Featured Application

This work provides an overview of 3D printing, include a survey on the related publications by different aspects as a benchmark for future research and development.

Abstract

Research interest in three-dimensional (3D) printing has been greatly aroused since 1990 due to its outstanding merits, such as freedom of design, mass customization, waste minimization and fast prototyping complex structures. To formally elaborate the research status of the 3D printing field, a bibliometric analysis is applied to evaluate the related publications from 1990 to 2020 based on the Science Citation Index Expanded database and Social Science Citation Index database. The overview with detailed discussions is cataloged by keywords, citation, h-index, year, journal, institution, country, author, patent and review. The statistical results show that the United States plays a dominant role in this research field, followed by China and the UK. Singapore is the most productive country with the highest average citations per publication (ACPP), and the second most cooperative country. Among all the institutions, Chinese Academy of Sciences is most productive, and Harvard University has the highest ACPP and h-index. Among all the journals, Materials ranks first in the number of publications in this field. The most attractive research area is “Materials science, Multidisciplinary”, with 4053 publications. Moreover, the major hot topics derived from authors’ keywords are “3D printing”, “additive manufacturing” and “tissue engineering”. Commercial and medical applications appear to be the initial driving force and end goal for the development of the 3D printing technology.

1. Introduction

3D printing, also referred to as additive manufacturing (AM), is a set of layer-by-layer processes to form 3D objects with various structures and complex geometries directly from digital models [1]. It has gained popularity in consumer-maker communities and the media as well as scientific researchers in many areas [2,3,4]. With recent increasing interests, this technology is continuously expanding into areas such as automotive [5,6,7], aerospace [8,9,10], electronic [11,12,13], medicine [14,15,16], biology [17,18,19], architecture [20,21,22], sports [23,24], toy industries [25,26,27], food supply chains [28,29,30], agriculture [31], earth science [32] and robotics [33,34].

The 3D printing manufacturing process was initially developed by Charles Hullin in 1984 in a process named as stereolithography [35], which is the pioneer of all 3D printing technologies [36,37], and one of the most popular rapid prototyping technologies for plastic fabrication. Technologies like powder bed fusion [38,39,40], fused deposition modelling (FDM) [41,42,43], inkjet printing and contour crafting (CC) [44,45,46] direct energy deposition (DED) [47,48,49] and laminated object manufacturing (LOM) [50,51,52] subsequently appeared with more advancements in this field after the stereolithography technology. Current 3D printing technologies are able to combine different materials in precise positions to achieve the multifunctional properties of the manufactured parts [53]. However, it faces a lot of challenges such as limited materials, high cost, inconsistent quality and regulatory issues [54]. The limitations of the exiting techniques spur the promotion of more advanced methods in 3D printing field. For instance, the multi-jet FDM method attracts increasing attentions in bio-printing of the complex hydrogel scaffolds with cells [55]. Moreover, multi-material manufacturing processes and multifunctional applications are achieved by the assists of the computer-aided design and optimization techniques [56].

The 3D-printing process concerning various novel materials, methods and equipment has been developing rapidly over the years, which reformed the traditional manufacturing processes that involve material removal or energy-intensive process [57,58,59,60]. And it is quite an achievement that 3D printed prototypes or products have been commercially utilized in various industries [61,62,63]. A wide range of materials from cereal to advanced multifunctional materials in diverse forms of filaments, wire, powder, paste, sheets and inks can be fabricated thanks to the 3D printing technologies [64,65]. Polymers like polyamide [66,67,68], polylactic acid [69,70,71] and polystyrene [72,73] are among the most common composites in the 3D printing applications. Plentiful plyometric materials are continuing coming forth for 3D printing with excellent mechanical properties by synthesizing other matrix material. Waste reduction of expensive materials accelerates the application of 3D printing with metals or alloys such as titanium [74,75,76]. Metallic alloys are typically used in the aerospace area by prototyping complex and customized structures [77,78] as traditional processes are time-consuming, difficult and costly [79,80,81]. Ceramics, in the form of powders or paste, can be 3D printed by applying heat up to their melting point or an adhesive binder, and are readily fabricated into strong and versatile ceramic scaffolds with complex shapes [82,83,84]. Therefore, customized small-batch products for patient-specific necessities can be manufactured in time with relatively low costs [85], which particularly meet the requirement of biomedical field [86,87,88]. Concrete is the most used human-made material in construction [89,90,91], houses can be built at a staggering speed and at low cost [92,93,94] by 3D printing. All this suggests a bright future to the construction industry due to the advantages such as mass-customization, no need for formwork and design flexibility.

A bibliometric study is a measurement of all aspects related to the publication and reading of books or documents [95], which applies a citation analysis by constructing a citation graph, a network or graph representation of the citations between documents. Many research fields use bibliometric methods to explore the impact of the papers within a specific research field, as well as to identify the impact of certain research areas or researchers. It has been adopted in a variety of academic areas, such as materials [96], chemistry [97], computer science [98], economics [99], society [100], architecture [101], education [102], medicine [103], energy [104], robotics [105], etc. However, to the best of the authors’ knowledge, this is the first bibliometric analysis to assess the 3D printing research field. The analysis in this paper includes the following subjects: (1) a topic historical map; (2) the main contributors organized in countries, institutes, research groups, authors, and leading research areas; (3) the cooperation relationship between these contributors; (4) the major journals; (5) the highest citation articles and patents; and (6) research interests and perspectives.

2. Materials and Methods

This analysis is based on the publications related to ‘‘3D printing’’ from 1990 to 2020. Literature was retrieved through the Science Citation Index-Expanded and Social Science Citation Index on 12 June 2020, searched with formula of “3D printing” or “3 D printing” or “Three-dimensional printing” or “3 dimensional printing” or “3D Printable” or “3 D Printable” or “Three-dimensional Printable” or “3 dimensional Printable” or “3D print” or “3 D print” or “Three-dimensional Print” or “3 dimensional print” or “3D Printed” or “3 D Printed” or “Three-dimensional Printed” or “3 dimensional Printed” or “3D bioprinting” or “3 D bioprinting” or “Three-dimensional bioprinting” or “3 dimensional bioprinting” or “3D bioprint” or “3 D bioprint” or “3D bioprinted” or “3 D bioprinted” or “3 dimensional bioprinted” or “Three-dimensional bioprinted” or “3D bioprintable” or “Three-dimensional bioprintable” or “3 dimensional bioprintable” or “bioprinting” or “bioprint” or “bioprinted” or “bioprintable”, defining the document type as article and review in the field of this topic. Articles authored from the United States, China, UK, Germany, South Korea, Australia, Canada, Italy, France and Singapore were investigated. Keyword and international cooperation were analyzed by the Derwent Data Analyzer. And patents are extracted from Derwent Innovations Index database. The impact factor (IF) for each journal was determined according to the 2020 Journal Citation Reports. Since the WOS ‘‘topic’’ searching was only applied to the title, abstract, and keyword fields defining the document type as article and review, it might cause some deviations as some other related publications may not be counted while still cited in this work.

3. Results

3.1. Global Contribution and Leading Countries

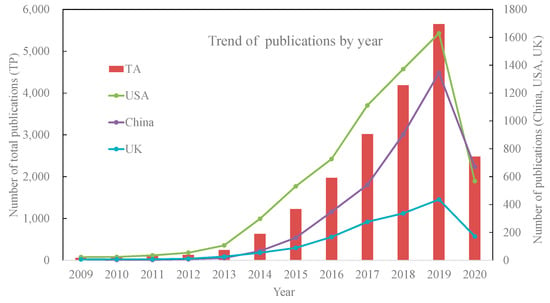

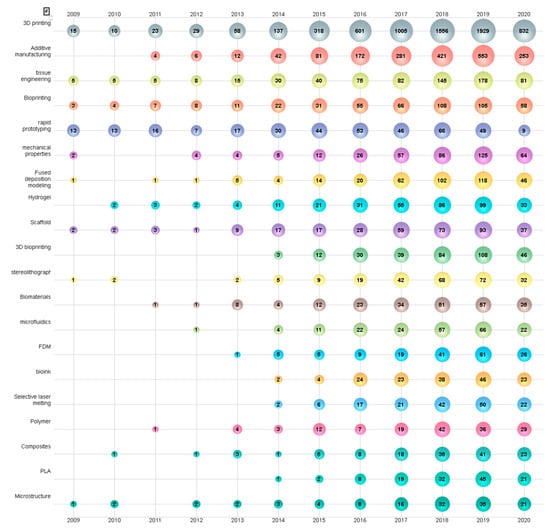

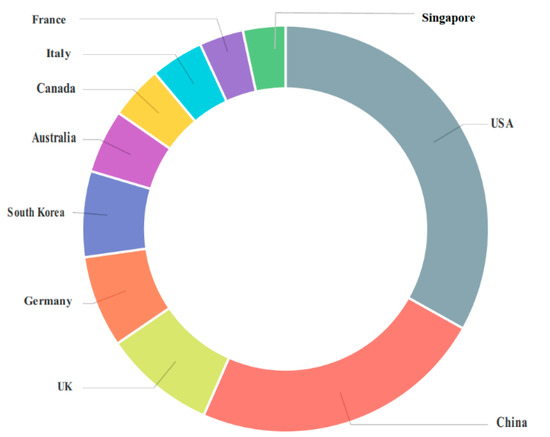

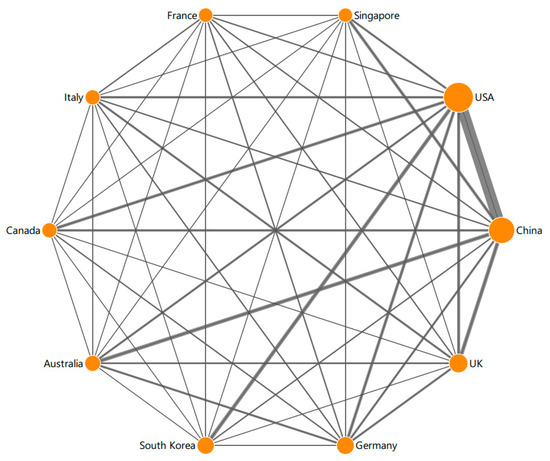

As a result, 17,505 publications were collected from InCites data set, in which English is the most used language (99.18%), then German and Chinese. Since 1990, there are more than 118 countries involved in the 3D printing research field with 16,022 publications in article and 1483 in review, among them, 394 publications are Essential Science Indicators (ESI) highly-cited articles and 13 publications are ESI hot articles. Although 3D printing is a young industry, it has grown to almost $3 billion in value in 2012 [1]. As shown in Figure 1. The number of total publications per year was relatively small but quickly increased from 51 to 474 during 2009–2014, suggesting that this research domain started to attract more scientists and engineers during that time. The publications had more than doubled in the following year of 2015. Since then, the rising rate of yearly publications has been decreasing, but retained high percentages of 71%, 59%, 46% and 37%, respectively, in 2016, 2017, 2018, and 2019. The urgent needs of the industry and interests of the researchers has led to an enormous growth in this field in the last few years, which is reflected in the number of publications. The total number of published articles on this topic in the last three years is more than that in the first 27 years since 1990. ‘‘3D printing’’ has been widely adopted as a keyword in scientific articles since 2009, especially after 2014, as shown in Figure 2. The second most frequently used keyword is “additive manufacturing”, followed by tissue engineering, bioprinting and rapid prototyping, which also to some extent indicates the popularity of 3D printing technology in the medical or biology. The top 10 countries contributing most publications in this field are shown in Table 1, and their proportions are presented in a pie chart, as shown in Figure 3. The United States, with 5546 articles, is the most productive country, followed by China (3914 articles) and the UK (1469 articles). The national development programs, research fundings and institutions played an essential role in the arena of 3D printing technology. For example, the National Science Foundation (NSF) in the United States has supported most influential researchers, roadmaps, conferences, networking events, patents, and manufacturing firms. It awarded almost 600 grants worth over 200 million dollars by 2005, promoting the emergence and development of 3D printing [106]. The National Additive Manufacturing Innovation Institute (NAMII or America Makes) [107], which was funded with $45 million in 2012, is the first national network of institutes that focuses on the development of the 3D printing. The reasons for the mass output increase from China are the launching of initiative projects like “Made in China 2025” [108] and “National Additive Manufacturing Industry Development Plan 2015–2016”, which have motivated the development of the domestic 3D printing manufacturing industry. An earlier development program launched in 2008, i.e., the Comac C919 aircraft [109], also needs massive parts from 3D printing and has presented tremendous technological demands. Moreover, China surpassed the UK and has occupied the second place in the number of publications since 2014, as shown in Figure 1. 3D printing in Europe, including the UK, has received European Union (EU) funding since the first Framework Programme (FP) (1984–1987). During 2007 and 2013, a total budget of around €225 million spent on this field in EU, in which over €160 million successfully supported more than 60 3D printing technology projects [110]. Among the top 10 countries’ publications, a large number (>39%) involve international cooperation, especially for France (56.11%), Australia (54.18%) and Singapore (53.69%). However, Singapore has the highest ACPP (23.00) that indicates its non-negligible influence in this field. Therefore, scientists and engineers involved deeply in the aspect of communication and cooperation in the 3D printing field. Despite the large publications number from China, the ACPP is relatively low, only 10.98%. Possible reasons are the language barrier and variable quality in the incremental research papers. Figure 4 shows the top 10 productive countries’ collaboration relationships. The node size of each country is proportional to the number of articles. The lines represent the collaboration between countries with their thickness indicating the intensity. The United States is the most active country that collaborated with 138 countries, especially with China and South Korea. Meanwhile, China ranks the second place on the list, followed by the UK and Germany.

Figure 1.

Trends in the number of publications (all types) related to 3D printing by year.

Figure 2.

Bubble chart of top 20 author keywords by year.

Table 1.

The top 10 most productive countries and regions.

Figure 3.

Shares of the total publications of the top 10 productive countries.

Figure 4.

Collaboration matrix map among the top 10 productive countries.

3.2. Contribution of Leading Institutions

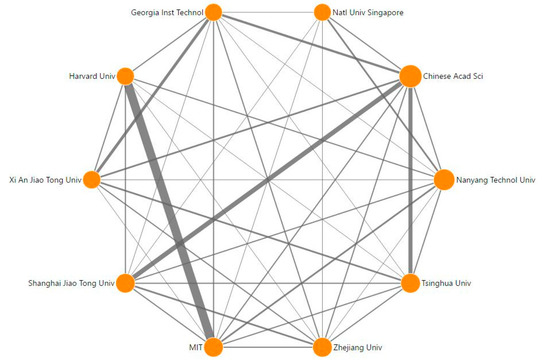

Table 2 lists the top 10 institutions in the 3D printing field, ranked by their number of publications, citations and h-index. The Chinese Academy of Sciences contributes the most publications among all institutions, followed by Nanyang Technological University and Tsinghua University. As for the ACPP and h-indexes, Harvard University has the highest ACPP (77.99) and highest h-indexes (61), followed by the Massachusetts Institute of Technology (MIT) with ACPP 40.23 and h-indexes 51. Nanyang Technological University has the third highest ACPP (29.94). Clearly, these institutions play key roles in the development and promotion of this field. Although there are five Chinese institutions on the top 10 list, their ACPP and TPR results are relatively low. As shown in Figure 5, although the Chinese Academy of Sciences published the largest number of articles, their collaborations intensity is relatively low compared with Harvard University. Most collaborations are concentrated on domestic institutions, such as Harvard University with MIT, Chinese Academy of Sciences with Shanghai Jiao Tong University or Tsinghua University. Georgia Institute of Technology has the strongest connections with the international institutions, with e.g., Chinese Academy of Sciences and Shanghai Jiao Tong University.

Table 2.

The top 10 most productive institutions.

Figure 5.

The collaboration matrix map among the top 10 Most Productive Institutions.

3.3. Contribution of Leading Research Areas

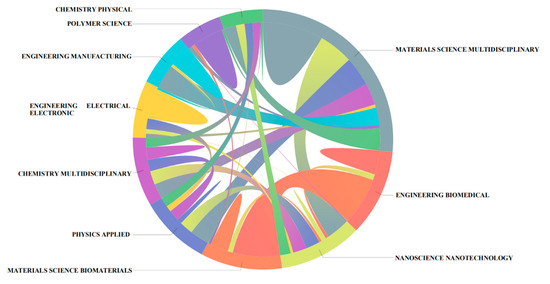

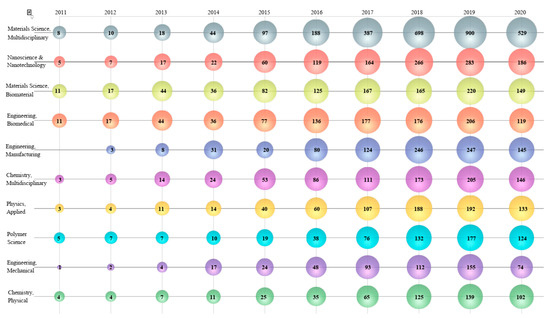

It is a consensus that 3D printing is a fast-developing multidisciplinary field [111], which can also be concluded from the articles distributed in 212 WOS research areas. Table 3 illustrates the top 10 WOS hot research areas in 3D printing ranked by the article numbers. There is no doubt that “Materials Science Multidisciplinary’’ dominates this research area with 4053 articles, followed by ‘‘Engineering Biomedical’’ and ‘‘Nanoscience Nanotechnology’’, which are the main scientific areas on 3D printing. The most active interdisciplinary research area collaborated with “Materials Science Multidisciplinary’’ is “Physics Applied”, following by ‘‘Nanoscience Nanotechnology’’, and “Engineering Manufacturing”, as shown in Figure 6. Moreover, ‘‘Chemistry Physical’’, ‘‘Chemistry Multidisciplinary’’ and “Materials Science Biomaterials’’ occupy the first three positions in areas with high ACPP, which are 29.05, 26.40, and 26.28, respectively. Accordingly, the chemistry and material areas, with high ACPP, are vital for 3D printing development.

Table 3.

Contribution of leading research areas.

Figure 6.

The intersection matrix map among leading research areas.

3.4. Leading Journals in Terms of Number of Publications in 3D Printing Research

17,505 articles related to 3D printing were published during 1990–2020 in 2551 different journals. As listed in Table 4, Materials takes the leading position with 282 articles concerning 3D printing, followed by Additive Manufacturing (274), ACS Applied Materials Interfaces (273), Biofabrication (271), Scientific Reports (267) and Rapid Prototyping Journal (255). The aforementioned six journals have similar paper amounts and share 10.12% of the total publications, and the top 10 journals listed in Table 4 have produced 2267 articles for a share of 14.15%. Moreover, each of the rest of the non-top journals contribute with a share of far less than 1%. In terms of IF, Additive Manufacturing has a high IF of 7.173 follow by the four material and biology-related journals, namely, Advanced Materials, Advanced Functional Materials, ACS Applied Materials Interfaces and Biofabrication. To create a historical map of 3D-printing-related publications in journals by year, we employ the bubble chart of the top 10 productivity journals, as shown in Figure 7. A handful of articles can be found from 1990 to 2014 in the 3D printing field, but evident growth in publications is witnessed and continues after 2014, which agrees with the pattern shown in Figure 1. Apart from manufacturing-oriented journals like Additive Manufacturing, International Journal of Advanced Manufacturing Technology and Rapid Prototyping Journal, the top journals contributing to this increasing trend in 3D printing are journals in the fields of materials science or biology, such as ACS Applied Materials Interfaces, Advanced Materials, Advanced Functional Materials, Materials Design and Biofabrication.

Table 4.

The Top10 journals publishing articles.

Figure 7.

Bubble chart of the top 10 most productive journals by year.

3.5. Contribution of Leading Authors

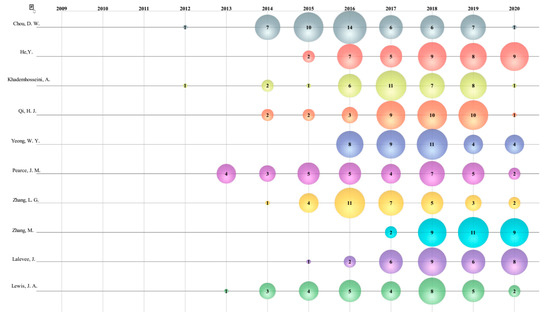

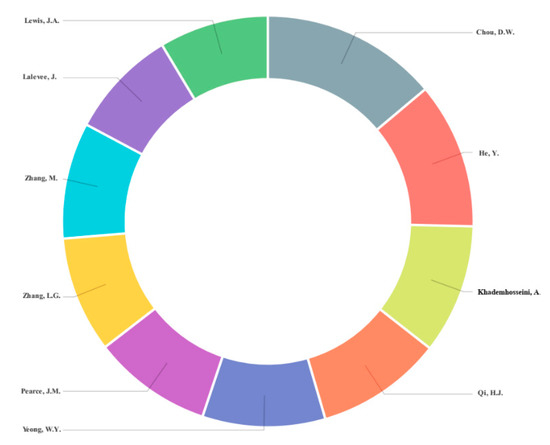

Table 5 shows the top 10 most productive authors based on their publication numbers, among which Dong-Woo Cho (52) leads the list with a total number of publications of 67, followed by Yong He (43), Ali Khademhosseini (38) and H. Jerry Qi (37). For the ACPP, the Jennifer A. Lewis group ranks the first with 187.94, followed by Ali Khademhosseini (99.82) and Dong-Woo Cho (68.8). Moreover, Lewis and Khademhosseini both achieve the highest h-index of 26, followed by Dong-woo Cho (25) and Lijie Grace Zhang (23). Yong He and Min Zhang started publishing work on 3D printing in 2015 and 2017, respectively, and remain very active in this area, as shown in Figure 8. So far, there is no sign of cooperation between these ten authors, as shown in Figure 9. The majority of top 10 productive authors are from the top three most productive countries, except those from South Korea, Singapore and France i.e., Dong-woo Cho, Yong He and Jacques Lalevee. Nevertheless, the share of articles of the top 10 authors in total publications is only 2.1%, which means that a large number of researchers are working in this field and making contributions to the total of 17,505 publications. The vast population in the research community promises new developments and breakthroughs in 3D printing shortly.

Table 5.

Contribution of the top 10 authors.

Figure 8.

Bubble chart of top 10 productive authors by year.

Figure 9.

Pie chart of the contributions of the top 10 most productive authors.

3.6. Patent Status of 3D Printing

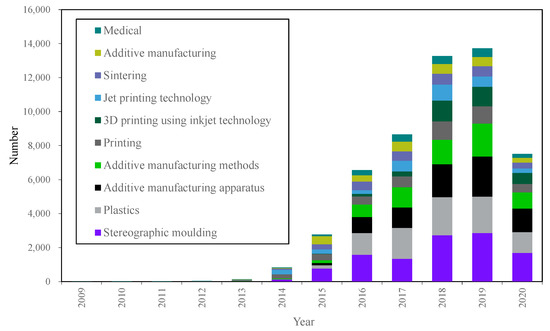

Patents as a form of intellectual property refer to the business behavior of the owner to protect the legal rights to their inventions. So far, there are 27,462 patents applications on 3D printing all over the world according to the Derwent Innovations Index database. As shown in Figure 10, the participation of individuals patenting in the 3D printing field was initially stagnant until 2013, increased significantly thereafter and peaked in 2019. The number of patent applications in 2019 (6098) was 190 times that of 2009, which represents a greater growth in quantity than that of academic publications (Figure 1) though with a similar trend. More specifically, the most frequently mentioned content in Derwent World Patents Index (DWPI) is “stereographic moulding”, followed by “plastics” and “additive manufacturing apparatus”, showing that a large portion of the patents concern the advancements in 3D printing devices and manufacturing technologies like moulding, extrusion, forming, laminating or spinning of materials, especially for plastics.

Figure 10.

Annual applications and DWPI distribution of 3D printing patents.

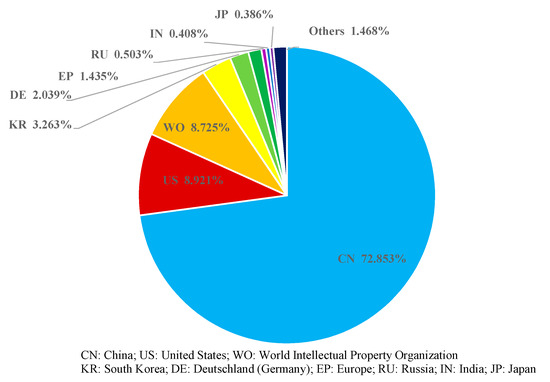

Although the United States is the most productive country in academic publications on 3D printing, China is the largest producer of patents in this field with 72.853% of the total filed patents, followed by the United States (8.921%) and the World Intellectual Property Organization (8.725%) as shown in Figure 11. China’s strong performance in the area of 3D printing intellectual property has led to a new highest record number of intellectual property applications worldwide.

Figure 11.

Distribution of 3D printing patents by countries/regions.

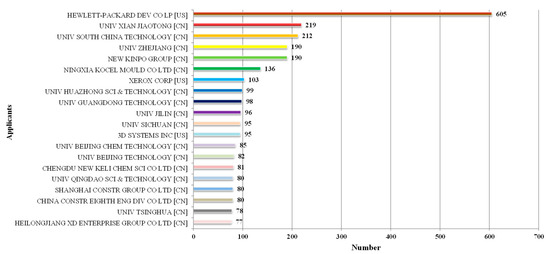

The important contributors of the 3D printing patents are revealed in Figure 12. Most of the top contributors are from the universities of China, however, the Hewlett-Packard Development Company, L.P. from the United States ranks the first of the top patent applicant list. It owns a number of patents to the number of the top three applicants from China combined. Moreover, all the top contributors in the United States are enterprises, indicating compared with China the main driving force of the 3D printing patent applications are economic interests rather than research interests.

Figure 12.

The major contributors to 3D printing patents.

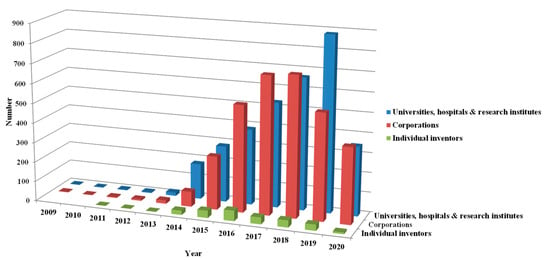

The categorization of the top one hundred 3D printing patent contributors is shown in Figure 13, where three major sorts of contributors can be distinguished, namely “universities, hospitals and research institutes”, “corporations” and “individual inventors”. The “corporations” lead, with enormous increments from 2016 to 2018 until they were finally overtaken by the “universities, hospitals and research institutes” group in 2019.

Figure 13.

The contributor types of 3D printing patents.

3.7. Analysis of the Most Highly Cited Papers

Citation impact is a widely accepted index to evaluate scientific articles, despite the fact it is affected by many factors [105]. The top 10 ESI highly cited papers are analyzed, as shown in Table 6. The most highly cited article is ‘‘3D bioprinting of tissues and organs’’ published in Nature Biotechnology by Murphy et al. [112]. It leads the list with 2142 citations in total and gains the highest total citation per year (TCY), which reveals the wide interest in biomedical applications to some extent. Meanwhile ‘‘Metal Additive Manufacturing: A Review’’ [113] and ‘‘3D Bioprinting of Vascularized, Heterogeneous Cell-Laden Tissue Constructs’’ [114] take the second and third place with 1471 and 865 citations, and quite high annual citations of 166 and 97.6, respectively. Most of the top 10 articles were published in top journals such as Nature [112,115], Advanced Materials [114], Biomaterials [116], etc. It is noteworthy that eight of the ten top papers are from institutions in the United States, showing that the United States is the leading country in this research field. The authors of the other two articles are from the Netherlands [116] and Germany [117], respectively. In addition, only one of the most highly cited papers is contributed by one of the ten top authors i.e., Jennifer Lewis [114]. Two of the most highly cited papers are from same institute i.e., Wake Forest University (USA) and both are authored by Atala [112,115], which shows his position and influence in 3D printing though he is not on the list of the top 10 most productive authors.

Table 6.

Top 10 highly cited papers during the period of 2009–2020.

3.8. Research Interests and Perspectives

As listed in Table 7, the earliest review articles on 3D printing were published in 2010 [116,117]. After that, review articles on 3D printing have appeared every year, and have witnesses an explosive increase since 2014. It is remarkable that there were hundreds of reviews annually published after 2015, which is a strong evidence that 3D printing is a thriving field in the research community. The multidisciplinary characteristic of 3D printing and the variety background of authors results in a diversity of contents, analysis perspectives, and arguments in their publications. The reviews listed in Table 8 are classified based on authors’ technical standpoints, such as materials, performance property, multiscale structure, defect control, efficiency, hybrid print, cost reduction, support framework and post process. The top ten research areas of the publications citing these reviews are multidisciplinary materials science, nanoscience nanotechnology, materials science biomaterials, biomedical engineering, manufacturing engineering, multidisciplinary chemistry, applied physics, polymer science, mechanical engineering, physical chemistry, etc., which are shown in Figure 14.

Table 7.

Reviews on topic of 3D printing.

Table 8.

Technical contents of 3D printing related reviews.

Figure 14.

Research areas bubble chart of the publications citing the reviews on topic of 3D printing.

The review articles covered the latest work around the world and concluded with the recent challenges and future work in this field. These conclusions and suggestions are meaningful for the followers and potential researchers in this field, thus, readers are encouraged to refer to the reviews listed in Table 7 to seek the most creative publications. For example, Liang et al. [122] stressed that more advanced topology optimization methods need to be developed to meet the urgent need of designing high-performance and light-weight structures for multifunctional monolithic products with considering the fabrication speed and resolution. Goh et al. [123] advocated that more research work should be carried out in the material development field so that more choice of materials can be found for specific 3D printing techniques, meanwhile, the selected printing parameters also need to be investigated to improve the static and dynamic mechanical performance properties of the printed materials. Frazier [113] emphasized the importance of closed-loop, real-time, sensing, and control systems for minimizing the defects that dominates the fatigue properties of the 3D printed alloys. Murphy [112] stated that the printability of biocompatible materials is mainly determined by the physiochemical parameters of the hydrogel used, such as the rheological properties and crosslinking mechanisms. However, the challenge is the compatibility of the materials that interact with endogenous tissues and the immune system. Duballet [124] proposed a classification method to explore the variations of parameters and their combinations that shape the possible 3D printing building systems characteristics, but the challenge of the systems is to create new complex building elements of greater performances with considering several disciplines such as rheology, robotics, structural engineering and civil engineering, and not only to speed up the building process. Wallin [125] pointed out that the tight link between soft robotics and 3D printing techniques with materials science is being strengthened. A combination of different 3D printing manufacturing technologies is urgently required for the complex assembly of actuators, sensors, controls and power systems in soft robotics, which need a deep understanding of the thermodynamics, kinetics, phase space and morphological transitions of polymer systems.

Nevertheless, materials science plays a protagonist role in the field of the 3D printing technology, integrating expertise from the fields of electrical engineering, mechanical engineering, chemical engineering, cell biology, biomedical engineering and others [126]. Furthermore, they are all involved in an interdisciplinary cooperation in the 3D printing area to make more substantive achievements. Novel material and multi-material composites were mentioned and discussed in depth in most reviews (referring to Table 8) [126,127,128,129,130], which is an undoubtedly another hotspot in 3D printing. Another vogue is smart materials, which are addressed in [126,131,132]. They can be employed by adding stimuli-responsive materials that can render constructs dynamic and responsive to changes in temperature, pH, electrical or magnetic fields. This is conceiving a next-generation inspiring research ground of the 4D printing technology. Moreover, hybrid systems, combining inkjet printing and FDM, and allowing complex structures to take shape, are another trend in 3D printing that has the potential to mitigate the disadvantages of any single 3D printing technique [126,130,131,132,133,134,135,136,137]. Different from the conventional manufacturing technology, 3D printing is driven by the needs of cost and lead time reduction for developing prototypes of designed parts and products [138], and now it is expected to produce mature products for commercial and medical use. This involves significant challenges in performance properties [139], defect control [113], cost reduction [138] and efficiency [140]. Despite all these aspects, the development of useful and sustainable 3D printing machines will require advances toward more suitable materials and manufacturing technologies, which leads to a systematic work process.

4. Conclusions

Although 3D printing is a relatively new field, there is no doubt that it is growing rapidly. This is supported by the surges in publications, new journals, and general public interest. According to the bibliometric analysis, the institutions in the North America, Asia, and Europe are actively engaged in the 3D printing research, with the United States taking the leading position, followed by China and the UK. Singapore has the highest ACPP, and is the second most active country in cooperating with other countries, especially with China. The Chinese Academy of Sciences is the most productive institution, while Harvard University has the highest ACPP and h-index.

The growth of 3D printing demands new developments in material science, structural topology, and manufacturing process technology. This is reflected in the number and prominence of articles or journals in this field, the science journals discussing biomaterial applications and material performances are in the top list of 3D printing publications. Meanwhile, Materials ranks first among the top 10 journals on 3D printing, whereas “Materials science, Multidisciplinary” is the most attractive area, with 4053 publications.

Jennifer A. Lewis, Ali Khademhosseini, and Dong-woo Cho are the top three most productive authors considering their ACPP and h-index ranks. Despite the top ten authors’ powerful influence, a large number of other researchers are working in this field contributing 97.9% of the total publications. Furthermore, two of top ten highly cited paper are from Wake Forest University (USA) and both of them are authored by Atala though he is not on the list of top ten leading authors.

Despite the limitations of bibliometric studies like a lack of standardization of authors’ name or the unfeasibility to make all-inclusive search queries to search for papers, our study of the reviewed articles on 3D printing suggests that the following aspects are most important aspects to researchers: materials, performance property, multiscale structure, etc. Although there are obstacles to the commercialization and medical applications of 3D printing as discussed in these review articles, advancements of fundamental material theory and manufacturing technology over multidisciplinary areas are expected to be the hotspot and core contributor to motivate the future development of 3D printing.

Author Contributions

Writing—original draft preparation, W.B.; data curation, H.F.; formal analysis, Y.W. (Yawen Wang); investigation, Q.Z.; writing—review and editing, G.H.; supervision, funding acquisition and project administration, G.B.; conceptualization and methodology, Y.W. (Yuehua Wan). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Key Research and Development Program of Zhejiang Province, P. R. China (Grant No. 2020C01150), the National Natural Science Foundation of China (Grant No. 52105127).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors are thankful for the advice and recommendation of the reviewers and editors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gao, W.; Zhang, Y.B.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of Addit. Manuf. in engineering. Comput. Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Bos, F.F.; Wolfs, R.; Ahmed, Z.Z.; Salet, T.T. Addit. Manuf. of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Liu, H.L.; Ahlinder, A.; Yassin, M.A.; Finne-Wistrand, A.; Gasser, T.C. Computational and experimental characterization of 3D-printed PCL structures toward the design of soft biological tissue scaffolds. Mater. Des. 2020, 188, 108488. [Google Scholar] [CrossRef]

- Kim, H.W.; Bae, H.; Park, H.J. Classification of the printability of selected food for 3D printing: Development of an assessment method using hydrocolloids as reference material. J. Food Eng. 2017, 215, 23–32. [Google Scholar] [CrossRef]

- Bockin, D.T.A. Environmental assessment of the automotive industry. J. Cleaner Prod. 2019, 226, 977–987. [Google Scholar] [CrossRef]

- Allarton, R.; Yao, J.; Clifford, T.; Hitchborn, B.; Parker, L.J.; Shaw, J. Surface flow modification of aerofoils for auto-motive racing car applications. Int. J. Mod. Phys. B 2020, 34, 2040096. [Google Scholar] [CrossRef]

- Delic, M.; Eyers, D.R.; Mikulic, J. Additive manufacturing: Empirical evidence for supply chain integration and performance from the automotive industry. Supply Chain Manag. Int. J. 2019, 24, 604–621. [Google Scholar] [CrossRef]

- Tiwary, V.K.; Ravi, N.J.; Arunkumar, P.; Shivakumar, S.; Deshpande, A.S.; Malik, V.R. Investigations on friction stir joining of 3D printed parts to overcome bed size limitation and enhance joint quality for unmanned aircraft systems. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 4857–4871. [Google Scholar] [CrossRef]

- Saorín, J.L.; Lopez-Chao, V.; De La Torre-Cantero, J.; Díaz-Alemán, M.D. Computer Aided Design to Produce High-Detail Models through Low Cost Digital Fabrication for the Conservation of Aerospace Heritage. Appl. Sci. 2019, 9, 2338. [Google Scholar] [CrossRef]

- Abrams, M. 3D Printing in Space. Mech. Eng. 2019, 141, 72. [Google Scholar]

- Cui, H.; Hensleigh, R.; Yao, D.; Maurya, D.; Kumar, P.; Kang, M.G.; Priya, S.; Zheng, X. Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nat. Mater. 2019, 18, 234–241. [Google Scholar] [CrossRef]

- Lyu, Z.; Lim, G.J.H.; Guo, R.; Kou, Z.; Wang, T.; Guan, C.; Ding, J.; Chen, W.; Wang, J. 3D-Printed MOF-Derived Hierarchically Porous Frameworks for Practical High-Energy Density Li-O2 Batteries. Adv. Funct. Mater. 2018, 29. [Google Scholar] [CrossRef]

- Kamyshny, A.; Magdassi, S. Conductive nanomaterials for 2D and 3D printed flexible electronics. Chem. Soc. Rev. 2018, 48, 1712–1740. [Google Scholar] [CrossRef] [PubMed]

- Noor, N.; Shapira, A.; Edri, R.; Gal, I.; Wertheim, L.; Dvir, T. 3D Printing of Personalized Thick and Perfusable Cardiac Patches and Hearts. Adv. Sci. 2019, 6, 1900344. [Google Scholar] [CrossRef]

- Koffler, J.; Zhu, W.; Qu, X.; Platoshyn, O.; Dulin, J.N.; Brock, J.; Graham, L.; Lu, P.; Sakamoto, J.; Marsala, M.; et al. Biomimetic 3D-printed scaffolds for spinal cord injury repair. Nat. Med. 2019, 25, 263–269. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; He, C.; Yang, W.; Qi, F.; Xie, D.; Shen, L.; Peng, S.; Shuai, C. Mg bone implant: Features, developments and perspectives. Mat. Des. 2020, 185, 108259. [Google Scholar] [CrossRef]

- Groll, J.; Burdick, J.A.; Cho, D.-W.; Derby, B.; Gelinsky, M.; Heilshorn, S.C.; Jüngst, T.; Malda, J.; Mironov, V.A.; Nakayama, K.; et al. A definition of bioinks and their distinction from biomaterial inks. Biofabrication 2018, 11, 013001. [Google Scholar] [CrossRef] [PubMed]

- Pati, F.; Gantelius, J.; Svahn, H.A. 3D Bioprinting of Tissue/Organ Models. Angew. Chem. Int. Ed. 2016, 55, 4650–4665. [Google Scholar] [CrossRef]

- Lee, A.; Hudson, A.R.; Shiwarski, D.J.; Tashman, J.W.; Hinton, T.J.; Yerneni, S.; Bliley, J.M.; Campbell, P.G.; Feinberg, A.W. 3D bioprinting of collagen to rebuild components of the human heart. Science 2019, 365, 482–487. [Google Scholar] [CrossRef]

- Yang, H.; Zhu, K.; Zhang, M. Analysis and Building of Trading Platform of Construction 3D Printing Technology and Products. Math. Probl. Eng. 2019, 2019, 1–11. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Baz, B.; Aouad, G.; Leblond, P.; Al-Mansouri, O.; D’Hondt, M.; Remond, S. Mechanical assessment of concrete—Steel bonding in 3D printed elements. Constr. Build. Mater. 2020, 256, 119457. [Google Scholar] [CrossRef]

- Soltani, A.; Noroozi, R.; Bodaghi, M.; Zolfagharian, A.; Hedayati, R. 3D Printing On-Water Sports Boards with Bio-Inspired Core Designs. Polymers 2020, 12, 250. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Sun, Y. A hybrid intelligence technique based on the Taguchi method for mul-ti-objective process parameter optimization of the 3D additive screen printing of athletic shoes. Text. Res. J. 2019, 90, 1067–1083. [Google Scholar] [CrossRef]

- Nur-A-Tomal, S.; Pahlevani, F.; Sahajwalla, V. Direct transformation of waste children’s toys to high quality products using 3D printing: A waste-to-wealth and sustainable approach. J. Clean. Prod. 2020, 267, 122188. [Google Scholar] [CrossRef]

- León-Cabezas, M.; García, A.M.; Varela-Gandía, F. Innovative functionalized monofilaments for 3D printing using fused deposition modeling for the toy industry. Procedia Manuf. 2017, 13, 738–745. [Google Scholar] [CrossRef]

- Rutkin, A. 3D printing masters the art of soft toys. New Sci. 2014, 222, 21. [Google Scholar]

- He, C.; Zhang, M.; Fang, Z. 3D printing of food: Pretreatment and post-treatment of materials. Crit. Rev. Food Sci. Nutr. 2019, 60, 2379–2392. [Google Scholar] [CrossRef] [PubMed]

- Dick, A.; Bhandari, B.; Prakash, S. 3D printing of meat. Meat Sci. 2019, 153, 35–44. [Google Scholar] [CrossRef]

- Brunner, T.; Delley, M.; Denkel, C. Consumers’ attitudes and change of attitude toward 3D-printed food. Food Qual. Prefer. 2018, 68, 389–396. [Google Scholar] [CrossRef]

- Francik, S.; Ślipek, Z.; Frączek, J.; Knapczyk, A. Present trends in research on application of artificial neural networks in agricultural engineering. Agric. Eng. 2016, 20, 15–25. [Google Scholar] [CrossRef][Green Version]

- Gizzi, F.T. Worldwide trends in research on the San Andreas Fault System. Arab. J. Geosci. 2015, 8, 10893–10909. [Google Scholar] [CrossRef]

- Schaffner, M.; Faber, J.A.; Pianegonda, L.; Rühs, P.A.; Coulter, F.; Studart, A.R. 3D printing of robotic soft actuators with programmable bioinspired architectures. Nat. Commun. 2018, 9, 878. [Google Scholar] [CrossRef] [PubMed]

- Carabin, G.; Scalera, L.; Wongratanaphisan, T.; Vidoni, R. An energy-efficient approach for 3D printing with a Linear Delta Robot equipped with optimal springs. Robot. Comput. Integr. Manuf. 2021, 67, 102045. [Google Scholar] [CrossRef]

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent Appl., No. 638905, Filed, 1984. [Google Scholar]

- Juskova, P.; Ollitrault, A.; Serra, M.; Viovy, J.-L.; Malaquin, L. Resolution improvement of 3D stereo-lithography through the direct laser trajectory programming: Application to microfluidic deterministic lateral displacement device. Anal. Chim. Acta 2018, 1000, 239–247. [Google Scholar] [CrossRef]

- Zou, Y.; Han, Q.; Weng, X.; Zou, Y.; Yang, Y.; Zhang, K.; Yang, K.; Xu, X.; Wang, C.; Qin, Y.; et al. The precision and reliability evaluation of 3-dimensional printed damaged bone and prosthesis models by stereo lithography appearance. Medicine 2018, 97, e9797. [Google Scholar] [CrossRef]

- Chen, C.; Xiao, Z.; Zhu, H.; Zeng, X. Distribution and evolution of thermal stress during multi-laser powder bed fusion of Ti-6Al-4 V alloy. J. Mater. Process. Technol. 2020, 284, 116726. [Google Scholar] [CrossRef]

- Calta, N.; Martin, A.; Hammons, J.A.; Nielsen, M.H.; Roehling, T.T.; Fezzaa, K.; Matthews, M.J.; Jeffries, J.R.; Willey, T.; Lee, J.R. Pressure dependence of the laser-metal interaction under laser powder bed fusion conditions probed by in situ X-ray imaging. Addit. Manuf. 2020, 32, 101084. [Google Scholar] [CrossRef]

- Contuzzi, N.; Campanelli, S.L.; Caiazzo, F.; Alfieri, V. Design and Fabrication of Random Metal Foam Structures for Laser Powder Bed Fusion. Materials 2019, 12, 1301. [Google Scholar] [CrossRef]

- Zekavat, A.R.; Jansson, A.; Larsson, J.; Pejryd, L. Investigating the effect of fabrication temperature on mechanical properties of fused deposition modeling parts using X-ray computed tomography. Int. J. Adv. Manuf. Tech. 2019, 100, 287–296. [Google Scholar] [CrossRef]

- Yu, H.; Hong, H.; Cao, S.; Ahmad, R. Topology Optimization for Multipatch Fused Deposition Modeling 3D Printing. Appl. Sci. 2020, 10, 943. [Google Scholar] [CrossRef]

- De Toro, E.V.; Sobrino, J.C.; Martínez, A.M.; Eguía, V.M.; Pérez, J.A. Investigation of a Short Carbon Fibre-Reinforced Polyamide and Comparison of Two Manufacturing Processes: Fused Deposition Modelling (FDM) and Polymer Injection Moulding (PIM). Materials 2020, 13, 672. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Jiang, Y.; Xiao, Y.; Meng, B.; Xing, C.; Zhang, H.; Peng, Z. A fully inkjet-printed transparent humidity sensor based on a Ti3C2/Ag hybrid for touchless sensing of finger motion. Nanoscale 2019, 11, 21522–21531. [Google Scholar] [CrossRef]

- Walczak, R.; Kawa, B.; Adamski, K. Inkjet 3D printed microfluidic device for growing seed root and stalk mechanical characterization. Sensors Actuators A Phys. 2019, 297, 111557. [Google Scholar] [CrossRef]

- Beedasy, V.; Smith, P.J. Printed Electronics as Prepared by Inkjet Printing. Materials 2020, 13, 704. [Google Scholar] [CrossRef] [PubMed]

- Biegler, M.; Marko, A.; Graf, B.; Rethmeier, M. Finite element analysis of in-situ distortion and bulging for an arbitrarily curved Addit. Manuf. directed energy deposition geometry. Addit. Manuf. 2018, 24, 264–272. [Google Scholar] [CrossRef]

- Hamilton, R.F.; Bimber, B.A.; Palmer, T.A. Correlating microstructure and superelasticity of directed energy deposition additive manufactured Ni-rich NiTi alloys. J. Alloy. Compd. 2018, 739, 712–722. [Google Scholar] [CrossRef]

- Kledwig, C.; Perfahl, H.; Reisacher, M.; Brückner, F.; Bliedtner, J.; Leyens, C. Analysis of Melt Pool Characteristics and Process Parameters Using a Coaxial Monitoring System during Directed Energy Deposition in Additive Manufacturing. Materials 2019, 12, 308. [Google Scholar] [CrossRef]

- Gomes, C.M.; Rambo, C.R.; De Oliveira, A.P.N.; Hotza, D.; Gouvea, D.; Travitzky, N.; Greil, P. Colloidal Processing of Glass-Ceramics for Laminated Object Manufacturing. J. Am. Ceram. Soc. 2009, 92, 1186–1191. [Google Scholar] [CrossRef]

- Liao, Y.; Li, H.; Chiu, Y. Study of laminated object manufacturing with separately applied heating and pressing. Int. J. Adv. Manuf. Technol. 2005, 27, 703–707. [Google Scholar] [CrossRef]

- Windsheimer, H.; Travitzky, N.; Hofenauer, A.; Greil, P. Laminated Object Manufacturing of Preceramic-Paper-Derived Si-SiC Composites. Adv. Mater. 2007, 19, 4515–4519. [Google Scholar] [CrossRef]

- Vaezi, M.; Chianrabutra, S.; Mellor, B.; Yang, S. In Multiple material additive manufacturing—Part 1: A review. In Proceedings of the 2018 IEEE International Conference on Smart Cloud, New York, NY, USA, 21–23 September 2018; pp. 19–50. [Google Scholar]

- Rodrigues, T.A.; Duarte, V.; Avila, J.A.; Santos, T.G.; Miranda, R.M.; Oliveira, J.P. Wire and arc additive manufaturing of HSLA steel: Effect of thermal cycles on microstructure and mechanical properties. Addit. Manuf. 2019, 27, 440–450. [Google Scholar]

- Jung, J.W.; Lee, J.S.; Cho, D.W. Computer-aided multiple-head 3D printing system for printing of heterogeneous organ/tissue constructs. Sci. Rep. 2016, 6, 21685. [Google Scholar] [CrossRef] [PubMed]

- Gaynor, A.T.; Meisel, N.A.; Williams, C.B.; Guest, J.K. Multiple-Material Topology Optimization of Compliant Mechanisms Created Via PolyJet Three-Dimensional Printing. J. Manuf. Sci. Eng. Trans. Asme 2014, 136, 061015. [Google Scholar] [CrossRef]

- Ngo, T.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2018, 25, 122–130. [Google Scholar] [CrossRef]

- Layani, M.; Wang, X.; Magdassi, S. Novel Materials for 3D Printing by Photopolymerization. Adv. Mater. 2018, 30, e1706344. [Google Scholar] [CrossRef] [PubMed]

- Ang, B.W.K.; Yeow, R.C.H. A Novel Fold-Based Design Approach toward Printable Soft Robotics Using Flexible 3D Printing Materials. Adv. Mater. Tech. 2018, 3, 1700172. [Google Scholar]

- Canzi, P.; Magnetto, M.; Marconi, S.; Morbini, P.; Benazzo, M. New frontiers and emerging applications of 3D printing in ENT surgery: A systematic review of the literature. Acta Otorhinolaryngol. Ital. 2018, 38, 286–303. [Google Scholar] [PubMed]

- El-Sayegh, S.; Romdhane, L.; Manjikian, S. A critical review of 3D printing in construction: Benefits, challenges, and risks. Arch. Civ. Mech. Eng. 2020, 20, 34. [Google Scholar] [CrossRef]

- Ni, Y.; Ji, R.; Long, K.; Bu, T.; Chen, K.; Zhuang, S. A review of 3D-printed sensors. Appl. Spectrosc. Rev. 2017, 52, 623–652. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, M.; Devahastin, S. 3D extrusion-based printability evaluation of selected cereal grains by computational fluid dynamic simulation. J. Food Eng. 2020, 286. [Google Scholar] [CrossRef]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in Addit. Manuf. on new materials: A review. J. Mater. Sci. Technol. 2018, 35, 242–269. [Google Scholar] [CrossRef]

- Chowdhury, M.R.; Steffes, J.; Huey, B.D.; McCutcheon, J.R. 3D printed polyamide membranes for desalination. Science 2018, 361, 682–686. [Google Scholar] [CrossRef]

- Laura, S.; Jesús, C.; Albert, E.N.; Xavi, I.; Enric, C.; Gorka, O.; María, H.; Rosa, V.; Luis, P.J.; Mar, A. 3D Printed porous polyamide macrocapsule combined with alginate microcapsules for safer cell-based therapies. Sci. Rep. 2018, 8, 8512. [Google Scholar]

- Cruz, P.; Shoemake, E.; Adam, P.; Leachman, J. Tensile strengths of polyamide based 3D printed polymers in liquid nitrogen. IOP Conf. Ser. Mater. Sci. Eng. 2015, 102, 012020. [Google Scholar] [CrossRef]

- Travieso-Rodriguez, J.A.; Jerez-Mesa, R.; Llumà, J.; Traver-Ramos, O.; Gomez-Gras, G.; Rovira, J.J.R. Mechanical Properties of 3D-Printing Polylactic Acid Parts subjected to Bending Stress and Fatigue Testing. Materials 2019, 12, 3859. [Google Scholar] [CrossRef]

- Li, N.; Li, Y.; Liu, S. Rapid prototyping of continuous carbon fiber reinforced polylactic acid composites by 3D printing. J. Mater. Process. Technol. 2016, 238, 218–225. [Google Scholar] [CrossRef]

- Wang, M.; Favi, P.; Cheng, X.; Golshan, N.H.; Ziemer, K.S.; Keidar, M.; Webster, T.J. Cold atmospheric plasma (CAP) surface nanomodified 3D printed polylactic acid (PLA) scaffolds for bone regeneration. Acta Biomater. 2016, 46, 256–265. [Google Scholar] [CrossRef] [PubMed]

- Lerman, M.J.; Muramoto, S.; Arumugasaamy, N.; Van Order, M.; Lembong, J.; Gerald, A.G.; Gillen, G.; Fisher, J.P. Development of surface functionalization strategies for 3D-printed polystyrene constructs. J. Biomed. Mater. Res. Part B Appl. Biomater. 2019, 107, 2566–2578. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Mao, J.; Zhu, Y.; Zhang, K.; Wu, G.; Wu, J.; Zhang, H. Structure and properties of microwave transparent crosslinked polystyrene prepared through 3D printing bulk polymerization. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Gupta, V.; Talebi, M.; Deverell, J.; Sandron, S.; Nesterenko, P.; Heery, B.; Thompson, F.; Beirne, S.; Wallace, G.; Paull, B. 3D printed titanium micro-bore columns containing polymer monoliths for reversed-phase liquid chromatography. Anal. Chim. Acta 2016, 910, 84–94. [Google Scholar] [CrossRef] [PubMed]

- Barnes, J.E. Manufacturing a human heel in titanium via 3D printing. Med. J. Aust. 2015, 202, 118. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef] [PubMed]

- Daly, A.C.; Riley, L.; Segura, T.; Burdick, J.A. Hydrogel microparticles for biomedical applications. Nat. Rev. Mater. 2019, 5, 20–43. [Google Scholar] [CrossRef]

- Miri, A.K.; Khalilpour, A.; Cecen, B.; Maharjan, S.; Shin, S.R.; Khademhosseini, A. Multiscale bioprinting of vascularized models. Biomaterials 2019, 198, 204–216. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, J.; Liu, J.; Qin, H.; Ren, Z.; Doll, G.; Dong, Y.; Ye, C. The effects of electrically-assisted ultrasonic nanocrystal surface modification on 3D-printed Ti-6Al-4V alloy. Addit. Manuf. 2018, 22, 60–68. [Google Scholar] [CrossRef]

- Han, C.; Fang, Q.; Shi, Y.; Tor, S.B.; Chua, C.K.; Zhou, K. Recent Advances on High-Entropy Alloys for 3D Printing. Adv. Mater. 2020, 32, e1903855. [Google Scholar] [CrossRef] [PubMed]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Tayebi, L. 3D Printing of Customized Implants for Treatment of Orofacial Deformities and Defects. Faseb J. 2016, 30, 13.3. [Google Scholar]

- Chen, H.; Zhang, J.; Li, X.; Liu, L.; Zhang, X.; Ren, D.; Ma, C.; Zhang, L.; Fei, Z.; Xu, T. Multi-level customized 3D printing for autogenous implants in skull tissue engineering. Biofabrication 2019, 11, 045007. [Google Scholar] [CrossRef] [PubMed]

- Shao, G.; Hai, R.; Sun, C. 3D Printing Customized Optical Lens in Minutes. Adv. Opt. Mater. 2019, 8. [Google Scholar] [CrossRef]

- Srinivasan, R.; Giannikas, V.; McFarlane, D.; Thorne, A. Customising with 3D printing: The role of intelligent control. Comput. Ind. 2018, 103, 38–46. [Google Scholar] [CrossRef]

- Cesarano, J.; Stuecker, J.; Calvert, P. 3D Printing of Ceramics: Processes and Constraints. Adv. Mater. Process. 2019, 177, 28–31. [Google Scholar]

- Warnke, P.H.; Seitz, H.; Warnke, F.; Becker, S.T.; Sivananthan, S.; Sherry, E.; Liu, Q.; Wiltfang, J.; Douglas, T. Ceramic scaffolds produced by computer-assisted 3D printing and sintering: Characterization and biocompatibility investigations. J. Biomed. Mater. Res. Part B Appl. Biomater. 2010, 93, 212–217. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Sun, J.; Dai, N.; Wu, Z.; Wu, H.; Yang, C. Crystal structure, infrared spectra and microwave dielectric properties of novel extra low-temperature fired Eu2Zr3(MoO4)9 ceramics. J. Eur. Ceram. Soc. 2018, 39, 1127–1131. [Google Scholar] [CrossRef]

- Jeong, H.; Han, S.J.; Choi, S.H.; Lee, Y.J.; Yi, S.T.; Kim, K.S. Rheological Property Criteria for Buildable 3D Printing Concrete. Materials 2019, 12, 657. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Liu, G.; Yang, Y.; Wu, M.; Pang, B. Fresh properties of a novel 3D printing concrete ink. Constr. Build. Mater. 2018, 174, 263–271. [Google Scholar] [CrossRef]

- Vantyghem, G.; Corte, W.D.; Shakour, E.; Amir, O. 3D printing of a post-tensioned concrete girder designed by topology optimization. Autom. Constr. 2020, 112, 103084. [Google Scholar]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Xiao, L.P.; Liu, X.M.; Zhong, R.T.; Zhang, K.Q.; Zhang, X.D.; Zhou, X.M.; Lin, B.C.; Du, Y.G. A rapid, straightforward, and print house compatible mass fabrication method for integrating 3D paper-based microfluidics. Electrophoresis 2013, 34. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Rousseau, R. Forgotten founder of bibliometrics. Nature 2014, 510, 218. [Google Scholar] [CrossRef]

- Simmons, P.; McElroy, T.; Allen, A.R. A Bibliometric Review of Artificial Extracellular Matrices Based on Tissue Engineering Technology Literature: 1990 through 2019. Materials 2020, 13, 2891. [Google Scholar] [CrossRef]

- Ho, Y.-S. Top-cited Articles in Chemical Engineering in Science Citation Index Expanded: A Bibliometric Analysis. Chin. J. Chem. Eng. 2012, 20, 478–488. [Google Scholar] [CrossRef]

- Shukla, A.K.; Muhuri, P.K.; Abraham, A. A bibliometric analysis and cutting-edge overview on fuzzy techniques in Big Data. Eng. Appl. Artif. Intell. 2020, 92, 103625. [Google Scholar] [CrossRef]

- Bahoo, S.; Alon, I.; Floreani, J. Corruption in economics: A bibliometric analysis and research agenda. Appl. Econ. Lett. 2020, 28, 565–578. [Google Scholar] [CrossRef]

- Yun, B.; Lee, J.Y.; Ahn, S. The Intellectual Structure of Women’s Studies: A Bibliometric Study of its Research Topics and Influential Publications. J. Asian Women 2020, 36, 1–23. [Google Scholar] [CrossRef]

- Zhao, X.; Zuo, J.; Wu, G.; Huang, C. A bibliometric review of green building research 2000–2016. Arch. Sci. Rev. 2018, 62, 74–88. [Google Scholar] [CrossRef]

- Liu, Z.; Moon, J.; Kim, B.; Dai, C.-P. Integrating adaptivity in educational games: A combined bibliometric analysis and meta-analysis review. Educ. Technol. Res. Dev. 2020, 68, 1931–1959. [Google Scholar] [CrossRef]

- Hernández-Torrano, D.; Ibrayeva, L.; Sparks, J.; Lim, N.; Clementi, A.; Almukhambetova, A.; Nurtayev, Y.; Muratkyzy, A. Mental Health and Well-Being of University Students: A Bibliometric Mapping of the Literature. Front. Psychol. 2020, 11. [Google Scholar] [CrossRef]

- Yu, D.; He, X. A bibliometric study for DEA applied to energy efficiency: Trends and future challenges. Appl. Energy 2020, 268, 115048. [Google Scholar] [CrossRef]

- Bao, G.; Fang, H.; Chen, L.; Wan, Y.; Xu, F.; Yang, Q.; Zhang, L. Soft Robotics: Academic Insights and Perspectives Through Bibliometric Analysis. Soft Robot. 2018, 5, 229–241. [Google Scholar] [CrossRef] [PubMed]

- Peña, V.; Lal, B.; Micali, M.U.S. Federal Investment in the Origin and Evolution of Additive Manufacturing: A Case Study of the National Science Foundation. 3D Print. Addit. Manuf. 2014, 1, 185–193. [Google Scholar] [CrossRef]

- Harris, G.; Caudle, L. A Systems Approach to Establishing an Advanced Manufacturing Innovation Institute. Systems 2019, 7, 41. [Google Scholar] [CrossRef]

- Wang, J.; Wu, H.; Chen, Y. Made in China 2025 and manufacturing strategy decisions with reverse QFD. Int. J. Prod. Econ. 2019, 224, 107539. [Google Scholar] [CrossRef]

- Tyroler-Cooper, S.; Peet, A. The Chinese Aviation Industry: Techno-Hybrid Patterns of Development in the C919 Program. J. Strat. Stud. 2011, 34, 383–404. [Google Scholar] [CrossRef]

- E.U. Commission. Additive Manufacturing in FP7 and Horizon 2020: Report from the EC Workshop on Additive Manufacturing held on 18 June 2014; EU Commission: Brussels, Belgium, 2014. [Google Scholar]

- Ho, C.M.B.; Ng, S.H.; Yoon, Y.J. A review on 3D printed bioimplants. Int. J. Precis. Eng. Manuf. 2015, 16, 1035–1046. [Google Scholar] [CrossRef]

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mat. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Kolesky, D.B.; Truby, R.; Gladman, A.S.; Busbee, T.A.; Homan, K.A.; Lewis, J.A. 3D Bioprinting of Vascularized, Heterogeneous Cell-Laden Tissue Constructs. Adv. Mater. 2014, 26, 3124–3130. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.-W.; Lee, S.J.; Ko, I.K.; Kengla, C.; Yoo, J.J.; Atala, A. A 3D bioprinting system to produce human-scale tissue constructs with structural integrity. Nat. Biotechnol. 2016, 34, 312–319. [Google Scholar] [CrossRef] [PubMed]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef]

- Rengier, F.; Mehndiratta, A.; Tengg-Kobligk, H.V.; Zechmann, C.M.; Unterhinninghofen, R.; Kauczor, H.U.; Giesel, F.L. 3D printing based on imaging data: Review of medical applications. Int. J. Comput. Assisted Radiol. Surg. 2010, 5, 335–341. [Google Scholar] [CrossRef] [PubMed]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Debroy, T.; Wei, H.L.; Zuback, J.; Mukherjee, T.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone tissue engineering using 3D printing. Mater. Today 2013, 16, 496–504. [Google Scholar] [CrossRef]

- Gross, B.C.; Erkal, J.L.; Lockwood, S.Y.; Chen, C.; Spence, D.M. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences. Anal. Chem. 2014, 86, 3240–3253. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, W.; Quan, D.; Shi, G.; Tang, L.; Hou, Y.; Breitkopf, P.; Zhu, J.; Gao, T. From Topology Optimization Design to Additive Manufacturing: Today’s Success and Tomorrow’s Roadmap. Arch. Comput. Methods in Eng. 2019, 27, 805–830. [Google Scholar] [CrossRef]

- Goh, G.D.; Yap, Y.L.; Tan, H.; Sing, S.L.; Goh, G.L.; Yeong, W.Y. Process–Structure–Properties in Polymer Addit. Manuf. via Material Extrusion: A Review. Critical Rev. Solid State Mater. Sci. 2019, 45, 113–133. [Google Scholar] [CrossRef]

- Duballet, R.; Baverel, O.; Dirrenberger, J. Classification of building systems for concrete 3D printing. Autom. Constr. 2017, 83, 247–258. [Google Scholar] [CrossRef]

- Wallin, T.J.; Pikul, J.; Shepherd, R.F. 3D printing of soft robotic systems. Nature Rev. Mater. 2018, 8, 84–100. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, F.; Yan, Z.; Ma, Q.; Li, X.; Huang, Y.; Rogers, J.A. Printing, folding and assembly methods for forming 3D mesostructures in advanced materials. Nature Rev. Mater. 2017, 2, 17019. [Google Scholar] [CrossRef]

- Butscher, A.; Bohner, M.; Hofmann, S.; Gauckler, L.; Mueller, R. Structural and material approaches to bone tissue en-gineering in powder-based three-dimensional printing. Acta Biomater. 2011, 7, 907–920. [Google Scholar] [CrossRef] [PubMed]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Mandrycky, C.; Wang, Z.; Kim, K.; Kim, D.-H. 3D bioprinting for engineering complex tissues. Biotechnol. Adv. 2016, 34, 422–434. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Ashammakhi, N.; Hasan, A.; Kaarela, O.; Byambaa, B.; Sheikhi, A.; Gaharwar, A.K.; Khademhosseini, A. Advancing Frontiers in Bone Bioprinting. Adv. Healthc. Mater. 2019, 8, 1801048. [Google Scholar] [CrossRef]

- Matai, I.; Kaur, G.; Seyedsalehi, A.; McClinton, A.; Laurencin, C.T. Progress in 3D bioprinting technology for tissue/organ regenerative engineering. Biomaterials 2020, 226, 119536. [Google Scholar] [CrossRef]

- Do, A.-V.; Khorsand, B.; Geary, S.M.; Salem, A.K. 3D Printing of Scaffolds for Tissue Regeneration Applications. Adv. Healthc. Mater. 2015, 4, 1742–1762. [Google Scholar] [CrossRef] [PubMed]

- Ho, C.; Ng, S.; Li, K.; Yoon, Y.J. 3D printed microfluidics for biological applications. Lab Chip 2015, 15, 3627. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. Trans. Asme 2015, 137, 014001. [Google Scholar] [CrossRef]

- Truby, R.L.; Lewis, J.A. Printing soft matter in three dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, G.; Johnson, B.N.; Jia, X. Three-dimensional (3D) Printed Scaffold and Material Selection for Bone Repair. Acta Biomater. 2018, 84, 16–33. [Google Scholar] [CrossRef] [PubMed]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Müllhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Tan, C.; Li, L. Review of 3D printable hydrogels and constructs. Mat. Des. 2018, 159, 20–38. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Fu, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2018, 39, 661–687. [Google Scholar] [CrossRef]

- Dai, L.; Cheng, T.; Duan, C.; Zhao, W.; Zhang, W.; Zou, X.; Aspler, J.; Ni, Y. 3D Printing Using Plant-derived Cellulose and Its Derivatives: A Review. Carbohydr. Polym. 2018, 203, 71–86. [Google Scholar] [CrossRef] [PubMed]

- Velasco-Hogan, A.; Xu, J.; Meyers, M.A. Additive Manufacturing as a Method to Design and Optimize Bioinspired Structures. Adv. Mater. 2018, 30, 103084. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dental Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Bhattacharjee, N.; Urrios, A.; Kanga, S.; Folch, A. The upcoming 3D-printing revolution in microfluidics. Lab Chip 2016, 16, 1720–1742. [Google Scholar] [CrossRef] [PubMed]

- Malda, J.; Visser, J.; Melchels, F.P.; Juengst, T.; Hennink, W.E.; Dhert, W.J.A.; Groll, J.; Hutmacher, D.W. 25th Anniversary Article: Engineering Hydrogels for Biofabrication. Adv. Mater. 2013, 25, 5011–5028. [Google Scholar] [CrossRef]

- Ozbolat, I.T.; Yu, Y. Bioprinting Toward Organ Fabrication: Challenges and Future Trends. IEEE Trans. Biomed. Eng. 2013, 60, 691–699. [Google Scholar] [CrossRef] [PubMed]

- Derby, B. Printing and Prototyping of Tissues and Scaffolds. Science 2012, 338, 921–926. [Google Scholar] [CrossRef] [PubMed]

- Melchels, F.P.W.; Domingos, M.A.N.; Klein, T.J.; Malda, J.; Bartolo, P.J.; Hutmacher, D.W. Additive manufacturing of tissues and organs. Prog. Polym. Sci. 2012, 37, 1079–1104. [Google Scholar] [CrossRef]

- Guillotin, B.; Guillemot, F. Cell patterning technologies for organotypic tissue fabrication. Trends Biotechnol. 2011, 29, 183–190. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).