Abstract

During antiquity, it is known that glass was produced in specialized primary workshops in Levant and Egypt, and this glass was melted and formed into objects in secondary workshops, and distributed in most cities and towns of the Roman Empire. Great efforts, although it is difficult, have been made to distinguish where it was produced. In this study, we perform chemical analysis on 48 glass samples (22 moils and 26 glass artefacts) dated to the 6th century CE from Vasileos Irakleiou Street, 45, Thessaloniki in northern Greece by using Scanning Electron Microscopy (SEM) with Energy–Dispersive X-ray microanalysis (EDX). All glasses were produced with natron as a flux and based on the sodium oxide content we divided them into two groups. Most of the glasses’ chemical analysis indicates that they originated from Egypt, and can be categorized as HIMT and others as Roman Mn or Roman Mn-Sb. MnO is the main decolorizer, while in some samples MnO coexists with Sb2O3. Finally, recycling processes are evident in most of the samples.

Keywords:

ancient glass; glass recycling; glass provenance; natron glass; HIMT; colorants; Roman glass 1. Introduction

Glass production in ancient times required three basic components. The main material was a network former (silica source), usually quartz–limestone sand or quartz pebbles, the second was a flux, for example natron (soda–lime–silica glass), or soda ash from halophytic plants (such as Salsola kali or Salicornia), or potash ash from trees (oak, beech, birch), and the third was a stabilizer, usually limestone or sea shells (which sometimes the sand already contained) [1]. The natron type glass (soda–lime–silica glass), which is characterized by the low magnesium and potassium content, used to be the dominant type of glass from the 10th century B.C. until almost the 9th century A.D. [2,3,4,5].

During the Roman and early Byzantine period, within natron type glasses, two new types of glass were making their way to the glass industry. The first type is called HIMT (High Iron Manganese and Titanium) glass, because of the high contents of these three elements [6], and it was possibly produced using a silica source originating from Egypt [7,8,9,10]. The main reason the HIMT type glass began to become in demand was probably because of its lower sand quality, which could suggest a lower price [11,12]. The second type is called Levantine I glass and its silica source came from the Syro–Palestinian coast [11,13,14,15].

In the same period, the production of glass was intense, thus there was an imperative need for large quantities of raw materials and production sites. According to Freestone 2008 [16], the production sites were either primary or secondary. Primary workshops produced raw glass by processing the raw materials (i.e., sand and natron). Afterwards, this raw glass was broken into chunks and then the chunks were transferred to secondary workshops where glass artefacts were made [13,14,17,18]. This production theory is suggested by Pliny the Elder in his Naturalis Historia [16] and by several archaeological excavations on the Syro–Palestinian coast [12,13,19], in Egypt [20,21], Greece [22,23], France and the United Kingdom [24,25].

The glass imported in Greece (mainly from the 1st to 6th century A.D.) was coming from primary workshops in Egypt and Near East sites and was fused locally to produce artefacts. Nonetheless, in Thessaloniki during the Late Roman period, the manufacture of glass artefacts was verified by Antonaras 2011 [26], and it also seems that in Northern Greece (Macedonia) the glass products were plentiful [27]. The existence of different primary and secondary workshops makes distinguishing between local and foreign production of the glasses difficult, thus it is very important to chemically analyze the glass as this can give us information not only about their components but also on the production technologies and consequently on the origin of raw materials [9,23,25,28,29,30,31,32,33,34,35]. Such information can also provide us with economic, cultural and social connections between the different geo-political Eastern Mediterranean regions during antiquity.

Therefore, the existence in Greece of local production centers of glasses, as well as the trade of raw materials and glass artefacts which were probably produced in Near-East or Middle-East countries, draws attention to the importance of trying to identify the origin of Late Antique glass objects produced in Greece, to distinguish the different raw materials and fluxes used for glass production, and to define the production technologies.

The Site

Recent excavations in Thessaloniki’s center have unearthed two sites dated from the late 3rd century A.D. The eastern site was a glass workshop from the late 5th to 7th century A.D. In addition, Antonaras, 2011 [26] suggested that there were at least three other glass workshops between the 4th and the 6th century A.D. Other glass workshops appear to be active on the site of the eastern necropolis, very close to the city walls and probably on the road leading from the main eastern city gate towards the hinterland. The selected pieces of glass were recovered from the excavation of a late-6th century CE secondary glass workshop. This is the first and, for the time being, the only Late Roman–Early Byzantine glass-working site that has been archaeologically investigated in Thessaloniki. It was situated in a corner shop at a crossroad in the city’s center [36]. Three glass furnaces, at least one of them with several phases of use, were revealed, in addition to a large number of glass finds (in total weighing ca 3 kg, approx. 97% greenish and 3% bluish): wasters (distorted vessels, e.g., stemmed beakers and stemmed lamps) [37,38], oversized glass gems [39] and other working remains (raw glass, testing droplets, moils, cullet, i.e., broken pieces of glass vases and window panes, for recycling) [36]. A total of 48 samples of all characteristic products and types (22 moils and 26 artefacts) of working remains, dated to the 6th century CE from Vasileos Irakleiou Street, 45, Thessaloniki, Greece, were selected for analytical research.

Thus, in this article, we are trying to identify from which primary workshop the moils originated and whether the artefacts were produced in the local workshops or not. Furthermore, this is the first batch of glass samples studied from this site and the outcome could provide the basis for future studies of similar glass samples. Finally, this work could contribute to the knowledge of the manufacturing technology of ancient glass (which ingredients/raw materials/natural materials were used) in order to preserve other ancient glass artefacts/monuments with the same ancient technology instead of using modern techniques. Furthermore, providing information of economic, cultural and social relationships could give explanations and will expand the existing knowledge of archaeological facts and history.

2. Materials and Methods

2.1. Materials

In this study, 48 glasses dated from the 6th century CE were examined and are divided into 22 moils and 26 glass artefacts. Most of the glasses are light green, five are light yellow, two are light blue, two are blue and thirteen of them are colorless. In Figure 1 we present some of our samples.

Figure 1.

Representative photos of our samples.

2.2. Methods

Chemical analysis was performed by Scanning Electron Microscopy (SEM) with Energy–Dispersive X-ray microanalysis (EDX). Energy Dispersive X-ray Spectroscopy (EDS or EDX) calculated element concentrations based on the energy measurement of X-rays. The X-Rays are produced after an electron beam strikes the given point or area. Electrons from inner shells are released, and outer shell electrons cover their positions. The X-ray has a specific energy that is equal to the energy difference between the two shells and is characteristic to each element. The spectrum is taken at the same time for all energies. All the peaks are being evaluated, and those that have a value above the detection limit are presented in the results. The detection limit is not strictly dictated, and it depends on the area or the element; commonly it is somewhere between 0.1 and 0.2%, but it could be more or less than these values. Samples were measured through a Jeol JEE-4X, with an attached Rontec EDX microanalysis system equipped with a windowless Si (Li) detector, using acceleration voltage 15 kV and 20 kV. Before the measurement, small parts of each glass were mounted in epoxy resin blocks, then polished with a 1 μm diamond paste and, last, to ensure conductivity, samples were coated with a thick carbon layer. Conductivity is necessary for observation, photography and analysis in an SEM-EDS. Standardization for the EDS analysis is achieved by a daily Co analysis. The EDS spectra is taken at the same time for all elements. The same peaks (K, L or M) are placed linearly. Each peak has on its right the next heavier element’s same peak, and on its left the previous lighter element’s same peak (Kα, Lβ, etc.). By analyzing Co we are taking a standard point for our spectra, and all other peaks are positioned accordingly. For each glass sample, we measured 5 different areas/angles and we present the mean value as a result.

3. Results and Discussion

In Table 1, we compare the average concentration obtained from our glass samples (first four rows) with glass samples of comparable date, as presented in the literature. In Table 2, we present in detail the results of chemical analysis for both groups (moils and finished products). The chemical composition of all these glass artefacts is rather heterogeneous.

Table 1.

Comparison of major oxide composition of Roman glasses from this study with glasses from a similar period from the literature.

Table 2.

Chemical analysis results.

The chemical composition of the finished products shows SiO2 contents ranging from 63.4 to 78.1 wt% with a mean value of 67 ± 3 wt%, Na2O from 9.3 to 23.7 wt% with a mean value of 16 ± 3 wt%, and K2O and MgO from 0.3 to 1.2 wt% with a mean value of 0.8 ± 0.2 wt%, and from 0.6 to 1.5 with a mean value of 1.1 ± 0.2 wt%, respectively.

The Al2O3 content varies between 1.6 and 4.6 wt% with a mean value of 2.7 ± 0.6 wt% and the CaO between 4.4 and 9.2 wt% with a mean value of 7 ± 1 wt%. Additionally, the Fe2O3 content ranges from 0.2 to 2.7 wt%, the TiO2 from 0.09 to 0.6 wt% and MnO from 0.1 to 1.7 wt%. The respective mean values are 1.1 ± 0.5 wt% for Fe2O3, 0.2 ± 0.1 wt% for TiO2 and 1.1 ± 0.4 wt% for MnO.

The chemical composition of the moils shows SiO2 content ranging from 64.6 to 74.9 wt% with a mean value of 69 ± 3 wt%, Na2O from 10.1 to 21.5 wt% with a mean value of 13 ± 3 wt%, and K2O and MgO from 0.6 to 1.7 wt% with a mean value of 0.9 ± 0.3 wt%, and from 1.1 to 1.3 with a mean value of 1.0 ± 0.2 wt%, respectively, while the Al2O3 content varies between 2.5 and 6.8 wt% with a mean value of 3 ± 0.6 wt% and the CaO between 4.1 and 9.4 wt% with a mean value of 7 ± 1 wt%. Additionally, the Fe2O3 content ranges from 0.3 to 3.3 wt%, the TiO2 from 0.2 to 0.3 wt% and MnO from 0.1 to 1.9 wt%. The respective mean values are 1.4 ± 0.8 wt% for Fe2O3, 0.2 ± 0.1 wt% for TiO2 and 1.3 ± 0.5 wt% for MnO.

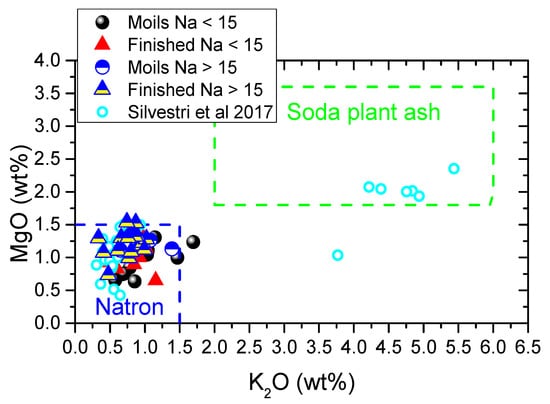

All glass finds from Vasileos Irakleiou Street, 45, are classified as natron glasses based on low K2O and MgO concentrations of below 1.3 wt% (Figure 2). Natron is a relatively pure mineral source of soda containing low magnesia and potash content, showing that all the measured samples are silica–soda–lime glasses and were produced according to the Roman glassmaking tradition employing natron as a flux [23,40].

Figure 2.

MgO vs. K2O contents of Vasileos Irakleiou Street, 45 glasses compared with Silvestri et al., 2017 [23].

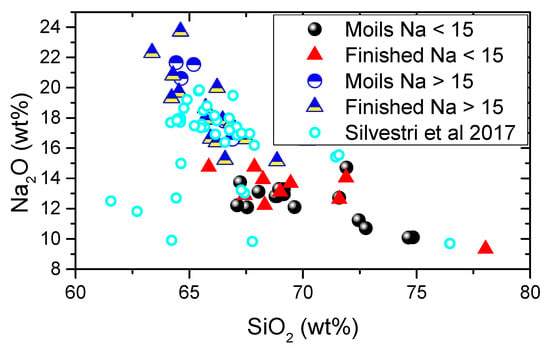

The Vasileos Irakleiou Street, 45 chemical data for finished glass and moils allow a relatively clearcut subdivision of them in two groups based of Na2O and SiO2 contents: the low Na2O (13 wt%) and high SiO2 (at around 70 wt%) group YK1, and the inverse high Na2O (at around 19 wt%) and low SiO2 (at around 66 wt%) group YK2, as shown in Figure 3.

Figure 3.

Na2O vs. SiO2 contents of Vasileos Irakleiou Street, 45 glasses compared with Silvestri et al., 2017 [23].

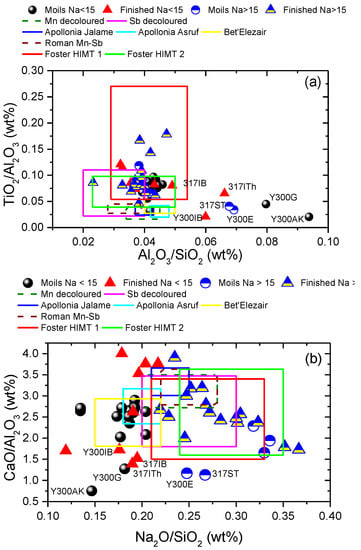

During the first millennium AD, there were major primary glass production centers in the Levant and Egypt, which produced different types of glasses. Among them we mention the Levantine I glass type, which was produced at Apollonia, Israel, 4–7th centuries, and the HIMT glass type, produced from the 4th century in Egypt [12,14]. In order to understand in which production center Vasileos Irakleiou Street, 45 glasses were produced, we used the ratios Al2O3/SiO2 versus TiO2/Al2O3 and Na2O/SiO2 versus CaO/Al2O3 (Figure 4) [9,10,41,42].

Figure 4.

Al2O3/SiO2 versus TiO2/Al2O3 (a) and Na2O/SiO2 versus CaO/Al2O3 (b) of Vasileos Irakleiou Street, 45 glasses compared with bibliographic data [10,13,16,17,25].

The high TiO2 contents of the majority of Vasileos Irakleiou Street, 45 glasses suggest an Egyptian origin [10,18]. Most of our samples (from both groups, YK1 and YK2) have ratios between 0.03 and 0.05 (Al2O3/SiO2) and 0.05 and 0.1 (TiO2/Al2O3): these, of group YK2, present high Na2O, MgO, MnO, and Fe2O3 characteristic of Egyptian composition, for which production is generally dated to the sixth century, while the samples of group YK1 present low Na2O and, also, high MgO, MnO, and Fe2O3.

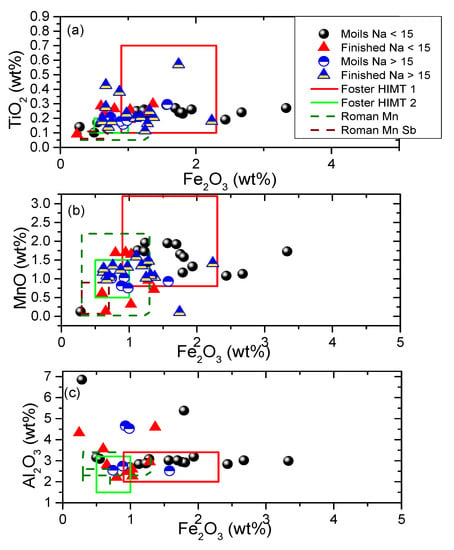

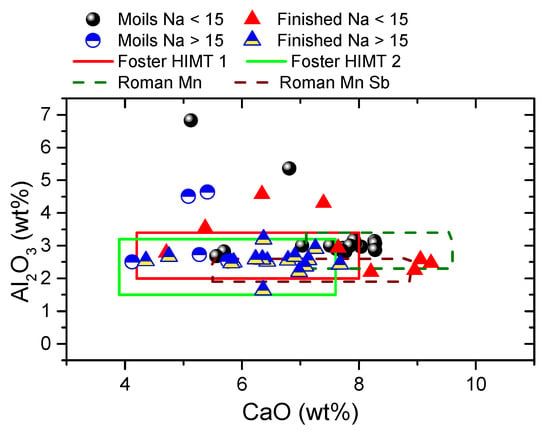

In particular, most of the samples (finished glass and moils) are classified as Roman glasses, decolored by the addition of antimony and/or manganese, of the HIMT 1 and HIMT 2 type [25]. The HIMT 1 glasses are defined by high levels of iron (1.4 ± 0.26 wt% as Fe2O3), manganese (1.7 ± 0.3 wt% as MnO) and titanium (0.3 ± 0.1 wt% as TiO2), with PbO at 0.01 ± 0.04 wt%, Sb2O3 at 0.04 ± 0.03 wt% and CuO with a mean value of 91 ppm, and their yellow-green color is due to the amount of iron, suggestive of a relatively impure sand source [25]. In addition, the HIMT 2 glasses have lower content of the above oxides (i.e., 0.7 ± 0.1 wt% of Fe2O3, 1.0 ± 0.2 wt% of MnO and 0.1 ± 0.12 wt% of TiO2) with higher PbO and Sb2O3 contents of 0.02 ± 0.04 wt% and 0.09 ± 0.05 wt%, and CuO with a mean value of 105 ppm, respectively [25]. These are, also, the key characteristics of Vasileos Irakleiou Street, 45 glass samples, which have high Fe2O3 (1 to 2.7 wt%), MnO (1 to 1.7 wt%) and TiO2 (0.1 to 0.38 wt%) contents (Figure 5). Thus, these samples are not “typical” HIMT glasses, such as ‘Group 1′ in Foy et al. [2003] [9], showing a better fit with ‘Group 2’ [9], (dated to the late Antique period) and HIMT 1 and HIMT 2 in Foster and Jackson, 2009 [25], which may be considered as “weak” HIMT glass due to lower contents of the key oxides of HIMT glass artefacts [25]. ‘HIMT 1′ glasses contain, on average, double the proportion of oxides of iron, manganese and titanium than that found in the “weak” HIMT samples. Additionally, we have seven samples (Y300G, Y300AK, 317ITh, Y300IB, 317IB, 317ST and Y300E) that can be recognized as outliers (Figure 4) as they do not fit strictly into any of the recognized Egyptian types due to both their high Al2O3 (Figure 6) (above 3.5 wt%) and their high K2O (above 0.9 wt%) in combination with their P2O5 (0.15 wt% to 0.70 wt%), concentrations implying that these glass samples have experienced significant recycling.

Figure 5.

Fe2O3 versus TiO2 (a), Fe2O3 versus MnO (b) and Fe2O3 versus Al2O3 (c) of Vasileos Irakleiou Street, 45 glasses compared with bibliographic data [10,25].

Figure 6.

CaO versus Al2O3 of Vasileos Irakleiou Street, 45 glasses compared with bibliographic data [10,25].

In Table 3 we have summarized the possible origin of each glass sample for this study.

Table 3.

Origin of glass samples.

Furthermore, in Figure 6 we plotted the CaO and Al2O3 concentration values of Vasileos Irakleiou Street, 45 glasses, in order to highlight the different lime/feldspar contents of the sand used for the production of the Vasileos Irakleiou Street, 45 glasses. The Vasileos Irakleiou Street, 45 glass finds can be compared with the known late/post Roman glasses such as the Roman Mn, the Roman Mn-Sb [10] and the “HIMT 1 and 2” group [25], and were, probably, produced in Egypt [8,9]. These kinds of glasses are also found in the rest of the areas covered by the Roman Empire, as far as the Netherlands or the United Kingdom [8,25]. The Vasileos Irakleiou Street, 45 glasses (Figure 6) appear to be mainly centered on the ‘HIMT 1 and 2’ area, confirming their age. Some glasses (mainly moils) are outside of the ‘HIMT’ area, confirming the use of recycled glass in glassmaking [12,14].

Regarding the metal decolorants, most of our samples have significant amounts of both manganese and antimony. Glass production techniques refer to the addition of either MnO or Sb2O3 as a decolorant agent, therefore the concomitance of these two oxides suggest a different production process [43]. Furthermore, we observe elevated contents of trace elements such as CuO, SnO2 and P2O5 in most of the samples. Foy et al., (2003) [9] have identified the levels of copper and antimony present, probably as natural impurities in raw, unrecycled, materials of HIMT glass, which are being found at mean concentrations of <0.01 wt%. The chemical composition of Vasileos Irakleiou Street, 45 samples is far from the levels proposed by Foy et al., (2003) [9]. These elements occur in higher concentrations, so it should be attributed to the recycling of earlier colored glass, as these concentrations are higher than those attributable to impurities in the raw materials but too low to have any technological significance [3]. In addition, Paynter and Jackson, 2016 [43] suggested that the mixture of antimony and manganese could be the result of recycling, while Jackson, 2005 [44] reports that if glasses dated after 4th century AD, contain low levels of antimony, it could indicate recycled glass. Recycling is probably explained by the inclusion of cullet, perhaps glass tesserae, containing high amounts of one or more of these elements, in the glass batch.

In addition, among the YK1 group (Na2O < 15 wt%), there are some samples (Y300AK, Y317B, 317IB) that have low MnO (<0.7 wt%) and Fe2O3 (<0.7 wt%) content (Figure 5). This is consistent with the amount of MnO and Fe2O3 that are naturally present in the glassmaking sand. This natron glass group also presents an amount of CuO and PbO below 1 wt% and 0.5 wt%, respectively. Specifically, samples Y300AK and Y317B present no manganese (MnO < 0.2 wt%), but contain antimony (Sb2O3 at around 0.4 wt%). Antimony was very common as a decolorizer until the 3rd century AD [45,46], while from 4th century AD manganese seems to replace antimony as the main decolorizer [43,47], showing that the age of these samples is perhaps earlier.

Manganese and iron oxide contents over 1 wt% and 1.5 wt%, respectively, are observed in the glass moils of both YK1 and YK2 groups, indicating that this MnO content may be related to its voluntary introduction in the glass batch in order to counteract the green color that would be developed due to the iron content, or to a systematic presence of MnO in the raw glass [13]. These moils also contain relatively high concentrations of CuO, SnO2, and P2O5, confirming the inclusion of cullet, perhaps opaque mosaic tesserae containing high quantities of one or more of these elements, in the glass batch.

The glasses of the YK2 group are Sb-rich glasses that contain both MnO and Sb2O3 above the sand background. The occurrence of both Sb2O3 and MnO in a natron glass is generally taken as evidence of the mixing of Sb- and Mn-bearing glasses [43,48]. Most glasses of both Vasileos Irakleiou Street, 45 groups (1,2) have contents of Sb2O3 > 0.3 wt%, MnO > 0.8 wt% and TiO2 > 0.2 wt%. The high TiO2 contents of most of the Vasileos Irakleiou Street, 45 glasses correspond more with glasses originating from Egypt rather than in the Levant [9,10,41,42].

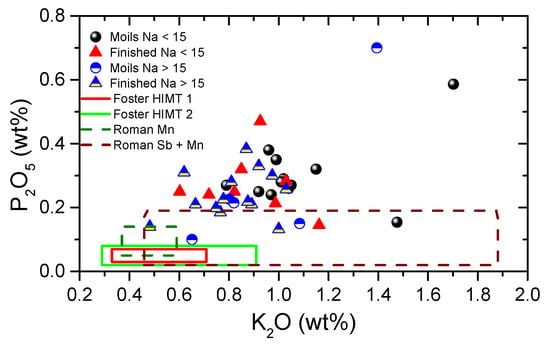

Therefore, if we consider recycling in terms of the variations of Na2O, K2O and especially of Mn and Sb elements which are unintentionally incorporated into the batch glass during re-melting episodes [43,49], then these components can provide an indication that recycling has occurred. However, their concentrations depend on the amount of decolored glass added to the batch glass, and to the context, e.g., longer melting durations and higher temperature. The elements that reflect the amount of time at high temperature are the K2O and P2O5 concentrations. In the Vasileos Irakleiou Street, 45 glasses a simultaneous enrichment in both K2O and P2O5 concentrations is observed (Figure 7), which is possibly due to the contamination of the glass by fuel ash vapor [10,50,51].

Figure 7.

P2O5 vs. K2O of Vasileos Irakleiou Street, 45 glasses.

4. Conclusions

In this work we present the chemical analysis of 48 glasses dated to the 6th century CE excavated in Vasileos Irakleiou Street, 45. The samples are divided into moils and finished products, and based on the low K2O and MgO concentrations (<1.3 wt%) are both classified as natron glasses. The Na2O content is quite diverse, thus we can recognize two groups between our samples: the YK1 group with Na2O content < 15 wt%, and YK2 group with Na2O content > 15 wt%. The high TiO2, Fe2O3 and MnO contents of all glasses suggest an Egyptian origin and some of them are, also, comparable with HIMT 1 and HIMT 2 of Foster and Jackson, 2009 [25] and others with Roman Mn or Roman Mn-Sb [10]. On the other hand, seven samples do not fit into the Egyptian type glasses and have probably experienced significant recycling. Furthermore, we suggest, based on the chemical analysis, that the finished products of the YK1 group and YK2 group have been produced by moils of the YK1 group and YK2 group, respectively. In addition, for all the samples, the great variance of Al2O3 (1.6 wt% to 4.6 wt%) and CaO (4.4 wt% to 9.2 wt%) concentrations indicate multiple types of sand. Regarding the colorants, most of the samples have MnO content >1 wt%, implying its voluntary addition as a decolorizer, while in some samples (especially in YK2 group) MnO coexists with Sb2O3. Finally, most of the samples present Sb2O3, CuO, SnO2, and P2O5 in concentrations higher than those attributable to impurities in the raw materials, but too low to have any technological significance [3], hence, this is another factor that suggests recycling. The results of these analyses are very important for the archaeological research of the central Macedonian region, because they elucidate for the first time the chemical nature of the glass used for the production of major groups of objects produced in Thessaloniki’s market in the late 6th century. They also provide us with proofs of the trade of Egyptian raw materials, probably directly imported from Egypt, since it was raw glass imported from there that was in use in this centrally situated workshop. In addition, they prove that all statistically selected objects were indeed produced in the workshop of Vasileos Irakleiou 45. Moreover, it shows that beakers, lamps, and glass gems were made—or discarded—at the same time as different batches of glass imported from the same region, probably loaded in ships at different times, or sold at the local market in different times. Further investigation has already begun with analysis of oxygen isotopes in the current samples, which will provide us with more evidence concerning the samples’ origin. Additionally, more samples from the same region have been excavated in order to be analyzed.

Author Contributions

Conceptualization, P.K. and E.D.; methodology, P.K. and E.D.; validation, E.D.; formal analysis: M.T. and A.E.P.; investigation, P.K., E.D., A.G. and A.A.; resources, E.D.; data curation, P.K., A.E.P. and M.T.; writing—original draft preparation, P.K. and E.D.; writing—review and editing, P.K., E.D., A.A. and A.G.; supervision, E.D. and A.G.; project administration, M.T. and A.E.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Davison, S.; Newton, R.G. Conservation and Restoration of Glass; Routledge: New York, NY, USA, 2008. [Google Scholar]

- Sayre, E.V.; Smith, R.W. Compositional categories of ancient glass. Science 1961, 133, 1824–1826. [Google Scholar] [CrossRef] [PubMed]

- Henderson, J. The raw materials of early glass production. Oxf. J. Archaeol. 1985, 4, 267–291. [Google Scholar] [CrossRef]

- Gratuze, B.; Barrandon, J.N. Islamic glass weights and stamps: Analysis using nuclear techniques. Archaeometry 1990, 32, 155–162. [Google Scholar] [CrossRef]

- Wedepohl, K.H. Chemical composition of medieval glass from excavations in West Germany. Glass Sci. Technol. 1997, 70, 246–255. [Google Scholar]

- Freestone, I.C. Chemical analysis of ‘raw’glass fragments. Excav. Carthage 1994, 2, 290. [Google Scholar]

- Schibille, N.; Meek, A.; Tobias, B.; Entwistle, C.; Avisseau-Broustet, M.; Da Mota, H.; Gratuze, B. Comprehensive chemical characterisation of Byzantine glass weights. PLoS ONE 2016, 11, e0168289. [Google Scholar] [CrossRef]

- Freestone, I.; Wolf, S.; Thirlwall, M. The production of HIMT glass: Elemental and isotopic evidence. In Proceedings of the Annales du 16e Congrès de l’Association Internationale pour l’Histoire du Verre: London 2003, London, UK, 7–13 September 2003; pp. 153–157. [Google Scholar]

- Foy, D.; Picon, M.; Vichy, M.; Thirion-Merle, V. Caractérisation des verres de la fin de l’Antiquité en Méditerranée occidentale: L’émergence de nouveaux courants commerciaux. In Échanges et Commerce du Verre dans le Monde Antique; Monique Mergoil Montagnac: Aix-en-Provence et Marseille, France, 2003; pp. 41–85. [Google Scholar]

- Schibille, N.; Sterrett-Krause, A.; Freestone, I.C. Glass groups, glass supply and recycling in late Roman Carthage. Archaeol. Anthropol. Sci. 2017, 9, 1223–1241. [Google Scholar] [CrossRef]

- Cagno, S.; Favaretto, L.; Mendera, M.; Izmer, A.; Vanhaecke, F.; Janssens, K. Evidence of early medieval soda ash glass in the archaeological site of San Genesio (Tuscany). J. Archaeol. Sci. 2012, 39, 1540–1552. [Google Scholar] [CrossRef]

- Freestone, I.C.; Greenwood, R.; Gorin-Rosen, Y. Byzantine and early Islamic glassmaking in the Eastern Mediterranean: Production and distribution of primary glass. In Proceedings of the Hyalos-Vitrum-Glass: Proceedings of the First Hellenic Glass Conference, Rodos, Greece, 15 January 2001; Glasnet Publications: Athens, Greece, 2002; pp. 167–174. [Google Scholar]

- Freestone, I.C.; Gorin-Rosen, Y.; Hughes, M.J. Primary glass from Israel and the production of glass in late antiquity and the early Islamic period. MOM Éd. 2000, 33, 65–83. [Google Scholar]

- Freestone, I.C.; Ponting, M.; Hughes, M.J. The origins of Byzantine glass from Maroni Petrera, Cyprus. Archaeometry 2002, 44, 257–272. [Google Scholar] [CrossRef]

- Freestone, I.C.; Leslie, K.; Thirlwall, M.; Gorin-Rosen, Y. Strontium isotopes in the investigation of early glass production: Byzantine and early Islamic glass from the Near East. Archaeometry 2003, 45, 19–32. [Google Scholar] [CrossRef]

- Freestone, I.C.; Jackson-Tal, R.E.; Tal, O. Raw glass and the production of glass vessels at late Byzantine Apollonia-Arsuf, Israel. J. Glass Stud. 2008, 50, 67–80. [Google Scholar]

- Brill, R.H. Scientific investigations of the Jalame glass and related finds. In Excavations at Jalame: Site of a Glass Factory in Late Roman Palestine; University of Missouri Press: Columbia, MI, USA, 1988; pp. 257–294. [Google Scholar]

- Picon, M.; Vichy, M. D’Orient en Occident: L’origine du verre à l’époque romaine et durant le haut Moyen Âge. In Échanges et Commerce du Verre Dans le Monde Antique; Monique Mergoil Montagnac: Aix-en-Provence et Marseille, France, 2003; pp. 17–31. [Google Scholar]

- Gorin-Rosen, Y. The ancient glass industry in Israel: Summary of the finds and new discoveries. MOM Éd. 2000, 33, 49–63. [Google Scholar]

- Nenna, M.-D.; Vichy, M.; Picon, M. L’atelier de verrier de Lyon, du Ier siècle apr. J.-C, et l’origine des verres «romains». ArchéoSci. Revue D’archéométrie 1997, 21, 81–87. [Google Scholar] [CrossRef]

- de los Angeles Vázquez, M.M. La route du verre: Ateliers primaires et secondaires du second millénaire av. J.-C. au Moyen Âge. In Gallaecia: Revista de Arqueoloxía e Antigüidade; Nenna, M.D., Ed.; Maison de l’Orient et de la MéDiterranée, Jean-Pouilloux—MOM: Lyon, France, 2002; Volume 21, pp. 413–415. ISSN 0211-8653. [Google Scholar]

- Dotsika, E.; Ignatiadou, D.; Longinelli, A.; Poutoukis, D.; Diamantopoulos, G. The fingerprint of Greek raw materials in the composition of ancient glasses with “unexpected” isotopic compositions. J. Archaeol. Sci. Rep. 2018, 22, 559–567. [Google Scholar] [CrossRef]

- Silvestri, A.; Dotsika, E.; Longinelli, A.; Selmo, E.; Doukata-Demertzi, S. Chemical and oxygen isotopic composition of roman and late antique glass from northern greece. J. Chem. 2017, 2017, 2956075. [Google Scholar] [CrossRef]

- Foy, D.; Vichy, M.; Picon, M. Lingots de verre en Méditerranée (IIIe s. av. J.-C.- VIIe s. ap. J.-C.), approvisionnement et mise en oeuvre; les données archéologiques et les données de laboratoire. In Proceedings of the Annales du 14eme Congres de l’Association Internationale pour l’Histoire du Verre, AIHV, Venise-Milan, Lochem, The Netherlands, 28 October–1 November 1998. [Google Scholar]

- Foster, H.E.; Jackson, C.M. The composition of ‘naturally coloured’late Roman vessel glass from Britain and the implications for models of glass production and supply. J. Archaeol. Sci. 2009, 36, 189–204. [Google Scholar] [CrossRef]

- Antonaras, C. Glass working in Roman and early Christian Thessaloniki: Older and more recent finds. In Proceedings of the History, Technology and Conservation of Ancient Metals Glasses and Enamels International Symposium, Athens, Greece, 16–19 November 2011. [Google Scholar]

- Dotsika, E.; Poutoukis, D.; Tzavidopoulos, I.; Maniatis, Y.; Ignatiadou, D.; Raco, B. A natron source at Pikrolimni Lake in Greece? Geochemical evidence. J. Geochem. Explor. 2009, 103, 133–143. [Google Scholar] [CrossRef]

- Wedepohl, K.H.; Baumann, A. Isotope composition of Medieval lead glasses reflecting early silver production in Central Europe. Mineral. Depos. 1997, 32, 292–295. [Google Scholar] [CrossRef]

- Aerts, A.; Velde, B.; Janssens, K.; Dijkman, W. Change in silica sources in Roman and post-Roman glass. Spectrochim. Acta Part B Atom. Spectrosc. 2003, 58, 659–667. [Google Scholar] [CrossRef]

- Henderson, J.; Evans, J.; Sloane, H.; Leng, M.; Doherty, C. The use of oxygen, strontium and lead isotopes to provenance ancient glasses in the Middle East. J. Archaeol. Sci. 2005, 32, 665–673. [Google Scholar] [CrossRef]

- Silvestri, A.; Molin, G.; Salviulo, G. Roman and medieval glass from the Italian area: Bulk characterization and relationships with production technologies. Archaeometry 2005, 47, 797–816. [Google Scholar] [CrossRef]

- Barfod, G.H.; Freestone, I.C.; Lichtenberger, A.; Raja, R.; Schwarzer, H. Geochemistry of Byzantine and early Islamic glass from Jerash, Jordan: Typology, recycling, and provenance. Geoarchaeology 2018, 33, 623–640. [Google Scholar] [CrossRef]

- Al-Bashaireh, K.; Alama, E.; Al-Housan, A.Q. Analytical and technological study of Roman, Byzantine and early Islamic (Umayyad) glasses from Al-Fudein archaeological site, Jordan. Mediterr. Archaeol. Archaeom. 2016, 16, 257–268. [Google Scholar]

- Maltoni, S.; Silvestri, A.; Marcante, A.; Molin, G. The transition from Roman to Late Antique glass: New insights from the Domus of Tito Macro in Aquileia (Italy). J. Archaeol. Sci. 2016, 73, 1–16. [Google Scholar] [CrossRef]

- Conte, S.; Chinni, T.; Arletti, R.; Vandini, M. Butrint (Albania) between eastern and western Mediterranean glass production: EMPA and LA-ICP-MS of late antique and early medieval finds. J. Archaeol. Sci. 2014, 49, 6–20. [Google Scholar] [CrossRef]

- Antonaras, A. An early Christian glass workshop at 45, Vasileos Irakleiou Street in the centre of Thessaloniki. In Neighbours and Successors of Rome: Traditions of Glass Production and Use in Europe and the Middle East in the Later First Millennium AD; Keller, D., Price, J., Jackson, C., Eds.; Oxbow Books: Oxford, UK, 2014; pp. 95–113. [Google Scholar]

- Antonaras, A. Glass lamps of the Roman and Early Christian periods. Evidence from the Thessaloniki area. In Lychnological Acts 2. Acts of the 2nd International Congress on Ancient and Middle Age Lighting Devices (Zalau –Cluj-Napoka, 13th–18th of May 2006). Trade and Local Production of Lamps from the Prehistory until the Middle Age; Roman, C.-A., Gudea, N., Eds.; Mega: Cluj-Napoca, Romania, 2008; pp. 23–30. [Google Scholar]

- Antonaras, A. Stemmed beakers with stamped bases from an Early Christian glass workshop at the center of Thessaloniki. In Corpus des Signatures et Marques sur Verres Antiques; Foy, D., Nenna, M.D., Eds.; Association Française pour l’Archéologie du Verre: Aix-en-Provence and Lyon, France, 2011; Volume 3, pp. 239–242. [Google Scholar]

- Antonaras, A. Emulation of Luxury in Glass. In Autour des Métiers du Luxe à Byzance; Martiniani-Reber, M., Rey, A.L., Lini, G., Liaudet, N., Eds.; The Mary Jaharis Center for Byzantine Art and Culture: Geneva, Switzerland, 2022; pp. 196–221. [Google Scholar]

- Lilyquist, C.; Brill, R.H.; Brill, R.H.; Wypyski, M.T. Studies in Early Egyptian Glass; Metropolitan Museum of Art: New York, NY, USA, 1993. [Google Scholar]

- Freestone, I.C.; Degryse, P.; Lankton, J.; Gratuze, B.; Schneider, J. HIMT, glass composition and commodity branding in the primary glass industry. In Things That Travelled: Mediterranean Glass in the First Millennium CE; Rosenow, M., Phelps, A., Meek, I.C., Freestone, Eds.; UCL Press: London, UK, 2018; pp. 159–190. [Google Scholar]

- Freestone, I.C. Glass production in the first millennium CE: A compositional perspective. Vom Künstlichen Stein Zum Durchsichtigen Massenprodukt 2021, 67, 245. [Google Scholar]

- Paynter, S.; Jackson, C. Re-used Roman rubbish: A thousand years of recycling glass. Post-Class. Archaeol. 2016, 6, 31–52. [Google Scholar]

- Jackson, C.M. Making colourless glass in the Roman period. Archaeometry 2005, 47, 763–780. [Google Scholar] [CrossRef]

- Glass, C.M.o.; Brill, R.M. Chemical Analysis of Early Glasses: The Catalogue; Corning Museum of Glass: Corning, NY, USA, 1999. [Google Scholar]

- Jackson, C.; Paynter, S. A great big melting pot: Exploring patterns of glass supply, consumption and recycling in Roman Coppergate, York. Archaeometry 2016, 58, 68–95. [Google Scholar] [CrossRef]

- Sayre, E.V. The intentional use of antimony and manganese in ancient glasses. In Advances in glass technology: History papers and discussions of the technical papers; Matson, F.R., Rindone, G.E., Eds.; Plenum Press, 1963; pp. 263–282. [Google Scholar]

- Silvestri, A. The coloured glass of Iulia Felix. J. Archaeol. Sci. 2008, 35, 1489–1501. [Google Scholar] [CrossRef]

- Rehren, T.; Connolly, P.; Schibille, N.; Schwarzer, H. Changes in glass consumption in Pergamon (Turkey) from Hellenistic to late Byzantine and Islamic times. J. Archaeol. Sci. 2015, 55, 266–279. [Google Scholar] [CrossRef]

- Rehren, T.; Marii, F.; Schibille, N.; Stanford, L.; Swan, C. Glass supply and circulation in early Byzantine southern Jordan. In Glass in Byzantium e Production, Usage, Analyses; RGZM: Mainz, Germany, 2010; pp. 65–81. [Google Scholar]

- Freestone, I.C.; Jackson-Tal, R.E.; Taxel, I.; Tal, O. Glass production at an early Islamic workshop in Tel Aviv. J. Archaeol. Sci. 2015, 62, 45–54. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).