Abstract

This study focuses on the development of new methodological approaches to dust-preparation and burning of separated particles, including through the use of polyfractional ensembles. Coal dust screening by means of sieve analysis is described in standard methods. However, in order to further use the results obtained during mathematical modeling of particle motion in fuel-air mixture and exothermal reactions of oxidation while burning in a torch, it must be possible to differentiate and integrate continuous functions. The methodology is based on the continuity of particle motion in a mixture with air in the calculation of aerodynamic and heat-mass exchange processes in a torch. The paper employs new scientific approaches to transforming and normalizing a continuously differentiable function described by the Gauss curve. We propose to combine mathematical modeling of such functions with methods of approximation of piece-linear functions developed by Professor S. V. Aliukov. The implementation of such methods helps reduce calculation errors of particle size and deviations thereof from average equivalent diameter and to avoid the Gibbs effect while differentiating. The paper contains analytical calculations based on the proposed method and experimental data. Quantitative and qualitative results of comparing analytical and experimental data are also presented. We provide recommendations on the further use and extension of the range of the results obtained in a computer simulation of fuel production and burning processes in a torch.

1. Introduction

1.1. Information about Developments in the Scientific Field of Coal Dust Sieving and Its Further Combustion

Scientists around the world have studied the processes of burning and producing solid fuel. The most comprehensive overview of the preparation of coal dust at thermal power stations can be found in [1]. One of the main conditions for effective and high-quality burning of solid fuel is taking its polyfractional composition into account, which can be confirmed by mathematical models presented in [2]. The presence of a sufficient amount of oxygen as an oxidizing agent and the fineness of grinding are mentioned in [3]. There are various models of burning [4], screening, and preparing solid fuel [1,5]. Moreover, we should not forget the basics of practical combustion theory [6], which were developed alongside studies in mathematical modeling [3]. The lack of natural gas in separate coal-producing countries gave rise to the development of new methodological approaches to the screening and burning of lignites. One of the major works in this field is [7], which also first raised the problem of dust screening and approximation of the results obtained, which later was reflected in the aforementioned source [1]. Modern computer programs of mathematical modeling of coal dust burning take into account thermal and physical characteristics of fuel and average equivalent particle size. It also should be noted that existing software provides an understanding of the temperature field distribution, velocities and concentrations which are connected with known dependences [3,4], although accuracy and validity of the results obtained does not always satisfy the criteria necessary for the initial design of a boiler unit or to make changes to the dust production system. In any case, it is necessary to conduct experiments and compare them with the results of computer modeling. The authors of [8] mention that it is impossible to implement standard methods with coal particles after micro-grinding, which can be proved by the experimental results [9]. The same scholars propose to take into account the influence of particle size on the absolute ignition temperature according to the well-known equation [9] based on the law of conservation of energy which can be employed for a single particle:

where: is the mass of a single particle, kg, is the heat capacity of a particle, J/(kg·K), is the equivalent size of a particle (a radius in this case), m, is the absolute temperature on the particle surface, K, ε is the degree of particle blackness, σ is the Stefan-Boltzmann constant, W/( m2·K4), is the convective heat transfer coefficient, W/( m2·K), is the absolute temperature of gas medium, K, is the absolute temperature of the radiation volume, K, Q is the specific thermal effect of oxidation of carbon residue, J/kg, H is the oxidation rate of carbon residue, kg/sec.

1.2. Current Hypotheses and Their Confirmation by Researchers

The L. Rosendahl research, conducted relatively recently, shows that the theory of heat and mass transfer, in particular, the sieving and burning of coal dust, has its drawbacks in relation to experimental studies of boiler plants. L. Rosendahl and M. Mando presented the results of the research in the form of a developed model [10]. Researchers, such as T. Asotani [11] and his colleagues proposed a hypothesis of the behavior of coal particles in the air flow, and this hypothesis was partially confirmed by the developed mathematical model, which is consistent with the results of the studies of L. Rosendahl and M. Mando [10]. The hypotheses considered in the review were confirmed by the construction of mathematical models. These models are quite consistent with each other, as well as with the basic physical laws, in particular, the equations of conservation of mass and energy, as well as the boundary conditions of heat exchange processes.

Thus, with a certain modern models and tested hypotheses [10,11] occurs at least one task, namely improving the efficiency of the applied mathematical apparatus when considering the ideal conditions for the grinding of coal dust and its combustion. The solution of the problem will lead to the achievement of the research goal-simplification of mathematical calculations of dust sieving and combustion in real conditions of the boiler unit using piecewise linear functions. Piecewise linear functions, in contrast to the continuous description of dust sieving and successive entry into oxidative combustion reactions developed by the authors, allow us to take into account the smallest changes in the composition of the particle mass after grinding and sieve analysis. This leads to the positive trends of the operational account the slightest changes in the fractional composition, while the continuous function or Gauss curve is a spline line is well matched to the ideal or theoretical conditions of grinding and combustion of coal dust.

1.3. The Purpose and Objectives of the Study

Throughout experiments related to the dust production of a new type of solid fuel or production of a solid fuel in new conditions, the coefficients b, n may change. Mathematical modeling of solid fuel preparation and combustion can be performed without costly tests and experiments.

The purpose of the study is to develop new methodological approaches to dust preparation and combustion of separate particles including a polyfractional ensemble.

To achieve this, the authors divided the study into separate scientific tasks.

- Transform the standard function of coal dust screening during sieve analysis into a continuous integrated function for further application in the mathematical modeling of coal dust burning in an ensemble.

- Apply the density of normal distribution of probable deviations from the mean for mathematical description of screening; use the Gauss curve according to the selected type of function.

- Normalize the function describing the ensemble of particles gradually undergoing exothermic oxidation while burning in a torch.

- Use differential curves in piece-linear functions or their approximation of recursive functions for reducing errors in mathematical modeling.

- Verify the adequacy of mathematical modeling methods; compare the calculation errors of the standard method with the method developed by the authors.

1.4. Scientific Novelty of the Methods and Methodology of the Research

The scientific novelty of the research lies in the improved theoretical and methodological base for coal dust investigation using sieve analysis and heat exchange during coal dust combustion. This base is founded on the concept of a continuum as a continuous medium in which the processes of combustion and heat exchange are investigated. We developed and implemented a method of mathematical modeling based on new approaches to approximation of piece-linear functions. This method increases the accuracy and validity of the results being adapted to possibilities of modern technologies, the effect produced on fuel and air flow, and regulation of thermal characteristics of the flow, and the quality of the supplied coal dust. The developed method gave rise to a program algorithm which enables us to calculate the necessary equivalent particle size and can be further applied for defining the characteristics of torches.

1.5. Practical Value of the Research

The practical value of the research lies in the increasing number of designed mill devices as well as in the extension of the service life and improvement of those in use, as it will support making quick adaptations to variations in fuel and oxidant properties during coal particle burning.

From the point of view of economic benefits for science, the developed software does not involve complicated or costly calculation systems for modeling, as do ANSYS [12], Comsol [13], MathCad [14], SolidWorks [15]; its algorithms are built on using empirical data. To implement the objectives of the research we chose test samples of coal burnt on a BKZ-210-140F boiler unit manufactured by the Chelyabinsk Thermal Power Station.

2. Materials and Methods

2.1. Measurement Methods in Conducting Experimental Works for the Sieving of Coal Dust and Its Burning

Certified laboratory equipment was used for the sieve analysis of coal dust crushed in coal-grinding mills. The methods of conducting sieve analysis and dust sampling comply with the standards for research in the field of physical chemistry and heat power engineering.

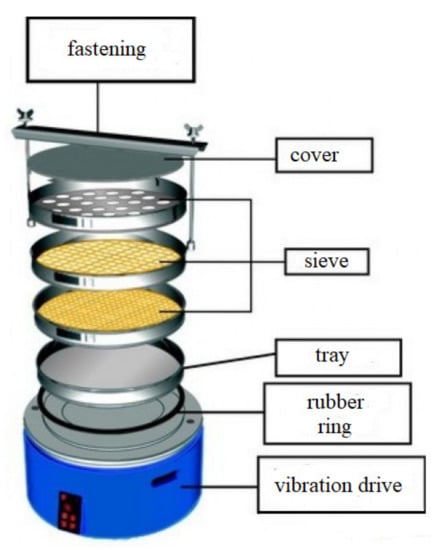

The method of performing the sieve analysis is as follows. Determine the mass of each sieve with an accuracy of 0.1 g. The exact weight of the test sample is placed on the upper sieve and closed with a lid. Sifting is carried out for 5 min, then each sieve is weighed again without loss of substance and the mass of the substance on each of the sieves is determined. In the same way, the mass of the substance on the pallet is determined. Collect the set of sieves again, shake for 5 min and weigh each sieve as described above. These procedures are repeated until the change in the mass of the powder on any of the sieves is less than 5% (10%—in the case of 76 mm sieves) or less than 0.1 g compared to the previous mass of the substance on this sieve, Figure 1 and Figure 2.

Figure 1.

Photo of the screen analysis stand.

Figure 2.

Image of the analysis of the performed measurements on the computer screen.

If the mass of the substance on any of the sieves is less than 5% of the total mass of the test sample, the mass change should not exceed 20% compared to the previous mass on the same sieve. If any of the sieves contains more than 50% of the total mass of the test sample, then in the absence of other indications, the test is repeated, but a coarser sieve is added to the set of sieves: between the one that carries the excess mass and the previous, coarser sieve.

In addition, experiments were conducted to measure the length of the torch, in particular, its initial section, as well as the height of the zone of intense combustion. In the course of the experiments, the methods approved for the operation and measurement of parameters in high-temperature installations were used, for example, the errors of primary and secondary measuring devices were multiplied. The discrepancy between the results of theoretical and experimental studies on the measurement of the temperature and the length of the torch tended to be minimal, which can be explained by some error in conducting experiments at high temperatures in boiler installations, for example, re-emission and high dust content of the torch in the furnace space. The length Lf and the temperature of the torch at the length of the torch Lf during the operation of the steam generator. The data is given depending on the steam capacity of the boiler unit. Rated boiler load Dnom f steam per second. In addition, the data provided when burning Shoptykol coal of the Maikuben coal basin of the Republic of Kazakhstan.

2.2. Review of Coal Dust Screening Methods and Plotting Curves of Particle Distribution

From Equation (1), it is clear that one of the important parameters of burning is particle size. Besides, real pulverized coal combustion depends on its fractional composition since when moving in a flame continuum during heating, volatilization, and burning of volatiles and coke, the fuel dust flows in as a mixture according to its particle size small particles of δmin being the first and large particles of δmax being the last. Thus, to analyze the thermal and temperature processes in a flame continuum it is necessary to relate the analysis of the total residue to the local particle size value in the ensemble of fuel particles F(δi).

The processes of fractional extraction and screening can be described through functions of distribution. For instance, the most widespread functions of distribution are the fractional distribution function [5] or the Tromp curve [7], which shows the dependence of the degree of fractional extraction into large fractions from the quantity of particles in each fraction. However, in some countries scientists use the degree of fractional extraction into small fractions , thus these characteristics are connected with each other . The grounds for defining the degree of fractional extraction of narrow size classes into small and large fractions are given in [5,7]. The defined value represents the probability of a certain class of particles obtaining into a larger product. In order to experimentally define , we should know the particle size distribution. In particular, in a sieve analysis, Figure 1, we should define the weights of certain fractions between adjacent sieves (screens), as well as mass output of particles of large fractions, .

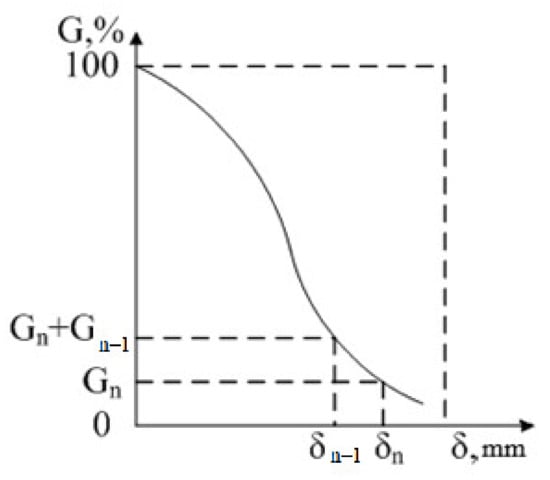

The principle of plotting an integral curve of particle size distribution (certain size class) is the following: first we should calculate the content of separate fractions, Figure 3:

where mi is the mass of this fraction’s particles, G1 + G2 +…+ Gn = 100%.

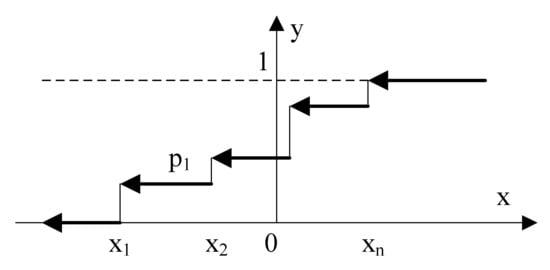

Figure 3.

Integral characteristics.

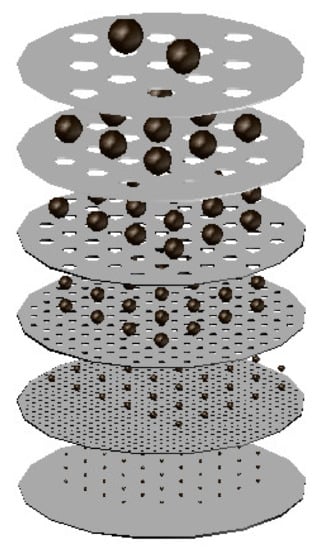

While plotting the integral curve, Figure 3, we set the values of the certain characteristic particle sizes on the X-axis, starting with the sizes of the smallest particles. The Y-axis contains the growing total content (%) of all particles from the smallest to the given size, referring to it as the largest size in this fraction. For instance, the content of the smallest particles (smaller than δn) is Gn; for larger particles (from δп up to δп−1) the total content equals Gn + Gn−1. studies are carried out by sieve analysis. This method is shown schematically in Figure 4. The photo of the stand and the approximate result are shown in Figure 1 and Figure 2.

Figure 4.

A sketch of a sieve analysis.

Thus, the last total value G, corresponding to the δ1 up to δmax fraction and referred to δmax will be 100%, Figure 3.

Depending on the sphere of industry being discussed, the aforementioned characteristics can be designated differently in power engineering is designated by , where R is the residue, and the index x shows the size of a screen, e.g., .

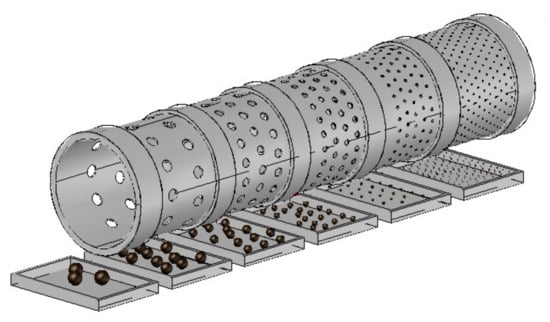

It should be noted that the proposed methods of mathematical modeling can be applied to coal dust screening on a vibrating screen, Figure 5.

Figure 5.

Rotating coal vibrating screen.

2.3. Existing Methods of Approximation of Fractional Distribution Functions

The properties of fractional distribution functions are already presented in the literature [7,16,17]. The difficulty of using such functions is connected with the methods of their approximation. The most widely applied in technology are the following:

where , presents the border of distribution, i.e., the size corresponding to an even particle distribution into large and small fractions; p is the coefficient which characterizes the steepness of the curve. This distribution (2) is called the logarithmic normal distribution.

where designations are similar to (2). This distribution is called the Rosin–Rammler–Bennet modified approximation.

In power engineering, according to [18], when using a sieve analysis we should apply the Rosin–Rammler approximation (3), written as:

where b, n are trial coefficients.

2.4. Development of Basic Mathematical Equations

The fractional residue on the screen can be described in the range of the characteristic size δ. In so doing, the intervals should be F(δ1/δ2) and F(δ2/δ3). In this case taking into account (4), we obtain the following:

While defining the fractional residue according to Equation (5) we have specific points Fi. These specific points form a continuous curve characterizing the ensemble of fuel particles. Due to its continuity, the fractional composition curve can be differentiated or integrated to obtain a detailed description of mixing, ignition, and burning processes or in the future to build a mathematical model of coal dust screening. The validity of the decision should be increased alongside an increase in the number of direct laboratory measurements made on each screen.

Moreover, given the transition to the continuous probability function and obligatory increase in the number of measurements of the residue on the screens, having analyzed the fundamental basics of the distribution theory, we can come to the conclusion that the Gauss curve corresponds to the chosen type of the function.

The density of normal distribution of probable deviations from the mean, which will be designated as , will be defined according to the standard formula:

According to Formula (6), the function’s argument u is the standard normal deviation:

According to Formula (7), ξ is the value corresponding to the size δ, which refers to the maximum on the curve under consideration (Fi); σ is the deviation standard, where σ2 is the dispersion.

Having placed the ensemble of particles according to their number near maximum ξ and having brought the value to the dimensionless form, we can normalize the given function. Having defined the characteristics of the ensemble to the type of dependence from the deviation standard σ, we can standardize the function.

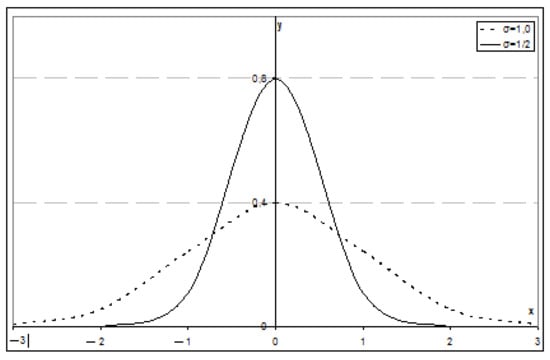

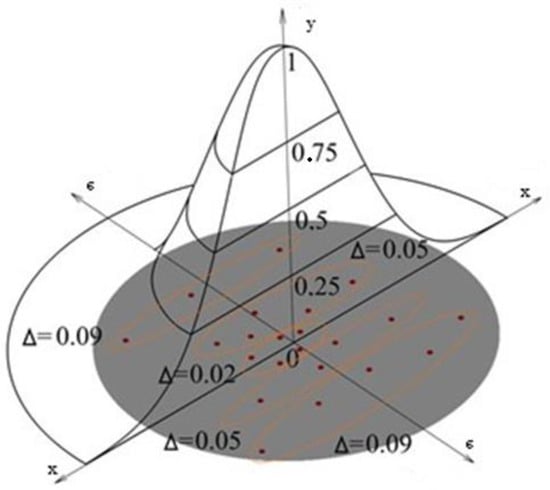

In fact, the error function , obtained according to (6), should be called the deviation function. It is tabulated and presented in handbooks, which is also mentioned in [17]. For the conditions considered in this paper the deviation function is given in Figure 6. Methods of statistics and mathematical analysis are given in the special literature. For example, G. James, D. Witten, T. Hastie, R. Tibshirani in the book [18] give a detailed analysis of the methods of statistical data processing. J. D. Long, P. Teetor in the book [19] also give the basics of statistics and its application for computer technology, as well as other industries.

Figure 6.

The Gaussian distribution density of the normalized random variable y = , where x = u = (δi – ξ)/(ξ·σ), with the centre ξ and dispersion σ2.

Standard deviation clearly defines Function (6) and the values u =1 and u = −1 correspond to inflection points on a curve plotted according to the dependence (6).

Besides, according to the curve plotted in correspondence with the fractional composition, we can easily define the dispersion σ2 = (δ – ξ)2/(ξ·u)2. Having defined the coefficient of correlation between practical results in reference to fuel dust screening and the Gauss curve, we can quantify the accuracy of description (5). This method can also be applied at the stage of defining F(δi).

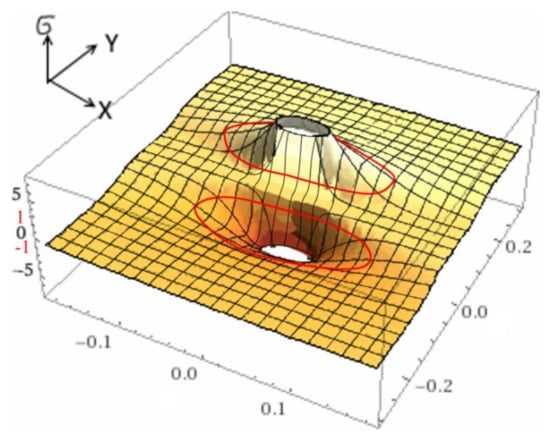

We stress that the developed method of the Gauss function normalization can be applied outside of coal dust screening. This procedure is appropriate for conducting sieve analysis of powder-like substances. The Gaussian distribution of the normalized value in 3D is presented in Figure 7 and Figure 8, where we can see that this distribution is shifted into the area of positive values x.

Figure 7.

The Gaussian distribution density of the normalized random variable y = φ(u).

Figure 8.

Hodograph of the Gaussian distribution density of the normalized random variable y = φ(u).

2.5. Application of Differential Curves for Describing Particle Distribution

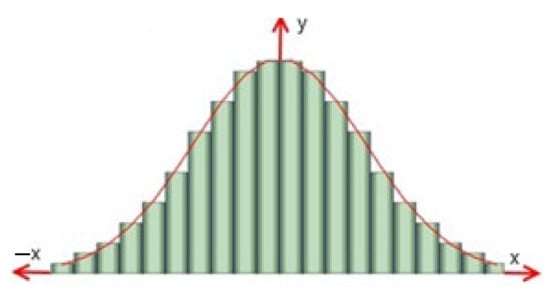

For mathematical modeling of coal dust screening and further combustion of the single particle, we need an equivalent size corresponding to the most frequent particle size in this system. This size can be obtained from the differential distribution curve. In order to plot it, the integral curve (Figure 3) should be processed with the aforementioned method. Through equal intervals of sizes Δδ, which are chosen at random, we plot ordinates till the intersection with the integral curve, mark these points on the y-axis, and find the value for ΔG the remainder between two adjacent coordinates. The number of segments Δδ, plotted on the x-axis, should be no less than 8. Then, we place values of equivalent sizes δ on the x-axis, and draw rectangles on the y-axis—ΔG/Δδ, based on equal intervals of size Δδ and height ΔG/Δδ, Figure 9.

Figure 9.

The differential distribution curve y = φ(u), where x = u = (δi – ξ)/(ξ·σ) based on the histogram.

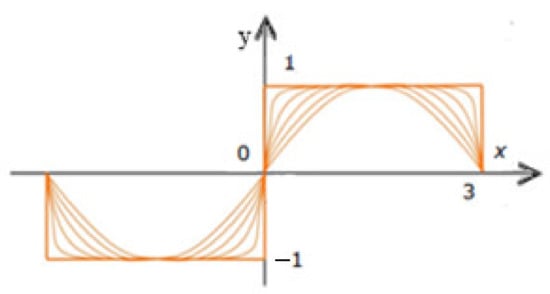

2.6. Application of Piece-Linear Functions and Approximations by Means of Recursive Functions for Mathematical Description of the Coal Dust Screening

To achieve our set task, we propose utilizing the distribution graph of a stepped figure, Figure 10, which can be described by the piece-linear continuous function . We can obtain the solution by applying the methods of linear system theory at each segment of such a function. However, issues often occur when building the solution in the domain of the piece-linear function and making decisions on segments with the necessity to apply special mathematical methods. In order to simplify the calculations, working with piece-linear functions is often combined with approximation methods. One of the most widely applied methods of piece-linear function approximation is decomposing these functions with the help of a Fourier series:

Figure 10.

Piece-linear distribution function y = φ(u), where x = u = (δi – ξ)/(ξ·σ) based on the histogram.

This Formula (8) contains an orthogonal system in a functional Hilbert space L2[−π, π] of measurable functions square Lebesgue integrable:

The orthogonal system is frequently presented by means of the trigonometric system 2π—periodic functions .

Applying a Fourier series has a number of drawbacks. For instance, when we have a relatively small number of addends in a Fourier series, used for decomposing the piece-linear function, the approximation function is distinctly wave-like even within one linear segment of the piece-linear function, which may lead to the considerable approximation error. Professor S. V. Aliukov’s studies [20,21] demonstrate that for the rectangular pulse function:

the point x = π/m, m = 2[(n + 1)/2] and [(n + 1)/2], the integer part of the number (n + 1)/2, is the maximum of the partial sum of the trigonometric Fourier series [20,21], while:

Thus, the absolute error will be equal to:

Then, the relative error will be more than 17% regardless of the number of addends in the partial sum of a Fourier series.

The use of a new method for approximating piecewise linear functions, developed by one of the authors of the article (S. V. Aliukov), allows us to improve the procedure for approximating any existing, including discontinuous, function. The approximation is performed not by using the Fourier method, which has been proven to give a significant error, but by using recursive functions. Thus, a quantitative error comparison should be made between two methods: the transformation of the sieve analysis curve to the Gaussian curve under ideal conditions, and the transformation of the sieve analysis curve to a step histogram and piecewise linear functions using a new approximation method. As a result, we have that for ideal conditions of sieve analysis and further combustion, the improvement in calculations will be approximately 2–3%. The second method reduces the calculation error in real conditions by 1–2%. Which would seem not to be essential. However, in the conditions of a real boiler unit that consumes several kilograms of fuel per second, these 1–2% become significant.

Moreover, the approximation function graph has the greater approximation error in a vicinity of the points of discontinuity of the original function. Here we observe the so-called Gibbs phenomenon [20]. With a growing number of harmonics, the Gibbs phenomenon does not disappear, which may lead to extremely negative consequences of using the approximation function.

2.7. New Approaches to Piece-Linear Function Approximation

In order to eliminate the aforementioned drawbacks, we propose to approximate the original stepped Function (8) with a sequence of recursive periodic functions [19]:

The approximation (13) is based on the use of trigonometric expressions, not in the form of addends like in a Fourier series, but in the form of embeddings.

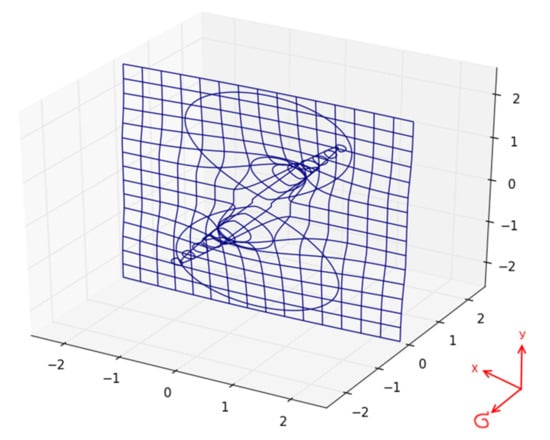

The graphs of the stepped Function (13) and its four subsequent approximations in this case look like (Figure 11).

Figure 11.

Graphs of the stepped function and its four subsequent approximations with the help of embedded functions.

It should be noted that with relatively low values of while applying the procedure (13) the graph of the approximation function approximates the original function y rather well. In the case of the proposed approximation method, the sinusoid stretches along the linear segments in the graph of the original function. There are no variations of the approximation function within linear segments of the original stepped function. The Gibbs phenomenon is also not observed.

3. Results

The subsequent introduction of fuel particles in heat exchange processes in a torch and additive dependence of the whole heat content refers to the integral of the distribution function of probable deviations (6). The limits of integration here should be set from –∞ up to the maximum value of the fuel particle size δmax, corresponding to the upper limit of integration:

The lower limit of integration is defined by means of the fractional composition of fuel particles in the range of small values δ and is of great importance for calculating the igniting processes of the fuel–air mixture, whereas the upper limit is connected with the calculation of fuel under-burning with the given length of a torch, or with the definition of the necessary length of a torch under given under-burning of fuel, which is also connected with the fractional composition of fuel in the range of large values δ. Thus, the dependence described (14) helps define the onset of the concrete temperature regime depending on the particle size and conditions of its motion with a polyfractional torch. In order to define the burn-out of fuel particles of various sizes, we can add to the scheme the conditions of the burning particle interaction with the flow of fuel and torch environment. The results demonstrated that with the help of new approximation methods and analysis of air flow velocity deviations in the channel, we can obtain more accurate results of experimental and numerical investigations, Figure 12. In particular, we can see below the 3D deviation distribution in the air velocity calculation.

Figure 12.

Results of the new mathematical modeling application. (calculation 1 according to Table 1).

Thus, we get that as a result of comparing the test (experimental) data and the calculated data (Table 2), the maximum deviation of the equivalent particle diameter decreases in real conditions when using a new method of approximation of piecewise linear functions by recursive functions. The Gauss curve for ideal conditions also provides a good agreement with the experimental data, but is still more suitable for the ideal case without taking into account external factors that affect the grinding, sieving and combustion processes under real conditions.

Table 2.

Results of analytical calculations using the Gaussian curve, a new approximation method compared to experimental data.

The results of the calculations depend upon a large number of sources of slight accidental errors. All calculations have the symmetric Gauss function in the form of the bell as a limiting distribution, Figure 12. The distribution centre which coincides with its maximum will be the true value of the measured value.

The tests were conducted in collaboration with the Chelyabinsk Thermal Power Station (TETz-2) on BKZ boiler units with a front burner layout. The boiler room uses B3 coal of the Shoptykolsk and Sarykolsk deposits from the Maikuben basin as fuel. The properties of the coals are similar, although there are some differences. There are some data on the composition of the Maikuben basin coals presented by the specialists from the Ural Heat Engineering Research Institute and Ural Heat Engineering laboratory (UralVTI) [22]. Below are the average characteristics of the three coal types under study: = 15,755–19,570 kJ/kg Ad = 13–28, Wd = 18, Vdaf = 41–43%, Cdaf = 72–74%, CaO = 3–6%.

We underline that test burns are regularly conducted on coals from different deposits, including the Kansk-Achinsk and Kuznetsk basins, which are extremely different from the Chelyabinsk design coals and coals from the Maikuben basin, which is burnt regularly.

When describing the coal dust screening function according the proposed method, the results were more reliable than when using the standard methods and functions of screening.

We compared our data with the results of the Maikuben basin coal screening. We propose that similar studies be conducted for coal from other deposits.

The data obtained through these comparisons allow us to improve the design processes of mill devices and computer simulation of coal dust screening and combustion.

Since the approximation was conducted through generalized functions, we can differentiate these approximation functions and find their derivatives of any order. Thus, the main functions of the parameters for k-omega computer simulation of the fuel and air flow can be approximated applying the new method, which has not been used previously.

The approximations obtained describe the original function more precisely. The suggestions on improving the mathematical device of the standard K-omega model will help researchers develop the approximation theory using Dr. S. V. Aliukov’s recursive functions [23]. The results obtained will resolve one of the main tasks of modeling at this stage of development—the reduction of calculation time and adequacy of the model for similar plants and devices.

4. Conclusions

The conclusions presented correspond to the scientific objectives of the study, namely: the standard function of coal dust screening through sieve analysis is transformed into a continuously differentiable function which makes it applicable for the mathematical modeling of the ignition of coal particles in an ensemble. We applied the density of normal distribution of probable deviations from the mean to the continuously differentiable function obtained described by means of the Gauss curve. The obtained continuously differentiable function was normalized. For the first time, we used piece-linear functions and their approximation of recursive functions in order to describe coal dust screening by means of sieve analysis. We compared the analytical calculations according to the developed algorithm with the experimental data. We checked the calculation error using the standard methods and our own developed method. The use of a new method for approximating piecewise linear functions, developed by one of the authors of the article (S. V. Aliukov), allows us to improve the procedure for approximating any existing, including discontinuous, function. The approximation is performed not by using the Fourier method, which has been proven to give a significant error, but by using recursive functions. Thus, a quantitative error comparison should be made between two methods: the transformation of the sieve analysis curve to the Gaussian curve under ideal conditions, and the transformation of the sieve analysis curve to a step histogram and piecewise linear functions using a new approximation method. As a result, we have that for the first method under ideal conditions of sieve analysis and further combustion, the improvement in calculations will be approximately 2–3%. The second method, relative to the first, reduces the calculation error in real conditions by 1–2%. In the conditions of a real boiler unit that consumes several kilograms of fuel per second, these 1–2% become significant.

Author Contributions

Conceptualization, S.A. and K.O.; Data curation, S.A. and K.O.; Formal analysis, S.A.; Investigation, S.A. and K.O.; Methodology, S.A. and K.O.; Project administration, S.A.; Supervision, S.A. and K.O.; Validation, K.O.; Visualization, K.O.; Writing—original draft, K.O.; Writing—review and editing, S.A. and K.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The study did not report any data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Noble, A.; Luttrell, G.H. A review of state-of-the-art processing operations in coal preparation. Int. J. Min. Sci. Tech. 2015, 25, 511–521. [Google Scholar] [CrossRef]

- Peng, L.; Wang, Z.; Ma, W.; Chen, X.; Zhao, Y.; Liu, C. Dynamic influence of screening coals on a vibrating screen. Fuel 2018, 216, 484–493. [Google Scholar] [CrossRef]

- Williams, F.A. Combustion Theory Benjamin/Cummings; Westview Press: Menlo Park, CA, USA, 1985. [Google Scholar]

- Spalding, D.B. Some Fundamentals of Combustion; Academic Press: London, UK, 1955. [Google Scholar]

- Ponomarev, V.B. Calculation and Design of Equipment for Air Separation of Bulk Materials; Publishing House Ural University: Yekaterinburg, Russia, 2017. [Google Scholar]

- Pomerantsev, V.V.; Arefyev, K.M.; Akhmedov, D.B. Fundamentals of the Practical Theory of Combustion; Energoatomizdat: Leningrad, Russia, 1986. [Google Scholar]

- Barsky, M.D. Fractionation of Powders; Nedra: Moscow, Russia, 1980. [Google Scholar]

- Chernetsky, M.Y.; Gavrilov, A.A.; Dekterev, A.A.; Surzhikova, N.S. Mathematical model of the processes of aerodynamics and heat transfer in pulverized coal furnace devices: Scientific publication. Therm. Fund. Energy Tech. 2009, 1, 159–166. [Google Scholar]

- Burdukov, P.A.; Popov, V.I.; Chernetskiy, M.Y.; Dekterev, A.; Hanjalić, K. Autothermal combustion of mechanically-activated micronized coal in a 5 MW pilot-scale combustor. Fuel 2014, 122, 103–111. [Google Scholar] [CrossRef]

- Asotani, T.; Yamashita, T.; Tominaga, H.; Uesugi, Y.; Itaya, Y.; Mori, S. Prediction of ignition behavior in a tangentially fired pulverized coal boiler using CFD. Fuel 2008, 87, 482–490. [Google Scholar] [CrossRef]

- Mandø, M.; Rosendahl, L.; Yin, C.; Sørensen, H. Pulverized straw combustion in a low-NOx multifuel burner: Modeling the transition from coal to straw. Fuel 2010, 89, 3051–3062. [Google Scholar] [CrossRef]

- Ansys. Available online: https://www.ansys.com (accessed on 16 November 2020).

- Comsol. Available online: https://www.comsol.ru (accessed on 26 November 2020).

- MathCad. Available online: https://www.mathcad.com (accessed on 3 November 2020).

- SolidWorks. Available online: https://www.solidworks.com (accessed on 8 November 2020).

- Toropov, E.; Osintsev, K.; Alykov, S. New theoretical and methodological approaches to the study of heat transfer in coal dust combustion. Energies 2019, 12, 136. [Google Scholar] [CrossRef]

- Toropov, E.V.; Osintsev, K.V.; Alykov, S.V. Analysis of the calculated and experimental dependencies of the combustion of coal dust on the basis of a new methodological base of theoretical studies of heat exchange processes. Int. J. Heat Tech. 2018, 36, 1240–1248. [Google Scholar] [CrossRef]

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R. An Introduction to Statistical Learning; Springer: Manhattan, NY, USA, 2013. [Google Scholar]

- Long, J.D.; Teetor, P. R Cookbook: Proven Recipes for Data Analysis, Statistics and Graphics; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2019. [Google Scholar]

- Aliukov, S.V. Approximation of step funcions in problems of mathematical modeling. Math. Models Comp. Sim. 2011, 3, 611. [Google Scholar]

- Aliukov, S.V. On Analysing Cost for Optimizing the Watcher Subscription Time in the IMS Presence Service. Que. At. Sci. Tech. Ser. Math. Modeling Phys. Proc. 2013, 2, 5–62. [Google Scholar]

- Bogomolov, V.V.; Alekhnovich, A.N.; Artemyeva, N.V.; Abishev, M.V.; Kirichenko, G.N.; Rodionov, V.A.; Larionov, P.V. Mineral Part of Fuel, Slagging, Pollution and Cleaning of Boilers; UralVTI: Chelyabinsk, Russia, 2007; pp. 17–29. [Google Scholar]

- Osintsev, K.; Aliukov, S.; Prikhodko, Y. New Methods for Control System Signal Sampling in Neural Networks of Power Facilities. IEEE Access 2020, 8, 192857–192866. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).