Alignment Control Reconfigurability Analysis and Autonomous Control Methods of Air Spring Vibration Isolation System for High Power Density Main Engine (HPDME-ASVIS)

Abstract

:1. Introduction

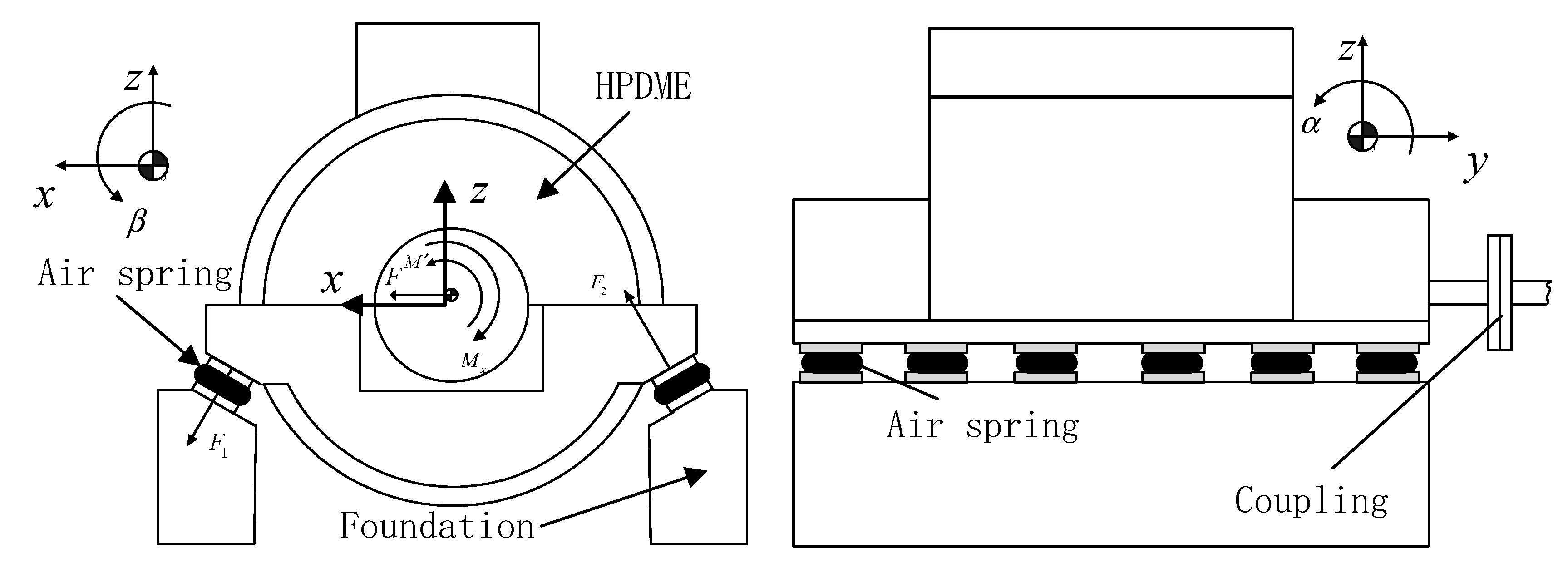

2. Mechanical Analysis and Research Problem

2.1. Preliminary Knowledge

2.2. Mechanical Analysis

2.2.1. Mechanical Influence Analysis of Output Torque

2.2.2. Vertical Deformation Analysis of Air Springs

2.2.3. Mechanical Influence Analysis of Additional Force

3. Alignment Control Response Model

4. Reconfigurability Judgment Analysis and Autonomous Control Method

4.1. Alignment Controllability Judgement Analysis

4.2. Alignment Controllability Judgment Model

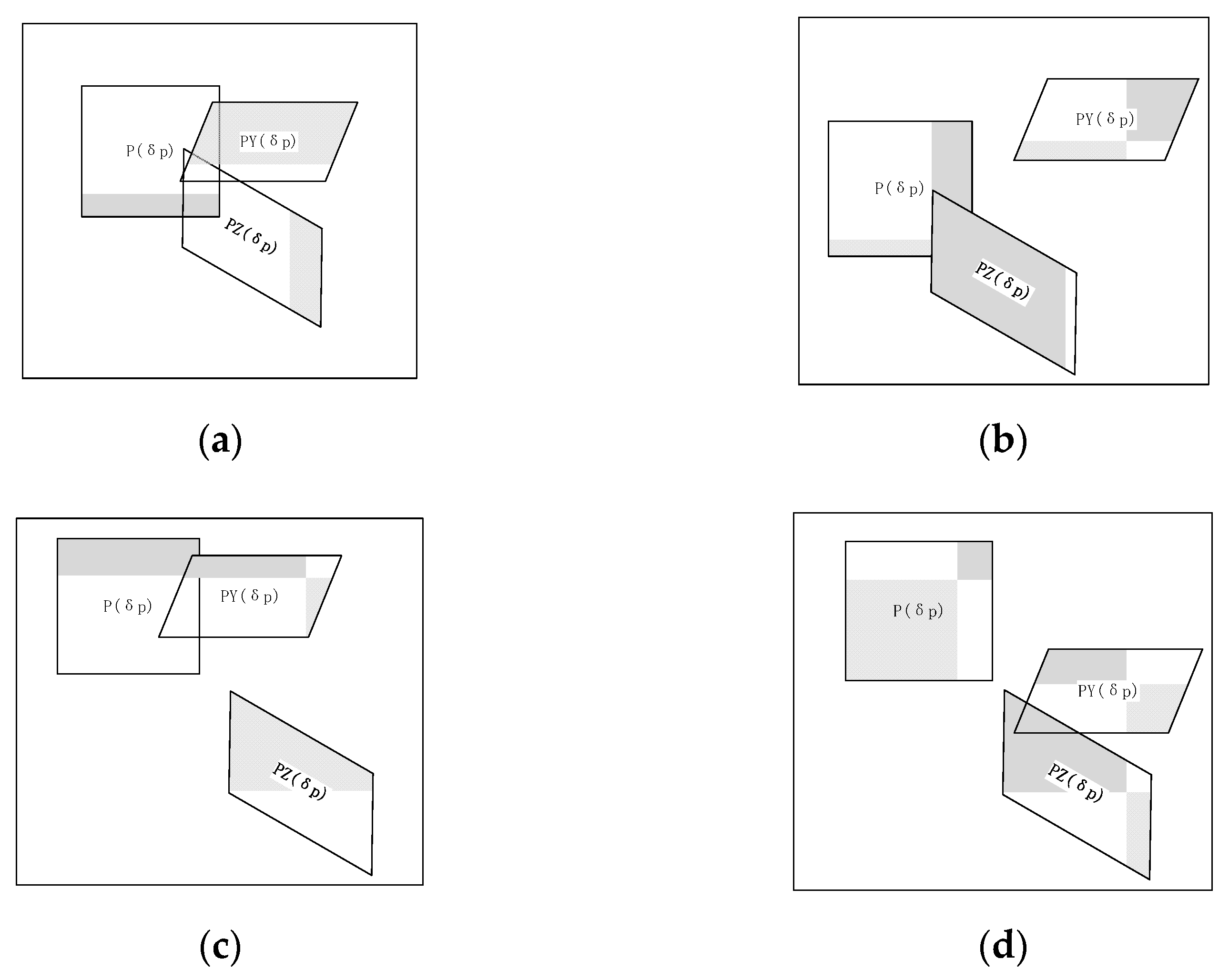

4.2.1. Alignment Controllability Judgment Model under Hard Constraints

4.2.2. Alignment Controllability Judgment Model under Soft Constraints

4.3. Alignment Reconfigurability Analysis

- When the alignment control system under hard constraints is judged as controllable, the state is classified as a fault-free state (F state). It can achieve full alignment control objectives.

- When the alignment system under hard constraints is judged as uncontrollable but is judged as controllable under soft constraints, the state is classified as I alignment control fault state (I state). At this time, the alignment of control objectives can be achieved by changing the control algorithm, which is also called software adjustment, but the alignment control precision will decrease.

- When the alignment system under hard and soft constraints is judged as uncontrollable, the state is classified as an II alignment control fault state (II state). At this time, the minimum safety goal cannot be achieved by changing the control algorithm. The emergency protection device should be enabled. The emergency protection device is rigidly connected with the HPDME-ASVIS through the hydraulic cylinder, whose mechanism has been described in the literature [2]. The system is supported in a rigid rather than the air spring vibration isolation system. The spatial configuration of HPDME-ASVIS is changed, which is also called hardware adjustment. The safety alignment goal is achieved by sacrificing the vibration isolation of the HPDME-ASVIS.

- When the alignment system under hard and under soft constraints are judged as uncontrollable and the emergency protection device failure occurs, this state is classified as a III alignment control fault state (III state). At this time, the safety and stability of the device cannot be guaranteed. HPDME-ASVIS must be shut down to assure safety immediately.

4.4. Alignment Autonomous Control Method

5. Experiment

5.1. Experiment Settings

5.2. Experiment Results

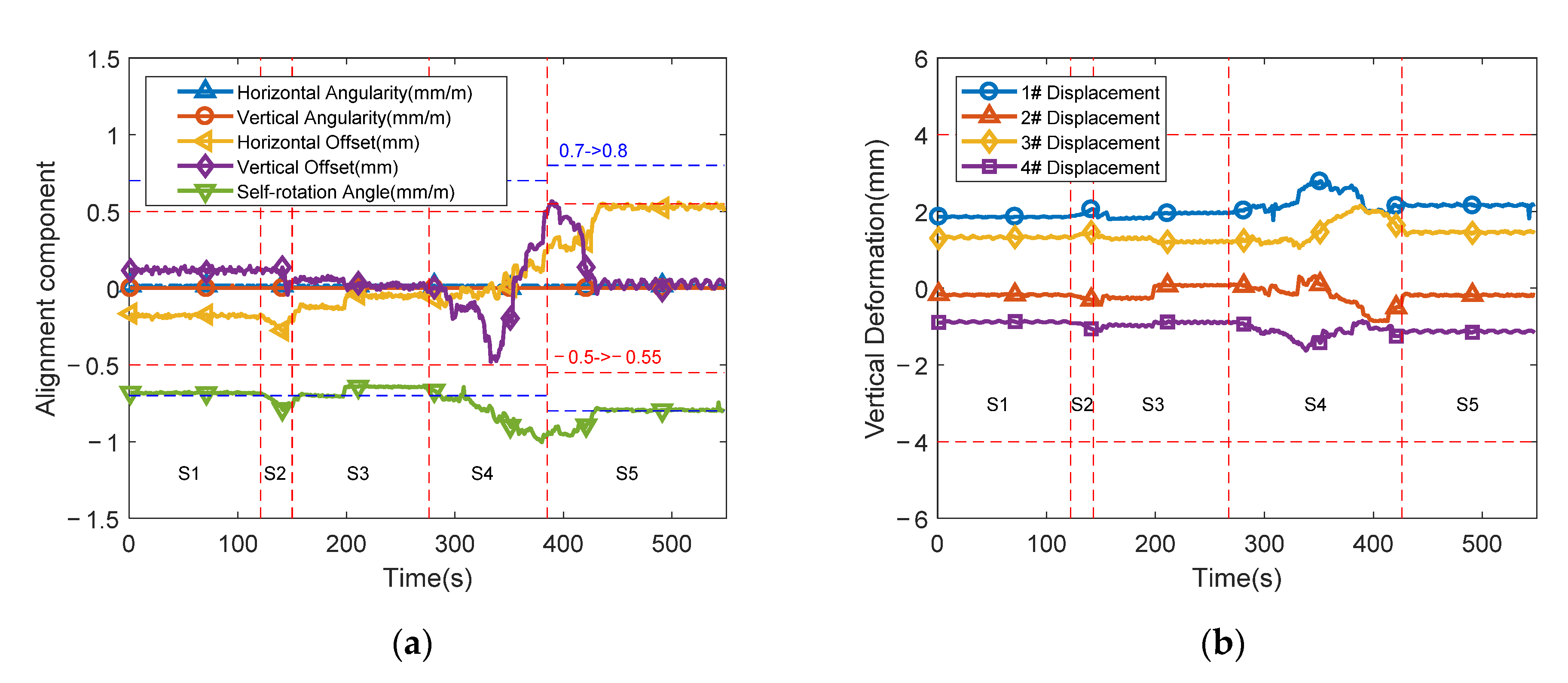

5.2.1. Mechanical Analysis Verification Experiment

5.2.2. Validation Experiment of Alignment Autonomous Control Method

6. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| additional force generated by each air spring vibration isolator | the mass matrix of HPDME-ASVIS | ||

| the external force vector exerted on HPDME-ASVIS | output torque | ||

| the initial air pressure distribution of the air springs | the initial alignment state | ||

| the air pressure variation of each air spring | the air pressure variation of i-th air spring | ||

| the position transformation matrix of the coupling center point in the global coordinate system | |||

| the position transformation matrix of the i# air spring in the global coordinate system | |||

| , , | the air spring pressure variation, the alignment control vector, and the vertical deformation vector of the air spring in steady state condition | ||

| ,,,, | the adjustment amount of the boundary of each soft constraint | ||

| ,,,, | the maximum value of each corresponding acceptable adjustment amount | ||

References

- Shi, L.; He, L.; Bu, W.J.; Xu, W. Response characteristic analysis and alignment control algorithm for a main engine air suspension system. J. Vib. Shock 2012, 31, 136–139. [Google Scholar]

- He, L.; Xu, W.; Bu, W.J.; Shi, L. Dynamic analysis and design of air spring mounting system for marine propulsion system. J. Sound Vib. 2014, 333, 4912–4929. [Google Scholar] [CrossRef]

- Hujare, D.P.; Karnik, M.G. Vibration responses of parallel misalignment in Al shaft rotor bearing system with rigid coupling. Mater. Today Proc. 2018, 5, 23863–23871. [Google Scholar] [CrossRef]

- Patel, T.H.; Darpe, A.K. Vibration response of misaligned rotors. J. Sound Vib. 2009, 325, 609–628. [Google Scholar] [CrossRef]

- Bu, W.J.; He, L.; Shi, L.; Zhao, Y.L. Output shaft alignment attitude real time monitoring for a marine main engine air mounting system. J. Vib. Shock 2009, 28, 210–217. [Google Scholar]

- Xu, W.; He, L.; Shi, L. Alignment disturbance control of an air-suspended main engine. J. Vib. Shock 2011, 30, 6–10. [Google Scholar]

- Bu, W.J.; He, L. Alignment control straegy for an air spring mounting system of marine propulsion engine. J. Vib. Shock 2012, 31, 112–115. [Google Scholar]

- Shi, L.; He, L.; Xu, W.; Bu, W.J. Alignment controllability of ship main engine air suspension system. J. Nav. Univ. Eng. 2011, 23, 27–30, 35. [Google Scholar]

- Bu, W.J.; He, L.; Shi, L. Alignment controllability of air spring vibration isolation system of a ship propulsion plant. J. Vib. Shock 2015, 34, 56–60. [Google Scholar]

- Zhao, X.Q.; Shuai, C.G.; Xu, W. On design of vibration-isolating system for high-power-density propulsion motor. J. Nav. Univ. Eng. 2019, 31, 31–35. [Google Scholar]

- Zhao, J.M.; Bu, W.J.; Shi, L.; Hu, Z. Stability Design of Air Vibration Isolation Device for a High Power Density Main Engine. Symmetry 2021, 13, 1244. [Google Scholar] [CrossRef]

- Gao, J.J. Ji Qi Gu Zhang Zhen Zhi Yu Zi Yu Hua; Higher Education Press Beijing: Beijing, China, 2012. (In Chinese) [Google Scholar]

- Li, Y.F.; Mi, J.; Huang, H.Z.; Xiao, N.C.; Zhu, S.P. System reliability modeling and assessment for solar array drive assembly based on bayesian networks. China Sci. 2012, 15, 986–991. [Google Scholar]

- Liu, C.; Wang, D. Reconfigurability Analysis Method for Spacecraft Autonomous Control. Math. Probl. Eng. 2014, 2014, 105–110. [Google Scholar]

- Wang, D.Y.; Tu, Y.Y.; Liu, C.R.; He, Y.Z.; Li, W.B. Connotation and Research of Reconfigurability for Spacecraft Control Systems: A Review. Acta Autom. Sin. 2017, 43, 1687–1702. [Google Scholar]

- Contreras, B.; Checa, N.D.; Aguilar, M.; Michcol, B.C.; Morales Lopez, F.E. Using a Realization Technique for System Reconfigurability Evaluation: Simulation Application on a DC Motor. In Proceedings of the 2011 IEEE Electronics, Robotics and Automotive Mechanics Conference, Cuernavaca, Mexico, 15–18 November 2011. [Google Scholar]

- Yang, Z.Y. Reconfigurability analysis for a class of linear hybrid systems. IFAC Proc. Vol. 2006, 39, 974–979. [Google Scholar] [CrossRef]

- Huang, C.K.; Yang, H.; Ren, W.J.; Jiang, B. Reconfigurability Analysis for a Class of Meta Aircraft Based on Interconnected System Method. Inf. Control 2018, 47, 290–296. [Google Scholar]

- Shaker, H.R.; Shaker, F. Control configuration selection for linear stochastic systems. J. Process Control 2014, 24, 146–151. [Google Scholar] [CrossRef]

- Du, G.X.; Quan, Q.; Yang, B.X.; Cai, K.Y. Controllability analysis for multirotor helicopter rotor degradation and failure. J. Guid. Control Dyn. 2015, 38, 978–985. [Google Scholar] [CrossRef]

- Vey, D.; Lunze, J. Structural reconfigurability analysis of multirotor UAVs after actuator failures. In Proceedings of the 2015 54th IEEE Conference on Decision and Control (CDC), Osaka, Japan, 15–18 December 2015. [Google Scholar]

- Ren, W.; Yang, H.; Jiang, B.; Staroswiecki, M. Fault recoverability analysis of switched nonlinear systems. Int. J. Syst. Sci. 2017, 48, 471–484. [Google Scholar] [CrossRef]

- Li, Y.F.; Zhu, S.P.; Li, J.; Peng, W.W.; Huang, H.Z. Uncertainty Analysis in Fatigue Life Prediction of Gas Turbine Blades Using Bayesian Inference. Int. J. Turbo Jet Engines 2015, 32, 319–324. [Google Scholar] [CrossRef]

- Brito, M.; Griffiths, G. A Bayesian approach for predicting risk of autonomous underwater vehicle loss during their missions. Reliab. Eng. Syst. Saf. 2016, 146, 55–67. [Google Scholar] [CrossRef]

- Mi, J.H.; Li, Y.F.; Yang, Y.J.; Peng, W.W.; Huang, H.Z. Reliability assessment of complex electromechanical systems under epistemic uncertainty. Reliab. Eng. Syst. Saf. 2016, 152, 1–15. [Google Scholar] [CrossRef]

- Li, X.Y.; Huang, H.Z.; Li, Y.F.; Xiong, X. A Markov Regenerative Process model for phased mission systems under internal degradation and external shocks. Reliab. Eng. Syst. Saf. 2021, 215, 107796. [Google Scholar] [CrossRef]

- Li, X.Y.; Huang, H.Z.; Li, Y.F. Reliability analysis of phased mission system with non-exponential and partially repairable components. Reliab. Eng. Syst. Saf. 2018, 175, 119–127. [Google Scholar] [CrossRef]

- Li, X.Y.; Huang, H.Z.; Li, Y.F.; Zio, E. Reliability assessment of multi-state phased mission system with non-repairable multi-state components. Appl. Math. Model. 2018, 61, 181–199. [Google Scholar] [CrossRef]

- Fu, G.Z.; Huang, H.Z.; Li, Y.F.; Zhou, J. An adaptive hybrid evolutionary algorithm and its application in aeroengine maintenance scheduling problem. Soft Comput. 2021, 25, 1–12. [Google Scholar] [CrossRef]

- Xi, Y.; Li, K. Feasibility Analysis of Constrained Multi-Objective MultiDegree-of-Freedom Optimization Control in Industrial Processes. Control Theory Appl. 1995, 12, 590–596. [Google Scholar]

- Luo, X.L.; Zhou, X.L.; Wang, S.B. Analysis of constrained optimal control with related constraints of input variables. Acta Autom. Sin. 2013, 39, 679–689. [Google Scholar] [CrossRef]

- Xi, Y.G.; Gu, H.Y. Feasibility analysis and soft constraints adjustment of CMMO. Acta Autom. Sin. 1998, 24, 727–732. [Google Scholar]

- Zhang, X.L.; Wang, S.B.; Luo, X.L. Feasibility analysis and constraints adjustment of constrained optimal control in chemical processes. CIESC J. 2011, 62, 2546–2554. [Google Scholar]

- Jiang, D.; Liu, X.J.; Kong, X.B. Soft Constrained MPC on Water Level Control in Steam Generator of a Nuclear Power Plant. Acta Autom. Sin. 2019, 45, 1111–1121. [Google Scholar] [CrossRef]

- Lu, S.; Lee, J.H.; You, F. Soft-constrained model predictive control based on data-driven distributionally robust optimization. AIChE J. 2020, 66, e16546. [Google Scholar] [CrossRef]

- Wabersich, K.P.; Krishnadas, R.; Zeilinger, M.N. A Soft Constrained MPC Formulation Enabling Learning From Trajectories With Constraint Violations. IEEE Control Syst. Lett. 2022, 6, 980–985. [Google Scholar] [CrossRef]

- Bu, W.J. Research on Alignment Detection and Control of Air Spring Vibration Isolation Technology for Ship Propulsion Main Engine; Naval University of Engineering: Wuhan, China, 2010. (In Chinese) [Google Scholar]

- Zhu, S.J.; Lou, J.J.; He, Q.W.; Wen, X.T. Vibration Theory and Vibration Isolation; National Defense Industry Press: Beijing, China, 2006. (In Chinese) [Google Scholar]

- Xu, W. Theoretical and Experimental Research on Air Spring Vibration Isolation Technology for Recommended Main Engines on Ships; Naval University of Engineering: Wuhan, China, 2010. (In Chinese) [Google Scholar]

| Condition | Constraints | Reconfiguration Method | Reconfiguration Goal | State |

|---|---|---|---|---|

| controllable under hard constraints | hard constraints | - | full goal | F |

| uncontrollable under hard constraints controllable under soft constraints | soft constraints | software adjustment | full goal | I |

| uncontrollable under hard constraints uncontrollable under soft constraints | - | hardware adjustment | safety goal | II |

| other cases | - | - | unreconfigurable | III |

| Device | Abbreviation | Number | Function |

|---|---|---|---|

| Industrial Personal Computer | IPC | 1 | collect sensor data, control the alignment state of HPDME-ASVIS, control the emergency protection device, carry out fault diagnosis and maintenance suggestions for HPDME-ASVIS, display data information, etc. |

| Displacement Sensor | DS | 7 | monitor the displacement |

| Air Spring | - | 12 | support the weight of the HPDME-ASVIS and isolate vibration |

| Emergency Protection Device | EPD | 6 | fix HPDME-ASVIS to limit excessive displacement in emergencies |

| Gas Source Unit | GSU | 1 | control gas source. |

| Air Control Unit | ACU | 6 | control the inflation/deflation of air spring, adjust air pressure |

| Hydraulic Control Unit | HCU | 1 | control emergency protector |

| Hydraulic Line | HL | 1 | connect hydraulic source and protection |

| Air Line | - | 1 | connect the gas source and air springs |

| Gas Source | Gas | 1 | provide a clean and stable air source for the air spring |

| Hydraulic Source | Hydraulic | 1 | provide stable hydraulic oil for the emergency protection device |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bu, W.-J.; Cheng, J.-W.; Shi, L. Alignment Control Reconfigurability Analysis and Autonomous Control Methods of Air Spring Vibration Isolation System for High Power Density Main Engine (HPDME-ASVIS). Appl. Sci. 2022, 12, 8211. https://doi.org/10.3390/app12168211

Bu W-J, Cheng J-W, Shi L. Alignment Control Reconfigurability Analysis and Autonomous Control Methods of Air Spring Vibration Isolation System for High Power Density Main Engine (HPDME-ASVIS). Applied Sciences. 2022; 12(16):8211. https://doi.org/10.3390/app12168211

Chicago/Turabian StyleBu, Wen-Jun, Jian-Wei Cheng, and Liang Shi. 2022. "Alignment Control Reconfigurability Analysis and Autonomous Control Methods of Air Spring Vibration Isolation System for High Power Density Main Engine (HPDME-ASVIS)" Applied Sciences 12, no. 16: 8211. https://doi.org/10.3390/app12168211

APA StyleBu, W.-J., Cheng, J.-W., & Shi, L. (2022). Alignment Control Reconfigurability Analysis and Autonomous Control Methods of Air Spring Vibration Isolation System for High Power Density Main Engine (HPDME-ASVIS). Applied Sciences, 12(16), 8211. https://doi.org/10.3390/app12168211