Abstract

Fissures substantially impact the engineering stability of rock masses, making research on rock masses with preexisting fissures essential for engineering activities. The development of specimens with different preexisting fissure types was examined in this study. Three different types of specimens with preexisting fissures can be broadly categorized: specimens with few preexisting fissures, specimens with multiple preexisting fissures, and specimens with preexisting fissures and other flaws. Uniaxial compression tests of specimens with preexisting fissures of two unequal lengths were conducted, and the influence of preexisting fissure angle, the distance between the two fissures and fissure length on the peak strength and coalescence mode of specimens were analyzed. A large preexisting fissure length significantly influenced the peak strength and coalescence, and the uniaxial compressive strength (UCS) values of the rock-like materials decreased. In contrast, increasing the long preexisting fissure length influenced the crack propagation and coalescence more extensively in the case of a long preexisting fissure. The preexisting fissure angle and two preexisting fissure distances had a negligible effect on the UCS values of the rock-like materials. However, with increasing long preexisting fissure length, the short preexisting fissure was subject to crack propagation and coalescence.

1. Introduction

As complex geological media, rock masses frequently contain various discontinuities, including joints, fissures, bedding planes, shear zones, faults, and weak surfaces. These discontinuities, which can range in size from microscopic to macroscopic, are caused by the processes of tectonic motion and the initial stages of rock mass formation. Joints and fissures typically appear in sets that are roughly parallel and evenly spaced. Existing joints or fissures have a significant impact on the stability of rock mass engineering. As a result of the applied load, cracks can proceed from the locations of preexisting fissures, spread, and cause the rock mass to coalesce. Rock or rock-like materials may degrade nonlinearly as a result of the start, development, and coalescence of micro- and macro-fissures, leading to the breakdown of structures created from them.

Intact rock behaves mechanically very differently from jointed rock materials because it ignores the influence of the fissures in the rock mass; therefore, it is more convenient to prepare and conduct physical experiments with intact rock than with jointed rock materials, which may cause the strength of the rock mass to be overestimated. Therefore, experimental results from intact rock materials should be interpreted with caution.

To explore the mechanical behavior of rock masses with fissures, two kinds of specimens were utilized: rock and rock-like materials. For the former, preexisting fissures were prepared directly using a high-pressure water jet cutting machine [1]. For rock-like materials, other kinds of materials were used to simulate the fragility of rock materials, such as inserting metal shims at the intended location to create a preexisting fissure. The shims were removed once the rock-like materials had hardened, leaving cracks in the specimens with straight openings [2,3]. These two specimens were used to study the peak strength, crack generation, crack expansion, and coalescence of rock masses with fissures.

To better understand the influence of prefabricated cracks on the rock mass, specimens containing a variety of preexisting fractures were prepared for physical or numerical experiments. Our study is reviewed and described in the following sections.

1.1. Specimens Contain Various Preexisting Fissures Used for Physical and Numerical Experiments

To better comprehend the fracture behavior of rock masses, numerous researchers have performed experiments and numerical work, and different kinds of specimens (rock, rock-like materials, and numerical simulations) with various preexisting fissures have been used. Based on the number and shape of the preexisting fissures, these experiments can usually be grouped into three classifications: experiments on specimens with few preexisting fissures, specimens with multiple preexisting fissures, and specimens with fissures and other flaws (holes and inclusions).

In the initial stages of investigations of rock masses with preexisting fissures, specimens with single, two, or three preexisting fissures are frequently adopted. Crack generation, expansion, and specimen coalescence are not intricate, making them convenient for results analyses. The peak strength, crack propagation process and coalescence mode are the main research objectives, and related research provides a foundation for further study. According to analyses of the experiments, the geometry of the preexisting fissures, including the preexisting fissure angle, ligament angle, and preexisting fissure length, has a significant impact on the peak strength and crack propagation [4]. Due to the impact of the arrangement of preexisting fissures and experimental setups, different kinds of cracks and coalescence modes can be observed. Generally, cracks are initiated because of two forms of stress: shear or tensile. Hence, the crack types can be classified into S mode (shear stress) and T mode (tensile stress) [3]. However, Sagong and Bobet (2002) [5] proposed that crack types should be classified into tensile cracks and quasi-coplanar shear cracks. This classification describes the crack type more specifically. In addition, the shear crack was further classified in the study by Sagong and Bobet (2002) [5]. It is possible to obtain a larger set of coalescence modes with crack propagation by linking one or more of these fundamental crack types. Due to the difference in the arrangements of preexisting crevices and experimental setups, the crack propagation process may also be different, and the coalescence mode can be classified into three categories [6], nine categories [7], or more. The classification results are correlated with the arrangement of preexisting fissures, crack generation, crack propagation, crack coalescence and the failure modes of specimens.

Numerical simulations and many software applications, such as PFC2D [8,9,10,11,12,13,14,15,16,17,18], PFC3D [19,20,21], RFPA2D [22], DDM [23], FLAC3D [4,24,25,26], ANSYS [27], XFEM [28], ABAQUS [29,30,31], and UDEC [32], have been utilized to analyze the cracking processes of real rock materials. This is because numerical simulations can be repeated with a little economic cost, and the process of crack initiation and crack growth can be specifically observed. Numerical simulations have shown that the primary cause of wing cracks is tensile stress, while secondary cracks are caused by shear stress. Yang (2016) [33], found that fissure length and location and stress interactions among nearby fissures have a great influence on crack generation, expansion, and coalescence behaviors, which are consistent with the physical experimental results.

Although our specimens contained few preexisting fissures, they were easy to prepare, and our results were easy to analyze. However, in natural rock mass engineering, many sets of preexisting fissures exist. Therefore, experiments on specimens with multiple preexisting fissures may provide results which are closer to the reality of engineering practice, and the experimental results can provide a more useful basis for rock mass engineering. By using the artificial method, a specimen with a different alignment of preexisting flaws, such as parallel fissures [34,35,36], nonpersistent fissures [37,38,39,40], and intersecting fissures [41], can be prepared. The cracking process was recorded during the experiments, and these preexisting fractures were found to interact with the intact rock, which can affect the mechanical properties of the rock mass [42]. Meanwhile, the occurrence of cracks in specimens containing multiple preexisting cracks may be more complicated compared to those in specimens with a few preexisting fissures, and the crack propagation process may be harder to describe. To examine the influence of preexisting fissure geometry on failure mode, unconfined compressive strength, and deformation modulus, a large number of experiments have been performed [43,44]. Peak strength and failure mode were the primary areas of interest in analyses of these experimental results. The failure mode of specimens containing various preexisting fissures can usually be sorted into three categories: failure through a planar surface, stepped failure, and failure by rotation of new blocks [45]. Due to the difference in experimental setups, the failure mode can be classified as intact rock failure, step-path failure, or planar failure [46]. The coalescence type and failure modes can have different classifications, which depend on the mechanical characteristics of the specimens, the experimental setup, and the distribution of preexisting fissures.

However, specimens with multiple preexisting fissures can provide results which more closely reflect engineering practice. Preexisting fissures are not the only discontinuities in the rock mass; other forms exist, such as holes [47,48], elliptical holes [49], and inclusions [8,50,51]. In most cases, holes are distributed with preexisting fissures. By using these combined flaws [42,52,53], the coupling effects between preexisting fissures and holes can be considered, which can more accurately reflect engineering practice compared with the experiments on specimens with preexisting fissures.

1.2. Objectives of This Paper

Our physical and mathematical experiments provided insights into the importance of preexisting fissures on the mechanical behavior of rock masses with joined fissures. However, our study focused on how equal preexisting fissures affected peak strength, crack initiation, crack propagation, crack coalescence, and specimen failure. Rock masses with unequal preexisting fissures have rarely been investigated and seldom reported.

Therefore, to better understand the mechanical behavior of rock masses containing unequal parallel preexisting fissures, rock-like materials with two unequal parallel preexisting fissures were prepared, and uniaxial compression tests were performed [7]. In our experiments, stress-strain experimental data were recorded, and the influence of the preexisting fissure angle, the distance between preexisting fissures, and fissure length on the peak uniaxial compressive strength and coalescence were analyzed. This study can serve as an experimental foundation for the design and implementation of rock mass engineering techniques.

2. Uniaxial Compressive Test of Rock-like Materials with Two Unequal Parallel Preexisting Fissures

2.1. Preparation of Specimens

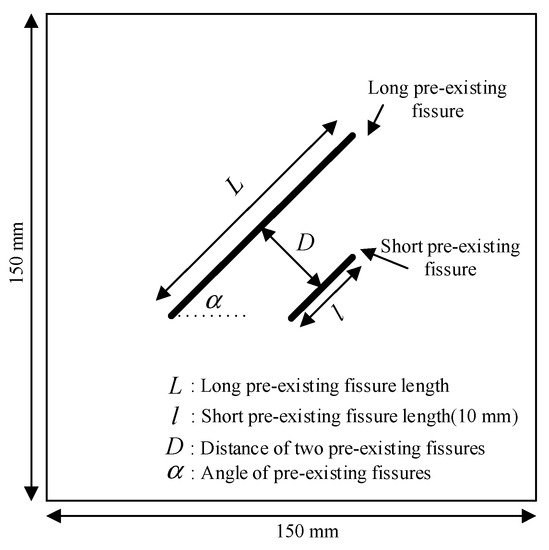

In this study, square rock-like materials with dimensions of 150 mm 150 mm 40 mm were prepared. The prefabricated fissure angle, short prefabricated fissure length, long prefabricated fissure length, and distance between the two fissures are the four parameters that define the geometry of the preexisting flaws. The geometry of the specimens is illustrated in Figure 1.

Figure 1.

The geometry of the specimen with two unequal parallel prefabricated fissures.

As illustrated in Figure 1, for specimens containing two open unequal parallel straight prefabricated fissures, the short prefabricated fissure length was 10 mm. The other parameters are listed in Table 1.

Table 1.

Geometric parameters of two unequal parallel preexisting fissures.

By combining the different kinds of preexisting fissure angles (), fissure distances (), and fissure lengths (), a total of 280 specimens were prepared. To facilitate the experiments, the prepared specimens were marked with the geometric parameters of the preexisting fissures (--). For example, for a specimen with a preexisting fissure angle of 30°, a distance between fissures of 35 mm, and a large preexisting fissure length of 50 mm was labeled 30-35-50.

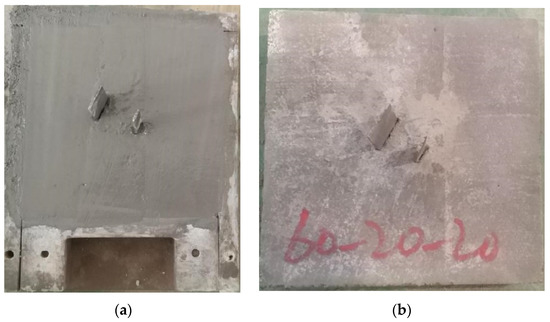

To obtain reliable experimental results, the rock-like material preparation procedures were carefully regulated. An electronic balance weighed the materials to a precision of 0.01 kg. The mixture (the mass ratio of cement, sand, and water was 26:25:10.) was poured into a mold. By placing metal shims into fresh rock-like materials at the intended location, preexisting fissures were made (Figure 2a). When the rock-like materials hardened, the mold was dismantled (Figure 2b), and the shims were gradually removed, leaving the specimen interiors with straight openings.

Figure 2.

The preparation of rock-like specimens. (a) Mixture poured in the mold; (b) Dismantled mold.

2.2. Testing Procedure

A RYL-600 rock mechanics shear creep testing system was utilized to conduct uniaxial compressive tests (Figure 3). All experiments were conducted under force-controlled conditions with a force rate of 100 N/s, and the specimens were loaded uniaxially to achieve failure. During the process, the stress–strain curve and crack propagation process were recorded, which was useful for analyzing the experimental data.

Figure 3.

RYL-600 rock mechanics shear creep testing system.

During the test, the basic mechanical parameters of the rock-like materials were obtained. The tensile strength was 3.42 MPa, Young’s modulus was 2.066 GPa, Poisson’s ratio was 0.31, and the uniaxial compressive strength was 41.43 MPa.

3. Experimental Results Analysis

During the physical experiments, the stress-strain curve was recorded using the RYL-600 controller, and a digital camera captured the crack propagation of the rock-like materials under uniaxial compression.

3.1. Peak Strength Analysis

This section discusses the influence of preexisting fissure length, angle, and distance on the UCS values of rock-like materials.

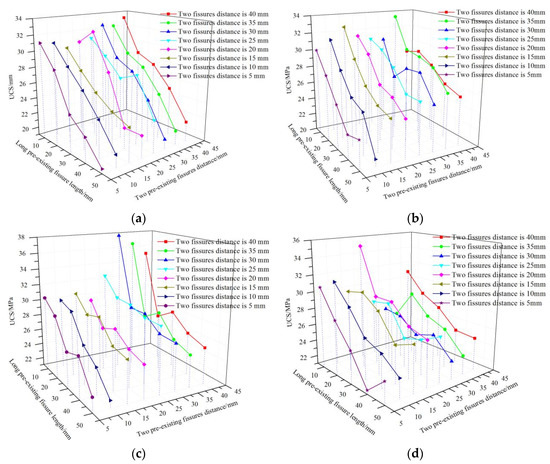

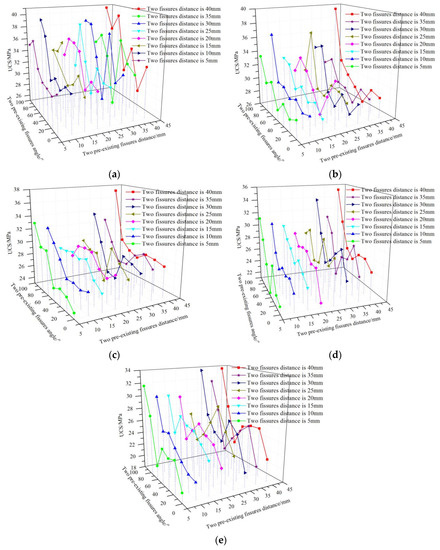

A greater preexisting fissure length substantially impacts the UCS of rock-like materials. Figure 4 shows that the UCS value decreases with increasing preexisting fissure length, especially when the fissure angles were and . Through an analysis of the experimental results, it could be concluded that, compared with short preexisting fissures, long fissures have larger influence areas on rock-like materials. During the loading process, the newly generated cracks appeared more easily at or near the tip of the long preexisting fissures. These newly generated cracks typically caused the failure of the specimens. The UCS values of rock materials decreased with increasing the fissure length. However, the UCS value did not increase with an increase in fissure angle (fissure angle and fissure distance of 20 mm); this was mainly caused by differences in the specimens, but the results were acceptable. Hence, in engineering practice, more attention should be given to long preexisting fissures.

Figure 4.

UCS of rock-like materials with a variation in preexisting fissure length. (a) Fissure angles of 0° (b) 15°; (c) 30°; (d) 45°; (e) 60°; (f) 75°; and (g) 90°.

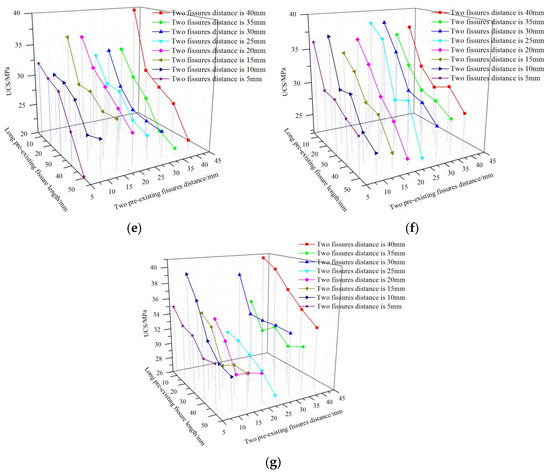

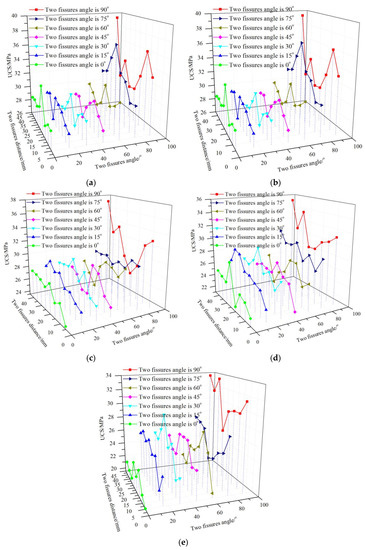

However, the influence of the preexisting fissure angle (Figure 5) on the UCS value of rock-like materials was not obvious. The UCS value of the rock-like materials with large preexisting fissure angles was larger than that with small fissure angles. For example, for rock-like materials with a fissure lengths of 50 mm and a distance of 40 mm, the UCS value of specimens with a fissure angle of 90° was 33.71 MPa, while that of specimens with a fissure angle of 15° was 25.77 MPa. Due to the interactions of long and short preexisting fissures, and of preexisting fissures and newly generated cracks, the variation in the UCS values of rock-like materials containing two unequal parallel preexisting fissures were not obvious; however, it should be noted that specimens with small preexisting fissures have low strength; as such, these results are similar to those for specimens with multiple equal parallel fissures [10].

Figure 5.

UCS of rock-like materials with variations in the preexisting fissure angle. (a) Preexisting fissure length is 10 mm; (b) 20 mm; (c) 30 mm; (d) 40 mm; and (e) 50 mm.

The influence of fissure distance (Figure 6) on the UCS value of rock-like materials is the same as that of the preexisting fissure angle. It can be difficult to find a clear trend with an increase in the distance between two preexisting fissures. Nonetheless, the impact of long preexisting fissure is so great that the impact of the two previous fissures can be ignored.

Figure 6.

UCS of rock-like materials with variations in fissure distance. (a) 10 mm; (b) 20 mm; (c) 30 mm; (d) 40 mm; and (e) 50 mm.

3.2. Crack Propagation and Coalescence Analysis

The influence of preexisting fissure length, angle and distance on crack coalescence is discussed below.

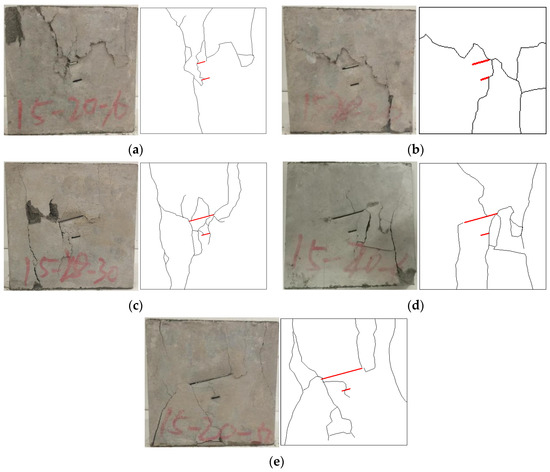

A greater preexisting fissure length more significantly affected the crack propagation and coalescence of rock-like materials. The experimental results of rock-like materials with a fissure angle of 15° and a distance of 20 mm are taken as examples. As illustrated in Figure 7, long preexisting fissures played a key role in the propagation and coalescence of rock-like materials. With increasing the preexisting fissure length, an increasing number of newly generated cracks were connected with the preexisting fissure, especially for failure specimen 15-20-50. Most newly generated cracks were connected with long preexisting fissures, while only one newly generated crack propagated across a short preexisting fissure. In contrast, when the long preexisting fissure was not long enough, more newly generated cracks appeared around the short preexisting fissure, as demonstrated by failure specimen 15-20-30. Therefore, the length of preexisting fissure greatly affects the propagation and coalescence of rock-like materials containing two unequal parallel preexisting fissures.

Figure 7.

Influence of preexisting fissure length on crack propagation and coalescence. (a) Failure specimen 15-20-10; (b) 15-20-20; (c) 15-20-30; (d) 15-20-40; (e) 15-20-50.

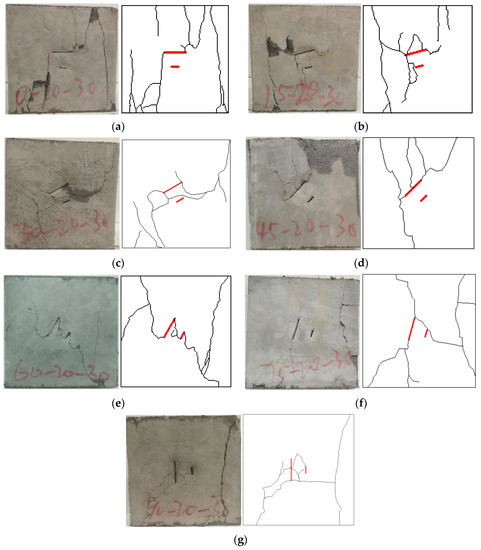

As illustrated in Figure 8, with an increase in the preexisting fissure angle, the short preexisting fissures played an increasingly significant role in rock propagation and crack coalescence. When the preexisting fissure angle was small, long preexisting fissures dominated the crack propagation and coalescence. With increasing the preexisting fissure angle, an increasing number of newly generated cracks appeared in the short preexisting fissures. Taking the failure specimens with a fissure distance of 20 mm and a fissure length of 30 mm as examples, few or even no newly generated cracks appeared in the fissures when the fissure angle was small (i.e., 0°, 15°, 30°, or 45°). Short preexisting fissures began to develop increasing numbers of cracks as the preexisting fissure angle increased, especially in specimens with fissure angles of 90°. It was clear that short preexisting fissures play a significant role in crack propagation and coalescence and specimen failure.

Figure 8.

Influence of the preexisting fissure angle on crack propagation and coalescence. (a) Failure specimen 0-20-30; (b) 15-20-30; (c) 30-20-30; (d) 45-20-30; (e) 60-20-30; (f) 75-20-30; and (g) 90-20-30.

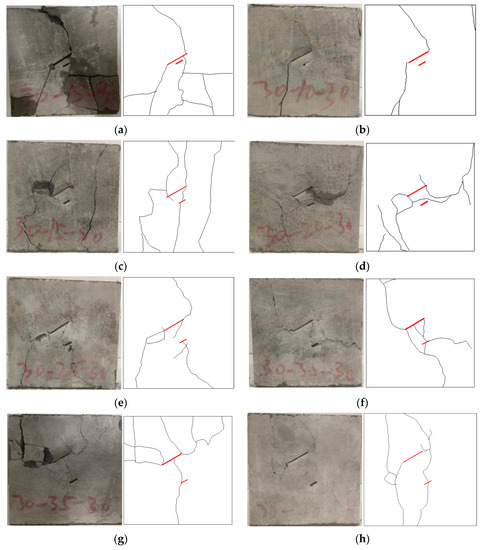

The fissure distances also influenced the crack propagation and coalescence of rock-like materials. Short preexisting fissures played an increasingly significant role in crack propagation and coalescence by increasing the fissure distances. Examples were specimens containing fissures at an angle of 30 mm and a length of 30 mm (Figure 9) when the distance between two fissures was 5 mm, 10 mm, 15 mm, or 20 mm. Long preexisting fissures were more crucial to crack expansion and coalescence. No newly generated cracks propagated through short fissures. However, when the distances between the two preexisting crack were 25 mm, 30 mm, 35 mm and 40 mm, the short fissures had an impact on the growth of cracks and the coalescence of rock-like materials, with newly generated cracks connecting with short preexisting fissures.

Figure 9.

Influence of fissure distance on crack propagation and coalescence. (a) Failure specimen 30-5-30; (b) 30-10-30; (c) 30-15-30; (d) 30-20-30; (e) 30-25-30; (f) 30-30-30; (g) 30-35-30; and (h) 30-40-30.

4. Discussion

A rock mass is a type of natural geological medium that contains different kinds of flaws (such as holes, fissures, and inclusions). Joints, cracks, flows, and fissures have a significant impact on the engineering stability of rock masses. To gain a deeper comprehension of fracture mechanisms, it is important to research the behavior of rock that has undergone the process of fracture evolution and contains preexisting fissures. This can benefit rock mass engineering processes, such as rock slope and tunnel support.

A number of studies were reviewed. To research the mechanical behavior of rock masses containing fissures, two kinds of specimens were frequently utilized: rock and rock-like materials. For the former, preexisting fissures were prepared directly, while for the latter, other kinds of materials were used to simulate the fragility of rock materials. Preexisting fissures were prepared by inserting metal shims into fresh rock-like materials at the desired location. When the rock-like materials hardened, the shims were removed, leaving straight openings and preexisting fissures in the specimens. Based on the arrangement, number, and shape of the preexisting fissures, the experiments were divided into three categories: experiments of specimens with few preexisting fissures, of specimens with multiple preexisting fissures and of specimens with preexisting fissures and other voids. In addition, these studies concentrated on crack type and propagation and coalescence mode, and have contributed to our knowledge on fracture rock mechanics.

However, our analysis indicated that in the previous research, all of the preexisting fissures were of equal length, which is different from engineering practice. Therefore, in this paper, 280 total rock-like materials with two unequal parallel preexisting fissures were prepared, and uniaxial compression tests were performed in which the peak strength and crack coalescence were analyzed. It was found that long prefabricated fractures have a great impact on the UCS values of rock-like materials and crack propagation. The UCS values of the rock-like materials decreased as the length of the prefabricated fracture increased. In addition, the long prefabricated fractures had a greater impact on crack propagation and coalescence. The UCS values of the rock-like materials and crack propagation were not greatly affected by the prefabricated fracture angle or the distance between the two prefabricated fractures.

However, in this paper, only two preexisting fissure types were applied, and only limited kinds of specimens with few preexisting fissure angles, lengths, and distances were considered. Additionally, the specimens were subjected to uniaxial compression tests, which are different from engineering practice. The rock mass with joints was under a triaxial compression state; this will be the focus of our future work.

5. Conclusions

In this paper, research on specimens containing prefabricated fractures was reviewed, and specimens containing two prefabricated fractures of unequal length were prepared. Subsequently, the prepared specimens were used to explore the mechanical behavior of rock masses containing unequal prefabricated fractures under an uniaxial compression state. The primary conclusions of this study are as follows.

- Rock masses with preexisting fissures can be divided into three categories according to the arrangement of the prefabricated cracks: specimens with few preexisting fissures, with multiple preexisting fissures, and with preexisting fissures and other voids.

- Our analysis of the experimental results suggested that long preexisting fissures have a great impact on the UCS values of rock-like materials and crack propagation. With an increase in the number of prefabricated cracks, the UCS values of the rock-like materials decreased, while the crack propagation and coalescence were found to be influenced more significantly by longer prefabricated cracks. The prefabricated crack angle and the two prefabricated crack distances were found to have little impact on the UCS values of rock-like materials and crack propagation.

Author Contributions

Data curation, M.W.; Investigation, W.Z.; Methodology, D.Z.; Supervision, J.L.; Writing—original draft, P.F. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the National Natural Science Foundation of China under the grant (42130810); supported by the Department of Natural Resources of Hunan Province, China (2020-03); and supported by the Department of Emergency Management of Hunan Province, China (2020-06).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare that they have no conflict of interest.

References

- Yang, S.-Q.; Jing, H.-W. Strength failure and crack coalescence behavior of brittle sandstone samples containing a single fissure under uniaxial compression. Int. J. Fract. 2011, 168, 227–250. [Google Scholar] [CrossRef]

- Wong, R.H.C.; Chau, K.T.; Tang, C.A.; Lin, P. Analysis of crack coalescence in rock-like materials containing three flaws-Part I: Experimental research. Int. J. Rock Mech. Min. 2001, 38, 909–924. [Google Scholar] [CrossRef]

- Wong, L.; Einstein, H. Systematic evaluation of cracking behavior in specimens containing single flaws under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2009, 46, 239–249. [Google Scholar] [CrossRef]

- Wang, M.; Wan, W.; Zhao, Y. Prediction of uniaxial compressive strength of rocks from simple index tests using random forest predictive model. Comptes Rendus Mec. 2020, 348, 3–32. [Google Scholar] [CrossRef]

- Sagong, M.; Bobet, A. Coalescence of multiple flaws in a rock-model material in uniaxial compression. Int. J. Rock Mech. Min. Sci. 2002, 39, 229–241. [Google Scholar] [CrossRef]

- Bobet, A.; Einstein, H. Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int. J. Rock Mech. Min. Sci. 1998, 35, 863–888. [Google Scholar] [CrossRef]

- Wang, M.; Wan, W. A new empirical formula for evaluating uniaxial compressive strength using the Schmidt hammer test. Int. J. Rock Mech. Min. Sci. 2019, 123, 104094. [Google Scholar] [CrossRef]

- Yang, S.Q.; Jing, H.W.; Xu, T. Mechanical behavior and failure analysis of brittle sandstone specimens containing com-bined flaws under uniaxial compression. J. Cent. South Univ. 2014, 21, 2059–2073. [Google Scholar] [CrossRef]

- Zhang, X.-P.; Wong, L.N.Y. Cracking Processes in Rock-Like Material Containing a Single Flaw Under Uniaxial Compression: A Numerical Study Based on Parallel Bonded-Particle Model Approach. Rock Mech. Rock Eng. 2012, 45, 711–737. [Google Scholar] [CrossRef]

- Zheng, L.; Huang, D.; Li, X.; Hu, X. Numerical Analysis of Fracture Behaviour on Marble Samples Containing Two Flaws. Adv. Civ. Eng. 2020, 2020, 6278289. [Google Scholar] [CrossRef]

- Dai, B.; Chen, Y.; Zhao, G.; Liang, W.; Wu, H. A Numerical Study on the Crack Development Behavior of Rock-Like Material Containing Two Intersecting Flaws. Mathematics 2019, 7, 1223. [Google Scholar] [CrossRef]

- Cao, R.; Cao, P.; Lin, H.; Fan, X. Experimental and numerical study of the failure process and energy mechanisms of rock-like materials containing cross un-persistent joints under uniaxial compression. PLoS ONE 2017, 12, e0188646. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhang, S.; Cheng, C. Numerical Study on Effect of Joint Strength Mobilization on Behavior of Rock Masses with Large Nonpersistent Joints under Uniaxial Compression. Int. J. Géoméch. 2018, 18, 04018140. [Google Scholar] [CrossRef]

- Chong, Z.; Li, X.; Yao, Q.; Zhang, J.; Chen, T. Anchorage behaviour of reinforced specimens containing a single fissure under uniaxial loading: A particle mechanics approach. Arab. J. Geosci. 2016, 9, 592. [Google Scholar] [CrossRef]

- Ghazvinian, A.; Sarfarazi, V.; Schubert, W.; Blumel, M. A Study of the Failure Mechanism of Planar Non-Persistent Open Joints Using PFC2D. Rock Mech. Rock Eng. 2012, 45, 677–693. [Google Scholar] [CrossRef]

- Jiang, M.; Liu, J.; Crosta, G.B.; Li, T. DEM analysis of the effect of joint geometry on the shear behavior of rocks. Comptes Rendus Mec. 2017, 345, 779–796. [Google Scholar] [CrossRef]

- Manouchehrian, A.; Marji, M.F. Numerical analysis of confinement effect on crack propagation mechanism from a flaw in a pre-cracked rock under compression. Acta Mech. Sin. 2012, 28, 1389–1397. [Google Scholar] [CrossRef]

- Manouchehrian, A.; Sharifzadeh, M.; Marji, M.; Gholamnejad, J. A bonded particle model for analysis of the flaw orientation effect on crack propagation mechanism in brittle materials under compression. Arch. Civ. Mech. Eng. 2014, 14, 40–52. [Google Scholar] [CrossRef]

- Huang, Y.-H.; Yang, S.-Q.; Zhao, J. Three-Dimensional Numerical Simulation on Triaxial Failure Mechanical Behavior of Rock-Like Specimen Containing Two Unparallel Fissures. Rock Mech. Rock Eng. 2016, 49, 4711–4729. [Google Scholar] [CrossRef]

- Huang, Y.-H.; Yang, S.-Q.; Tian, W.-L. Crack coalescence behavior of sandstone specimen containing two preexisting flaws under different confining pressures. Theor. Appl. Fract. Mech. 2019, 99, 118–130. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, H.; Zhu, W.; Li, S.; Liu, J. Numerical investigations on slope stability using an elasto-brittle model considering fissure water pressure. Arab. J. Geosci. 2015, 8, 10277–10288. [Google Scholar] [CrossRef]

- Tang, C.; Lin, P.; Wong, R.; Chau, K. Analysis of crack coalescence in rock-like materials containing three flaws—Part II: Numerical approach. Int. J. Rock Mech. Min. Sci. 2001, 38, 925–939. [Google Scholar] [CrossRef]

- Vasarhelyi, B.; Bobet, A. Modeling of Crack Initiation, Propagation and Coalescence in Uniaxial Compression. Rock Mech. Rock Eng. 2000, 33, 119–139. [Google Scholar] [CrossRef]

- Liu, H.; Xie, T. Numerical simulation of the mechanical behavior of rock mass with different scale flaws and its application. Arab. J. Geosci. 2020, 13, 264. [Google Scholar] [CrossRef]

- Fu, J.W.; Zhu, W.S.; Wang, L.G.; Wang, X.G. Numerical Simulation of the Crack Propagation Processes in Rocks with Double Joints. Appl. Mech. Mater. 2011, 90–93, 559–564. [Google Scholar] [CrossRef]

- Fu, J.-W.; Zhang, X.-Z.; Zhu, W.-S.; Chen, K.; Guan, J.-F. Simulating progressive failure in brittle jointed rock masses using a modified elastic-brittle model and the application. Eng. Fract. Mech. 2017, 178, 212–230. [Google Scholar] [CrossRef]

- Song, Y.-Q.; Li, X.-S.; Zhou, T.; Li, M. Experimental and finite element analysis of marble with double preexisting flaws under loading-unloading conditions. Arab. J. Geosci. 2020, 13, 392. [Google Scholar] [CrossRef]

- Haeri, H.; Sarfarazi, V.; Ebneabbasi, P.; Nazari maram, A.; Shahbazian, A.; Fatehi Marji, M.; Mohamadi, A.R. XFEM and experimental simulation of failure mechanism of nonpersistent joints in mortar under compression. Constr Build Mater. 2020, 236, 117500. [Google Scholar] [CrossRef]

- Silva, B.G.D.; Einstein, H.H. Finite element study of fracture initiation in flaws subject to internal fluid pressure and vertical stress. Int. J. Solids Struct. 2014, 51, 4122–4136. [Google Scholar] [CrossRef]

- Pakzad, R.; Wang, S.; Sloan, S. Numerical Study of the Failure Response and Fracture Propagation for Rock Specimens with Preexisting Flaws under Compression. Int. J. Géoméch. 2018, 18, 04018070. [Google Scholar] [CrossRef]

- Pakzad, R.; Wang, S.; Sloan, S.W. Three-dimensional finite element simulation of fracture propagation in rock specimens with preexisting fissure(s) under compression and their strength analysis. Int. J. Numer. Anal. Methods Géoméch. 2020, 44, 1472–1494. [Google Scholar] [CrossRef]

- Dai, B.; He, G.C.; Zhang, Z.J. A numerical research on crack process of gypsum containing single flaw with different angle and length in uniaxial loading. Shock Vib. 2018, 2018, 2968205. [Google Scholar]

- Yang, X.; Jing, H.; Chen, K. Numerical simulations of failure behavior around a circular opening in a non-persistently jointed rock mass under biaxial compression. Int. J. Min. Sci. Technol. 2016, 26, 729–738. [Google Scholar] [CrossRef]

- Park, C.; Bobet, A. Crack coalescence in specimens with open and closed flaws: A comparison. Int. J. Rock Mech. Min. Sci. 2009, 46, 819–829. [Google Scholar] [CrossRef]

- Prudencio, M.; van Sint Jan, M. Strength and failure modes of rock mass models with non-persistent joints. Int. J. Rock Mech. Min. Sci. 2007, 44, 890–902. [Google Scholar] [CrossRef]

- Lin, P.; Wong, R.; Fu, Y.F.; Tang, C.A.; Zhou, W. Coalescence Mechanism of Multiple Flaws in Brittle Medium under Compressive Loads. Key Eng. Mater. 2003, 243–244, 273–278. [Google Scholar] [CrossRef]

- Fan, X.; Kulatilake, P.; Chen, X. Mechanical behavior of rock-like jointed blocks with multi-non-persistent joints under uniaxial loading: A particle mechanics approach. Eng. Geol. 2015, 190, 17–32. [Google Scholar] [CrossRef]

- Chen, X.; Liao, Z.; Peng, X. Deformability characteristics of jointed rock masses under uniaxial compression. Int. J. Min. Sci. Technol. 2012, 22, 213–221. [Google Scholar] [CrossRef]

- Bahaaddini, M.; Hagan, P.; Mitra, R.; Hebblewhite, B.K. Numerical Study of the Mechanical Behavior of Nonpersistent Jointed Rock Masses. Int. J. Géoméch. 2016, 16, 04015035. [Google Scholar] [CrossRef]

- Yang, S.Q.; Tian, W.L.; Huang, Y.H.; Ranjith, P.G.; Yang, J. An experimental and numerical study on cracking behavior of brittle sandstone containing two non-coplanar fissures under uniaxial compression. Rock Mech. Rock Eng. 2016, 49, 1497–1515. [Google Scholar] [CrossRef]

- Kulatilake, P.H.S.W.; Malama, B.; Wang, J.L. Physical and particle flflow modeling of jointed rock block behavior under uniaxial loading. Int. J. Rock Mech. Min. Sci. 2001, 38, 641–657. [Google Scholar] [CrossRef]

- Yang, X.X.; Jing, H.W.; Tang, C.A.; Yang, S.Q. Effect of parallel joint interaction on mechanical behavior of jointed rock mass models. Int. J. Rock Mech. Min. 2017, 92, 40–53. [Google Scholar] [CrossRef]

- Yang, X.X.; Jing, H.W.; Chen, K.F.; Yang, S.Q. Failure behavior around a circular opening in a rock mass with nonpersistent joints: A parallel-bond stress corrosion approach. J. Cent. South Univ. 2017, 24, 2406–2420. [Google Scholar] [CrossRef]

- Tang, C.; Kou, S. Crack propagation and coalescence in brittle materials under compression. Eng. Fract. Mech. 1998, 61, 311–324. [Google Scholar] [CrossRef]

- Wang, M.; Lu, Z.; Wan, W.; Zhao, Y. A calibration framework for the microparameters of the DEM model using the improved PSO algorithm. Adv. Powder Technol. 2021, 32, 358–369. [Google Scholar] [CrossRef]

- Yang, S.Q.; Xu, T.; He, L.; Jing, H.W.; Wen, S.; Yu, Q.L. Numerical study on failure behavior of brittle rock specimen containing preexisting combined flaws under different confining pressure. Arch. Civ. Mech. Eng. 2015, 15, 1085–1097. [Google Scholar] [CrossRef]

- Li, Y.-P.; Chen, L.-Z.; Wang, Y.-H. Experimental research on pre-cracked marble under compression. Int. J. Solids Struct. 2005, 42, 2505–2516. [Google Scholar] [CrossRef]

- Wu, T.; Gao, Y.; Zhou, Y.; Li, J. Experimental and numerical study on the interaction between holes and fissures in rock-like materials under uniaxial compression. Theor. Appl. Fract. Mech. 2020, 106, 102488. [Google Scholar] [CrossRef]

- Liu, X.-R.; Yang, S.-Q.; Huang, Y.-H.; Cheng, J.-L. Experimental study on the strength and fracture mechanism of sandstone containing elliptical holes and fissures under uniaxial compression. Eng. Fract. Mech. 2018, 205, 205–217. [Google Scholar] [CrossRef]

- Yang, X.X.; Kulatilake, P.H.S.W.; Jing, H.W.; Yang, S.Q. Numerical simulation of a jointed rock block mechanical behavior adjacent to an underground excavation and comparison with physical model test results. Tunn. Undergr. Space Technol. 2015, 50, 129–142. [Google Scholar] [CrossRef]

- Yang, X.X.; Kulatilake, P.H.S.W.; Chen, X.; Jing, H.W.; Yang, S.Q. Particle flow modeling of rock blocks with nonpersistent open joints under uniaxial compression. Int. J. Geomech. 2016, 16, 04016020. [Google Scholar] [CrossRef]

- Yang, S.-Q.; Yin, P.-F.; Zhang, Y.-C.; Chen, M.; Zhou, X.-P.; Jing, H.-W.; Zhang, Q.-Y. Failure behavior and crack evolution mechanism of a non-persistent jointed rock mass containing a circular hole. Int. J. Rock Mech. Min. Sci. 2019, 114, 101–121. [Google Scholar] [CrossRef]

- Yin, Q.; Jing, H.; Su, H. Investigation on mechanical behavior and crack coalescence of sandstone specimens containing fissure-hole combined flaws under uniaxial compression. Geosci. J. 2018, 22, 825–842. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).