Featured Application

Review on performance regarding mechanical, sustainability, permeability, design, and Life Cycle Assessment characteristics of asphalt pavement and interlocking concrete block pavement for urban road applications.

Abstract

This paper aims to review the performance analysis of interlocking concrete block pavement with by-products such as coconut fibers, and construction and demolition recycled materials, and to compare their skills with asphalt pavement, especially for light-traffic urban road applications. The focus is on mechanical behavior (mix parameters and the influence of by-products), pavement design, sustainability (the heat island effect), the management of contaminant concentrations within infiltration related to permeability, and Life Cycle Assessment. Considering the overall performance analysis, interlocking concrete block pavement was the most attractive alternative because it was approximately 33–44% cheaper in the maintenance process, cooler over a range of 2.2–15 °C, and more permeable by 0.4 cm/s to 0.6 cm/s than asphalt pavement, saving costs and improving drainage and human thermal comfort. However, asphalt pavement was around 35% cheaper during the construction phase (mainly due to energy consumption), and it presented a 32% lower nitrogen oxide concentration. This paper showed the advantages and disadvantages of both types of pavements. A further breakdown should be developed and integrated into the decision-making process about choosing between solutions.

1. Introduction

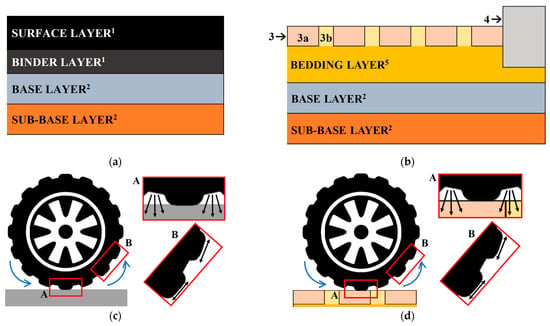

The interlocking concrete block pavement (ICBP) consists of concrete paving blocks (CPBs) available in many shapes and combinations [1,2]. Figure 1a,b shows ICBP and conventional asphalt pavement (AP) layers: sub-base, base, and surface layer (asphalt concrete for AP or paving blocks + joint materials for ICBP). In addition, the AP surface layer consists of relatively homogenous mixes with high stiffness (Figure 1c) [3]. However, ICBP consists of CPBs with increased stiffness and joint materials with low stiffness (Figure 1d) [4].

Figure 1.

Interlocking Concrete Block Pavement (ICBP) and Asphalt Pavement (AP) in terms of layers and contact with the traffic load (adapted from [3]). 1 Asphalt concrete (AC); 2 Continuously graded aggregates; 3 Surface layer; 3a Concrete paving blocks (CPBs); 3b Joints’ material; 4 Lateral confinement at the edge of the shoulder or at the sidewalk; 5 Controlled sand material. (a) AP layers, (b) ICBP layers, (c) AP surface layer, (d) ICBP surface layer.

ICBP and AP under assessment are mainly applied to light-traffic urban roads. Then, it is essential to compare their skills because CPBs can be more attractive as a repairable system than asphalt concrete (AC) for heavy-loaded vehicles (even if in small numbers) at low speeds over the pavement [5].

Worldwide, a revolution in paving blocks took place in the Netherlands, with the production of CPBs in the 1950s [6]. Over the years, in Rio de Janeiro, Brazil, urbanization programs, such as “Rio Cidade” and “Favela Bairro”, provided 1,000,000 m2 of CPBs [7]. In Fortaleza, Brazil, the requalification of the “Beira Mar” and “Desembargador Moreira” avenues was done using CPBs, where approximately 66,705 m2 and 6500 m2 of CPBs were used, respectively [8]. In the USA, this technology application grows by about 100% every five years, and similar growth rates have been recorded in Belgium, Germany, Australia, New Zealand, and South Africa [9].

On the mechanical behavior of ICBP, the joint material “networks” decrease the surface layer’s total stiffness and provide horizontal distribution and vertical load transmission through shear stresses. In addition, the bedding layer is compacted by the traffic load during post-construction, which results in some surface deformation [4]. Furthermore, the CPBs need to have certain mechanical and physical properties, such as compressive strength (fc) and water absorption (wa), according to various standards: Brazilian ABNT NBR 9781 [10], American ASTM C936 [11], European CEN EN 1338 [12], Australian AS/NZS 4456.4 [13], and Chinese CNSA GB 28635 [14]. Concerning alternative materials, in general, the by-products of some industries can be used to manufacture CPBs. Examples are recycled asphalt pavement (RAP), recycled concrete aggregates (RCAs)—both classified as construction and demolition waste (CDW), and coconut fibers [15,16,17].

In Fortaleza, Brazil, the amount of CDW discharged in the 61 eco-points in the city is 276,000 tonnes per year [18]. In the EU, CDW activities generated over 850 million tonnes of by-products [19]. Furthermore, Santos et al. [20] provided the amount of CDW generated per capita in six regions of Portugal. Results showed that the amount of CDW ranged from 206 kg/hab/year in Lisbon to 711 kg/hab/year in the Algarve. Another by-product is coconut fiber, produced from the coir’s waste and potentially used to reinforce bounded materials [21]. More than 405 million coconuts were produced in Ceara, Brazil, in 2020 [22]. During their decomposition, which can take more than eight years, as 80% to 85% of the coconut weight becomes waste, their disposal causes a decrease in the lifetime use of landfills [23,24]. Evaluating ways of reusing these by-products by public or private companies is essential. Then, research that evaluated the application of CDW recycled aggregates [25,26] and fibers [27,28] in concrete can be cited in Brazil and Portugal. Furthermore, studies in China [29], Turkey [30], Indonesia [31], and Sri Lanka [32] can also be cited. Therefore, by-products from different sources can be used in engineering works by determining the most appropriate concrete mixture for CPBs.

For more practical pavement construction, it is essential to use an appropriate design method. However, most ICBP design methods come from the adaptations of AP [7]. Then, due to the difficulties in structurally verifying pavements with CPBs, efforts were made to investigate the ICBP working mechanism, and a fair approach was reached [33]. Then, the elasticity modulus (Em) is a characteristic that should be included in the ICBP design. In Brazil and Portugal, on experimental tracks in Sao Paulo and Lisbon, respectively, the Em of the surface layer was calculated via back-analysis using the deflections provided by the Falling Weight Deflectometer (FWD) [9,34]. In the US, experimental studies were made in ICBP with FWD, observing a progressive increase in the surface layer’s stiffness [35].

In urban areas, such as roads and parking areas, the land is usually covered with conventional AP, which is impervious and results in rainwater being directed to storm drains instead of the foundation through infiltration [36,37]. Furthermore, over 90% of pavements are AP in the USA [38]. Then, there are high AP surface temperatures during summer during hot periods. In addition, the increase in traffic density leads to a higher concentration of contaminants on the pavement’s surface layer. A solution for these problems is the application of ICBP because of its potential for temperature reduction, stormwater management, and the retention of contaminants [38,39]. This solution positively influences the Life Cycle Assessment (LCA) to evaluate the sustainability and economic advantages of the complete structure.

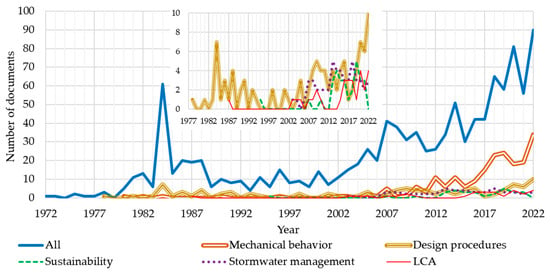

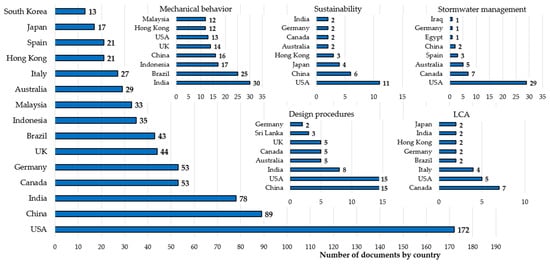

This paper aims to review the performance analysis of ICBP with by-products, such as coconut fibers and recycled materials from CDW, and to compare the skills with AP, especially for light-traffic urban roads applications. For this aim, the authors analyzed the studies published on the Scopus search engine (www.scopus.com) related to ICBP. This tool was used by searching in the article’s title, abstract, and keywords with the following query string: (“concrete” AND “paving” AND “blocks”) OR (“interlocking” AND “pavements”). The search provided 1125 documents from 1972 to 2022, separated into six groups: 1. mechanical behavior via mix parameters or the influence of by-products; 2. sustainability via the heat island effect (HIE) or contaminants concentrations; 3. stormwater management; 4. design procedures; 5. LCA, and 6. others. Figure 2 and Figure 3 show the queries’ outcomes by year and country, respectively. The main direct inferences were as follows. 1. Research efforts that considerably increased after 2002; 2. Stormwater management, sustainability, and LCA applied on ICBP began to have more visibility only after 2006, 2012, and 2015, respectively; 3. The US and China are the countries that have contributed the most to the number of documents on ICBP; and 4. Apart from the US, only Canada has published documents on the three most recent ICBP knowledge areas: stormwater management, sustainability, and LCA.

Figure 2.

Evolution of the number of documents on ICBP over the years.

Figure 3.

Distribution of documents on ICBP by country.

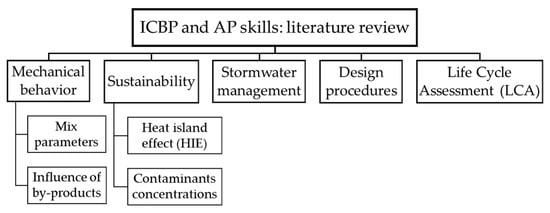

Finally, this review paper focuses on pavements’ mechanical behavior and design. In addition, it provides the sustainability seen as contributing to the HIE, the management of contaminant concentrations within infiltration related to permeability, and LCA. Figure 4 presents the general framework of this review paper.

Figure 4.

Review framework.

2. Mechanical and Durability Properties of Asphalt Concrete and Concrete Paving Block

2.1. Influence of Mix Parameters on Pavement Performance

The results from recent research have indicated that the structural and functional performances of AP and ICBP can be affected by many factors. The following aspects can be mentioned: surface type and geometrical configurations, e.g., cross-sectional design, aggregate characteristics, and environmental conditions, e.g., rainfall and HIE [3,40,41,42,43]. Then, this section emphasized some parameters, e.g., aggregate packing and mixing temperature, on the AC and CPB properties for AP and ICBP, respectively.

Pioneering studies investigating the beneficial effects of aggregate packing on CPB and AC properties have been abundant in the literature [44,45,46,47]. Fuller and Thompson [44] analyzed the influences of graded particles on concrete strength, and an optimum grading curve of aggregates was proposed that showed the highest packing density. Lees [45] proposed a method for designing dense AC based on aggregate grading. Then, Al-Hdabi et al. [46] studied the use of cement on gap-graded cold AC, which improved on its mechanical properties compared to the conventional hot mix, within a one-day curing period. In addition, Gardete et al. [47] linked bulk specific gravity procedures (dry, saturated surface dry, paraffin, vacuum-sealed, and dimensions) to the AC performance. This approach showed the anticipated variations in the AC properties, such as workability, stiffness, and fatigue resistance, throughout a mix-design, considering the different bulk specific gravity results.

Concerning mixing temperature, Navaro et al. [48] described experiments with RAP and mixes produced at different temperatures. The microscopic observations showed that agglomerations of materials were present on the largest aggregate surface when the RAP components were blended. These agglomerations, called clusters, were composed of small particles of RAP’s aggregate and binder, which manifested in the mixes having worse mechanical and durability properties. Furthermore, it was found by Bressi et al. [49] that there was a direct relationship between mixing temperature, clustering, RAP quantity in the mixtures, and particle size. It is also necessary to note the differences between warm and hot AC. Warm AC constituents are typically mixed at temperatures varying from 100 °C to 140 °C, while hot AC is produced at between 140 °C and 160 °C [50]. This temperature reduction is possible due to additives such as organic waxes and chemical surfactants [51]. Finally, the effects on the mechanical performances of warm and hot AC by incorporating RCAs are presented in Table 1, which show satisfactory results for marshal stability [52]. On the contrary, using RCAs in AC led to a weak resistance to water result.

Table 1.

Mechanical performances of AC with recycled concrete aggregates (RCAs) (adapted from [52]).

Table 2 lists studies on the influence of the mix parameters on the properties of AC and CPB.

Table 2.

Effects of mix parameters on properties of asphalt concrete and concrete paving block.

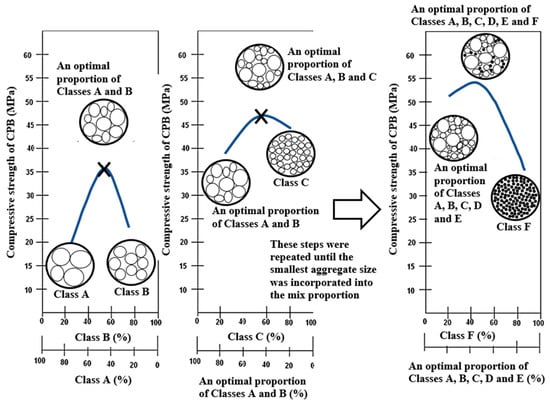

Chu et al. [42] showed that the packing density was the critical factor that influences the CPB’s properties, regardless of the aggregate type, which allows a better understanding of the characteristics of the concrete’s components. For an advanced packing optimization, the aggregates were classified into six classes (A, B, C, D, E, and F) according to their size ranges (A: 5–10 mm, B: 2.36–5 mm, C: 1.18–2.36 mm, D: 0.6–1.18 mm, E: 0.3–0.6 mm, and F: 0–0.3 mm). The materials were sequentially introduced into the mix, from the coarsest to the finest. A detailed procedure is presented in Figure 5.

Figure 5.

Steps for advanced packing optimization (adapted from [42]).

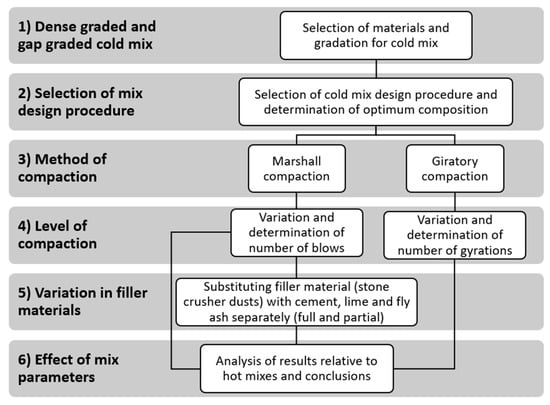

Dash and Panda [53] highlighted that higher compaction should be avoided in the cased of both Marshall and gyratory compaction. It may influence a decrease in the cold AC’s workability. Then, a greater compression level can be challenging to apply in the field. The cold mix-design procedure is shown in Figure 6.

Figure 6.

The overall experimental methodology, represented by a block diagram (adapted from [53]).

The research by Cavalli et al. [54] analyzed 2D cross-sections taken for three AC cylindrical samples at the same depth in the fused 3D binary images, in which the voxels belong to recycled and natural aggregates. The X-ray analysis showed that the RAP aggregates were covered by a RAP binder, which tended to decrease by increasing the mixing temperature. This decrease can be due to a higher volatility loss of the AC’s components with increasing mixing temperature. Furthermore, the spatial heterogeneities in the viscous properties can be responsible for the anisotropic aggregate distributions. Then, higher temperatures might contribute to a more homogeneous and isotropic spatial distribution of the aggregates, manifesting in better AC mechanical and durability properties.

2.2. Influence of Fibers and Recycled Materials from Civil Construction on Pavements’ Performances

The increasing growth of urban sectors has led to a higher usage of natural resources and the generation of vast quantities of CDW. With around 1.3 billion tonnes of solid by-products annually from world cities, it is expected to increase to 2.2 billion tonnes by 2025 [55]. CDW, when reused as aggregates in new construction, can be known as RCAs from the demolition of concrete structures, or RAP from the pavement repair process. Table 3 shows the CDW’s compositions and the waste recycling percentages in some countries.

Table 3.

Construction and demolition waste (CDW) characteristics and recycling processes in different locations worldwide.

In other countries, the CDW recycling rate is not significant, such as in Portugal (9.0%) and Brazil (16.1%) [57,58]. However, in Japan and Australia, it should be noted that financial support for the high technology required for separation and processing has resulted in increased motivation in the industrial sectors to use recycled materials [59]. Then, sustainable pavement design is essential for AP and ICBP construction.

Studies into the knowledge and application of CDW are ongoing, mainly in AC, CPB, and the pavement’s base layer [15,16,60,61,62,63]. Furthermore, various waste plastics such as polyethylene terephthalate (PET) and low-density polyethylene (LDPE), can be used as an alternative to replace aggregates. Then, the research by Rodrigues et al. [64], Almeida et al. [65], and Fonseca et al. [66] for AC; and the studies by Ohemeng et al. [67], Mashudi et al. [68], and Gungat et al. [69] for CPB can be cited. Incorporating CDW aggregate into pavement structures provides environmental and economic benefits. Because of the workability and air permeability, a relevant proposal would include this by-product in permeable pavements. Pervious AP or ICBP has a surface layer that allows air and water to pass easily from the pavement top and through an interconnected network of void structures to the underlying layers.

Bang [17] analyzed some materials for fibers, such as nylon, steel, coconut, glass, and polypropylene. In addition, concrete blocks for ICBP were investigated with and without fibers. The results showed that the compressive and flexural strength properties increased at 7, 14, and 28 days of age. Furthermore, fibers were also used in AC, such as cellulose and polyester materials [70]. Cellulosic fibers present essential advantages such as a low cost and a zero carbon footprint, and they enjoyable physical and mechanical properties, e.g., low density and well-balanced stiffness [71]. Then, cellulosic fibers can be helpful for AC due to decreased stop binder drainage, preventing their loss during storage and transport [72].

Table 4 lists studies on the influences of fibers, RCAs, and RAP on AC, CPB, and granular materials properties for the bases of pavements.

Table 4.

Effects of alternative materials on properties of AC and CPB.

Research by Nwakaire et al. [60] highlighted that AC with RCAs would require a higher bitumen content for optimum performance than the control mix R0. The alternative mixtures, CR80 (7.5%), CR100 (8.0%), and FCR100 (9.9%) showed an optimum binder content above the 7% maximum recommended for the mix design. This increase is due to the porous nature of RCAs, which tend to imbibe part of the binder meant for the surface bonding of the aggregates. Then, there was an insufficient aggregate coating at the lower binder contents.

Bang [17] found reduced cost and carbon footprints of the ICBP structure for using fibers in CPB. For example, coconut fibers are cheap and available in large amounts, and they minimize concrete cracking. The advantages of glass fibers are in improving the concrete’s matrix densification and the durability to reinforcement corrosion. The addition of nylon fibers helps with the concrete’s workability. In addition, polypropylene is a thermoplastic polymer, which can be necessary for better CPB performance in the industrial field.

Based on the research by Avirneni et al. [63], the 80RAP:20VA samples crushed by the fc test at 28 days showed no evidence of stripping the bitumen from the RAP aggregate’s surface. Furthermore, weaker zones were observed on the portion of the RAP particles coated with bitumen in the entire mix, which may have contributed to a lower mixture’s fc.

3. Sustainability Aspects of Asphalt and Interlocking Concrete Block Pavements

3.1. The Heat Island Effect from Pavement Surfaces

A built environmental issue related to pavements is the HIE. Heat islands are generally considered at the surface and atmospheric effects, affecting air quality and human thermal comfort [73]. Furthermore, in many areas in the US, over 90% of pavements are black AC or dark seal-coated pavements [38]. Then, there are high AP surface temperatures over summer, during the hot periods. An analysis of the HIE in Osaka, Japan, demonstrated that the CPB’s albedo (the proportion of the incident radiation reflected by a horizontal surface) was around five times higher than AC [74]. This increase provided a higher amount of reflection from block surfaces, resulting in less absorbed thermal energy. These considerations on the CPB’s characteristics of HIE were consistent with the results reported by Shackel [75] in Australia. Then, the study by Jamshidi et al. [3] found CPBs to be approximately 14 °C lower than the adjacent AC.

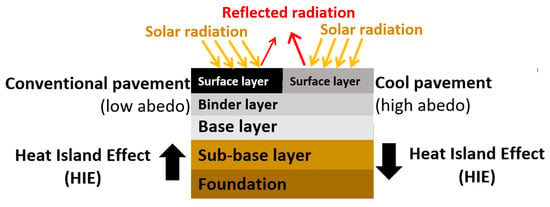

In the USA, in summer, the surface temperature on AP increased to 70–80 °C in Phoenix, Arizona, rising up to 70 °C in Davis, California, and contributing to the HIE [76]. Then, a strategy to reduce the HIE uses the ICBP’s water retention potential. The water absorbed by the pavement can be evaporated gradually, which decreases the surface temperature by 10–20 °C compared with an AP [77]. Another strategy to counterbalance the HIE is the development of cool AP (Figure 7), presenting a high thermal emissivity with less heat absorbed [78]. The new AP has a typical albedo of 0.05, and with a 0.6 increase; the daytime pavement surface temperature was reduced by 20 °C [79,80].

Figure 7.

Conventional and cool pavement structures (adapted from [78]).

Finally, the HIE is not always negative because of the countries’ climatic conditions, e.g., the temperature ranges of each season. Then, while HIE produces negative impacts during hot climates, it can also benefit people near the pavement surfaces, reducing building heating energy with less human thermal discomfort in the cold regions. Therefore, the insulation from the aggregate in the concrete composition delays the formation of a frost layer in a pervious pavement [81]. In addition, RCAs and RAPs were used in geothermal pavement construction, which had a heat exchanger system to extract the renewable thermal energy from the water for household and industrial purposes [82].

Table 5 lists the studies conducted through field experiments to identify the impacts of AP and ICBP on urban heat island mitigation.

Table 5.

Effect of AP and ICBP on urban heat island.

Based on the research by Li et al. [38], an average albedo of 0.27 from ICBP at 16:00 on 9 July 2012 can significantly reduce the pavement surface temperature. However, the surrounding buildings or vehicle surfaces absorbed the increased reflected solar radiation caused by high albedo from the ICBP sections. Then, the solar radiation reflected could increase human thermal discomfort during the hot periods, which takes the future research of applying AP and ICBP on-site for one year to ensure the most significant long-term benefit concerning HIE.

Research by Cheng et al. [83] analyzed the continuous time variation of the surface temperature for a bicycle lane and pedestrian walkway over 14 months. The time series data showed that ICBP in a pedestrian walkway had lower temperatures than AP in a bicycle lane, especially during summer and fall. In summary, under dry climatic conditions, ICBP might show a faster temperature rise when the air temperature increases. Still, this pavement also presented a quicker temperature drop as the air temperature decreased. Furthermore, Shimazaki et al. [84] found that air temperature (≈33 °C) and humidity (≈59%) exhibited similar values for the AP (AS) and ICBP (WR13 and W25) sections at 1.0 m height. The radiation influences the black-globe temperature, depending on the downward and upward components of both solar and infrared radiation. The upward radiation values were 624 W/m2 for WR13, 693 W/m2 for WR25 and 694 W/m2 for AS due to the higher black-globe temperatures in the AS section. Then, despite the lowest reflected solar radiation in the AS section (≈74 W/m2), the highest infrared radiation from the ground (≈620 W/m2) resulted in the most increased surface temperature (52.9 °C).

3.2. Contaminant Concentrations from Pavement Infiltration

An increased traffic density leads to a higher concentration of contaminants on the pavement’s surface. Regarding the pollutants, there are suspended solids (TSS) and heavy metals such as cadmium (Cd), iron (Fe), manganese (Mn), copper (Cu), lead (Pb), and zinc (Zn). In addition, the pollutants are chemical oxygen demand (COD), and nutrients, which are total nitrogen (TN), total phosphorus (TP), and ammonia (NH3), causing water pollution [85]. A heavy metal concentration above this criterion can affect human health, harming the central nervous system, lungs, kidneys, liver, and blood composition at sub-lethal levels [86]. Furthermore, nitrification is a microbial process that causes a reduction in the nitrogen compounds concentration, such as NH3, via oxidation to nitrite (NO2–) and nitrate (NO3–) [87]. This process can be a reason for the nitrogen compounds of permeable AP and ICBP infiltrates in open-air experimental fields [88].

As concrete for CPBs has pores in its structure, pollutants can be effectively retained inside the pervious ICBP system using filtration, sedimentation, and microbial removal [39]. Furthermore, the pervious AP consists of porous AC on the surface layer, and this pavement can contribute to the retention of contaminants such as ICBP.

Runoff water quality samples of AP and ICBP in two replicates were collected during research by Gilbert and Clausen [89]. An analysis was made weekly for 22 months, and the following data were total TSS and TP. The results showed that AC presented higher pollutant concentrations (TSS = 47.8 mg/L; TP = 0.244 mg/L) than CPBs (TSS = 15.8 mg/L; TP = 0.162 mg/L). Furthermore, Drake et al. [90] compared the winter quality of stormwater outflows between two ICBP structures and an AP control structure. Then, compared to AP, the ICBP systems performed similarly in reducing the total pollutant loadings for Cu, Fe, Mn, and Zn by 62%, 70%, 86%, and 80%, respectively. In addition, Bean et al. [91] investigated two ICBP sites with a control AP. Then, regarding runoff through the pavement section, NO2– + NO3– concentration from ICBP (0.44 mg/L) was 46.7% higher than AP (0.30 mg/L). Nitrification was the reason for these results, and a riparian buffer application for denitrification was recommended for future research.

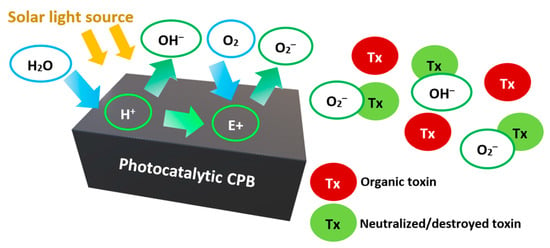

The photocatalytic CPB application is an innovative ICBP technology for reducing pollutant emissions. Fujishima and Honda [92] describe the mechanism of the photocatalytic reaction of titanium dioxide (TiO2). Figure 8 shows the photodegradation of organic toxins under light energy. Then, \photocatalytic concrete in urban areas can reduce the air’s nitrogen oxides (NOx) concentration. Witkowski et al. [93] and Beeldens [94] studied CPB performance with TiO2 in air purification measured as NOx reduction through laboratory and field tests.

Figure 8.

Photocatalytic process for CPB (adapted from [95]).

Table 6 lists studies conducted by laboratory or field experiments to identify the purification effects of AP and ICBP on stormwater runoff quality.

Table 6.

Effects of AP and ICBP on nutrient and metal concentrations.

The research by Zhang et al. [96] found that the difference in average metal removal between ICBP and AP was only about 5%. Still, the ICBP section permapave performed best for removing heavy metals because the permapave average outflow heavy metal concentrations were 71% and 56% of those from the hydrapave and porous ACs, respectively. In addition, the AP section showed the lowest average removal for Cu (66.5%), Zn (55.5%), and Mn (18.5%) because the basalt material from the AP base layer was much coarser than the stones and gravel in the ICBP sections, hydrapave, and permapave, respectively.

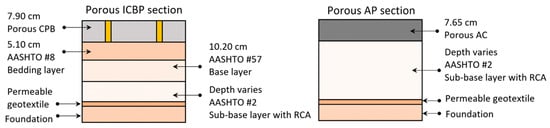

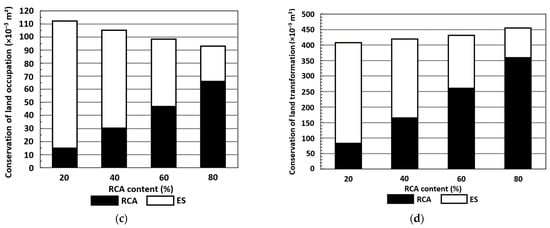

Based on the research by Liu and Borst [97], the Cu, Mn, Fe, and magnesium (Mg) concentrations in the ICBP infiltrates were higher than for AP. The reason for this is that suspended solids or salt particles trapped in the gap between the ICBP and the underlying aggregate were directly flushed into the water tank. Razzaghmanesh and Borst [88] used the same experimental field as Liu and Borst [97], and the AP section infiltrates had higher NH3 (0.070 mg/L), NO2– (0.165 mg/L), and TN (1.005 mg/L) mean concentrations than the ICBP section (NH3: 0.040 mg/L, NO2–: 0.024 mg/L, and TN: 0.775 mg/L). In addition, the leaching of CDW was more likely to be the source of contaminations because RCAs were used in the AP underground layer. Figure 9 shows the studied pavement structures by Razzaghmanesh and Borst [88].

Figure 9.

The profiles of pavement layers (adapted from [88]).

4. Stormwater Management in Permeable Pavements

The land for transport applications in urban areas, such as roads, parking areas, and sidewalks is usually covered with conventional AP [36]. Then, as most of the conventional APs are impervious, the rainwater is directed to storm drains instead of the foundation through infiltration [37]. A solution for this problem is the application of porous pavement, considered a cost-effective stormwater management practice that absorbs runoff in urban areas [98]. Therefore, the most common permeable pavements include porous AC, concrete, and CPB [38]. These structures are generally used in parking lots but they are usually not applicable for high-speed traffic.

Simulating and monitoring rainfall conditions under different types of porous pavements showed that the total runoff volume and peak flow were reduced by 97% and 93%, respectively [99]. Alsubih et al. [100] found that the porous pavements’ contribution to rainfall-runoff attenuation was more than 40% of the total rainfall retained in the structures compared to the reference impervious pavement. Furthermore, pervious pavements responded more effectively to rainfall events, with shorter return periods, reduced runoff volume, and peak discharge [101].

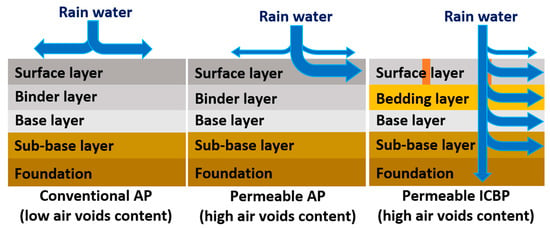

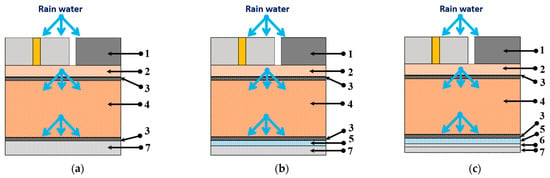

Porous AP is a typical permeable structure, but early failure due to a lack of fine materials and clogging are the main problems for its use in urban design [3]. Then, permeable ICBP is becoming more popular because of its harmony with the environment and urban streets, and its potential for temperature reduction [102]. Figure 10 shows the runoff movements in conventional AP, permeable AP, and ICBP structures for light traffic, such as pedestrian walkways. The materials used in each layer absorb part of the runoff, which depends on its saturation degree, porosity, and permeability coefficient.

Figure 10.

Mechanism of run-off infiltration in permeable pavement layers (adapted from [3,78]).

Table 7 lists studies conducted through field experiments to identify the impacts of AP and ICBP on stormwater management.

Table 7.

Effects of asphalt and interlocking concrete block pavements on stormwater management.

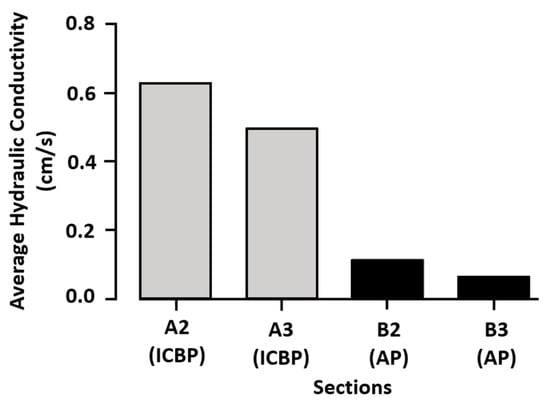

The average permeability or hydraulic conductivity found by Li et al. [38] for the AP (B2 and B3) and ICBP (A2 and A3) sections is shown in Figure 11. According to the results, the ICBP sections had the highest permeabilities or infiltration rates, equal to approximately 0.62 cm/s. In contrast, AP showed the lowest hydraulic conductivity (≈0.05 cm/s), but it was still sufficient to drain the rainwater without generating surface runoff during rain events.

Figure 11.

Average hydraulic conductivities of four pavement sections (adapted from [38]).

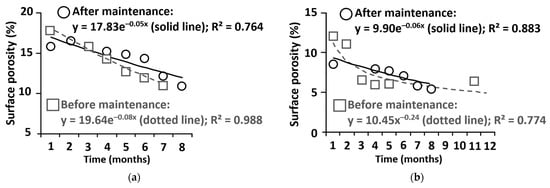

The research by Huang et al. [103] presented a regression analysis of the surface porosity, depending on the operation time for AP and ICBP in Figure 12. Types of regression were selected based on the R2 values. As pressure washing was an effective way to recover the surface infiltration rates, a regression analysis was made before and after pressure washing. Then, the temporal variation of pavement performance was successfully captured by introducing functions to reflect the changes in the porosities in the pavement’s surface layer from external factors such as traffic and maintenance activities.

Figure 12.

Surface porosity degradation before and after pressure washing (adapted from [103]). (a) Surface porosity of AP, (b) Surface porosity of ICBP.

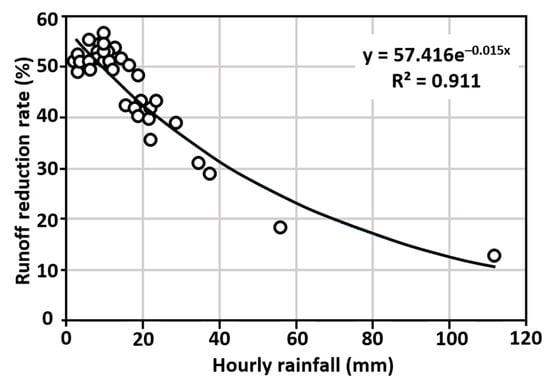

Based on the research by Cheng et al. [83], regression analysis were made on the relationship between the runoff reduction rate by the ICBP pedestrian walkway and the rainfall parameters, such as the total volume per specific period, intensity, and time variation. The runoff reduction rate versus the total amount of rainfall per hour had the highest correlation (R2 = 0.9109), and Figure 13 shows this relation. The runoff reduction averaged 35% to 41%, according to stormwater management model (SWMM) simulations. However, the reduction rate decreased to approximately 10% when the hourly rainfall exceeded 100 mm. Then, low-impact development practices, mostly designed for 1-year to 2-year return period storms, could only control smaller storm events. For storms, a combination of green infrastructure was needed.

Figure 13.

Relation between runoff reduction rate and hourly rainfall (adapted from [83]).

5. Structural Design of Asphalt and Interlocking Concrete Block Pavements

Pavements are designed to carry various types of traffic, such as pedestrians, bicycles, cars, and trucks. The design process must be performed with post-work evaluation over the years. Then, evaluating key indicators for AP, such as the structural behavior, is necessary, as derived from FWD campaigns, the International Roughness Index (IRI), and transversal roughness results [104].

For structures with low-speed traffic, such as pedestrian walkways and parking lots, there are a few critical issues with the structural performances of conventional impermeable or permeable pavements [38]. Furthermore, the structural design of permeable pavements should be performed to avoid surface runoff during rainfall [105]. Moreover, specific attention was given to geotextiles, materials made of woven or non-woven permeable fabrics, which can filter and drain the pavement system [106]. Geotextiles are usually set between the bedding layer and the sub-base, or at the lower level separating the sub-base from the foundation. Figure 14 shows these structures for AP and ICBP with light traffic, such as pedestrian walkways.

Figure 14.

Structures of pavements with geotextiles (adapted from [107]). 1 Surface materials, such as CPB or AC; 2 Laying course; 3 Geotextiles (optional); 4 Coarse aggregates; 5 Drainage pipe; 6 Impermeable membrane; 7 Foundation. (a) Full infiltration pavement, (b) Partial infiltration pavement, (c) No-infiltration pavement.

Specific methodologies consider ICBP and AP as being structurally similar but fundamentally different behaviors. AC shows visco-elastic characteristics, which depend on temperature, while concrete behavior is temperature-independent. Kasahara and Matsuno [108] found a decreased Em from the AP’s surface layer with higher temperatures. In contrast, CPB did not its lose structural performance at high temperatures [3]. Furthermore, the stresses under the CPB layer were not symmetrical due to the concrete segmental nature [109], while the stress distribution was approximately circular under the course layer in an AP [110]. In addition, the load distribution close to the ICBP surface layer is more highly concentrated than in an AP [3]. Then, a fully equal performance of ICBP and AP is almost impossible to realize.

Due to the difficulties in structurally verifying ICBPs, efforts were made to investigate this pavement’s working mechanism rigorously [33]. Then, a mechanism called interlocking is essential for better ICBP structural performance. Furthermore, research by Miura et al. [111] showed that the stress generated beneath the CPB surface decreased as the loading increased. The reason for this was the progressive increase in the interlocking of CPBs. The same observation was observed by analyzing ICBP using FWD [112]. Furthermore, there are methods to evaluate the ICBP structural performance, such as the Benkelman beam and the plate bearing test. However, these methods are quite time-consuming, and a solution was the use of small FWD, which is portable, to analyze the structural performance in terms of rutting [113].

Table 8 lists studies that analyze some software that have been specifically developed for the analysis of AP and ICBP designs, such as Flexible Pavement (FlexPAVE) [114], National Design Method (MeDiNa) [115], Permeable Interlocking Concrete Pavement (PICP) tool [116], and Design of Concrete Block Pavements (DesignPave) [117].

Table 8.

Mechanistic–empirical design methods for AP and ICBP.

Based on the research by Nemati et al. [118], the design parameters, cross-section details, and the FlexPAVE analysis showed the evolution of cracking with the number of failed elements (DF = 1) for 240 months (20 years). Furthermore, the FlexPAVE simulation results met expectations concerning AP’s design properties. Then, a better fatigue performance for AC with higher binder contents, greater stiffness, or stiffer binder types was highlighted.

The research by Silva and Santos [119] showed more reliability from the software MeDiNa than the empirical design methods. The reason for this was that MeDiNa allowed for different data sources for each material in the pavement structure, which was helpful due to the various climatic conditions of the region under study. Another favorable condition was the quality of AC to predict the fatigue action.

Li et al. [120] found that the best strategy for designing ICBP was by using the shear stress to shear the strength ratios at the top of the sub-base and foundation. These properties worked as inputs for modeling the rut development rate at the top of these layers for dry and wet conditions. Then, the PICP tool was validated, and the results were calibrated with the data collected.

Analyzing the research by Silva [8], applying all concrete mixes for CPB in the software DesignPave to construct a parking area was possible. As the foundation strength increased, smaller thicknesses were needed for the granular layers (base and sub-base), which was consistent. Therefore, DesignPave provided an alternative design based on the deformability properties of the materials (Em).

6. Pavement Construction, Maintenance, and Rehabilitation Based on Life Cycle Assessment

The pavements’ economic advantages and disadvantages are based on the LCA outputs. It is a difficult task to use LCA to solve all of the pavement design problems [121]. However, LCA is a tool for making better decisions based on several variables. Furthermore, amid so much risk in a transportation infrastructure project, a sensitivity analysis on the Life Cycle Cost (LCC) model is used as the decision support tool [122]. LCC can be optimized for better transportation infrastructure investments in developing countries [123]. Based on the pavement’s construction, using by-products such as RAP and RCAs is an alternative to reducing costs. In a field application, warm AC with RAP and RCAs was 5% to 8% less costly (direct and environmental) than a conventional hot AC [124].

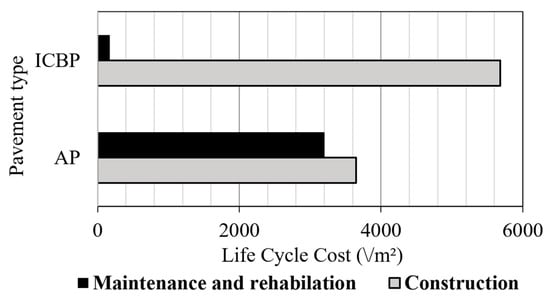

Ishai [125] reported that ICBP is an attractive alternative for heavy-duty applications in terms of maintenance costs rather than for applications with light traffic. Figure 15 shows that the major cost of an ICBP occurs during the construction phase, while the maintenance cost is much lower than for AP. The reason for this is that CPBs are reusable, significantly reducing the time and cost of maintenance and rehabilitation [125]. Therefore, the economic analysis of the ICBP life cycle shows an attractive pavement alternative.

Figure 15.

Costs based on Life Cycle Cost (LCC) (adapted from [3]).

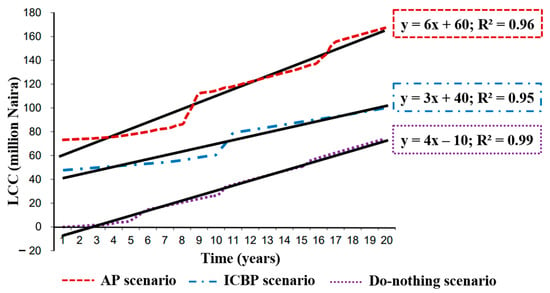

The research by Audu et al. [123] used a Present Worth Cost model of a transportation infrastructure project [126] for the following three pavement systems construction: the AP, ICBP, and do-nothing scenario courses. The combined LCC and the pavement age plot for the three systems at a 6.2% interest rate are shown in Figure 16.

Figure 16.

LCC versus pavement age for the three systems (adapted from [123]).

The AP and ICBP structures met the required level of services. At the same time, the Do-nothing scenario was unsuitable based on poor driving characteristics and potholing, which could worsen after the rainy season without a wearing surface course. Therefore, the Do-nothing scenario was an unacceptable option. Furthermore, the ICBP construction proved to be less expensive than AP, again showing the CPB maintenance process over the years as a more viable option than AC. In addition, the regression modeling analysis had a Durbin-Watson statistic coefficient of 0.95, indicating that the LCC model is highly robust in replicating the project data.

Table 9 lists the studies conducted by field or laboratory experiments to identify the ICBP components’ impact on LCA.

Table 9.

Effects of ICBP components on Life Cycle Assessment (LCA).

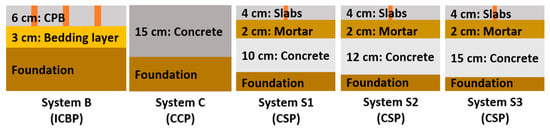

The research by Oliver-Solà et al. [127] analyzed different sidewalk systems, e.g., B: ICBP; C: continuous concrete pavement (CCP); and S1, S2, and S3: the concrete slab pavement (CSP) being not structurally equivalent, as shown in Figure 17 (without scale). In addition, the life cycle impacts for 1 m2 of the pavements are presented in absolute values in Table 10.

Figure 17.

Pavement systems B, C, and S1–3 (adapted from [127]).

Table 10.

LCA results for each pavement (adapted from [127]).

ICBP (system B) showed the lowest environmental impacts by far, with the effects being reduced by approximately 70% in all impact categories compared to the highest impact type (CSP: system S3). Then, CPB was the best choice in urban environments, but these blocks may have functional and maintenance problems, depending on the use conditions. In light of this finding, redesigning sidewalks using environmental criteria brought significant benefits.

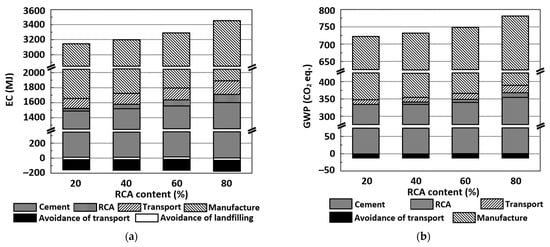

The research by Luo et al. [29] tested concrete mixtures put into built-in molds of manufacturing machinery to produce CPB being compacted to a height of 60 mm, using a vibrational pressure with a frequency of 90 Hz. Furthermore, Figure 18 compares the energy consumption (EC), global warming potential (GWP), saved land occupation, and saved the land transformation for the CPB with 20–80% RCA content.

Figure 18.

LCA results of concrete blocks with various amounts of RCAs (adapted from [29]). (a) EC, (b) GWP, (c) Saved land occupation, (d) Saved land transformation.

LCA demonstrated that the EC of the CPBs with 80% RCA rose by 9.80% compared to 20% RCA, while changing the RCA content from 20% to 80% increased the GWP by 8.10%. Furthermore, the area of the saved land occupation and transformation decreased by 17.15% and increased by 11.56%, respectively, when the RCA content changed from 20% to 80%. Then, the crushing process was needed to obtain RCAs, which meant a higher EC in the extraction phase for CPBs with more recycled materials. However, considering the land saving, a CPB with 80% RCA could be recommended in practice, saving 0.55 m2 of land resources and being 5.36% higher than 20% RCA.

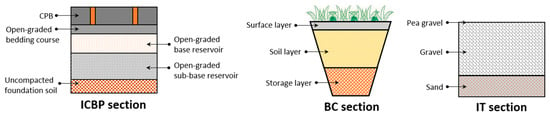

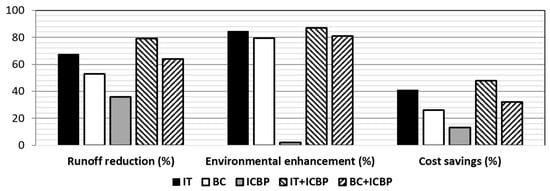

Analyzing the research by Abdeljaber et al. [132], firstly, Figure 19 shows cross-sections of the scenarios: ICBP, bioretention cells (BC), and infiltration trenches (ITs). Then, Figure 20 demonstrates the benefits of all scenarios compared to an equivalent conventional pipe drainage network with AP in terms of runoff reduction, environmental enhancement, and cost savings.

Figure 19.

Cross-sections of the sections BC, IT, and ICBP (adapted from [132]).

Figure 20.

Summary of the scenarios for runoff reduction, environmental enhancement, and cost savings compared to the baseline scenario with AP (adapted from [132]).

The technical analysis showed that the scenarios significantly decreased the runoff by minimizing the waterproof cover and introducing natural filtration and storage systems. Furthermore, the financial feasibilities of IT, BC, and ICBP with the net present costs of $11.6, $14.5, and $17.0 million, respectively, were concluded. Combining ICBP with IT and BC reduced the net present cost by about 48% and 32%, respectively. In addition, the study demonstrated that hybrid scenarios with IT + ICBP and BC + ICBP reduced runoff significantly compared to the conventional system with AP by 78.2% and 63.5%, respectively. ICBP with IT and BC lowered the environmental impacts by 84% and 79%, respectively. Finally, all scenarios had lower environmental impacts and were more cost-effective than conventional stormwater, encouraging implementation.

7. Conclusions

This review addressed the performance analysis from ICBP to AP with by-products such as coconut fibers and recycled materials from civil construction, regarding mechanical, sustainability, permeability, design, and LCA characteristics. The authors worked extensively in AP with by-products [21,51,52,62,64,65,66,104,124], and are recently searching to involve ICBP with by-products [8] in practical solutions for urban light-traffic pavements. These years of work in paving technologies have induced the need to make available more sustainable solutions, and have justified the present review.

Based on mechanical performance, some mixture parameters, e.g., aggregate packing, and mixing temperature, can improve the properties of AC and CPBs, such as stiffness, fatigue resistance, and fc. Furthermore, applying recycled aggregates from CDW and coconut fibers in CPBs and AC is technically possible, which provides environmental and economic benefits for the company responsible for pavement construction.

Based on the pavement’s sustainability, studies about HIE have shown that CPBs absorb less thermal energy due to a higher albedo than AC, which contributes to lower temperatures. In addition, as concrete for CPBs has pores in its structure, the pollutants can be retained inside the ICBP surface layer using filtration, sedimentation, and microbial removal.

Concerning the pavements’ permeability, as most conventional APs are impervious, a solution involved applying porous pavement (ICBP), which is considered to be a cost-effective stormwater management practice. According to the structural designs of pavements, because a fully equal performance of ICBP and AP is almost impossible, it is necessary to develop software for each structure. Regarding the pavement evaluation based on the LCA outputs, ICBP technology is an attractive alternative for light traffic in terms of the maintenance costs.

This review allows for the following direct inferences:

- Mix parameters (Section 2.1): fc was increased by 156% for CPB with appropriate packing optimization. Gyratory compaction was enough for an adequate air void range (3–5%) for AC, according to studies found in the literature. Furthermore, a higher mixing temperature led to a lower clustering of RAP in an AC, which contributed to a more isotropic spatial distribution of the aggregates, and then better AC mechanical and durability properties;

- Influence of by-products (Section 2.2): For AC with RCAs, alternative mixes showed 13–45% higher results for the tests of Marshall stability than the control mix, according to studies found in the literature. Furthermore, applying fibers contributed to a 10.52% increase in fc and a 45% increase in abrasion resistance for CPB, according to research in the literature;

- HIE effect (Section 3.1): ICBP was approximately cooler than AP by 2.2–15.0 °C, based on studies found in the literature, which implied that reflective pavement mitigated the HIE and improved human thermal comfort. However, ICBP might show a faster temperature rise when the surrounding buildings absorb the reflected solar radiation using ICBP;

- Contaminant concentrations (Section 3.2): ICBP and AP had the most effective contaminant removal rates for Pb (70–98%) and Fe (64–90%), but NO2– + NO3– (nitrogen oxides) concentrations in the AP infiltrates were 32% lower than in ICBP, according to studies found in the literature. Then, for better ICBP construction practices, the riparian buffer was highlighted for denitrification;

- Stormwater management (Section 4): The runoff reduction by permeable pavements averaged 35% to 41% in SWMM simulations, but the rate decreased when the rainfall intensity increased, based on studies found in the literature. Furthermore, permeable ICBP showed permeability or infiltration rate results higher than porous AP by 0.4–0.6 cm/s, but the rate decreased over the months, indicating the need for more frequent routine maintenance;

- Structural design (Section 5): Software developed for each pavement (FlexPAVE and MeDiNa for AP, PICP tool, and DesignPave for ICBP) were used to provide information such as fatigue cracking, stress–strength ratios, and the quantity of materials for the structures. Then, the design made using mechanistic–empirical programs assisted in the pavement’s long-term viability compared to empirical design methods;

- LCA (Section 6): ICBP was approximately 33–44% cheaper than AP in the maintenance phase. However, AP was around 35% cheaper during the construction phase (mainly due to energy consumption). Furthermore, in ICBP construction, cement production and CPB manufacturing took up about 50% and 48% of the total embodied energy, respectively, according to studies found in the literature. In addition, the by-products are alternatives for reducing costs for pavement construction. In a field application, warm AC with RAP and RCAs was 5–8% less costly (direct and environmental) than a conventional hot AC.

8. Future Directions

Table 11 presents future directions or recommendations for further research in each review section, which can be incorporated into pavement planning, design, and maintenance decision-making.

Table 11.

Future directions or recommendations for further research.

Finally, the recommendations in Table 11 benefit other ICBP experimental applications with recycled materials to effectively evaluate the pavement’s behavior for different conditions. For example, the authors are presently developing ICBP solutions using recycled materials from CDW and coconut fibers.

Author Contributions

Conceptualization, W.S. and S.B.; methodology, W.S.; validation, W.S.; formal analysis, W.S., A.E.C. and L.P.-S.; investigation, W.S. and L.P.-S.; resources, L.P.-S.; writing—original draft preparation, WS; writing—review and editing, S.B., A.E.C., L.P.-S. and R.S.; supervision, L.P.-S. and R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001. It is also part of the research activity carried out at the Civil Engineering Research and Innovation for Sustainability (CERIS) research center of Instituto Superior Técnico da Universidade de Lisboa, which received financial support from the Fundação para a Ciência e a Tecnologia (FCT) in the framework of project UIDB/04625/2020.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript.

| 1.4–DB | Dichlorobenzene | IT | Infiltration trenches |

| AC | Asphalt concrete | K | Potassium |

| ADP | Abiotic depletion potential | LCA | Life Cycle Assessment |

| AP | Asphalt pavement | LCC | Life Cycle Cost |

| APO | Acidification potential | LDPE | Low-density polyethylene |

| BC | Bioretention cells | MeDiNa | National Design Method |

| C2H4 | Ethylene | Mg | Magnesium |

| Ca | Calcium | Mn | Manganese |

| CCP | Continuous concrete pavement | Na | Sodium |

| Cd | Cadmium | NH3 | Ammonia |

| CDW | Construction and demolition waste | NO2– | Nitrite |

| CFC–11 | Trichlorofluoromethane | NO3– | Nitrate |

| CO2 | Carbon dioxide | NOx | Nitrogen oxides |

| COD | Chemical oxygen demand | ODP | Ozone layer depletion potential |

| CPBs | Concrete paving blocks | Pb | Lead |

| CSP | Concrete slab pavement | PET | Polyethylene terephthalate |

| Cu | Copper | PICP | Permeable Interlocking Concrete Pavement |

| DesignPave | Design of Concrete Block Pavements | PO43– | Phosphate |

| EC | Energy consumption | POCP | Photochemical ozone creation potential |

| Em | Elasticity modulus | RAP | Recycled asphalt pavement |

| EP | Eutrophication potential | RCAs | Recycled concrete aggregates |

| ES | Excavated soil | Sb | Antimony |

| fc | Compressive strength | SO2 | Sulfur dioxide |

| Fe | Iron | SWMM | Stormwater management model |

| FlexPAVE | Flexible Pavement | TiO2 | Titanium dioxide |

| FWD | Falling Weight Deflectometer | TN | Total nitrogen |

| GWP | Global warming potential | TP | Total phosphorus |

| HIE | Heat island effect | TSS | Total suspended solids |

| HTP | Human toxicity potential | wa | Water absorption |

| ICBP | Interlocking concrete block pavement | Zn | Zinc |

| IRI | International Roughness Index |

References

- Dietz, M.E. Low Impact Development Practices: A Review of Current Research and Recommendations for Future Directions. Water Air Soil Pollut. 2007, 186, 351–363. [Google Scholar] [CrossRef]

- Scholz, M.; Grabowiecki, P. Review of permeable pavement systems. Build. Environ. 2007, 42, 3830–3836. [Google Scholar] [CrossRef]

- Jamshidi, A.; Kurumisawa, K.; White, G.; Nishizawa, T.; Igarashi, T.; Nawa, T.; Mao, J. State-of-the-art of interlocking concrete block pavement technology in Japan as a post-modern pavement. Constr. Build. Mater. 2019, 200, 713–755. [Google Scholar] [CrossRef]

- Panda, B.C.; Ghosh, A.K. Structural Behavior of Concrete Block Paving. I: Sand in Bed and Joints. J. Transp. Eng. 2002, 128, 123–129. [Google Scholar] [CrossRef]

- Shackel, B. The evolution and application of mechanistic design procedures for concrete block pavements. In Proceedings of the SEPT Third International Conference on Concrete Block Paving, Rome, Italy, 17–19 May 1988. [Google Scholar]

- Sivakumar, M.; Ramachandran, A.; Palaninathan, J.; Ranjitha, K. Investigation of Geopolymer Paver Block using Plastic Waste. Int. Res. J. Eng. Technol. 2021, 8, 770–774. [Google Scholar]

- Cruz, L.O.M. Interlocking Concrete Pavement: Study of Elements and Design Methods. Master’s Thesis, Federal University of Rio de Janeiro, Rio de Janeiro, Brazil, 2003. (In Portuguese). [Google Scholar]

- Silva, W.B.C. Analysis of the Feasibility of Manufacturing Interlocking Concrete Paving Blocks with the Use of Waste from Thermal Power Plants and Recycled Aggregates from the Construction Industry. Master’s Thesis, Federal University of Ceara, Fortaleza, Brazil, 2020. (In Portuguese). [Google Scholar]

- Morgado, P.R.S. Conception and Design of Block Pavements. Master’s Thesis, Instituto Superior Técnico, Universidade de Lisboa, Lisboa, Portugal, 2008. (In Portuguese). [Google Scholar]

- ABNT NBR 9781; Concrete Paving Units—Specification and Test Methods. Brazilian National Standards Organization: Rio de Janeiro, Brazil; ABNT: Rio de Janeiro, Brazil, 2013. (In Portuguese)

- ASTM C936; Standard Specification for Solid Concrete Interlocking Paving Units. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2022.

- CEN EN 1338; Concrete Paving Blocks—Requirements and Test Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2003.

- AS/NZS 4456.4; Masonry Units and Segmental Pavers and Flags—Methods of Test—Determining Compressive Strength of Masonry Units. Standards Australia (SA): Sydney, Australia, 2003.

- CNSA GB 28635; Precast Concrete Paving Units. China National Standardization Administration (CNSA): Shenzhen, China, 2012.

- Poon, C.S.; Chan, D. Effects of contaminants on the properties of concrete paving blocks prepared with recycled concrete aggregates. Constr. Build. Mater. 2007, 21, 164–175. [Google Scholar] [CrossRef]

- Hossiney, N.; Sepuri, H.K.; Mohan, M.K.; Chandra, K.S.; Kumar, S.L.; H K, T. Geopolymer concrete paving blocks made with Recycled Asphalt Pavement (RAP) aggregates towards sustainable urban mobility development. Cogent Eng. 2020, 7, 1824572. [Google Scholar] [CrossRef]

- Bang, T.C. Study on Fly Ash Based Interlocking Concrete Paver Block Using Chopped Fibers. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Chennai, India, 25–26 September 2020; Volume 988, p. 012060. [Google Scholar] [CrossRef]

- Eco Nordeste. Rubble Becomes Construction Material Again. Available online: http://agenciaeconordeste.com.br/entulho-volta-a-ser-material-de-construcao/ (accessed on 28 August 2022). (In Portuguese).

- Sáez, P.V.; Osmani, M. A diagnosis of construction and demolition waste generation and recovery practice in the European Union. J. Clean. Prod. 2019, 241, 118400. [Google Scholar] [CrossRef]

- Santos, M.T.; Lamego, P.; Frade, P. Management Options for Construction and Demolition Wastes from Residential Recuperation. Waste Biomass Valorization 2017, 8, 1679–1687. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J. Cement-treated pavement layers incorporating construction and demolition waste and coconut fibres: A review. Int. J. Pavement Eng. 2022, 23, 4877–4896. [Google Scholar] [CrossRef]

- Brito, J.R. Effect of Adding Coconut Fibers in Cemented Mixtures with Recycled Aggregates for Pavement Sublayers. Master’s Thesis, Federal University of Ceara, Fortaleza, Brazil, 2022. (In Portuguese). [Google Scholar]

- Carrijo, O.A.; De Liz, R.S.; Makishima, N. Fiber of green coconut shell as an agricultural substrate. Hortic. Bras. 2002, 20, 533–535. [Google Scholar] [CrossRef]

- Corradini, E.; Rosa, M.F.; Macedo, B.P.; Paladin, P.D.; Mattoso, L.H.C. Chemical composition, thermal and mechanical properties for cultivars of immature coconut fibers. Rev. Bras. Frutic. 2009, 31, 837–846. [Google Scholar] [CrossRef]

- Francisco, J.T.M.; De Souza, A.E.; Teixeira, S.R. Construction and demolition waste in concrete: Property of pre-molded parts for paving. Cerâmica 2019, 65 (Suppl. S1), 22–26. [Google Scholar] [CrossRef]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Performance of concrete made with recycled aggregates from Portuguese CDW recycling plants. Key Eng. Mater. 2014, 634, 193–205. [Google Scholar] [CrossRef]

- Scheffer, J.C.; Andrade, R.G.M.; Reis, A.S. Experimental evaluation of green coconut fibre reinforced concrete blocks as interlocking paver. Rev. Mundi Eng. Tecnol. Gestão 2018, 3, 80-1–80-18. (In Portuguese) [Google Scholar] [CrossRef]

- Cravidão, J.M.M.C.M. Economic Comparison of New Fibre Placement Methods—Dry Fibre Placement and Tailored Fibre Placement. Master’s Thesis, Instituto Superior Técnico, Universidade de Lisboa, Lisboa, Portugal, 2021. [Google Scholar]

- Luo, W.; Liu, S.; Hu, Y.; Hu, D.; Kow, K.-W.; Pang, C.; Li, B. Sustainable reuse of excavated soil and recycled concrete aggregate in manufacturing concrete blocks. Constr. Build. Mater. 2022, 342, 127917. [Google Scholar] [CrossRef]

- Özalp, F.; Yılmaz, H.D.; Kara, M.; Kaya, Ö.; Şahin, A. Effects of recycled aggregates from construction and demolition wastes on mechanical and permeability properties of paving stone, kerb and concrete pipes. Constr. Build. Mater. 2016, 110, 17–23. [Google Scholar] [CrossRef]

- Mudiyono, R.; Sudarno, S. The Influence of Coconut Fiber on the Compressive and Flexural Strength of Paving Blocks. Eng. Technol. Appl. Sci. Res. 2019, 9, 4702–4705. [Google Scholar] [CrossRef]

- Gamage, S.; Palitha, S.; Meddage, D.P.P.; Mendis, S.; Azamathulla, H.M.; Rathnayake, U. Influence of Crumb Rubber and Coconut Coir on Strength and Durability Characteristics of Interlocking Paving Blocks. Buildings 2022, 12, 1001. [Google Scholar] [CrossRef]

- Shackel, B. Design and Construction of Interlocking Concrete Block Pavements, 1st ed.; Elsevier Applied Science: London, UK; New York, NY, USA, 1990. [Google Scholar]

- Hallack, A. Design of Pavements with Precast Concrete Coating for Port and Industrial Areas. Master’s Thesis, University of Sao Paulo, Sao Paulo, Brazil, 1999. (In Portuguese). [Google Scholar]

- Shackel, B. Computer based procedures for the design and specification of concrete block pavements. In Proceedings of the SEPT Fourth International Conference on Concrete Block Paving, Auckland, New Zealand, 16–19 February 1992. [Google Scholar]

- Akbari, H.; Rose, L.S.; Taha, H. Characterizing the Fabric of the Urban Environment: A Case Study of Sacramento, 1st ed.; Environmental Protection Agency: Berkeley, CA, USA, 1999. [Google Scholar] [CrossRef]

- Brattebo, B.O.; Booth, D.B. Long-term stormwater quantity and quality performance of permeable pavement systems. Water Res. 2003, 37, 4369–4376. [Google Scholar] [CrossRef]

- Li, H.; Harvey, J.T.; Holland, T.J.; Kayhanian, M. The use of reflective and permeable pavements as a potential practice for heat island mitigation and stormwater management. Environ. Res. Lett. 2013, 8, 015023. [Google Scholar] [CrossRef]

- Singare, P.U.; Trivedi, M.P.; Mishra, R.M. Assessing the Physico-Chemical Parameters of Sediment Ecosystem of Vasai Creek at Mumbai, India. Mar. Sci. 2011, 1, 22–29. [Google Scholar] [CrossRef]

- Weiss, P.T.; Kayhanian, M.; Gulliver, J.S.; Khazanovich, L. Permeable pavement in northern North American urban areas: Research review and knowledge gaps. Int. J. Pavement Eng. 2019, 20, 143–162. [Google Scholar] [CrossRef]

- Abdollahian, S.; Kazemi, H.; Rockaway, T.; Gullapalli, V. Stormwater quality benefits of permeable pavement systems with deep aggregate layers. Environments 2018, 5, 68. [Google Scholar] [CrossRef]

- Chu, S.H.; Poon, S.C.; Lam, C.S.; Li, L. Effect of natural and recycled aggregate packing on properties of concrete blocks. Constr. Build. Mater. 2021, 278, 122247. [Google Scholar] [CrossRef]

- Rodriguez-Hernandez, J.; Andrés-Valeri, V.C.; Ascorbe-Salcedo, A.; Castro-Fresno, D. Laboratory study on the stormwater retention and runoff attenuation capacity of four permeable pavements. J. Environ. Eng. 2016, 142, 04015068. [Google Scholar] [CrossRef]

- Fuller, W.B.; Thompson, S.E. The laws of proportioning concrete. Trans. Am. Soc. Civ. Eng. 1907, 59, 67–143. [Google Scholar] [CrossRef]

- Lees, G. The rational design of aggregate gradings for dense asphaltic compositions. J. Assoc. Asph. Paving Technol. 1970, 39, 60–97. [Google Scholar]

- Al-Hdabi, A.; Nageim, H.A.; Seton, L. Performance of gap graded cold asphalt containing cement treated filler. Constr. Build. Mater. 2014, 69, 362–369. [Google Scholar] [CrossRef]

- Gardete, D.; Picado-Santos, L.; Capitão, S.; Luzia, R. Asphalt mix design: Discussion on the bulk specific gravity procedure influence on the results obtained from empirical, volumetric, and performance-based methods. Constr. Build. Mater. 2022, 342, 127870. [Google Scholar] [CrossRef]

- Navaro, J.; Bruneau, D.; Drouadaine, I.; Colin, J.; Dony, A.; Cournet, J. Observation and evaluation of the degree of blending of reclaimed asphalt concretes using microscopy image analysis. Constr. Build. Mater. 2012, 37, 135–143. [Google Scholar] [CrossRef]

- Bressi, S.; Cavalli, M.C.; Partl, M.N.; Tebaldi, G.; Dumont, A.G.; Poulikakos, L.D. Particle clustering phenomena in hot asphalt mixtures with high content of reclaimed asphalt pavements. Constr. Build. Mater. 2015, 100, 207–217. [Google Scholar] [CrossRef]

- Silva, H.M.R.D.; Oliveira, J.R.M.; Ferreira, C.I.G.; Pereira, P.A.A. Assessment of the Performance of Warm Mix Asphalts in Road Pavements. Int. J. Pavement Res. Technol. 2010, 3, 119–127. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Picado-Santos, L.G.; Capitão, S.D. Influence of recycled concrete and steel slag aggregates on warm-mix asphalt properties. Constr. Build. Mater. 2018, 185, 684–696. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Picado-Santos, L.G.; Capitão, S.D. Feasibility Assessment of the Use of Recycled Aggregates for Asphalt Mixtures. Sustainability 2018, 10, 1737. [Google Scholar] [CrossRef]

- Dash, S.S.; Panda, M. Influence of mix parameters on design of cold bituminous mix. Constr. Build. Mater. 2018, 191, 376–385. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Griffa, M.; Bressi, S.; Partl, M.N.; Tebaldi, G.; Poulikakos, L.D. Multiscale imaging and characterization of the effect of mixing temperature on asphalt concrete containing recycled components. J. Microsc. 2016, 264, 22–33. [Google Scholar] [CrossRef]

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management, 15th ed.; World Bank: Washington, DC, USA, 2012. [Google Scholar]

- Weissheimer, L.F. The influence of the use of stabilized mortar in reducing environmental impacts. Master’s Thesis, University of Bells’ River Valley, Sao Leopoldo, Brazil, 2017. (In Portuguese). [Google Scholar]

- Brasileiro, L.L.; Matos, J.M.E. Literature review: Reuse of construction and demolition waste in the construction industry. Cerâmica 2015, 61, 178–189. [Google Scholar] [CrossRef]

- Angulo, S.C.; Oliveira, L.S.; Machado, L. ABRECON 2020 Sector Research: The Recycling of Construction and Demolition Waste in Brazil, 1st ed.; Epusp: Sao Paulo, Brazil, 2022; (In Portuguese). [Google Scholar] [CrossRef]

- Tam, V.W.Y. Comparing the implementation of concrete recycling in the Australian and Japanese construction industries. J. Clean. Prod. 2009, 17, 688–702. [Google Scholar] [CrossRef]

- Nwakaire, C.M.; Yap, S.P.; Yuen, C.W.; Onn, C.C.; Koting, S.; Babalghaith, A.M. Laboratory study on recycled concrete aggregate based asphalt mixtures for sustainable flexible pavement surfacing. J. Clean. Prod. 2020, 262, 121462. [Google Scholar] [CrossRef]

- Shao, H.; Sun, L.; Liu, L.; You, Z.; Yang, X. A novel double-drum mixing technique for plant hot mix asphalt recycling with high reclaimed asphalt pavement content and rejuvenator. Constr. Build. Mater. 2017, 134, 236–244. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J. Mechanical Performance of Cement Bound Granular Mixtures Using Recycled Aggregate and Coconut Fiber. Appl. Sci. 2022, 12, 1936. [Google Scholar] [CrossRef]

- Avirneni, D.; Peddinti, P.R.T.; Saride, S. Durability and long term performance of geopolymer stabilized reclaimed asphalt pavement base courses. Constr. Build. Mater. 2016, 121, 198–209. [Google Scholar] [CrossRef]

- Rodrigues, C.; Capitão, S.; Picado-Santos, L.; Almeida, A. Full Recycling of Asphalt Concrete with Waste Cooking Oil as Rejuvenator and LDPE from Urban Waste as Binder Modifier. Sustainability 2020, 12, 8222. [Google Scholar] [CrossRef]

- Almeida, A.; Capitão, S.; Bandeira, R.; Fonseca, M.; Picado-Santos, L. Performance of AC mixtures containing flakes of LDPE plastic film collected from urban waste considering ageing. Constr. Build. Mater. 2020, 232, 117253. [Google Scholar] [CrossRef]

- Fonseca, M.; Capitão, S.; Almeida, A.; Picado-Santos, L. Influence of Plastic Waste on the Workability and Mechanical Behaviour of Asphalt Concrete. Appl. Sci. 2022, 12, 2146. [Google Scholar] [CrossRef]

- Ohemeng, E.A.; Yalley, P.P.-K.; Dadzie, J.; Djokoto, S.D. Utilization of Waste Low Density Polyethylene in High Strengths Concrete Pavement Blocks Production. J. Civ. Environ. Res. 2014, 6, 126–135. [Google Scholar]

- Mashudi, I.; Suardana, N.P.G.; Arya Thanaya, I.N.; Bandem Adnyana, I.W.; Kencanawati, C.I.P.K. Compressive strength and truck run over ability of plastic/sand paving block composites. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kuala Lumpur, Malaysia, 2–5 December 2019; Volume 839, p. 012011. [Google Scholar] [CrossRef]

- Gungat, L.; Anthony, F.; Mirasa, A.K.; Asrah, H.; Bolong, N.; Ispal, N.A.; Matlan, S.J. Development of Paver Block Containing Recycled Plastic. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Batu Pahat, Malaysia, 1–2 December 2020; Volume 1144, p. 012094. [Google Scholar] [CrossRef]

- Shao-peng, W.; Gang, L.; Lian-tong, M.; Zheng, C.; Qun-shan, Y. Effect of fiber types on relevant properties of porous asphalt. Trans. Nonferrous Met. Soc. China 2006, 16 (Suppl. S2), s791–s795. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable composites based on lignocellulosic fibers—An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Martinho, F.; Lanchas, S.; Nunez, R.; Batista, F.; Miranda, H. The Portuguese experience in SMA bituminous mixtures with cellulosic fibers. In Proceedings of the Seventh Portuguese Road Congress, Lisboa, Portugal, 10–12 April 2013. (In Portuguese). [Google Scholar]

- Menon, S.; Akbari, H.; Mahanama, S.; Sednev, I.; Levinson, R. Radiative forcing and temperature response to changes in urban albedos and associated CO2 offsets. Environ. Res. Lett. 2010, 5, 014005. [Google Scholar] [CrossRef]

- Takebayashi, H.; Moriyama, M.; Nishioka, M.; Kimishima, T.; Nabeshima, M.; Kagata, M.; Honda, T. Study on urban heat island mitigation effect based on surface heat budget on environmental consideration type pavements. J. Environ. Eng. 2008, 73, 77–83. [Google Scholar] [CrossRef]

- Shackel, B. The challenges of concrete block paving as a mature technology. In Proceedings of the SEPT Seventh International Conference on Concrete Block Paving, Sun City, South Africa, 12–15 October 2003. [Google Scholar]

- Li, H. Evaluation of Cool Pavement Strategies for Heat Island Mitigation. PhD’s Thesis, University of California, Davis, CA, USA, 2012. [Google Scholar]

- Aoki, H.; Baba, T. Development and practical use of joint sand to inhibit plant germination and growth on block pavements. In Proceedings of the SEPT Seventh International Conference on Concrete Block Paving, Sun City, South Africa, 12–15 October 2003. [Google Scholar]

- Almeida, A.; Picado-Santos, L. Asphalt Road Pavements to Address Climate Change Challenges—An Overview. Appl. Sci. 2022, 12, 12515. [Google Scholar] [CrossRef]

- Hendel, M. 6—Cool pavements. In Eco-Efficient Pavement Construction Materials, 1st ed.; Pacheco-Torgal, F., Amirkhanian, S., Wang, H., Schlangen, E., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 97–125. [Google Scholar]

- Luo, Y.; Zhang, Z.; Cheng, G.; Zhang, K. The deterioration and performance improvement of long-term mechanical properties of warm-mix asphalt mixtures under special environmental conditions. Constr. Build. Mater. 2017, 135, 622–631. [Google Scholar] [CrossRef]

- Kevern, J.T.; Schaefer, V.R.; Wang, K. Temperature Behavior of Pervious Concrete Systems. Transp. Res. Rec. 2009, 2098, 94–101. [Google Scholar] [CrossRef]

- Baghban, H.; Arulrajah, A.; Narsilio, G.A.; Horpibulsuk, S. Evaluating the effective thermal conductivity of geothermal pavements constructed using demolition wastes by DEM and 3D printing techniques. Acta Geotech. 2022, 17, 1681–1697. [Google Scholar] [CrossRef]

- Cheng, Y.-Y.; Lo, S.-L.; Ho, C.-C.; Lin, J.-Y.; Yu, S.L. Field Testing of Porous Pavement Performance on Runoff and Temperature Control in Taipei City. Water 2019, 11, 2635. [Google Scholar] [CrossRef]

- Shimazaki, Y.; Aoki, M.; Karaki, K.; Yoshida, A. Improving outdoor human-thermal environment by optimizing the reflectance of water-retaining pavement through subjective field-based measurements. Build. Environ. 2022, 210, 108695. [Google Scholar] [CrossRef]

- Tirpak, A.; Winston, R.J.; Feliciano, M.; Dorsey, J.D. Stormwater quality performance of permeable interlocking concrete pavement receiving run-on from an asphalt traffic lane in a cold climate. Environ. Sci. Pollut. Res. 2020, 27, 21716–21732. [Google Scholar] [CrossRef] [PubMed]

- NYCRR Part 703. Surface Water and Groundwater Quality Standards and Groundwater Effluent Limitations. In New York Codes, Rules and Regulations; NYCRR: New York, NY, USA, 2021.

- Environmental Protection Agency. Nitrification; EPA: Washington, DC, USA, 2002.

- Razzaghmanesh, M.; Borst, M. Long-term effects of three types of permeable pavements on nutrient infiltrate concentrations. Sci. Total Environ. 2019, 670, 893–901. [Google Scholar] [CrossRef]

- Gilbert, J.K.; Clausen, J.C. Stormwater runoff quality and quantity from asphalt, paver, and crushed stone driveways in Connecticut. Water Res. 2006, 40, 826–832. [Google Scholar] [CrossRef]

- Drake, J.; Bradford, A.; Van Seters, T. Hydrologic Performance of Three Partial-Infiltration Permeable Pavements in a Cold Climate over Low Permeability Soil. J. Hydrol. Eng. 2014, 19, 04014016. [Google Scholar] [CrossRef]

- Bean, E.Z.; Hunt, W.F.; Bidelspach, D.A. Evaluation of Four Permeable Pavement Sites in Eastern North Carolina for Runoff Reduction and Water Quality Impacts. J. Irrig. Drain. Eng. 2007, 133, 583–592. [Google Scholar] [CrossRef]

- Fujishima, A.; Honda, K. Electrochemical Photolysis of Water at a Semiconductor Electrode. Nature 1972, 238, 37–38. [Google Scholar] [CrossRef]

- Witkowski, H.; Jackiewicz-Rek, W.; Chilmon, K.; Jarosławski, J.; Tryfon-Bojarska, A.; Gąsiński, A. Air Purification Performance of Photocatalytic Concrete Paving Blocks after Seven Years of Service. Appl. Sci. 2019, 9, 1735. [Google Scholar] [CrossRef]

- Beeldens, A. An environmental friendly solution for air purification and self-cleaning effect: The application of TiO2 as photocatalyst in concrete. In Proceedings of the TRA First Transport Research Arena, Göteborg, Sweden, 12–15 June 2006. [Google Scholar]

- Nath, R.K.; Zain, M.F.M.; Jamil, M. An environment-friendly solution for indoor air purification by using renewable photocatalysts in concrete: A review. Renew. Sustain. Energy Rev. 2016, 62, 1184–1194. [Google Scholar] [CrossRef]

- Zhang, K.; Yong, F.; McCarthy, D.T.; Deletic, A. Predicting long term removal of heavy metals from porous pavements for stormwater treatment. Water Res. 2018, 142, 236–245. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Borst, M. Performances of metal concentrations from three permeable pavement infiltrates. Water Res. 2018, 136, 41–53. [Google Scholar] [CrossRef]

- Borst, M. Green Infrastructure Research: Permeable Pavement at EPA’S Edison Environmental Center, 1st ed.; Environmental Protection Agency: Washington, DC, USA, 2016. [Google Scholar]

- Rodríguez-Rojas, M.I.; Huertas-Fernández, F.; Moreno, B.; Martínez, G. Middle-Term Evolution of Efficiency in Permeable Pavements: A Real Case Study in a Mediterranean climate. Int. J. Environ. Res. Public Health 2020, 17, 7774. [Google Scholar] [CrossRef]

- Alsubih, M.; Arthur, S.; Wright, G.; Allen, D. Experimental study on the hydrological performance of a permeable pavement. Urban Water J. 2017, 14, 427–434. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, D.; Cheng, Y.; Tan, S.K. Assessing performance of porous pavements and bioretention cells for stormwater management in response to probable climatic changes. J. Environ. Manag. 2019, 243, 157–167. [Google Scholar] [CrossRef]

- Ito, N.; Yazawa, S.; Arai, S. Follow-up survey of permeable interlocking blocks applied to the roadway in cold, snowy areas. In Proceedings of the SEPT Sixth International Conference on Concrete Block Paving, Tokyo, Japan, 6–8 November 2000. [Google Scholar]

- Huang, J.; He, J.; Valeo, C.; Chu, A. Temporal evolution modeling of hydraulic and water quality performance of permeable pavements, Journal of Hydrology. J. Hydrol. 2016, 533, 15–27. [Google Scholar] [CrossRef]

- Picado-Santos, L.G.; Capitão, S.D.; Dias, J.L.F. Crumb rubber asphalt mixtures by dry process: Assessment after eight years of use on a low/medium trafficked pavement. Constr. Build. Mater. 2019, 215, 9–21. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, S.; Hu, G.; Yang, T.; Du, C.; Oeser, M. Infiltration Capacity and Structural Analysis of Permeable Pavements for Sustainable Urban: A Full-scale Case Study. J. Clean. Prod. 2021, 288, 125111. [Google Scholar] [CrossRef]

- Scholz, M. Water Quality Improvement Performance of Geotextiles Within Permeable Pavement Systems: A Critical Review. Water 2013, 5, 462–479. [Google Scholar] [CrossRef]

- Wang, J.; Meng, Q.; Zou, Y.; Qi, Q.; Tan, K.; Santamorius, M.; He, B.-J. Performance synergism of pervious pavement on stormwater management and urban heat island mitigation: A review of its benefits, key parameters, and co-benefits approach. Water Res. 2022, 221, 118755. [Google Scholar] [CrossRef]

- Kasahara, A.; Matsuno, S. Estimation of apparent elastic modulus of concrete block layer. In Proceedings of the SEPT Third International Conference on Concrete Block Paving, Rome, Italy, 17–19 May 1988. [Google Scholar]

- Algin, H.M. Interlock Mechanism of Concrete Block Pavements. J. Transp. Eng. 2007, 133, 318–326. [Google Scholar] [CrossRef]

- White, G. Shear stresses in an asphalt surface under various aircraft braking conditions. Int. J. Pavement Res. Technol. 2016, 9, 89–101. [Google Scholar] [CrossRef]

- Miura, Y.; Takaura, M.; Tsuda, T. Structural design of concrete block pavements by CBR method and its evaluation. In Proceedings of the SEPT Second International Conference on Concrete Block Paving, Delft, The Netherlands, 10–12 April 1984. [Google Scholar]

- Nishizawa, T.; Furukawa, M.; Nagata, K.; Hyodo, H.; Ueda, N. A structural model of interlocking concrete block pavements for heavy duty roads. J. Jpn. Soc. Civ. Eng. 2017, 73, I_27–I_34. [Google Scholar] [CrossRef]

- Lin, W.; Cho, Y.H.; Kim, I.T. Development of Deflection Prediction Model for Concrete Block Pavement Considering the Block Shapes and Construction Patterns. Adv. Mater. Sci. Eng. 2016, 2016, 5126436. [Google Scholar] [CrossRef]

- Oshone, M.; Mensching, D.J.; Daniel, J.S.; McCarthy, L.M. Comparative evaluation of mechanistic–empirical performance models as a tool for establishing pavement performance specifications. Road Mater. Pavement Des. 2019, 20, 895–913. [Google Scholar] [CrossRef]

- Fritzen, M.A. Development and Validation of a Transfer Function for Predicting Fatigue Damage in Asphalt Pavements. PhD’s Thesis, Federal University of Rio de Janeiro, Rio de Janeiro, Brazil, 2016. (In Portuguese). [Google Scholar]

- Li, H.; Jones, D.; Wu, R.; Harvey, J.T. Development and HVS Validation of Design Tables for Permeable Interlocking Concrete Pavement: Final Report, 1st ed.; Concrete Masonry Association of California and Nevada: Davis, CA, USA, 2014. [Google Scholar]

- Rahman, M.M.; Beecham, S.; Mclntyre, E.; Iqbal, A. Mechanistic design of concrete block pavements. In Proceedings of the 2018 Australian Geomechanics Society Victorian Symposium, Melbourne, Australia, 24 October 2018. [Google Scholar]

- Nemati, R.; Dave, E.V.; Sias, J.E.; Thibodeau, E.S.; Worsman, R.K. Evaluation of Laboratory Performance and Structural Contribution of Cold Recycled Versus Hot Mixed Intermediate and Base Course Asphalt Layers in New Hampshire. Transp. Res. Rec. 2019, 2673, 467–476. [Google Scholar] [CrossRef]