Abstract

A cryogen-free portable 3 T high-temperature superconducting magnet for an electromagnetic property measurement system has been developed to serve as a user facility at the Korea Basic Science Institute. The metallic insulation method was adopted to reduce the charging delay without sacrificing the self-protecting feature. A genetic-algorithm-aided optimized design was carried out to minimize the superconducting tape consumption while satisfying several design constraints. After the design, the compact high-temperature superconducting magnet composed of eight double-pancake coil modules was wound with high-temperature superconducting tape and stainless steel tape, and integrated with a two-stage cryo-cooler. The 3 T magnet was successfully cooled to approximately 20 K with a cryo-cooler and reached the target field of 3 T without any problems. Long-term measurements and a range of other tests were also implemented to verity the performance of the magnet. Test results demonstrated the feasibility of a cryogen-free portable high-temperature superconducting magnet system for electromagnetic property measurement experiments.

1. Introduction

As superconducting wires allow the flow of very high current density levels compared to copper wires, superconducting magnets generate a high magnetic field with compact and light windings. There are many industrial and scientific devices employing superconducting magnets to generate a high magnetic field, and several devices have been commercialized given their high performance and quality levels [1,2,3,4,5]. Superconducting magnets are classified as low-temperature superconducting (LTS) magnets wound with lower temperature superconducting wires, such as NbTi and Nb3Sn [6,7], and high-temperature superconducting (HTS) magnets fabricated with high-temperature superconducting tapes such as Rare-earth barium copper oxide (REBCO) and Bismuth strontium calcium copper oxide (BSCCO) [8,9]. LTS wires, which were commercialized much earlier than HTS tapes, are much less costly than HTS tapes but require liquid helium or massive and expensive cryo-coolers to keep the magnet temperature under 4.2 K due to the low critical temperature required (< 10 K). Recently commercialized HTS tapes, on the other hand, have a high critical temperature (> 90 K) and do not need liquid helium to cool the magnets [8]. This means that it is possible to operate a superconducting magnet with an inexpensive and compact liquid-helium-free system. Therefore, the handling and operation of the HTS magnet system would be very safe and comfortable for both users and vendors [10]. For these reasons, research on HTS magnets has been active recently. Many research institutes adopt or consider the use of HTS tapes to develop nuclear magnetic resonance (NMR) systems that exceed 1 GHz [11,12,13,14,15]. Magnetic resonance imaging (MRI) researchers have also been developing liquid-helium-free HTS MRI systems to manufacture robust, safe and compact MRI system [16,17,18,19,20]. HTS magnets have also been applied to dipole magnets in relation to research on accelerators [21,22,23,24] and rotating machines for power generation and ship propulsion [25,26,27,28]. In addition, many studies of HTS magnet applications are underway in many other fields.

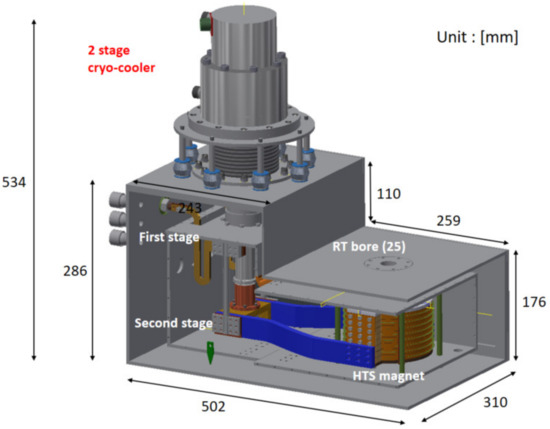

The Korea Basic Science Institute (KBSI) also commenced a research project to develop a conduction-cooled HTS magnet for an electromagnetic property measurement system (EMPS) in 2020. The goal of the project is to develop a liquid-helium-free 3 T/25 mm REBCO magnet for various physical property measurements and optical experiments. The operating temperature of the magnet will exceed 20 K, and a cost-effective small cryo-cooler can sufficiently cool the magnet. Because the total system volume including the HTS magnet, cryostat, and cryo-cooler is smaller than those of other LTS magnet systems or a conventional electromagnet, users can transport our system easily and safely. The low magnetic field error is another merit of our system. In general, the center magnetic field at room-temperature (RT) bore is approximately calculated by the pre-acquired magnet constant (center field per the operating current). The center field, however, can vary slightly under identical operating conditions due to many reasons, such as the characteristics of the magnetic components of the cryostat, the screening current used, and others [29,30,31,32,33]. To compensate for these types of field errors, we installed a cryogenic Hall sensor at the top of the REBCO magnet. The ratio of the center field and the magnetic field measured by the Hall sensor is pre-calculated, and users can determine the center field value easily with the Hall sensor. A drawing of the 3 T HTS EMPS system is shown in Figure 1. The system mainly consists of a cryostat, a REBCO magnet, a Gifford-McMahon (GM) 20 K cryo-cooler [34], thermal shields, HTS current leads, and thermal links for conduction-cooling, among other components.

Figure 1.

Drawing of the 3 T HTS electromagnetic property measurement system (EMPS).

The 3 T REBCO magnet was designed using a genetic algorithm, often used in relation to the optimization theories, to minimize the consumption of the HTS tape [35,36]. To protect the magnet from the quench phenomenon without a charging delay, the well-known approach, known as ‘metallic insulation’ (MI), is applied to the magnet [37,38,39]. The 3 T REBCO magnet was fabricated based on the design result and integrated with a 20 K cryo-cooler and a cryostat. After the construction step, the 3 T magnet was cooled to the operating temperature of 20 K with a two-stage cryo-cooler. The magnet successfully charged to the target field and long-term charging tests were repeated to verify the performance capabilities of the magnet. After a few physical property measurement tests, the 3 T magnet system will be operated as a new EMPS user facility.

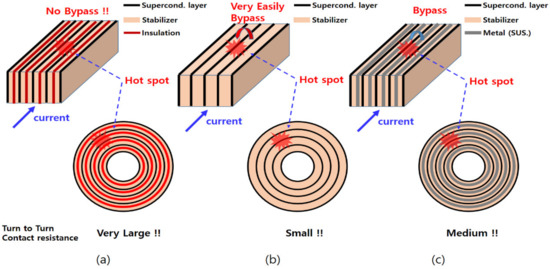

2. HTS Magnet Design with Genetic Algorithm

SuNAM REBCO tapes (4.1 mm width and 0.14 mm thickness) were used to fabricate the 3 T HTS magnet. The superconducting layer of the tape is located between the 20 um copper stabilizer and the stainless steel substrate layer as shown in reference [40]. The minimum critical current of the tape is about 200 A @ 77 K self-field. As mentioned in the introduction, MI winding method was applied to the magnet for the quench protection with charging delay reduction [37,38,39]. Figure 2 shows the quench-protection mechanism of the MI technique. There are three types of winding methods for a REBCO magnet: (1) insulation winding, as shown in Figure 2a; (2) no-insulation winding, as shown in Figure 2b [41,42]; and (3) metallic insulation winding, as shown in Figure 2c [37,38,39]. For the insulation type of winding, an insulation layer with a material such as Kapton is co-wound with the HTS tape to electrically insulate each HTS tape. Accordingly, the turn-to-turn contact resistance of the magnet is very high and the magnet current does not bypass when a fault occurs. As the normal zone propagation velocity of HTS tape is very slow, the generated heat is accumulated at that hot spot and the magnet is easily damaged. On the other hand, the no-insulation type of winding has very low contact resistance, and the magnet current is very easily bypassed through the turn-to-turn contact when a fault occurs. This technique protects the HTS magnet, but it leads to a charging delay when charging the magnet [38,43]. The MI is a compromise technique between protection and charging delay of a HTS magnet. Given that the turn-to-turn contact resistance of the MI is not exceedingly high, the charging delay is reduced without sacrificing the self-protection capability. Many studies demonstrate protecting performance by the MI technique [37,38,39].

Figure 2.

Quench-protection mechanism of the (a) insulation winding, (b) no-insulation winding, and (c) metallic-insulation winding.

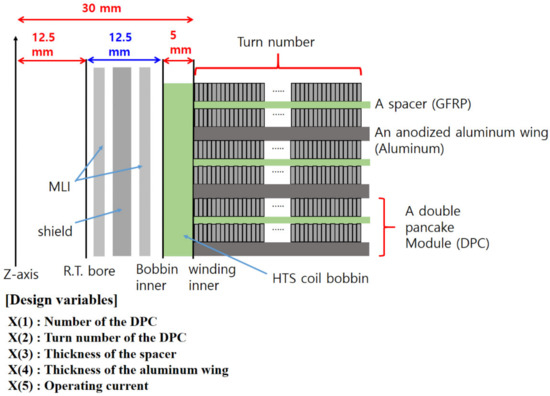

As the target RT bore is approximately 1 inch (25 mm), the inner radius of the RT bore cylinder is 12.5 mm. Considering the thickness of the RT bore thermal shield and multi-layer insulation (MLI) between the RT bore and HTS magnet bobbin for conduction cooling, the required distance between the RT bore cylinder and bobbin is about 12.5 mm. Therefore, the required minimum winding radius is 30 mm. The objective function of the design is the HTS tape total length, and there are six constraints to consider during the optimization process. The design variables and the design constraints are shown in Figure 3 and Table 1, respectively. The variable 1 is the number of the double pancake coil (DPC) related to the stack number of the module coil and the variable 2 is the radial turn number of the each DPC. The variable 3 and 4 are the thickness of a spacer located inside a DPC, which insulates two adjacent pancake coils electrically and the thickness of a wing between two adjacent DPCs, respectively. The last variable is magnet operating current. As the magnetic field and uniformity are influenced by the radial-direction turn (variable 2) and axial-direction turn (variable 1), a magnet designer optimally selects these turn numbers to satisfy the field performance. The variable 3 and 4 are especially related with the field uniformity at the magnet center. By changing these terms, we can get the desired field uniformity of the magnet. The last variable is related with only field strength and should be carefully selected considering critical current margin and generated joule heat at the current leads [6,8].

Figure 3.

Structure and design variables of the 3 T REBCO magnet.

Table 1.

Design Constraints of the 3 T REBCO EMPS Magnet.

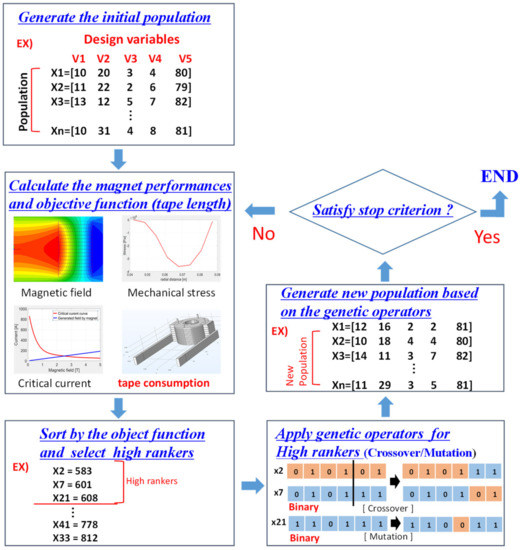

The design algorithm based on the Genetic algorithm (GA) finds the optimized design variables which minimize the tape consumption while satisfying the six constraints [35,36]. Figure 4 represents the main algorithm of the design. An optimization variables set refers to an ‘individual’, and a ‘population’ is composed of several tens of individuals. Initially, the initial population is generated randomly and tape consumptions (objective function) and magnetic performances, such as center field, field uniformity, mechanical stress, and critical current are calculated by the design program. After that, the design program sorts the design variables set according to the tape consumption and selects those that are highly ranked. The tournament selection method is used in applications. The sets that are highly ranked with a small tape consumption evolve to the next generation according to the GA operators used here, in this case ‘cross-over’ and ‘mutation’. This process is repeated until the termination conditions are satisfied.

Figure 4.

Magnet design algorithm based on the GA.

The center field and field homogeneity constraints are related to the axial-direction magnetic field in the air core space. The axial-direction magnetic field with a spherical coordination can be calculated by a harmonic analysis, and the relevant equations are expressed here as Equation (1).

where Pn0(cosθ) is the associated Legendre polynomial [8,44,45].

The critical current constraint, referring to the transporting current limit, is related to the operation margin. Because the critical current varies with respect to the applied magnetic field and temperature, it is very important to calculate the angle and amplitude of the applied magnetic fields in the magnet [6,8]. Using the vector potential, we can calculate the axial and radial field components at specific positions, as shown by Equation (2) [46],

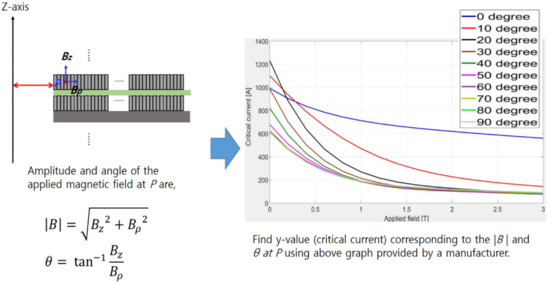

where a2 and a1 are the outer radius and inner radius of the coil, and b2 and b1 are the axial coordinates of the top and bottom of the coil, respectively. Aij and bij are correspondingly the radial and axial position of the center point of each HTS turn, and K and E are parameters related to the elliptic integral. When designing a magnet, the design program calculates the angle and amplitude at every HTS turn and finds the minimum critical current using the measured critical current data with respect to the temperature and magnetic field, as provided by the HTS tape manufacturer. Details of the critical current calculation are presented in Figure 5. The optimization process then finds the proper operating current based on the critical current constraint.

Figure 5.

Details of the critical current calculation method.

Because excessive magnetic hoop stress can damage the magnet and reduce the critical current [46,47,48], the determination of the maximum magnetic hoop stress is essential in the design stage. That is, the generated hoop stress should be lower than the permissible tensile stress of the HTS tape. Based on the specifications of the SuNAM REBCO tape, we set the permissible tensile stress to 250 MPa. The equations used to determine the magnetic hoop stress at the magnet are shown below as Equation (3).

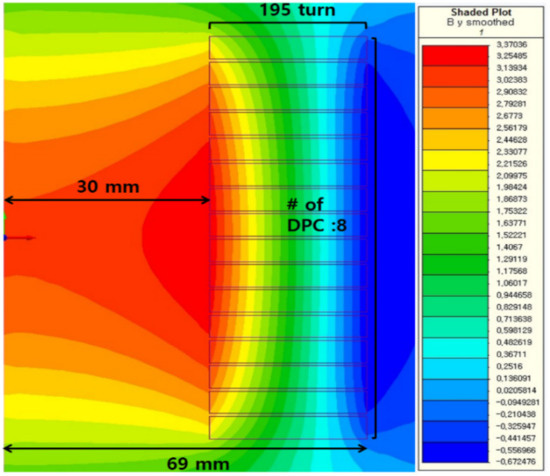

where Y is Young’s modulus, v is Poisson’s ratio, B is the applied magnetic field, J is the magnet current density, u is the displacement, and σh is the magnetic hoop stress [6,8,46,49,50]. With the repetitive optimization process, we derived the final design of the 3 T REBCO magnet, as shown in Table 2. Figure 6 shows the magnetic field distributions of the design result.

Table 2.

Specifications of the Designed 3 T REBCO EMPS Magnet @ 20 K.

Figure 6.

Magnetic field distributions of the 3 T REBCO magnet design result.

The REBCO magnet is composed of eight coil modules, called double-pancake coils (DPC), and generates over 3 T at an operating current of 99 A.

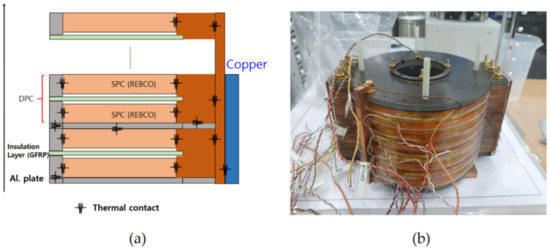

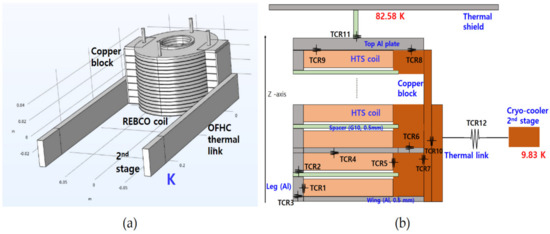

3. Magnet Construction

The 3 T REBCO magnet consists of eight coil modules, called DPCs, which are electrically connected in a series to generate a target field of 3 T. Each DPC is composed of two single-pancake coils (SPC) wound with REBCO tape and stainless steel tape, with an insulation layer between the two SPCs and an aluminum plate between every two DPCs. To cool the magnet, the eight DPCs are also thermally connected through anodized aluminum plates and copper blocks. To enhance the heat transfer efficiency, thermal grease, and indium sheets are applied among all thermal contacts [51,52]. The cross-sectional structure and a picture of the fabricated magnet are presented in Figure 7.

Figure 7.

(a) The cross-sectional structure, and (b) front view of the 3 T REBCO magnet.

After the REBCO magnet was assembled, a two-stage cryo-cooler (Sumitomo, CH-204) [34] was connected to the magnet through two thermal links made of oxygen-free high-conductivity copper (OFHC). One pair of highly efficient HTS current leads was installed between the first and second stage of the cryo-cooler to supply magnet current to the REBCO magnet.

4. Magnet Operation

4.1. Charging Tests

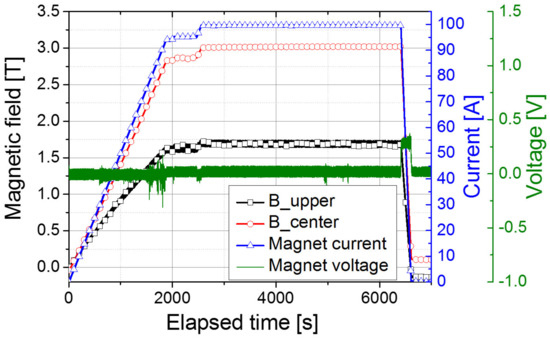

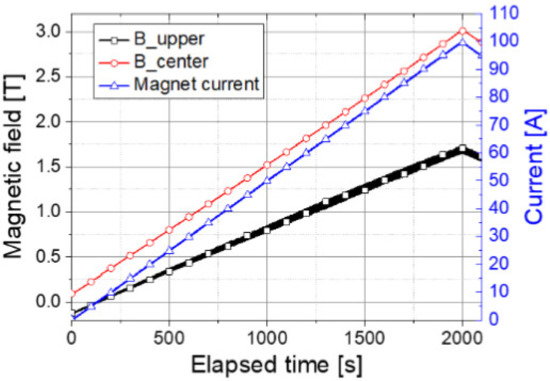

After the fabrication, the 3 T magnet was ramped up to the target field of 3 T at a sweeping rate of 0.05 A/s and the center field, the upper part field (an additional Hall sensor is located on the top of the magnet) and the magnet voltages were measured using a data acquisition device (National Instruments, SCXI 1001) and a gauss meter (Lakeshore, model 475). The magnet current was measured by using a shunt, of which the ratio is 2000. Figure 8 presents the first charging test results.

Figure 8.

Center and upper part magnetic field, magnet current and voltage of the first charging test.

The magnet was successfully charged to the target field without any problems. The magnet voltage was also very stable during the charging test. The second charging test results are also presented in Figure 9, and the performance during the second trial was also stable. The measured magnetic field at the magnet upper part is about 1.7 T when the center field is 3 T at 99 A. By using the ratio of the center field to upper part field (3/1.7), we can estimate the center field without a center magnetic field sensor in this system.

Figure 9.

Second charging test results of the 3 T magnet system.

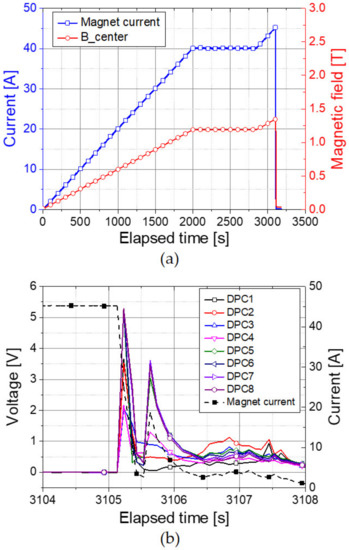

4.2. Survival after a Sudden Discharge Due to a Magnet Power Supply Trip

Before the first successful charging test, the magnet experienced a sudden discharge at a current of 45 A due to an unexpected power supply trip. Because of the fabrication error of the connecting copper block between the cryo-cooler 2nd stage and the HTS current lead, the HTS tapes (between the 1st stage and 2nd stage at the Figure 1) in the current lead were broken and the magnet current was suddenly discharged due to the voltage limit. Figure 10 shows the power supply current, magnet voltages, and magnetic field during the sudden discharge. After the magnet current dropped to zero, the eight voltages of the DPC all fluctuated due to self and mutual inductances of the coil. This is a typical phenomenon of insulation-free and metallic-insulation coils [53,54,55]. After repair of the current leads and cooling parts, the system was energized to the target field and the magnet successfully generated 3 T, as shown in Figure 8. This means that the superconducting magnet survived after the sudden discharge, possibly confirming the self-protecting feature of the metallic-insulation coil technology.

Figure 10.

(a) Center magnetic field and current, and (b) voltages and current of eight DPC during the sudden discharge of the 3 T system.

5. Thermal Analysis with the Finite Element Method (FEM)

A thermal analysis of the 3 T REBCO magnet was carried out to verify the thermal characteristics and temperature distributions with COMSOL, a finite element method (FEM) program. Figure 11 presents the heat transfer FEM model and the corresponding simplified thermal resistance circuit model. There are 12 thermal contacts in the model, and the heat is transferred from a thermal shield, of which the temperature is maintained at 82.58 K, to the second stage of the cryo-cooler (9.8 K) through thermal contacts. As the thermal contact resistance (TCR) depends on the surface material, surface roughness and contact pressure, it is very difficult to predict the thermal contact resistance accurately [51,52,56,57]. Because the goal of the simulation is to verify the tendency of the temperature distributions, we roughly estimated the thermal contact resistances using values from an earlier study (reference [57]). As the TCR1, TCR4, TCR 6, TCR 8, and TCR 9 represent thermal contacts between aluminum and copper, we averaged thermal contact resistance of Al-Al 490 N and Cu-Cu 490 N at 10 K to calculate these values. Since indium sheets were inserted between the contact 7 and 12, TCR7 and TCR12 were calculated by thermal contact resistance of In-Cu 490 N at 10 K. On the other hand, TCR 10 was calculated by only Cu-Cu 50 490 N due to the absence of an indium sheet. We assumed that thermal contact 5 is very poor and the TCR5 value was set to 50. Since it was very difficult to find thermal contact resistance between GFRP materials, we also assumed that the thermal contact resistances at 2, 3, and 11 are same with that of the Al-Al 490 N at 10 K. The roughly calculated thermal contact resistance values considering the temperature (10 K) are shown in Table 3.

Figure 11.

(a) The heat transfer FEM model, and (b) simplified thermal contact resistance circuit.

Table 3.

Estimated Thermal Contact Resistance for the FEM Simulation.

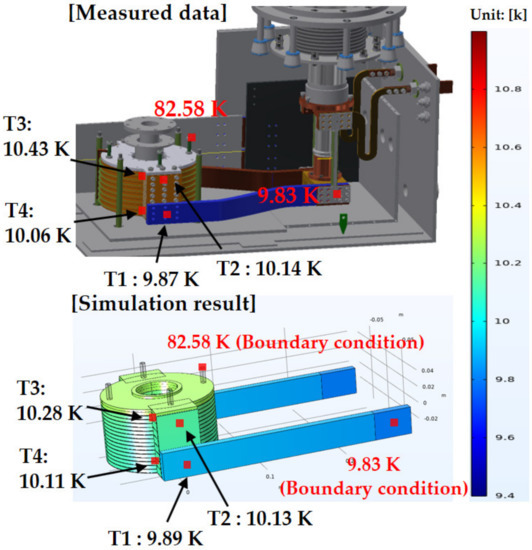

Considering boundary conditions such as the thermal contact, heat flux from radiation and the temperature, we carried out FEM simulations and compared these outcomes with the result from measured data using Cernox temperature sensors. The FEM simulation results are shown in Figure 12. Although there are slight errors between the simulation and experimental results due to the thermal contact resistance values, the tendency of the temperature distributions in the simulation result is similar to that of the measured data (T3 > T2 > T4 > T1).

Figure 12.

FEM simulation result of the 3 T system.

6. Conclusions

We successfully designed, fabricated, and tested a conduction-cooled 3 T HTS magnet system with a compact size and good portability. With the GA, an optimization theory, the 3 T HTS magnet composed of eight double-pancake coils was optimally designed considering the mechanical hoop stress, critical current, and magnetic field distributions. A metallic form of insulation was adopted for quench protection without a charging delay. After the fabrication process, the magnet was cooled to the target temperature in one day. At the target temperature (<20 K), the system generated 3 T at the target current without any problems and survived a sudden discharge at about 45 A (half of the operating current) of current due to the power supply voltage limit. A thermal analysis with the roughly calculated thermal contact resistances was also implemented to verify the temperature trends of the magnet, and the simulation results were found to be similar to the measured data. From these results, we demonstrated that the 3 T liquid-helium-free compact magnet system can be a proper property measurement system for convenient property measurement tests. We expect that the system will be operated as a new user facility at KBSI after lengthy operating tests.

Author Contributions

Design, J.Y.J.; fabrication, M.S.K. and Y.J.H.; test and data acquisition, M.S.K., Y.J.H., S.S., J.Y.J., and Y.C.; writing—original draft preparation, J.Y.J.; writing—review and editing, Y.S.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Korea Basic Science Institute (KBSI), specifically by grant number D110200.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Parrell, J.A.; Zhang, Y.; Field, Y.; Cisek, P.; Hong, S. High field Nb/sub 3/Sn conductor development at Oxford Superconducting Technology. IEEE Trans. Appl. Supercond. 2003, 13, 3470–3473. [Google Scholar] [CrossRef]

- Maeda, H.; Yamazaki, T.; Nishiyama, Y.; Hamada, M.; Hashi, K.; Shimizu, T.; Suematsu, H.; Yanagisawa, Y. Development of Super-High-Field NMR Operated Beyond 1 GHz Using High-Temperature Superconducting Coils. eMagRes 2016, 5, 1109–1120. [Google Scholar]

- Schwalbe, H. New 1.2 GHz NMR Spectrometers—New horizons? Angew. Chem. Int. Ed. Engl. 2017, 56, 2–4. [Google Scholar] [CrossRef] [PubMed]

- Barth, C.; Komorowski, P.; Vonlanthen, P.; Herzog, R.; Tediosi, R.; Alessandrini, M.; Bonura, M.; Senatore, C. Generation of 25 T with an all-superconducting magnet system: Field profile and field quality measurements of a layer-wound 4 T REBCO insert coil for a 21 T LTS magnet. Supercond. Sci. Technol. 2019, 32, 075005. [Google Scholar] [CrossRef]

- Ma, W.; Hollis, T.; Viznichenko, R.; Twin, A.; Clarke, N.; Warren, D. Development of a 20 T 100 mm Cold Bore Superconducting Magnet System. J. Phys. Conf. Ser. 2020, 1559, 012120. [Google Scholar] [CrossRef]

- Wilson, W. Superconducting Magnets; Clarendon Press: Oxford, UK, 1987. [Google Scholar]

- Breschi, M.; Trevisani, L.; Bottura, L.; Derved, A.; Trillaud, F. Comparing the thermal stability of NbTi and Nb3Sn wires. Supercond. Sci. Technol. 2009, 22, 025019. [Google Scholar] [CrossRef]

- Iwasa, Y. Case Studies in Superconducting Magnets; Plenum Press: New York, NY, USA, 1994. [Google Scholar]

- Uglietti, D. A review of commercial high temperature superconducting materials for large magnets: From wires and tapes to cables and conductors. Supercond. Sci. Technol. 2019, 32, 053001. [Google Scholar] [CrossRef]

- Parkinson, B.J. Design considerations and experimental results for MRI systems using HTS magnets. Supercond. Scile. Technol. 2017, 30, 014009. [Google Scholar] [CrossRef]

- Kiyoshi, T.; Choi, S.; Matsumoto, S.; Zaitsu, K.; Hase, T.; Miyazaki, T.; Otsuka, A.; Yoshikawa, M.; Hamada, M.; Hosono, M.; et al. HTS-NMR: Present Status and Future Plan. IEEE Trans. Appl. Supercond. 2010, 20, 714–717. [Google Scholar] [CrossRef]

- Bascunan, J.; Hahn, S.; Park, D.K.; Iwasa, Y. A 2/4-GHz LTS/HTS NMR Magnet—A Progress Report. IEEE Trans. Appl. Supercond. 2011, 21, 2092–2095. [Google Scholar] [CrossRef]

- Bascunan, J.; Hahn, S.; Kim, Y.; Iwasa, Y. A New High-Temperature Superconducting (HTS) 700-MHz Insert Magnet for a 1.3-GHz LTS/HTS NMR Magnet. IEEE Trans. Appl. Supercond. 2013, 23, 4400304. [Google Scholar] [CrossRef] [PubMed]

- Iwasa, Y.; Bascunan, J.; Hahn, S.; Voccio, J.; Kim, Y.; Lecrevisse, T.; Song, J.; Kajikawa, K. A High-Resolution 1.3-GHz/54-mm LTS/HTS NMR Magnet. IEEE Trans. Appl. Supercond. 2015, 25, 4301205. [Google Scholar] [CrossRef] [PubMed]

- Piao, R.; Miyoshi, Y.; Yoshikawa, M.; Saito, K.; Hamada, M.; Matsumoto, S.; Suematsu, H.; Mochida, H.; Takao, T.; Suetomi, Y.; et al. Design and Development of a compact 1 GHz (23.5 T)-Class NMR Magnet with Bi-2223 Inner Coils. IEEE Trans. Appl. Supercond. 2019, 29, 4300407. [Google Scholar] [CrossRef]

- Kitaguchi, H.; Ozaki, S.; Miyazaki, T.; Ayai, N.; Sato, K.; Urayama, S.; Fukuyama, H. Development of a Bi-2223 HTS Magnet for 3 T MRI System for Human Brains. IEEE Trans. Appl. Supercond. 2010, 20, 710–713. [Google Scholar] [CrossRef]

- Slade, R.A.; Parkinson, J.; Walsh, R.M. Test Results for a 1.5 T MRI System Utilizing a Cryogen-free YBCO Magnet. IEEE Trans. Appl. Supercond. 2014, 24, 4400705. [Google Scholar] [CrossRef]

- Tosaka, T.; Miyazaki, H.; Iwai, S.; Otani, Y.; Takahashi, M.; Tasaki, K.; Nomura, S.; Kurusu, T.; Ueda, H.; Noguchi, S.; et al. R&D Project on HTS Magnets for Ultrahigh-Field MRI Systems. IEEE Trans. Appl. Supercond. 2016, 26, 4402505. [Google Scholar]

- Yokoyama, S.; Lee, J.; Imura, T.; Matsuda, T.; Eguchi, R.; Inoue, T.; Nagahiro, T.; Tanabe, H.; Sato, S.; Daikoku, A.; et al. Research and Development of the High Stable Magnetic Field ReBCO Coil System Fundamental Technology for MRI. IEEE Trans. Appl. Supercond. 2017, 27, 4400604. [Google Scholar] [CrossRef]

- Oya, M.; Matsuda, T.; Inoue, T.; Morita, T.; Eguchi, R.; Otake, S.; Nagahiro, T.; Tanabe, H.; Yokoyama, S.; Daikoku, A. Design and Manufacture of Half-size 3-T High-Temperature Superconducting Magnet for MRI. IEEE Trans. Appl. Supercond. 2018, 28, 4401205. [Google Scholar] [CrossRef]

- Bogdanov, I.V.; Kozub, S.S.; Sytnik, V.V.; Terskiy, I.S.; Tkachenko, L.M.; Trusov, O.V.; Shirshov, L.S.; Smirnov, V.M.; Shuvalov, V.I.; Shcherbakov, P.A.; et al. Design, fabrication and testing of a dipole magnet made with 2 G HTS wire. Supercond. Sci. Technol. 2016, 29, 105012. [Google Scholar] [CrossRef]

- John, J.H.; Badel, A.; Tixador, P. HTS Dipole Magnet for a Particle Accelerator Using a Twisted Stacked Cable. IEEE Trans. Appl. Supercond. 2016, 26, 4005205. [Google Scholar]

- Wang, X.; Abraimov, D.; Arbelaez, D.; Bogdanof, T.J.; Brouwer, L.; Caspi, S.; Dietderich, D.R.; Di Marco, J.; Francis, A.; Fajardo, L.G.; et al. Development and performance of a 2.9 Tesla dipole magnet using high-temperature superconducting CORC wires. Supercond. Sci. Technol. 2021, 34, 015012. [Google Scholar] [CrossRef]

- Rossi, L.; Senatore, C. HTS Accelerator Magnet and Conductor Development in Europe. Instruments 2021, 5, 8. [Google Scholar] [CrossRef]

- Kwon, Y.K.; Kim, H.M.; Baik, S.K.; Lee, E.Y.; Lee, J.D.; Kim, Y.C.; Lee, S.H.; Hong, J.P.; Jo, Y.S.; Ryu, K.S. Performance test of a 1 MW class HTS synchronous motor for industrial application. Phys. C 2008, 468, 2081–2086. [Google Scholar] [CrossRef]

- Sivasubramaniam, K.; Zhang, T.; Lokhandwalla, M.; Laskaris, E.T. Development of a High Speed HTS Generator for Airborne Applications. IEEE Trans. Appl. Supercond. 2009, 19, 1656–1661. [Google Scholar] [CrossRef]

- Nick, W.; Grundmann, J.; Frauenhofer, J. Test results from siemens low-speed, high-torque HTS machine and description of further steps towards commercialization of HTS machines. Phys. C 2012, 482, 105–110. [Google Scholar] [CrossRef]

- Herkert, M.O.; Bayer, D.; Kummeth, P.; Nick, W.; Arndt, T. Manufacturing and test of 2G-HTS coils for rotating machines: Challenges, conductor requirements, realizations. Phys. C 2012, 482, 111–118. [Google Scholar]

- Hahn, S.; Bascunan, J.; Kim, W.; Bobrov, E.S.; Lee, H.; Iwasa, Y. Field Mapping, NMR Lineshape, and Screening Currents Induced Field Analyses for Homogeneity Improvement in LTS/HTS NMR Magnets. IEEE Trans. Appl. Supercond. 2008, 18, 856–859. [Google Scholar] [CrossRef]

- Ahn, M.; Yagai, T.; Hahn, S.; Ando, R.; Bascunan, J.; Iwasa, Y. Spatial and Temporal Variations of a Screening Current Induced Magnetic Field in a Double-Pancake HTS Insert of an LTS/HTS NMR Magnet. IEEE Trans. Appl. Supercond. 2009, 19, 2269–2272. [Google Scholar]

- Koyama, Y.; Takao, T.; Yanagisawa, Y.; Nakagome, H.; Hamada, M.; Kiyoshi, T.; Takahashi, M.; Meda, H. Toward Beyond 1 GHz NMR: Mechanism of the Long-Term Drift of Screening Current-Induced Magnetic Field in a Bi-2223 Coil. Phys. C 2009, 469, 694–701. [Google Scholar] [CrossRef]

- Miyazoe, A.; Nakanishi, Y.; Sekino, M.; Kiyoshi, T.; Ohsaki, H. Magnetic Field Distribution Generated by Screening Current Flowing in Coated Conductor Arranged Edge-by-Edge and /or Face-to-Back. IEEE Trans. Appl. Supercond. 2012, 22, 4400504. [Google Scholar] [CrossRef]

- Jang, J.Y.; Hwang, Y.J.; Han, J.H.; Ahn, M.; Yang, H.; Hahn, S.; Bang, J.; Lee, S. Reproducibility of the field homogeneity of a metal-clad no-insulation all-REBCO magnet with a multi-layer ferromagnetic shim. Supercond. Sci. Technol. 2020, 33, 025005. [Google Scholar] [CrossRef]

- Sumitomo Cryogenic Group. CH-204 10K Cryocooler Series—SHI Cryogenics Group. Available online: http://www.shicryogenics.com/products/10k-cryocoolers/ch-204-10k-cryocooler-series (accessed on 25 February 2021).

- Coley, D.A. An Introduction to Genetic Algorithm for Scientists and engineers; World Scientific: Singapore, 1990. [Google Scholar]

- Cavaliere, V.; Formisano, A.; Martone, R.; Primizia, M. A genetic algorithm approach to the design of split coil magnets for MRI. IEEE Trans. Appl. Supercond. 2000, 10, 1376–1379. [Google Scholar] [CrossRef]

- Lecrevisse, T.; Iwasa, Y. A (RE)BCO Pancake Winding With Metal-as-Insulation. IEEE Trans. Appl. Supercond. 2016, 26, 4700405. [Google Scholar] [CrossRef]

- Sohn, M.; Sim, K.; Eom, B.; Ha, H.; Kim, H.; Seong, K. Controllability of the Contact Resistance of 2G HTS Coil With Metal Insulation. IEEE Trans. Appl. Supercond. 2018, 28, 4602705. [Google Scholar] [CrossRef]

- Song, J.; Chaud, X.; Borgnic, B.; Debray, F.; Fazilleau, P.; Lecrevisse, T. Construction and Test of a 7 T Metal-as-Insulation HTS Insert Under a 20 Thigh Background Magnetic Field at 4.2 K. IEEE Trans. Appl. Supercond. 2019, 29, 4601705. [Google Scholar] [CrossRef]

- Lee, J.; Lee, H.; Lee, J.; Choi, S.; Yoo, S.; Moon, S. RCE-DR, a novel process for coated conductor fabrication with high performance. Supercond. Sci. Technol. 2014, 27, 044018. [Google Scholar] [CrossRef]

- Hahn, S.; Kim, Y.; Park, D.K.; Kim, K.; Voccio, J.; Bascunan, J.; Iwasa, Y. No-insulation multi-width winding technique for high temperature superconducting magnet. Appl. Phys. Lett. 2013, 103, 173511. [Google Scholar] [CrossRef]

- Hahn, S.; Kim, Y.; Song, J.; Voccio, J.; Bascunan, J.; Iwas, Y. A-78mm/7-T Multi-Width No-Insulation ReBCO Magnet: Key Concept and Magnet Design. IEEE Trans. Appl. Supercond. 2014, 24, 4602705. [Google Scholar] [CrossRef]

- Kim, J.; Yoon, S.; Cheon, K.; Shin, K.H.; Hahn, S.; Kim, D.L.; Lee, S.; Lee, H.; Moon, S. Effect of Resistive Metal Cladding of HTS Tape on the Characteristic of No-Insulation Coil. IEEE Trans. Appl. Supercond. 2016, 26, 4601906. [Google Scholar] [CrossRef]

- Romeo, F.; Hoult, D.I. Magnet Field Profiling: Analysis and Correcting Coil Design. Magn. Reson. Med. 1984, 1, 44–65. [Google Scholar] [CrossRef]

- Li, F.X.; Voccio, J.; Ahn, M.; Hahn, S.; Bascunan, J.; Iwasa, Y. An analytical approach towards passive ferromagnetic shimming design for a high resolution NMR magnet. Supercond. Sci. Technol. 2015, 28, 075006. [Google Scholar] [CrossRef] [PubMed]

- Garret, M.W. Calculation of fields, forces and mutual inductance of current system by elliptic integrals. J. Appl. Phys. 1967, 38, 2538–2586. [Google Scholar] [CrossRef]

- Uglietti, D.; Seeber, B.; Abacherli, V.; Carter, W.L.; Flukiger, R. Critical currents versus applied strain for industrial Y-123 coated conductors at various temperatures and magnetic fields up to 19 T. Supercond. Sci. Technol. 2006, 19, 869–872. [Google Scholar] [CrossRef]

- Choi, S.; Kiyoshi, T.; Hahn, S.; Sugano, M. Stress Analysis of a High Temperature Superconductor Coil Wound With Bi-2223/Ag Tapes for High Field HTS/LTS NMR Magnet Application. IEEE Trans. Appl. Supercond. 2009, 19, 2237–2240. [Google Scholar] [CrossRef][Green Version]

- Montgomery, D.B. Solenoid Magnet Design; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 1969. [Google Scholar]

- Markiewicz, W.D.; Vaghar, M.R.; Dixon, I.R.; Garmestani, H. Generalized Plane Strain Analysis of Solenoid Magnets. IEEE Trans. Appl. Supercond. 1994, 30, 2233–2236. [Google Scholar] [CrossRef]

- June, Y.; Yee, A.L.; Schwall, R.E. Thermal conductance of Cu/Cu and Cu/Si interfaces from 85 K to 300 K. Cryogenics 1992, 32, 610–615. [Google Scholar]

- Nishimo, K.; Yamashita, S.; Torii, K. Thermal contact conductance under low applied load in a vacuum environment. Exp. Thermal Fluid. Sci. 1995, 10, 258–271. [Google Scholar] [CrossRef]

- Song, J.; Hahn, S.; Lecrevisse, T.; Voccio, J.; Bascunan, J.; Iwasa, Y. Over-current quench test and self-protecting behavior of a 7 T/78 mm multi-width no-insulation REBCO magnet at 4.2 K. Supercond. Sci. Technol. 2015, 28, 114001. [Google Scholar] [CrossRef]

- Kim, K.; Kim, K.; Bhattarai, K.R.; Radcliff, K.; Jang, J.Y.; Hwang, Y.J.; Lee, S.; Yoon, S.; Hahn, S. Quench behavior of a no-insulation coil wound with stainless steel cladding REBCO tape at 4.2 K. Supercond. Sci. Technol. 2017, 30, 075001. [Google Scholar] [CrossRef]

- Jang, J.Y.; Yoon, S.; Hahn, S.; Hwang, Y.J.; Kim, J.; Shin, K.H.; Cheon, K.; Kim, K.; In, S.; Hong, Y.; et al. Design, construction and 13 K conduction-cooled operation of a 3 T 100 mm stainless steel cladding all-REBCO magnet. Supercond. Sci. Technol. 2017, 30, 105012. [Google Scholar] [CrossRef]

- Kim, M.S.; Choi, Y.S. Interfacial Contact Resistance Along the Thermal Link in Conduction-Cooled Low-Temperature Superconducting Magnet System. J. Supercond. Nov. Magn. 2014, 28, 681–684. [Google Scholar] [CrossRef]

- Ekin, J.W. Experimental Techniques for Low Temperature Measurements; Oxford University Press: Oxford, UK, 2006. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).