Abstract

Container terminals are the main hubs of the global supply chain but, conversely, they play an important role in energy consumption, environmental pollution and even climate change due to carbon emissions. Assessing the environmental impact of this type of port terminal and choosing appropriate mitigation measures is essential to pursue the goals related to a clean environment and ensuring a good quality of life of the inhabitants of port cities. In this paper the authors present a Terminal Decision Support Tool (TDST) for the development of a container terminal that considers both operation efficiency and environmental impacts. The TDST provides environmental impact mitigation measures based on different levels of evolution of the port’s container traffic. An application of the TDST is conducted on the Port of Augusta (Italy), a port that is planning infrastructural interventions in coming years in order to gain a new role as a reference point for container traffic in the Mediterranean.

1. Introduction

The recent globalization process has deeply influenced the maritime transport industry, which experienced technological breakthroughs giving rise to containerization and other developments in cargo-handling facilities [1]. Such growth of containerization requires the optimal design of container seaport terminals not only in terms of requirements of space for activities, but also in terms of operations and related equipment. Of course, in the case of port cities such a growth of container units affects the relationship with the close urban areas: the added value created by ports can be mainly attributed to the economic benefits related to the crucial role played by container terminals in global supply chains [2]; while negative impacts are determined by several factors, such as the influence on the environment and the quality of life of a port city’s residents [3].

While the evaluation of the performance of the ports in terms of freight transport efficiency is now fairly standardized worldwide, environmental evaluation standards and tools are still not harmonized and there is no standard procedure for the evaluation of environmental sustainability of port operations [4]. Stojaković and Twrdy [5] developed a Decision Support Tool (DST) that helps terminal operators to determine which part of the terminal should be optimized in order to receive a desired ship size in the port. Nevertheless, nowadays it is no longer conceivable to think about the optimization without considering the impact that each stage of development has on the environment. In this regard both the International Maritime Organization and European Union bodies provide some important guidelines that should be considered before planning any port expansion [6,7,8,9,10].

Several documents and guidelines provide solutions to issues and impacts of environmental pollution caused by maritime transport in port areas; such documents usually aim to solve immediate problems, without focusing on a global approach to tackle with the different environmental issues. Based on this premise, this paper aims at proposing an integration of the evaluation of freight transport efficiency and environmental sustainability within commercial ports through an innovative Terminal DST (TDST) for the planning of a container terminal. The TDST takes into account both optimization of the efficiency terminal, considering the necessary equipment in the event of an increase in freight traffic, and the consequent environmental impacts.

The TDST has been tested on the case study of the port of Augusta, evaluating environmental issues in terms of climate change evaluation, noise pollution assessment and dredging impacts, in order to provide a suggestion for actions and measures for its future development. Nevertheless, the methodology is scalable to ports of different sizes and locations that want to optimize their container terminal capacity.

The remainder of the paper is organized as follows: in the following section state of the art is presented; then the methodology’s steps are illustrated; in the fourth section the methodology is applied to the Port of Augusta; finally, some recommendations for improving environmental issues are given and conclusions are drafted.

2. Literature Review

Efficient container terminals are considered the key factor for success of third generation of ports, due to the cost-effectiveness of transport and the specialization and efficient organization in the associated terminals [11].

An efficient planning of container terminals, considering the allocation of equipment, fuels and facilities is vital to achieving the climate and environmental goal of green port construction [12]. Traditional studies of port emissions are generally applied to existing solution. In this respect, several scholars developed different models in order to evaluate the environmental performance of container terminal. Sakhi et al. [13] evaluated environmental performance of container terminals in term of CO2, SO2, NOx and particle emissions with a model based on French standards and guidelines for emissions evaluations and applied it to the port of Tanger Med; Dong et al. [14] developed a tool based on DEA (Data Envelopment Analysis) to evaluate environmental and operational performance of containers port in terms of CO2 emissions and TEUs (twenty-foot equivalent units); Van Duin and Geerlings [15] and Sim [16] developed simple models to estimate CO2 emissions in container terminals based on type of equipment and transport mode.

Kegalj et al. [4] estimated a composite environmental index and applied it to the container terminal of the Port of Rijeka based on analytic hierarchy process evaluation of several environmental indicators (air and noise emissions, waste, energy consumption, water quality). Martinez-Moja et al. [16] developed a model for the evaluation of energy efficiency and CO2 emissions of port container terminal equipment.

A literature review shows that there are few studies focusing on the planning of the terminal, and very few papers focus on a comprehensive analysis of environmental issues due to port operation. Based on this premise, in this study the authors decided to propose a simplified framework to help port decision-makers in deciding the best infrastructure provisions to foster the efficiency of container terminals without neglecting environmental impacts.

In summary, our framework is intended to help decision makers answer the question: how should container terminals equip themselves to achieve new container traffic objectives and how can they limit the environmental effects that would be generated by these new port operations? The authors answered to this question by proposing a simplified terminal decision-making tool and showed its use by applying it in the case of the Port of Augusta.

3. Materials and Methods

The methodology will follow these different steps:

- Description of terminal optimization model

- Environmental evaluations and measures to reduce environmental impact

- Definition of a TDST framework

3.1. Terminal Optimization Model

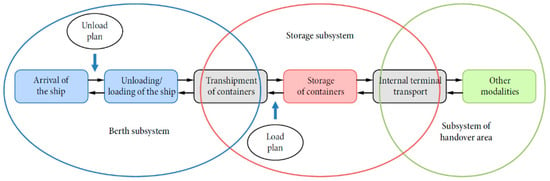

The terminal optimization model is based on a DST to enable container terminals to keep up with the increasing size of container ships, fully developed in Stojaković and Twrdy [5], taking into account the different processes occuring at a container terminal in all the subsystems (Figure 1); the optimization DST is an analytic interactive tool to aid decision-makers in understanding which are the parts of the container terminal that need to be optimized for the reception of a container ship with a desired size. The tool is composed of a flow chart with 6 decision elements that allows us to determine the correct sizing of the terminal components, knowing the capacity of container ships to be received and the characteristics that it requires at the terminal: sea depth evaluation and its potential deepening; optimal quay length assessment; adequate number of quay cranes purchased; size and possible extension of the storage area; land equipment at storage subsystem; connections with hinterland and their optimization. The DST has been tested for 12 ports covering the Black Sea, the western and eastern part of the Mediterranean, for the acceptance of both one and two vessels with 6000 TEUs capacity. For a detailed description of the DST please consult Stojaković and Twrdy [5].

Figure 1.

Processes at a container terminal [5].

In this paper, the DST developed in Stojaković and Twrdy [5] will be enhanced by the introduction of environmental evaluations and measures to reduce environmental impact.

3.2. Environmental Evaluations and Measures to Reduce Environmental Impact

Each year the European Sea Ports Organisation (ESPO) defines the top 10 high priority environmental issues on which ports are working and sets the framework for guidance and initiatives [6]. The issues are the following: (1) air quality, (2) energy consumption, (3) noise, (4) relationship with the community, (5) ship waste, (6) port development (land), (7) climate change, (8) water quality, (9) dredging operations, (10) garbage disposal (ESPO, 2018). Most of such environmental issues may arise in each of the processes described for the container terminal. In particular, (1) (2) (3) (4) (7) occur in all of the processes, while (5) (8) (9) are more related to the berth subsystem, and (6) (10) to the storage subsystem.

Notwithstanding the importance of all of the aforementioned environmental issues, in this paper we decided to analyse port-related issues that occur due to the realization of a new terminal and the consequent new port operations and that could be computed through an analytic approach: in particular, we decided to exclude social-related issues (e.g., (4) and (6)), and, for the sake of simplicity, we analysed more in-depth air pollution (with a particular focus on climate change emissions), noise pollution and dredging issues, as described in the following.

3.2.1. Air Pollution and Climate Change

Maritime transport emits around 940 million tonnes of CO2 annually and is responsible for about 2.5% of global greenhouse gas (GHG) emissions [10]. Road transport is still the biggest emitter of GHG emissions, and it must be noted its fundamental role when it comes to maritime freight transportation in the final door-to-door delivering service to companies. Carbon emissions are produced at all the stages of container processing, since the arrival of the ship at the port to the final delivery operation by container trailers from port to the hinterland facilities and vice versa. Scholars developed different models to estimate emissions at port terminal facilities, most of which depend on energy used by each mode (kWh or fuel consumption) and emission factors related to each pollutant [17]. These types of methodologies are applicable to any polluting emission into the atmosphere. In the case of CO2 emissions at container terminals, which we decided to analyse more in depth in our paper, a specific methodology is that elaborated by Sim [18]. In Sim [18], total carbon emissions at the container terminal are calculated by the summation of carbon emissions from vessel maneuver, vessel at berth, container loading and unloading, container transportation, and container receiving and delivery. Each of these factors is evaluated according to carbon emission density of vessel/equipment (depending on the activity type) and the amount of containers in TEU, according to Equation (1) [18]:

where:

- -

- CEDi = carbon emission density per activity type (kg O2 – e/TEU)

- -

- TEU = the transported amount of containers

In general, most effective measures of mitigation for air pollutants are those related to the use of alternative fuels for ship propulsion [17,19]. However, site-based measures can be effective at reducing the impact for local communities, e.g., in the case of shore side electrical power (also known as cold ironing), providing an alternative power source to their own engines for vessels at berth; this might be considered a long-term solution with considerable costs of realization. Other economic measures might be effective, such as tax rewards and bonuses for vessels with clean fuel, even if it is important to have that port administrators find stakeholders’ support in its implementation. The first step is, however, the installation of monitoring station to constantly evaluate emissions and air quality.

3.2.2. Noise Pollution

The operational noise assessment considers the noise generated by the container ship entering the port and when berthed, its loading or offloading, and noise from associated container handling plant and vehicles, and impacts on residential properties in the immediate vicinity of the container terminal. Sound power levels according to type of ships can be estimated according to a regression line developed by Witte [20]. The evaluation of noise associated to yard activities (container handling, cranes, vehicles, auxiliary equipment, etc.) requires the knowledge of sources’ location and height, working hours and sound power level. Such data can be obtained by means of direct noise measurements or by using default values and available noise source databases, to be validated with a following direct measurement. Also, traffic-related noise for hinterland delivery should be taken into account; it is mainly influenced by the location of roads and road surface (e.g., asphalt, bricks) and traffic volume and speed in the case of road traffic; location of railway traffic volume, average speed, rail support (wooden or concrete sleepers, etc.) and data on rail tracks (joined rail, switches and crossings, etc.) for rail traffic. Models for noise pollution impact on port communities usually takes into account the sound pressure levels and the distance between the port and the urban area [17]. In this paper we made reference to the formula provided by Lloyd’s Register [21], according to Equation (2):

where:

- -

- Lp: sound pressure level in the receiving position, dB

- -

- Lw: sound power level of source, dB

- -

- r: distance between the source and receiver

Mitigation measures for noise impacts might be related to all the port subsystems [22]. Low noise driving training for drivers (ECO-driving) might be a low-cost solution; yard planning (e.g., moving the noisiest activities away from the port border) and change working period hours (e.g., avoiding nighttime operations) might improve impact in port communities; finally, technological measures, such as isolation of sound intensive components and use of softer grounds in terminal building, might result in an effective mitigation.

3.2.3. Dredging Impacts

In the process of designing a new container terminal, dredging is fundamental since water deepening might be required. Costs and methods of disposal will be influenced by the type of dredged material: it can be re-used in reclamation processes (e.g., for industry, roads or housing); sand is the most suitable material together with all granular materials, while clay is generally only suitable as agricultural fill [23]. The method of disposal also depends on the contamination potential of the sediments and an impact assessment should be carried out also in the case of clean material, since the removal of the material in itself has many potential impacts on the environment. Moreover, the method of removal has many potential impacts, such as the creation of a dust plume blocking the sunlight and choking fishes, the dispersion of fines in the water column, the eventual use of blasting techniques, killing marine life indiscriminately in the vicinity of the project.

Impacts of dredging disposal can be minimized by ensuring that the dredged material and the sediments in the receiving area are similar. Of course, monitoring is important to assess impacts and compliance with permit requirements and the condition and changes in the condition of the receiving area.

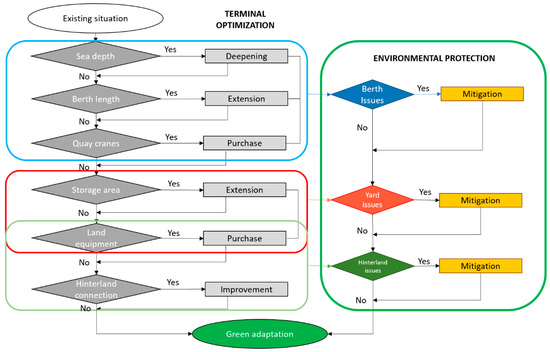

3.3. Definition of a Terminal Decision Support Tool (TDST) Framework

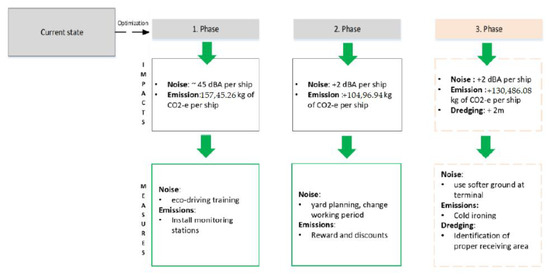

The comprehensive TDST framework includes both the terminal optimization tool described in Section 3.1 (on the left side) and environmental protection evaluation and mitigation measures presented in Section 3.2 (on the right side). The DST, starting from the one developed in [5], takes into account environmental issues and mitigation measures as described in the previous section (Figure 2).

Figure 2.

Comprehensive Decision Support Tool (DST) framework.

4. Case Study Application: Towards an Efficient Terminal Container in the Port of Augusta

4.1. Territorial Framework

The situation of ports in Italy has evolved in recent years, particularly from an administrative point of view. In particular, since 2016, the government promoted a rationalization of port management with the introduction of 15 Port Systems Authorities, decision-making centres grouping together different ports considered part of the same territorial system from the point of view of sea traffic; if one single port authority can address the planning and operation of several ports, optimization and performance can be increased through an effective division of tasks. Such division allows the specialization of each port of the systems, such in the case of the Eastern Sicily Port System, which includes the two ports of Catania and Augusta: the first one is a commercial port located close to the city centre, with increasing freight traffic in the last few years but suffering a lack of space for further expansion; the second one is mainly an industrial port with large spaces whose commercial activity has been steady for years and which can be seen as a possible area for development of the maritime transport of goods of Eastern Sicily, starting indeed from container traffic. The Port of Augusta is currently more focused on its industrial activity (being the third port in Italy for liquid bulk), and it is the one with the highest city–port distance [24], which makes it a good candidate to become a major trading port, due to the lower impact that operation at terminal would have on the closest urban community. The upgrade of an effective terminal container in a port that for a long time has been in a deadlock situation should be planned to guarantee freight handling optimization, but must also pass through more sustainable scenarios in line with European Union policies [25,26]. The current situation of the Easter Sicily Port System sees the port of Catania mainly focused on roll on–roll off (Ro-Ro) traffic, which is currently its main business. The future plans cover the shift of container traffic to Augusta where large areas are available and rapid development is possible. In this sense, the upgrade of an effective container terminal in a port that for a long time has been in a deadlock situation represents a great opportunity to relieve the port of Catania and increase container volume, making the terminal the most important one in Sicily. This could allow the port system to cover both segments within the Mediterranean Short Sea Shipping market [27] and to try to gain a role in international maritime traffic. In order to achieve that, an improvement of the current terminal capacities is needed, and attention should be paid to the consequent environmental impact.

4.2. The Port of Augusta in the Eastern Sicily Port System

The Eastern Sicily port system is a public body in charge of the management of the two Sicilian ports of Catania and Augusta. The Port of Catania, a medium-sized city of about 300.000 inhabitants, is an international seaport with a high proximity to the city centre, the airport, the railway station and the main logistic centres. This proximity makes the port of Catania home to a mixed use of its space, ranging from cruise, leisure, yachting activities, vessels’ construction, Ro-Ro and container freight traffic. The Port of Augusta, a small city of about 35.000 inhabitants, is one of the Strategic Ports of the European Union of the TEN-T (Trans-European Transport Network) "CORE" network and the largest natural harbour in the lower Mediterranean area. It is location is very close to an important petroleum centre and a big portion of its harbour is reserved to the industrial port. The port also counts on a military base, a Ro-Ro Terminal, a container terminal and a port/city (Figure 3).

Figure 3.

Port of Augusta layout (source: https://www.adspmaresiciliaorientale.it/porto-di-augusta/. accessed on 28 February 2021).

Currently, the only container traffic managed by the Eastern Sicily Port System is held by the Port of Catania and it amounts at 59.746 TEUs/year. The terminal business includes among its clients Maersk, CMA CGM, ZIM and Tarros line services connecting Catania to Italian and Mediterranean ports. Nevertheless, the ship capacity in those services does not exceed 1300 TEU, meaning that the port operates as a small feeder port of regional importance. As mentioned in the introduction, due to the lack of space in the port of Catania, the port of Augusta will undertake the major container traffic, which makes its level of development of crucial importance to preserve the current business and for future plans. The current capacities of the Augusta container terminal are presented in the next section.

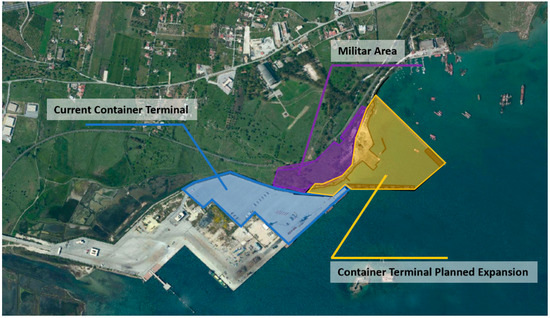

4.3. Container Terminal Characteristics and Future Projects

Even though the utilization of the container terminal in the port of Augusta is currently very low, it has huge development possibilities. The biggest advantage of the terminal are its exceptional conditions at the berth and the storage subsystem which makes the acceptance of larger ships possible. At the moment the infrastructural conditions are sufficient to enable the reception of ships that currently are calling at the port of Catania, nevertheless the terminal lacks of appropriate mechanization and good hinterland connections. The detailed characteristics are presented in Table 1, Figure 4 and Figure 5.

Table 1.

Port of Augusta container terminal characteristics.

Figure 4.

Current layout of terminal container and planned expansion (own elaboration).

Figure 5.

Hinterland connection opportunities.

The terminal is currently connected to the hinterland by an arterial road linked to the A44 Highway, which gives access to the main logistic centres currently located close to the city of Catania. The port operational plan also outlines a future railway connection with the single rail track connecting the port to the railway logistic terminal Catania Bicocca.

Infrastructure developments from the three-year port operational plan for 2019–2021 [28] outline an expansion strategy for the container terminal of the Port of Augusta (with a current size of about 100.000 m2), of which some work yards are already active; the expansion is structured in different phases and forecasts a total increase of about 116.000 m2 (Figure 4).

This would give the terminal the possibility to increase its capacity and obtain new services, including those with larger ships, which would give the port greater regional importance and the possibility to compete for wider hinterland area. In that case it could became a threat even for the port of Palermo of which traffic was in 2018 estimated at 15,962 TEU and at the moment represents the only competitor to the port of Catania in the container business.

5. Application and Results

The application of the framework to the case study of the port of Augusta is based on the following phases:

- Definition of three future scenarios for the container terminal;

- Results of the optimization model for the three scenarios;

- Simplified environmental impacts evaluation, focusing on CO2 emissions and noise pollution;

- Final DST framework for the Port of Augusta.

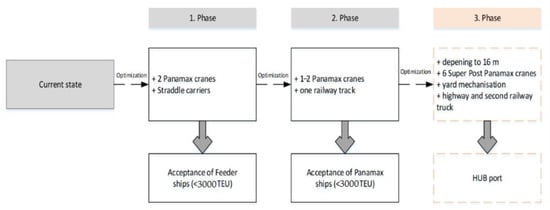

5.1. Possible Scenarios

The current berth capacities in the Augusta container terminal are limited to 1200 meters of quay length and 14 meters of draft, while ships are being served by 3 mobile cranes. Furthermore, the storage area is quite large and would enable the reception of large quantities of containers. Our aim is, therefore, to find out which are the optimization measures that the port will have to take to relieve the Catania container business and which are its further development possibilities. The proposed improvement measures have been divided into three phases according to the objective the port wants to achieve (Figure 4):

- Acceptance of feeder ships (< 3000 TEUs)

- Acceptance of Panamax ships (< 5000 TEUs)

- Hub configuration, acceptance of Post-Panamax ships (10,000 TEUs)

These phases are not selected after a demand forecast of the port but have been supposed as baseline for the DTS (aimed to enable container terminals to keep up with the increase in container ships’ size) in the case of a potential improvement of the port attractiveness, as supposed by the Port Authority in their plans.

All the calculation procedures have been performed using Excel software, while spatial representation of impacts is performed with QGIS software.

5.2. Terminal Equipment Results

The first improvement step of the port will have to be at the berth subsystem where at least two Panamax cranes would have to be purchased in order to enable the smooth reception of ship that are now calling Catania port and in case of necessity (acquisition of new services) also larger feeders up to 3000 TEU could be accommodate. Nevertheless, the terminal will still remain a small feeder terminal, so expensive and different land equipment would not be necessary at this stage. The most appropriate solution would therefore be straddle carriers that could be used for transfer purposes of containers from the berth subsystem to the storage area and vice versa as also for the final container stacking manipulations. In the second phase the berth subsystem and the subsystem of the handover area would have to be optimized in order to be able to accommodate Panamax ships up to 5000 TEU at the port. For that purpose, additional one or two Panamax cranes would have to be purchased and a railway track connecting the port to the hinterland zone would have to be constructed. Storage capacities would in that case be sufficient despite the arrival of larger ships and higher fluctuations of containers. This optimization phase would bring the port to the position of the leading container port in Sicily. In case the port operators would in the future want to make even a bigger leap and develop the port into a Hub port of the region, competing with Gioia Tauro and Marsaxlokk, the third optimization phase would be required. In that case the most challenging measures would have to be handled at the berth subsystem where deeper draft and Super Post-Panamax cranes would be needed in order to accommodate the largest ships exceeding 10,000 TEUs. Furthermore, different yard mechanization and enhanced road and rail connections would become a necessity. Nevertheless, this kind of investment in such a small terminal is not expected in the near future. However even a small improvement of the terminal (which would enable the reception of larger feeder ships), would bring significant growth that would increase the annual level (depending on the amount of weekly movements), and consequently greatly improve the ports position among its competitors.

Based on the framework in Figure 2, the optimization for the terminal has been conducted for the three scenarios; results are reported in Figure 6.

Figure 6.

Optimization model result for the three scenarios.

5.3. Environmental Evaluation

In this section an environmental evaluation has been conducted for the scenarios presented in the previous section in order to determine which measures should be undertaken by the Augusta container terminal in different development phases.

As already stated in Section 2, a first approximate environmental evaluation was conducted taking into consideration:

- -

- CO2 emissions for the three scenarios according to Sim [16];

- -

- noise pollution for the three scenarios according to Witte [20] and Lloyd’s Register [21];

- -

- dredging activities due to deepening.

5.3.1. CO2 Emissions

According to Sim (2018), the total CO2 emission at a container terminal CDCNTR can be calculated by the summation of carbon emissions from the processes of ship manoeuvre inside the port basin (CDCNTR;M), ship at berth (CDCNTR;B), container loading and unloading (CDCNTR;L), container transportation (CDCNTR;T) and container receiving and delivery (CDCNTR;R). Each of the total components are calculated according to Equation (1), in which carbon emission density of major vessel and equipment activities values are those estimated by Sim [16]. The results of total carbon emission for the terminal container of the Port of Augusta are reported in Table 2.

Table 2.

Results of total carbon emission for the terminal container of the Port of Augusta (kg).

5.3.2. Noise Pollution

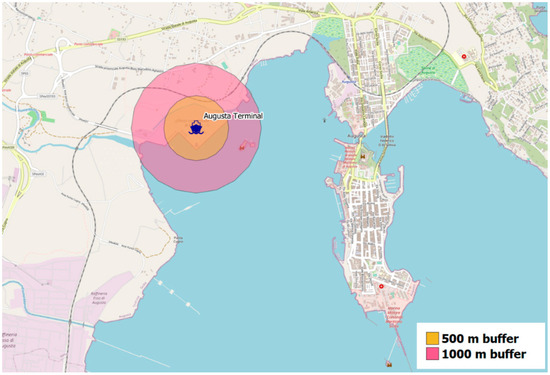

Sound pressure level in the receiving position (Lp) has been evaluated according to Lloyd’s Register (2010), with Lw based on regression line between DWT and sound power level for the different scenario’s ships [20]. The results for distance between the source and receiver of 500 m (LP500) and 1000 m (LP1000) in comparison to conservative limits for noise pollution (Lmax(dB(A))) according to the European legislation [8] are reported in Table 3.

Table 3.

Results of noise pollution for the terminal container of the Port of Augusta.

Results show that in any of the scenarios conservative limits for emissions are touched, but not overcome; moreover, as shown in Figure 7, the urban centre of the city of Augusta is located at distances greater than 1000 m, and the impact of noise emissions would be even lower. However, there are some small conurbations close to the port area which could be impacted by the operation; for this reason, it was nevertheless decided to include some measures to reduce noise emissions in the TDST.

Figure 7.

The 500 m and 1000 m buffers from the planned container terminal.

6. Discussion: An TDST Framework for the Container Terminal Port of Augusta

Based on the analysis of the environmental impacts and the possible mitigation measures presented in the previous sections, a proposal for the TDST with recommendation for the three phases of the case study is reported in Figure 8.

Figure 8.

Terminal Decision Support Tool’s (TDST) result for the three scenarios.

Scenario 1 (1. Phase) can be considered as a baseline scenario, since new operations never performed at the terminal are implemented. The start-up of the terminal’s activities will generate new CO2 and noise emissions: for these reasons, proper training of drivers on ECO driving behaviours and the installation of emission monitoring units are recommended as first mitigation measures. Scenario 2 (2. Phase) will see an increase in activities at the terminal and consequently in the related emissions; this will also translate into an increase in trade (and revenues) that could allow the implementation of more incisive mitigation measures, such as a different planning of the yard and a modification of working hours for the most impactful operations. Finally, in the Hub configuration, in addition to the implementation of even more incisive mitigation measures for noise and atmospheric emissions (softer ground at terminal and cold ironing), planning of the appropriate reception site for waste material due to dredging operations should be envisaged.

7. Conclusions and Future Research

In recent years, the maritime transport of freight has been undergoing an exponential growth, in particular thanks to the development of containerization. In order to maintain a good level of competitiveness, ports must necessarily equip their infrastructures and their terminals in order to receive container ships that are becoming increasingly large and to handle the goods transported efficiently. If the infrastructural improvement leads to an increase in port traffic, and therefore to a greater economic development of the region, it is important not to underestimate the environmental impact that these new port activities exert in the communities to which they belong, especially in the case of port cities.

This paper presents a comprehensive decision support framework for port terminal planning that aims at an efficient handling of goods transported by container ships, while guaranteeing a minimization of the environmental footprint linked to these port activities, calculating their impact. The framework was applied to the case study of the port of Augusta, whose administration is planning infrastructural improvements to allow it to enter the container traffic market. Different ship reception scenarios have been analyzed through the framework, with infrastructural improvements that allow the port to progressively accept Feeder and Panamax ships and also aspire to become a Hub port. The results of an initial analysis of the environmental impact carried out demonstrate an increase in CO2 emissions and noise emissions that will inevitably impact the community of the town of Augusta. Of course, a proper demand forecast for the port [29] would help to correctly estimate the environmental impact of future infrastructure projects. Attention should be paid also to other impacts that have not been investigated in depth in this paper (e.g., waste and garbage disposal); in future research a qualitative approach could be developed to take into account social-related issues concerning the construction of a new container terminal. Moreover, a proper estimation of economic costs for both new terminal equipment and infrastructure and environmental measures should be performed to verify the balance with the benefits associated to the improvements. However, the adoption of this simplified framework to the case study provides a first suggestion of impact mitigation measures that can be of help to port administrators in making their own decisions.

Author Contributions

Conceptualization, N.G., M.S., E.T., M.I.; methodology, N.G., M.S., E.T., M.I.; software, N.G., M.S.; data curation, N.G., M.S.; writing—original draft preparation, N.G., M.S.; writing—review and editing, N.G., M.S., E.T., M.I.; supervision, E.T., M.I.; funding acquisition, M.I. All authors have read and agreed to the published version of the manuscript.

Funding

The work has been partially financed by the project “THALASSA–Technology and materials for safe low consumption and low life cycle cost vessels and crafts” (unique project code CUP B46C18000720005) under the programme “PON Ricerca e Innovazione 2014–2020”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available from the authors upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Olivier, D.; Slack, B. Rethinking the Port. Environ. Plan. A Econ. Space 2006, 38, 1409–1427. [Google Scholar] [CrossRef]

- Urbanyi-Popiołek, I.; Klopott, M. Container terminals and port city interface–a study of Gdynia and Gdańsk ports. Transportation Research Procedia 2016, 16, 517–526. [Google Scholar] [CrossRef]

- Merk, O. The Competitiveness of Global Port-Cities: Synthesis Report. In OECD Regional Development Working Papers; OECD: Paris, France, 2013. [Google Scholar]

- Kegalj, I.; Traven, L.; Bukša, J. Model of calculating a composite environmental index for assessing the impact of port processes on environment: A case study of container terminal. Environ. Monit. Assess. 2018, 190, 591. [Google Scholar] [CrossRef] [PubMed]

- Stojaković, M.; Twrdy, E. A Decision Support Tool for Container Terminal Optimization Within The Berth Subsystem. Transport 2015, 31, 29–40. [Google Scholar] [CrossRef]

- ESPO. Environmental Report: EcoPortsinSights 2020. Available online: https://www.espo.be/media/Environmental%20Report-WEB-FINAL.pdf> (accessed on 28 February 2020).

- MARPOL. International Convention for the Prevention of Pollution from Ships (MARPOL). 1978. Available online: http://www.mar.ist.utl.pt/mventura/Projecto-Navios-I/IMO-Conventions%20%28copies%29/MARPOL.pdf (accessed on 28 February 2020).

- EC—European Commission. Handbook for the Implementation of EC Environmental Legislation. Section 9—Noise Pollution; EC: Brussels, Belgium, 2008. [Google Scholar]

- EEA. Greenhouse Gas Emissions from Transport in Europe. 2019. Available online: https://www.eea.europa.eu/data-and-maps/indicators/transport-emissions-of-greenhouse-gases/transport-emissions-of-greenhouse-gases-11 (accessed on 16 December 2019).

- EC—European Commission. Maritime. What Do We Want to Achieve? EC: Brussels, Belgium, 2020. [Google Scholar]

- UNCTAD. Port Marketing and the Challenge of the Third Generation Port; Trade and Development Board Committee on Shipping ad hoc Intergovernment Group of Port Experts; UNICTAD: Geneva, Switzerland, 1994. [Google Scholar]

- Peng, Y.; Wang, W.Y.; Song, X.Q.; Zhang, Q. Optimal allocation of resources for yard crane network management to mini-mize carbon dioxide emissions. J. Clean. Prod. 2016, 131, 649–658. [Google Scholar] [CrossRef]

- Sakhi, F.E.; Allal, A.A.; Mansouri, K.; Qbadou, M. Toward a Study of Environmental Impact of the Tangier Med Port Container Terminals. In Proceedings of the Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2019; pp. 222–235. [Google Scholar]

- Dong, G.; Zhu, J.; Li, J.; Wang, H.; Gajpal, Y. Evaluating the Environmental Performance and Operational Efficiency of Container Ports: An Application to the Maritime Silk Road. Int. J. Environ. Res. Public Heal. 2019, 16, 2226. [Google Scholar] [CrossRef] [PubMed]

- Van Duin, J.; Geerlings, H. Estimating CO2footprints of container terminal port-operations. Int. J. Sustain. Dev. Plan. 2011, 6, 459–473. [Google Scholar] [CrossRef]

- Martínez-Moya, J.; Vazquez-Paja, B.; Maldonado, J.A.G. Energy efficiency and CO2 emissions of port container terminal equipment: Evidence from the Port of Valencia. Energy Policy 2019, 131, 312–319. [Google Scholar] [CrossRef]

- Ignaccolo, M.; Giuffrida, N.; Inturri, G. Environmental Sustainability of Ports: Top Issues, Approaches and Mitigation Strategies; PORTUSplus. 9; RETE: Venice, Italy, 2020. [Google Scholar]

- Sim, J. A carbon emission evaluation model for a container terminal. J. Clean. Prod. 2018, 186, 526–533. [Google Scholar] [CrossRef]

- Smith, T.W.; Jalkanen, J.P.; Anderson, B.A.; Corbett, J.J.; Faber, J.; Hanayama, S.; O’keeffe, E.; Parker, S.; Johanasson, L.; Aldous, L.; et al. Third IMO GHG Study; IMO: London, UK, 2015. [Google Scholar]

- Witte, J. Noise from moored ships. In INTER-NOISE and NOISE-CON Congress and Conference Proceedings; Institute of Noise Control Engineering: Reston, VA, USA, 2010; pp. 3202–3211. [Google Scholar]

- Lloyd’s Register, O.D.S. Noise from Ships in Ports: Possibilities for Noise Reduction; Danish Environmental Protec-tion Agency: København, Denmark, 2010. [Google Scholar]

- Van Breemen, T. Good Practice Guide on Port Area Noise Mapping and Management, Noise Management in European Ports (NoMEPorts) Project; EC: Brussels, Belgium, 2008; pp. 44–50, LIFE05 ENV/NL/000018. [Google Scholar]

- Sciortino, J.A. Fishing Harbour Planning, Construction and Management; Food and Agriculture Organization of the United Nations: Rome, Italy, 2010. [Google Scholar]

- Russo, F.; Musolino, G. Quantitative characteristics for port generations: The italian case study. Int. J. Transp. Dev. Integr. 2020, 4, 103–112. [Google Scholar] [CrossRef]

- Ignaccolo, M.; Inturri, G.; Giuffrida, N.; Torrisi, V.; Cocuzza, E. Sustainability of freight transport through an inte-grated approach: The case of the eastern sicily port system. Transportation Research Procedia 2020, 45, 177–184. [Google Scholar] [CrossRef]

- Giuffrida, N.; Ignaccolo, M.; Inturri, G.; Torrisi, V. Port-City Shared Areas to Improve Freight Transport Sus-tainability. In International Conference on Computational Science and Its Applications; Springer: Cham, Switzerland, 2020; pp. 67–82. [Google Scholar]

- Russo, F.; Musolino, G.; Assumma, V. Competition between ro–ro and lo–lo services in short sea shipping market: The case of Mediterranean countries. Res. Transp. Bus. Manag. 2016, 19, 27–33. [Google Scholar] [CrossRef]

- Adsp Sicilia Orientale. Piano Operativo Triennale 2019–2021. 2020. Available online: http://ww2.gazzettaamministrativa.it/opencms/export/sites/default/_gazzetta_amministrativa/amministrazione_trasparente/_sicilia/_autorita___di_sistema_portuale_del_mare_di_sicilia_orientale/190_pia_gov_ter/2020/Documenti_1596614703113/1596614703699_pot_2019_2021_revisone_annuale_2020.pdf (accessed on 28 February 2020).

- Russo, F.; Musolino, G.; Assumma, V. An integrated procedure to estimate demand flows of maritime container transport at international scale. Int. J. Shipp. Transp. Logist. 2014, 6, 112. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).