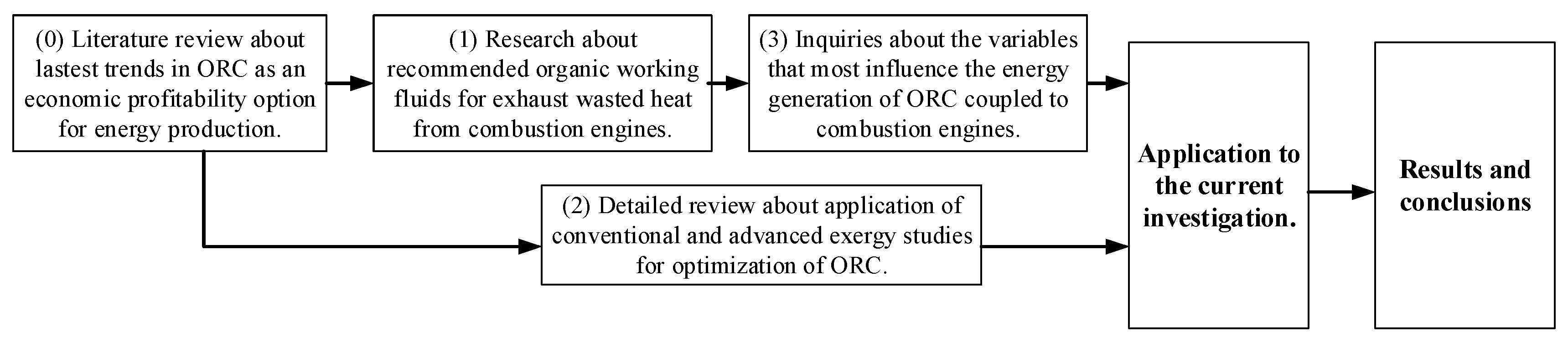

1. Introduction

Given the current high energy demand, improvements of waste-to-energy conversion systems are necessary to promote the rational use of energy and environmental preservation. The human population is growing, and as a consequence, the energy sector needs to meet the increasing demand. In addition, the generation of electricity from materials such as coal, oil, among others, leads to severe damage to the environment, not to mention the fact that these resources are limited [

1]. Therefore, some waste heat recovery systems such as bottoming cycles have been studied to increase the global energy efficiency of the power generation process [

2].

Organic Rankine cycle (ORC) systems are appropriate for this type of use, due to their ability to recover heat in low-temperature applications and the option of implementing them in lower capacity decentralized power plants [

3], as well as, if widely applied in industry, ORC systems should contribute to the global trend in energy efficiency and greenhouse gas emissions. According to the energy consumption trend, by 2050, an increase of 70% in worldwide energy demands and an increase of 60% in greenhouse gas emissions are predicted related to 2011. Related to emissions and their consequences, by 2050, the global temperature is predicted to increase by 6 °C and, potentially, would have devastating impacts such as climate change, energy security, as well as an unsustainable future [

4]. More specifically, about half of the energy consumed in the world is wasted in heat because of the limitations of energy conversion processes [

5].

ORC is a cost-effective waste-to-energy technology oriented to produce energy from various thermal sources such as biomass, solar [

6,

7], geothermal, or waste heat recovery (WHR) available from industrial processes or internal combustion engines (ICEs) [

8,

9]. In recent years, ORC technology has gained sufficient global attention because of its adaptability to different heat capacities and source temperatures, and currently, it is the most appropriate technology applied for obtaining thermal energy from external sources by conversion [

10]. Typical techniques for developing low-quality heat utilization consist of an energy cycle represented by the ORC and the reverse steam compression cycle represented by the cooling and heating cycle [

11].

The ORC has been used to recover waste heat, which is considered to be 50% of the heat produced in industrial processes [

12,

13]. Solar radiation is among the energy sources that have higher capacity and low maintenance times [

14], from which it is possible to obtain thermal energy by conversion of the ocean and solar ponds; these energies are called low-quality energy sources [

15]. Due to its use in residential and commercial buildings, ORC technology is an excellent small-scale alternative for the replacement of power generation systems [

16], where it is also applicable to the cogeneration of heating and cooling, which is considered to be an advantage in terms of distributed power generation [

17]. In power generation applications, the organic Rankine cycle is considered due to modest structure and excellent performance, because it has been found in numerous studies in the literature that ORC improves the energy production of systems that generate waste heat [

18,

19,

20] in addition to low maintenance costs [

21].

An ORC operates analogous to a traditional steam cycle system with an organic fluid in place of water [

22]. The impacts of some organic fluids on energy efficiency and heat recovery efficiency have been researched, and play a relevant function in the performance of this thermal cycle [

23]. However, it is very difficult to find the best organic fluid that adjusts to the system at low source temperatures [

24]. Due to international policies related to climate change mitigation and environmental preservation, the use of chlorofluorocarbons (CFCs) has been limited in thermal systems. Thus, selection of the appropriate organic fluid has become a major challenge under study [

25].

New fluids with almost zero ozone depletion potential and global warming have begun to be used in these systems as compared with the conventional refrigerants and working fluids that have been used today. Thus, the HFO (hydrofluoroolefin) group refrigerants are currently used as part of fluorinated refrigerants and are substitutes for CFCs. PFCs (perfluorocarbons) are also used to avoid destroying the ozone layer. In this paper, refrigerants from the alkane group were chosen because of their critical favorable conditions at high temperatures [

26], in addition to being environmentally friendly, as are siloxanes. HCFCs (hydrochlorofluorocarbons) and CFCs (chlorofluorocarbons) were not considered because of their environmental effects under the Montreal Protocol [

27]. HFCs (hydrofluorocarbons) were also excluded under the Kyoto Protocol [

28].

The problems produced by the consumption of fossil fuels have led to the search for alternatives, one example being ORC, which is a recommended option for obtaining electricity using low-quality waste heat [

29,

30]. A rise in the fuel market and the policy of reducing carbon dioxide emissions have created a massive interest in increasing the thermal efficiency of engines, surpassing techniques already in use. The conversion of waste heat from engines has been considered to be an alternative method for generating energy according to the need that is required [

31].

The economic profitability of ORC systems as waste heat recovery systems at a medium quality temperature depends very much on the operating parameters, the configuration of the cycle, and the organic fluid that it is going to be used. Therefore, there have been analyses conducted on new methods to improve the selection of these variables. For example, Toffolo et al. [

32] proposed a thermodynamic optimization of the system configuration with the primary variable being the design parameters, and analyzed all the possible adjustments and design recommendations according to the objective function and values it offered economic modeling as compared with real costs, and considerations of the behavior of this configuration without the design parameters.

Nishith et al. [

33] suggested a simplified methodology for selection according to thermal-economic assessment and a comparative diagram based on working fluids for the power generation cycle. Additionally, Ziviani et al. [

21] presented a summary of the problems associated with the modeling of ORC, and provided some strategies to advance an efficient and great simulation tool. Imran et al. [

34] showed a thermoeconomic optimization of simple ORC and recuperative ORC for WHR applications, resulting in a 1.01% average increase in thermal efficiency from a simple ORC to a one-stage recuperative ORC, representing an extra expense of

$187/kW, whereas, from a simple ORC to a dual-stage recuperative ORC, there was a 1.45% extra increase in thermal efficiency, and an extra expense of 297

$/kW in cost.

Alternatively, Mohammadi et al. [

35] conducted a study, using a combination of conventional and advanced exergetic analysis, on a supercritical CO

2 recompression cycle to establish the potential for improving the performance of the thermal cycle, in which the maximum optimal potential of the system was 106.85 MW, the overall exergetic efficiency reached 17.13%, and about 35% of exergy destruction could be avoided by focusing on components such as the turbine, the heat exchanger, and the main compressor. In search of improvement potentials in the applications of turbocharged combustion engines, a conventional exergetic study gave the expander and evaporator priority improvement potential, while an advanced exergetic analysis indicated that the pump and expander were a priority, and the destruction of the exergetic cycle could be reduced by 36.5% [

36]. Studies with advanced exergy analyses which took into account the recovery of waste heat in geothermal applications, low temperature solar applications, and the recovery of waste heat from exhaust gases of combustion engines, have shown that the exergetic efficiency of ORC improved by 20%, and have proposed that the evaporator, the expander, the pump and the condenser are equipment with significant improvement potential [

37].

In addition, El-Emam et al. [

38] developed a thermal analyses of a geothermal recuperative ORC, and found that the first and second thermodynamic efficiency values were 16.37% and 48.8%, respectively, when the geothermal water rejection temperature ranged from 78.49 to 116.2 °C. Khaljani et al. [

39] considered as objective functions the first and second law efficiencies, and the total system cost rates. The results presented the highest irreversibility in the combustion chamber, followed by the steam heat exchanger and the turbine, respectively, with a full cycle exergy-economic factor of 10.59%, representing an exergy destruction cost value higher than the capital investment cost.

Complementarily, Safarian et al. [

40] showed the results of one primary and three modified ORCs and reported that the evaporator made an important contribution to the exergy destroyed, which was reduced by increasing the evaporation pressure. Then, the results corroborated that the combined ORC with the regeneration of the turbine had the highest thermal efficiency (22.8%) and exergy efficiency (35.5%), and the smallest exergy loss (42.2 kW) due to the reduction in cooling thermal demand and an increase in the power output. Li et al. [

41] explored the thermal performance of ORC under source temperatures ranging from 100 to 70 °C, and found that with a temperature of 80 °C on the hot side, they were able to achieve a thermal efficiency of 7.4%, and an isentropic turbine efficiency of 68%. The total exergy efficiency of the system was approximately 40%. König-Haagen et al. [

42] used energy storage systems (TESS) and the optimization increased the overall exergy efficiency ranging from 36% to 43%. However, they asserted that detailed exergy studies on the optimization potential and the influence of TESS were still lacking.

Heat recovery from diesel engines by means of ORC systems has also aroused research interest. Jannatkhah et al. [

43] studied a combined heating, cooling, and power generation system for the recovery of waste heat from the exhaust gases of a diesel engine fed with different fuels and biofuels supplied to the engine at different speeds and loads to evaluate the energy system and exergetically. Ong et al. [

44,

45] developed studies for the recovery of waste heat from diesel engines in the marine industry. Their studies focused on the recovery of both the waste heat from engine exhaust gases and the waste heat due to the heating of engine cylinder liner cooling water. These two currents were used to evaporate and preheat the ORC working fluid, which they evaluated with the maximum net power output for different working fluids verifying the influence of the preheating temperature on the system performance.

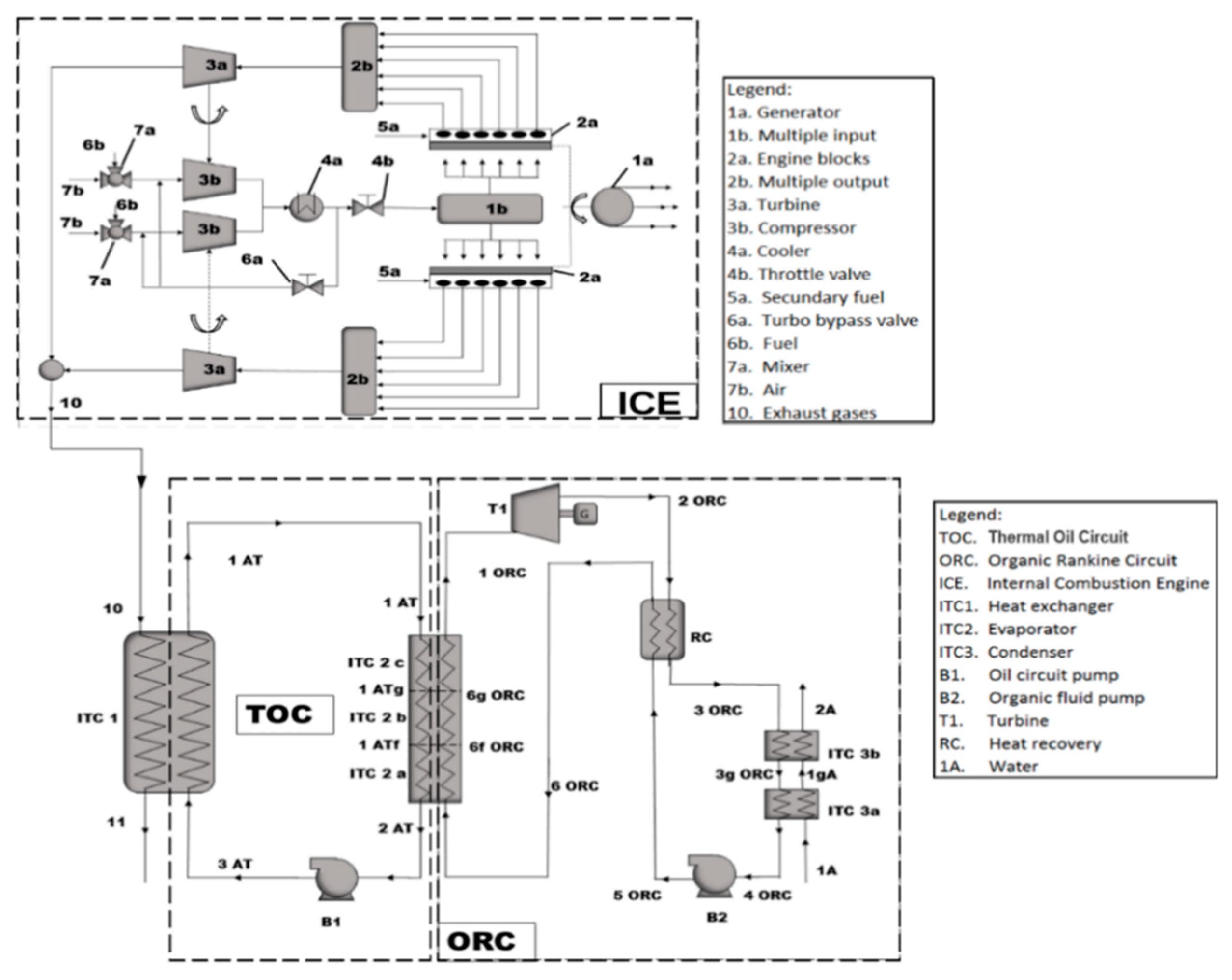

Focusing only on heat recovery from internal combustion engines, Oliveira et al. [

46] for example, conducted a technical and economic analysis of waste heat energy recovery from internal combustion engines using the organic Rankine cycle in order to increase the efficiency of electrical productivity. Although heat recovery from internal combustion engines by means of ORC systems has been studied, few advanced exergetic analyses have been developed for these systems. Galindo et al. [

36] developed an advanced exergy analysis for an ORC coupled to an internal combustion engine. The parameters of the engine used were obtained from previous work [

47] where they used an engine placed on a test bench with the necessary instrumentation to measure the operating parameters of the engine. The engine was an in-line four-cylinder turbocharger with a volumetric capacity of two liters and a maximum power of 153 kW at 5500 rpm and 100% load, as well as a maximum torque of 308 Nm at 3000 rpm and 100% load. With respect to the ORC, the isentropic efficiency of the turbine and compressor was 43% and 89%, respectively, and the pinch point of the condenser and evaporator was 5 and 50 °C, respectively.

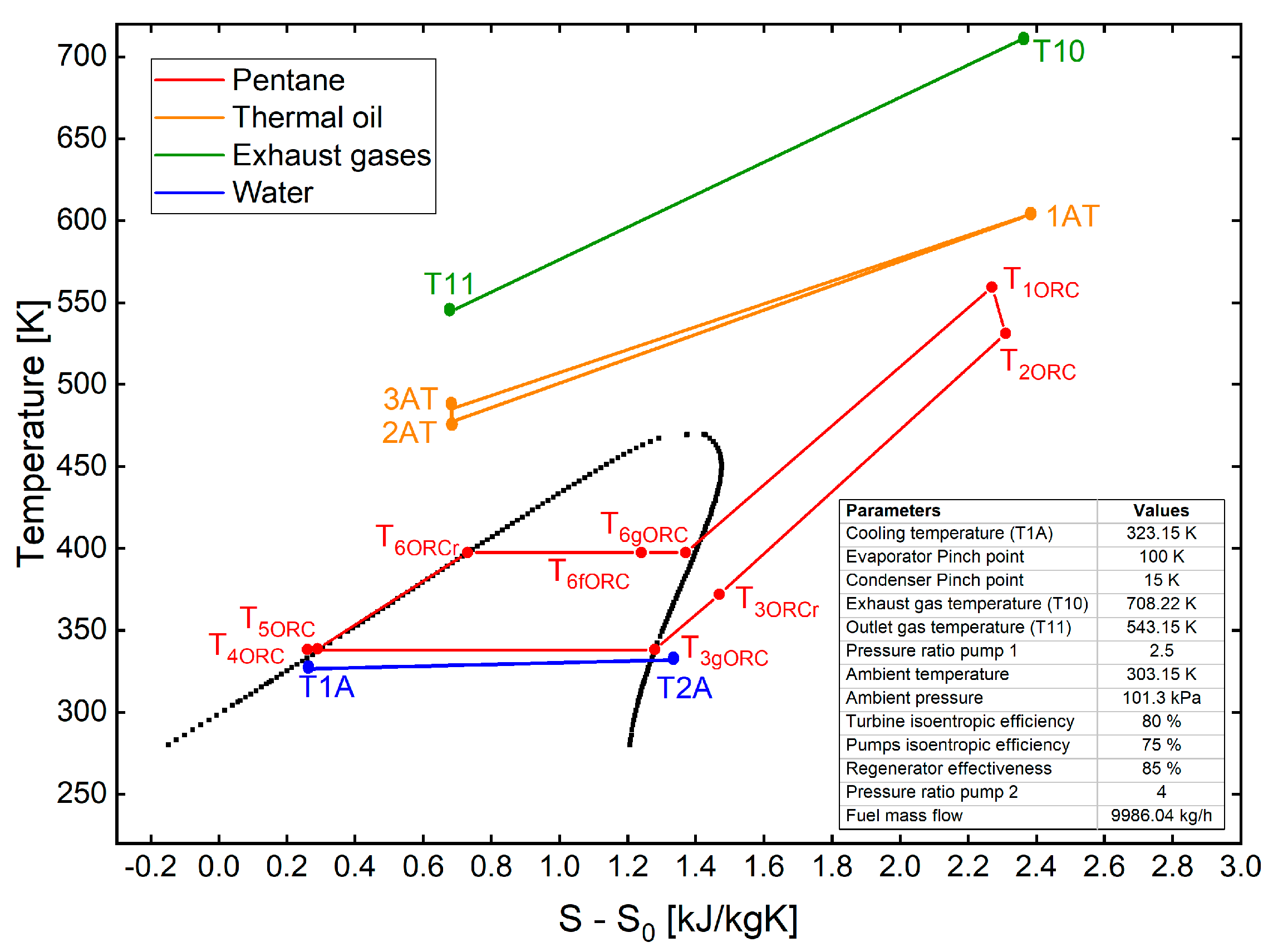

There has been no advanced exergetic analysis, including a sensitivity analysis to evaluate the effect of the condensing temperature, the evaporator pinch, and the pressure ratio with the net power, thermal efficiencies, and exergetic efficiency, developed in the literature for an ORC system coupled to a 2 MW internal combustion Jenbacher engine, which is operating in the city of Barranquilla Colombia at a temperature between 30 and 40 °C and a relative humidity of approximately 80%, using pentane, hexane, and octane as working fluids for the ORC system.

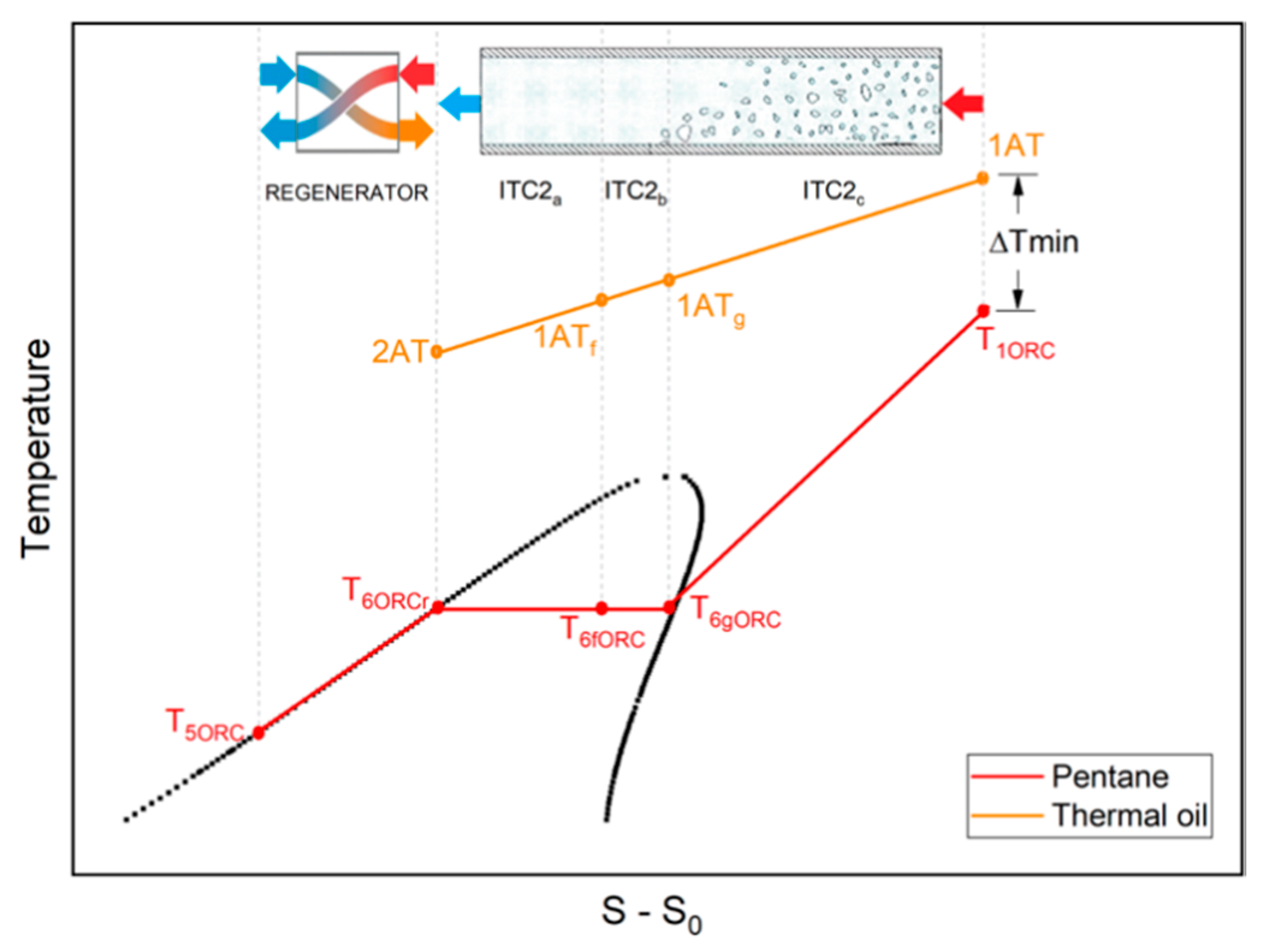

Taking into account that approximately 35% of the energy in the combustion process of an ICE is waste from the exhaust gas, there is a need to implement high efficiency energy recovery systems that are easy to implement, with the aim to improve the overall efficiency of these thermal machines, and therefore decrease the carbon footprint. For this reason, an exergetic analysis of the recuperative organic Rankine cycle (RORC) was achieved to determine the exogenous, endogenous, avoidable, and unavoidable exergy destruction of the investigated cycles. This investigation analyzes an energy recovery system based on ORC, studying different work fluids and operating conditions, in order to minimize the generation of entropy, as a key parameter that maximizes the energy recovered and makes possible the massification of this type of technology, increasing its efficiencies. The present article is structured as follows: The Methodology section presents a detailed description of the system and its parameters as well as the approach to perform a traditional and advanced exergetic analysis on the system; the Results and Discussions section presents a parametric study on the effect of pressure ratio, condensing temperature, and evaporator pinch point temperature on thermal and exergy indicators, as well as the operating conditions of the thermal system; and the final section presents the conclusions regarding the results, as well as the recommendations for future studies.

4. Conclusions

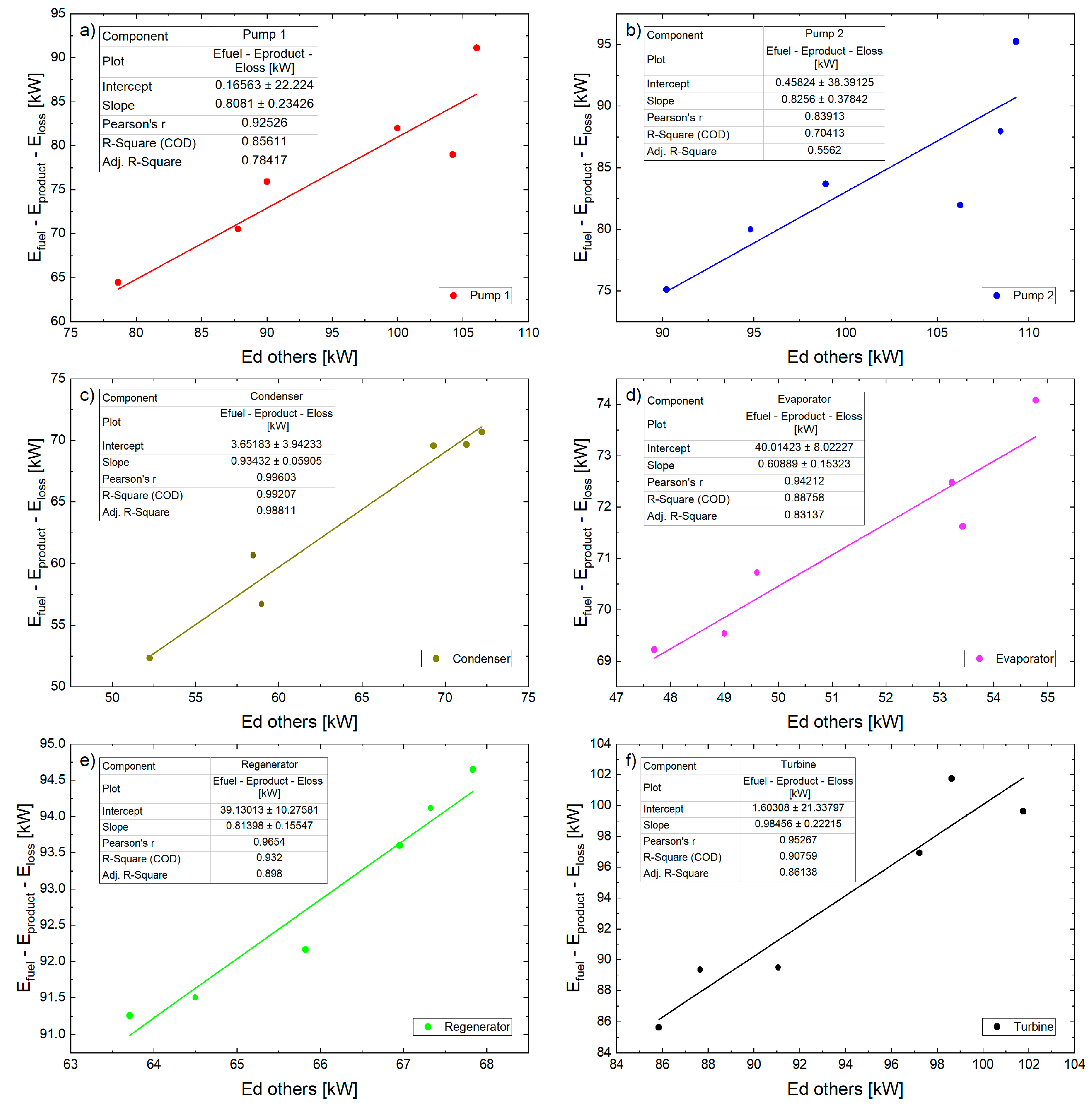

The total exergy destruction of each component in a system can be divided into endogenous and exogenous, and each can be avoidable and unavoidable, to determine, besides the avoidable part due to the destruction of exergy identified by the traditional exergy analysis, which part is due to the structure or the operating conditions for the component in question. Therefore, many opportunities for improvement focus on the avoidable endogenous/exogenous fraction, where it is considered whether the improvement of the system depends on the device itself or on the interaction with the other components of the WHR system using ORC.

The traditional exergy analysis of an ORC-based waste WHR system was performed using working fluids such as pentane, hexane, and octane, and the thermal inefficiencies of the primary devices were observed. However, it was not possible to determine the proportion of inefficiencies, how they could be avoided, or to study how they affected the interactions among each of the components that composed the system using only traditional exergy analysis.

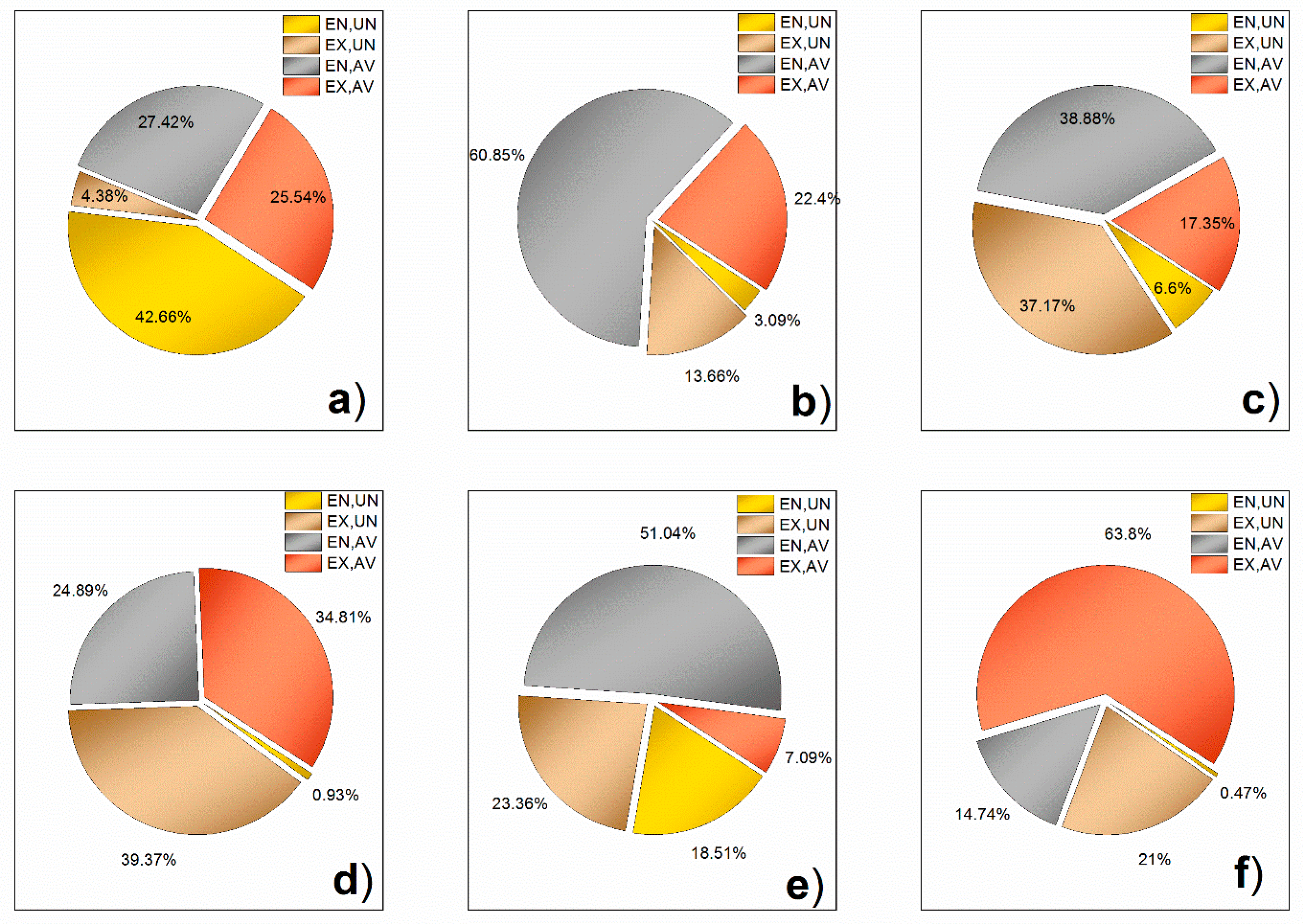

In most components, the exergy destroyed was usually produced by the nature of the component itself, however, there were also opposite cases such as the case of Pump 2 and the evaporator where, in percentage terms, the exogenous exergy destroyed was 36.06% and 54.52%, most of it being unavoidable. Thus, the interaction between components also plays an important role in some components, that is, an improvement in the others will positively affect components such as Pump 2 and the evaporator, which translates into a lower exergy destroyed.

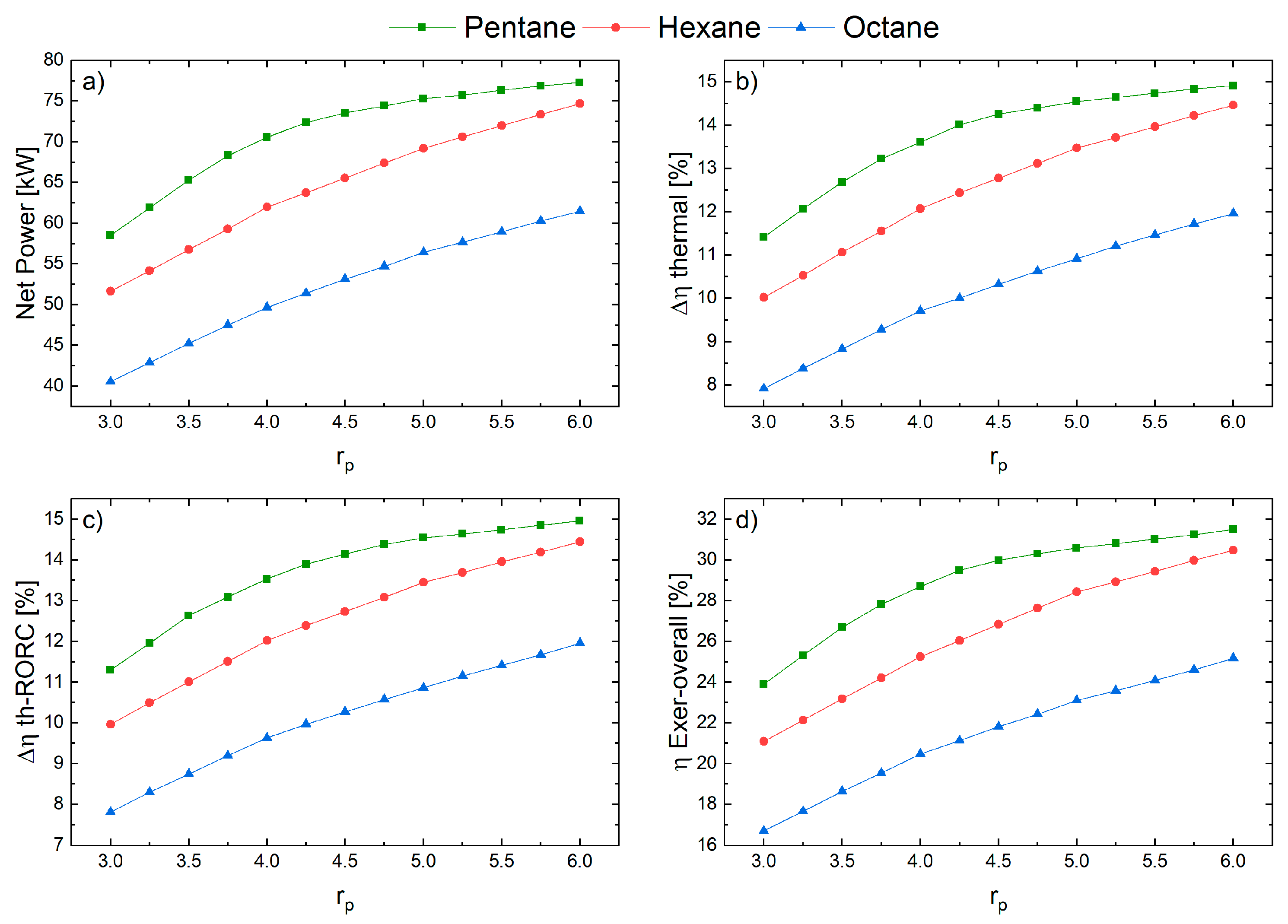

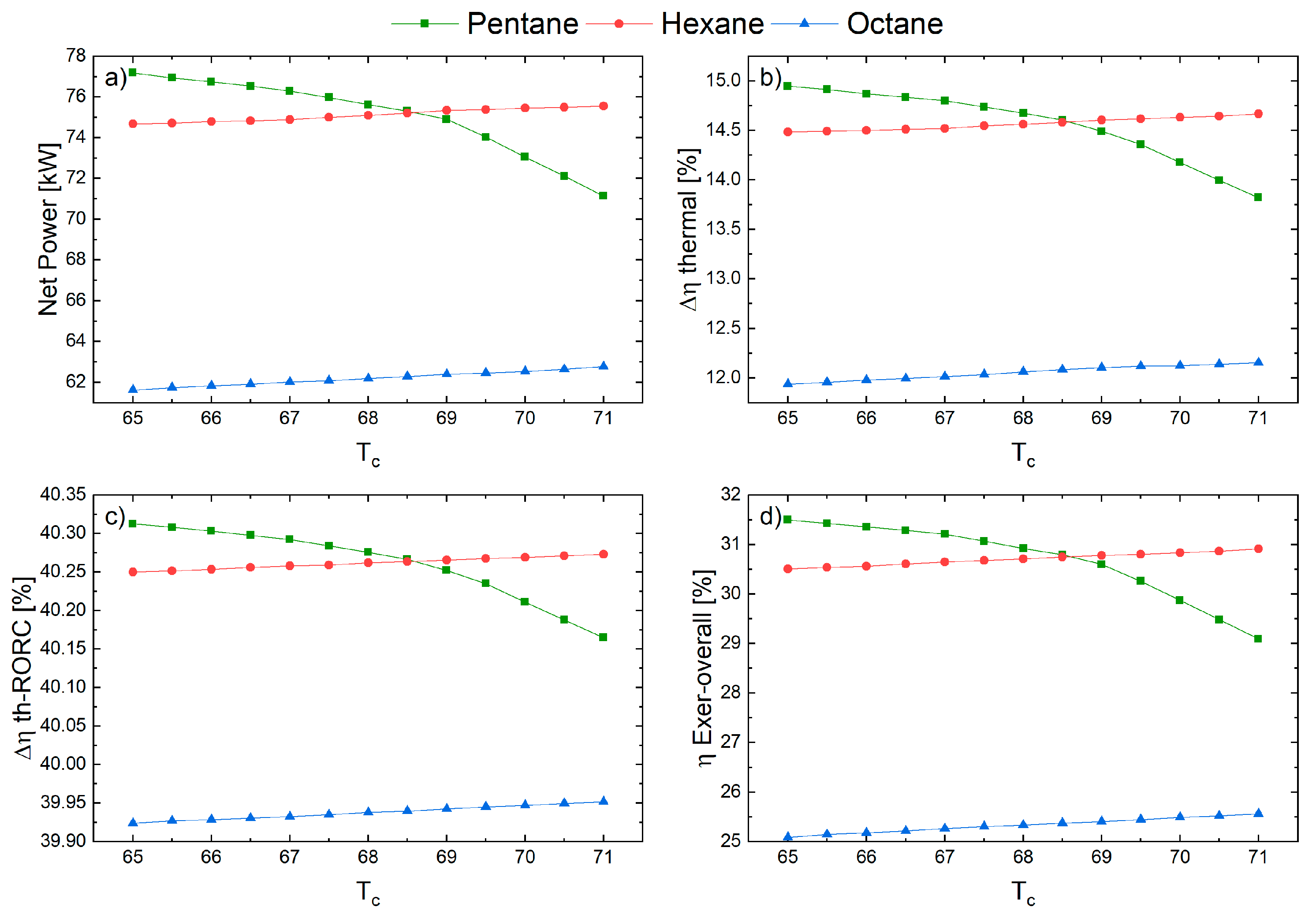

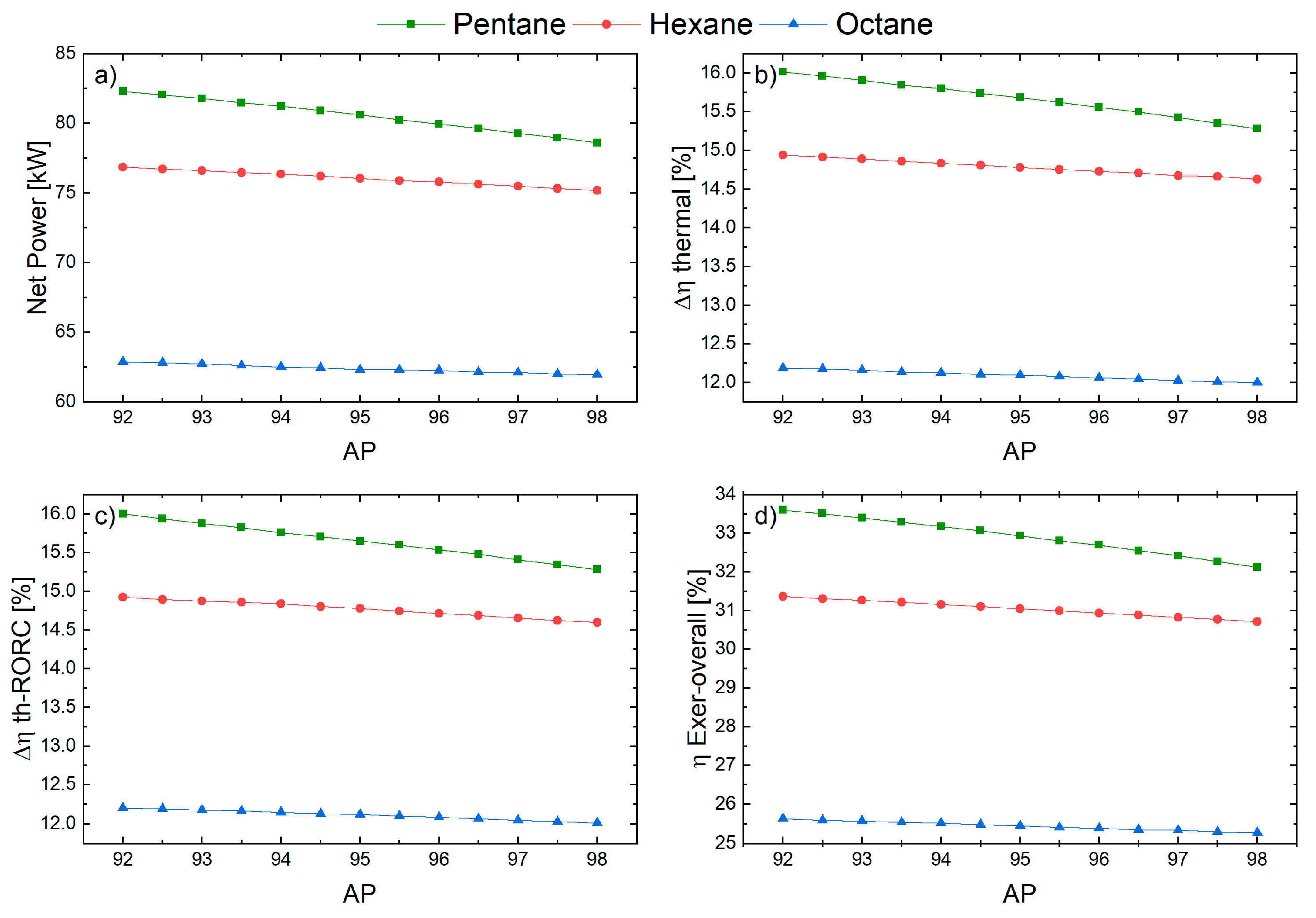

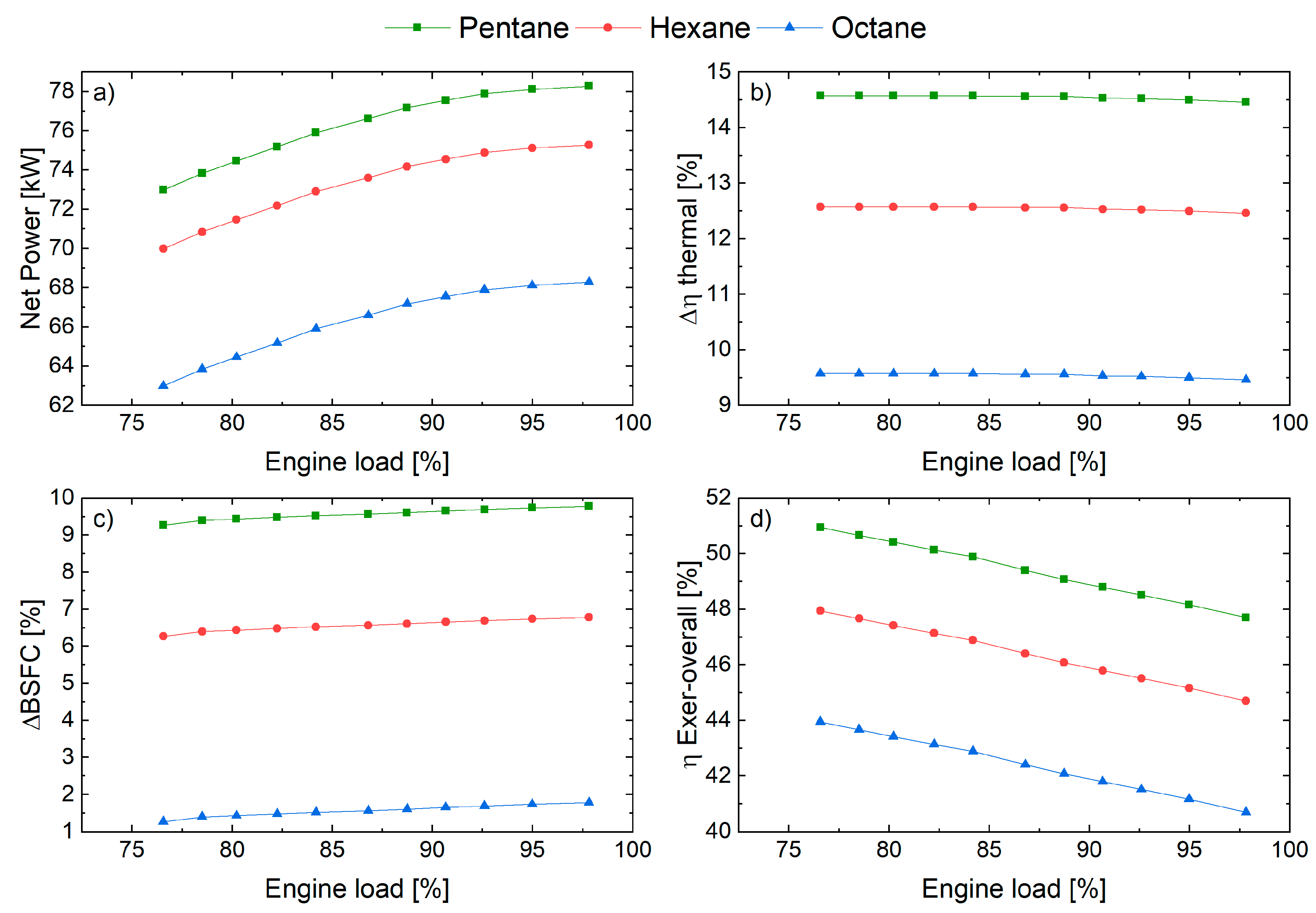

On the basis of the operating conditions of the WHR systems on ORC-based, the results showed that pentane was the working fluid with the best results, with 28% of net power higher than octane. For the condensing temperature using octane, there was no significant influence on the net power. However, for pentane, a decrease in net power was observed as the condensing temperature increased, and the opposite behavior was presented with hexane. In addition, the pinch point temperature of the evaporator rise implied a decrease in the thermal efficiency, with was a consequence of the higher irreversibilities presented in the evaporator heat exchanger. However, it was shown that the effect is less accentuated in the case of pentane, which maintained an exergetic overall efficiency above 32%, with an evaporator pinch point ranging from 92 to 98 °C.

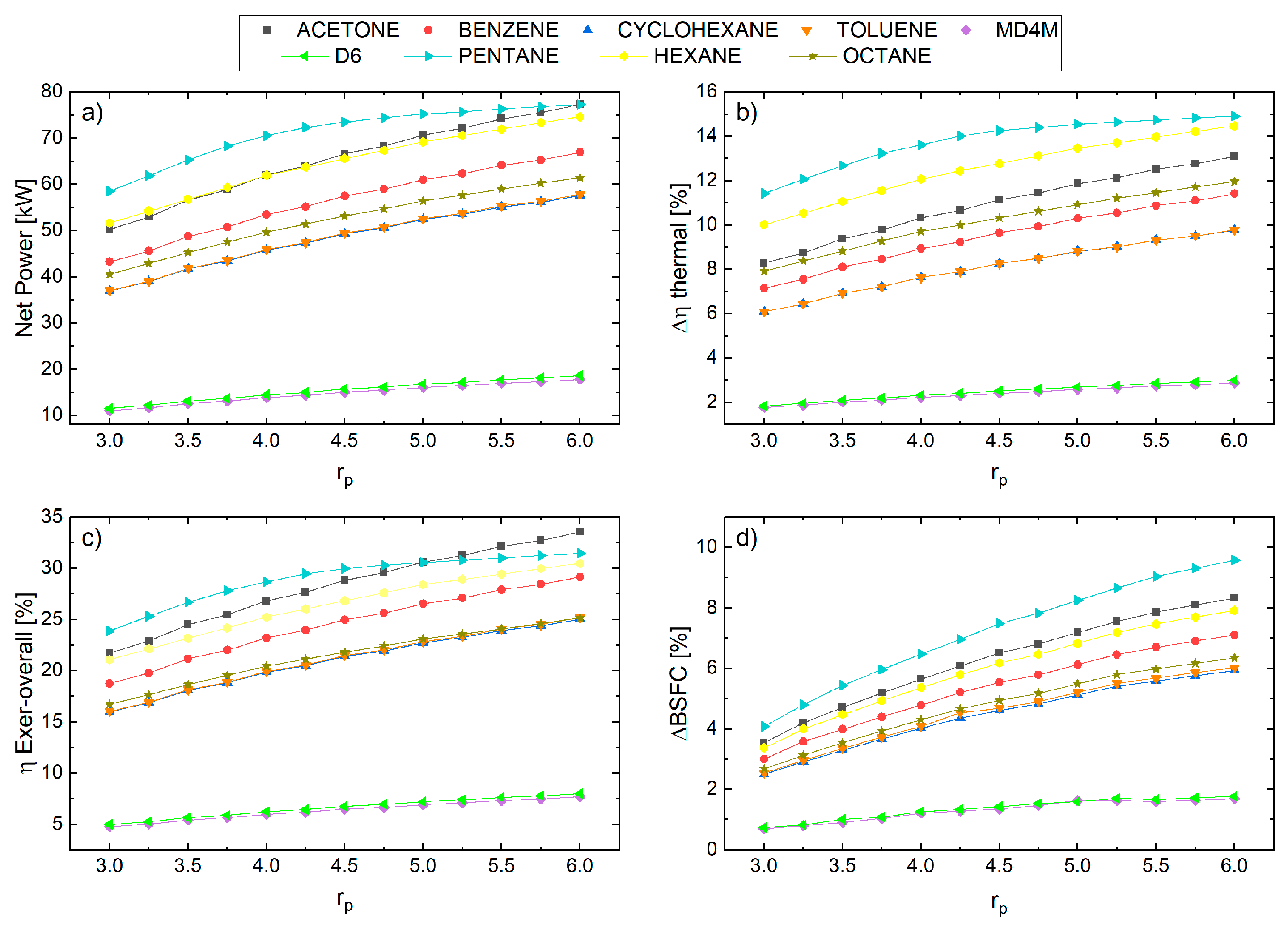

In addition, the effect of increased thermal efficiency, evaporation pressure on net energy production, overall energy conversion efficiency, and specific fuel consumption and exergy destruction were also investigated. The results showed that the best configuration is that of RORC with toluene as the working fluid, because it improves operational performance by achieving an overall conversion efficiency of 11.58%, a net power of 146.25 kW, a reduction in fuel consumption of 7.67% and an ORC thermal efficiency of 28.4% at an engine speed of 1482 rpm, 1.78 lambda, a natural gas flow of 120.2 L/min, and 1758.77 kW of mechanical engine power. However, to contribute in the industrial adoption of this technology, it is necessary to conduct energy, exergy, and thermoeconomic optimization to obtain performance indicators of the waste heat recovery system, and viable thermal solutions to increase the thermal efficiency of this type of natural gas engine.

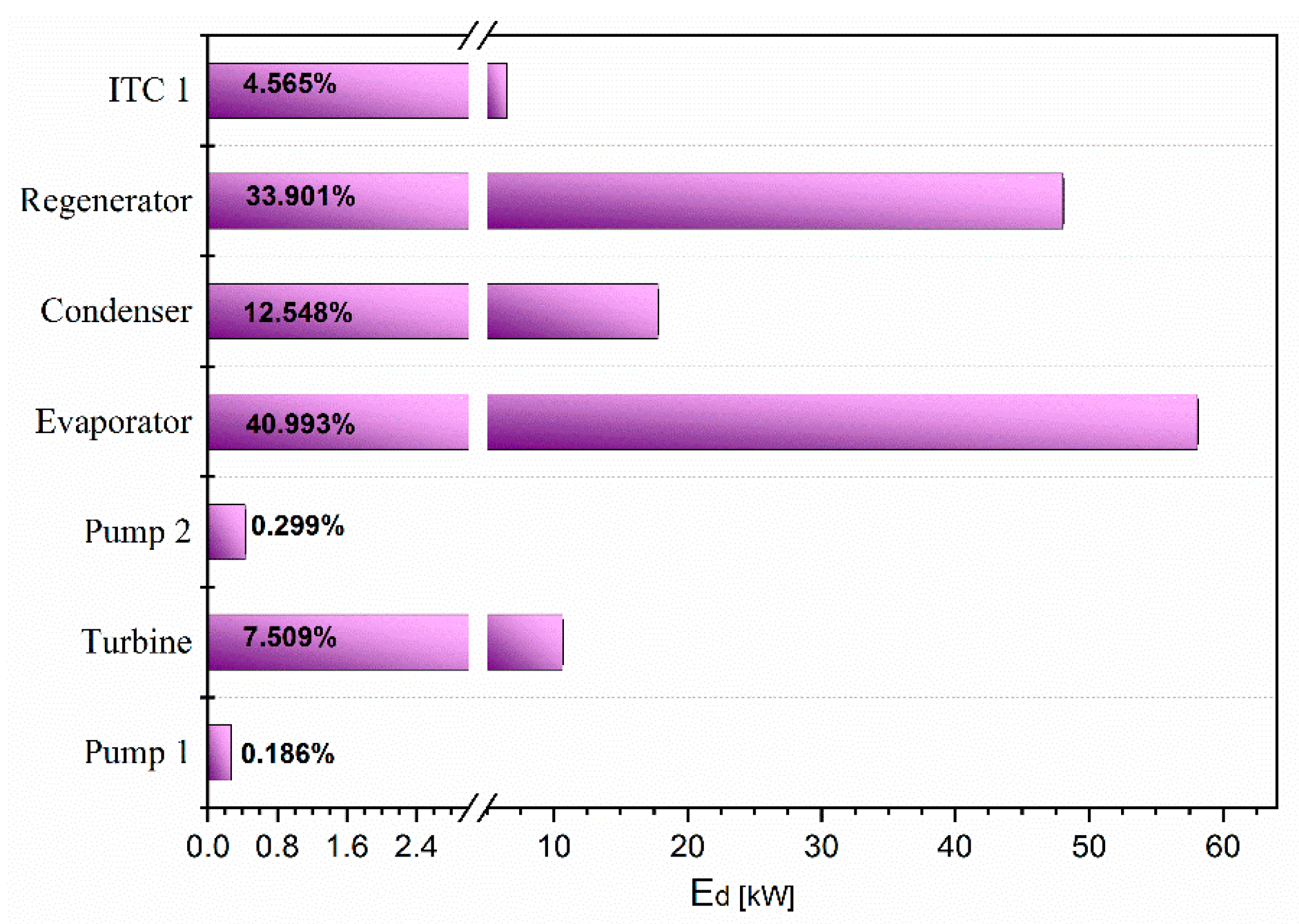

The exergetic analysis showed that the condenser had the highest percentage of exergy destroyed with 40.99%, while the lowest was obtained in Pump 1 with a value of 0.19%. The components with greater irreversibilities such as the evaporator, regenerator, and condenser were the devices that allow, according to the proposed analysis methodology, for the improvement of the system under consideration, since they concentrated 85% of the destroyed exergy and had greater opportunities for improvement. Due to this, the conditions were analyzed where the endogenous destroyed exergy was greater than zero and less than the for each device. The advantages of performing an advanced exergetic analysis for each component was that we established that the most significant opportunities for improvement occurred in the turbine with 63.8% of exogenous character and in the evaporator with 38.88% of endogenous character and 17.35% of exogenous character. For future study, it is recommended to apply an optimization of the heat transfer mechanisms on the components to minimize the exergy destroyed, since this could represent a limitation if a more realistic model was desired, which could be complemented with a computational fluid dynamic (CFD) analysis of some components such as the turbines.