Abstract

This work describes an approach for the Digital Transformation (DT) of a manufacturing SME in the mold production industry. The phases for changing from manual and non-adding value labor-intensive practices to digital and smart manufacturing configurations are described. Initially, the needs of the SME are presented in terms of improving the planning and monitoring capabilities. Following the requirements analysis, a set of digital functionalities are proposed and mapped to the specific needs. The digital solution presented includes technologies such as the Internet of Things, data management, intelligent production planning and web technologies. The industrial pilot case has showed how the use of open-source off-the-shelf technology, integrated with the facility’s legacy systems can reduce daily production management tasks and ease the burden of planning and monitoring. The engineers and management team of the SME have acquired first-hand experience on the benefits digitalization of process can bring to the organization that is valuable for proceeding with the DT of the organization.

1. Introduction

Planning and monitoring of manufacturing systems to achieve desired performance targets in terms of cost, quality, time and flexibility, is of paramount importance and has received significant attention from researchers [1]. Under this perspective, industrial processes could greatly benefit from the integration of Industry 4.0 digital solutions [2]. Industry 4.0 transition and the underlying Digital Transformation (DT) are believed to provide manufacturing SMEs with valuable advantages vital to their future competitiveness and survival, such as manufacturing productivity, reduced operating costs, improved product quality and product innovation [3]. Research results show that SMEs do not exploit all the resources for implementing Industry 4.0 and often limit themselves to the adoption of Cloud Computing and the Internet of Things (IoT). SMEs find it difficult to implement Industry 4.0 technologies due to a lack of economies of scale and their position in the value chain. Many SMEs are mid-tier suppliers, they usually have limited impact on the value chain and benefit from the digitalization of end products or implementation of ‘manufacturing as a service concept. Hence the benefits of Industry 4.0 tend to accrue to OEMs [4]. SMEs seem to have adopted Industry 4.0 concepts only for monitoring industrial processes and there is still an absence of real applications in the field of production planning [5]. Significant advantages in the domains of ubiquitous connectivity, intelligent machines, IoT, adaptive user interfaces and intelligent user support have been achieved in recent years. Smart factory technology envisages factories that are adaptive and able to quickly react to changes either coming from internal factors (e.g., machine failure) or external factors (e.g., an urgent high-priority customer order). Modern Cyber-Physical Production Systems (CPPS) rely on the collaboration between production equipment and parts to be produced. Parts, sub-assemblies and products will be produced by loosely defined production schedules that can be efficiently adjusted to the dynamic changes in the shop floor. In many cases, the production schedule needs to be adapted due to unpredictable situations such as machine break-downs, unplanned production orders, missing materials, human errors and so forth [6].

This work proposes an Industry 4.0 solution for DT and investigates the digital transformation of an SME that manufactures molds to ease the burden of planning and monitoring. In chapter 2 the literature review is presented with a focus on Industry 4.0 and Digital Transformation technologies. Chapter 3 describes a system for digitalizing production planning and monitoring. Chapter 4 presents the SME’s DT pilot case and discusses the expected benefits as well as lessons learnt. Finally, chapter 5 concludes with a discussion of the key findings and the way ahead.

2. Literature Review

The digital transformation in manufacturing mandates a transition of manufacturing business models from “bolts” to “bits”, as mentioned in [7], where a framework for measuring the digital transformation of manufacturing industries is presented. In particular, the application of cyber-physical features in production systems holds the promise of enabling a smarter production paradigm with higher productivity, efficiency, and self-managing production processes allowing for innovative control and increased levels of automation, as highlighted in [8,9]. Technologies such as cloud services and resource virtualization are considered important drivers [10] along with low-code development platforms [11]. Such a digital transition requires as well standardized implementation protocols and more important a realistic view of return on investment as highlighted in [12].

Recently, the COVID-19 pandemic has influenced dramatically the daily operations of manufacturing firms [13] mandating them to drastically increase their efforts in their digital transformation. Five industrial case studies showcasing the use of advanced information and operational technologies in manufacturing are presented in [14], demonstrating the increased automated support because of increased automation levels. Although the pandemic has intensified the need for manufacturers to incorporate Industry4.0 technologies, the barriers to this happening are still present.

However, the capability of a firm to pursue and accomplish its digital transformation is dependent on its capabilities and dynamic management profile. The authors in [15] propose a systematic model for SMEs to better understand their capabilities and digital maturity and identify their competence elements. In a similar approach, a framework for the digital transformation of SMEs is provided [16]. The framework is also suggested for benchmarking the capabilities relevant to the digital transformation of SMEs.

Considering that manufacturing companies including SMEs need digital solutions to demonstrate increasing levels of resiliency in today’s market demands as well as disturbances, such as the COVID-19 pandemic, novel solutions for production planning are of major importance to improve their flexibility and adaptability. A literature review on production scheduling in Industry 4.0 is presented in [17] including the review of 53 papers. A conceptual framework for smart production planning and control in Industry 4.0 is discussed in [18], including scheduling, job sequencing, controlling and data management. A model for integrated planning and scheduling of engineer-to-order products is presented in [19] using a mixed-integer programming formulation. The results indicate a large computing time is required for large sized-instances. Also, a mixed integer linear programming extended with a Lagrange relation method is used [20] for energy-efficient scheduling under time-of-use pricing. The integration of industrial IoT with operational technologies to support the dynamic scheduling and rescheduling operations in a personalized production environment is proposed in [21]. Such approaches can enable data-driven decision-making and control facilitating the adoption of proactive strategies for a resilient and sustainable production system [22]. Regarding the knowledge that IoT data can reveal, and that traditional scheduling methods ignore, [23] propose a cyber-physical architecture for dynamic scheduling using reinforcement learning techniques. Also in that direction, a context-aware scheduling and control architecture is proposed by [24] and [25]. A manufacturing ontology is adopted to formalize raw data into structured information while rule-based control approaches are being followed in both. A Markov decision-making process for scheduling in semiconductor fabrication is employed in [26], while a control algorithm based on Kalman filters is discussed in [27] for non-stationary batch service production, with promising results. In [28] they quantify the production recovery of SMEs in the post COVID-19 era according to their openness to Industry 4.0 technologies, indicating the importance of adaptive production planning and control in the management of the disruptive effect generated by the COVID-19 pandemic.

It becomes clear that the resiliency of a manufacturing company when it comes to production planning and scheduling is highly dependent on data acquisition and their conversion to meaningful information. This work discusses a unified approach for enabling the digital transformation of manufacturing companies, focusing on SMEs, regarding the aspects of production planning and monitoring.

3. Method Description

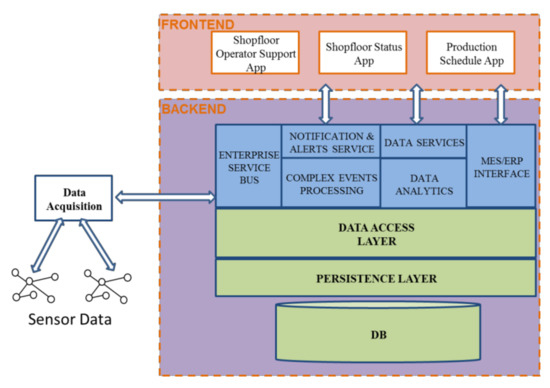

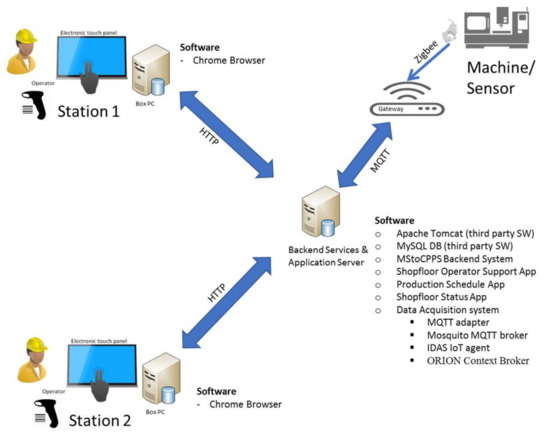

This chapter presents the proposed solution for the system for Digital Transformation (DT) of the mold production processes. As depicted in Figure 1, the proposed solution consists of two main parts: the backend and the front end.

Figure 1.

System architecture.

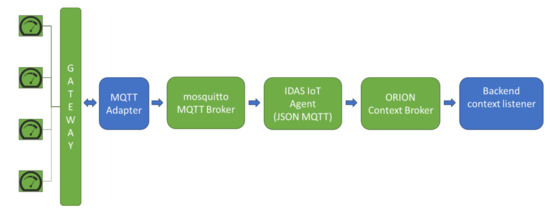

The “Data Acquisition” component of the proposed solution is an IoT stack supported by FIWARE components. The main components integrated into the solution are the ORION Context Broker to manage the application context and the IDAS IoT Agent (JSON-MQTT) to mediate between an MQTT-enabled sensor and the context broker. The architecture of the Data Acquisition solution is depicted in Figure 2. The main components are:

Figure 2.

Data Acquisition Architecture based on FIWARE components.

- The MQTT adapter (implementation of the MQTT client protocol) transforms non-MQTT devices into MQTT-enabled devices. It transforms data from arbitrary formats (XML, JSON, binary signals) into MQTT messages. The body of such messages follows a JSON format, and its model is dictated by the IDAS IoT Agent.

- MQTT Broker is an essential component for transferring data fast, efficient and reliable from shopfloor (connected IoT devices) towards an arbitrary number of client devices.

- An IDAS IoT Agent configured to serve as a proxy between the MQTT protocol (supported by the mosquito MQTT broker) and the NGSI protocol (supported by the ORION context broker).

- ORION Context broker supporting the NGSI standard.

- The context listener component is a client of Context Broker which uses the NGSI protocol to access context-related information and provide them towards the main backed application through its dedicated ESB.

In the backend system, the major layer is the business layer (represented in blue in Figure 2) which consists of the following services/components:

- Enterprise Service Bus (ESB): The communication channel for data transfer from the “Data Acquisition” (see Figure 1) system towards the “Business Layer”. (implemented using Apache’s Camel and Active MQ)

- MES/ERP Interface: A generic Interface to communicate with MES/ERP systems. The solution provides an API for production schedule creation and management. The API is implemented through a set of Rest Services exchanging JSON formatted data.

- Data Services: This component provides the API for accessing the data managed by the backend system. Again, these services/API are implemented as Rest services (JSON) and are utilized to develop the “apps” in the Frontend layer.

- Notification & Alerts Service: This module provides the Frontend layer with simple and complex events generated by the CEP component. The CEP component is precond to fire complex events from the IoT data that each third-party application (in our case the Front-End apps) can be registered to receive and act upon.

- Complex Event Processing (CEP): This component is connected to the ESB to retrieve events from sensors and combined with historical information from the “Data Access Layer” generates alerts and notifications. The generated events are preconfigured through a rule-based system and upon their creation are propagated to the registered services through the HTTP protocol as JSON messages.

- Data Analytics: This component is a group of services that produce high-level information from the low-level shop floor and production data like business KPIs.

The other two layers, namely the “Data Access Layer” and “Persistence Layer” their roles are to make sure that data are securely stored and efficiently retrieved from the physical storage (RDBMS system).

The front end consists of the following apps:

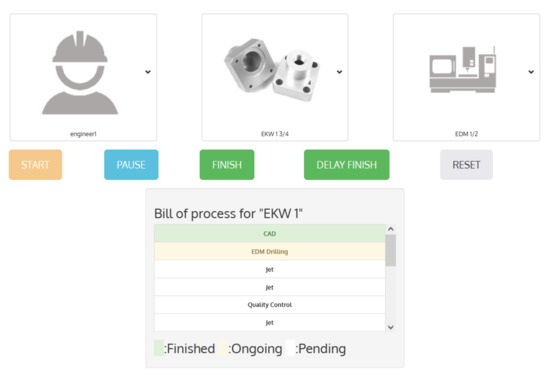

- Shopfloor Operator Support App: This app (see Figure 3) is used to guide an Operator to perform a “task”. Upon reaching a workstation, he scans his badge, and a list of “products” and corresponding “machines” are presented to select and start/finish a process. This application utilizes the assignments monitoring functionalities of the backend system along with the work order configuration to get a list of assignments and present the end user with the status of a product allowing them to advance it (further process the product). Functionalities include:

Figure 3. Operator Support App allows user to “Finish” the current process.

Figure 3. Operator Support App allows user to “Finish” the current process.- a.

- Production plan monitoring

- b.

- Location of products on the shopfloor (user interface only, it utilizes backend system functionality of sensor monitoring)

- c.

- User Interface for Operator Support (personalized production plan per operator)

- d.

- Alerts from the shop floor. Mainly information about machine breakdowns derived from installed sensors.

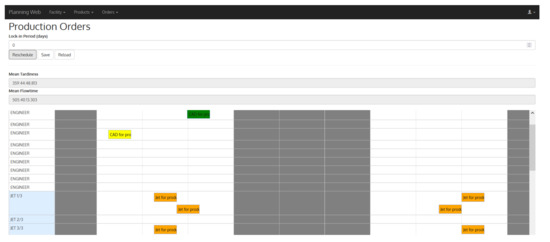

- Production Schedule App: This application (see Figure 4) creates a production schedule that is fed to the backend system services for monitoring. It provides capabilities for facility configuration, bill of processes configuration and finally workload definition. The core of the scheduling application has been based on advanced search [29] which has been utilized also in other cases (e.g., [30]). The output is a set of work orders to be released to the shop floor.

Figure 4. Production Schedule App.

Figure 4. Production Schedule App.

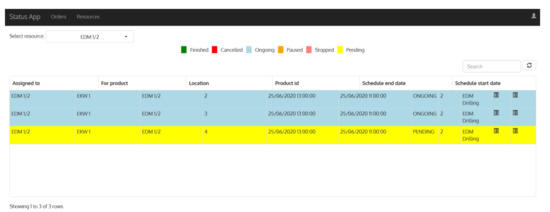

- Shopfloor Status App: This application (see Figure 5) provides the management personnel with a view of the shopfloor activities. It provides information about where each product is located on the shop floor, what task each machine/resource is currently running and finally metadata for the product, like what processes each product has already finished (from the Bill Of Processes) and what would be the expected time of the product to be available to be shipped to the customer.

Figure 5. Shopfloor status app–Orders monitoring view.

Figure 5. Shopfloor status app–Orders monitoring view.

4. Industrial Pilot Case

4.1. Industrial Pilot Case Description

A mold is used for shaping materials into parts or products, and the mold production industry is essential for the mass production of various products such as plastic ones. Most mold manufacturing companies are SME companies (e.g., [1]), and therefore, it is important to investigate methods to improve the digital maturity of such companies. In molds’ production, the core business activities can be classified into three business sectors: 1. Design and manufacturing of Injection Molds, 2. Design and manufacturing of Cutting and Forming Dies and 3. Manufacturing of High Precision Parts. All products and subcomponents are processed in the same resources and part flow covers most of the machining centers, depending on the particularities of each case. Common ground for all three of the above-mentioned business sectors is the demanding and complex manufacturing processes and the high precision required. The first two sectors, best fit the Engineer to Order business models, as the final products are unique, first-time-right complex assemblies, which vary greatly in terms of functionality, lead times and cost. Design, engineering and manufacturing start as soon as the customer demand comes in. While, the third sector, best fits the Make to Order business model, since the parts produced in single or very low-volume quantities, are engineered by the customer, and a detailed CAD drawing is provided. The industrial pilot case will focus on the third sector, Make to Order of High Precision Parts since it will allow for initial validation of the digital manufacturing solutions to be introduced as the significantly shorter lead times, and the more ordinary distribution of demand throughout the year, make it feasible to test and demonstrate the functionalities of the proposed digital manufacturing solutions in real conditions, via executing actual manufacturing orders. In addition, the company experts are convinced that the results of the testing and validation can be transferred to the other two business sectors. The basic differences are: (a) molds and dies are assemblies, but a high precision part can be considered a component of such an assembly in terms of manufacturing processes complexity and handling, and (b) mold and dies require design and engineering before being introduced in the shop-floor as manufacturing orders, while for high precision parts, CAD drawings and engineering information are already available, which makes the pilot case easier to implement and allow for early validation results.

The overall manufacturing operations are sub-optimal, and identified weaknesses, described in this chapter, are also considered points of improvement, that can yield great benefits if addressed efficiently.

- Planning & scheduling: There is no planning or scheduling taking place other than the rough manual prioritization of the jobs in progress. Senior engineers and management have a deep understanding of each project and the efforts required to complete it and give instructions to the shopfloor personnel. Once a job is close to completion, or finished on a specific resource or department, a decision is made about which job is going to be processed next. Usually, to stay efficient and avoid resources staying idle, waiting for instructions, departments are assigned to be occupied with the same project, and engineers undertake projects personally so that they can manage them efficiently. All instructions to the shop floor, and work assignments, are orally provided, and the only information available is the order confirmation date and required delivery time.

- Monitoring & control: Since there is no schedule or production plan, following a project during its execution can be very demanding. There is no overview of which job is being processed in which machine since this information is dispersed among the operators and responsible engineers and requires person-to-person communication. Possible delays are identified only when it is already too late to respond. The timesheet-based system of documenting efforts spent on each project is considered of low quality and provides insight only after the completion of a task.

- Uninformed decision making: Given the lack of scheduling and monitoring of the manufacturing operations, a lot of personal and team efforts are required, to maintain the system functioning. Priority conflicts are daily resolved informally on a personal level or with short meetings of every stakeholder involved, and adaptations are being made constantly. The impact of those adaptations is impossible to consider in detail and to meet deadlines, a lot of extra working hours are required, leading to extra costs, which again cannot be quantified. The same applies to each new order coming to the shop floor since delivery times have already been agreed upon with little consideration of the available capacity of the current period.

Overall, the lack of systematic support for planning and monitoring activities hampers knowledge reuse and continuous improvement activities. Experience gained over the years remains as tacit knowledge in minds of the engineers, while valuable information—such as actual processing times—is not gathered, and thus cannot be used to plan an identical (rarely) or very similar job in the future. Lack of data also makes improvements in the manufacturing processes hard to implement and follow, since there is no hard evidence to compare and assess.

Table 1 summarizes the main challenges faced by mold production industry and their impact on the business side.

Table 1.

Summary of main challenges and their impact on the business process.

Following the analysis of the industrial needs, some Key Performance Indicators (KPIs) have been defined (see Table 2) for measuring the success of the DT project. Then KPIs are mapped to the new functionality to be provided. Table 2 below summarizes the main functionalities provided by the proposed solution and how they contribute to the expected benefit. This has helped in prioritizing the developments of the DT project and was also used during the validation phase to assess the impact of the solution.

Table 2.

The expected contribution of digital tools to the company’s KPIs.

4.2. Validation and Lessons Learnt

The solution presented in chapter 3 has been validated in the industrial pilot case. As presented in Figure 6 the digital solution has been deployed on the shop floor as follows:

Figure 6.

Solution deployment on the shop-floor.

- Two client workstations (PCs) to monitor the process execution by retrieving information from the operators of the machines close to each of the workstations. A touch screen was installed in each client workstation to allow for interaction with the operators. A standard web browser (Google Chrome) was used for providing access to the functionality of the apps.

- One Zigbee-enabled sensor for collecting energy consumption data from one production machine.

- A server for local, on-site installation of the proposed solution. The backend part of the solution was installed on the server side.

All HW components, namely: server, client PCs and gateway were connected to the same LAN through Ethernet cabling. In Figure 7 the deployment of the solution in an operational shop-floor environment is presented.

Figure 7.

Installation of HW/SW on the shopfloor during the experiments.

Both estimated measurements during the experiments and as well as experts’ judgment have verified that the solution can bring a considerable impact on several business processes (production scheduling, shop-floor operators’ activities/tasks and monitoring of the production process). The validation tests have verified that the proposed DT approach for supporting the operators on the shop floor and especially the interaction of the operator with the product/part as well as the interaction with the shopfloor’s production plan is technically feasible and the required modification in the established business process is acceptable. The required modifications, which introduce additional verification steps taken by the operator through the solution, have been received by the operators and engineers without major concerns. Finally, the expected impacts of the solution to the mold-shop that have been identified in the early phases of the digital transformation project, such as increased resource utilization, decrease extra working hours spent on scheduling/rescheduling, decrease non-added value activities for engineers, reduce delays in projects’ delivery time, percentage of total time spent on documenting efforts and time spent on a project and percentage of erroneous data records have been verified through the experiments. An exception was the human-errors reduction that had initially been overestimated, however during the experiments it was evident that the solution marginally contributes to quality improvements and that is mainly achieved by increasing the awareness of the shop-floor operators on the sequence of the production steps. Table 3 below summarizes the expected benefits for mold producers by applying the proposed DT solution.

Table 3.

Business Performance Indicators (BPIs).

From a technical and software systems perspective, it was clear to the development team that the open-source components used (ORION and IDAS IoTAgent) are mature solutions with straightforward integration steps within the backend system of the system. Moreover, the execution performance of the FIWARE tools was also within the expectation with no major issues identified in aspects like response times or stability.

On a technical scale, the solution demonstrates how a traditional manufacturing system can be transformed into a CPS system by integrating IoT technology with smart capabilities such as dynamic scheduling. In Table 4 key findings from the qualitative analysis from the technical point of view are presented.

Table 4.

Experiment with qualitative analysis from a technical point of view.

5. Conclusions

This work demonstrates a feasible way for manufacturing SMEs to adopt digital manufacturing technologies that can bring benefits to their processes. Addressing real industrial cases helps understand the real-world implications and thus provides practical approaches to resolve them. The proposed technologies facilitate the digitization and use of production and operational resource data within a mold production environment. The DT project has brought improvements in capturing the production activity, both by the operators and the machines, offering the capability to the production manager for up-to-date information on the work-in-progress on the factory floor as well as the capability to schedule and re-schedule the production to address disturbances in the environment. Moreover, at the technical level, the DT project has shown that open-source solutions used from the FIWARE community are mature ones which can be successfully integrated into production environments. At an organizational level, the active engagement of the shop-floor personnel and engineering department from the early phases plays a crucial role in user acceptance. Moreover, incremental deployment of the solution relieves the frustration of changing business processes from the management personnel as it allows for smooth communication of the changes to the shop-floor personnel.

As the next steps in the DT project are under discussion, it is envisaged to enrich the functionality of the existing apps. The Production Schedule app should be enriched with functionality that will allow users to perform “quick” plans based on input scenarios for estimating capacity and capabilities of the production to manage it. The Shopfloor Status app will be enriched with additional views i.e., per department and WorkCentre as well as with visual indication of production status (i.e., ahead green light, behind orange light, overdue red light).

Author Contributions

Conceptualization, K.A.; methodology, K.A., N.N. and E.X.; software, E.X.; validation, K.A. and E.X.; writing—review and editing, K.A., N.N. and E.X.; supervision, K.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work has received funding from the European Union’s Horizon 2020 research and innovation programme under Grant Agreement No. 873086.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chryssolouris, G. Manufacturing Systems: Theory and Practice, 2nd ed.; Springer: New York, NY, USA, 2006. [Google Scholar]

- Alexopoulos, K.; Sipsas, K.; Xanthakis, E.; Makris, S.; Mourtzis, D. An industrial Internet of things based platform for context-aware information services in manufacturing. Int. J. Comput. Integr. Manuf. 2018, 31, 1111–1123. [Google Scholar] [CrossRef]

- Chen, C.-L. Value creation by SMEs participating in global value chains under industry 4.0 trend: Case study of textile industry in Taiwan. J. Glob. Inf. Technol. Manag. 2019, 22, 120–145. [Google Scholar] [CrossRef]

- European Commission. Smart Industrial Remoting: Remote Working in Non-Digitalised Industries—Pilot Project, Gap Analysis Report. 2022. Available online: https://ppmi.lt/storage/app/media/docs/sird2gapanalysisreportvpublication.pdf (accessed on 18 September 2022).

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

- Mourtzis, D.; Vlachou, E.; Xanthopoulos, N.; Givehchi, M.; Wang, L. Cloud based-adaptive process planning considering availability and capabilities of machine tools. J. Manuf. Syst. 2016, 39, 1–8. [Google Scholar] [CrossRef]

- Bajgar, M.; Calligaris, S.; Calvino, F.; Criscuolo, C.; Timmis, J. Bits and Bolts: The digital Transformation and Manufacturing; OECD Science, Technology and Industry Working Papers; OECD Publishing: Paris, France, 2019. [Google Scholar] [CrossRef]

- Krüger, J.; Wang, L.; Verl, A.; Bauernhansl, T.; Carpanzano, E.; Makris, S.; Fleischer, J.; Reinhart, G.; Franke, J.; Pellegrinelli, S. Innovative control of assembly systems and lines. CIRP Ann. 2017, 66, 707–730. [Google Scholar] [CrossRef]

- Nikolakis, N.; Senington, R.; Sipsas, K.; Syberfeldt, A.; Makris, S. On a containerized approach for the dynamic planning and control of a cyber—Physical production system. Robot. Comput.-Integr. Manuf. 2020, 64, 101919. [Google Scholar] [CrossRef]

- Borangiu, T.; Trentesaux, D.; Thomas, A.; Leitão, P.; Barata, J. Digital transformation of manufacturing through cloud services and resource virtualization. Comput. Ind. 2019, 108, 150–162. [Google Scholar] [CrossRef]

- Sanchis, R.; García-Perales, Ó.; Fraile, F.; Poler, R. Low-Code as Enabler of Digital Transformation in Manufacturing Industry. Appl. Sci. 2020, 10, 12. [Google Scholar] [CrossRef]

- Butt, J. A Conceptual Framework to Support Digital Transformation in Manufacturing Using an Integrated Business Process Management Approach. Designs 2020, 4, 17. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Anagiannis, I.; Nikolakis, N.; Chryssolouris, G. A quantitative approach to resilience in manufacturing systems. Int. J. Prod. Res. 2022, 60, 4342–4360. [Google Scholar] [CrossRef]

- Li, D.; Fast-Berglund, Å.; Paulin, D.; Thorvald, P. Exploration of digitalized presentation of information for Operator 4.0: Five industrial cases. Comput. Ind. Eng. 2022, 168, 108048. [Google Scholar] [CrossRef]

- González-Varona, J.M.; López-Paredes, A.; Poza, D.; Acebes, F. Building and development of an organizational competence for digital transformation in SMEs. J. Ind. Eng. Manag. 2021, 14, 15–24. [Google Scholar] [CrossRef]

- Pieretto, E.; Hinterhuber, A. Digital transformation of manufacturing firms: Opportunities and challenges for SMEs. In Managing Digital Transformation; Routledge: London, UK, 2021; pp. 211–239. [Google Scholar] [CrossRef]

- Prashar, A.; Tortorella, G.L.; Fogliatto, F.S. Production scheduling in Industry 4.0: Morphological analysis of the literature and future research agenda. J. Manuf. Syst. 2022, 65, 33–43. [Google Scholar] [CrossRef]

- Cañas, H.; Mula, J.; Campuzano-Bolarín, F.; Poler, R. A conceptual framework for smart production planning and control in Industry 4.0. Comput. Ind. Eng. 2022, 173, 108659. [Google Scholar] [CrossRef]

- Neumann, A.; Hajji, A.; Rekik, M.; Pellerin, R. A model for advanced planning systems dedicated to the Engineer-To-Order context. Int. J. Prod. Econ. 2022, 252, 108557. [Google Scholar] [CrossRef]

- Park, M.J.; Ham, A. Energy-aware flexible job shop scheduling under time-of-use pricing. Int. J. Prod. Econ. 2022, 248, 108507. [Google Scholar] [CrossRef]

- Coito, T.; Firme, B.; Martins, M.S.E.; Costigliola, A.; Lucas, R.; Figueiredo, J.; Vieira, S.M.; Sousa, J.M.C. Integration of industrial IoT architectures for dynamic scheduling. Comput. Ind. Eng. 2022, 171, 108387. [Google Scholar] [CrossRef]

- Owida, A.; Galal, N.M.; Elrafie, A. Decision-making framework for a resilient sustainable production system during COVID-19: An evidence-based research. Comput. Ind. Eng. 2022, 164, 107905. [Google Scholar] [CrossRef]

- Gu, W.; Li, Y.; Tang, D.; Wang, X.; Yuan, M. Using real-time manufacturing data to schedule a smart factory via reinforcement learning. Comput. Ind. Eng. 2022, 171, 108406. [Google Scholar] [CrossRef]

- Wan, G.; Dong, X.; Dong, Q.; He, Y.; Zeng, P. Context-aware scheduling and control architecture for cyber-physical production systems. J. Manuf. Syst. 2022, 62, 550–560. [Google Scholar] [CrossRef]

- Nikolakis, N.; Sipsas, K.; Makris, S. A cyber-physical context-aware system for coordinating human-robot collaboration. Procedia CIRP 2018, 72, 27–32. [Google Scholar] [CrossRef]

- Lee, Y.H.; Lee, S. Deep reinforcement learning based scheduling within production plan in semiconductor fabrication. Expert Syst. Appl. 2022, 191, 116222. [Google Scholar] [CrossRef]

- Yousefnejad, H.; Monfared, M.S. A control algorithm for a non-stationary batch service production system using Kalman filter. Expert Syst. Appl. 2022, 207, 117916. [Google Scholar] [CrossRef]

- Cugno, M.; Castagnoli, R.; Büchi, G.; Pini, M. Industry 4.0 and production recovery in the covid era. Technovation 2022, 114, 102443. [Google Scholar] [CrossRef]

- Chryssolouris, G.; Lee, M. An Approach to Real-Time Flexible Scheduling. Int. J. Flex. Manuf. Syst. 1994, 6, 235–253. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Koukas, S.; Boli, N.; Mourtzis, D. Resource Planning for the Installation of Industrial Product Service Systems. In Advances in Production Management Systems. The Path to Intelligent, Collaborative and Sustainable Manufacturing; Lödding, H., Riedel, R., Thoben, K.D., von Cieminski, G., Kiritsis, D., Eds.; IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2017; p. 514. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).