Abstract

Sunflower threshing is one of the most interesting field processes for making the sunflower ready for seed handling, drying, cleaning and oil extraction. One of the biggest problems observed during the sunflower threshing process is the accumulation of threshed crop on the first third of the threshing roller and passing off some unthreshed parts of sunflower heads. To solve the aforementioned problem and optimize the efficiency of the sunflower threshing process, this research was focused on devising and testing a sunflower threshing machine with a close threshing box system equipped with a screw conveyor that evenly distributed the feedstock of sunflower heads on the entire length of the threshing roller. The machine was tested to assess the seed damage rate, unthreshed seed percentage, threshing efficiency, machine productivity, power requirements and specific energy consumption. The evaluation was done under different roller rotational speeds (150, 200, 250 and 300 rpm) and feeding rates (600, 700, 800 and 900 kg/h). The obtained results revealed that the threshing evaluation parameters were affected significantly by the roller rotational speed and feeding rate. The threshing efficiency was observed to rise with the rise in the roller rotational speed, and it also rose with the increasing feed rate up to 800 kg/h and then started to descend. The unthreshed seed percentage decreased with the increase in the roller rotational speed for all feed rates, and it decreased with the increasing feed rate up to 800 kg/h and then started to increase at the higher feed rates. The damaged seed percentage, power requirement and machine productivity increased with the increase of the roller speed and feed rate. The Buckingham π theorem was followed to find an equation to predict the threshing efficiency, resulting in an equation with an R2 value of 0.9309. With elimination of the blockage problem and better threshing efficiency, this machine could be a good choice for small- to medium-sized sunflower farms.

1. Introduction

Sunflower (Helianthus annuus L.) is one of the vital oilseed crops, grown throughout the world since 4000 years ago as a source of edible oil and dietary fiber that significantly enhances human health as well as livestock feed [1,2]. China plays a central role in the international production of sunflower oilseed crops. In 2018, the sunflower planting area in China reached 880,000 ha with 2.42 million tons of production, mainly distributed in the northeast, north and northwest regions [3]. At present, there is no specialized oil sunflower combine harvester in China, and all existing models are modified based on rice and wheat harvesters. Sunflower producers in many countries using rice or soya bean threshing machines to thresh sunflower heads, resulting in seeds damages amounting to more than 4–10% and seed losses of 3–13%, while some threshers resulted in grain losses of 20–35% [4].

The main purposes of mechanized sunflower threshing are to replace reduced manual labor efforts to thresh sunflower in fields, reduce threshing time, raise the quality of threshed seed and increase threshing efficiency. Productivity, threshing efficiency, broken seeds, grain loss, power consumption, cleaning efficiency and specific energy are the indicators for a thresher’s performance [5]. In Ref. [6], it was made clear that the sunflower threshing process is affected directly by the feed rate, roller speed, concave clearance and thresher type. The seed loss percentage may reach 6% in the threshing or striking process [7].

The untraditional methods of threshing sunflowers depend upon striking, friction and concurrent striking with friction [8]. The authors of [9] made and tested a rubbing thresher machine to thresh flax and sunflower crops. The performance of the rubbing threshing machine was estimated at different threshing roller speeds, threshing belt linear speeds and concave clearances. The data showed that for the two crops, the threshing efficiency increased with the increase in the roller speed, and it decreased with the increase in the concave clearance. Furthermore, the authors of [10] assessed several typical sunflower thresher machines, with the axial flow design being used. Their study indicated that it is better to thresh sunflower at a cylinder revolving speed of 6.5 m/s with a head feeding rate of 1500–2000 kg/h at a seed moisture content of 30% (w/w). The authors of [11] developed a test bench thresher for sunflower heads, applying fundamental techniques used for seed threshers. The test outcomes illustrated that the best thresher operation occurred at a feed rate of 180 kg/h, a cylinder rotational speed of 500 rpm and a crop moisture content of 9–13%. The authors in [12] examined some engineering parameters (concave hole size, concave clearance and roller speed) to evaluate a rasp-bar thresher used in the sunflower threshing process. The authors of [13] designed and tested the performance of a pedal-operated sunflower thresher according to its threshing efficiency, cleaning efficiency, damaged seed quantity, machine productivity and the consumed specific energy under three levels of the pressure surface pressing on the friction roller (2.0, 4.0 and 6.0 kg/cm2), four levels of the friction roller speed (2.8, 3.7, 4.9 and 6.9 m/s), different radial curves of the pressure surface (330, 345 and 365 mm) and different resting times of the sunflower heads inside the threshing chamber (5, 10, and 15 s). The authors in [14] designed and fabricated a sunflower seed extraction machine to separate the seeds from the sunflower heads in order to overcome the problems faced by farmers during the manual threshing process.

Many studies revealed that the broken grain percentage was increased with the increase in the thresher roller rotational speed while it was decreased with the increasing grain moisture content as well as unthreshed grains [15,16,17].

For axial flow threshers, about 80% of the crops are threshed in the first half of the threshing area, whereas just 20% of the crops are threshed in the other half [15], which may lead to decreased threshing efficiency and increased threshing power requirements, in addition to blockages and the machine sometimes ceasing to work.

The authors of [18] evaluated the screw conveyor performance through its output productivity, volumetric efficiency, seed damage percentage and specific conveying energy. Their results concluded that some operation parameters affect the performance efficiency of conveyors, like the transported materials’ properties, the difference between conveying place levels, conveyor size, conveyor screw speed, conveyor length and the distance between the ends of the screw and the inner diameter of the conveyor cylinder. The authors of [19] investigated the effect of the transport distance on the power requirements for screw conveyors at various speeds., while in [20], the authors developed a sunflower threshing device to separate seeds under the influence of centrifugal and gravitational forces. Meanwhile, the authors of [21] tested the air-jet effect on a sunflower seed separating from its head in static conditions.

Despite China having an advanced place between other countries in sunflower planting, however, the mechanization of sunflower treatment in China is not at the desired level [22,23].

This research was conducted to design an axial flow sunflower threshing machine attached with a screw conveyor and study the effect of the roller rotational speed and feeding rate to evaluate its performance and select the optimal operation conditions. A mathematical equation was developed to simulate and predict the threshing efficiency of the machine, which helped to save time and other resources by reducing the number of field experiments.

2. Materials and Methods

2.1. Materials

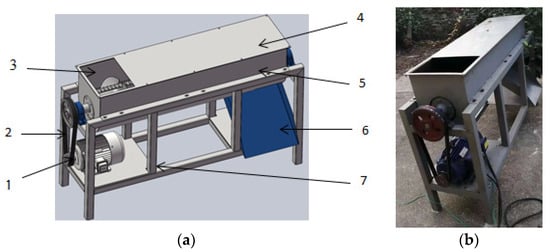

The current study was conducted at Taizi Town, Huangshi City, Hubei, China with the DW667 variety of sunflower oilseeds, which were harvested traditionally at a moisture content of 16.75% (w/w) for the seeds to test and evaluate the axial flow sunflower threshing machine attached with a screw conveyor. The stationary sunflower threshing machine used in the current work had dimensions of 1650 mm, 1000 mm and 500 mm for its length, height and width, respectively, as shown in Figure 1. It consisted of the following parts:

Figure 1.

Designed model (a) and prototype (b) of the sunflower threshing machine, consisting of the following functional parts: the power source (1), power transmission system (2), feed opening (3), cover (4), threshing box (5), output opening and tray (6) and thresher frame (7).

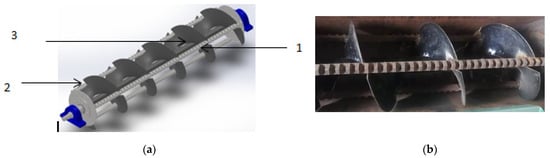

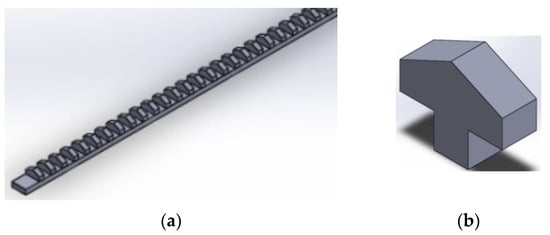

The threshing unit consisted of three steel loop bars attached with a steel screw conveyor, with 120 degrees between each bar (Figure 2). Each loop bar was made from steel and was 1305 mm length, 30 mm wide and 10 mm thick, containing 51 steel teeth with a tooth thickness of 10 mm and 15 mm high as shown in Figure 3a,b. A steel screw conveyor contained five patches, with a total length of 1350 mm, a patch length of 260 mm and an outer diameter of 310 mm, attached to loop bars. There was a vertical gap between the highest point of the teeth and the outer diameter of the screw equaling 15 mm to allow sunflower heads to pass between the teeth and the inner wall of the threshing unit.

Figure 2.

Designed model (a) and prototype (b) of the threshing roller and the screw conveyor, showing the loop threshing bar (1), the screw conveyor (2) and the main threshing shaft (3).

Figure 3.

(a) The loop threshing bar and (b) a threshing tooth.

The threshing box was a rectangular box with a semicircle base. It contained the threshing unit and a feed opening 335 mm in length and 250 mm wide, and it also had an outlet hole below the next end of the box with dimensions of 335 × 200 mm.

The mainframe was constructed from 45-mm square steel pipes to carry the threshing box, threshing unit, power source and power transmission system. The power was transmitted from a three-phase electric motor (3 kW and 1700 rpm) to the threshing unit by two aluminum pulleys and a V-belt with a reducing gearing ratio of 0.50 between the motor and roller.

The roller rotational speed was determined by a digital tachometer with an accuracy of ±0.05% + 1, ranging from 1 to 19,999 rpm (Shenzhen Victor Hi-Tech Co, Ltd.; DM6234P+; Guangzhou, Shenzhen, China). An electrical speed converter was used to control the motor revolving speed, which led to controlling the roller rotational speed. A CALDIPREE BM822A digital DC/AC clamp meter and multi-meter (Shenzhen Binjiang Electronic Technology Co, Ltd.; BM822A, Guangzhou, Shenzhen, China) capable of measuring the voltage in volts (V), current in amperes (A) and resistance in ohms (Ω) with a current accuracy of ±2% A was used to measure the current (A) to the power source (motor) to determine the required power for the threshing process.

2.2. Methods

2.2.1. Experiments Design

The platform was tested under four roller rotational speeds (150, 200, 250 and 300 rpm (1.39, 2.77, 3.47 and 4.2 m/s)) and four levels of feeding rates (10, 11.66, 13.33 and 15 kg/min) were used to achieve feeding rates of 600, 700, 800 and 900 kg/h, respectively. All treatments were replicated thrice, and the threshing time was recorded for each experimental test.

2.2.2. Theoretical Equations

Threshing Force

Separating seeds from, for example, pods, spikes or heads requires a detachment force F, which can be expressed as a function of the cylinder’s linear speed, the friction coefficient between crop parts and the friction coefficient between the crops and the thresher parts [24]:

where F is the total threshing force (N), Fc is the cylinder’s impact force (N) and Fr represents the friction forces.

The cylinder impact force can be calculated as a function of the feeding rate and the crop linear speed inside the threshing unit with the following equation [8]:

where q is the crop feeding rate in kg/s, is the crop speed at the end of the cylinder in m/s and is the crop speed as it enters the cylinder in m/s.

Usually, depends upon the cylinder’s linear speed, and it can be predicted from the following equation:

where is an empirical figure related to the cylinder length, straw moisture content, threshing bar shape, feeding rate and physical properties of the thresher. For a thresher 0.8 m in length with a moisture content of 15–25% and a feeding rate of 12,600 kg/h, the coefficient was determined equal to 0.70–0.85 [25], and is the linear speed of the cylinder:

where is a coefficient for the rasp-bar thresher type, which is equal to (0.65–0.75) [8], and F is the force needed for threshing crops (i.e., the total threshing force) [26].

By inserting Equations (2)–(4) into Equation (1), the resulting equation is as follows:

The required threshing force to overcome the seed’s attachment force can be calculated from Equation (6). According to this equation, the diameter of the threshing roller and the critical roller rotational speed are estimated, as well as the range of the feeding rate. It was taken into account that the directed force of the seeds should not exceed 8.5 N (the lowest average breaking force for under-studying seed at the same moisture content, which was determined by using a TMS-PRO texture analyzer device (Spectronic CamSpec Ltd., TMS-PRO, Chicago, IL, USA)):

The following equation is used to determine the suitable diameter of the steel shafts with almost no axial load [26], and it was designed with a safety factor of 3.81:

where n is a safety factor, τmax is the allowable stress (40–55 MPa), Kt and Kb are the combined shock and fatigue factors applied to bending and torsional moment, respectively, Mt is the torsional moment (N.mm) and Mb is the bending moment (N.mm). Kb = 1.2–2.0, and Kt = 1.0–1.5 [26].

The Seed Damage Percentage

The seed damage percentage was measured from the following equation:

where d is the mass of the damaged seed (g) and t is the total mass of the sample (g).

The Percentage of Unthreshed Seed

The percentage of unthreshed seed was calculated with the following equation:

where Utl is the percentage of unthreshed seed, Utm is the mass of the unthreshed seed (g) and Soutlet is the mass of the threshed seeds at the main seed outlet.

Threshing Efficiency

By knowing the damaged seed percentage and unthreshed seed percentage (total seed losses), the threshing efficiency can be calculated from the following equation:

Thresher Productivity (kg/h)

The thresher’s working productivity was calculated by using the recorded threshed quantity of sunflower heads and experiment running time according to the following equation:

where Sw is the mass of the threshed sunflower heads (kg) and T is the threshing time (s).

Power Requirements

For three-phase motors, by measuring the average value of the current line (in amperes) going to power source and the recorded voltage, the consumed power can be calculated by inserting these values in the following equation [27]:

where P is the power requirements (kW), I is the line current strength in amperes (A), V is the potential difference (V), which was equal to 380 V, η is the mechanical efficiency, which was assumed to be 95%, cos θ is the power factor (85%) and is the coefficient of consumed three-phase current ( motor specifications).

The Specific Energy

The specific consumed energy (kW.h/ton) was calculated according to the following equation:

Randomized complete block design (RCBD) analysis was conducted to design and analyze the experiments, with three replicates for each treatment and making use of the SPSS software program (SPSS Inc., version 20, Chicago, IL, USA), following the two-way ANOVA test method with the L.S.D at a 5% probability level.

Mathematical Modeling

According to Buckingham’s π theorem, the following dimensionless groups were obtained to predict the threshing efficiency during the threshing process:

, and , where η is the threshing efficiency, is the roller speed (m/s), is the threshing time (s), L is the roller length (m), FR is the feed rate (kg/s) and is the sunflower bulk density (kg/m3).

3. Results and Discussion

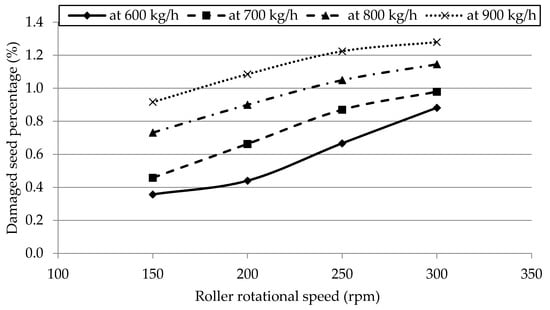

3.1. Effect of the Roller’s Rotational Speed on the Damaged Seed Percentage at Different Feed Rates

The experimental results obtained from the current study are represented by line charts. As is shown in Figure 4, the damaged seed percentage increased from 0.36% to 0.88%, 0.46% to 0.98%, 0.73% to 1.15% and 0.92% to 1.28% with the increase of the roller’s rotational speed to 150, 200, 250 and 300 rpm for 600 kg/h, 700 kg/h, 800 kg/h and 900 kg/h feed rates, respectively. At higher roller rotational speeds, the threshing bars struck the sunflower heads and seeds more strongly, breaking more seeds, which was why higher speeds resulted in higher damaged seed percentages. The results of the seed damage percentage of this study coincided with those in previous studies [8,28], while the accumulation of sunflower heads inside the threshing box at high feed rates also led to a rise in the broken seed percentage.

Figure 4.

Effect of the roller’s rotational speed (rpm) on the damaged seed percentage (%) at different feeding rates.

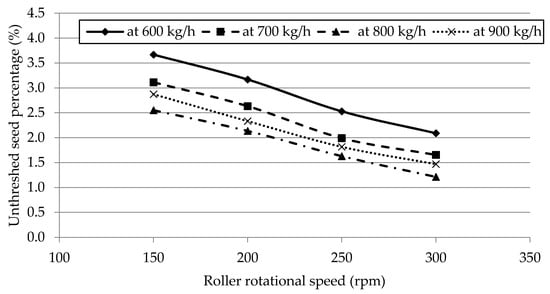

3.2. Effect of the Roller’s Rotational Speed on the Unthreshed Seed Percentage at Different Feed Rates

The unthreshed seed percentage decreased with the increase of roller rotational speed for all feeding rates. It decreased from 3.67% to 2.09%, 3.11% to 1.65%, 2.55% to 1.21% and 2.87% to 1.47% with increasing roller rotational speeds of 150, 200, 250 and 300 rpm at feed rates of 600 kg/h, 700 kg/h, 800 kg/h and 900 kg/h, respectively, as shown in Figure 5). These results were in agreement with previous studies [8] in the same operational conditions, while the obtained data of that study showed that the unthreshed seed decreased with the increase of the feed rate from 600 kg/h to 800 kg/h and then increased with the increase of the feed rate from 800 kg/h to 900 kg/h. The increase in the roller’s rotational speed may lead to increased sunflower head friction with the threshing bars and the threshing box wall, increasing the sunflower heads’s contact with each other and leading to a reduction of the unthreshed seed percentage. On the other hand, increasing the feed rate also led to an increase in the friction action between the sunflower heads up to a limited point.

Figure 5.

Effect of the roller’s rotational speed (rpm) on the unthreshed seed percentage (%) at different feed rates (kg/h).

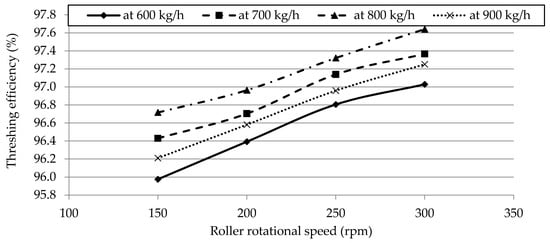

3.3. Effect of the Roller’s Rotational Speed on the Threshing Efficiency at Different Feed Rates

As is represented in Figure 6, the threshing efficiency increased with the increase in the roller’s rotational speed. It also increased with the increase of the feed rate from 600 kg/h to 800 kg/h, but it began to decrease with the feed rate increasing from 800 kg/h to 900 kg/h. The threshing efficiency increased from 95.98% to 97.03%, 96.43% to 97.37%, 96.72% to 97.64% and 96.21% to 97.25% for feed rates of 600 kg/h, 700 kg/h, 800 kg/h and 900 kg/h, respectively, which was in line with previous studies [8,28]. These results recorded a high threshing efficiency compared with the reported results [4]. The threshing efficiency was calculated from Equation (9), which included the unthreshed seed and damaged seed percentages. As the quantity of unthreshed seed was more than the damaged seed, the threshing efficiency was more highly affected by the unthreshed seed percentage than the damaged seed percentage.

Figure 6.

Effect of the roller’s rotational speed (rpm) on the threshing efficiency (%) at different feed rates (kg/h).

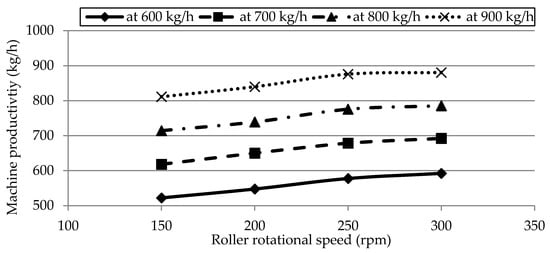

3.4. Effect of the Roller’s Rotational Speed on the Machine’s Productivity at Different Feed Rates

Figure 7 explains that the sunflower threshing machine’s output productivity was increased with the increase of both the roller’s rotational speed and feeding rate. This result agreed with [29] for the same range of operational conditions. The machine’s productivity increased from 522.16 kg/h to 592.34 kg/h, 618.24 kg/h to 692.46 kg/h, 714.30 kg/h to 785.46 kg/h and 811.35 kg/h to 880.45 kg/h when the roller’s rotational speed increased to 150 rpm, 200 rpm, 250 rpm and 300 rpm at feed rate levels of 600 kg/h, 700 kg/h, 800 kg/h and 900 kg/h, respectively. The increase in the machine’s productivity with the increased roller revolving speed may have been due to the action of the screw conveyor, which was affected directly by the rotational speed for its calculated productivity.

Figure 7.

Effect of the roller’s rotational speed (rpm) on the machine’s productivity (kg/h) at different feed rates (kg/h).

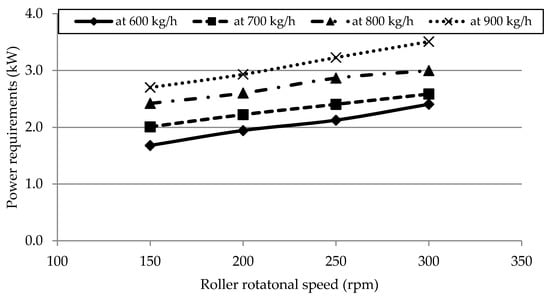

3.5. Effect of the Roller’s Rotational Speed on Power Requirements at Different Feed Rates

Figure 8 explains that the power requirement increased with the increase in both the roller’s rotational speed and the feeding rate. This result is in line with the results in [28,29]. With the roller rotational speeds increasing to 150 rpm, 200 rpm, 250 rpm and 300 rpm, the power requirement increased from 1.68 kW to 2.41 kW, 2.01 kW to 2.59 kW, 2.42 kW to 3 kW and 2.70 kW to 3.51 kW for feed rate levels of 600 kg/h, 700 kg/h, 800 kg/h and 900 kg/h, respectively. The increasing power requirements with the increase in both the roller’s rotational speed and the feeding rate was due to the increased load on the electric motor.

Figure 8.

Effect of the roller’s rotational speed (rpm) on the power requirements (kW) at different feed rates (kg/h).

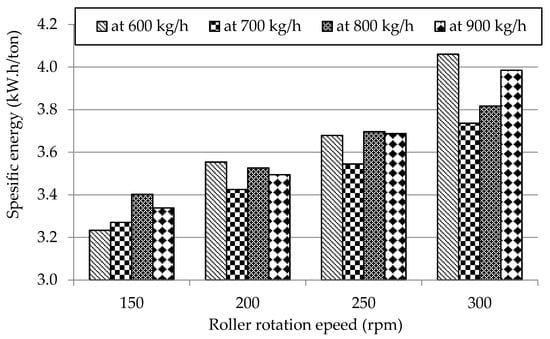

3.6. Effect of the Roller’s Rotational Speed on the Specific Energy at Different Feed Rates

The consumed specific energy increased with the increase of the roller’s rotational speed for all feeding rates, while the effect of the feeding rate on the consumed specific energy was non-significant, which caused an unclear impression on the diagram (Figure 9). It is noted that the consumed specific energy increased from 3.23 kW.h/ton to 4.06 kW.h/ton, 3.27 kW.h/ton to 3.74 kW.h/ton kW, 3.40 kW.h/ton to 3.80 kW.h/ton and 3.34 kW.h/ton to 3.98 kW.h/ton with the increasing roller rotational speed of 150 rpm, 200 rpm, 250 rpm and 300 rpm at feed rate levels of 600 kg/h, 700 kg/h, 800 kg/h and 900 kg/h, respectively. The unclear influence of the feed rate on the specific energy may have been due to the specific energy, which depends upon the machine’s productivity and power requirements, while the increase of the specific energy with the increasing roller rotational speed was because of the rate of the power requirement rising with the increasing roller speed, which was higher than the increase in the machine’s productivity rate.

Figure 9.

Effect of the roller’s rotational speed (rpm) on the specific energy (kg.h/ton) at different feed rates (kg/h).

3.7. Statistical Analysis

Table 1 represents the analysis of variance for the significance of the study parameters in relation to the performance of the sunflower threshing machine. It is clear that the damaged seed percentage was affected significantly at the probability level of 1% by increasing both the roller’s rotational speed and the feed rate. A higher effect was recorded for the feed rate than the roller’s rotational speed, while the effect of the interaction between the feed rate and the rotational speed was non-significant. The unthreshed seed was affected significantly at a probability level of 1% by both the roller’s rotational speed and the feed rate, with a greater effect for the roller’s rotational speed than the feed rate and without a significant effect for the interaction between the roller’s revolving speed and the feed rate. The threshing efficiency was affected significantly at a probability level of 1% by both of the study variables, with a greater impact from the roller’s rotational speed than the feed rate, while the interaction between the study variables had a non-significant effect on the threshing efficiency. The machine’s productivity was influenced remarkably at a probability of 1% by the roller’s rotating speed and the feeding rate, with a high effect from the feed rate. Otherwise, the effect of the interaction between the feed rate and the roller’s revolving speed had no significant effect. The power requirement was affected significantly at a probability of 1% by the feed rate and the roller’s rotational speed, with a significance level for the feed rate greater than the roller’s rotational speed, while the effect of the interaction between the feed rate and the roller’s rotational speed was non-significant. The obtained data show that the specific energy was affected significantly at a probability level of 1% by the roller’s rotational speed values, while the effect of the feed rate and the interaction between the roller’s rotational speed and the feed rate was non-significant. The obtained data represented that the operational conditions of 300 rpm with 800 kg/h recorded the highest threshing efficiency, a close value to the lowest consumed specific energy and the closest value to the highest production efficiency. Therefore, this operation conditions was considered the optimal operation condition.

Table 1.

Analysis of variance for the effectiveness of the study parameters on the performance of the sunflower threshing machine.

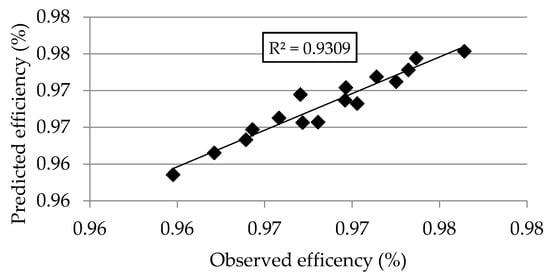

3.8. Mathematical Modeling for Threshing Efficiency

The most important evaluation parameter for threshing machines is the threshing efficiency. In this study, the Buckingham π theorem was followed to find an equation connecting the factors affecting the threshing process to predict the threshing efficacy. This will help to reduce the number of field experiments that are necessary to assess the threshing efficiency [30]. The following innovative mathematical equation simulates the threshing process for calculating the threshing efficiency:

Figure 10 presents the relation between the observed and predicted threshing efficiencies with a correlation coefficient R2 of 0.9309.

Figure 10.

The relationship between the observed and predicted threshing efficiencies (%).

4. Conclusions

- The thrreshing efficiency increased with the increase in the roller’s rotational speed and feed rate up to a feed rate level of 800 kg/h. The maximum threshing efficiency (97.64%) was recorded at a roller rotational speed of 300 rpm and a feed rate of 800 kg/h. The power requirements and machine productivity increased with the increases of both the roller’s rotational speed and the feed rate. The maximum power consumption value (3.51 kW) and maximum machine productivity value (880.45 kg/h) were recorded at a 300 rpm roller rotational speed and a 900 kg/h feed rate.

- Because it recorded the highest threshing efficiency (97.64%) and the closest value of the lowest consumed specific energy (3.80 kW.h/ton), the operational condition of 300 rpm roller rotational speed with 800 kg/h feed rate was considered as the optimal operation condition.

- The equation of can be used to predict the threshing efficiency of the machine under examination with a correlation coefficient of 0.9309.

- With better threshing efficiency, the newly designed sunflower threshing machine with the new add-on of a screw conveyer to avoid blockage problems, compared with the rice and soya bean threshing machines used in threshing sunflower crops, is considered suitable threshing equipment for farmers who have small- and medium-sized sunflower cultivation areas.

Author Contributions

Conceptualization, W.Z. and K.A.M.A.; methodology, K.A.M.A.; software, L.Y.; validation, W.Z., L.M. and K.A.M.A.; formal analysis, K.A.M.A.; investigation, W.Z.; resources, L.Y.; data curation, K.A.M.A.; writing—original draft preparation, K.A.M.A.; writing—review and editing, H.M.-T.; visualization, L.M.; supervision, W.Z.; project administration, W.Z.; funding acquisition, W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development, grant number 2016YFD0702104.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on demand from the first author at (khaledabdeen@azhar.edu.eg).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Khan, S.; Choudhary, S.; Pandey, A.; Khan, M.K.; Thomas, G. Sunflower oil: Efficient oil source for human consumption. Emergent Life Sci. Res. 2015, 1, 1–3. [Google Scholar]

- Radanović, A.; Miladinović, D.; Cvejić, S.; Jocković, M.; Jocić, S. Sunflower genetics from ancestors to modern hybrids—A review. Genes Basel 2015, 9, 528. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- FAO. Food and Agricultural Organization. 2021. Available online: http://www.fao.org/faostat/ar/#data/QC (accessed on 7 July 2021).

- Peeneejdangang, S. Field Tests of an Axial Flow Rice Thresher for Sunflower Threshing; A Paper Presented at SEMINAR II; Agricultural Engineering Department, Khon Kaen University: Khon Kaen, Thailand, 1997. [Google Scholar]

- Kibria, S.A.M.S. RNAM Test Codes & Procedures for Farm Machinery. In Economic and Social Commission for Asia and the Pacific Regional Network for Agricultural Machinery, Technical Series 12, 2nd ed.; Publisher: Bangkok, Thailand, 1995. [Google Scholar]

- Ali, K.A.M.; Huang, X.; Zong, W.; Abdeen, M.A.M. Mechanical structure and operating parameters of sunflower harvesting machines: A review. Int. Agric. Eng. J. 2020, 29, 143–153. [Google Scholar]

- Rembold, F.; Hodges, R.; Bernard, M.; Knipschild, H.; Léo, O. The African Postharvest Losses Information System (APHLIS): An Innovative Framework to Analyse and Compute Quantitative Postharvest Losses for Cereals under Different Farming and Environmental Conditions in East and Southern Africa; University of Greenwich: London, UK, 2011. [Google Scholar]

- Abdollahpour, S.; Ghassemzadeh, H. Designing, fabrication and evaluation of threshing unit edible sunflower. Agric. Eng. Int. CIGR J. 2019, 21, 52–58. [Google Scholar]

- El-Shal, M.S.; El-Ashry, A.S.; El-Shal, A.M.; Fakhrany, W.B. Development Of A Rubbing Thresher For Some Seed Crops. Misr. J. Agric. Eng. 2014, 31, 133–154. [Google Scholar] [CrossRef]

- Bansal, N.K.; Agarwal, S.; Sharma, T.R. Performance evaluation of a sunflower thresher. In A Paper Presented at the XXIX Annual Convention of India Society of Agricultural Engineering; India Society of Agricultural Engineering: Delhi, India, 1994. [Google Scholar]

- Anil, J.; Guruswamy, T.; Desai, S.R.; Basavaraj, T.; Joshi, A. Effect of cylinder speed and feed rate on the performance of thresher. J. Agric. Sci. 1998, 4, 1120–1123. [Google Scholar]

- Sudajan, S.; Salokhe, V.M.; Chusilp, S. Effect of concave hole size, concave clearance and drum speed on rasp-bar drum performance for threshing sunflower. Agric. Mech. Asia Afr. Lat. Am. 2005, 36, 52–57. [Google Scholar]

- Ismail, Z.E.; Elhenaway, M.N. Optimization of machine parameters for a sunflower thresher using friction drum. J. Agric. Sci. Mansoura Univ. 2009, 34, 10293–10304. [Google Scholar]

- Azharuddin, K.; Mir, S.; Narasimhan, M.M.; Kumar, G.P. Design and fabrication of sunflower seed extracting machine. Int. J. Latest Technol. Eng. Manag. Appl. Sci. 2016, 5, 90–97. [Google Scholar]

- Alizadeh, M.R.; Khodabakhshipour, M. Effect of threshing drum speed and crop moisture content on the paddy grain damage in axial flow thresher. Cercet. Agron. Moldova 2010, 3, 5–11. [Google Scholar]

- Kumar, A.; Kumar, A.; Khan, K.; Kumar, D. Performance evaluation of harvesting and threshing methods for wheat crop. Int. J. Pure App. Biosci. 2017, 5, 604–611. [Google Scholar] [CrossRef]

- Srison, W.; Chuan-Udom, S.; Saengprachatanarak, K. Effects of operating factors for an axial-flow corn shelling unit on losses and power consumption. Agric. Nat. Resour. 2016, 50, 421–425. [Google Scholar] [CrossRef]

- Kilbas, A.A.; Srivastava, H.M.; Trujillo, J.J. Theory and Applications of Fractional Differential Equations; Elsevier: Amsterdam, The Netherlands, 2006; Volume 204. [Google Scholar]

- O’callaghan, J.R. Some experiments on the intake process in a vertical screw conveyor. J. Agric. Eng. Res. Jg 1962, 7, 282–287. [Google Scholar]

- Lofty, A. Constraction and performance evaluation of a local device for separating sunflower seeds and environment preservation. Ama Agric. Mech. Asia Afr. Lat. Am. 2009, 40, 73. [Google Scholar]

- Mirzabe, A.H.; Chegini, G.R. Effect of air-jet impingement parameters on the removing of sunflower seeds from the heads in static conditions. Agric. Eng. Int. Cigr. J. 2016, 18, 43–59. [Google Scholar]

- Zhou, Y.; Zhang, J.; Zhu, H.; Zhao, X.; Liu, Y.; Yang, W. Research status and development prospects of sunflower harvester in China. China Acad. Publ. House 2015, 5, 11–14. (In Chinese) [Google Scholar]

- Zong, W.; Liu, Y.; Huang, X.; Ma, L.; Tang, S. Present Situation and Developmental Strategies for Sunflower Mechanized Harvest in China. Acta Agric. Univ. Jiangxiensis 2017, 39, 600–606. (In Chinese) [Google Scholar]

- Popov, I.F.; Kienen, N.I.; Asakun, V. Agricultural Machine; Balkema, A., Roterdam, A., Eds.; Print India in New Delhi: New Delhi, India, 1986; pp. 433–451. [Google Scholar]

- Hall, A.S.; Holowenko, A.R.; Laughlin, H.G. Theory and Problems of Machine Design (Schaum’s Outline Series); McGraw Hill B. Co.: New York, NY, USA, 1981. [Google Scholar]

- Mohtasebi, S.M.; Behroozilar, J.; Alidadi, K.B. A new design for grain combine thresher. Int. J. Agric. Biol. 2006, 8, 680–683. [Google Scholar]

- Lockwood, F.B.; Dunstan, R. Electrical Engineering Principles; Heinemann Educational Books: Portsmouth, NH, USA, 1971. [Google Scholar]

- Sudajan, S.; Salokhe, V.M.; Triratanasirichai, K. PM—Power and machinery: Effect of type of drum, drum speed and feed rate on sunflower threshing. Biosyst. Eng. 2002, 83, 413–421. [Google Scholar] [CrossRef]

- Sudajan, S.; Salokhe, V.M.; Chusilp, S.; Plermkamon, V. Power requirement and performance factors of a sunflower thresher. Agric. Sci. J. 2003, 34, 4–6. [Google Scholar]

- Kutzbach, H.D. Approaches for mathematical modelling of grain separation. In International Conference on Crop Harvesting and Processing 64; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2003. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).