Experimental Study on Pot Damage and Contact Stress Distribution Characteristics of Oil Sunflower Plug Seedlings

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Material

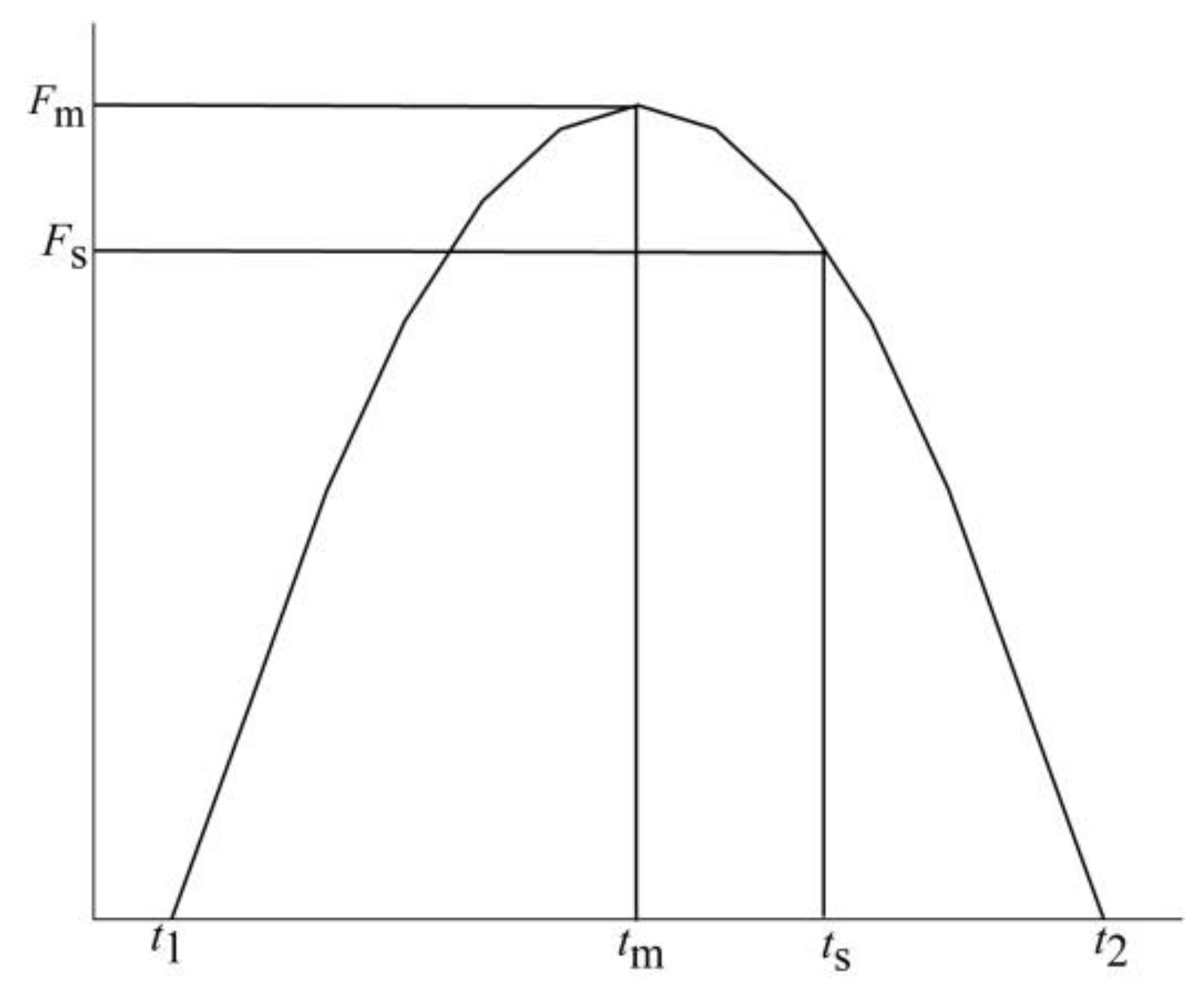

2.2. Collision Impact Force Analysis of Oil Sunflower Plug Seedlings

2.2.1. Analysis of Collision Impact Force Change Process of Oil Sunflower Seedlings

2.2.2. Theoretical Analysis on Contact Force of Oil Sunflower Plug Seedlings

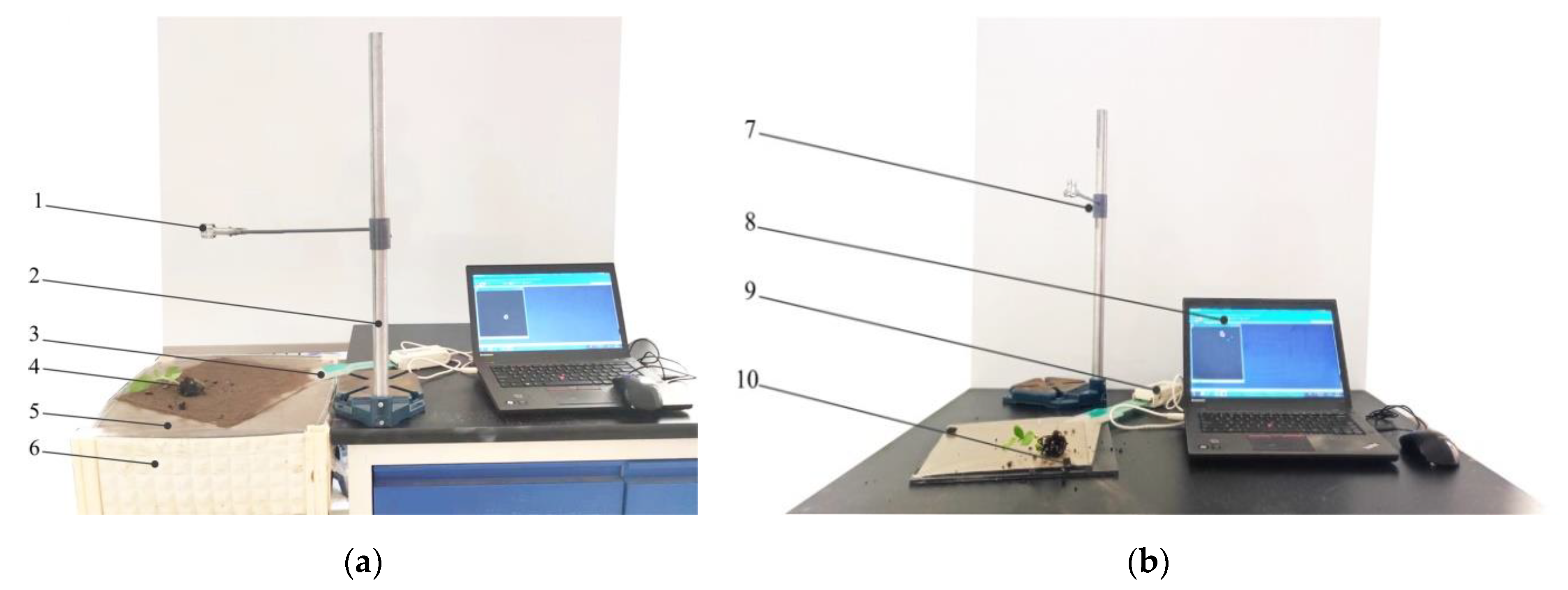

2.3. Drop Impact Test on Oil Sunflower Plug Seedlings

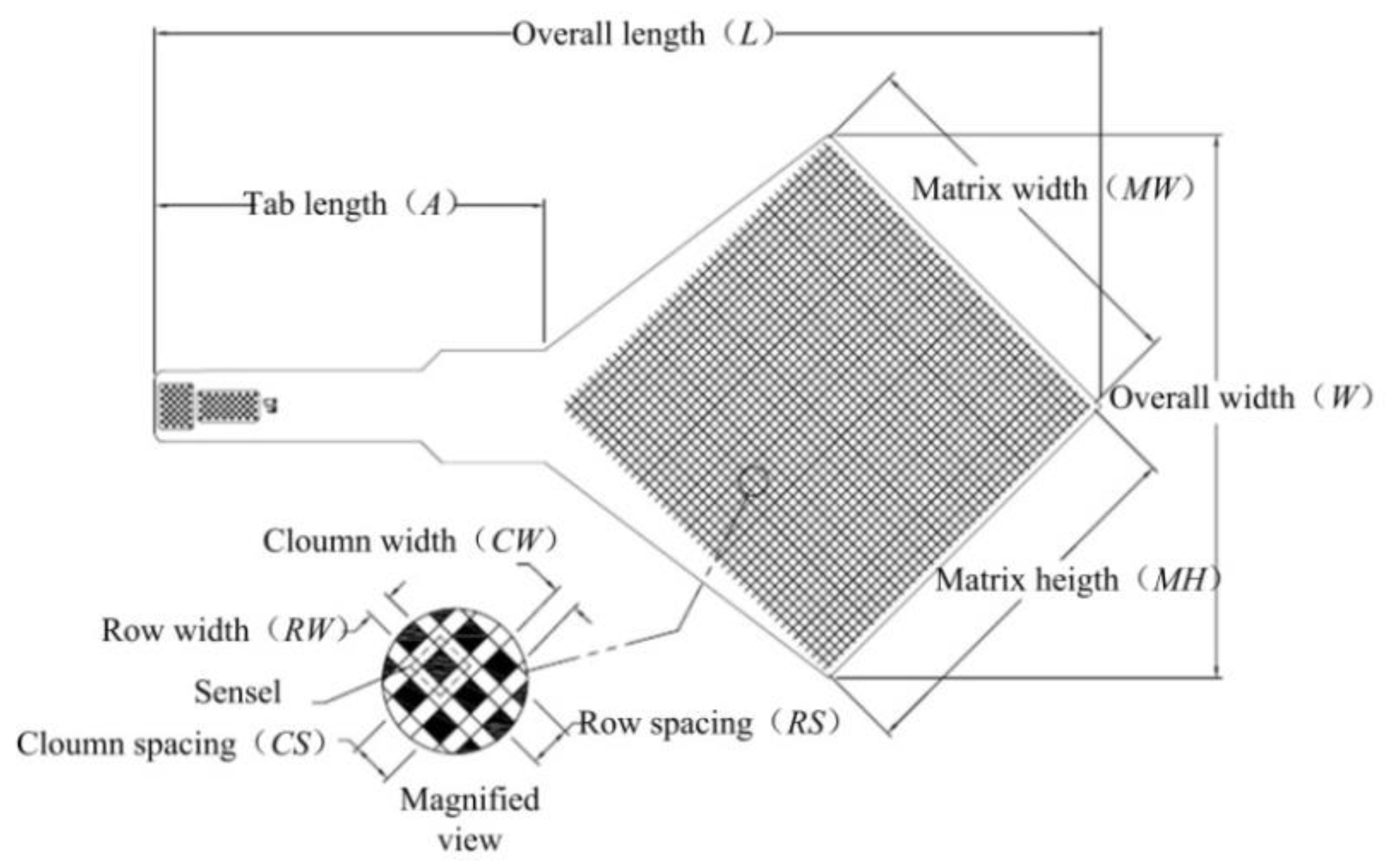

2.4. Testing Principle and Method of the Flexible Film Network Tactile Pressure Sensor

2.5. Pot Damage Measurement Method

2.6. Orthogonal Test and Significance Analysis

3. Results and Discussion

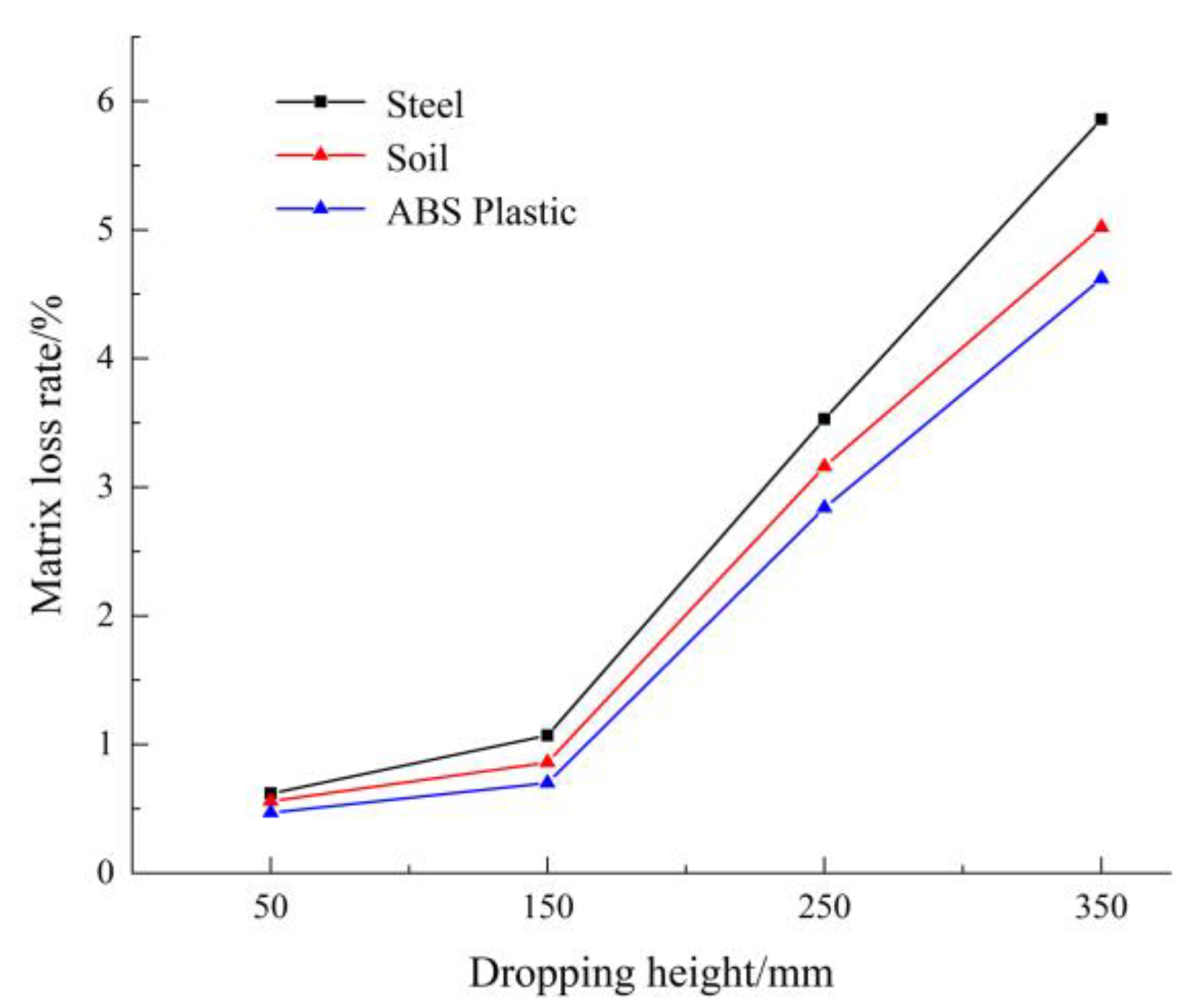

3.1. Variation Law of Collision Impact Damage of the Pot

3.1.1. Variation Law of the Collision Impact Damage under Different Contact Materials

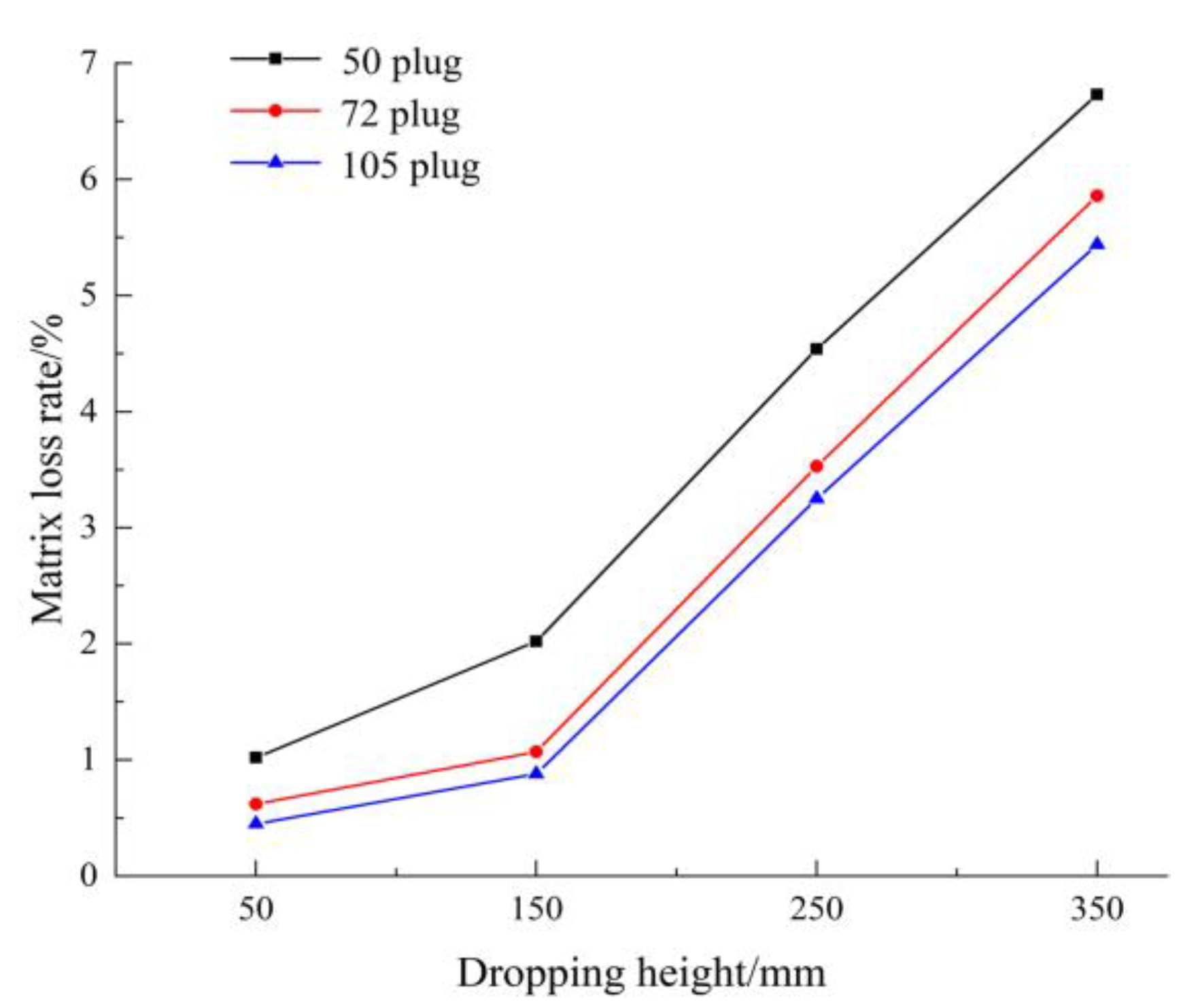

3.1.2. Variation Law of Collision Impact Damage under Different Plug Specifications

3.2. Establishment of Collision Impact Force Model and Regression Analysis

3.3. Analysis of Collision Contact Stress Distribution between Oil Sunflower Plug Seedlings and Contact Materials

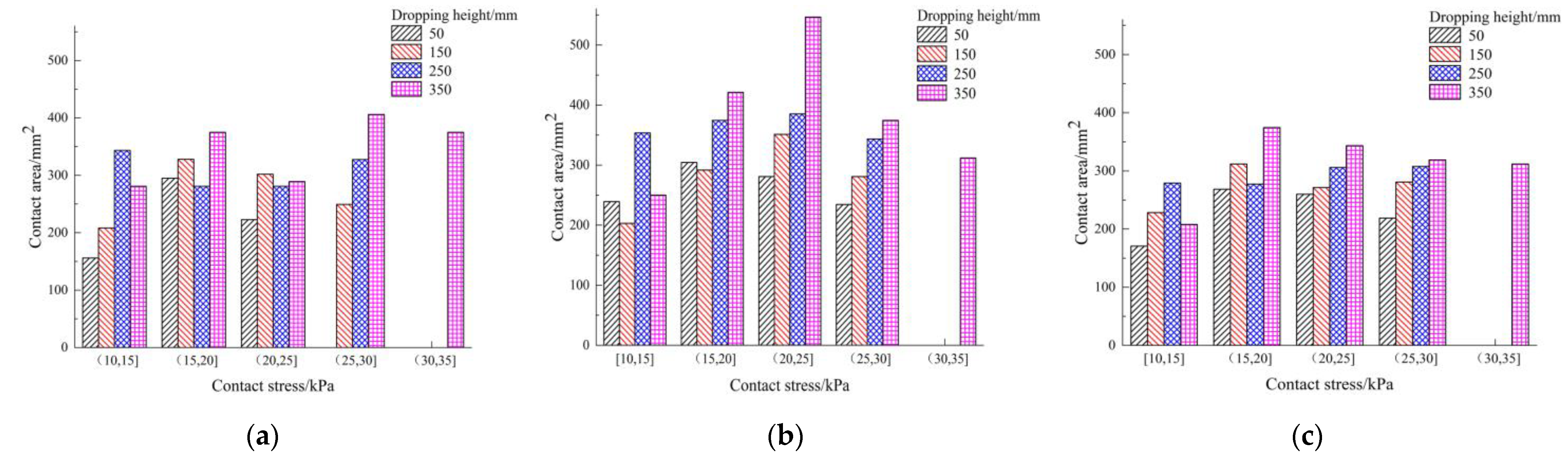

3.3.1. Collision Contact Stress Distribution Characteristics of Contact Material to Plug Seedlings

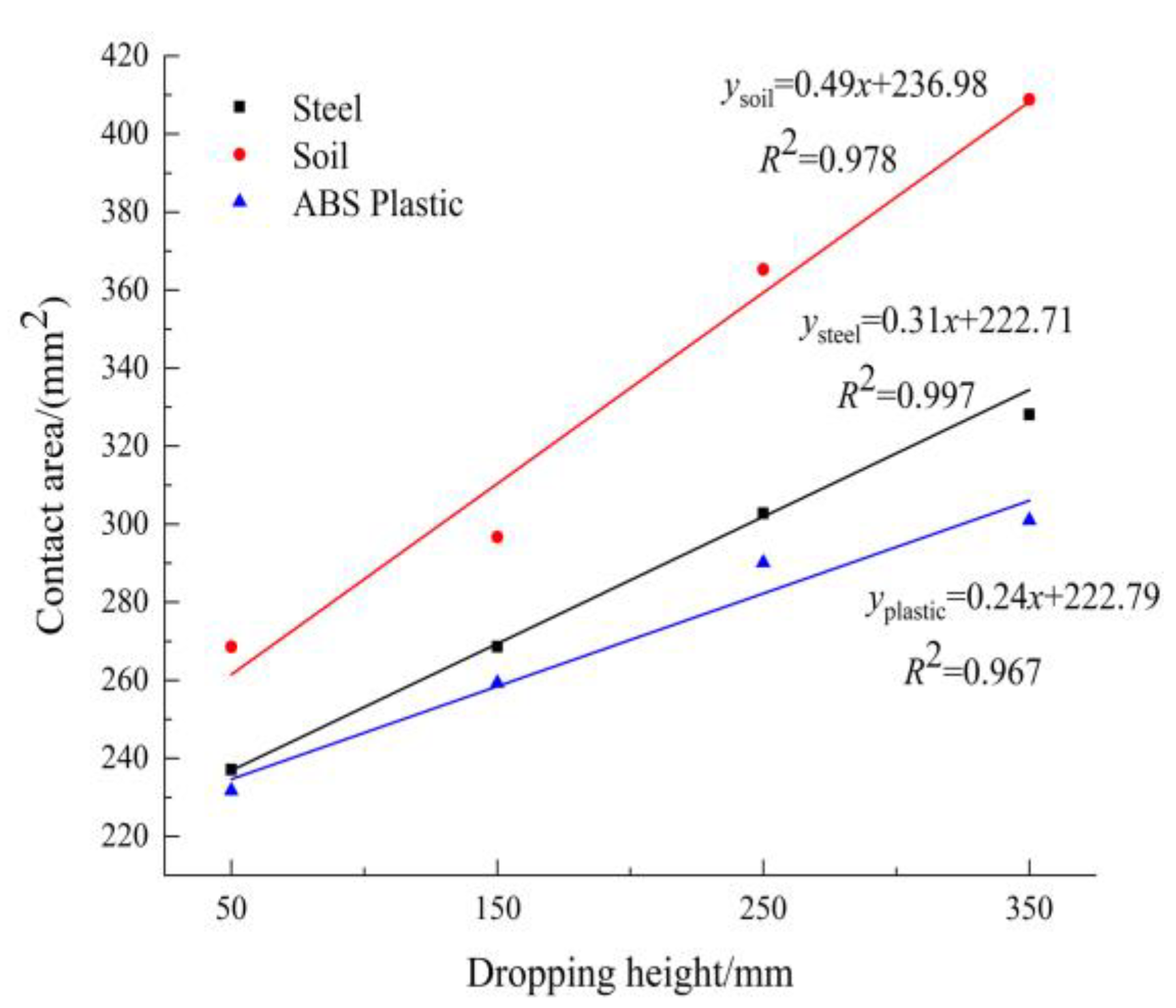

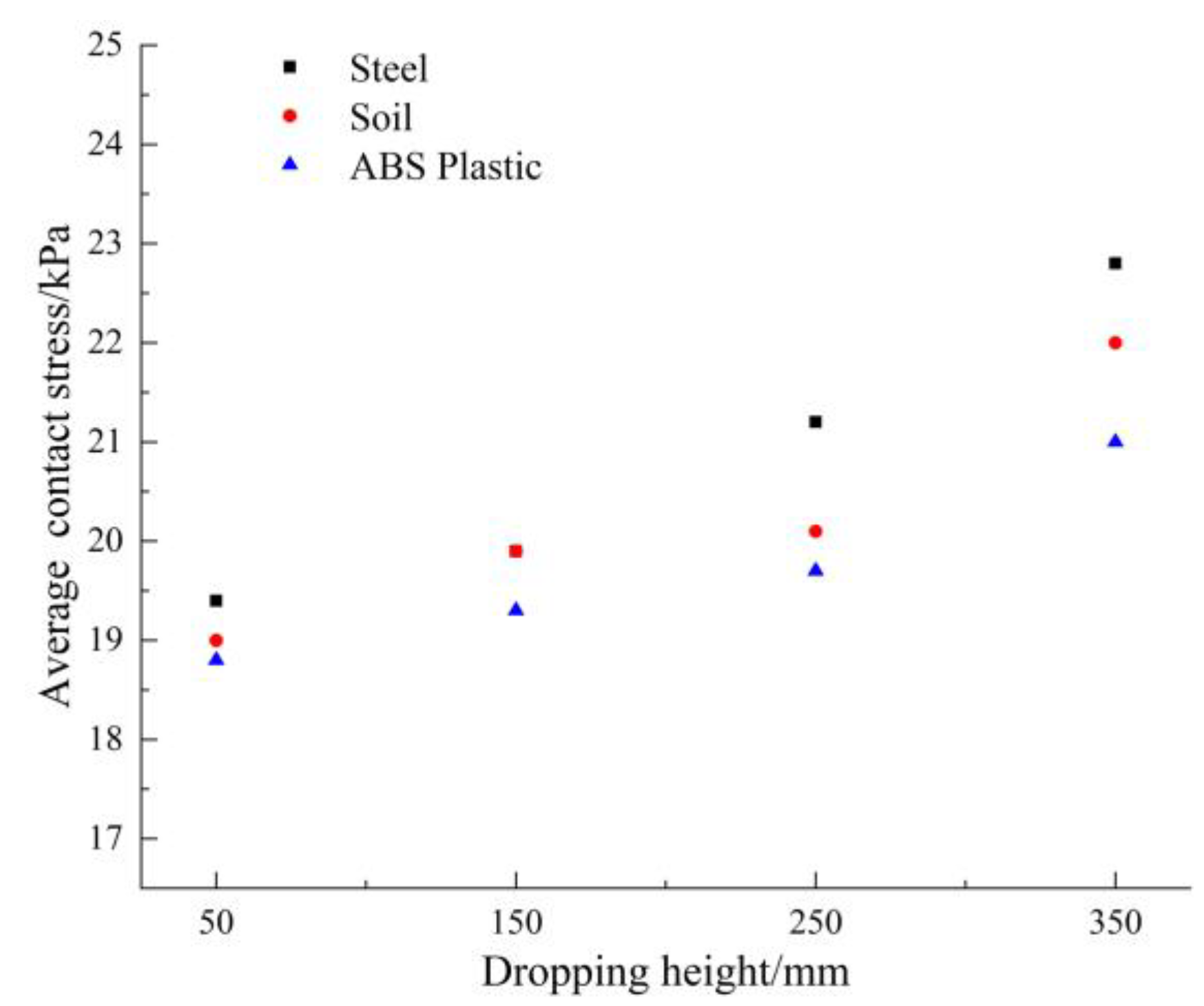

3.3.2. Average Contact Stress and Contact Area of the Seedlings

3.3.3. Relationship between the Contact Stress Distribution of the Seedlings and Pot Damage

3.4. Analysis of Collision Contact Stress Distribution between Oil Sunflower Plug Seedlings and Plug Specifications

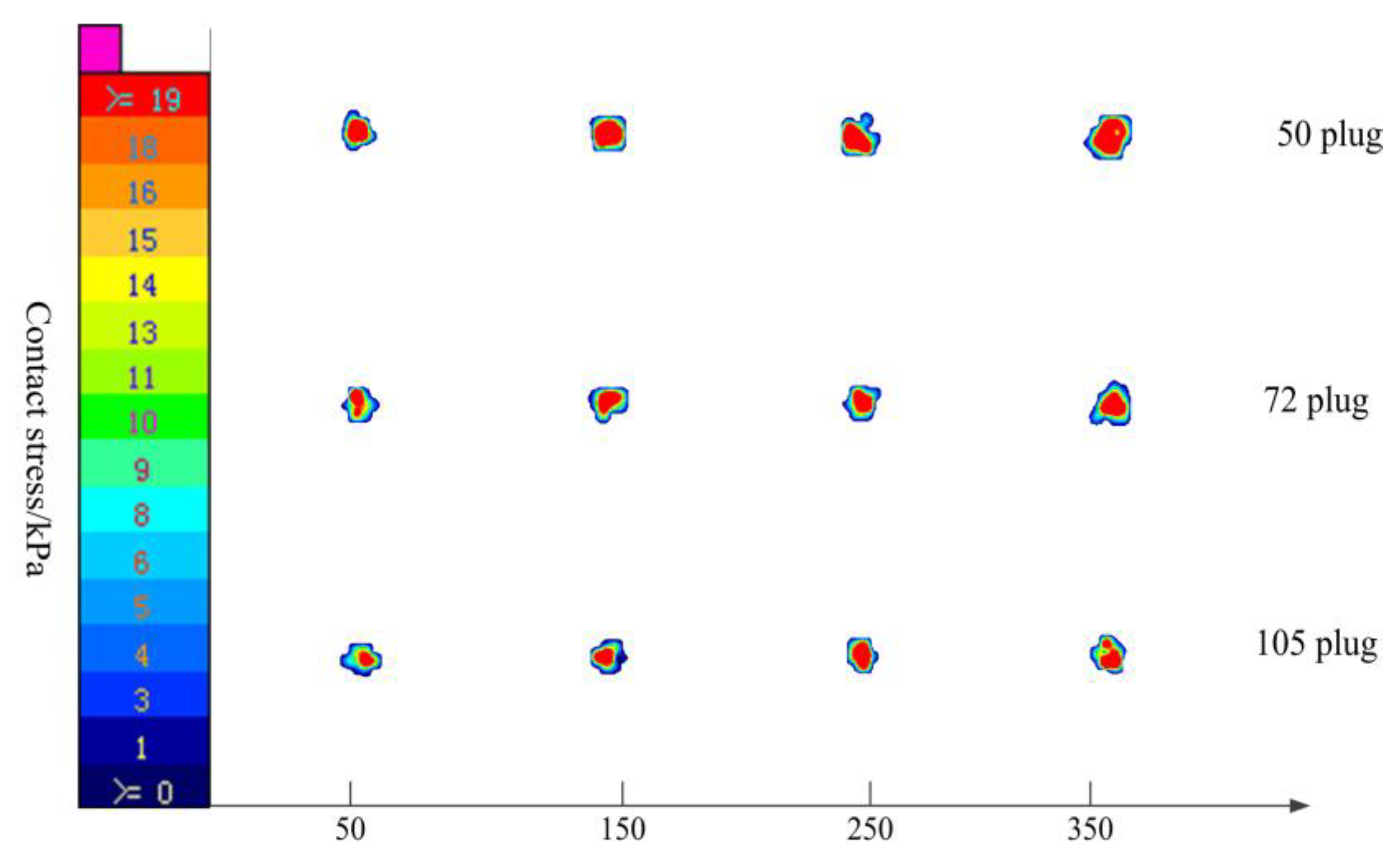

3.4.1. Distribution Characteristics of the Collision Contact Stress between the Steel Plate and the Plug Seedlings with Different Plug Specifications

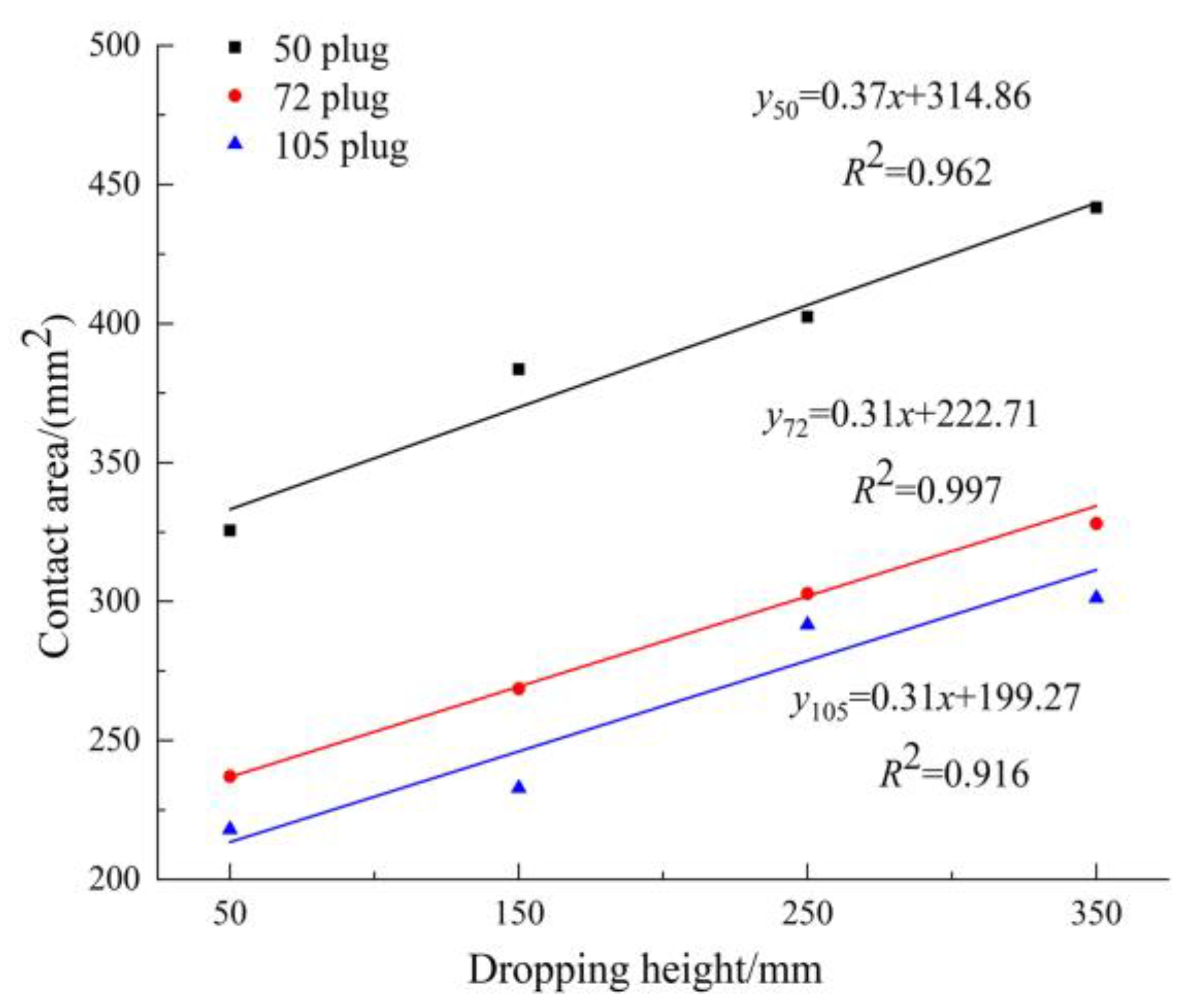

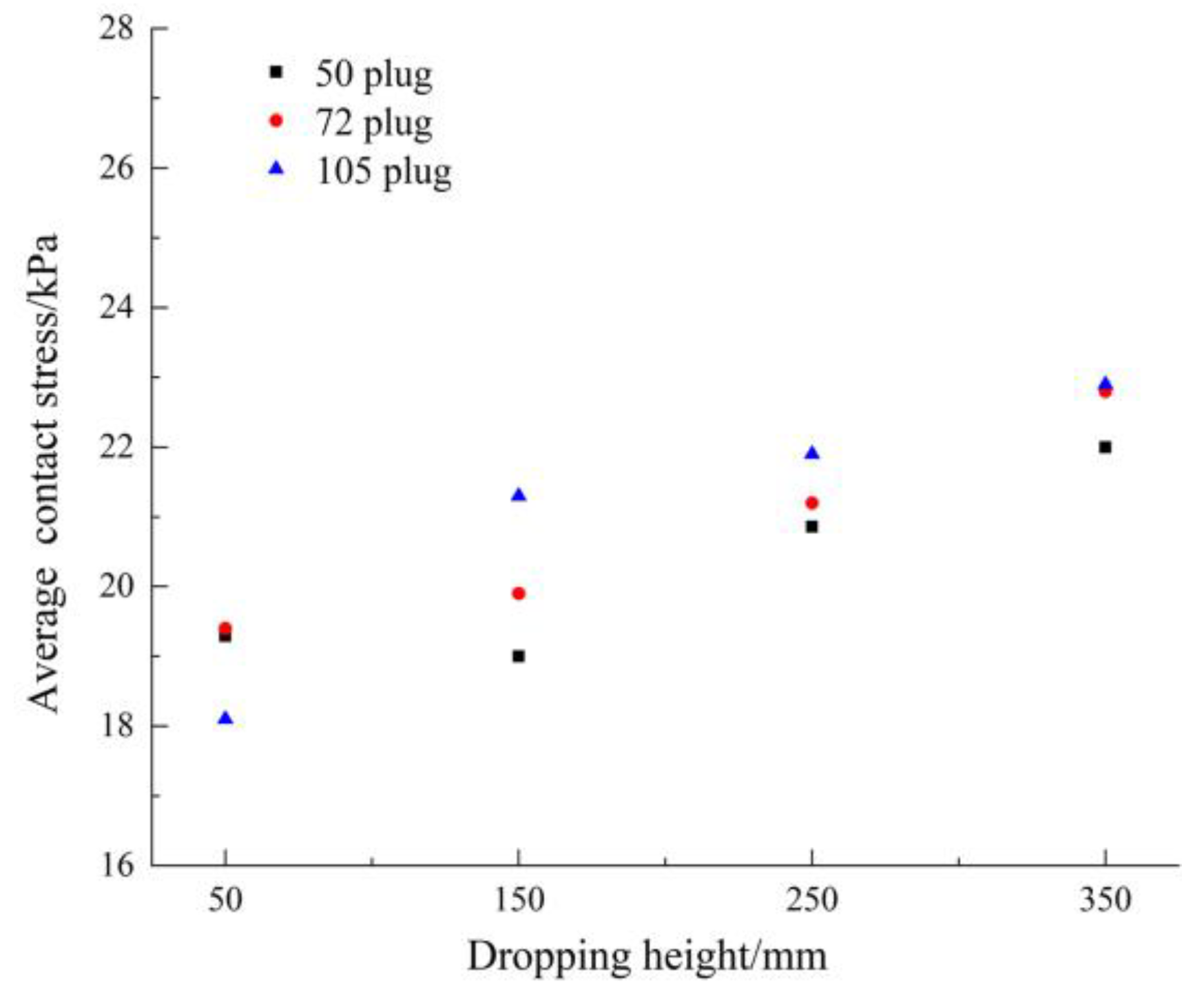

3.4.2. Average Contact Stress and Contact Area between the Steel Plate and the Plug Seedlings with Plug Specifications

3.4.3. Relationship between the Contact Stress Distribution of Plug Seedlings and Pot Damage

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumawat, L.; Raheman, H.; Singh, V. Design and development of a tractor drawn automatic onion transplanter. Int. J. Curr. Microbiol. Appl. Sci. 2020, 9, 2020. [Google Scholar] [CrossRef]

- Li, M.; Jin, X.; Ji, J.; Li, P.; Du, X. Design and experiment of intelligent sorting and transplanting system for healthy vegetable seedlings. Int. J. Agric. Biol. Eng. 2021, 14, 208–216. [Google Scholar] [CrossRef]

- Pérez-Ruiz, M.; Slaughter, D.C. Development of a precision 3-row synchronised transplanter. Biosyst. Eng. 2021, 206, 67–78. [Google Scholar] [CrossRef]

- Baydar, H.; ERBAŞ, S. Influence of seed development and seed position on oil, fatty acids and total tocopherol contents in sunflower (Helianthus annuus L.). Turk. J. Agric. For. 2005, 29, 179–186. [Google Scholar]

- Izquierdo, N.G.; Aguirrezábal, L.A.N. Genetic variability in the response of fatty acid composition to minimum night temperature during grain filling in sunflower. Field Crops Res. 2008, 106, 116–125. [Google Scholar] [CrossRef]

- Steer, B.T.; Seiler, G.J. Changes in fatty acid composition of sunflower (Helianthus annuus) seeds in response to time of nitrogen application, supply rates and defoliation. J. Sci. Food Agric. 1990, 51, 11–26. [Google Scholar] [CrossRef]

- Hua, H.L.; Francis, K.; Ping, M.H.; Ping, H.J. Design and tests of a multi-pin flexible seedling pick-up gripper for automatic transplanting. Appl. Eng. Agric. 2019, 35, 949–950. [Google Scholar]

- Jin, X.; Ji, J.T.; Huang, Z.Z. Seedling pick-up mechanism of five-bar combined with ordinary gear train. Int. Agric. Eng. J. 2017, 26, 151–158. [Google Scholar]

- Paradkar, V.; Raheman, H.; Rahul, K. Development of a metering mechanism with serial robotic arm for handling paper pot seedlings in a vegetable transplanter. Artif. Intell. Agric. 2021, 5, 52–63. [Google Scholar] [CrossRef]

- Jiang, Z.H.; Hu, Y.; Jiang, H.Y.; Tong, J.H. Design and force analysis of end-effector for plug seedling transplanter. PLoS ONE 2017, 12, e0180229. [Google Scholar] [CrossRef]

- Chen, J.N.; Xia, X.D.; Wang, Y.; JunYan, J.; Zhang, P.H. Motion differential equations of seedling in duckbilled planting nozzle and its application experiment. Trans. Chin. Soc. Agric. Eng. 2015, 31, 31–39. [Google Scholar]

- Jin, X.; Ji, J.T.; Liu, W.X.; He, Y.K.; Du, X.W. Structural optimization of duckbilled transplanter based on dynamic model of pot seedling movement. Trans. Chin. Soc. Agric. Eng. 2018, 34, 58–67. [Google Scholar]

- Liu, Y.; Mao, H.P.; Wang, T.; Li, B.; Li, Y.X. Collision optimization and experiment of tomato plug seedling in basket-type transplanting mechanism. Trans. Chin. Soc. Agric. Mach. 2018, 49, 143–151. [Google Scholar]

- Deng, W.; Wang, C.; Xie, S. Collision simulation of potato on rod separator. Int. J. Food Eng. 2020, 17, 435–444. [Google Scholar] [CrossRef]

- Deng, W.; Wang, C.; Xie, S. Impact peak force measurement of potato. Int. J. Food Prop. 2020, 23, 616–626. [Google Scholar] [CrossRef]

- Lu, F.; Ishikawa, Y.; Kitazawa, H.; Satake, T. Impact damage to apple fruits in commercial corrugated fiberboard box packaging evaluated by the pressure-sensitive film technique. J. Food Agric. Environ. 2010, 8, 218–222. [Google Scholar]

- Lu, F.; Ishikawa, Y.; Kitazawa, H.; Satake, T. Measurement of impact pressure and bruising of apple fruit using pressure-sensitive film technique. J. Food Eng. 2010, 96, 614–620. [Google Scholar] [CrossRef]

- Herold, B.; Geyer, M.; Studman, C.J. Fruit contact pressure distributions—equipment. Comput. Electron. Agric. 2001, 32, 167–179. [Google Scholar] [CrossRef]

- Komarnicki, P.; Stopa, R.; Szyjewicz, D.; Kuta, Ł.; Klimza, T. Influence of Contact Surface Type on the Mechanical Damages of Apples under Impact Loads. Food Bioprocess Technol. 2017, 10, 1479–1494. [Google Scholar] [CrossRef][Green Version]

- Zeng, F.D.; Li, X.Y.; Li, X.; Su, Q.; Zhang, Y.Z. Experiment and analysis of high-speed photographic techniques for throwing motion of seedlings. J. China Agric. Univ. 2021, 26, 168–176. [Google Scholar]

- Hua, H.L. Mechanical Analysis of the Root Lumps and Development of a Robotic Transplanter for Vegetable Plug Seedlings. Ph.D. Thesis, Jiangsu University, Zhenjing, China, 2014. [Google Scholar]

- He, J.Y.; Liu, W.M.; Xie, B.; Wang, J.; Hao, L. Calculation methods during crashing based on spring-damping model. Mech. Manag. Dev. 2016, 31, 7–8+50. [Google Scholar]

- Hunston, M. Innovative thin-film pressure mapping sensors. Sens. Rev. 2002, 22, 319–321. [Google Scholar] [CrossRef]

- Wu, J.; Guo, K.Q.; Ge, Y.; Wang, Y.Y. Contact pressure distribution characteristics of Korla pear fruit at moment of drop impact. Trans. Chin. Soc. Agric. Eng. 2012, 28, 250–254+300. [Google Scholar]

- Agins, H.J.; Harder, V.S.; Lautenschlager, E.P.; Kudrsna, J.C. Effects of sterilization on the Tekscan digital pressure sensor. Med. Eng. Phys. 2003, 25, 775–780. [Google Scholar] [CrossRef]

- Yang, L.J.; Zhang, Y.; Liu, D.H.; Xu, B.P.; Liu, C.X. Early recognition for dairy cow lameness based on pressure distribution measurement system. Trans. Chin. Soc. Agric. Mach. 2016, 47, 426–432. [Google Scholar]

- Tang, Y.H. Reaserch on Parameters Optimization and Performance Test for the Dibble-Type Planting Apparatus of Vegetable Pot Seedling Transplanter. Master’s Thesis, Zhejiang University, Hangzhou, China, 2016. [Google Scholar]

- Chen, Z.H.; Duan, H.B.; Cai, X.K.; Wang, J.Q.; Xu, T.; Yu, S.S.; Yao, F.H.; Yan, F.Y. Distribution characteristics of potato contact stress during the drop impact. J. South China Agric. Univ. 2020, 41, 99–108. [Google Scholar]

| Type of Material | Thickness/mm | Density/(g/cm3) | Elastic Modulus/GPa | Poisson’s Ratio |

|---|---|---|---|---|

| Steel | 5 | 7.85 | 182 | 0.3 |

| ABS plastic | 5 | 1.07 | 2.2 | 0.39 |

| Soil | 160 | 1.452 | 0.00284 | 0.42 |

| Factors | The Level of Coding | ||

|---|---|---|---|

| −1 | 0 | +1 | |

| Plug specification | 50 plug | 72 plug | 105 plug |

| Contact material | Steel | Soil | ABS Plastic |

| Dropping height/mm | 50 | 150 | 250 |

| No. | Test Factor Level Value | Collision Impact Force/N | ||

|---|---|---|---|---|

| X1 | X2 | X3 | ||

| 1 | 0 | 0 | 0 | 6.08 |

| 2 | −1 | −1 | 0 | 7.42 |

| 3 | 0 | 1 | 1 | 5.77 |

| 4 | 0 | 0 | 0 | 6.08 |

| 5 | 1 | 1 | 0 | 4.62 |

| 6 | 1 | 0 | 1 | 6.55 |

| 7 | 0 | 0 | 0 | 6.18 |

| 8 | 0 | −1 | 1 | 6.39 |

| 9 | −1 | 0 | 1 | 8.66 |

| 10 | 0 | 1 | −1 | 4.48 |

| 11 | −1 | 1 | 0 | 6.81 |

| 12 | 1 | −1 | 0 | 5.08 |

| 13 | −1 | 0 | −1 | 7.33 |

| 14 | 0 | 0 | 0 | 6.08 |

| 15 | 0 | 0 | 0 | 6.58 |

| 16 | 0 | −1 | −1 | 4.63 |

| 17 | 1 | 0 | −1 | 4.33 |

| Source | Sum of Squares | Freedom | Mean Square | F Value | p Value |

|---|---|---|---|---|---|

| Model | 21.80 | 9 | 2.42 | 62.21 | <0.0001 ** |

| X1 | 11.62 | 1 | 11.62 | 298.34 | <0.0001 ** |

| X2 | 0.42 | 1 | 0.42 | 10.87 | 0.0132 * |

| X3 | 5.45 | 1 | 5.45 | 139.85 | <0.0001 ** |

| X1 X2 | 0.005625 | 1 | 0.005625 | 0.14 | 0.7151 |

| X1 X3 | 0.20 | 1 | 0.20 | 5.09 | 0.0587 |

| X2 X3 | 0.055 | 1 | 0.055 | 1.42 | 0.2725 |

| X12 | 1.47 | 1 | 1.47 | 37.80 | 0.0005 ** |

| X22 | 2.75 | 1 | 2.75 | 70.73 | <0.0001 ** |

| X32 | 0.023 | 1 | 0.023 | 0.59 | 0.4682 |

| Residual | 0.27 | 7 | 0.039 | ||

| Lack of Fit | 0.085 | 3 | 0.028 | 0.6 | 0.6484 |

| Pure Error | 0.19 | 4 | 0.047 | ||

| Cor Total | 22.07 | 16 | |||

| R2 | 0.9877 | ||||

| Contact Material | Regression Equation | R2 |

|---|---|---|

| Steel | K = 1.81 × P × A × 10−3 − 8.13 | 0.976 |

| Soil | K = 1.22 × P × A × 10−3 − 5.98 | 0.965 |

| ABS Plastic | K = 2.11 × P × A × 10−3 − 9.43 | 0.940 |

| Sizes | Regression Equation | R2 |

|---|---|---|

| 50 plug | K = 1.56 × P × A × 10−3 − 8.57 | 0.958 |

| 72 plug | K = 1.81 × P × A × 10−3 − 8.13 | 0.976 |

| 105 plug | K = 1.73 × P × A × 10−3 − 6.99 | 0.915 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, F.; Li, X.; Bai, H.; Cui, J.; Liu, X.; Zhang, Y. Experimental Study on Pot Damage and Contact Stress Distribution Characteristics of Oil Sunflower Plug Seedlings. Appl. Sci. 2022, 12, 10889. https://doi.org/10.3390/app122110889

Zeng F, Li X, Bai H, Cui J, Liu X, Zhang Y. Experimental Study on Pot Damage and Contact Stress Distribution Characteristics of Oil Sunflower Plug Seedlings. Applied Sciences. 2022; 12(21):10889. https://doi.org/10.3390/app122110889

Chicago/Turabian StyleZeng, Fandi, Xuying Li, Hongbin Bai, Ji Cui, Xuening Liu, and Yongzhi Zhang. 2022. "Experimental Study on Pot Damage and Contact Stress Distribution Characteristics of Oil Sunflower Plug Seedlings" Applied Sciences 12, no. 21: 10889. https://doi.org/10.3390/app122110889

APA StyleZeng, F., Li, X., Bai, H., Cui, J., Liu, X., & Zhang, Y. (2022). Experimental Study on Pot Damage and Contact Stress Distribution Characteristics of Oil Sunflower Plug Seedlings. Applied Sciences, 12(21), 10889. https://doi.org/10.3390/app122110889