Abstract

The paper presents issues associated with the experimental study of the vibration of a spot welding gun mounted on a robotic arm. The main aim of the study was to assess the vibration of the robot flange and the vibration of the mounted tool. Because of the tools’ large size and weight (up to 150 kg), manipulating it in a limited space is a challenge for programmers when defining trajectories. The article presents the results of inertial measurements of the KUKA KR120 R2500 industrial robot equipped with a pneumatic welding tool, paying particular attention to the vibrations occurring at the process points. Inertial tests on the robotic station were made using triaxial accelerometers and a high-speed camera. The methodology developed by the authors confirmed the existence of structural vibrations and allowed for defining the relationship between the robot’s motion parameters (notably velocity and acceleration) and the size of the vibrations present. The paper presents selected test results for various parameters of robot motion (speeds from 2000 mm/s to 500 mm/s and acceleration ramps ranging from 100% to 25%). In the course of the study, a disturbance was noticed in the form of a reduction in the value of maximum acceleration. This could be attributed to the appearance of the structure’s natural vibrations. Their character is not constant, and they are damped.

1. Introduction

Due to their high accuracy and repeatability of movements (approximately 0.1 mm), industrial robots are often used in the automotive industry [1], performing processes such as arc welding, painting and spot welding. Among the main advantages of six-axis robotic systems, we can include: working in conditions unfavorable for humans (standard welders on overhead cranes, moved by workers), access to hard-to-reach places (unlike stationary welders), due to the heating of the material spot welding must be performed in different places, too many points next to each other can lead to loss of material properties, do not require downtime [2]. These advantages make the robotization of the car body welding process, for which it is necessary to perform several thousand welds, an effective and profitable investment [3,4].

To meet the needs of the market, the largest robot manufacturers offer specialized equipment to support the process of robotized welding. Due to the large weight of the tool (around 90 kg), six-axis robots with a lifting capacity of more than 100 kg are most often used, their advantage is a wide range and the ability to approach hard-to-reach parts of the workpiece. In addition, manufacturers provide, among other things:

- Specialized software to support programming (RobotWare Spot from ABB, KUKA. SpotTech from KUKA, Spot Tool from FANUC);

- DressPacks-channels protecting the wires, tailored in shape to the type of robot;

- Specialized HMIs for programmers and operators;

- Advanced controllers that allow direct communication with the welding machine controller;

- Automatic recalculation of the tool’s TCP after tip dressing.

Due to the comparatively low cost, simplicity of the process and the possibility of joining complex parts, resistance welding is a very attractive process for manufacturers. The possibility of relatively simple robotization of the welding process and its reliability causes the continuous development of dedicated solutions (Figure 1). Given the high demand for robotic welding workstations, global market leaders are also providing libraries and software to support offline programming and simulation.

Inertial tests were carried out using triaxial accelerometers and a high speed camera. The work resulted in the acquisition of acceleration values appearing on the robot’s flange and mounted tool, and the impact of the robot’s trajectory parameters on the occurrence of construction vibrations on the robot was investigated. Despite the fact that the problem of tool vibration is important and often addressed by engineers integrating robots at real production workstations, there is a lack of scientific publications addressing implemented production stations. According to the authors, the best effect is given by experimental determination of tool vibrations on a specific production station [5]. The development of a measuring test bench provides an opportunity to support industrial robot developers in the preparation of robot motion trajectories with optimal motion parameters, allowing for shortening production cycles. Reducing production cycles by even a few percent in high-volume production can lead to significant savings.

Figure 1.

General view of KUKA robots in the spot welding process [6].

The premise and novelty of the presented approach is how to use IMU and high-speed camera equipment and developed software to analyze robot vibrations at specific production stations equipped with specific tools. The idea of the authors is to use the proprietary measurement station to optimize the production process and then remove the sensory elements from the test object. This approach has the following advantages:

- Multiple use of the measuring station reduces the cost of the proposed vibration reduction method-no need to purchase sensory elements for each robot to be optimized;

- No interference with the design and software of the existing production stand;

- Possibility to apply the stand to robots from different manufacturers and different generations of robot operating systems;

- Taking into account the harsh working conditions of industrial robots, if fixed sensing elements are used, there is a risk of deterioration of the conditions of realization of the production process.

Section 2 of the article explores the current state of knowledge related to robotization of the spot welding process and the occurrence of undesirable phenomena (e.g., vibration) of tools at process points. Section 3 presents the kinematic model of the robot being tested, its digital twin and the test stand used in the work carried out. Section 4 includes the results of the conducted tests and their analysis. In Section 5, the authors have included conclusions.

2. Related Work

The welding process is associated with the simultaneous interaction of two types of energy-thermal and mechanical-on the materials being welded together. For welding, i.e., inseparable joining with the application of pressure, various physical phenomena are used, which are most often the source of heat. The following types of welding can be distinguished: resistance (resistive), frictional, explosive, ultrasonic, impact and crush welding. Spot welding is one of the most popular methods of resistance welding, and it involves joining parts at separate locations called spots. The high efficiency of the process, the low manufacturing costs, the possibility of robotizing the work, and the ongoing correction of welding parameters make spot welding a competitive welding and mechanical joining. However, it is not without drawbacks; the need to press the parts to be joined, high current densities, and ensuring high surface cleanliness limit the efficiency of spot welding [7,8,9,10].

The design and commissioning of robotic production workstations is a complex issue and requires a great deal of effort on the part of engineers. In the past, this was carried out without the use of high-tech software environments (e.g., RobotStudio, RoboGuide, KUKA Sim), which usually caused delays in the deployment schedule of the workstations. The development of programming environments and hardware has meant that some tasks are implemented in virtual environments using digital twins. This allows the project to be implemented in a hybrid manner, where some activities are carried out online and some offline (also in virtual reality) [11,12]. The biggest advantage of such an approach is that it reduces the start-up time of the workstations, as a lot of work can be carried out in parallel (e.g.,: robot programming, workstation construction) [13]. Manufacturers of offline robot programming environments assure that simulations conducted in the environments are able to almost 100% replicate the real conditions of a robotic workstation. One of the most important advantages of the environments is the ability to easily generate motion trajectories, which allows the determination of production cycle times. However, it is worth noting here that it remains a problem to conduct analyses related to real accelerations, torques and forces acting on cooperating devices. A comprehensive picture of these quantities can only be obtained by conducting experimental studies. The use of triaxial IMUs makes it possible to measure the vibrations of the robot, these data allow analysis and optimization of the manipulator [14]. With the use of IMUs [15], it is possible to acquire data across the entire production.

A significant area of the robotic application research literature is the studies of the dynamic parameters and motion control of robotic manipulators [16]. When it comes to controlling the movement of mechanisms and its parameterization, one of the most important issues is to examine the moment of acceleration, deceleration and the accuracy of achieving set positions. The nature of the dynamics of the robot’s movements can significantly influence the forces that affect kinematic joints [17]. As presented in [18], the optimal time trajectory is extremely important for palletizing robots.During the operation of the workstation, the robot can execute complex motion, featuring sudden deceleration and acceleration episodes. These episodes (particularly during the change of direction) affect the longevity of the robot and the accuracy of the execution of the movement path, and their parameterization can accelerate the process of movement direction change and lower the vibrations of the robotic unit [19]. The dynamic studies of the robot workstation must take into account sensitive systems, especially those that are stressed during the robot’s operation. These may involve, for instance, the robot wrist, the tool mounting and the tool itself [20]. Hence, the analysis of dynamics in the flange and tool area is essential, as it provides insights into the impact of loads and tool design on the robot-tool system’s dynamic lifespan. This kind of study can allow for minimizing power consumption. Doing so is one of the postulates of Industry 4.0, which sees the decrease of energy consumption and the growth of smart production being taken into consideration in the designing of state-of-the-art production systems [21]. Improvements in the efficiency of resource usage can be achieved by analyzing energy consumption, equipment reliability, maintenance frequency and operating costs, in addition to life cycle evaluation [22,23].

Several research studies have analyzed the effect of vibrations on the dynamic performance of robotics manipulators. Among the topics is the modal analysis of robot manipulators; in [24], the effect of flexibility on the dynamics of a two-arm planar manipulator with two revolute joints is considered, while, in [25], authors focus on robotic manipulators with rigid links and flexible joints. Researchers are also expanding issues related to the control of robot manipulators with flexible elements [26,27,28,29,30,31]. Another solution, as shown in [32,33,34], is trajectory optimization, which leads to a reduction in robot vibration. Such research is being conducted not only by researchers [35,36], but also by robot manufacturers, as exemplified by FANUC. They are proposing a solution, based on removable sensors that allow for optimization of the welding process through vibration analysis. A potential solution to the problem presented could be the use of trajectory smoothing through trajectory planning methods. An example of such a solution can be the S-curve method, based on a segmented sigmoidal function [37]. According to the author of [38], a method to reduce residual vibrations by up to 90% is to shape the input signal. The publication [39] also confirms the desirability of conducting this type of research. The problem of vibrations of industrial robot manipulators exists (despite the efforts of manufacturers), and ongoing research work shows that it is possible to improve the quality of technological processes by reducing them. Most scientific publications focus on machining processes (cutting, deburring). Optimization of the robot’s path of motion in a given technological process is essential for productivity, and it is necessary to carry it out in every new application. Due to the nature of the problem, publications tend to focus on one of the mentioned aspects and deal with different processes. Although the number of publications on the welding process is limited, the problem exists as confirmed by the robot manufacturers and integrators responsible for installing new robotic stations.

3. Materials and Methods

Tool vibration is a common and unfavorable phenomenon occurring in the operation of mechanical equipment. During the programming and commissioning of robotic production workstations, the occurrence of tool vibrations at process points has been noted, which can lead to a decrease in the repeatability of tasks performed by the robot (thus, for example, to a decrease in the quality of manufactured products). The phenomenon of vibration appears especially when the robot is handling large masses or when manipulating objects whose masses are close to the robot’s payload. The first step of the work was the preparation of a virtual station, based on digital twin technology.

3.1. Virtual Station

This task was carried out in the KUKA.Sim Pro software environment. This environment allows for planning and simulating the operation of robotic stations equipped with KUKA machines and equipment. Thanks to the use of a rich libraries, including robots and their tools, conveyors and protective fences, among others, the software is an excellent tool for designing and simulating solutions under development. KUKA.Sim Pro uses virtual robot control (VRC), allowing robots to be programmed in the KUKA Robot Language (KRL). Simulations of the operation of the developed workstations can be performed according to accepted standards (including: collision detection, program code generation-in this case in KRL language, and real-time timing analysis). KUKA.Sim Pro software was used to prepare a model of the test stand, equipped with a KUKA KR 120 R2500 PRO robot, a pneumatic welding gun and a robot positioner manufactured by ABB.

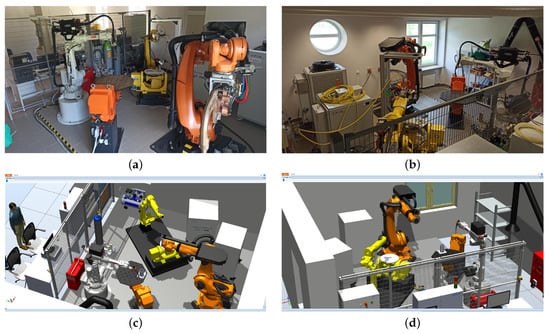

The components used and their layout correspond to the real stand (Figure 2) available at the Robotics Laboratory of the Military University of Technology (MUoT). The developed simulation in the KUKA.SIM Pro environment allows for planning the trajectory of the tool’s movement and plotting it using the tool’s position tracking option-Tool Center Point (TCP). According to the manufacturer’s declaration, the station, prepared on the basis of Digital Twin technology, reflects the operation of the real machine in 99%. As a result, it is a solution that speeds up the commissioning of the real station and helps to avoid potential collisions during robot operation. Figure 3 shows a general view of the test stand developed in the KUKA.SIM Pro environment. To improve visibility, components not used in this study have been hidden.

Figure 2.

Test stand: (a,b) real station; (c,d) simulation.

Figure 3.

General view of test stand developed in KUKA.SIM Pro.

3.2. Test Stand

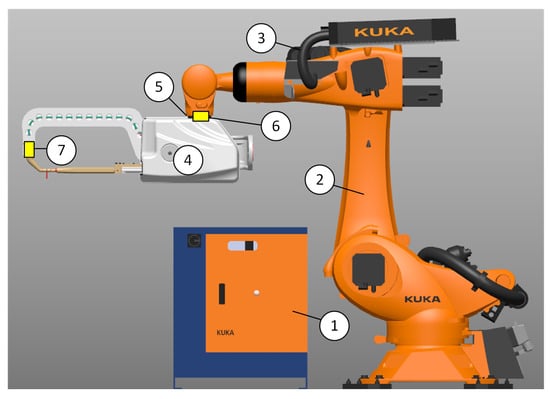

The tool was mounted on a KUKA KR 120 R2500 PRO robot. XSENS sensors were placed on the tool and the flange of the robot (Figure 4).

Figure 4.

Elements of the test bench: 1—robot controller, 2—manipulator, 3—dress pack, 4—weld gun, 5—flange, 6—vMTi-680, 7—MTi-300.

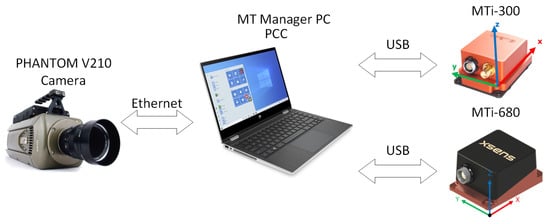

Figure 5 shows the diagram for connecting a PC to MTi XSENS sensors (MTi-300 and MTi-680). The MT Manager program was used to configure the sensors. The program allowed for tracking the acceleration of the robot tool in real time. However, the main objective of the research carried out with this measurement setup was to verify the influence of changes in the robot’s motion parameters (TCP velocity; acceleration and deceleration) on the welding gun’s vibration at the process point.

Figure 5.

Connection diagram of the computer with sensors (MTi XSENS) and camera (PHANTOM V210).

In addition, the test stand was equipped with a PHANTOM V210 high-speed camera. A computer with the PCC program made it possible to configure the PHANTOM V210 camera and capture video. The recorded videos made it possible to carry out analyses of the change in the position of the welding gun in workspace at the process point (the robot’s stopping point).

The focus of the authors was to develop a methodology to perform tests aimed at analyzing the characteristics of a robotic industrial process. Restrictions associated with the payload of the robot and the executed process were accounted for. The primary objective of the study was to verify the performance of the spot welding gun at the process points at which the maximum forces are applied to the robot tool. The assumption was made that, given the way spot welding is carried out, the instance for which the robot can run at the top speeds is motion at a fixed height with linear movement approaching the process point.

Accelerometers were attached to the spot gun. Of these, one sensor was installed at the flange of the robot, while the 2nd sensor was placed near the fixed electrode. In addition, the camera was placed in such a manner that image analysis could be carried out to evaluate the displacement of the marker located on the tool. Videos were recorded using a PHANTOM V210 high speed camera with a resolution of 800 × 600 [pix], at 2000 [frames/s]. Using PCC software, it was possible to analyze the nature of the tool’s vibration, including measuring its maximum displacement at the process point. Taking the values shown, a calibration was carried out to define the scale (the ratio between the 800 × 600 [pix] image resolution and the observed image in millimeters) before measuring the dislocations. As a result, the scale equaled 0.212 [mm/pix]. When calibrating the camera, an Edge Hipass 5 × 5 filter was applied. A control program was prepared on the test stand for the KUKA KR120 R2500 robot, taking into account its workspace and possible kinematic singularities. A linear movement TCP was prepared with a beginning point P1 with coordinates x = −220 [mm], y = 1500 [mm], z = 1455 [mm] and an ending point P2 with coordinates x = 1680 [mm], y = 1500 [mm], z = 1455 [mm]. Point P2 was used as a process point.

4. Tests

Vibration tests of the pneumatic welding gun in the process point were performed in the MUoT Mechatronics Laboratory.

4.1. Results

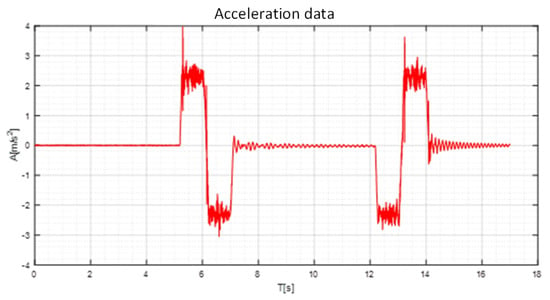

Despite displaying results of the motion study in one axis, it was crucial for data processing to analyze all axes. Only then can a complete picture of the behavior of the object under study during motion be obtained. The analysis was performed using software and scripts written in the MATLAB software environment. Prior to the analysis, the data were prepared for processing. As such, it involved the following steps:

- Creation of Matlab structure from imported data;

- Defining and picking a range of data for analysis;

- Minimizing the constant bias component through analysis of the silence period (before the robot actually starts moving).

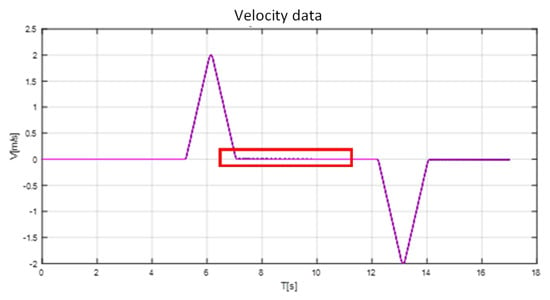

The results obtained for the axis in which the programmed movement of the robot took place are shown below (Figure 6, Figure 7, Figure 8 and Figure 9).

Figure 6.

Acceleration plot obtained with MTi XSENS installed on robot flange and welding gun for V2000, ACC100.

Figure 7.

Velocity plot obtained with MTi XSENS installed on robot flange and welding gun for V2000, ACC100.

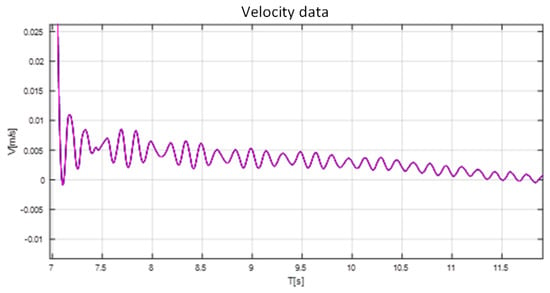

Figure 8.

Highlighted area of the velocity plot as the robot stops for V2000, ACC 100.

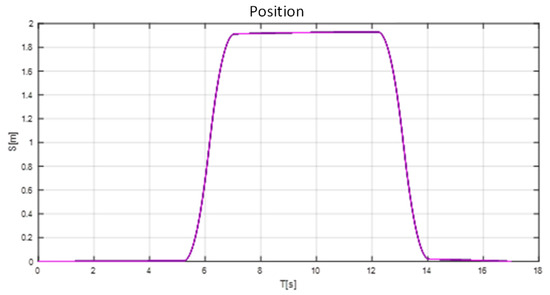

Figure 9.

Graph of traveled distance calculated from data registered by the MTi XSENS installed on the robot flange and welding gun for the V2000, ACC 100.

The results obtained during the tests are shown in the table below (Table 1). Included are the values of maximum accelerations of the tool and flange for the set motion parameters after stopping the robot at the process point. There, the vibrating robot tool moves back and forth from its normal stationary position. A full cycle of vibration occurs when the tool moves from one extreme position to the other extreme position and back again. The magnitude of acceleration (a measure of vibration intensity) varies from zero to a maximum during each vibration cycle. It increases as the vibrating tool moves away from its preset, stationary position. These values were read from processed XSENS MTi sensor data. Every test was performed 5 times each, reading selected parameters for the implementation of the robot’s motion trajectory. The table shows the average values calculated from 5 runs for each test.

Table 1.

Maximum tool and flange acceleration values for the set motion parameters after stopping at the process point.

4.2. Discussion

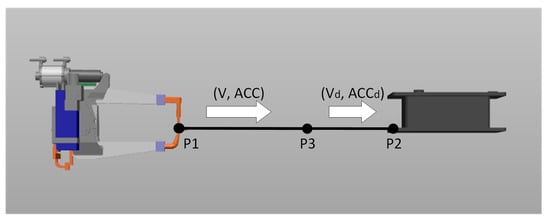

Analyzing the results of performed tests, it is possible to confirm the assumption of the influence of changes in motion parameters on the vibration of the welding gun at the process point. It is also noted that, for small values of acceleration (ACC25, ACC50), the maximum values of vibration do not differ significantly. Thus, it should be concluded that a large reduction in the value of the ACC parameter will not improve the quality of the robot’s stopping at the process point. Incorrect handling of acceleration and deceleration also causes the robot to fail to reach target speeds and may even prolong the production process cycle, which, in the case of welding applications, is an unfavorable phenomenon. It seems that a greater impact could be had by changing the speed target before the process point, while maintaining the value of the ACC parameter. For example, by adding an additional point, the position of which, depending on the tool used or the approach to the process point, could be dynamically selected (Figure 10).

Figure 10.

Robot approach to process point. P1—start point, P2—process point, P3—additional point, V-linear speed of the robot, ACC-acceleration coefficient, -modified linear speed of the robot, -modified acceleration coefficient.

Due to the great interest in the possibility of shortening production cycles in welding applications, especially in the automotive industry, this thesis will be the next step of the research conducted on the test bench.

5. Conclusions

This paper presents a study of the effect of altering the robot’s movement parameters on the vibration of the welding gun when stopped at a process point. This research was carried out using an industrial robot from KUKA, a pneumatic welder and a positioner from ABB. In order to verify the occurrence of the vibration phenomenon and its magnitude, the authors proposed testing using XSENS triaxial sensors and a high speed camera (such as the PHANTOM V210). The methodology of tests proposed by the authors makes it possible to verify the behavior of the tool when stopped at the process point.

The work also included the development of a theoretical model and a digital twin of the station, which allowed a preliminary study of the phenomenon and the planning of the studied motion trajectories. The paper presents selected test results for various parameters of robot motion (speeds from 2000 mm/s to 500 mm/s and acceleration ramps ranging from 100% to 25%). Presented in the form of tables, the test results confirmed the influence of changes in motion parameters on the value of tool vibration at the process point. Comparing the obtained results with [5], it can be concluded that the difference between the acceleration values on the flange and the robot tool is smaller for the welding robot. This is due to differences in the design of the robot (four-axis vs. six-axis) and the design of the tool—its dimensions, mass, stiffness and the position of the center of gravity. Nevertheless, in both cases, the problem occurs, and it is purposeful to try to eliminate it.This is a very unfavorable phenomenon, especially in high-volume production, where very short production cycle times are required. Such a situation is encountered in car production, where 3000 to 5000 welds are made on each car body. Given the number of cars produced on a single production line, even a slight shortening of the production cycle can lead to large economical savings and increased production.

The study proves that the use of triaxial sensors and high speed cameras makes it possible to effectively conduct analyses associated with the determination of vibration values at the process point. In a future work, the authors are going to focus on the possibility of applying the proposed test to reduce vibrations of chosen robotic industrial processes.

Author Contributions

Conceptualization, S.B., W.K. and D.L.; methodology, W.K.; software, S.B. and W.K.; validation, W.K. and D.L.; formal analysis, W.K.; investigation, S.B. and W.K.; resources, S.B., W.K. and R.P.; data curation, S.B. and W.K.; Writing—Original draft preparation, S.B., W.K. and D.L.; Writing—Review and editing, S.B., W.K. and R.P.; visualization, S.B.; supervision, W.K. and D.L.; project administration, W.K., D.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was cofinanced by Military University of Technology under research project UGB 893/2021.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bartoš, M.; Bulej, V.; Bohušík, M.; Stanček, J.; Ivanov, V.; Macek, P. An overview of robot applications in automotive industry. Transp. Res. Procedia 2021, 55, 837–844. [Google Scholar] [CrossRef]

- Chemweno, P.; Torn, R.J. Innovative robotization of manual manufacturing processes. Proc. Procedia Cirp 2022, 106, 96–101. [Google Scholar] [CrossRef]

- Lopes, T.C.; Sikora, C.; Molina, R.G.; Schibelbain, D.; Rodrigues, L.; Magatão, L. Balancing a robotic spot welding manufacturing line: An industrial case study. Eur. J. Oper. Res. 2017, 263, 1033–1048. [Google Scholar] [CrossRef]

- Banga, H.K.; Kalra, P.; Kumar, R.; Singh, S.; Pruncu, C.I. Optimization of the cycle time of robotics resistance spot welding for automotive applications. J. Adv. Manuf. Process. 2021, 3, e10084. [Google Scholar] [CrossRef]

- Kaczmarek, W.; Borys, S.; Panasiuk, J.; Siwek, M.; Prusaczyk, P. Experimental Study of the Vibrations of a Roller Shutter Gripper. Appl. Sci. 2022, 12, 9996. [Google Scholar] [CrossRef]

- KUKA. Automated Resistance Spot Welding with KUKA. Available online: https://www.kuka.com/en-de/industries/metal-industry/spot-welding (accessed on 24 October 2022).

- Batista, M.; Furlanetto, V.; Brandi, S.D. Development of a resistance spot welding process using additive manufacturing. Metals 2020, 10, 555. [Google Scholar] [CrossRef]

- Żółtowski, P.; Bużantowicz, W. Self-Balancing Power Amplifier with a Minimal DC Offset for Launcher Automation Control Circuits of a Surface-to-Air Missile System. Appl. Sci. 2022, 12, 3532. [Google Scholar] [CrossRef]

- Lisiecki, A.; Burdzik, R.; Siwiec, G.; Konieczny, L.; Warczek, J.; Folega, P.; Oleksiak, B. Disk laser welding of car body zinc coated steel sheets. Arch. Metall. Mater. 2015, 60, 2913–2922. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P. Critical review of automotive steels spot welding: Process, structure and properties. Sci. Technol. Weld. Join. 2013, 18, 361–403. [Google Scholar] [CrossRef]

- Kaczmarek, W.; Panasiuk, J.; Borys, S.; Banach, P. Industrial robot control by means of gestures and voice commands in offline and online mode. Sensors 2020, 20, 6358. [Google Scholar] [CrossRef]

- Kaczmarek, W.; Lotys, B.; Borys, S.; Laskowski, D.; Lubkowski, P. Controlling an industrial robot using a graphic tablet in offline and online mode. Sensors 2021, 21, 2439. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Li, L.; Tang, W. An offline programming system for palletizing robot. Int. J. Adv. Robot. Syst. 2016, 13, 1–7. [Google Scholar] [CrossRef]

- Hsieh, Y.F.; Ye, J.H.; Wu, N.J.; Hsu, Q.C. Intelligent automatic deburring system by integrating palletizing robot with image and vibration sensors. Sensors Mater. 2021, 33, 933–945. [Google Scholar] [CrossRef]

- De Souza, J.P.C.; Amorim, A.M.; Rocha, L.F.; Pinto, V.H.; Moreira, A.P. Industrial robot programming by demonstration using stereoscopic vision and inertial sensing. Ind. Rob. 2022, 49, 96–107. [Google Scholar] [CrossRef]

- Zhu, L.; Gu, Z.; Shi, J.; Liu, W. Research on dynamic performance and motion control of robot manipulator. J. Vibroeng. 2015, 17, 3092–3103. [Google Scholar]

- Enescu, I. Performances and shapes of acceleration-deceleration curve of kinematical linkages. Int. J. Mech. 2020, 14, 125–129. [Google Scholar] [CrossRef]

- Xu, Y.P.; Hong, Y. Time optimal path planning of palletizing robot. Appl. Mech. Mater. 2014, 470, 658–662. [Google Scholar] [CrossRef]

- Shen, H.; Jiang, L.; Zhang, Q.; Tao, Y.; Cao, Y. A new method for high speed and smooth transfer of robot motion trajectory. Adv. Mech. Eng. 2016, 8, 1–9. [Google Scholar] [CrossRef]

- He, Y.; Mei, J.; Zang, J.; Xie, S.; Zhang, F. Multicriteria optimization design for end effector mounting bracket of a high speed and heavy load palletizing robot. Math. Probl. Eng. 2018, 2018, 6049635. [Google Scholar] [CrossRef]

- Guerra-Zubiaga, D.A.; Luong, K.Y. Energy consumption parameter analysis of industrial robots using design of experiment methodology. Int. J. Sustain. Eng. 2021, 14, 996–1005. [Google Scholar] [CrossRef]

- Stuhlenmiller, F.; Weyand, S.; Jungblut, J.; Schebek, L.; Clever, D.; Rinderknecht, S. Impact of cycle time and payload of an industrial robot on resource efficiency. Robotics 2021, 10, 33. [Google Scholar] [CrossRef]

- Borys, S.; Kaczmarek, W.; Laskowski, D. Selection and optimization of the parameters of the robotized packaging process of one type of product. Sensors 2020, 20, 5378. [Google Scholar] [CrossRef] [PubMed]

- Mishra, N.; Singh, S. Determination of modes of vibration for accurate modelling of the flexibility effects on dynamics of a two link flexible manipulator. Int. J. Non. Linear. Mech. 2022, 141, 103943. [Google Scholar] [CrossRef]

- Do, T.T.; Vu, V.H.; Liu, Z. Linearization of dynamic equations for vibration and modal analysis of flexible joint manipulators. Mech. Mach. Theory 2022, 167, 104516. [Google Scholar] [CrossRef]

- Shang, D.; Li, X.; Yin, M.; Li, F. Vibration Suppression Method Based on PI Fuzzy Controller Containing Disturbance Observe for Dual-flexible Manipulator with an Axially Translating Arm. Int. J. Control. Autom. Syst. 2022, 20, 1682–1694. [Google Scholar] [CrossRef]

- Shi, M.; Cheng, Y.; Rong, B.; Zhao, W.; Yao, Z.; Yu, C. Research on vibration suppression and trajectory tracking control strategy of a flexible link manipulator. Appl. Math. Model. 2022, 110, 78–98. [Google Scholar] [CrossRef]

- Valizadeh, A.; Shariatee, M. PZT Actuators’ Effect on Vibration Control of the PRRRP 2DOF Flexible Parallel Manipulator. Shock Vib. 2021, 2021, 6985661. [Google Scholar] [CrossRef]

- Huang, J.; Ji, J. Vibration control of coupled Duffing oscillators in flexible single-link manipulators. J. Vib. Control 2021, 27, 2058–2068. [Google Scholar] [CrossRef]

- Li, K.; Wang, H.; Liang, X.; Miao, Y. Visual Servoing of Flexible-Link Manipulators by Considering Vibration Suppression without Deformation Measurements. IEEE Trans. Cybern. 2021, 52, 12454–12463. [Google Scholar] [CrossRef]

- Meng, Q.; Lai, X.; Yan, Z.; Su, C.Y.; Wu, M. Motion Planning and Adaptive Neural Tracking Control of an Uncertain Two-Link Rigid–Flexible Manipulator With Vibration Amplitude Constraint. IEEE Trans. Neural Netw. Learn. Syst. 2022, 33, 3814–3828. [Google Scholar] [CrossRef]

- Ge, L.; Chen, J.; Li, R. Algorithm of palletizing robot vibration suppression based on the principle of optimal trajectory planning. In Proceedings of the 2017 29th Chinese Control In addition, Decision Conference (CCDC), Chongqing, China, 28–30 May 2017; pp. 92–96. [Google Scholar] [CrossRef]

- Berscheid, L.; Kroger, T. Jerk-limited Real-time Trajectory Generation with Arbitrary Target States. Proc. Robot. Sci. Syst. 2021. [Google Scholar] [CrossRef]

- Jalendra, C.; Rout, B.K.; Marathe, A. Vision sensor based residual vibration suppression strategy of non-deformable object for robot-assisted assembly operation with gripper flexibility. Ind. Rob. 2022, 49, 851–864. [Google Scholar] [CrossRef]

- Cooper, M.P.; Griffiths, C.A.; Andrzejewski, K.T.; Giannetti, C. Motion optimisation for improved cycle time and reduced vibration in robotic assembly of electronic components. AIMS Electron. Electr. Eng. 2019, 3, 274–289. [Google Scholar] [CrossRef]

- Ariano, A.; Perna, V.; Senatore, A.; Scatigno, R.; Nicolò, F.; Fazioli, F.; Avallone, G.; Pesce, S.; Gagliano, A. Simulation and experimental validation of novel trajectory planning strategy to reduce vibrations and improve productivity of robotic manipulator. Electronics 2020, 9, 581. [Google Scholar] [CrossRef]

- Fang, Y.; Hu, J.; Liu, W.; Shao, Q.; Qi, J.; Peng, Y. Smooth and time-optimal S-curve trajectory planning for automated robots and machines. Mech. Mach. Theory 2019, 137, 127–153. [Google Scholar] [CrossRef]

- Thomsen, D.K.; Søe-Knudsen, R.; Balling, O.; Zhang, X. Vibration control of industrial robot arms by multi-mode time-varying input shaping. Mech. Mach. Theory 2021, 155, 104072. [Google Scholar] [CrossRef]

- Yu, H.; Sun, Q.; Wang, C.; Zhao, Y. Frequency response analysis of heavy-load palletizing robot considering elastic deformation. Sci. Prog. 2020, 103, 0036850419893856. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).