Research on the Tunnel Boring Machine Selection Decision-Making Model Based on the Fuzzy Evaluation Method

Abstract

:1. Introduction

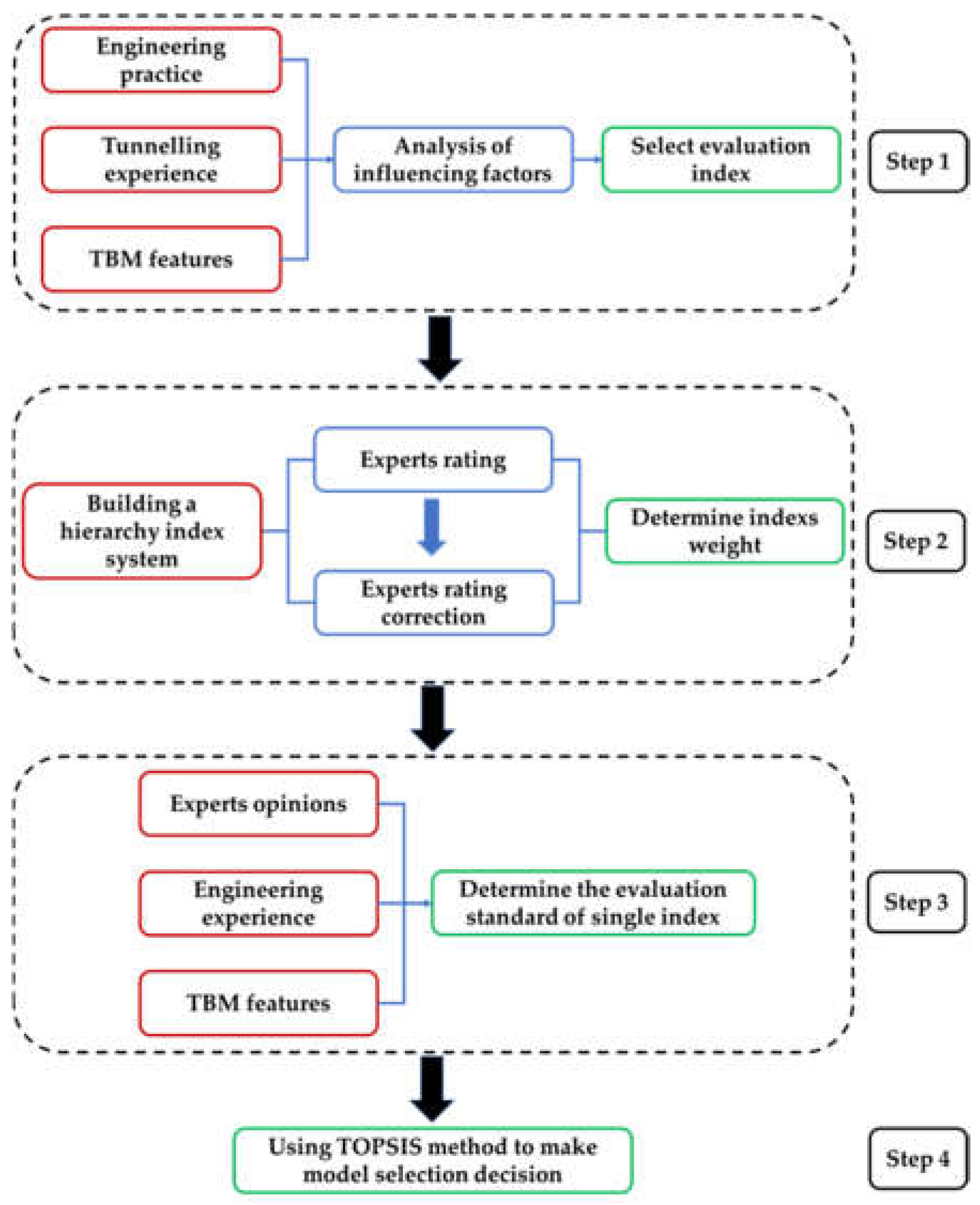

2. TBM Selection Decision-Making Method

2.1. Method Overview

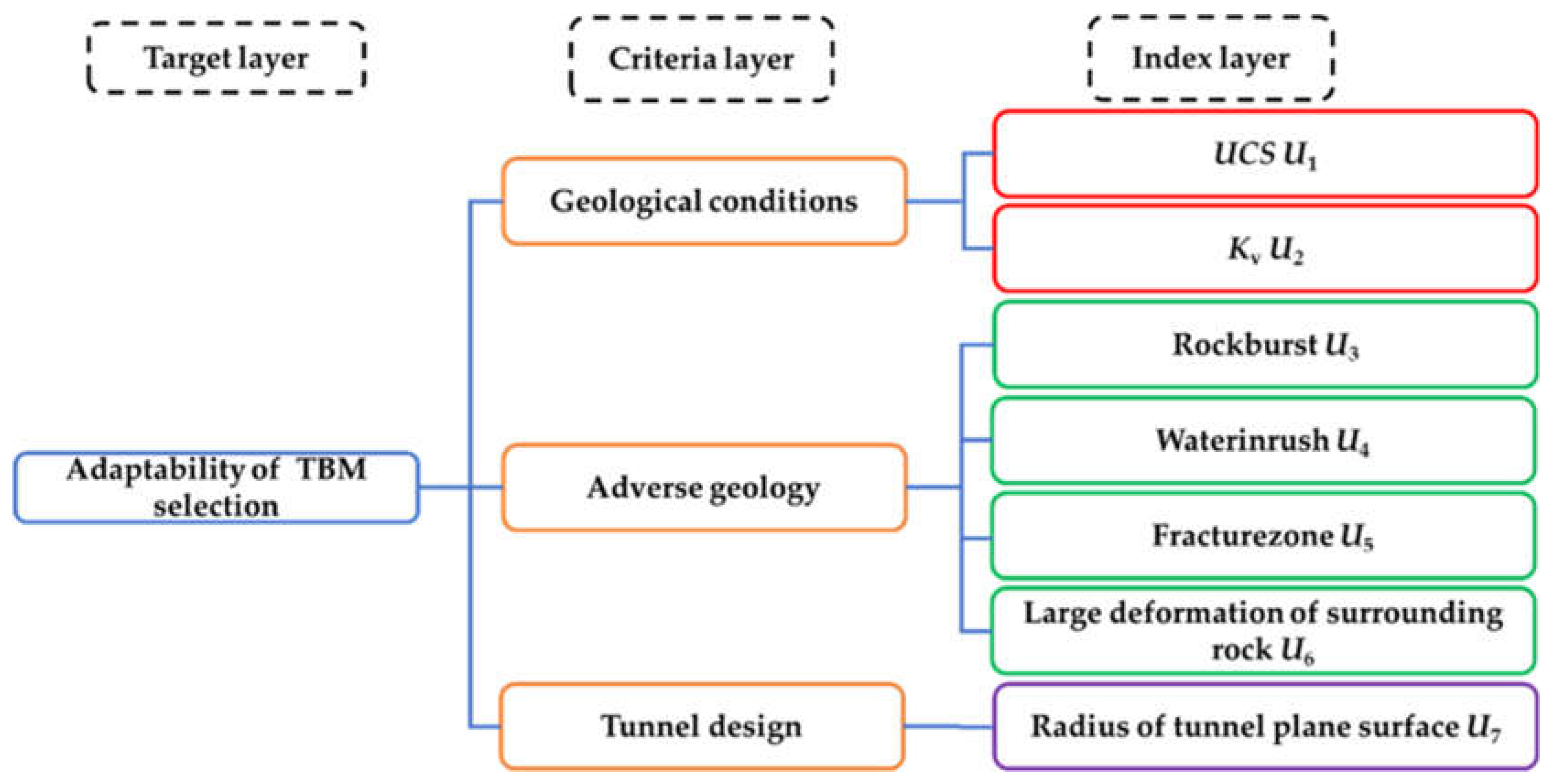

2.2. Analysis of Influencing Factors

- Geological conditions. One of the geological conditions affecting the TBM selection is the uniaxial compressive strength (UCS) of rock mass, and the other is the integrity of rock mass (Kv). Open TBM is mainly applicable to hard rock stratum with relatively complete rock mass. Single-shield TBM is mainly applicable to soft rock with a certain self-stabilizing ability. Double-shield TBM is mainly applicable to a soft rock~hard rock stratum with relatively complete rock mass and a certain self-stabilizing ability. Based on this, two factors affecting the TBM selection are determined, namely UCS and Kv.

- Adverse geology. Adverse geology will lead to a significant reduction in TBM tunnelling efficiency, and even cause serious problems, such as TBM jamming and shutdown. Different types of TBM have different adaptability levels to adverse geology. For example, when the open TBM meets a rock burst disaster, the protection of personnel and equipment is poor. Shield TBM can resist rock bursts to a certain extent. After comprehensive consideration, four factors affecting adverse geology are determined in this paper, including rock burst, water inrush, fracture zone and large deformation of the surrounding rock.

- Tunnel design. The design scheme of the tunnel will also limit the selection of TBM, and the turning radius of different types of TBM is different. Therefore, the size of the radius of the tunnel’s flat surface will limit the selection of TBM. In the aspect of tunnel design, one influencing factor is determined as the radius of the tunnel’s flat surface.

2.3. Determination Method of Evaluation Index Weight

2.3.1. Construction Requirements of Evaluation Index System

- Comprehend the main factors when decomposing and simplifying problems, and do not omit or select many;

- Pay attention to the intensity relationship between the comparison elements, and the elements with too great a difference cannot be compared at the same level.

2.3.2. Expert Survey Scoring and Scoring Correction Method

2.3.3. Determination Method of Index Weight

2.4. Determination Method of Single Index Evaluation Standard

2.5. TBM Selection Decision-Making Method

2.6. Text Project Overview and Required Data Acquisition

3. Result and Analysis

3.1. Determination of Evaluation Index Weight

3.1.1. Establishment of Evaluation Index System

3.1.2. Determining Expert Scores

3.1.3. Weight Determination by AHP

3.2. Determination of Single Index Evaluation Standard

3.3. TBM Selection Decision-Making

3.4. Comparison with Previous Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Koizumi, Y.; Inaba, T.; Yamamoto, T. Theoretical analysis and seismic investigation for TBM jamming in squeezing fissile slate. Tunn. Undergr. Space Technol. 2016, 57, 284–286. [Google Scholar] [CrossRef]

- Goel, R.K. Experiences and lessons from the use of TBM in the Himalaya—A review. Tunn. Undergr. Space Technol. 2016, 57, 277–283. [Google Scholar] [CrossRef]

- Bilgin, N. An appraisal of TBM performances in Turkey in difficult ground conditions and some recommendations. Tunn. Undergr. Space Technol. 2016, 57, 265–276. [Google Scholar] [CrossRef]

- Gong, Q.; Yin, L.; Ma, H.; Zhao, J. TBM tunnelling under adverse geological conditions: An overview. Tunn. Undergr. Space Technol. 2016, 57, 4–17. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Huang, H.W.; Zhang, D.M.; Zhou, M.L.; Tang, C.; Liu, D.J. Effect of ground surface surcharge on deformational performance of tunnel in spatially variable soil. Comput. Geotech. 2021, 136, 104229. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Phoon, K.K.; Zhang, D.M.; Huang, H.W.; Tang, C. Novel approach to estimate vertical scale of fluctuation based on CPT data using convolutional neural networks. Eng. Geol. 2021, 294, 106342. [Google Scholar] [CrossRef]

- YTao, Q.; Sun, H.L.; Cai, Y.Q. Predictions of deep excavation responses considering model uncertainty: Integrating BiLSTM neural networks with Bayesian updating. Int. J. Geomech. 2021, 22, 04021250. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Huang, H.W.; Zhang, D.M.; Phoon, K.K.; Liu, Z.Q.; Tang, C. Quantitative evaluation of geological uncertainty and its influence on tunnel structural performance using improved coupled Markov chain. Acta Geotech. 2021, 16, 3709–3724. [Google Scholar] [CrossRef]

- Phoon, K.K.; Kulhawy, F.H. Characterization of geotechnical variability. Can. Geotech. J. 1999, 36, 612–624. [Google Scholar] [CrossRef]

- Xu, C.J.; Wang, L.; Tien, Y.M.; Chen, J.M.; Juang, C.H. Robust design of rock slopes with multiple failure modes: Modeling uncertainty of estimated parameter statistics with fuzzy number. Environ. Earth Sci. 2014, 72, 2957–2969. [Google Scholar] [CrossRef]

- Choi, H.H.; Cho, H.N.; Seo, J.W. Risk assessment methodology for underground construction projects. J. Const. Eng. Manag. 2004, 130, 258–272. [Google Scholar] [CrossRef]

- Zhou, H.B.; Zhang, H. Risk assessment methodology for a deep foundation pit construction project in Shanghai, China. J. Const. Eng. Manag. 2011, 137, 1185–1194. [Google Scholar] [CrossRef]

- Hyun, K.C.; Min, S.; Choi, H.; Park, J.; Lee, I.M. Risk analysis using fault-tree analysis (FTA) and analytic hierarchy process (AHP) applicable to shield TBM tunnels. Tunn. Undergr. Space Technol. 2015, 49, 121–129. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Chen, C. Fuzzy comprehensive Bayesian network-based safety risk assessment for metro construction projects. Tunn. Undergr. Space Technol. 2017, 70, 330–342. [Google Scholar] [CrossRef]

- Wei, D.; Xu, D.; Zhang, Y. A fuzzy evidential reasoning-based approach for risk assessment of deep foundation pit. Tunn. Undergr. Space Technol. 2020, 97, 103232.1–103232.16. [Google Scholar] [CrossRef]

- Lin, S.S.; Zhang, N.; Zhou, A.; Shen, S.L. Risk evaluation of excavation based on fuzzy decision-making model. Autom. Constr. 2022, 136, 104143. [Google Scholar] [CrossRef]

- Tan, Z.; Li, Z.; Zhou, Z.; Lai, H.; Jiao, Y.; Li, F.; Wang, L. Research on an Evaluation Method for the Adaptability of TBM Tunnelling. Appl. Sci. 2022, 12, 4590. [Google Scholar] [CrossRef]

- Shahriar, K.; Sharifzadeh, M.; Hamidi, J.K. Geotechnical risk assessment based approach for rock TBM selection in difficult ground conditions. Tunn. Undergr. Space Technol. 2008, 23, 318–325. [Google Scholar] [CrossRef]

- Khademi Hamidi, J.; Shahriar, K.; Rezai, B.; Rostami, J.; Bejari, H. Risk assessment based selection of rock TBM for adverse geological conditions using Fuzzy-AHP. Bull. Eng. Geol. Environ. 2010, 69, 523–532. [Google Scholar] [CrossRef]

- Golestanifar, M.; Goshtasbi, K.; Jafarian, M.; Adnani, S. A multi-dimensional approach to the assessment of tunnel excavation methods. Int. J. Rock Mech. Min. Sci. 2011, 48, 1077–1085. [Google Scholar] [CrossRef]

- Yazdani-Chamzini, A.; Yakhchali, S.H. Tunnel Boring Machine (TBM) selection using fuzzy multicriteria decision making methods. Tunn. Undergr. Space Technol. 2012, 30, 194–204. [Google Scholar] [CrossRef]

- Wu, S.; Wang, G.; Xu, J.; Wang, J. Research on tbm type-selection and key construction technology for jinping ii hydropower station. Chin. J. Rock Mech. Eng. 2008, 27, 2000–2009. (In Chinese) [Google Scholar]

- Zhang, J.; Mei, Z.; Gao, J.; Tang, Y.; Zhang, Y. Study on TBM Type-selection and Key Technologies in Dahuofang Water Diversion Tunnel. Mod. Tunn. Technol. 2010, 47, 1–10. (In Chinese) [Google Scholar] [CrossRef]

- Wang, M. Type Selection of Shield TBMs and Hard Rock TBMs for Different Geological Conditions. Tunn. Constr. 2006, 2, 1–3, 8. (In Chinese) [Google Scholar]

- Zhang, Z.; Liu, X.; Yang, S. A Note on the 1-9 Scale and Index Scale in AHP; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Deng, X.; Li, J.; Zeng, H.; Chen, J.; Zhao, J. Research on computation methods of AHP wight vector and its application. Mathmatics Pract. Theory 2012, 42, 93–100. (In Chinese) [Google Scholar]

- Mao, W. An Exploration into the Choice of the Right Type of Tunnel-Boring Machines(TBM). Traffic Eng. Technol. Natl. Def. 2011, 9, 4, 15–17. (In Chinese) [Google Scholar] [CrossRef]

- Zhan, J. Method and Decision Support System for Evaluating TBM Selection and Tunneling Adaptability Based on Artificial Intelligence. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2019. (In Chinese). [Google Scholar]

- Zhou, Z.; Tan, Z.; Li, Z.; Ma, D.; Zhao, J.; Lei, K. A Data Mining Based Prediction Model for Penetration Rate. J. Basic Sci. Eng. 2021, 29, 1201–1219. (In Chinese) [Google Scholar] [CrossRef]

| Scale | Definition |

|---|---|

| 1 | Factor “i” is as important as factor “j”. |

| 3 | Factor “i” is slightly more important than factor “j”. |

| 5 | Factor “i” is more important than factor “j”. |

| 7 | Factor “i” is strongly more important than the factor “j”. |

| 9 | Factor “i” is definitely more important than the factor “j”. |

| 2, 4, 6, 8 | Intermediate state scale value. |

| Reciprocal | Inversely proportional. |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| RI | 0 | 0 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 |

| Open TBM | Double-Shield TBM | Single-Shield TBM |

|---|---|---|

| It is difficult to construct under the conditions of soft and broken surrounding rock; In case of geological disasters such as rock bursts, the protection ability of personnel is poor; When encountering the surrounding rock with strong convergence, the ability to escape from difficulties is good; Compared with shield TBM, it has a higher economy; Compared with shield TBM, the hole formation time is longer; Flexible means of initial support and forepoling; Under suitable surrounding rock conditions, the penetration rate is fast; The flat surface radius adapts to a wide range; The adaptability to adverse geology is extremely poor. | It can be constructed under the conditions of the soft and broken surrounding rock, mainly facing the medium hard rock and relatively complete soft rock stratum; In case of geological disasters such as rock bursts, the protection ability of personnel is good; When encountering the surrounding rock with strong convergence, the ability to escape from difficulties is poor; Continuous construction is possible; High construction cost; Fast hole-forming speed; When the surrounding rock is better, the penetration rate is faster; The flat surface radius has a moderate adaptability range; Good adaptability to adverse geology. | It can realize safe and rapid construction under the condition of soft and broken surrounding rock; In case of geological disasters such as rock bursts, the protection ability of personnel is good; When encountering the surrounding rock with strong convergence, the ability to escape from difficulties is poor; The construction consists of two processes and cannot be constructed continuously; High construction cost; Fast hole-forming speed; When the surrounding rock is better, the penetration rate is faster; Flat surface radius adaptability is small; Poor adaptability to adverse geology. |

| U1 | U2 | U3 | U4 | U5 | U6 | U7 | |

|---|---|---|---|---|---|---|---|

| Project 1 | 68 | 0.68 | 6 | 1 | 5 | 0.41 | 300 |

| Project 2 | 45 | 0.46 | 0.5 | 40 | 27 | 0.12 | 600 |

| Project 3 | 70 | 0.60 | 2.1 | 20 | 23 | 0.3 | 400 |

| Expert | P1(0) | μ1(0) | P1(1) | μ1(1) | P1(2) | μ1(2) | P1(3) | μ1(3) | P1(4) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0.1406 | 1.1406 | 0.2289 | 1.2289 | 0.2574 | 1.2574 | 0.2660 | 1.2660 |

| 2 | 1 | 0.4650 | 1.4650 | 0.3811 | 1.3811 | 0.3610 | 1.3610 | 0.3554 | 1.3554 |

| 3 | 1 | −0.2866 | 0.7134 | −0.3139 | 0.6861 | −0.3217 | 0.6783 | −0.3240 | 0.6760 |

| 4 | 1 | 0.1406 | 1.1406 | 0.2289 | 1.2289 | 0.2574 | 1.2574 | 0.2660 | 1.2660 |

| 5 | 1 | 0.1406 | 1.1406 | 0.2289 | 1.2289 | 0.2574 | 1.2574 | 0.2660 | 1.2660 |

| (0) = 3.8000 | (1) = 3.6438 | (2) = 3.5978 | (3) = 3.5843 | (4) = 3.5804 | |||||

| Expert | P1(0) | μ1(0) | P1(1) | μ1(1) | P1(2) |

|---|---|---|---|---|---|

| 1 | 1 | 0.1414 | 1.1414 | 0.1671 | 1.1671 |

| 2 | 1 | 0.1414 | 1.1414 | 0.1671 | 1.1671 |

| 3 | 1 | −0.1280 | 0.8720 | −0.1388 | 0.8612 |

| 4 | 1 | −0.1280 | 0.8720 | −0.1388 | 0.8612 |

| 5 | 1 | −0.1819 | 0.8181 | −0.1664 | 0.8336 |

| (0) = 0.3833 | (1) = 0.3793 | (2) = 0.3778 | |||

| Expert | P1(0) | μ1(0) | P1(1) | μ1(1) | P1(2) | μ1(2) | P1(3) |

|---|---|---|---|---|---|---|---|

| 1 | 1 | −0.1607 | 0.8393 | −0.1290 | 0.8710 | −0.1158 | 0.8842 |

| 2 | 1 | −0.1607 | 0.8393 | −0.1290 | 0.8710 | −0.1158 | 0.8842 |

| 3 | 1 | −0.2904 | 0.7096 | −0.3125 | 0.6875 | −0.3211 | 0.6789 |

| 4 | 1 | −0.2904 | 0.7096 | −0.3125 | 0.6875 | −0.3211 | 0.6789 |

| 5 | 1 | −0.1607 | 0.8393 | −0.1290 | 0.8710 | −0.1158 | 0.8842 |

| (0) = 2.4000 | (1) = 2.3605 | (2) = 2.3448 | (3) = 2.3386 | ||||

| Expert | P1(0) | μ1(0) | P1(1) | μ1(1) | P1(2) | μ1(2) | P1(3) |

|---|---|---|---|---|---|---|---|

| 1 | 1 | −0.1607 | 0.8393 | −0.1290 | 0.8710 | −0.1158 | 0.8842 |

| 2 | 1 | −0.1607 | 0.8393 | −0.1290 | 0.8710 | −0.1158 | 0.8842 |

| 3 | 1 | −0.2904 | 0.7096 | −0.3125 | 0.6875 | −0.3211 | 0.6789 |

| 4 | 1 | −0.2904 | 0.7096 | −0.3125 | 0.6875 | −0.3211 | 0.6789 |

| 5 | 1 | −0.1607 | 0.8393 | −0.1290 | 0.8710 | −0.1158 | 0.8842 |

| (0) = 2.4000 | (1) = 2.3605 | (2) = 2.3448 | (3) = 2.3386 | ||||

| Expert | P1(0) | μ1(0) | P1(1) | μ1(1) | P1(2) | μ1(2) | P1(3) |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 0.0281 | 1.0281 | 0.1236 | 1.1236 | 0.1485 | 1.1485 |

| 2 | 1 | 0.0281 | 1.0281 | 0.1236 | 1.1236 | 0.1485 | 1.1485 |

| 3 | 1 | 0.0281 | 1.0281 | 0.1236 | 1.1236 | 0.1485 | 1.1485 |

| 4 | 1 | −0.3983 | 0.6017 | −0.4355 | 0.5645 | −0.4437 | 0.5563 |

| 5 | 1 | 0.0281 | 1.0281 | 0.1236 | 1.1236 | 0.1485 | 1.1485 |

| (0) = 2.1276 | (1) = 2.3605 | (2) = 2.1116 | (3) = 2.1080 | ||||

| Geological Condition | Adverse Geology | Tunnel Design | |

|---|---|---|---|

| Geological condition | 1 | 0.279 | 2.632 |

| Adverse geology | 3.58 | 1 | 9.091 |

| Tunnel design | 0.38 | 0.110 | 1 |

| U1 | U2 | |

|---|---|---|

| U1 | 1 | 1 |

| U2 | 1 | 1 |

| U3 | U4 | U5 | U6 | |

|---|---|---|---|---|

| U3 | 1 | 0.222 | 0.427 | 0.474 |

| U4 | 4.51 | 1 | 1.923 | 2.128 |

| U5 | 2.34 | 0.520 | 1 | 1.111 |

| U6 | 2.11 | 0.470 | 0.900 | 1 |

| Geological Condition | Adverse Geology | Tunnel Design | Index Weight | |

|---|---|---|---|---|

| Geological condition | 1 | 0.279 | 2.632 | 0.2032 |

| Adverse geology | 3.58 | 1 | 9.091 | 0.7187 |

| Tunnel design | 0.38 | 0.110 | 1 | 0.0781 |

| U1 | U2 | Index Weight | |

|---|---|---|---|

| U1 | 1 | 1 | 0.5 |

| U2 | 1 | 1 | 0.5 |

| U3 | U4 | U5 | U6 | Index Weight | |

|---|---|---|---|---|---|

| U3 | 1 | 0.222 | 0.427 | 0.474 | 0.1004 |

| U4 | 4.51 | 1 | 1.923 | 2.128 | 0.4522 |

| U5 | 2.34 | 0.520 | 1 | 1.111 | 0.2353 |

| U6 | 2.11 | 0.470 | 0.900 | 1 | 0.2121 |

| Indexes | Index Weight |

|---|---|

| U1 | 0.1016 |

| U2 | 0.1016 |

| U3 | 0.0722 |

| U4 | 0.3250 |

| U5 | 0.1691 |

| U6 | 0.1524 |

| U7 | 0.0781 |

| Score | U1 (MPa) | U2 | U3 | U4 (L/s) | U5 (m) | U6 (%) | U7 (m) |

|---|---|---|---|---|---|---|---|

| 5 | (100, 150] | (0.65, 0.75] | >4 | (0, 5] | (0, 16] | (0.4, 0.45] | (300, 350] |

| 4 | (80, 100] | (0.55, 0.65] | (2.5, 4] | (5, 15] | (16, 22.5] | (0.36, 0.4] | (350, 400] |

| 3 | (60, 80] | (0.45, 0.50] | (2.0, 4] | (15, 20] | (22.5, 25] | (0.32, 0.36] | (400, 500] |

| 2 | (30, 60] | (0.45, 0.50] | (1, 2.0] | (20, 45] | (25, 30] | (0.28, 0.32] | (500, 600] |

| 1 | (10, 30] | (0.35, 0.45] | (0, 1] | (45, 100] | (30, 40] | (0, 0.28] | (600, 800] |

| 0 | (0, 10] | (0, 0.35] | - | >100 | >40 | >0.45 | <300 |

| U1 | U2 | U3 | U4 | U5 | U6 | U7 | |

|---|---|---|---|---|---|---|---|

| Project 1 | 3 | 5 | 5 | 5 | 5 | 5 | 5 |

| Project 2 | 2 | 2 | 1 | 2 | 2 | 1 | 1 |

| Project 3 | 3 | 4 | 3 | 3 | 3 | 2 | 3 |

| Positive and Negative Ideal Solution Distance | ||||||||

|---|---|---|---|---|---|---|---|---|

| Project 1 | 0.088365 | 0.35346 | 0.255175 | 0.17673 | 0.429985 | 0 | 0 | 0.429985 |

| Project 2 | 0 | 0.435205 | 0.217602 | 0.217602 | 0.435205 | 0 | 0.241131 | 0.202175 |

| Project 3 | 0 | 0.435205 | 0.217602 | 0.217602 | 0.435205 | 0 | 0.124689 | 0.322176 |

| Geotechnical Hazards | Rating of Likelihood of Hazard Occurrence | ||

|---|---|---|---|

| Project 1 | Project 2 | Project 3 | |

| Hard and abrasive rock | 4 | 2 | 3 |

| High water inrush | 2 | 3 | 3 |

| Tunnel wall instability | 2 | 4 | 4 |

| Tunnel face instability | 2 | 4 | 4 |

| Karstic voids | 2 | 3 | 3 |

| Fault zones | 2 | 2 | 3 |

| Squeezing | 4 | 2 | 2 |

| Geotechnical Hazards | Rating of Consequences of Hazard Occurrence | ||

|---|---|---|---|

| Open TBM | Double Shield TBM | Single Shield TBM | |

| Hard and abrasive rock | 2 | 2 | 2 |

| High water inrush | 4 | 2 | 2 |

| Tunnel wall instability | 5 | 3 | 3 |

| Tunnel face instability | 4 | 3 | 3 |

| Karstic voids | 5 | 3 | 3 |

| Fault zones | 4 | 2 | 2 |

| Squeezing | 1 | 4 | 4 |

| Geotechnical Hazards | TBM Risk Score of Project 1 | ||

|---|---|---|---|

| Open TBM | Double Shield TBM | Single Shield TBM | |

| Hard and abrasive rock | 8 | 8 | 8 |

| High water inrush | 8 | 4 | 4 |

| Tunnel wall instability | 10 | 6 | 6 |

| Tunnel face instability | 8 | 6 | 6 |

| Karstic voids | 10 | 6 | 6 |

| Fault zones | 8 | 4 | 4 |

| Squeezing | 4 | 16 | 16 |

| Total | 56 | 50 | 50 |

| Geotechnical Hazards | TBM Risk Score of Project 2 | ||

|---|---|---|---|

| Open TBM | Double Shield TBM | Single Shield TBM | |

| Hard and abrasive rock | 4 | 4 | 4 |

| High water inrush | 12 | 6 | 6 |

| Tunnel wall instability | 20 | 12 | 12 |

| Tunnel face instability | 16 | 12 | 12 |

| Karstic voids | 15 | 9 | 9 |

| Fault zones | 8 | 4 | 4 |

| Squeezing | 2 | 8 | 8 |

| Total | 77 | 55 | 55 |

| Geotechnical Hazards | TBM Risk Score of Project 3 | ||

|---|---|---|---|

| Open TBM | Double Shield TBM | Single Shield TBM | |

| Hard and abrasive rock | 6 | 6 | 6 |

| High water inrush | 12 | 6 | 6 |

| Tunnel wall instability | 20 | 12 | 12 |

| Tunnel face instability | 16 | 12 | 12 |

| Karstic voids | 15 | 9 | 9 |

| Fault zones | 12 | 6 | 6 |

| Squeezing | 2 | 8 | 8 |

| Total | 83 | 59 | 59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Z.; Lai, H.; Li, Z.; Zhou, Z.; Jiao, Y.; Li, F.; Wang, L. Research on the Tunnel Boring Machine Selection Decision-Making Model Based on the Fuzzy Evaluation Method. Appl. Sci. 2022, 12, 10802. https://doi.org/10.3390/app122110802

Tan Z, Lai H, Li Z, Zhou Z, Jiao Y, Li F, Wang L. Research on the Tunnel Boring Machine Selection Decision-Making Model Based on the Fuzzy Evaluation Method. Applied Sciences. 2022; 12(21):10802. https://doi.org/10.3390/app122110802

Chicago/Turabian StyleTan, Zhongsheng, Haixiang Lai, Zonglin Li, Zhenliang Zhou, Yifeng Jiao, Fengyuan Li, and Liming Wang. 2022. "Research on the Tunnel Boring Machine Selection Decision-Making Model Based on the Fuzzy Evaluation Method" Applied Sciences 12, no. 21: 10802. https://doi.org/10.3390/app122110802

APA StyleTan, Z., Lai, H., Li, Z., Zhou, Z., Jiao, Y., Li, F., & Wang, L. (2022). Research on the Tunnel Boring Machine Selection Decision-Making Model Based on the Fuzzy Evaluation Method. Applied Sciences, 12(21), 10802. https://doi.org/10.3390/app122110802