Abstract

China’s total coal production in 2021 exceeded 4.13 billion tons, 52% of the world’s total. Coal gangue, a solid waste of coal mining accounts for 15–20% of coal production, when directly discharged on the ground surface as waste heaps, it occupies large areas of land and cause environmental pollution. This paper summarizes the existing gangue backfilling methods, their working principles, efficiency, and application status. The methods that are meeting Middle and Western China’s mining demands are discussed in detail. The state-of-the-art technologies that can realize high-efficiency, centralized, and large-scale underground backfilling of coal gangue are analyzed. This paper shows that the industrial implementation of these technologies can increase the current maximum disposal capacity of coal gangue by three times, reaching five million tons per year. The equipment innovation and automation are analyzed, and the environmental effect of coal gangue backfilling is discussed. This review offers inspirations and guidelines for coal gangue disposal and the environmental hazard reduction of coal mining.

1. Introduction

According to the statistics released by the International Energy Agency (IEA), the world’s total coal production increased continuously from 2017 to 2019. However, due to the impact of COVID-19, the world’s coal production in 2020 dropped to 7.721 billion tons, a reduction of 4.8%. Except for China, the coal production in many countries, including Indonesia, Russia, Australia, Mongolia, and the United States declined. The top ten countries in terms of coal production were China, India, Indonesia, the United States of America, Australia, Russia, South Africa, Kazakhstan, Germany, and Poland [1]. The world’s total coal production rebounded in 2021, but is still not at pre-COVID-19 levels. China’s coal production in 2021 amounted to 4.13 billion tons [2], 52.4% of the world’s total. Offering robust support to the national economic and social stability of China, coal will remain its main energy source in the foreseeable future [3]. A large amount of coal gangue is generated during coal mining, accounting for 15–20% of the total coal production. The solid wastes discharged on the ground surface then form waste heaps. According to incomplete statistics, the accumulated coal gangue in China has exceeded six billion tons, with waste heaps numbering between 1500 and 1700 and occupying over 13,300 hectares. The annual increase of the coal gangue in China is 500 to 800 million tons (e.g., 795 million tons were produced in 2020) [4,5,6]. Coal gangue accumulated on the ground occupies large areas of land, causing severe air pollution and presenting other environmental hazards, including vegetation damage, water and soil loss, groundwater pollution, or even spontaneous combustion of waste heaps and landslides [7].

Given the environmental impact of coal gangue in the mining areas, many countries have elaborated their national gangue management regulations and strategies. Since the 1960s, developed countries, such as Germany and U.K., have issued plans to encourage the use of coal gangue to build materials in land reclamation, roads, and dams. Some western countries have established waste exchange systems, which makes waste exchange a resource [8]. In France, Germany, and the U.K., coal gangue was used as filling material for road embankments or the road base of arterial highways [9]. The use of coal gangue for power generation started early in developed countries. For example, Germany and Holland began to build coal power plants alongside coal preparation plants in the 1970s to recycle coal gangue for power generation. As some developed countries become less dependent on coal over time, the projects utilizing coal gangue for power generation have stalled in recent years [10]. Coal gangue combined with sulfate-reducing bacteria (SRB) could be used as a microbial organic fertilizer [11]. Land reclamation using coal gangue has been proven successful in Hungary, the former Soviet Union, the U.K., and the U.S. Coal gangue can also be used as cover material [12,13]. Although aboveground utilization of coal gangue in China has started only recently, an explosive development has occurred. Currently, about 140 million tons of coal gangue in China are annually used for power generation, which is equivalent to conserving approximately 38 million tons of standard coal [14]. Since the 1980s, China has consolidated the subgrade use of coal gangue as filling materials during road engineering [15].

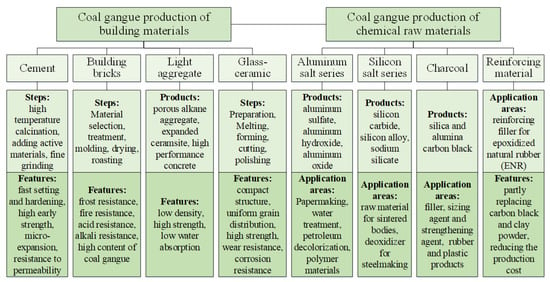

Extensive theoretical and practical explorations of coal gangue recycling to prepare building materials and chemical raw materials have been conducted worldwide. Because of the high content of SiO2, Al2O3, and Fe2O3 [16], coal gangue has been used for manufacturing building materials, such as cement [17,18], bricks [19,20], lightweight aggregate concrete [21,22], and glass-ceramics [23]. Coal gangue, rich in Si, C, and Al, is also used to develop aluminum salt chemicals [24,25], silicon salt chemicals [26,27], carbon chemicals [28], and reinforcing materials [29]. Coal-producing countries keep developing and deepening the utilization of coal gangue on the ground, as shown in Figure 1.

Figure 1.

The utilization of coal gangue on the ground.

Australia, Russia, Germany, Poland, the Ukraine, and other countries have also carried out backfill mining research on coal mining with pneumatic stowing [30], backfilling in highwall mining [31], partial backfilling [32], cemented paste backfilling [33,34,35,36] and other innovations in backfill mining [37,38,39,40].

The utilization rate of coal gangue in China has reached 73% [3]. Some major progress has been made in the industrialization of coal gangue recycling. However, due to the intrinsic features of coal gangue, technical limitations, and other external factors, the number of gangue recycling programs that can generate high economic yield and are practically feasible is limited [41]. More than 35% of coal gangue still exists in the form of waste heaps [42]. Given the huge annual production of coal gangue in China, the coal gangue recycling on the ground alone cannot meet the growing demands for gangue disposal. China encourages gangue backfill mining to control ground subsidence, farmland destruction, and coal gangue discharge on the ground. In particular, China has formulated favorable policies to push forward the disposal of coal gangue. According to the environmental protection tax law of China, the entities conducting coal gangue recycling in accordance with the national and local environmental protection standards are exempt from the environmental protection taxes (CNY 5 per ton of coal gangue). The resource tax will be cut by 50% for backfill mining. At present, the commonly used gangue backfilling technologies are mechanical backfilling, fully mechanized mining with solid backfilling [43], mixed workface using a gangue backfilling and caving method, longwall-roadway cemented backfilling, and paste backfilling [44,45]. These backfilling technologies are mainly intended for coal mining under buildings (structures), railways, and water bodies and are considered the key technologies for green coal mining [46]. The development of the underground disposal of coal gangue, especially gangue backfilling, is not only directly envisaged by the national policies, but meets the practical needs of backfill disposal.

The remaining part of this paper contains a review of existing gangue backfilling technologies. Their principles, advantages and deficiencies, efficiencies, and application conditions are discussed, and the latest progress in the high-efficiency, large-scale underground gangue backfilling technology is summarized. The key equipment for the underground gangue backfilling technology is also analyzed. This paper provides theoretical support for large-scale gangue backfilling in China.

2. The Current Status of Coal Gangue Discharge on the Ground in China

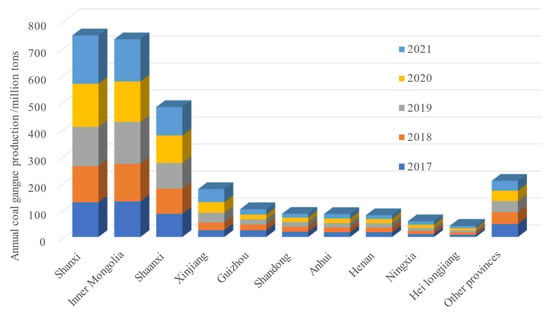

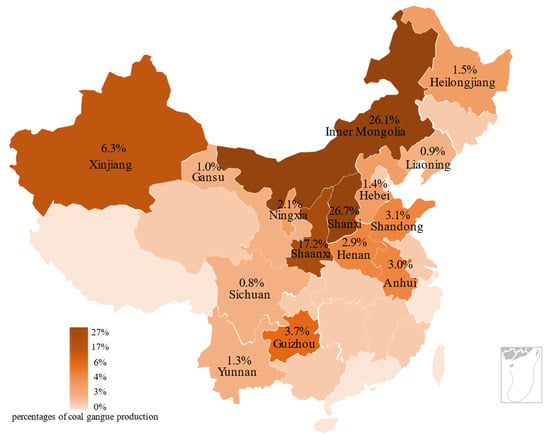

Coal gangue, as a solid waste generated during coal mining and washing, is a black-gray rock with low carbon content, low calorific value, and hard texture. Coal gangue is subdivided into the gangue generated during underground drifting and mining and the gangue generated during washing and dressing [47]. In addition to containing 20~30% carbon, coal gangue is generally dominated by oxides: SiO2 at 30~60%, Al2O3 at 15~40%, Fe2O3 at 2~10%, CaO, MgO, and K2O at 1~4%. There are also other trace elements such as boron and nickel. More coal gangue is generated in North and Northwest China than in South and Northeast China. The amount of coal gangue discharged in North China is close to 3.5 billion tons, which far exceeds that in other areas and accounts for about 50% of the total discharge [48]. As shown in Figure 2, the total amount of coal gangue generated in 25 coal-producing provinces of China from 2017 to 2021 was estimated as 2.80 billion tons. This estimate was made by conservatively assuming that gangue accounted for 15% of coal production. Besides, the coal gangue produced in these five years accounted for 40.0% of the total amount of coal gangue. The top ten provinces in terms of coal production generated 2.59 billion tons of coal gangue in the five years. As shown in Figure 3, darker areas on the map indicate greater coal gangue production. The coal gangue produced by the top ten provinces accounted for 92.6% of the total in the past five years, while that produced by Shanxi, Shaanxi, and Inner Mongolia accounted for 70% [3], which shows the characteristics of intensive coal gangue production.

Figure 2.

The annual coal gangue production in different provinces of China from 2017 to 2021.

Figure 3.

The percentages of coal gangue production in different provinces of China from 2017 to 2021.

As the intensification and the scale of China’s coal production have been rising, coal gangue production is increasing, and the centralized tendency of gangue production has become more pronounced. At present, most coal mines adopt two types of gangue disposal. The first one is to discharge the coal gangue aboveground and allow it to be utilized by other enterprises. However, the industrial and mining enterprises only utilize the coal gangue to a minimal degree due to the following factors: the high coal gangue discharge cost, scattered distribution of aboveground gangue disposal facilities, environmental protection policies applicable to gangue transportation, high gangue utilization costs, the complex process and technology of aboveground gangue disposal, and the high requirements for recycling due to the gangue composition [49,50]. The second one is to dump the gangue at a specified site in or near the mining area, thus forming waste heaps of varying sizes [51]. These waste heaps occupy valuable land resources, and the water leaching from the gangue pollutes the surrounding soil and groundwater [52]. Besides, the coal gangue contains combustible components, which may ignite spontaneously under proper conditions, leading to instability of the coal gangue [53,54]. Noxious gases generated by the spontaneous combustion, including sulfur dioxide, nitrogen oxides, carbon oxides, and smoke, can cause air and ecological pollution, which threatens local residents’ health [55].

The recycling of coal gangue on the ground can hardly meet the gangue disposal requirements. In contrast, underground gangue disposal technology has the benefits of high-efficiency, in-situ disposal, and the centralized distribution of disposal facilities. There is an urgent need to develop underground gangue backfilling technology, which meets the demand for centralized, high-yield, and large-scale gangue disposal.

3. Gangue Backfilling Technologies

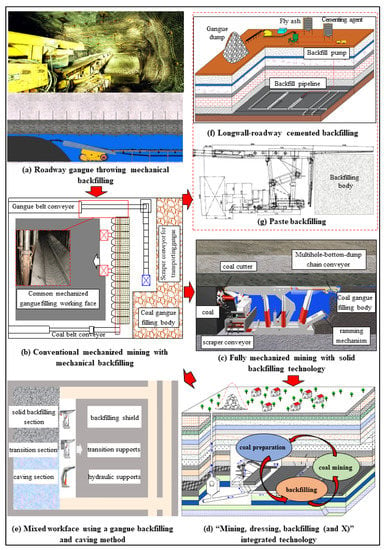

Figure 4 shows the development process of gangue backfilling [44,45,56]. These technologies can accomplish the basic goals of backfilling, strata movement control, and safe production [57].

Figure 4.

The history of the gangue backfilling technology development.

3.1. Mechanical Backfilling

Mechanical backfilling [58] is subdivided into roadway throwing-gangue mechanical backfilling (Figure 4a) and conventional mechanized mining with mechanical backfilling (Figure 4b). The key equipment in mechanical backfilling is the high-speed gangue throwing machine, mainly composed of an electric motor, driving roller, steering roller, carrier roller, gangue throwing belt, and the support [59]. The gangue throwing machine casts the gangue at a high speed into the goaf, thus using the gangue as backfill.

3.2. Fully Mechanized Mining with Solid Backfilling Technology

Fully mechanized mining with solid backfilling technology [60,61,62] (Figure 4c) is a suitable method for coal mining under buildings (structures), railways, and water bodies. The gangue produced by underground coal mining is initially crushed mechanically and then transported to the working face for in-situ backfilling. The filling materials in the goaf are compacted by the ramming mechanism [63,64]. The integrated underground mining-dressing-backfilling technology that combines solid backfilling mining and underground gangue dressing has appeared in response to China’s policies of green mine construction and to accommodate deep coal resources [65]. On this basis, the technical concept of “mining, dressing, backfilling + X” integrated green mining (Figure 4d) has been proposed. The “X” consists of active control for strata movement, gob-side entry retaining, gas extraction, disaster prevention and control, and water conservation mining [66,67,68].

3.3. Mixed Workface Using a Gangue Backfilling and Caving Method

A mixed workface using a gangue backfilling and caving method [69,70] (Figure 4e) refers to the use of a solid backfilling section, a conventional caving section, and a transition section in the same working face. The equipment for fully mechanized mining with solid backfilling technology and that of conventional fully mechanized mining are arranged in the same working face and work jointly to complete backfilling mining. In the working face of the backfilling section, backfilling shield and rear multihole-bottom-dump chain conveyor are arranged to backfill the gangue to the goaf for roof management. For the caving section’s working face, a conventional fully mechanized working is employed, and the conventional hydraulic supports are arranged. The goaf is managed by the caving method. Transition supports are installed in the transition segment [71].

3.4. Longwall-Roadway Cemented Backfilling

Longwall-roadway cemented backfilling [72] (Figure 4f) involves solid waste (such as coal gangue and fly ash) as the filling materials. The solid wastes are added with a cementing agent at a specific ratio to prepare a high-concentration paste by mixing without the additional need for dehydration [73]. The paste is delivered underground by a pipeline pumping system to backfill the goaf. In longwall-roadway cemented backfilling, the coal is broken using a bolter miner instead of a coal cutter via the longwall mining system. After the connection roadway has been excavated, the roadway is backfilled with cemented filling materials [74]. Another connection roadway is excavated simultaneously while the roadway is backfilled.

3.5. Paste Backfilling

Paste backfilling [75] (Figure 4g) uses paste transportation behind the hydraulic supports in the working face via the pipelines based on the original working face for fully mechanized mining. The backfilling, which is performed through the space dug out by the coal cutter, can proceed continuously along with the advancing working face. Fly ash, cement, and coal gangue are used as the primary filling materials for paste backfilling in fully mechanized mining. They are mixed at a specific ratio in the presence of additive material to prepare a paste without a critical flow rate or the need for dehydration. The main process consists of coal cutting, bag hanging, backfilling, and solidification. The key equipment used for paste backfilling behind the hydraulic support in fully mechanized mining is the backfilling shield, with a long rear top beam. The latter provides the roof support behind the working face, offers enough backfilling space, and prevents the roof caving or the paste entering into the working face [76].

3.6. Hybrid Gangue Backfilling Technology

Under the conditions of particular coal mines, two or more backfilling technologies may be used in combination, depending on ground control requirements. If there is a shortage of the fill materials, such as coal gangue, the above-mentioned backfilling technologies can be used concomitantly with superhigh water-filling materials. The combination of different backfilling technologies is common for aboveground gangue disposal while ensuring safe coal production [77].

4. Gangue Backfilling Technologies: Advantages and Deficiencies

Mechanical backfilling has a limited coal gangue disposal ability, and it is suitable only for a few roadways. This backfilling technology has been gradually abandoned [78].

Fully mechanized mining with solid backfilling technology has developed the key equipment, the backfilling shield and the multihole-bottom-dump chain conveyor, and formed a complete set of mature processes with a huge demand for underground coal gangue disposal. This technology reduces coal gangue discharge, alleviates the surface subsidence induced by mining, and improves the mining resource recovery rate [79,80]. However, this technology is associated with a high investment cost and high requirements for the working face. For example, the working face is required to be straight and the roof of the coal seam has to be intact.

The mixed workface using a gangue backfilling and caving method mainly applies to coal mines where there is a need to protect the aboveground structures, accompanied by a working face length above 220 m and the backfilling section’s maximum length of 150 m. This backfilling technology does not interfere with the mining operation and can protect the ground surface. In addition, its efficiency is 4–6 times that of the simple backfilling working face [81].

In longwall-roadway cemented backfilling, the working face can be arranged flexibly. This backfilling technology is more favored for residual mining area where the fully mechanized working face is difficult to arrange. It can be used for large-scale disposal of solid wastes such as coal gangue and fly ash. The paste is backfilled to the goaf via a pipeline pumping system from the surface backfilling stations, and the backfilled ratio can exceed 90%. This technology can effectively support the goaf, control the movement of the overlying strata, and protect the environment of the mining area [82].

Paste backfilling combines the advantages of cemented backfilling and fully mechanized mining with solid backfilling. The cemented filling materials are backfilled to the goaf of the fully mechanized working face via the pipeline. This technology has the benefits of the high degree of mechanization and high production capacity in the working face, its simple process, and its high system stability. It can effectively control the movement of overlying strata in the mining area and dispose of solid wastes such as coal gangue and fly ash on a large scale, hence protecting mines environment [83,84].

Some typical examples of applying underground gangue backfilling in coal mines in China are listed in Table 1. They are mainly concentrated in Shandong, Hebei, Shanxi, Henan, Anhui, and other provinces which have large populations and dense buildings. Coal gangue backfilling can reduce the impact of mining on the surface. Fully mechanized mining with solid backfilling technology is the most widely used among these applied technologies.

Table 1.

The application of the gangue backfilling technologies in some coal mines of China.

5. Problems and Proposed Solutions

5.1. Problems

At present, ground and aquifer control should be considered for most underground gangue backfilling technologies, which have to meet a specified backfilling ratio to ensure the stability of aboveground structures and aquifers [85,86]. For this reason, coal production and gangue disposal depend, to a certain degree, on the effect of backfilling. Backfilling may interfere with the mining operation, leading to a low gangue disposal efficiency. The backfilling efficiency is also influenced by the following factors: (i) a complex ramming mechanism in backfilling shields, (ii) the small transport capacity of the multihole-bottom-dump chain conveyor, and (iii) the insufficient automation degree, reliability, and/or efficiency of the key backfilling equipment. Due to these deficiencies, the current gangue backfilling technologies can hardly satisfy the demands of large-scale coal gangue disposal in China.

5.1.1. The Backfilling Process Effect on Gangue Backfilling Efficiency

Coal resources in Eastern China are being gradually exhausted, and their potential for coal production growth is limited. Considering that Eastern China is densely populated and built-up, its coal mining mostly occurs under buildings (structures), railways, and water bodies, which is becoming increasingly difficult. Large coal mines are mainly located in Middle and Western China, where coal production and the demand for coal gangue disposal has been growing [87,88,89,90,91]. For example, the annual amount of coal gangue at the Daliuta coal preparation plant of the Shandong Coal Group reached 5.10 million tons and at the Buertai Coal Mine it was approximately 3 million tons. At present, utilization and disposal technologies can hardly handle such a large amount of coal gangue efficiently.

For coal mines in Eastern China, backfilling materials need more strength to control the surface movement. However, for coal mines in Middle and Western China, the backfilling mining technologies no longer need to achieve a better backfilling effect, but aim to backfill efficiently under normal production. Backfill mining aimed at coal mining has been transferred from Eastern China to Middle and Western China. Therefore, the gangue backfilling technologies, adapted to coal mining under buildings (structures), railways, and water bodies, are no longer applicable to the large-scale coal gangue disposal in Middle and Western China.

5.1.2. The Effect of Equipment Performance on Gangue Backfilling Efficiency

Backfilling shields have undergone modification and innovation from a six-prop to four-prop configuration as the backfill mining technology has been improved over the years. Six generations of backfilling shields have been designed and optimized successively [92,93,94]. The backfilling shields can accommodate the change in mining height from 2.0 to 5.0 m. The support resistance offered by the shields has also increased from 4500 to 11,000 kN. These backfilling shields are mainly intended for coal mining under buildings (structures), railways, and water bodies. However, as the application scenarios change, the backfilling shields’ ramming mechanism has become a barrier to improving the backfilling efficiency. The purpose of the ramming is to compact the fill body and control ground movement. However, in Middle and Western China, there is no rigorous demand for surface protection and backfilling material strength, so the current ramming mechanism can no longer adapt to the new backfilling, which aims to dispose of coal gangue.

Several models of the multihole-bottom-dump chain conveyor have been designed, including SGBC630/150, SGBC764/250, SGBC764/300, and SGZC764/250 [95,96,97,98]. However, the existing multihole-bottom-dump chain conveyors generally have the deficiencies of low transport capacity, high accident rate, and low reliability. They generally fail in the task of disposing of a large amount of coal gangue. Multihole-bottom-dump chain conveyors have a low transport capacity, with a small dumping hole that is less optimized in shape, resulting in a limited dumping amount. They may bend, twist, or even rupture due to the hanging method and the multihole-bottom-dump chain conveyor may be clogged by coal gangue, leading to a rupture and a high accident rate. Therefore, the available multihole-bottom-dump chain conveyors can hardly satisfy the coal gangue requirements.

5.2. Prospects

The existing backfilling technologies and key equipment seem to impede the high-efficiency, large-scale backfilling of coal gangue. To satisfy the growing demands for gangue backfilling in the underground coal mines of Middle and Western China, innovative gangue backfilling technologies and more reliable key equipment are required. In addition, automation should be improved and the environmental effect of the coal gangue should be considered.

5.2.1. Innovative Gangue Disposal

- (1)

- Slurry backfilling in the goaf

The materials of slurry backfilling in the goaf consist of coal gangue from the coal preparation chamber and the water, which is prepared into a slurry with a certain concentration in the backfilling material preparation chamber. The rheological properties of slurry are excellent, stable, and convenient for pipeline transportation. The backfilling pump provides the power and transports the slurry to the roadway via the pipeline. Following this, the backfill slurry is placed into the adjacent or current goafs [99,100]. Its technical principles are illustrated in Figure 5. For adjacent goafs, slurry backfilling is undertaken at a certain distance ahead of the current working face. Through the section’s coal pillars between the two working faces, the slurry is injected from the roadway on the working face into the adjacent goaf. For the current goafs, pipeline laying and grouting are arranged at a triangular zone formed in the roadway after roof caving. As soon as the single-hole grouting is finished, the drill hole is sealed. The drill hole grouting is repeated at certain distances until slurry backfilling is completed for the entire goaf.

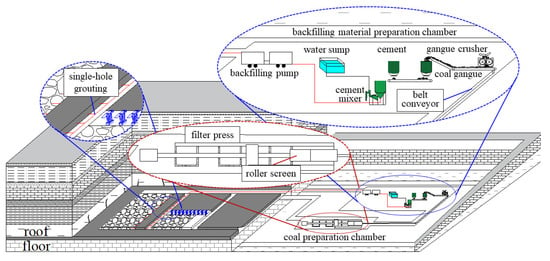

Figure 5.

Schematic diagram of slurry backfilling in the goaf.

Slurry backfilling in the goaf has the benefits of being a simple process, having a high mechanization degree, large spaces of coal gangue backfilling, and a low investment cost. This technology is suitable for coal mining without ground protection, and due to having no ground structures, slurry materials don’t need great strength.

- (2)

- High-efficiency gangue backfilling in a super-long mining workface

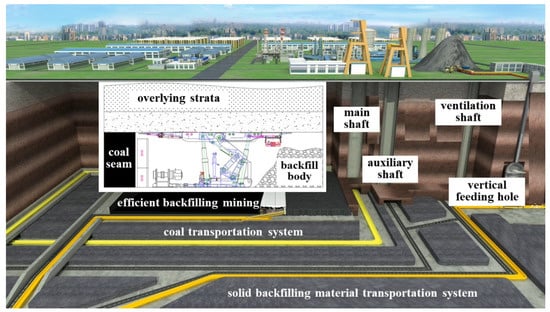

High-efficiency gangue backfilling in a super-long mining workface is developed based on fully mechanized mining with solid backfilling technology for the purpose of the high-efficiency backfilling of a large amount of coal gangue. This technology mainly uses the coal gangue as the backfilling materials, which enters the goaf via the backfilling material vertical feeding hole system and the underground solid backfilling material transportation system. Its technical principle is shown in Figure 6.

Figure 6.

Schematic diagram of high-efficiency gangue backfilling technologies.

The length of the working face in this backfilling technology usually exceeds 275 m. The maximum disposal capacity of coal gangue is more than five million tons per year, outperforming the previous gangue backfilling technologies by more than three times. This backfilling technology achieves high-efficiency disposal of a large-scale coal gangue without affecting the mine production capacity. Besides, it can reduce strata movement and protect the environment of the mining area. Because of these benefits, high-efficiency gangue backfilling in a super-long mining workface is particularly suitable for modern large coal mines in ecologically vulnerable regions of China, such as Shaanxi and Inner Mongolia.

5.2.2. Research and Development of New Equipment

- (1)

- Optimized design of the backfilling shield

The up-to-date high-efficiency backfilling mining should dispose of a large amount of coal gangue without affecting the coal mining. One significant change to the backfilling shield in response to this demand is removing the compactor. There has been a trend towards a compact structural design of backfilling shields to reduce the size, improve the space utilization rate, and support the efficiency of the shields. Specifically, the relative position between the four-bar linkage dimension, the linkage, and the post are optimized to achieve a compact spatial layout. The design of the working space under backfilling reduces the amount of ineffective space and achieves compact, safe, and effective goals. The length of the front and rear top beams is optimized so that the support better accommodates the roof deformation. The supporting line is moved backward to the tail of the top beam to accommodate roof caving and improve the coal mining and backfilling efficiency [101,102,103].

- (2)

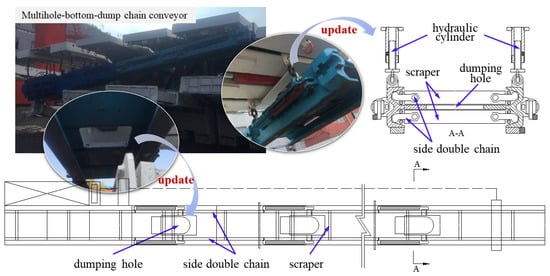

- Research and development of a novel type of multihole-bottom-dump chain conveyor

The following aspects of the multihole-bottom-dump chain conveyor should be optimized to achieve the high-efficiency, fixed-point, and quantitative unloading of the filling materials, which includes: the gradation of coal gangue; the hanging method of the multihole-bottom-dump chain conveyor; the method of connection between the scrapers; strength of key components; and the position, size, and switch mode of the dumping hole [104,105].

As shown in Figure 7, a hydraulic cylinder can be used to hang the multihole-bottom-dump chain conveyor. By changing the original hanging method, one can avoid bending and compression of the multihole-bottom-dump chain conveyor and improve its reliability. The conveyor’s central double chain design is changed to a side double chain, increasing the dumping area of the dumping hole. The conventional rectangular shape of the dumping hole is changed to a shape consisting of a rectangle and a semicircle. An arched connection is adopted between the flashboard and scraper of the dumping hole to avoid height difference and prevent clogging by the coal gangue. The multihole-bottom-dump chain conveyor’s preferred transport capacity is 1000 t/h and above, as required by the high-efficiency large-scale gangue disposal technology.

Figure 7.

Schematic diagram of a novel type of multihole-bottom-dump chain conveyor.

- (3)

- Research and development of the gangue pipeline pumping system

Slurry backfilling in the goaf requires that the pipeline pumping system should have the desired transport performance for coal gangue and water over long distances without clogging. To meet this demand, one should further optimize the gangue-based slurry’s mix ratio for backfilling to ensure favorable rheological properties, a low bleeding rate, a uniform composition, and the convenience of pipeline transportation of slurry. During the transport, the pumping system’s capacity should be improved to accommodate a long distance by adding a smooth coating inside the transporting pipeline and by increasing the pumping power, to facilitate the continuous transport of coal gangue, and the backfilling of the goaf. Moreover, the stope’s spatial distribution can be accurately determined by numerical simulation or surveying to make preliminary decisions concerning the laying of the pipeline pumping system.

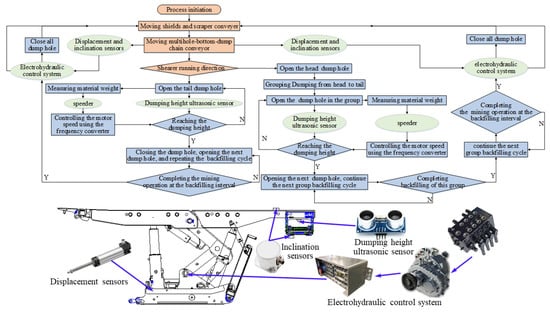

5.2.3. Automation

Australia, The United States, Canada, and other countries have carried out extensive research on the mechanization and automation of backfill mining, while in China, the current backfilling process primarily relies on the manual operation of machinery [106,107,108,109]. To increase the efficiency of coal gangue underground backfilling, the backfilling shield control program can be developed with the introduction of a digital electro-hydraulic control system, a displacement sensor, and an inclination sensor, which are essential for the automated control of support advancing and pushing. Meanwhile the automation of the pulling of the multihole-bottom-dump chain conveyor should be designed and implemented. These measures can achieve the goal of the automation of backfilling and support-advancing mining [110,111,112,113].

Dumping height ultrasonic sensors are used to detect the height and morphology of backfilling materials to achieve automatic control for opening or closing the dumping hole. The automation of the backfilling operation is realized by using signal acquisition with equipment such as ultrasound detectors, displacement sensors, and inclination sensors, and using the command control with the system controller [114,115,116].

After the backfilling operation is completed, the control system will receive signals and send automated commands about the support advancing and pushing; subsequently, signals will be sent back to the control system and trigger the automated control of the backfilling. Through the above process, a coordinated cyclic control system is established between the backfilling shield and the multihole-bottom-dump chain conveyor [117,118,119], achieving the automated control of the entire backfilling. The schematic diagram of an automated control system for backfilling is presented in Figure 8.

Figure 8.

Schematic diagram of an automated control system for backfilling.

While not affecting the normal coal mining procedure and ensuring safe production, high-efficiency automated backfill mining accomplishes the efficient automatic backfilling of coal gangue, to achieve zero discharge of the mine waste and accommodate the demand for intensive, high-yield, and large-scale utilization of coal gangue in China. High-efficiency automated backfill mining offers a breakthrough solution to coal gangue disposal.

5.2.4. Attaching Importance to the Environmental Effects

In the process of coal gangue underground backfilling and disposal, in addition to environmental protection of the ground, we should pay special attention to the underground environmental benefits of the gangue-based filling body and the interactions between the coal gangue and the water environment [120,121,122]. However, few papers have considered the environmental benefits of coal gangue backfilling. Limited studies have shown that: (i) based on short-term data the coal gangue backfilling doesn’t damage the groundwater environment and may have minimal potential risks in the future [5], (ii)materials in the coal gangue filling can retard heavy metal accumulation [123], and (iii)some risk prevention and control methods have been established for groundwater environmental pollution by backfill mining [124]. These will minimize the ecological and environmental damage from mining [125], and achieve an environmentally friendly underground gangue backfilling and green sustainable development [126,127,128,129].

6. Conclusions

This paper summarizes the recycling of coal gangue on the ground, the existing coal gangue backfilling technology, and the latest progress of high-efficiency and large-scale coal gangue disposal technology; innovations of the key equipment and automation of the technology and some environmental benefits of coal gangue backfilling are also mentioned. The main conclusions are as follows:

- (i)

- The recycling of coal gangue on the ground is restricted by high cost and difficult technologies, which cannot meet the demand for coal gangue disposal;

- (ii)

- The existing underground gangue backfilling technologies include: mechanical backfilling, fully mechanized mining with solid backfilling technology, mixed workface using a gangue backfilling and caving method, longwall-roadway cemented backfilling, and paste backfilling. These technologies are mainly applied to coal mining under buildings (structures), railways, and water bodies in Eastern China. However, they have quite limited gangue disposal capacity due to inadequate equipment and low automation;

- (iii)

- Slurry backfilling in the goaf and high-efficiency gangue backfilling in a super-long mining workface have been innovatively developed, showing that the maximum disposal capacity of coal gangue can increase by three times, reaching five million tons per year;

- (iv)

- The key equipment and automation of the technology have been innovated, which can facilitate the intensive, high-yield, large-scale utilization of coal gangue. The environmental benefits of coal gangue are also mentioned. These will achieve green sustainable coal mining development.

Author Contributions

Conceptualization, W.S., J.Z. and M.L.; investigation, H.Y. and Y.Y.; data curation, W.S. and N.Z.; writing—original draft preparation, W.S. and Y.G.; writing—review and editing, W.S. and J.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded the National Natural Science Foundation of China, grant number 52004271, the National Science Fund for Distinguished Young Scholars, grant number 51725403, the China Postdoctoral Science Foundation, grant number 2021M693417, the Jiangsu Postdoctoral Research Funding Program, grant number 2021K039A, and the Postgraduate Research & Practice Innovation Program of Jiangsu Province, grant number KYCX21_2359.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- BP. BP Statistical Review of World Energy 2021; BP: London, UK, 2021. [Google Scholar]

- National Bureau of Statistics of China. 2021 Statistical Bulletin of National Economic and Social Development of the People’s Republic of China; National Bureau of Statistics of China: Beijing, China, 2022. [Google Scholar]

- China National Coal Association. Annual Report on Coal Industry in China (2021); China National Coal Association: Beijing, China, 2022. [Google Scholar]

- National Energy Administration. The 13th Five-Year Plan for Coal Industry; National Energy Administration: Beijing, China, 2016. [Google Scholar]

- Qi, W.Y. Study on Environmental Effects of Gangue Backfilled Body in Underground Coal Mines. Ph.D. thesis, China University of Mining and Technology, Xuzhou, China, 2019. [Google Scholar]

- Yang, Y. Coal gangue stacked and its comprehensive utilization. China Resour. Compr. Util. 2014, 32, 18–22. [Google Scholar]

- Zhang, Y.Y.; Nakano, J.; Liu, L.; Wang, X.D. Trace element partitioning behavior of coal gangue-fired CFB plant: Experimental and equilibrium calculation. Environ. Sci. Pollut. Res. 2015, 22, 15469–15478. [Google Scholar] [CrossRef] [PubMed]

- He, Y. An analysis of waste solid exchange. Environ. Sci. Surv. 2008, 6, 23–25. [Google Scholar]

- Finkelman, R.B.; Orem, W.; Castranova, V.; Tatu, C.A.; Belkin, H.E.; Zheng, B.; Lerch, H.E.; Maharaj, S.V.; Bates, A.L. Health impacts of coal and coal use: Possible solutions. Int. J. Coal Geol. 2002, 50, 425–443. [Google Scholar] [CrossRef]

- Guo, Y.X.; Zhang, Y.Y.; Cheng, F.Q. Industrial development and prospect about comprehensive utilization of coal gangue. J. Chem. Ind. Eng. 2014, 65, 2443–2453. [Google Scholar]

- Wang, L.H.; Guan, Y.; Wang, D.H.; Liu, D.Y.; Fu, X.; Li, Y.L. Effects of gangue with different substrates on the growth of Chinese cabbage. J. Earth Environ. 2014, 4, 266–270. [Google Scholar]

- Wu, H.; Wen, Q.; Hu, L.; Gong, M.; Tang, Z. Feasibility study on the application of coal gangue as landfill liner material. Waste Manag. 2017, 63, 161–171. [Google Scholar] [CrossRef]

- Liu, M.; Lu, H.; Deng, Q.; Ji, S.; Qin, L.; Wan, Y. Shear strength, water permeability and microstructure of modified municipal sludge based on industrial solid waste containing calcium used as landfill cover materials. Waste Manag. 2022, 145, 20–28. [Google Scholar] [CrossRef]

- Peng, F.C.; Wang, Q.S. Research progress on domestic comprehensive utilization of coal gangue. Energy Environ. Prot. 2016, 30, 17–20. [Google Scholar]

- Tang, Q. Study on Coal Gangue Embankment Settlement and Slope Stability in Expressways. Master’s thesis, Central South University, Changsha, China, 2014. [Google Scholar]

- Li, J.; Wang, J. Comprehensive utilization and environmental risks of coal gangue: A review. J. Clean. Prod. 2019, 239, 117946. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, G.; Wang, D.; Liao, S.; Zhai, M. The hydration properties of blended cement containing ultrafine fly ash with particle size less than 17µm from the circulating fluidized bed combustion of coal gangue. J. Therm. Anal. Calorim. 2020, 139, 2971–2984. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Ling, T.-C. Reactivity activation of waste coal gangue and its impact on the properties of cement-based materials—A review. Construct. Build. Mater. 2020, 234, 117424. [Google Scholar] [CrossRef]

- Xu, H.; Song, W.; Cao, W.; Shao, G.; Lu, H.; Yang, D.; Chen, D.; Zhang, R. Utilization of coal gangue for the production of brick. J. Mater. Cycles Waste Manag. 2016, 19, 1270–1278. [Google Scholar] [CrossRef]

- Zhou, C.; Liu, G.; Cheng, S.; Fang, T.; Lam, P.K.S. The Environmental Geochemistry of Trace Elements and Naturally Radionuclides in a Coal Gangue Brick-Making Plant. Sci. Rep. 2014, 4, 1331–1340. [Google Scholar] [CrossRef]

- Schumacher, K.; Saßmannshausen, N.; Pritzel, C.; Trettin, R. Lightweight aggregate concrete with an open structure and a porous matrix with an improved ratio of compressive strength to dry density. Constr. Build. Mater. 2020, 264, 120167. [Google Scholar] [CrossRef]

- Yang, Y.R.; Ma, Y.L.; Wang, J.; Wang, J. Effect of coal gangue content on performance of fly ash porous ceramistibe. J. Inner Mong. Univ. Sci. Technol. 2017, 36, 187–190. [Google Scholar]

- Dang, W.; He, H.Y. Glass-ceramics fabricated by efficiently utilizing coal gangue. J. Asian Ceram. Soc. 2020, 8, 365–372. [Google Scholar] [CrossRef]

- Chen, J.; Li, X.; Cai, W.; Shi, Y.; Hui, X.; Cai, Z.; Jin, W.; Fan, J. High-efficiency extraction of aluminum from low-grade kaolin via a novel low-temperature activation method for the preparation of poly-aluminum-ferric-sulfate coagulant. J. Clean. Prod. 2020, 257, 120399. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Liu, X.; Du, Z.; Cheng, F. Effect of silicon content on preparation and coagulation performance of poly-silicic-metal coagulants derived from coal gangue for coking wastewater treatment. Sep. Purif. Technol. 2018, 202, 149–156. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, Z.; Liu, K.; Li, F.; Pang, Y.; Zhang, J.; Si, H. Preparation of nano-sized Mg-doped copper silicate materials using coal gangue as the raw material and its characterization for CO2 adsorption. Korean J. Chem. Eng. 2020, 37, 1786–1794. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Wang, S.; Du, Z.; Guo, Y.; Cheng, F. Synthesis and optimization of a novel poly-silicic metal coagulant from coal gangue for tertiary-treatment of coking wastewater. J. Chem. Technol. Biotechnol. 2017, 93, 365–371. [Google Scholar] [CrossRef]

- Chen, S.; Chen, J.; Xu, K.; Pan, R.; Peng, Z.; Ma, L.; Wu, S. Effect of coal gangue/carbon black/multiwall carbon nanotubes hybrid fillers on the properties of natural rubber composites. Polym. Compos. 2015, 37, 3083–3092. [Google Scholar] [CrossRef]

- Shan, X.P. Property Analysis of Coal Gangue and Feasibility Study of Using Coal Gangue as Rubber Reinforcing Fillers. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2014. [Google Scholar]

- Junker, M.; Witthaus, H. Progress in the research and application of coal mining with stowing. Int. J. Min. Sci. Technol. 2013, 23, 7–12. [Google Scholar] [CrossRef]

- Mo, S.; Canbulat, I.; Zhang, C.; Oh, J.; Shen, B.; Hagan, P. Numerical investigation into the effect of backfilling on coal pillar strength in highwall mining. Int. J. Min. Sci. Technol. 2017, 28, 281–286. [Google Scholar] [CrossRef]

- Matsui, K.; Shimada, H.; Sasaoka, T.; Ichinose, M.; Kubota, S. Highwall mining system with backfilling. In Mine Planning and Equipment Selection 2000; Routledge: London, UK, 2018; pp. 333–338. [Google Scholar]

- Kolikov, K.S.; Mazina, I.E.; Manevich, A.I. Stress-strain analysis in coal and rock mass under traditional mining with full caving and in technology with backfilling. Eurasian Min. 2018, 2018, 15. [Google Scholar] [CrossRef]

- Hefni, M.; Ahmed, H.A.; Omar, E.S.; Ali, M.A. The Potential Re-Use of Saudi Mine Tailings in Mine Backfill: A Path towards Sustainable Mining in Saudi Arabia. Sustainability 2021, 13, 6204. [Google Scholar] [CrossRef]

- Raffaldi, M.J.; Seymour, J.B.; Richardson, J.; Zahl, E.; Board, M. Cemented paste backfill geomechanics at a narrow-vein underhand cut-and-fill mine. Rock Mech. Rock Eng. 2019, 52, 4925–4940. [Google Scholar] [CrossRef]

- Xu, H.; Apel, D.B. Optimum location of last-mined stope with the influence of backfilling. J. Sustain. Min. 2020, 19, 212–220. [Google Scholar] [CrossRef]

- Adach-Pawelus, K.; Pawelus, D. Application of Hydraulic Backfill for Rockburst Prevention in the Mining Field with Remnant in the Polish Underground Copper Mines. Energies 2021, 14, 3869. [Google Scholar] [CrossRef]

- Skrzypkowski, K. 3D Numerical Modelling of the Application of Cemented Paste Backfill on Displacements around Strip Excavations. Energies 2021, 14, 7750. [Google Scholar] [CrossRef]

- Liu, Y.M.; Ma, J.S.; Guo, L.; Zhang, A.M.; Chen, X.W.; Zhang, S.J.; Xia, C.N. Summarization of mining technology with backfilling in foreign deep mines. China Mine Eng. 2018, 47, 6. [Google Scholar]

- Liang, L.I.; Zhang, X.W.; Ferri, H. Review on the basic theory of paste backfill in oversea. China Mining Mag. 2016, 25, 8. [Google Scholar]

- Luo, Y.F. A preliminary survey of comprehensive utilization of coal gangue in Shuicheng mining area. Coal Process. Compr. Util. 2020, 6, 81–85+91. [Google Scholar]

- Hao, Y.; Guo, X.; Yao, X.; Han, R.; Li, L.; Zhang, M. Using Chinese coal gangue as an ecological aggregate and its modification: A Review. Materials 2022, 15, 4495. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.X.; Miao, X.X.; Guo, G.L. Development status of backfilling technology using raw waste in coal mining. J. Mining Saf. Eng. 2009, 26, 395–401. [Google Scholar]

- Hu, B.N. Backfill mining technology and development tendency in China coal mine. Coal Sci. Technol. 2012, 40, 1–5+18. [Google Scholar]

- Liu, J.G.; Li, X.W.; He, T. Application status and prospect of backfill mining in Chinese coal mines. J. China Coal Soc. 2020, 45, 141–150. [Google Scholar]

- Qian, M.G.; Xu, J.L.; Miao, X.X. Green coal mining technology. J. China Univ. Mining Technol. 2003, 4, 5–10. [Google Scholar]

- Bian, Z.F.; Jin, D.; Dong, J.H.; Mu, S.G. Discussion on rational ways for coal gangue treatment and utilization. J. Mining Saf. Eng. 2007, 24, 132–136. [Google Scholar]

- Liu, W.C.; Pan, Y.T.; Zhao, Y.X.; Gao, Z.R.; Yin, S.Y.; Wu, P. The present situation and the treatment suggestions of coal gangue storage in Yangquan area. Coal Process. Compr. Util. 2018, 11, 78–81. [Google Scholar]

- Gu, C.; Li, Y. Study on progress in comprehensive utilization of coal-based solid wastes. Coal Chem. Ind. 2020, 43, 98–101+106. [Google Scholar]

- Wei, B.X.; Sun, X.L. The status quo of China’s comprehensive utilization of coal gangue and countermeasures. Nat. Resour. Econ. China 2016, 29, 51–53+72. [Google Scholar]

- Zhang, Y.J.; Chang, X.; Yang, J.H. Analysis on restoration and treatment technology of ecological environment for coal gangue dump. Shanxi Chem. Ind. 2019, 1, 185–188. [Google Scholar]

- Hua, C.; Zhou, G.; Yin, X.; Wang, C.; Chi, B.; Cao, Y.; Wang, Y.; Zheng, Y.; Cheng, Z.; Li, R. Assessment of heavy metal in coal gangue: Distribution, leaching characteristic and potential ecological risk. Environ. Sci. Pollut. Res. 2018, 25, 32321–32331. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, X.; Hu, S.; Shao, H.; Liao, Q.; Fan, Y. Experimental study of the effects of stacking modes on the spontaneous combustion of coal gangue. Process. Saf. Environ. Prot. 2018, 123, 39–47. [Google Scholar] [CrossRef]

- Li, B.; Wang, J.H.; Bi, M.S.; Gao, W.; Shu, C.M. Experimental study of thermophysical properties of coal gangue at initial stage of spontaneous combustion. J. Hazard. Mater. 2020, 400, 123251. [Google Scholar] [CrossRef]

- Wang, H.; Tan, B.; Zhang, X. Research on the technology of detection and risk assessment of fire areas in gangue hills. Environ. Sci. Pollut. Res. 2020, 27, 38776–38787. [Google Scholar] [CrossRef]

- Zhang, J.; Li, M.; Taheri, A.; Zhang, W.; Wu, Z.; Song, W. Properties and Application of Backfill Materials in Coal Mines in China. Minerals 2019, 9, 53. [Google Scholar] [CrossRef]

- Ma, D.; Zhang, J.; Duan, H.; Huang, Y.; Li, M.; Sun, Q.; Zhou, N. Reutilization of gangue wastes in underground backfilling mining: Overburden aquifer protection. Chemosphere 2020, 264, 128400. [Google Scholar] [CrossRef]

- Zhang, J.X.; Miao, X.X. Underground disposal of waste in coal mine. J. China Univ. Mining Technol. 2006, 35, 197–200. [Google Scholar]

- Zha, J.F. Study on Theory and Technology of Coal Gangue Backfill Strip Mining and Strata Control. Ph.D. thesis, China University of Mining and Technology, Xuzhou, China, 2008. [Google Scholar]

- Miao, X.X.; Zhang, J.X.; Guo, G.L. Study on waste-filling method and technology in fully-mechanized coal mining. J. China Coal Soc. 2010, 35, 1–6. [Google Scholar]

- Miao, X.X. Progress of fully mechanized mining with solid backfilling technology. J. China Coal Soc. 2012, 37, 1247–1255. [Google Scholar]

- Zhang, J.X.; Miao, X.X.; Guo, G.L. Consolidated Solid Backfill Mining Method and its Applications; Science Press: Beijing, China, 2015. [Google Scholar]

- Huang, P.; Zhang, J.; Yan, X.; Spearing, A.J.S.; Li, M.; Liu, S. Deformation response of roof in solid backfilling coal mining based on viscoelastic properties of waste gangue. Int. J. Min. Sci. Technol. 2021, 31, 279–289. [Google Scholar] [CrossRef]

- Le, Z.; Yu, Q.; Zhu, W.; Liu, H.; Yang, T. Experimental study on the effect of granular backfill with various gradations on the mechanical behavior of rock. Int. J. Min. Sci. Technol. 2021, 31, 889–899. [Google Scholar] [CrossRef]

- Zhang, J.X.; Zhang, Q.; Ju, F.; Zhou, N.; Li, M.; Sun, Q. Theory and technique of greening mining integrating mining, separating and backfilling in deep coal resources. J. China Coal Soc. 2018, 43, 377–389. [Google Scholar]

- Zhang, J.; Zhang, Q.; Spearing, A.S.; Miao, X.; Guo, S.; Sun, Q. Green coal mining technique integrating mining-dressing-gas draining-backfilling-mining. Int. J. Min. Sci. Technol. 2017, 27, 17–27. [Google Scholar] [CrossRef]

- Tu, S.; Hao, D.; Li, W.; Liu, X.; Miao, K.; Yang, Z.; Ban, J. Construction of the theory and technology system of selective mining in “mining, dressing, backfilling and X” integrated mine. J. Min. Saf. Eng. 2020, 37, 81–92. [Google Scholar]

- Zhang, J.X.; Zhang, Q.; Ju, F.; Zhou, N.; Li, M.; Zhang, W.Q. Practice and technique of green mining with integration of mining. dressing. backfilling and X in coal resources. J. China Coal Soc. 2019, 44, 64–73. [Google Scholar]

- Tai, Y.; Han, X.; Huang, P.; An, B. The mining pressure in mixed workface using a gangue backfilling and caving method. J. Geophys. Eng. 2019, 16, 1–15. [Google Scholar] [CrossRef]

- Wei, Y.; Xiexing, M.; Jixiong, Z.; Qiang, Z.; Qiang, S. Research on mixed mining technology with backfilling and caving methods. J. Min. Saf. Eng. 2016, 33, 845–852. [Google Scholar]

- Zhang, Q.; Du, C.-L.; Zhang, J.-X.; Wang, J.-Q.; Li, M.; Qi, W.-Y. Backfill support’s backfill and operation properties and evaluation. J. Cent. South Univ. 2018, 25, 1524–1534. [Google Scholar] [CrossRef]

- Xuejie, D.; Jixiong, Z.; Nan, Z.; Tailong, A.; Shuai, G. The research and application of longwall-roadway cemented backfilling mining technology in extra-thick coal seam. J. Min. Saf. Eng. 2014, 31, 857–862. [Google Scholar]

- Qin, J.; Zheng, J.; Li, L. An analytical solution to estimate the settlement of tailings or backfill slurry by considering the sedimentation and consolidation. Int. J. Min. Sci. Technol. 2021, 31, 463–471. [Google Scholar] [CrossRef]

- Deng, X.J.; Zhang, J.X.; Zhou, N.; de Wit, B.; Wang, C.T. Upward slicing longwall-roadway cemented backfilling technology for mining an extra-thick coal seam located under aquifers: A case study. Environ. Earth Sci. 2017, 76, 789. [Google Scholar] [CrossRef]

- Zhou, H.Q.; Hou, C.J.; Sun, X.K.; Zhai, Q.D.; Chen, D.J. Solid Waste paste filling for none-village-relocation coal mining. J. China Univ. Mining Technol. 2004, 2, 30–34+53. [Google Scholar]

- Chang, Q.; Chen, J.; Zhou, H.; Bai, J. Implementation of Paste Backfill Mining Technology in Chinese Coal Mines. Sci. World J. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Miao, X.X.; Ju, F.; Huang, Y.L.; Guo, G.L. New development and prospect of backfilling mining theory and technology. J. China Univ. Min. Technol. 2015, 44, 391–399+429. [Google Scholar]

- Li, M.; Zhang, J.; Li, A.; Zhou, N. Reutilisation of coal gangue and fly ash as underground backfill materials for surface subsidence control. J. Clean. Prod. 2020, 254, 120113. [Google Scholar] [CrossRef]

- Huang, P.; Spearing, A.J.S.; Feng, J.; Jessu, K.V.; Guo, S. Effects of solid backfilling on overburden strata movement in shallow depth longwall coal mines in West China. J. Geophys. Eng. 2018, 15, 2194–2208. [Google Scholar] [CrossRef]

- Huang, Y.L.; Zhang, J.X.; An, B.F.; Zhang, Q. Overlying strata movement law in fully mechanized coal mining and backfilling longwall face by similar physical simulation. J. Min. Sci. 2011, 47, 618–627. [Google Scholar]

- Yin, W. Ground Control Theory and Application of Backfilling Collaborate with Caving Fully-Mechanized Mining. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2017. [Google Scholar]

- Wang, Y.; Huang, Y.; Hao, Y. Experimental Study and Application of Rheological Properties of Coal Gangue-Fly Ash Backfill Slurry. Processes 2020, 8, 284. [Google Scholar] [CrossRef]

- Rong, K.; Lan, W.; Li, H. Industrial Experiment of Goaf Filling Using the Filling Materials Based on Hemihydrate Phosphogypsum. Minerals 2020, 10, 324. [Google Scholar] [CrossRef]

- Wei, C.; Wang, X.-M.; Zhang, Y.-H.; Zhang, Q.-L. Paste-like cemented backfilling technology and rheological characteristics analysis based on jigging sands. J. Cent. South Univ. 2017, 24, 155–167. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, S.; Zhang, N.; Zhao, C. The application of short-wall block backfill mining to preserve surface water resources in northwest China. J. Clean. Prod. 2020, 261, 121232. [Google Scholar] [CrossRef]

- Li, B.; Zhou, N.; Qi, W.; Li, A.; Cui, Z. Surface Subsidence Control during Deep Backfill Coal Mining: A Case Study. Adv. Civ. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Ju, Y.; Wang, X. Understanding the Capacity Utilization Rate and Overcapacity of China’s Coal Industry and Interprovincial Heterogeneity. IEEE Access 2019, 7, 111375–111386. [Google Scholar] [CrossRef]

- Li, C.; Wang, A.; Chen, X.; Chen, Q.; Zhang, Y.; Li, Y. Regional distribution and sustainable development strategy of mineral resources in China. Chin. Geogr. Sci. 2013, 23, 470–481. [Google Scholar] [CrossRef]

- Zhao, K.G.; Li, Y.P. Analysis and development suggestion for coal resources safety in China. Coal Eng. 2018, 50, 185–189. [Google Scholar]

- Xu, W.P. Study on innovation and development of shearer technology in China. Coal Mine Mach. 2021, 42, 27–29. [Google Scholar]

- Xu, Z.G. Review, rethink, and prospect of China’s modern and chemical industry development in recent 25 years. Coal Sci. Technol. 2020, 48, 1–25. [Google Scholar]

- Zhang, Q.; Zhang, J.-X.; Tai, Y.; Fang, K.; Yin, W. Horizontal roof gap of backfill hydraulic support. J. Cent. South Univ. 2015, 22, 3544–3555. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.-X.; Qi, W.-Y.; Zhou, N.; Tai, Y. Structure optimal design research on backfill hydraulic support. J. Cent. South Univ. 2017, 24, 1637–1646. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.X.; Tai, Y.; Ju, F.; Sun, Q. The theoretical research on basic characteristics of backfilling hydraulic support and its application. J. Min. Saf. Eng. 2014, 31, 845–851. [Google Scholar]

- Dolipski, M.; Remiorz, E.; Sobota, P. Determination of dynamic loads of sprocket drum teeth and seats by means of a mathematical model of the longwall conveyor. Arch. Min. Sci. 2012, 57, 1101–1119. [Google Scholar]

- Luan, L.J.; Fan, M.F.; Guo, J.S.; Gao, H. A study on the design of dumping hole in multihole-bottom-dump chain conveyor. Coal Mine Mach. 2016, 37, 5–7. [Google Scholar]

- Gao, H.; Zhao, L.; Du, X.S.; Yuan, W.J. Study and design of the multihole-bottom-dump filling scraper conveyor. Coal Mine Mach. 2014, 35, 131–133. [Google Scholar]

- Liu, W.L.; Xu, Y.M.; Qin, J.; Zhu, L.D. Improvement of the head and tail of the filling scraper conveyor. Min. Process. Equip. 2012, 40, 129–130. [Google Scholar]

- Ning, Y.L.; Ou, R.Z.; Lin, W.X.; Zhan, J. A study on the optimization and modification of the pumping system for full graded gravel cement filling materials. Nonferrous Met. 2017, 69, 7–9+17. [Google Scholar]

- Wang, L.H.; Bao, A.H.; Luo, Y.Y. Application and prospect of China’s filling technology. Min. Res. Dev. 2017, 37, 1–7. [Google Scholar]

- Huang, Z.; Zhang, L.; Ma, Z. Study on the Mechanical Relationship among the Backfilling Mining Support, Roof Rock Beam, and Gangue Filling Body in Comprehensive Mechanized Filling Mining Process. Adv. Civ. Eng. 2020, 2020, 1–15. [Google Scholar] [CrossRef]

- Zhao, L.S.; Guo, J.X.; Zhao, H.; Qie, L. A study on the automatic control system technology for the backfilling shield. Coal Technol. 2020, 39, 170–172. [Google Scholar]

- Zhang, Q.; Wu, Z.Y.; Du, E.B.; Chen, Y.; Huang, L.; Li, M. Working resistance design method of backfilling shield. J. Min. Saf. Eng. 2020, 37, 118–127. [Google Scholar]

- Gao, H. Mechanics properties research and structure on the main part of hanging scraper conveyor of solid backfill hydraulic support. Master’s Thesis, Liaoning Technical University, Fuxin, China, 2016. [Google Scholar]

- Zhang, D.S.; Yuan, S.; Yuan, Z.; Song, Q.S.; Gao, H. Simulation research of the hanging scraper conveyor of the solid filling hydraulic support. J. Mech. Transm. 2017, 41, 140–145+177. [Google Scholar]

- Ralston, J.C.; Hargrave, C.O.; Dunn, M.T. Longwall automation: Trends, challenges and opportunities. Int. J. Min. Sci. Technol. 2017, 27, 733–739. [Google Scholar] [CrossRef]

- Wang, G.; Xu, Y.H. Intelligent and ecological coal mining as well as clean utilization technology in China: Review and prospects. Int. J. Min. Sci. Technol. 2019, 29, 161–169. [Google Scholar] [CrossRef]

- Barnewold, L.; Lottermoser, B.G. Identification of digital technologies and digitalisation trends in the mining industry. Int. J. Min. Sci. Technol. 2020, 30, 747–757. [Google Scholar] [CrossRef]

- Rogers, W.P.; Kahraman, M.M.; Drews, F.A.; Powell, P.; Haight, J.M.; Wang, Y.; Baxla, K.; Sobalkar, M. Automation in the mining industry: Review of technology, systems, human factors, and political risk. Min. Metall. Explor. 2019, 36, 607–631. [Google Scholar]

- Meng, Z.S.; Zhang, S.; Xie, Y.Y.; Zeng, Q.L. Attitude Adjustment of Backfilling Support Based on Mechanical-Hydraulic Co-Simulation. Int. J. Simul. Model. 2020, 19, 399–409. [Google Scholar] [CrossRef]

- Peng, S.S.; Du, F.; Cheng, J.; Li, Y. Automation in U.S. longwall coal mining: A state-of-the-art review. Int. J. Min. Sci. Technol. 2019, 29, 151–159. [Google Scholar] [CrossRef]

- Bołoz, Ł.; Biały, W. Automation and Robotization of Underground Mining in Poland. Appl. Sci. 2020, 10, 7221. [Google Scholar] [CrossRef]

- Wang, J.; Huang, Z. The Recent Technological Development of Intelligent Mining in China. Engineering 2017, 3, 439–444. [Google Scholar] [CrossRef]

- Ranjith, P.; Zhao, J.; Ju, M.; De Silva, R.V.; Rathnaweera, T.; Bandara, A.K. Opportunities and Challenges in Deep Mining: A Brief Review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Liu, J.G.; Bi, J.M.; Zhao, L.T.; Xie, G.Q. Research and application of fully mechanized mining with solid backfilling technology. Coal Sci. Technol. 2016, 44, 149–156. [Google Scholar]

- Jiao, S.L.; Lin, J.G.; Shang, L. Automated system for fully mechanized mining with solid backfilling technology. Coal Sci. Technol. 2015, 43, 109–113+108. [Google Scholar]

- Huang, J.; Tian, C.; Xing, L.; Bian, Z.; Miao, X. Green and Sustainable Mining: Underground Coal Mine Fully Mechanized Solid Dense Stowing-Mining Method. Sustainability 2017, 9, 1418. [Google Scholar] [CrossRef]

- Zhou, N.; Yao, Y.N.; Song, W.J.; He, Z.W.; Meng, G.H.; Liu, Y. Present situation and prospect of coal gangue treatment technology. J. Min. Saf. Eng. 2020, 37, 136–146. [Google Scholar]

- Zhang, J.X.; Tu, S.H.; Cao, Y.J.; Tan, Y.L.; Xin, H.Q.; Pang, J.L. Research progress of technologies for intelligent separation and in-situ backfill in deep coal mines in China. J. Min. Saf. Eng. 2020, 37, 1–10+22. [Google Scholar]

- Ma, L.Q.; Sun, H.; Ngo, I.; Han, J. Infrared radiation quantification of rock damage and its constitutive modeling under loading. Infrared Phys. Technol. 2022, 121, 104044. [Google Scholar] [CrossRef]

- Ma, L.Q.; Khan, N.M.; Cao, K.W.; Rehman, H.; Salman, S.; Rehman, F.U. Prediction of sandstone dilatancy point in different water contents using infrared radiation characteristic: Experimental and machine learning approaches. Lithoshere 2021, 4, 3243070. [Google Scholar] [CrossRef]

- Ma, L.; Xu, Y.; Ngo, I.; Wang, Y.; Zhai, J.; Hou, L. Prediction of water-blocking capability of water-seepage-resistance strata based on AHP-fuzzy comprehensive evaluation method—A case study. Water 2022, 14, 2517. [Google Scholar] [CrossRef]

- Wang, P.; Hu, Z.; Wang, P. Attenuation of heavy metals by geosynthetics in the coal gangue-filled columns. Environ. Technol. 2013, 34, 2889–2895. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Wang, W.; Bian, Z. Prospects of resource utilization and disposal of coal-based solid wastes in Xinjiang. Coal Sci. Technol. 2021, 49, 319–330. [Google Scholar]

- Zhang, J.X.; Ju, Y.; Zhang, Q.; Ju, F.; Xiao, X.; Zhang, W.Q.; Zhou, N.; Li, M. Low ecological environment damage technology and method in coal mines. J. Min. Strata Control Eng. 2019, 1, 56–68. [Google Scholar]

- Guo, S.; Zhang, J.; Li, M.; Zhou, N.; Song, W.; Wang, Z.; Qi, S. A preliminary study of solid-waste coal gangue based biomineralization as eco-friendly underground backfill material: Material preparation and macro-micro analyses. Sci. Total Environ. 2021, 770, 145241. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.J.; Liu, M.; Xing, Y.W.; Li, G.S.; Luo, J.Q.; Gui, X.H. Current situation and prospect of underground coal preparation technology. J. Min. Saf. Eng. 2020, 37, 192–201. [Google Scholar]

- Sun, Q.; Zhang, J.; Qi, W.; Li, M. Backfill mining alternatives and strategies for mitigating shallow coal mining hazards in the western mining area of China. Q. J. Eng. Geol. Hydrogeol. 2019, 53, 217–226. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J.; Li, B.; Zhou, N.; Xiao, X.; Li, M.; Zhu, C. Environmental behavior of construction and demolition waste as recycled aggregates for backfilling in mines: Leaching toxicity and surface subsidence studies. J. Hazard. Mater. 2020, 389, 121870. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).