Abstract

Chemical mechanical planarization (CMP) is frequently used in semiconductor manufacturing to polish the surfaces of multiple layers in a wafer. The CMP uses a slurry that aids in fabricating a smooth surface by removing the excess materials. However, excessive use of slurry affects the environment and is expensive. Therefore, we propose a hybrid slurry supply system that combines ionization and atomization to reduce slurry consumption and improve the polishing quality. The proposed hybrid system atomizes the ionized slurry using electrolysis and a spray slurry nozzle. We compared the material removal rate (MRR) and polishing uniformity based on the slurry supply systems used in Cu and SiO2 non-patterned wafers. Additionally, the step height reduction and dishing were compared in the Cu-patterned wafers. The experimental analysis using the hybrid system confirmed a 23% and 25% improvement in the MRR and uniformity, respectively, in comparison with the conventional slurry supply system. This improvement can be attributed to the chemical activation and uniform supply of the ionized and atomized slurries, respectively. Moreover, a significant reduction was observed in dishing and pitch-size dependence. Furthermore, the proposed system prevents heat accumulation between the CMP processes, serving as a cooling system.

1. Introduction

Chemical mechanical planarization (CMP) is a global planarization technique commonly employed in semiconductor manufacturing to improve the topography of wafer surfaces. It is an essential process in manufacturing multilayered and highly dense semiconductor devices. However, semiconductor manufacturing adversely affects the environment [1], and the CMP, one of the processes, also has factors that affect the environment. The slurry is an acid or a base solution that contains components, such as complexing agents, abrasives, oxidizers, and corrosion inhibitors, which can negatively impact the environment [2]. Thus, among the various CMP consumables, such as slurry, polishing pads, and conditioners, the slurry has the most unfavorable impact on the environment. Additionally, it accounts for more than 50% of the cost of the consumables in the CMP process [3]. Therefore, a reduction in slurry consumption is indispensable.

Several studies [4,5,6] aimed to reduce the amount of slurry consumption by improving the slurry performance considering the types and concentrations of the chemical components. However, further improvement in the performance based on the chemical composition moderation is not feasible. Therefore, several researchers considered reducing the amount of slurry consumption by improving the low slurry-utilization efficiency of 2–22% [7].

Initially, studies focused on the development of consumables such as pad grooves [8,9] and retaining rings [10] to compensate for the low slurry-utilization efficiency at the wafer–pad interface. However, slurry supply systems were eventually developed as an alternative. Philipossian et al. developed a slurry injection system that improves the slurry-utilization efficiency without reducing the material removal rate (MRR) or increasing the defects [11]. This system floats on the pad and uses multi-point injectors to supply fresh slurry uniformly while removing the used slurry. Fujita et al. proposed a slurry supply mechanism based on the capillary effect. In this mechanism, the slurry was supplied uniformly using a fiber array on the pad [12]. However, the aforementioned studies are limited to large and complex devices, and the effects of the systems are insignificant.

Therefore, we propose a novel slurry supply system that can achieve excellent results when applied to any machine or material, despite its simplicity. The hybrid system ionizes the slurry through electrolysis and supplies the ionized slurry to the wafer–pad interface uniformly using a spray slurry nozzle. The ionized and atomized slurry is chemically activated and supplied uniformly to polish the wafer surfaces. This improves the MRR and uniformity while reducing the defects, such as dishing. We compared the experimental results obtained using the hybrid slurry supply system with those of the conventional slurry supply system, ionization system, and atomization system, used in the CMP processes of Cu and SiO2 non-patterned wafers (NPWs). Furthermore, the step height reduction, dishing, and pitch-size dependence were determined using the hybrid slurry supply system. A significant reduction was observed in the defects in comparison with those observed in the conventional system in a Cu-patterned wafer. Thus far, only the mechanical properties of equipment and consumables or the chemical properties of slurry components have been considered to enhance the CMP performance. However, we believe that the proposed hybrid slurry supply system can contribute to performance improvement by controlling not only mechanical properties but also chemical properties.

2. Materials and Methods

2.1. Hybrid Slurry Supply System

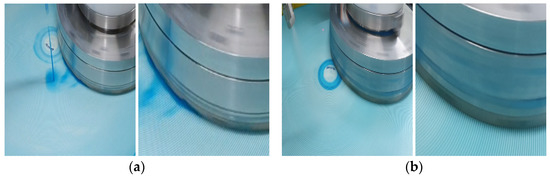

Conventional systems supply the slurry continuously through a single-tube nozzle at the end of the slurry arm. However, a large amount of the supplied slurry does not participate in the polishing process, resulting in wastage owing to the bow wave and centrifugal force [13]. Consequently, the efficiency of slurry utilization is reduced. Figure 1a depicts the slurry supply on the pad and the bow wave on the leading edge of the carrier of the conventional slurry supply system. The bow wave generated at several millimeters high interferes with the slurry entering the wafer–pad interface [14]. Figure 1b shows that when the hybrid slurry supply system is used, a thin slurry film is formed on the pad and bow wave is hardly observed.

Figure 1.

Comparison of the slurry supply on the pad and the bow wave using dyed slurry. Images of (a) the conventional slurry supply system and (b) the hybrid slurry supply system.

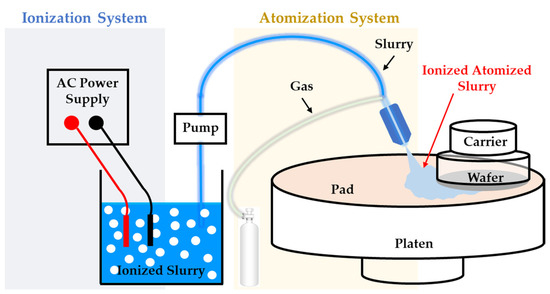

The proposed hybrid slurry supply system can enhance the polishing efficiency with minimal cost and minor modifications to the existing equipment. This system combines the slurry ionization and atomization using electrolysis and a spray slurry nozzle, respectively. Initially, the slurry is ionized using the cathode and anode connected to the alternating current (AC) power supply in the day tank. The slurry ionized by AC power supply has no pH change or aggregation. Subsequently, the slurry is supplied to the atomization system through a pump. The ionized slurry is atomized with oxygen or nitrogen gas using a spray slurry nozzle and supplied to the pad uniformly. Thus, the hybrid slurry supply system improves the MRR effectively, owing to the enhanced chemical activation based on the electrolytic ionized slurry. Additionally, the uniformity is improved owing to the atomized slurry supplied through the spray slurry nozzle. Moreover, it serves as a cooling system as the gas is supplied with the ionized slurry through the nozzle. Figure 2 illustrates the schematic of the proposed hybrid slurry supply system.

Figure 2.

Schematic of the proposed hybrid slurry supply system combining the ionization and atomization systems.

2.2. Experimental Method

The NPW CMP test is highly informative as both the planarization ability of the patterned wafer (PW) and the influence of the CMP consumables can be estimated. Therefore, the performance of the hybrid system was verified by determining the MRR and non-uniformity (NU) using Cu and SiO2 NPWs.

However, the local MRR that occurs during the CMP process differs in the NPW and PW tests. This is because the contact pressure varies based on the geometry of the pattern, causing a local non-planarity. The metal interconnections are separated owing to the over-polishing of the electroplated metal on the dielectric pattern surface. The metal loss in this process causes dishing as the MRR of the oxide is significantly lower than that of the metal [15]. Ideally, the final polishing results must be achieved with minimal defects. However, dishing and erosion occur during the Cu-clearing and over-polishing stages. Therefore, in the Cu PW CMP, the performance was verified by comparing the 2D pattern surface profile, average step height, and temperature of the hybrid slurry supply system with those of the conventional system.

2.3. Experimental Setup

2.3.1. Global Planarization

We used Cu and SiO2 as the representative materials in the interconnection wires and dielectrics, respectively. The thickness of the Cu film was measured considering 43 points in the diameter of the wafer with an edge exclusion of 10 mm using a four-point probe (Changmin Tech Co., Ltd., Korea), and the MRR of SiO2 wafer was measured considering 53 points in the diameter with an edge exclusion of 3 mm using a reflectometer (ST5030-SL, K-MAC, Korea). A downsized R&D machine (POLI-762, G&P technology, Korea) and ceria slurry, commonly used in the shallow trench isolation CMP [16], were used for the SiO2 CMP in these experiments. The process parameters were determined based on the well-established SiO2 CMP process. Table 1 lists the experimental conditions in detail.

Table 1.

Experimental conditions based on the wafer type for global planarization.

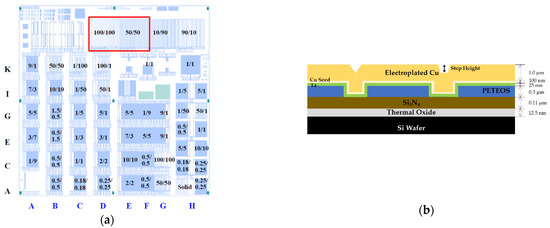

2.3.2. Step Height Reduction and Dishing during the CMP of Patterned Wafers

The 300-mm Cu-patterned wafer, SKW 6-3.18C (SKW Associates, Inc., USA), was designed as a damascene structure with an electroplated Cu layer. We investigated the reduction in step height and dishing based on the slurry supply systems. Figure 3 depicts the considered pattern lines with different pitches and the cross-sectional view of the PW used in this experiment. The step height of the film deposited on the patterns is considered as the vertical height of the surface asperity.

Figure 3.

Information on the Cu-patterned wafer. (a) Layout of the Cu patterns and the patterns considered in the experiment and (b) the cross-sectional view of the patterned wafer.

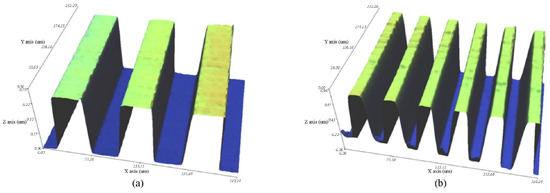

The patterns were measured before and after the completion of the CMP process using a non-contact 3D surface profiler (Nanoview, Nanosystems, Korea). Cu dishing is the difference in height between the center and the edge of the Cu line. As dishing primarily occurs in the wide trenches, 200-µm (100 µm /100 µm) and 100-µm (50 µm /50 µm) pitches of equal density (50%) were selected (Figure 4). The patterns were measured at 30, 60, 90, and 120 s during the process. Based on the process time when the Cu film was nearly removed, we performed over-polishing from 0% to 30%. The specific experimental conditions were identical to the experiment described in Section 2.3.1 (Table 1).

Figure 4.

As-received 50% density patterns. (a) 200-µm pitch (100 µm/100 µm) and (b) 100-µm pitch (50 µm/ 50 µm).

3. Results

3.1. Global Planarization

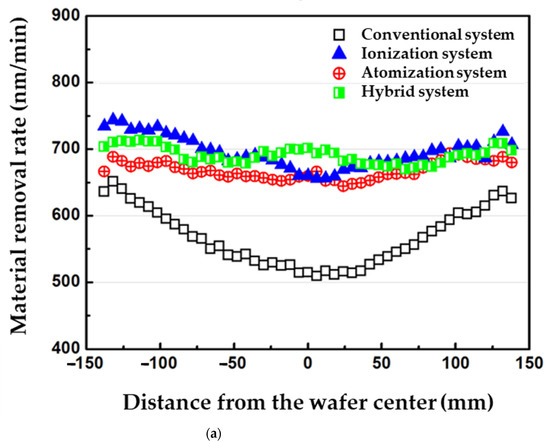

Figure 5 illustrates the MRR and uniformity of the 300-mm Cu NPW CMP using four types of slurry supply system. As indicated in the figure, the three slurry supply systems exhibit higher MRR and lower NU than those of the conventional system. The hybrid and ionization systems demonstrate 23% higher MRRs, whereas the NUs of the hybrid and atomization systems are approximately four times lower than those of the conventional system. Thus, we concluded that the efficiencies of the material removal and planarization were improved by the ionization system and the atomized slurry, respectively. Therefore, the proposed hybrid system is a combination of these two systems, achieving high MRR and uniformity.

Figure 5.

300-mm Cu non-patterned wafer (NPW) CMP results based on the types of slurry supply system. (a) MRR profiles and (b) average MRR and NU.

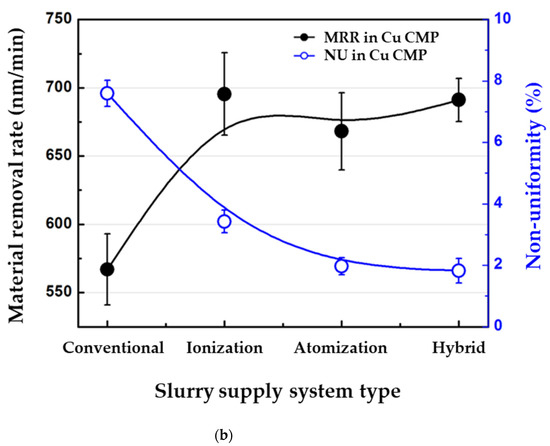

Furthermore, we applied the proposed system to other materials. Figure 6 illustrates the 300-mm SiO2 NPW CMP results, wherein the trend is similar to that observed in the Cu CMP test. Although the MRR profiles of the three systems cannot be distinguished clearly, the performances exhibited are superior to the conventional system. The hybrid and ionization systems exhibit high MRRs of 36% and 39%, respectively. Additionally, the NUs of the hybrid and atomization systems decreased by approximately 23%. In comparison with the conventional system, the effect of improved slurry supply systems on MRR is similar to that of the Cu CMP. However, the NU did not reduce when the ionization system was applied as the effect of the lubrication mechanism on the uniformity of the SiO2 CMP is higher than that of the chemical mechanism.

Figure 6.

300-mm SiO2 NPW CMP results based on the types of slurry supply systems. (a) MRR profiles and (b) average MRR and NU.

3.2. Step Height Reduction and Dishing during CMP of Patterned Wafers

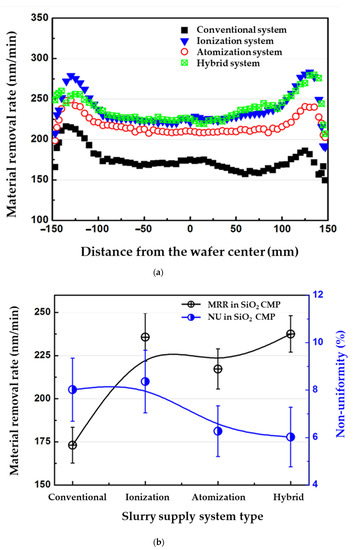

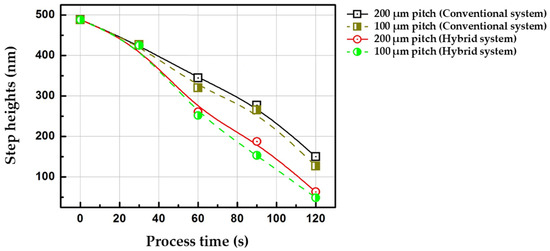

Figure 7 compares the 2D surface profiles of the patterns obtained in the die after the completion of the CMP processes in the conventional and hybrid systems. The average initial step height of the patterns before applying CMP was approximately 490 nm. As indicated in the figure, the hybrid system achieved planarization earlier than the conventional system. The result of the hybrid system at 30 s was similar to that of the conventional system, this is because the system is in a transient state and polishing does not occur properly in this short time. The step height difference between the conventional and hybrid systems was approximately 100 nm after 60 s. Therefore, the processes of the two systems attained a steady-state with a constant MRR as indicated by the rate of the step height reduction. Ideally, the material-removal mechanism of the PW must remove the materials only from the top of the step (upper layer), resulting in global planarization. However, polishing occurs simultaneously on the upper and lower layers in an actual CMP process. Thus, despite the same process conditions, the calculated MRR is different from the previously obtained results (Figure 5). In addition, the step height decreases at a faster rate when the pitch size is small regardless of the type of the slurry supply system. Vasilev et al. [17] reported that only those pad asperities with radii of curvatures of less than 7 mm at a 5 mm trench width were in contact with the lower layer. This indicates that the contact area between the pad and the lower layer is less when the trench width is small.

Figure 7.

The 2D patterns of the surface profiles at 200- and 100-µm pitches. (a) The conventional system and (b) the hybrid system.

To verify the effect of the hybrid slurry supply system, Figure 8 illustrates the average step height reduction as a function of the process time using the patterns of two pitch sizes. As indicated in the figure, the hybrid system completes the polishing process in a shorter time than the conventional system. Thus, the hybrid system can reduce the processing time in the case of patterned CMP. Based on the preliminary results, we determined the CMP endpoints for both systems. While the hybrid system revealed the patterns in a process time of 3 min 20 s, the conventional system performed the same process in 4 min 20 s.

Figure 8.

Average step height based on the process time. The effect of the hybrid system is verified at 200- and 100-µm pitches.

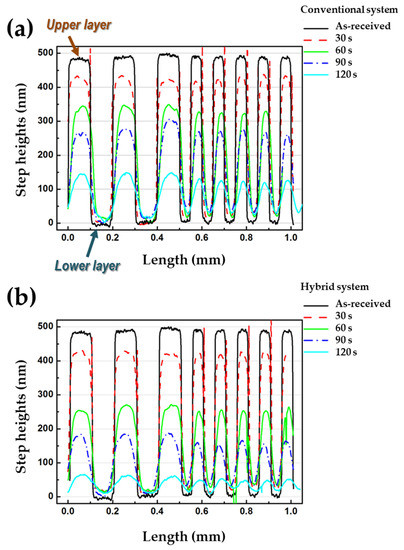

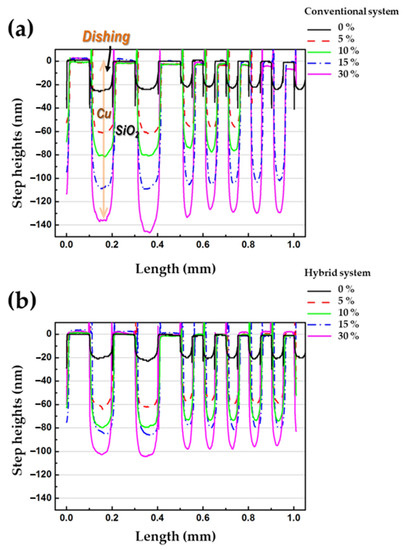

Figure 9a illustrates the dishing observed in the conventional system owing to the step height of the Cu loss. We ceased the CMP process after the endpoint detection, and the amount of dishing was 24 nm and 21 nm in the conventional and hybrid systems, respectively, before over-polishing occurred. Figure 9 illustrates the results of the Cu dishing based on the process of over-polishing. As indicated in the figure, the Cu dishing turns severe as the over-polishing progresses regardless of the slurry supply system.

Figure 9.

Dishing depth based on the over-polishing time. (a) The conventional system and (b) the hybrid system.

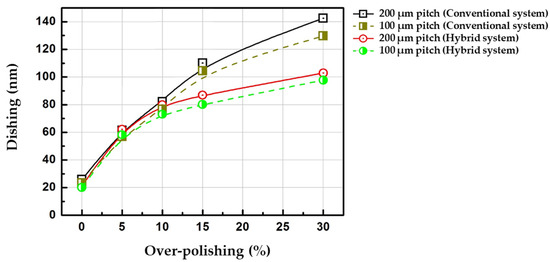

The Cu dishing in the hybrid system was 5%–28% less than that of the conventional system. As the over-polishing progressed, the dishing reduction effect of the hybrid system increased. As illustrated in Figure 10, the hybrid system can reduce the pitch dependence in the 10–30% of over-polishing.

Figure 10.

Cu dishing dependency on the over-polishing. The conventional and hybrid systems are compared considering different pitches.

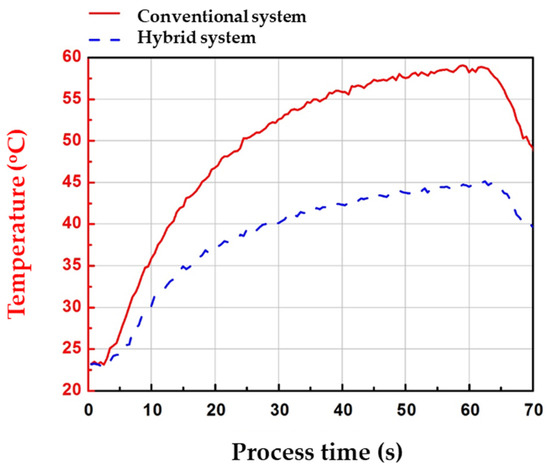

Figure 11 depicts the process temperatures of both the hybrid and conventional systems. As indicated in the figure, the temperature of the hybrid system was significantly lower than that of the conventional system. This is because the wide coverage of the atomized slurry and gas influences the pad temperature significantly. Additionally, this cooling effect primarily causes the reduction in dishing. Moreover, it prevents heat accumulation between the CMP processes.

Figure 11.

Pad temperature comparison between the conventional and hybrid systems based on the process time.

4. Discussion

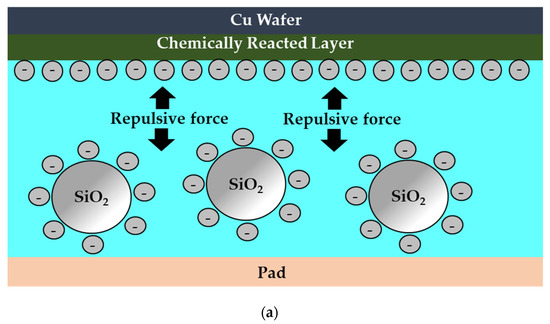

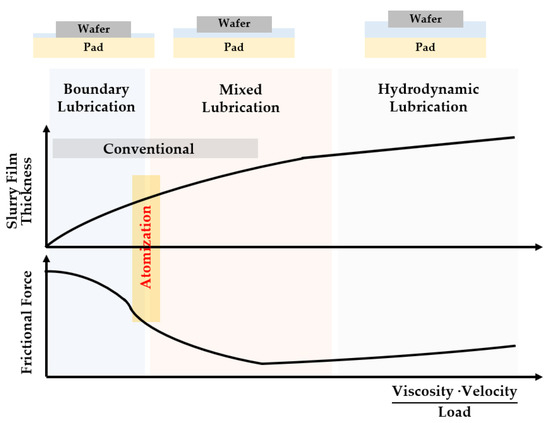

We evaluated a hybrid system that combines the ionization and atomization systems. The ionization of the slurry affects the MRR and the atomization system affects the uniformity, MRR, and pad temperature. Consequently, the MRR improved and the NU reduced by more than 23% and 25%, respectively, in comparison with the conventional system in global planarization. The ions generated during the electrolysis in the ionization slurry supply system reduce the repulsive force between the surface and abrasives. This increases the number of particles involved in the polishing process and improves the chemical reactivity at the Cu surface. Hence, the ionized slurries increase the MRR. Additionally, the hybrid system reduced the defects, such as dishing, by 5%–28% in the PW CMP process.

Typically, a slurry comprises compounds in which various atoms and elements are chemically bonded. In the ionization system, the chemical components in the slurry exchange electrons directly, and the compounds break the bonds to decompose and generate ions. The ionization of the slurry increases the ion motion and transportation, resulting in adequate charge conduction. The isoelectric points of the Cu oxide surface exhibit a negative potential under basic conditions [18]. In the case of conventional slurry, this generates a repulsive force between the reacted layer and the abrasives (Figure 12a). However, the ionized slurry reduces the electrostatic repulsion (Figure 12b). The ions in the ionized slurry are adsorbed on the abrasive or the surface of the Cu oxide, which reduces the repulsive force between the Cu oxide surface and the silica abrasives, owing to the screening of the surface charges [19]. And this phenomenon can also be explained by the zeta potential theory. The ionized slurry has a double-layer with non-uniform ion distribution due to the Cu oxide surface charge, which is composed of a stern layer and a diffused layer. The potential at the boundary between the double-layer and the area where the potential is balanced is called the zeta potential. The potential of the stern layer decreases linearly from the Cu oxide surface potential, and the potential of the diffused layer decreases exponentially with the ion concentration opposite to the surface charge contained in the ionized slurry. Therefore, the zeta potential decreases due to the increase of cations contained in the ionized slurry, resulting in an attractive force. And the electrostatic force between the reacted layer of Cu and the abrasives determines the actual contact pressure and the number of usable active abrasives on the surface [20]. As the ionized slurry contains a high amount of usable active abrasives and applies a high contact pressure on the surface, the MRR increases.

Figure 12.

Comparison of conceptual illustrations between the (a) conventional and (b) ionized slurry.

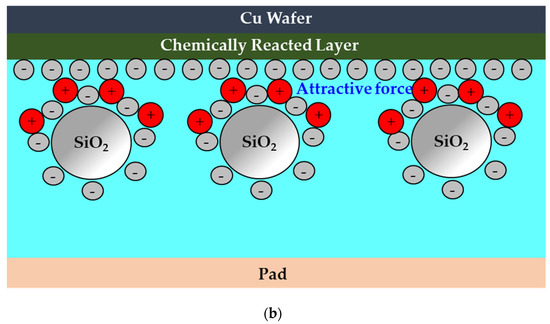

In addition, the ionized slurry accelerates oxidation and decreases the hardness of the Cu surface as the ions react with Cu atoms to oxidize and remove the atoms simultaneously [21]. Although the reaction layer is removed mechanically by the abrasives, it regenerates rapidly owing to the chemical reaction. Thus, this repeated cycle removes the material [22,23]. Figure 13 illustrates the measured results of the hardness of the reaction layer on the Cu surface obtained using a nano-indenter (HM2000, Fischerscope, Germany). Typically, nanoindentation measures the mechanical properties of thin films with a thickness of less than several nanometers to determine the wear resistance [24]. In this study, the results indicate that the surfaces etched into the slurries with higher ionization are more deeply indented with the same force. Moreover, the hardness of the surface is low at deeper indentations. Thus, the ionized slurry improves the chemical reactivity generating a thicker reaction layer of low hardness, which improves the MRR.

Figure 13.

Load-indentation depth curves for surfaces etched by slurries with different AC power strengths. The indentation occurred at a maximum load of 0.2 mN.

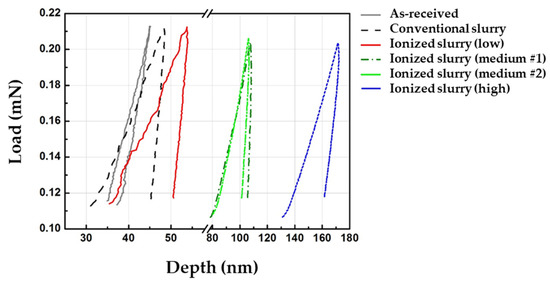

The atomization system improves uniformity owing to the uniform supply of slurry and the reduced deviation in the pad temperature distribution. The particles involved in the polishing process influence the material removal process significantly [2]. The spray slurry nozzle atomizes and supplies the ionized slurry to the pad with wide coverage. The abrasives participating in the polishing are distributed uniformly at the wafer–pad interface [25]. Moreover, the pad temperature distribution has a significant influence on uniformity [2,26]. The uniformity can be improved by reducing the temperature distribution deviation in the radial direction of the pad using the atomized slurry and gas. Furthermore, it serves as a cooling system that cools the pad through active heat transfer as the slurry is distributed thinly and widely on the pad and the gas is supplied with the slurry. Furthermore, the variations in temperature influence the Cu dishing significantly; the dishing decreases with the temperature [27,28]. Therefore, the pad temperature decreases owing to the cooling effect of the hybrid system, and the dishing and heat accumulation can be reduced. Also, dishing is affected by the MRR difference between Cu and SiO2. When the hybrid system was used in Cu CMP and SiO2 CMP, MRR increased 23% and 39%, respectively (Figure 5 and Figure 6). Also, when comparing the value of the MRR in SiO2 CMP divided by the MRR in Cu CMP between the conventional system and hybrid system, they were 0.306 and 0.346, respectively. When using a hybrid system, it can be seen that the MRR of Cu is relatively decreased compared to that of SiO2. Therefore, Cu loss is reduced during over-polishing, resulting in reduced dishing.

In addition, the atomization system increases the MRR. The slurry atomized by the spray slurry nozzle has a wider coverage than the tube nozzle at the same flow rate and is distributed widely on the pad surface to form a thin slurry film (Figure 1). Because of this, the bow wave, which is a phenomenon in which the slurry cannot participate in the polishing and is stagnant at the leading edge of the carrier, decreases. Thus, the number of particles participating in the polishing increases owing to the decrease in the bow wave height [29]. Furthermore, the slurry is distributed relatively wider and uniformly at the wafer–pad interface compared to the conventional system. The overall slurry film thickness becomes thinner, and frictional force increases due to change in lubrication condition (Figure 14). As a result, the MRR increases due to the increase in particles involved in the polishing process and increase in frictional force.

Figure 14.

The frictional force and slurry film thickness. Both the factors are expressed as a function of fluid viscosity and velocity divided by the load.

5. Conclusions

To reduce the slurry consumption in the CMP processes, we proposed a hybrid slurry supply system that combines the ionization and atomization systems. The experimental results of the CMP performed on Cu and SiO2 NPWs measured the MRR and uniformity based on the different slurry supply systems. And step height reduction and dishing were measured using the hybrid and conventional systems in the Cu PW CMP. During the experiment, the reaction between the Cu surface and the slurry enhanced owing to the increased slurry activity in the ionization system. Additionally, the atomization system contributed to improving the uniformity and cooling effect. Thus, we confirmed that the MRR can be increased by 23% and NU can be decreased by 25% or more. Moreover, the dishing and pitch-size dependence can be reduced using the hybrid slurry supply system with minor modifications to the existing equipment. Consequently, the efficiency of the CMP process can be improved, and the slurry consumption can be reduced by increasing the MRR of the hybrid slurry supply system. In addition, the polishing quality can be enhanced by improving the uniformity and reducing the dishing and pitch-size dependence.

Currently, in the advanced process control (APC) parameters on the CMP equipment, only the mechanical factors, such as multi-zone pressure [30], velocity [31], and conditioning [32] can be adjusted. To enhance CMP technology, chemical factors, such as a slurry must be considered in the APC parameters. The hybrid slurry supply system can be an actuator that can control the parameters, such as chemical activation, slurry distribution, and temperature. If the hybrid slurry supply system is applied to APC, the efficiency of the CMP process can be improved further by controlling both the chemical and mechanical factors.

Author Contributions

Conceptualization, D.S.L. and H.S.L.; methodology, D.S.L.; validation, D.S.L. and H.J.; investigation, D.S.L. and H.J.; data curation, D.S.L. and H.J.; writing—original draft preparation, D.S.L. and H.J.; writing—review and editing, H.J.; visualization, H.J. and S.H.J.; supervision, H.D.J. and H.S.L.; project administration, H.D.J. and D.S.L.; funding acquisition, H.D.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIP) (No. 2019R1A2B5B01070489 and NRF-2018R1D1A1B07043169) and BB21+ Project in 2020.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lee, H.; Park, S.; Jeong, H. Evaluation of environmental impacts during chemical mechanical polishing (CMP) for sustainable manufacturing. J. Mech. Sci. Technol. 2013, 27, 511–518. [Google Scholar] [CrossRef]

- Lee, H.; Park, B.; Jeong, H. Mechanical effect of process condition and abrasive concentration on material removal rate profile in copper chemical mechanical planarization. J. Mater. Process Technol. 2009, 209, 1729–1735. [Google Scholar] [CrossRef]

- Davis, S.; Holland, K.; Yang, J.; Fury, M.A.; Shon-Roy, L. The era of IoT advancing CMP consumables growth. In Proceedings of the 2015 International Conference on Planarization/CMP Technology (ICPT), Chandler, AZ, USA, 30 September–2 October 2015. [Google Scholar]

- Jeong, J.; Lee, H.; Lee, D.; Jeong, H. Effect of Hydrogen Peroxide and Oxalic Acid on Material Removal in Al CMP. J. Korean Soc. Precis. Eng. 2017, 34, 307–310. [Google Scholar] [CrossRef]

- Jang, S.; Jeong, H.; Yuh, M.; Park, I.; Park, J. Effect of glycine on copper CMP. Int. J. Precis. Eng. Manuf. 2016, 3, 155–159. [Google Scholar] [CrossRef]

- Lee, Y.; Seo, Y.; Lee, H.; Jeong, H. Effect of diluted colloidal silica slurry mixed with ceria abrasives on CMP characteristic. Int. J. Precis. Eng. Manuf. 2016, 3, 13–17. [Google Scholar] [CrossRef]

- Philipossian, A.; Mitchell, E. Slurry Utilization Efficiency Studies in Chemical Mechanical Planarization. Jpn. J. Appl. Phys. 2013, 42, 7259–7264. [Google Scholar] [CrossRef]

- Guo, Y.; Lee, H.; Lee, Y.; Jeong, H. Effect of pad groove geometry on material removal characteristics in chemical mechanical polishing. Int. J. Precis. Eng. Manuf. 2012, 13, 303–306. [Google Scholar] [CrossRef]

- Wu, C.; Sampurno, Y.; Liao, X.; Zhuang, Y.; Borucki, L.; Theng, S.; Philipossian, A. Effect of Pad Groove Design on Slurry Injection Scheme during Interlayer Dielectric Chemical Mechanical Planarization. ECS J. Solid State Sci. Technol. 2015, 4, P272–P276. [Google Scholar] [CrossRef][Green Version]

- Bengochea, L.V.; Sampurno, Y.; Stuffle, C.; Sudargho, F.; Han, R.; Philipossian, A. Effect of Retaining Ring Slot Designs, Conditioning Discs and Conditioning Schemes on the Slurry Bow Wave Width during Chemical Mechanical Planarization. ECS J. Solid State Sci. Technol. 2018, 7, P253–P259. [Google Scholar] [CrossRef]

- Philipossian, A.; Borucki, L.; Sampurno, Y.; Zhuang, Y. Novel Slurry Injection System for Improved Slurry Flow and Reduced Defects in CMP. Solid State Phenom. 2015, 219, 143–147. [Google Scholar] [CrossRef]

- Fujita, T.; Watanabe, J. Slurry Supply Mechanism Utilizing Capillary Effect in Chemical Mechanical Planarization. ECS J. Solid State Sci. Technol. 2019, 8, P3069–P3074. [Google Scholar] [CrossRef]

- Mu, Y.; Han, R.; Sampurno, Y.; Zhuang, Y.; Borucki, L.; Philipossian, A. Mean Residence Time and Dispersion Number Associated with Slurry Injection Methods in Chemical Mechanical Planarization. ECS J. Solid State Sci. Technol. 2016, 5, P155–P159. [Google Scholar] [CrossRef]

- Diaz, G.; Sampurno, Y.; Theng, S.; Philipossian, A. Inferences of Slurry Bow Wave Width from Mean Coefficient of Friction and Directivity in Chemical Mechanical Planarization. ECS J. Solid State Sci. Technol. 2018, 8, P3018–P3021. [Google Scholar] [CrossRef]

- Saka, N.; Lai, J.; Chun, J.; Sun, N.P. Mechanisms of the Chemical Mechanical Polishing (CMP) Process in Integrated Circuit Fabrication. CIRP Ann. Manuf. Technol. 2001, 50, 233–238. [Google Scholar] [CrossRef]

- Park, B.; Kim, Y.; Kim, H.; Jeong, H.; Dornfeld, D.A. Effect of ceria abrasives on planarization efficiency in STI CMP process. ECS Trans. 2009, 19, 51–59. [Google Scholar] [CrossRef]

- Vasilev, B.; Bott, S.; Rzehak, R.; Liske, R.; Bartha, J.W. A method for characterizing the pad surface texture and modeling its impact on the planarization in CMP. Microelectron Eng. 2013, 104, 48–57. [Google Scholar] [CrossRef]

- Lee, S.Y.; Lee, S.H.; Park, J.G. Interaction Forces Between Silica Particles and Wafer Surfaces during Chemical Mechanical Planarization of Copper. J. Electrochem. Soc. 2003, 150, 327–332. [Google Scholar] [CrossRef]

- Park, C.; Kim, H.; Cho, H.; Lee, T.; Kim, D.; Lee, S.; Jeong, H. Effect of Relative Surface Charge of Colloidal Silica and Sapphire on Removal Rate in Chemical Mechanical Polishing. Int. J. Precis. Eng. Manuf. 2019, 6, 339–347. [Google Scholar] [CrossRef]

- Wang, J.; Niu, X.; Liu, Y.; Wang, C.; Yang, S.; Zhang, K.; Xu, Y.; Ma, T.; Zhang, W. Improvement of Barrier CMP Performance with Alkaline Slurry: Role of Ionic Strength. ECS J. Solid State Sci. Technol. 2018, 7, 462–467. [Google Scholar] [CrossRef]

- Hernandez, J.; Wrschka, P.; Oehrlein, G.S. Surface Chemistry Studies of Copper Chemical Mechanical Planarization. J. Electrochem. Soc. 2001, 148, 389–397. [Google Scholar] [CrossRef]

- Guo, X.; Wang, X.; Jin, Z.; Kang, R. Atomistic mechanisms of Cu CMP in aqueous H2O2: Molecular dynamics simulations using ReaxFF reactive force field. Comput. Mater. Sci. 2018, 155, 476–482. [Google Scholar] [CrossRef]

- Qin, K.; Moudgil, B.; Park, C. A chemical mechanical polishing model incorporating both the chemical and mechanical effects. Thin Solid Films 2004, 446, 277–286. [Google Scholar] [CrossRef]

- Chen, J.; Shi, J.; Wang, Y.; Sun, J.; Han, J.; Sun, K.; Fang, L. Nanoindentation and deformation behaviors of silicon covered with amorphous SiO2: A molecular dynamic study. RSC Adv. 2018, 8, 12597–12607. [Google Scholar] [CrossRef]

- Lee, D.; Lee, H.; Jeong, H. The effects of a spray slurry nozzle on copper CMP for reduction in slurry consumption. J. Mech. Sci. Technol. 2015, 29, 5057–5062. [Google Scholar] [CrossRef]

- Kwon, D.; Kim, H.; Jeong, H. Heat and its effects to chemical mechanical polishing. J. Mater. Process Technol. 2006, 178, 82–87. [Google Scholar] [CrossRef]

- Sorooshian, J.; Hetherington, D.; Philipossian, A. Effect of Process Temperature on Coefficient of Friction during CMP. ECS Solid State Lett. 2004, 7, 222–224. [Google Scholar] [CrossRef]

- Mudhivarthi, S.; Gitis, N.; Kuiry, S.; Vinogradov, M.; Kumar, A. Effects of Slurry Flow Rate and Pad Conditioning Temperature on Dishing, Erosion, and Metal Loss during Copper CMP. J. Electrochem. Soc. 2006, 153, 372–378. [Google Scholar] [CrossRef]

- Lee, H.; Park, Y.; Lee, S.; Jeong, H. Preliminary study on the effect of spray slurry nozzle in CMP for environmental sustainability. Int. J. Precis. Eng. Manuf. 2014, 15, 995–1000. [Google Scholar] [CrossRef]

- Shiu, S.J.; Yu, C.C.; Shen, S.H. Multivariable control of multizone chemical mechanical polishing. J. Vac. Sci. Technol. B 2004, 22, 1679–1687. [Google Scholar] [CrossRef]

- Lee, C.; Park, J.; Kinoshita, M.; Jeong, H. Development of intelligent pad monitoring system and application to analysis of pressure distribution in chemical mechanical polishing process. Int. J. Precis. Eng. Manuf. 2014, 15, 2005–2009. [Google Scholar] [CrossRef]

- Lee, S.; Jeong, S.; Park, K.; Kim, H.; Jeong, H. Kinematical Modeling of Pad Profile Variation during Conditioning in Chemical Mechanical Polishing. Jpn. J. Appl. Phys. 2009, 48, 126502. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).