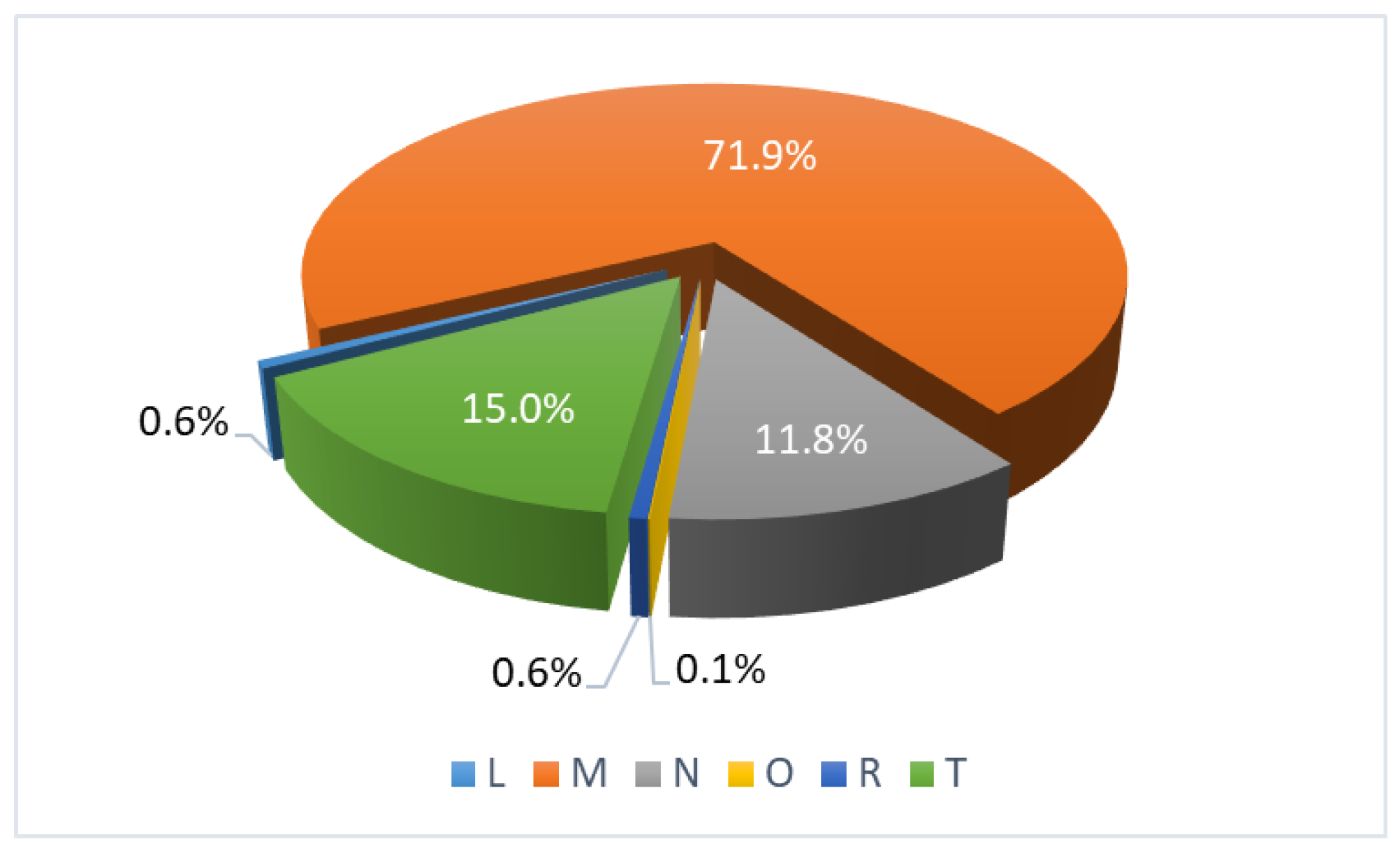

1.3. PTI in Slovak Republic

Back in 1935, the Slovak Republic, which was then part of Czechoslovakia, made an initial attempt to introduce mandatory periodic technical inspections (PTI). Nowadays, almost all vehicles in Slovakia are required to undergo inspection. This article’s main emphasis is on vehicle category M, passenger cars with four wheels, which must undergo the inspection within four years after their first registration and subsequently every two years thereafter. However, vehicles that are used for medical emergency services or mining rescue services, if they are equipped with priority driving rights—ambulance vehicles, vehicles used for the maintenance of gas facilities, and vehicles used for taxi services—have to undergo PTI every year. PTI intervals are comparable among the member states of the European Union and Slovakia is no exception. In Slovakia, the emission check is conducted as a distinct inspection procedure. The age of a vehicle is a crucial determinant of potential vehicle defects as the survey [

41] made in Germany which is the EU country with more than 48 millions of registered vehicles, which is the most amongst EU countries.

Table 1 shows a notable increase in the significant defect rate as vehicles age. In Slovakia, the average age of the registered vehicle is 14.3 years, which means significant defects appear with more than a 30% rate.

To combat fraudulent activities at PTI service stations, the Slovak Republic has implemented several changes to its PTI policies and supervisory measures. According to

Table 2, in 2019, over 50% of severe regulation breaches were associated with the service brake, while almost 30% were linked to the parking brake. In

Table 3, the data from 2020 indicate that service brake-related violations still account for over 50% of severe regulation breaches, but instances related to parking brakes have decreased to less than 15%.

In

Table 4, the data from 2021 show a similar percentage of service brake-related violations of over 50% of severe regulation violations and, again, similarly to 2020, the violations related to parking brake percentage are below 15%.

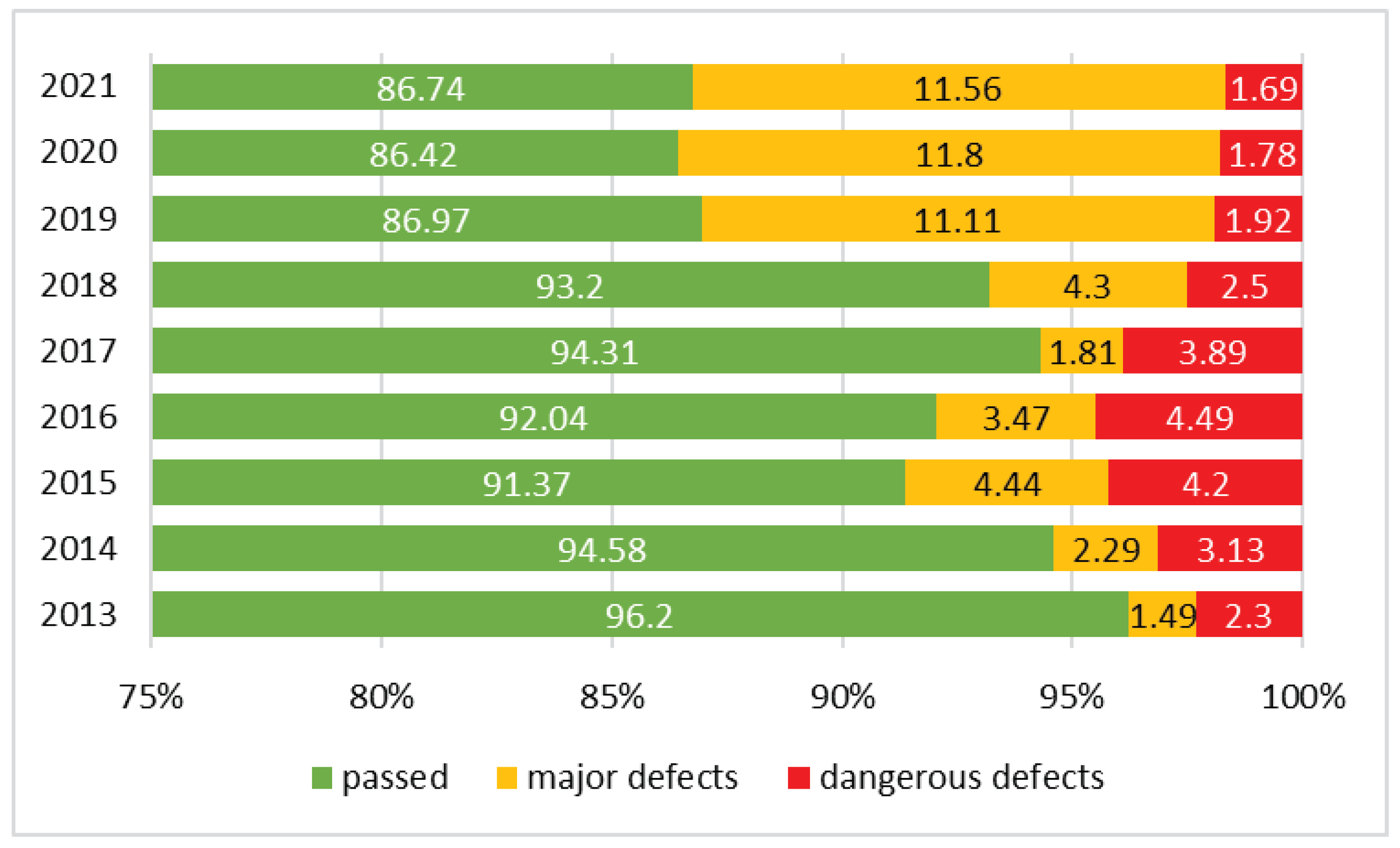

This paper did not aim to investigate the reasons behind these fraudulent practices or whether the regulations are excessively stringent. However, it is crucial to note that malfunctioning service brakes can result in highly hazardous situations on the road. Consequently, measures to mitigate fraudulent behavior at PTI stations have been implemented in Slovakia. Since 2019, it has been mandatory for all vehicle inspection stations in the Slovak Republic to install surveillance cameras as a preventive measure. The heightened monitoring has resulted in a higher failure rate during PTI inspections, which increased from 6.2% to 13.1% in March 2019, more than doubling the failure rate; the trend in failure rate from 2013 to 2021 is shown in

Figure 1. A comprehensive summary of the quality management and assessment of PTI stations in Slovakia and other selected EU countries is presented in [

42].

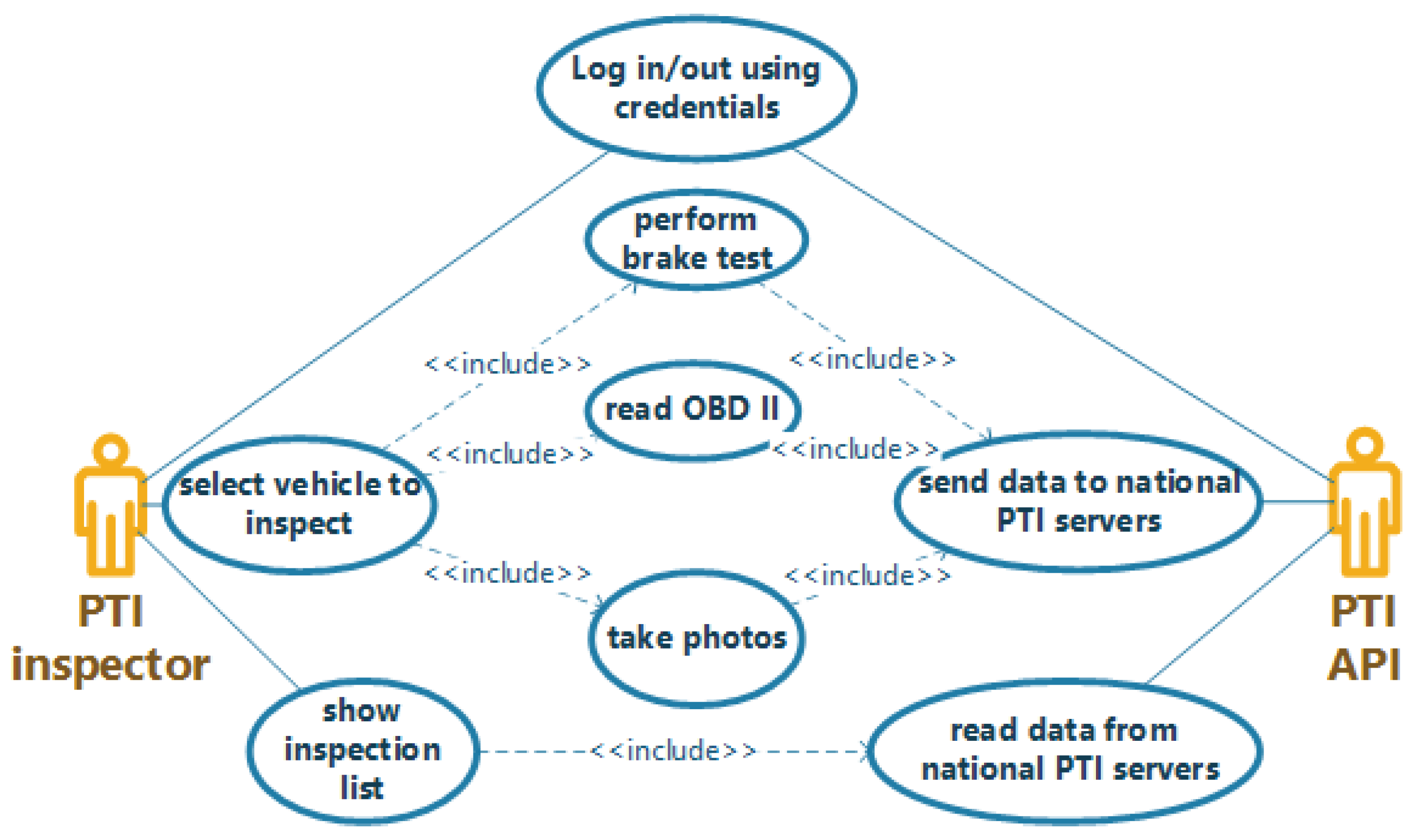

The implementation of a mobile application has been enhancing the supervision of technical vehicle inspection (PTI) in Slovakia since 1 January 2020. A mobile app provided a digital platform that allows inspectors to perform specific tasks on vehicles and record data using their mobile devices.

The app has been utilized to perform the following tasks (

Figure 2):

Taking and uploading a photograph of the odometer to the national PTI server;

Taking and uploading a photograph of the Vehicle Identification Number (VIN) to the national PTI server;

Reading diagnostic trouble codes from the car’s onboard diagnostics port (OBD) and uploading them to the national PTI server;

Measuring the vehicle’s acceleration during a brake test, calculating the results, and uploading both the measurement and the results to the national PTI server. Since 1 January 2021, the smartphone has become the only device by which the driving brake test can be performed.

2. Materials and Methods

The mSTK Android mobile application, available at [

43], was developed in the Java programming language in partnership with TESTEK a.s., which was established in 2004 due to changes in the legislation of the Slovak Republic. The new law increased the independence criteria required for the central organization responsible for technical vehicle inspections within the national system. Consequently, some specialists in the field founded TESTEK, which won the tender issued by the Ministry of Transport in 2005, and began operating as a “technical service for technical vehicle inspections” in the December of that year. TESTEK is accredited as a Type A Inspection Body in accordance with the ISO/IEC 17020:2012 standard and is a member of the International Motor Vehicle Inspection Committee (CITA). In 2014, TESTEK transformed from a limited liability company to a joint-stock company and a new sister company, TESTEK servis, was established to complement and expand TESTEK’s operations.

The utilization of the smart app in the PTI process helps prevent violations of rules and regulations in several ways. Firstly, an internet connection is required to perform any task using the app and the inspectors have to enter their credentials to access it. Secondly, the VIN photograph ensures that the correct vehicle is being tested, while the odometer photograph prevents the manipulation of odometer values in the national information system. The app also sends the location of the taken photographs to prevent tests from being performed outside of the PTI service station area, as the photograph cannot be taken without enabling location services.

Moreover, the app performs double checks on the VIN by reading it from the OBD and reads diagnostic trouble codes via OBD, which prevents the inspectors from ignoring these possible major defects. During the driving brake test, the location of the device is stored and uploaded to the national PTI server to verify that it was conducted at the declared location under the declared conditions.

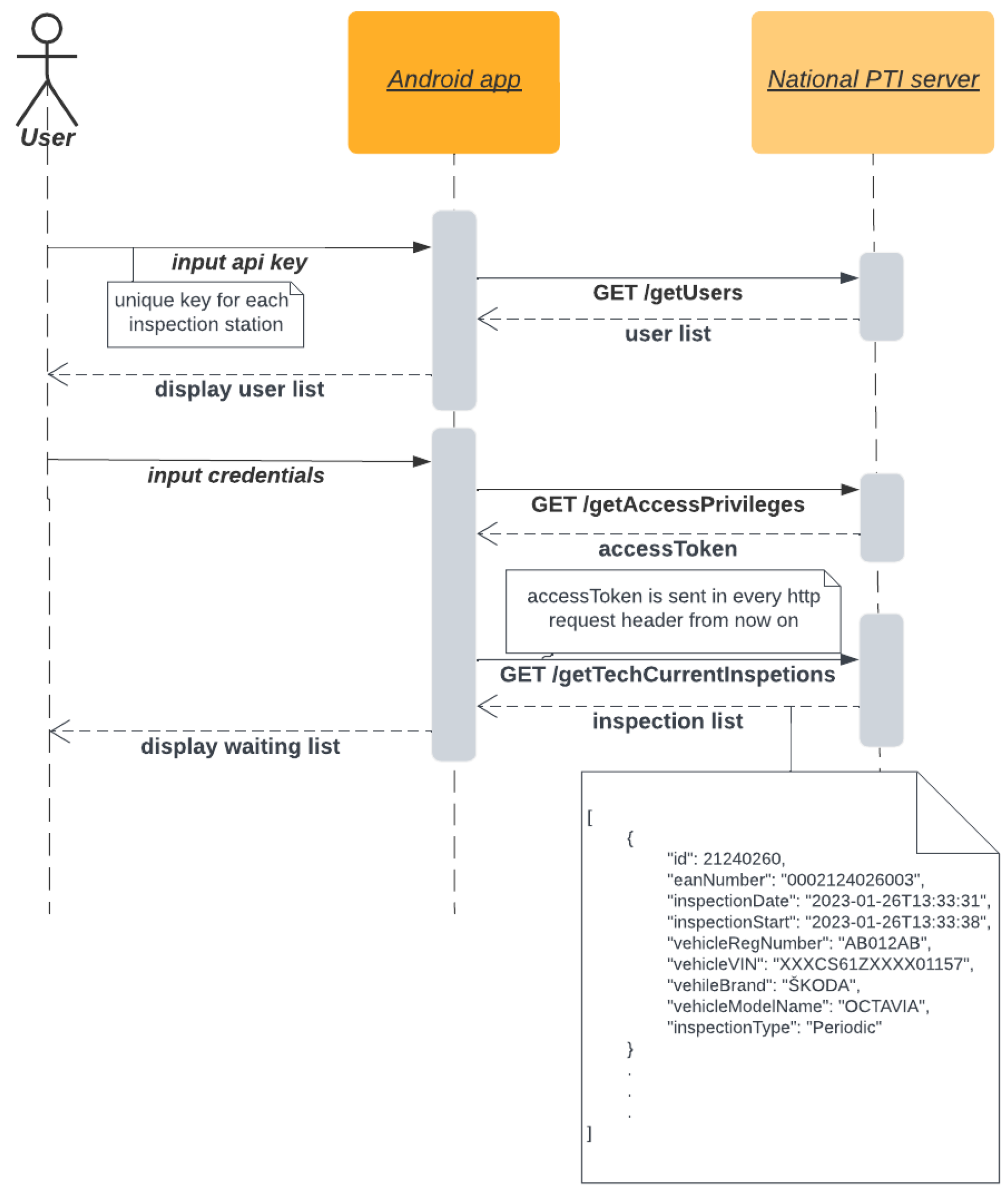

2.1. App Design

The inspector can perform the actions described in

Figure 2 in the application. First of all, the inspector must log into the application

Figure 3. Once successfully logged in, the inspector will see the main activity screen of the app, as displayed in

Figure 4, which begins with the inspector’s name displayed at the top. Beneath the name is the so-called waiting list, which includes a list of assigned inspections. The assigned inspections are identified by the car’s registration number, make, and model. When a specific inspection is selected by the inspector, the inspection details are displayed as shown in

Figure 4. At this time, the inspector may perform the following actions:

Take photos of the VIN, odometer and vehicle;

Read data from the OBD II diagnostic port of the vehicle;

Perform a brake test of the vehicle.

Data from all three actions are continuously uploaded to the national PTI server. Therefore, the developed application needs a continuous internet connection to function properly. The network architecture of the application can be seen in

Figure 5. The application operates in this architecture as a client and communicates with the server through a REST API, from which it retrieves the necessary data about inspections and sends measurements and photos. The communication between the server is encrypted and possible only after authentication and authorization of the user account on the client side (

Figure 3). There are two ways to connect a mobile application to the server: using a local Wi-Fi network or mobile data. The second option is advantageous, especially for inspections of agricultural vehicles that are performed outdoors or at the owner’s location.

During the process of taking photos and testing brakes, information about the mobile phone’s location is also obtained. The choice of navigation system (GPS, GALILEO, etc.) depends on the capabilities of the phone used, but precise location is required. Therefore, localization based on the GSM network is considered insufficient.

When reading data from the OBD II port, the mobile application obtains data from the ELM 327 module through Bluetooth technology.

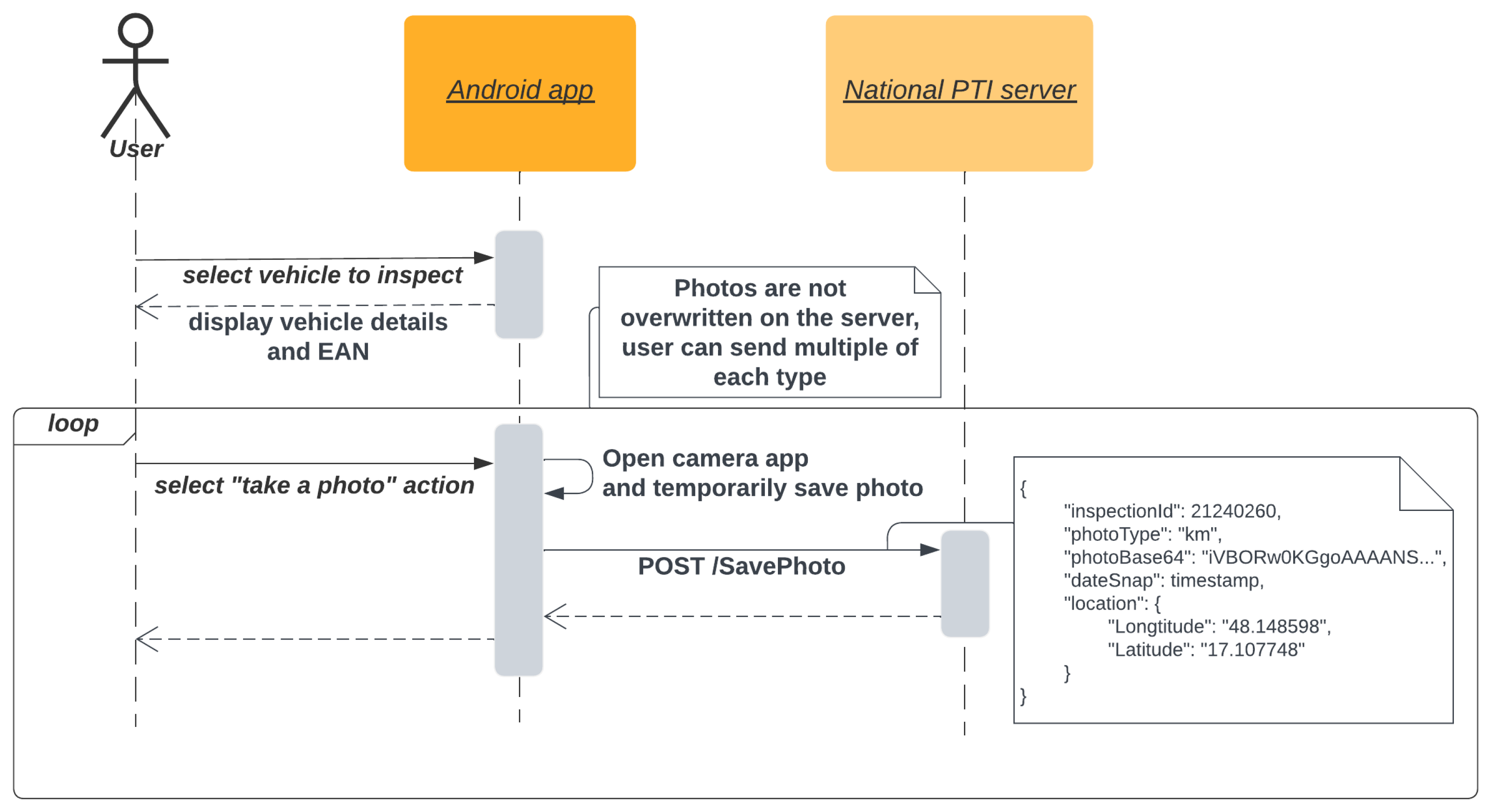

2.1.1. Photographs

Using the mobile device, the inspector can utilize any available camera to take pictures. Taking photos is possible only after selecting a specific vehicle for inspection. The inspector can take and send photos in three different categories. However, the process of capturing and sending a photo is the same. The sequence diagram of this action can be seen in

Figure 6. After selecting the photo category, the built-in camera of the mobile phone is activated, allowing the inspector to capture a photo.

Once captured, the photo is resized to 640 by 480 pixels and compressed into a JPEG format. To ensure the file size remains below 100 kilo bytes, a compression level is applied. However, to prevent any potential cheating, the files cannot be utilized as photographs. If the snapshot is confirmed, the photo is sent to the server.

The dashboard gauges photograph, depicted in

Figure 7, displays the malfunction indicator lamp activated. When encountering such a defect, it should be documented using the miscellaneous photo button to upload a photograph along with a brief description of the issue to the server. It is important to note that this type of defect typically appears on the diagnostic trouble codes list, and the presence of the MIL can be detected by reading the OBD as well.

2.1.2. OBD

Although it is possible to gather more data from a vehicle using proprietary hardware and software, the solution being presented aims to be independent of vehicle make or manufacturer by utilizing the OBD II standards outlined in [

44]. Special OBD readers, similar to the one described in [

45], can be designed and developed as well, but it would result in additional expenses not only for the development and design stages but also for the maintenance of the devices in future. Our solution does not require any additional expenses on equipment or software licenses for PTI service stations since it employs a low-cost and widely available wireless OBD interface, the ELM327 (refer to [

26]). The dongles utilized in the study were sourced from the lower end of the price range, approximately EUR 10 per unit. This device can also be used efficiently for research purposes, as demonstrated in [

46]. The primary objective was to retrieve diagnostic trouble codes (DTCs) available via the open OBD service. Numerous smartphone applications are available that can read Diagnostic Trouble Codes (DTCs) using an ELM327 On-Board Diagnostic (OBD) reader. However, this particular application incorporates further PTI responsibilities and procedures, with an emphasis on preventing fraud by obtaining the following data:

ELM327 voltage: This is not the voltage requested from vehicles ECUs using OBD requests, but it is the voltage measured by the ELM 327 reader on the OBD port pins;

VIN: The vehicle identification number is obtained by the OBD request. After successful parsing, it is compared with the VIN in the information system;

DTCs: A request is also made for the list of permanent diagnostic trouble codes.

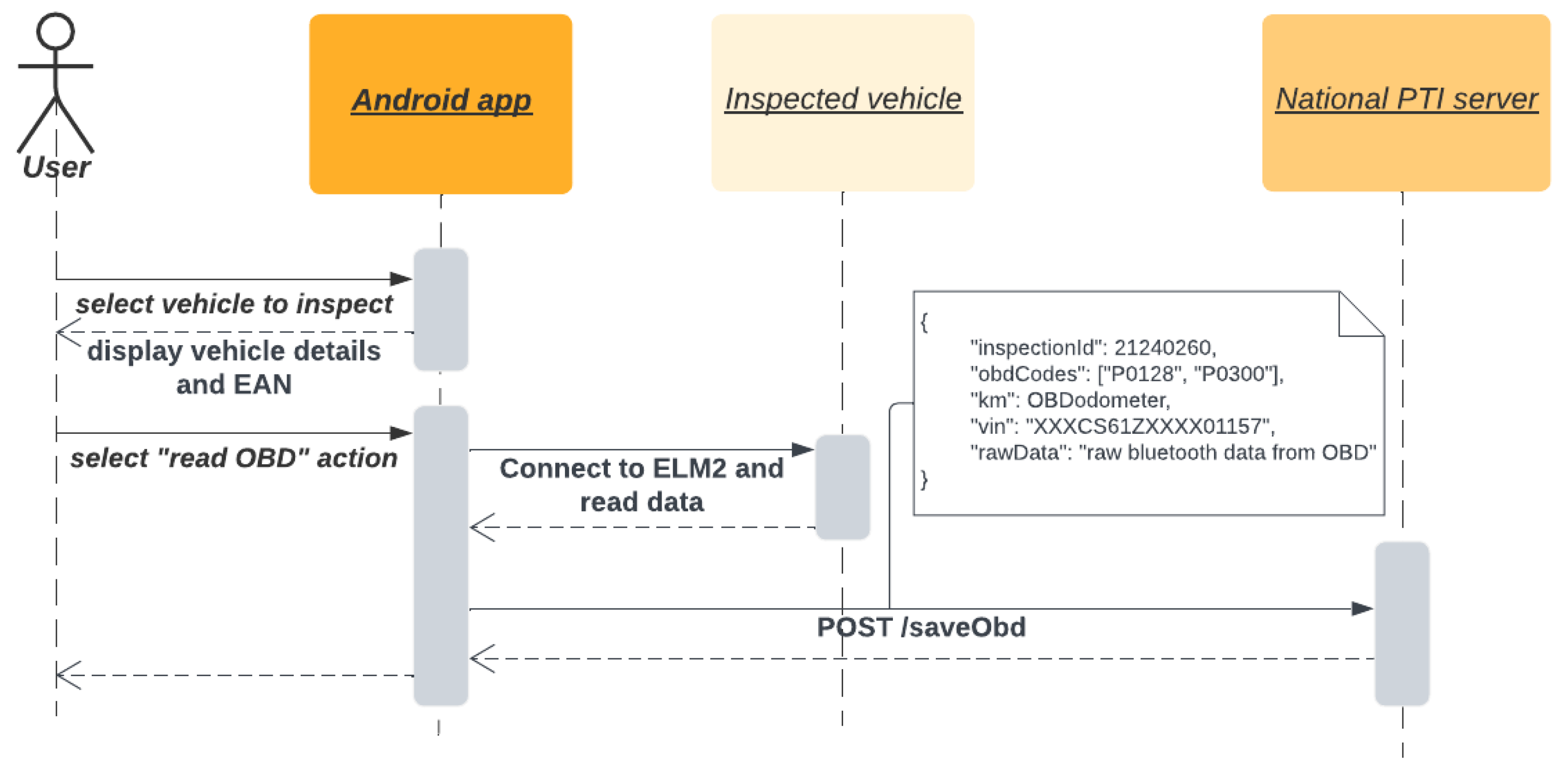

There are additional communication features between the phone and ELM327, such as resetting to defaults, detecting the vehicle OBD protocol, and providing a list of supported services. However, these features are not extensively discussed in this paper. The sequence diagram shown in

Figure 8 illustrates the process of gathering OBD data sending it to the national PTI server. After selecting the vehicle designated for inspection, the inspector can press the “read OBD” button. Communication is activated after selecting the correct ELM 327 module among Bluetooth devices. During OBD communication, requests are sent to the vehicle sequentially through the Bluetooth module, and incoming responses are processed accordingly. Every response from the vehicle is logged and transmitted to a central server for additional scrutiny in situations where the inspection has failed, the responses are incorrect, or there are any indications of possible fraudulent activity. Since 2020, these data have also been utilized in debugging and research endeavors, as it marks the initial year that such devices were integrated on a broad scale.

Figure 9 illustrates the OBD reading screen screenshot. The results from parsed OBD responses are displayed in the upper section, starting with the VIN if the car does provide it via standardized OBD request according to [

44]. Below the VIN number, one can see the status of self tests also referred to as readiness and the status of a malfunction indicator lamp also known as MIL. Then, the permanent DTCs are displayed below. The DTCs are displayed as hexadecimal figures and are subsequently parsed on the server.

The remaining portion of the screen displays the overall progress percentage, accompanied by check marks that indicated accomplished tasks, providing the inspector with more comprehensive feedback on the ongoing inspection. In case certain readings fail and must be repeated, delays may occur. Occasionally, some vehicles may not be compatible with the ELM327 reader, in which case the inspector must at least attempt to connect via Bluetooth, record the voltage, and submit requests to the vehicle multiple times. All communication is recorded and forwarded to the server and, if the reading is unsuccessful, the OBD reading button in the application changes to orange, as displayed in

Figure 4 on the right-hand side.

The rest of the screen shows overall progress in percentage, along with check marks indicating successfully completed tasks to provide the inspector with better feedback on the ongoing inspection. Delays may occur if some readings fail and must be repeated a few times. It is possible that some cars cannot be read by the ELM327 reader, in which case the inspector has to try to connect to the ELM327 via Bluetooth, read the voltage, and send requests to the car several times. All communication is saved and submitted to the server and, if the reading is unsuccessful, the OBD read button in the app is indicated in orange, as shown in

Figure 4 on the right.

2.1.3. Drive Brake Testing

Brake failure-related crashes were discussed in [

47], presenting an increasing rate of brake failure-related crashes with the age of the vehicle, which corresponds to conclusions in [

41] presented in

Table 1. Since the average age of a vehicle registered in Slovakia is still over 14 years, the drive brake testing feature has become a crucial aspect of this application.

While roller bench devices are commonly used to test vehicle brakes, not all roller benches are suitable for certain vehicles or situations. For instance, roller benches may not be suitable for 4-wheel drive or agricultural vehicles. According to a survey in [

48], dangerous defects related to brakes account for 2–3% of dangerous defects found in the agricultural vehicles category. In Slovakia, agricultural vehicle inspections can be performed on-site to avoid transporting the vehicles to PTI service stations. In such cases, the drive brake test serves as an alternative to the roller brake test, as stipulated by Slovak Republic legislation based on the United Nations Economic Commission for Europe Agreement [

49]. Prior to 2021, decelerometers, such as the MAHA VZM300 [

50], were used in these tests, which left ample room for fraudulent behavior since there was no way to verify the test results and there was no guarantee that the test had been conducted at all.

According to the regulations, the function of brakes must be determined by either measuring the stopping distance relative to the initial vehicle speed and/or by measuring the mean fully developed deceleration during the test; for further information on the calculation and test procedure one can refer to an ISO standard [

51].

There are multiple methods to measure the stopping distance using a mobile phone. One approach involves using GNSS sensors; however, these sensors have a limited update rate of no more than 1 Hz, as demonstrated in [

52]. A more preferable alternative is to utilize the phone’s inertial measurement unit (IMU), which typically generates data every 4–20 milliseconds, depending on the device’s manufacturer and operating system version. To obtain the braking distance, the acceleration sensor data must be double-integrated, which can result in accumulating measurement errors. This positioning approach, referred to as dead reckoning, is unsuitable to be the sole method for localizing a vehicle. The capabilities of IMU positioning are summarized in [

53], emphasizing its applicability for indoor use as well, while the effects of the cumulative error are discussed more closely in [

54]. Nevertheless, in this scenario, the driving brake test, the measurement takes only a few seconds, which limits the impact of the cumulative error on the results. Therefore, in this mobile application, the measurement is based on IMU data through dead reckoning.

The results provided by the phone measurements are consistent and offer a level of precision that is almost identical to that of the formerly used devices.

Calibrating and testing each device before using it to measure the brakes is necessary for ensuring the accuracy and reliability of the safety system. Without such measures, it would not be feasible to use any device for this critical task. It is necessary to test the accelerometers at steady states every two years to ensure accuracy. Fortunately, the cost and frequency of calibration are comparable to those of previously used devices, so there is no significant increase in cost associated with this process.

The process of performing a driving brake test is described in the sequence diagram shown in

Figure 10. After selecting the vehicle designated for inspection, the inspector can press the “driving brake test” button. At this moment, the mobile phone should be securely mounted in a stand. Subsequently, the inspector can initiate the test during which they follow the instructions displayed on the mobile device. After completing the drive, the measured data are evaluated directly on the mobile device and the results are displayed on the device’s screen. After confirming the test results, the test evaluation, along with the measured data, are sent to the national PTI server.

The user interface of the application is designed to be simple and user-friendly as it is meant to be used while driving.

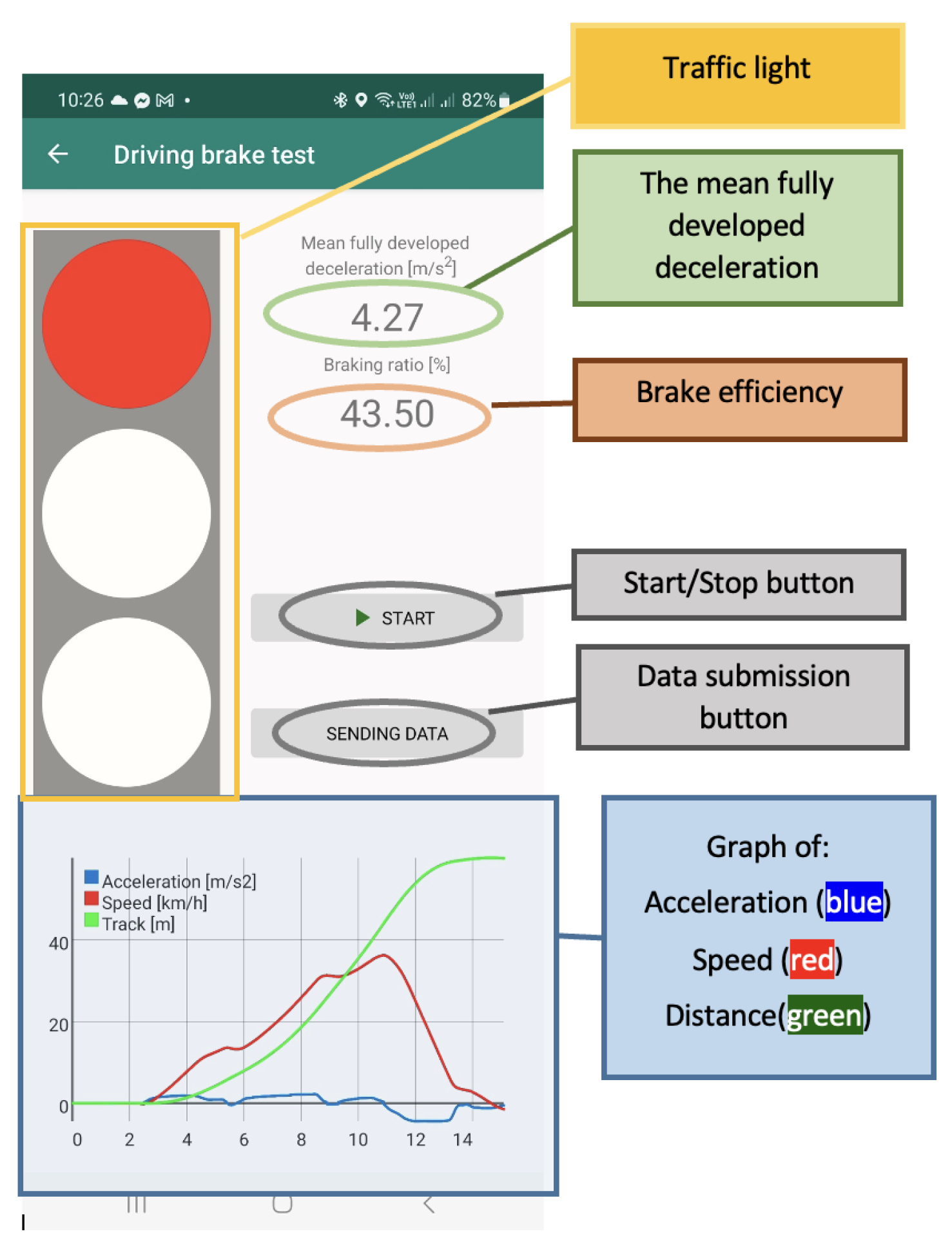

The screenshot from drive brake test activity is in

Figure 11. It shall be used in the following way:

The phone should be securely mounted on the vehicle, such as on the windscreen, using a holder that does not cause excessive vibrations. Shorter arms are recommended for this purpose;

The app requires a GNSS position to be available before the Start button can be pressed and the measurement can begin. Otherwise, the button is grayed out;

Once the first GNSS position is obtained, the measurement can be started by pressing the Start button. This initiates a self-adjustment measurement to determine the phone’s orientation, while the vehicle and phone have to be standstill, the engine can be idling. The yellow light is on during this process;

If the self-adjustment measurement is successful, the green light turns on. The driver should then accelerate the vehicle to the desired speed and then apply the brake;

After stopping the vehicle, the Stop button should be pressed to complete the measurement. The results are then evaluated and, if consistent, are displayed. The data can then be submitted.

4. Discussion

The novelty of the approach is in using the ELM327 device for OBD scans at such a large scale successfully. The results in

Table 5 show that a large number of malfunctions, 10,183, were read from cars’ OBDs at PTI stations in 2020 in Slovakia. Most of these cases were emission related and only 63 were classified as major defects at technical inspection. Nevertheless, it did detect the defects and the cars had to be repaired and inspected again within the 60-day period. By incorporating OBD readings into the PTI process through a mobile app, Slovakia has become the third country in the EU to do so and is in compliance with EU legislation. In 2021, there were similar results to those of 2020 regarding OBD readings, with more than 21,000 DTCs detected, out of which 77 were related to safety.

The number of brake driving tests performed by the presented app show the importance of designing this tool. The fact it became mandatory in 2021 will create a lot of supervision options for preventing fraud in brake assessment at PTI stations. The drive brake testing feature introduced an affordable, very easy way to test vehicle brakes and contributes significantly to road safety, particularly for older cars where major defects are more likely to occur. The ability to detect brake-related issues through OBD readings also helps to prevent brake failure-related accidents, which are known to increase with the age of the vehicle. An innovative aspect of the proposed method is also the utilization of a smartphone’s IMU for measuring vehicle deceleration, which detected more than 200 defects in vehicle brake systems, more than 20% of which were on heavy duty vehicles. This technology, combined with regular calibration of the phone’s accelerometers, provides a cost-effective solution for accurate drive brake testing and contributes to overall road safety. The app has already been expanded and new features, such as On-Board Fuel Consumption Meter (OBFCM) readings, have been field tested. The OBFCM reading functionality will be the next step in the app’s development, contributing to fuel consumption and emission monitoring in the EU passenger cars.

The technology is very affordable, making it suitable for countries where the cost of technical equipment is a barrier to implementing PTIs.

In conclusion, this paper highlighted the significance of utilizing smartphone applications in the PTI process. Recognizing the crucial role of road safety and the impact of vehicle defects on fatal accidents, the authors explored the potential of smart technologies to enhance the efficiency and effectiveness of vehicle inspections. By leveraging the capabilities of smartphones, including data collection from the vehicles and utilizing their own sensors for vehicle dynamics measurements, the authors successfully implemented low-cost devices at a large scale across the country. The outcomes of the first two years of utilizing this application at every technical inspection station in the Slovak Republic were discussed, showcasing the positive advancements made in transitioning to smart technologies while managing costs effectively.