Abstract

The abundant availability of crop waste and forestry residues in Texas provides great potential for producing renewable diesel in the local towns of Texas. This study aims to evaluate the environmental impacts of renewable diesel use in Texas transportation and the potential of renewable diesel production in Texas. The GREET model was used to customize the life cycle pathway of renewable diesel and evaluate its environmental impacts. The models of renewable diesel produced from forestry residue and corn stover were built to calculate life cycle gas emissions of combination short-haul heavy-duty trucks fueled with renewable diesel. Life cycle GHG emissions of renewable diesel are much lower than those of low-sulfur diesel. However, with respect to renewable diesel derived from corn stover, life cycle PM10 and PM2.5 emissions were almost double those of low-sulfur diesel in 2024, and both emissions will be reduced by 37–38% in 2035. The life cycle emission trends of SOx, black carbon, and primary organic carbon are very similar to those of PM10 and PM2.5. The total cost of ownership (TCO) of heavy-duty trucks using renewable diesel produced from forestry residues or corn stover would be 10.3–14.8% higher than those consuming regular low-sulfur diesel in Texas.

1. Introduction

Transportation is essential to any national or state economy, especially in Texas, a large and fast-growing state in energy production that has also seen significant population growth. Texas has 654,923 road miles, including 16 interstate highways and 45 US highways. It was estimated that Texas’ population would increase from 31.3 million in 2024 to 42.5 million in 2050 [1]. Such fast growth implies the need for significant expansion of the state transportation infrastructure, more vehicles, and more fuel consumption, resulting in more air pollutant emissions from passenger and freight vehicles. Currently, Texas is the No. 1 CO2 emitter in the US, twice as much as California, the second-highest state, in 2022 [2]. The transportation sector of Texas accounts for 34.5% of the total carbon emissions in Texas, only slightly lower than the emissions of its electricity generation. Thus, the use of renewable fuels, including methanol, ethanol, biodiesel, and renewable diesel, is essential for reducing carbon emissions from Texas transportation. Bioethanol and biodiesel are the two most popular renewable fuels for vehicles in the US, and they are vital for reducing fossil fuel use and alleviating the environmental burden of vehicles. Another alternative fuel, renewable diesel, is a relatively new fuel that is chemically similar to petroleum diesel and nearly identical in its performance characteristics [3,4]. Although renewable diesel and biodiesel can be produced from the same bio-resources, renewable diesel is distinct from biodiesel because it uses a different production process, including a hydrotreating step. Since the composition of renewable diesel is very similar to regular diesel, there are no special requirements for diesel vehicles, cold startup, and fuel storage, which need to be modified for a diesel blend containing more than 20% biodiesel.

It is known that the tailpipe greenhouse gas (GHG) emissions of biodiesel and renewable diesel are much lower than fossil diesel. Furthermore, renewable diesel is a better option due to its other benefits, such as emission reductions of particulate matter, hydrocarbons, and nitrogen oxides. Promoted by California’s Low Carbon Fuel Standard program, California has replaced a part of regular fossil fuel-based diesel with renewable diesel. The net supply of renewable diesel to the vehicle fuel market in California has significantly increased since 2011, reaching more than 50% of the total diesel supply in 2023 [5]. However, there is no similar low-carbon fuel plan in Texas. Currently, the State of Texas is providing several state incentives to reduce the emissions of vehicle pollutants, such as Alternative Fuel Infrastructure Grants, Biofuel Blend Tax Exemption, Clean School Bus Grants, and Clean Vehicle and Infrastructure Grants [6]. The state agency fleets are required to meet the regulations of Alternative Fuel Use and Vehicle Acquisition Requirements issued by the state of Texas [6]. Renewable diesel is even cleaner than biodiesel, and it holds significant promise as an alternative fuel in Texas, offering environmental benefits, compatibility with existing infrastructure, and economic opportunities through tax incentives and growing production capacity. Before starting a similar renewable energy adoption program in Texas, the first step is to evaluate the environmental impacts of renewable diesel use in Texas transportation through life cycle assessment (LCA) and then to assess the overall cost of renewable diesel production in Texas. To the best of our knowledge, no such principal study has been conducted for Texas, although some studies were performed for California and Canada.

LCA is a potent technique to assess the overall environmental impact of a product/process from cradle to grave, distinguishing it from an environmental impact assessment, which analyzes and documents potential environmental effects from the construction and operation of a proposed project [7]. Since biodiesel was partially added into conventional diesel by from 5% to 20% as fuel supplies in the US 20 years ago, its environmental impacts have been widely studied with LCA [3,8,9,10,11]. Hou et al. found that biodiesel produced from soybean, jatropha, and microalgae has a lower environmental impact than petroleum diesel in terms of global warming potential, abiotic depletion potential, and ozone depletion potential [12]. However, their study also disclosed that biodiesel production has a higher environmental impact than petroleum diesel in eutrophication, acidification, photochemical oxidation, and toxicity. Similarly, Krohn and Fripp concluded that biodiesel production from camelina in the USA has a lower environmental impact than petroleum diesel in terms of greenhouse gas emissions and fossil fuel use [13]. Camelina is a promising energy crop for biodiesel production because it can be grown in a variety of climates and soils, and it does not require a lot of water or fertilizer. Another benefit of camelina is that it is a non-food crop, which means that it does not compete with food production concerning cropland and water resources. Although renewable diesel is a relatively new fuel compared to biodiesel, some LCA studies have been completed on renewable diesel.

Early, the life cycle production of renewable diesel from algae was compared through lipid extraction and hydrothermal liquefaction pathways [14]. Recently, LCA studies of renewable diesel and its water footprint from soybean and lignocellulosic biomass, including forestry and agricultural residues, were also conducted [15,16,17,18,19,20,21,22]. Okeke et al. carried out LCA studies of renewable diesel production from miscanthus grown in strip-mined soils via anaerobic digestion of miscanthus and Fischer–Tropsch synthesis of biogas [18]. Their LCA was implemented using the SimaPro 8 software and following the ISO 14040 and 14044 series of standards [23]. The production of renewable diesel from miscanthus has great potential to reduce GHG emissions compared to conventional diesel from petroleum oil. The life cycle GHG emissions of renewable diesel were estimated to be 50% lower than those of petroleum diesel. In another case study, Larnaudie et al. evaluated the environmental impacts and total cost of renewable diesel produced from sorghum biomass in the Texas-Gulf region [19]. They concluded that renewable diesel production through the fermentation pathway resulted in low fuel yield and higher GHG emissions compared to the bioethanol production pathway [19]. Xu et al. investigated the life cycle GHG emissions of biodiesel and renewable diesel production from soybean oil, canola oil, corn oil, used cooking oil, and tallow in the US with the GREET model [24]. The GHG emissions of renewable diesel are higher than those of biodiesel due to the additional energy demand in hydro-processing during renewable diesel production.

Product cost analysis, also called techno-economic analysis, is an estimate of the total purchasing, operating, maintenance, and salvage cost of an alternative over the life span of a product. Earlier in 2012, a techno-economic model of renewable diesel produced from canola or camelina oil via hydro-processing was proposed, and the optimized plant size was 140 million L/year for a canola-press plant [4]. Some researchers also conducted a techno-economic analysis of renewable diesel production from algae, palm oil, rubber seed oil, biomass sorghum, woody and agricultural residues, etc. [16,19,25,26,27,28,29,30]. In the comparative production cost analysis of renewable diesel from woody and agricultural residues in Canada, Patel et al. found that the net energy ratios were 2.16, 1.5, and 1.16 for spruce, corn stover, and wheat straw, respectively [30]. Recent techno-economic analysis of renewable diesel produced from yellow grease and swine manure indicated that the estimated minimum fuel selling prices could fall within the range of USD 0.94–1.22 per gasoline liter equivalent [31].

LCA and product cost analysis must consider the impacts caused by regionality, space, and time. These challenges, as the environmental impacts of a product, process, or service, can vary depending on where biofuel is produced and used. No such comprehensive principal study of renewable diesel production from forestry and corn stover with LCA and cost analysis was conducted for transportation use in Texas. A novel and key component of our work would be the development of a decision-making tool that would determine the location of renewable diesel processing plants based on the function of distance to the bio-resource locations and their processing capacities. The goal of this paper is to evaluate the environmental impacts of renewable diesel use in transportation and the potential of renewable diesel production in Texas, further contributing to a circular economy in the US. The following are the major objectives that constitute realizing the overall goal:

- (i)

- Develop the framework for methodological environmental LCA of renewable diesel use in Texas transportation;

- (ii)

- Evaluate the net change in environmental impacts due to the use of renewable diesel in Texas transportation;

- (iii)

- Conduct a cost evaluation of renewable diesel production in two towns in Texas;

- (iv)

- Recommend stakeholders and community leaders within Texas to the adoption of renewable diesel production in Texas and its use in Texas transportation.

2. Methodology

2.1. Biomass Availability

Biomass, which consists of waste products of agriculture, forestry, and wood post-consumer waste, is an essential feedstock for a bio-refinery where these inputs are converted into fuel for energy use, fibers, molecules for chemicals and materials, and even food products. Texas provides many biomass feedstocks for bio-refinery. For example, 35% of agricultural income in East Texas depends on timber, and Northwest Texas produces a huge amount of agricultural waste from different crops [32]. Table 1 shows the regional distribution of crops and biomass production in Texas. The abundant availability of crops and biomass in Texas provides a great potential to produce renewable diesel in Texas’s local towns [33,34]. Bioethanol, biodiesel, and renewable diesel are oilseed-, grain-, or biomass-based fuels. With respect to the fuel used for heavy-duty trucks, renewable diesel has some advantages over biodiesel. There is no renewable diesel plant in Texas, although there are a few bioethanol and biodiesel plants in North Texas, West Texas, and East Texas. Prior to constructing a renewable diesel plant, it is crucial to carry out LCA and product cost studies for renewable diesel production from different biomass supplies in Texas.

Table 1.

Five regions in Texas for bioenergy and biomass production.

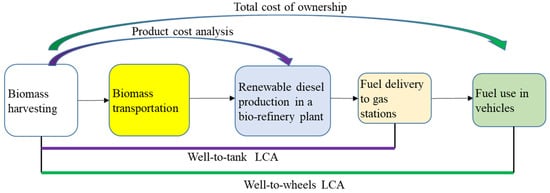

2.2. Life Cycle Inventory

Prior to the evaluation of the environmental impacts of renewable diesel and the cost analysis of renewable diesel production in Texas, we need to define the environmental scope, i.e., the system boundary. The environmental scope incorporates energy and water consumption and air pollutant emissions associated with fuel production and fuel use in vehicles. The cost analysis scope covers items ranging from inedible biomass harvesting to the final renewable diesel product available at the gas station. In the LCA and production cost studies, appropriate delimitation of system boundaries is key to interpreting results obtained from the production and use of renewable diesel. The system boundary in our study covers the two major components of renewable diesel production (well-to-tank) in Texas and fuel use in the state’s transportation sector, using combination short-haul heavy-duty trucks.

The quantification of the life cycle environmental impact of renewable biodiesel use in transportation requires a comprehensive LCA study with two major components: vehicles and renewable diesel. The cost analysis of renewable diesel production encompasses various facets, including feedstock type, biomass cost (harvesting and transportation cost), pyrolysis plant capital cost, bio-oil yield, and the upgrading of bio-oil to renewable diesel. Our study used an appropriate tool, the GREET model, to evaluate the environmental impacts of renewable diesel use in the Transportation of Texas. The GREET model, with a focus on fuels and vehicles, was developed by the Argonne National Laboratory of the US Department of Energy and is regularly updated [35,36]. Our cost analysis of renewable diesel production in Texas is based on the recently developed cost analysis model for renewable diesel [30].

Lignocellulosic biomass feedstocks abundantly available in Texas, such as forestry residue and agricultural residue–corn stover, were selected for this study. Each inventory at a single stage, as shown in Figure 1, was built based on the available data collected from the literature and the Texas agricultural database. It consists of water and energy use, various emissions, and costs. In our research scope, the conversion of biomass into renewable diesel consists of lignocellulosic biomass pretreatment, breaking down biomass into bio-oil, hydrogen separation from syngas, and upgrading the bio-oil to renewable diesel via hydro-processing with the aid of the Co-Mo catalyst [15]. The US vehicle emission inventories, which are integrated into the GREET model, are adopted for short-haul heavy-duty trucks.

Figure 1.

The system boundary and key stages of renewable diesel used in transportation.

2.3. Life Cycle Impact Assessment (LCIA)

The built life cycle inventory was integrated into the GREET model to customize the life cycle pathway of renewable diesel. The LCIA of regular diesel was evaluated first. Then, the scenarios of renewable diesel produced from forestry residue or corn stover were built and evaluated with respect to the various life cycle gas emissions, including WTP and WTW emissions, where WTP represents well-to-pump, and WTW is well-to-wheels. Various life cycle gas emissions, including GHG, carbon monoxide (CO), NOx, volatile organic carbons (VOCs), SOx, PM2.5, PM10, black carbon, and primary organic carbon, were evaluated for the two stages of WTP and WTW in 2024 and 2035.

2.4. Total Cost of Ownership (TCO) Analysis

TCO is a measure to estimate the total expenses associated with a product or asset over its entire lifespan. We use an online TCO tool, AFLEET [36], which was developed and is being maintained by the Argonne National Laboratory, to assess the TCO of heavy-duty trucks fueled with renewable diesel by comparing it with the traditional operation of heavy-duty trucks in Texas. The fuel efficiency of both renewable diesel and low-sulfur diesel is 1.913 km/L (4.5 miles/gallon). The price of low-sulfur diesel is USD 0.977/L (USD 3.7/gallon), and the price of renewable diesel is taken from our cost calculation of renewable diesel production in two regions in Texas. As suggested by the AFLEET tool, the purchase expense of a heavy-duty truck is USD 160,000, the vehicle mileage is 104,607 km (65,000 miles) per year, and the planned ownership is 15 years. The other costs associated with heavy-duty trucks, such as insurance, license, vehicle registration, etc., are the same in the two scenarios of renewable diesel and low-sulfur diesel since there is no specific requirement for trucks fueled with renewable diesel.

3. Results and Discussion

3.1. Environmental Impacts of Renewable Diesel Used in Texas Transportation

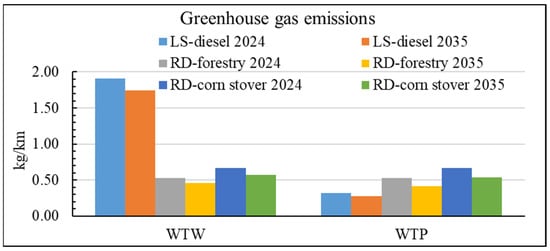

The life cycle GHG emissions were evaluated for the past year, 2024, and the future year, 2035, according to low-sulfur diesel (LS-diesel) and renewable diesel produced from forestry residue (RD-forestry) and corn stover (RD-corn stover) in Texas, as shown in Figure 2. The WTW GHG emissions of renewable diesel are significantly lower than those of low-sulfur diesel in both years, and all the GHG emissions in 2035 are slightly lower than those in 2024. We believe that technological advancements in fuel production and truck operation in the future will contribute to further emission reduction. The GHG emissions of renewable diesel are much lower than low-sulfur diesel since renewable diesel is much cleaner for internal combustion engines [37]. We can also see that the GHG emissions are comparable between low-sulfur diesel and renewable diesel, either produced from forestry residue or corn stover, at the WTP stage. Currently, soybean oil is the most significant contributor to renewable diesel production in the US, although animal fats, used cooking oil, and other vegetable oils are also used. In 2009, Huo et al., at the Argonne National Laboratory, conducted LCA of soybean-based fuel, including renewable diesel I and II, and found that the reduction of GHG emissions was greater than 57% compared to the petroleum diesel [20]. By considering the land-use change, some researchers at the Argonne National Laboratory recently revisited the LCA model of biodiesel and renewable diesel produced from soybean oil and expanded it to the production of renewable diesel from other oilseed crops, distillers corn oil, used cooking oil, and tallow [24]. They confirmed that for renewable diesel produced from soybean, canola, and carinata oils, the reduction of life cycle GHG emissions was in the range of 40–69%. In this study, we explored the significant environmental benefits of renewable diesel production from agricultural and forestry waste that is not edible and does not compete with human food supplies.

Figure 2.

Life cycle GHG emissions of low-sulfur diesel and renewable diesel.

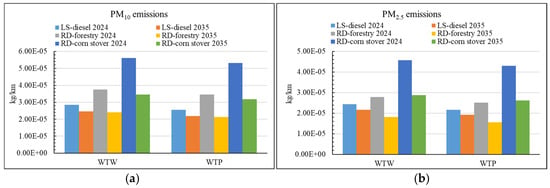

The life cycle emissions of PM10 and PM2.5 for both fuels used in heavy-duty trucks are presented in Figure 3. It can be seen that both emissions are comparable for low-sulfur diesel and renewable diesel produced from forestry residues in both 2024 and 2035. With respect to renewable diesel derived from corn stover, both PM10 and PM2.5 emissions are almost double those of low-sulfur diesel in 2024, and both will be reduced by 37–38% in 2035. The major reason is that the agricultural activities of corn production involve much more PM-intensive activities, such as corn planting, irrigation, cultivation, and harvesting with tractors, than simple forestry residue collection.

Figure 3.

Life cycle PM emissions of low-sulfur diesel and renewable diesel. (a) PM10; (b) PM2.5.

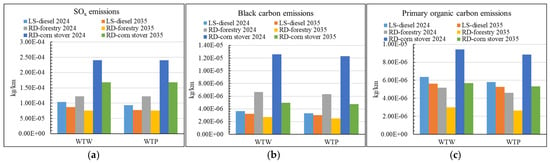

The life cycle emission trends of SOx, black carbon, and primary organic carbon are very similar to PM10 and PM2.5 (Figure 4) in 2024 and 2035. In detail, these emissions related to the renewable diesel produced from corn stover are greater than those of the renewable diesel derived from forestry residue primarily because the activities of corn cultivation and delivery of corn stover to a biomass processing plant intensively use fossil diesel as fuel for corn harvesters and transportation trucks.

Figure 4.

Life cycle emissions of (a) SOx, (b) black carbon, and (c) primary organic carbon.

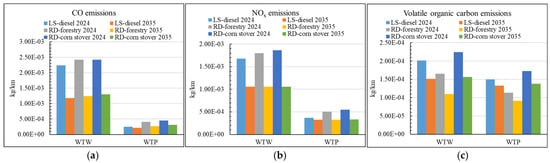

Moreover, the other life cycle gas emissions, such as CO, NOx, and VOCs, are also evaluated and presented in Figure 5. We can see that the emissions of CO and NOx have similar trends and that both emissions primarily occur during vehicle operation, i.e., tailpipe emissions. With respect to VOCs, we can see that the emissions for all the fuels primarily occur in the WTP stage, which includes fuel production and delivery to the gas stations. The six air pollutants, CO, lead, ground-level ozone, particulate matter, nitrogen dioxide, and sulfur dioxide, are publicly monitored criteria air pollutants. Ground-level ozone is a secondary pollutant produced from the photochemical reaction of NOx and VOCs under the sunshine in the air. We directly or indirectly evaluated five life cycle air criteria pollutants related to the production and use of renewable diesel and disclosed the environmental benefits of the use of renewable diesel in Texas transportation by comparing it with regular diesel.

Figure 5.

Life cycle emissions of (a) CO, (b) NOX, and (c) VOCs.

3.2. Cost Analysis of Renewable Diesel Production

3.2.1. General Cost Analysis

The costs of producing renewable diesel from different biomass feedstocks occur at various stages, including biomass planting, harvesting and transportation, renewable diesel production at a bio-refinery plant, and fuel transportation. The building of a biomass processing plant would be paid as capital costs. After the capital costs, operating costs become dominant for the rest life of a renewable diesel production plant. Various operating costs include raw material costs, biomass storage costs, maintenance costs, operating labor costs, overhead plant costs, costs, operating charges including general material supplies and energy use, water disposal costs, utility updating fees, and indirect costs, e.g., administrative costs. Fast pyrolysis and hydro-processing technologies are two critical control processes during renewable diesel production from biomass at a biomass processing plant. At the end of the hydro-processing, both renewable gasoline and renewable diesel can be produced, along with a byproduct of biochar, and renewable gasoline is equivalent to renewable diesel according to the market value in our study.

East Texas has plenty of pine trees. Wood waste from log thinning and logging residues, such as branches, tops, stumps, roots, bark, and other non-merchantable wood, are good resources for renewable diesel production in Texas. According to the 2006 investigation, the availability of logging residue in East Texas was 1.36 million dry t in 2006, of which 63% was from softwood and the rest was from hardwood [38]. Based on the statistical data on forestry waste available in East Texas, we selected the city of Jasper as the optimal production location for renewable diesel production from forestry residue.

With respect to biomass availability from agriculture, the biomass yield and moisture content change as a function of weather conditions and farmers’ plans. Texas farmers planted 0.85 million ha (2.1 million acres) of grain corn and harvested approximately 6.5 million t (256 million bushels) of grain in 2023 [39]. Generally, the yield of dry corn stover is equal to the grain yield for the corn grain field. Based on the 2007 investigation of US corn stover supplies, if 30% of corn stover could be collected at the cost of less than USD 33/dry-t, there would be 1.95 million t of corn stover available for renewable diesel production in Texas [40]. Referring to the design of a lignocellulosic biofuel supply chain system in Central Texas by An et al., the biomass storage costs are USD 15,153 for the fixed cost and USD 151.46/m2 as the variable cost [41]. The transportation costs are 6.81/t plus the delivery fee at the rate of USD 0.08/t-km. In Texas, the Northern High Plains account for about two-thirds of the total corn yield. Other production regions with significant corn production are the Blacklands, at 12%, the Upper Coast, at 6%, and South Central Texas, at 4%. According to the geographic distribution of corn yield in Texas, the top three counties are Sherman, Dallam, and Hartley in the Northern High Plains. We selected the city of Dalhart, the county seat of Dallam County, as the production location of renewable diesel derived from corn stover.

3.2.2. Current Bio-Refinery Plants in Texas

According to the continually updated data online [42,43], there are nine biodiesel plants and four bioethanol plants available in Texas, as shown in Table 2. Currently, the feedstocks for biodiesel production are primarily vegetable oils and animal fats in the US, including the Texas plants. All four ethanol plants in Texas are using corn to produce bioethanol as an additive for regular gasoline. To produce renewable diesel from forestry residue, corn stover, or other agricultural residue, some plants need to be modified to fit the two critical processes of fast pyrolysis and hydro-processing with the addition of hydrogen gas. These current bio-refinery plants are not optimal for renewable diesel production from forestry residue or corn stover since they are not centers of the forest- or corn-rich areas in Texas.

Table 2.

Current bio-refinery plants in Texas.

3.2.3. Production Cost of Renewable Diesel

Fast pyrolysis and hydro-processing technologies are critical control points in renewable diesel production. By using hydro-processing, both renewable gasoline, renewable diesel, and biochar can be produced, and renewable gasoline and biochar would be equivalent to renewable diesel according to the market value. Early in 2010, some researchers at Iowa State University conducted theoretical studies and calculated the minimum fuel selling price of biogasoline and biodiesel produced via fast pyrolysis and hydro-processing of biomass to be as low as USD 0.56/L [44]. Later in 2013, the same research group published a paper and disclosed that the production cost of the same fuels would be USD 0.79/L when the biofuels were produced from corn stover at a bioprocess 2000 dry t/d plant [45]. When the capacity of a biomass processing plant goes as small as 72 t/day, the cost of renewable diesel may go up to USD 2.17/L [46].

Recently, a Canadian research group studied the product cost of renewable diesel produced from different biomass, including spruce, corn stover, and wheat straw, with the same biomass processing capacity as Iowa State University’s, and they found that the cost would be USD 0.98/L for the case of spruce with hydrogen purchase and USD 1.11/L with hydrogen production in the plant [30]. For the scenarios of corn stover and wheat straw, the cost would be USD 1.19/L and USD 1.27/L with the on-site hydrogen production, where the biomass delivered costs, including field and transportation costs, were USD 72.66/t for wheat straw and USD 55.99/t for corn stover. Based on previous literature, the cost of raw materials is a big fraction of the final product cost. So, selecting the location for a bio-refinery plant is a very sensitive decision, heavily influenced by the proximity of biomass availability.

A decision-making tool can be developed according to both cases of the availability of forestry residue and agricultural residues in Texas by referring to the case studies of renewable diesel in Canada [30], Iowa [44,45], and jet fuel supply chains in California [47]. The developed Biofuel supply chain Geo-Spatial and Temporal Optimizer in the case study was adapted and used in our renewable diesel study for Texas transportation. Additionally, biomass availability on the border of neighboring states was considered. Biochar is another important byproduct of the renewable diesel production process. Based on the variations of the biochar selling price in Texas for agricultural and industrial purposes, the effect of the byproduct biochar on the renewable diesel cost was evaluated for both feedstocks, i.e., forestry residue and corn stover.

A centralized pyrolysis plant can handle large-scale production of renewable diesel from whole biomass feedstock at a single facility, which is a fixed facility where biomass is brought from its surrounding area. We assume that corn stover available in the Northern High Plains of Texas is harvested, chipped, and then trucked to the plant gate of the bio-refinery plant in Dalhart, Texas, and that forestry residue available in East Texas is delivered to the bio-refinery plant in Jasper, Texas, after the collection and chopping. Both plants have a processing capacity of 2000 t/d each.

As described in [30], lignocellulosic biomass goes through a series of pretreatments, such as chipping, drying, grinding, screening and milling, pyrolysis, and hydro-processing at both plants. The bio-oil update via hydro-processing is divided into three stages: first-stage hydrotreating, second-stage hydrotreating, and hydrocracking. Because both plants would be in small towns surrounded by rural areas, hydrogen production at the same plant was considered. Based on previous experience, the production cost of hydrogen locally is slightly higher than the scenario of hydrogen purchase. When considering hydrogen delivery to a rural area, local hydrogen production might be an efficient and economical option. The installed capital costs would be USD 322.7 M for hydrogen production at the plant processing corn stover and USD 300.6 M at the plant processing forestry residue. Annual operating costs are USD 170.6 M and USD 133 M, respectively, for forestry residue and corn stover in the H2 production scenario. Finally, the product cost of renewable diesel would be USD 1.19/L and 1.11/L for the fuel derived from corn stover and forestry residue, respectively, when considering the biochar selling price as USD 100/t.

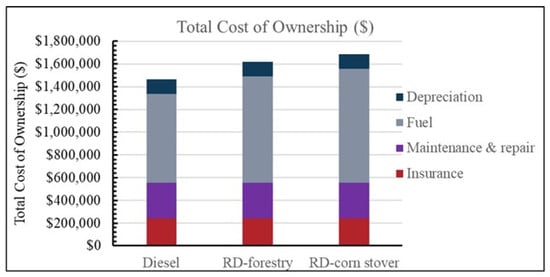

3.3. TCO of Combination Short-Haul Heavy-Duty Trucks

The TCO analysis was conducted for short-haul heavy-duty trucks with two options of low-sulfur diesel and renewable diesel in Texas. The terms of TCO cover depreciation, fuel, diesel exhaust fluid, maintenance and vehicle repair, vehicle insurance, and vehicle registration license. To simplify the TCO analysis, there is no consideration for financing vehicle purchases or insurance differences for different drivers. Figure 6 shows the TCO of owning and operating short-haul heavy-duty trucks fueled with low-sulfur diesel, forestry residue- and corn-stover-based renewable diesel in Texas. The TCO of trucks consuming low-sulfur diesel is about USD 1.49 M. The TCO of trucks taking forestry residue-based or corn-stover-based renewable diesel is 10.3% and 14.8% more, respectively. Currently, California is the only state that has heavy-duty trucks fueled with renewable diesel, and the renewable diesel consumed is produced in other states or imported from Southeast Asia. The selling price of renewable diesel, USD 1.30–1.42/L (USD 4.92–5.37/gallon) in 2024, was similar to that of low-sulfur diesel with the aid of California’s subsidies [48]. Suppose the state of Texas is willing to take renewable diesel as a fuel alternative; in that case, the government of Texas has to provide renewable diesel producers and fuel vendors with subsidies to balance the overall cost difference between low-sulfur diesel and renewable diesel, like California.

Figure 6.

TCO of heavy-duty trucks fueled with low-sulfur diesel and renewable diesel in Texas.

4. Conclusions

We evaluated the environmental impacts of short-haul heavy-duty trucks powered by renewable diesel and assessed the production cost of renewable diesel from forestry residue in East Texas and corn stover in Northwest Texas. We draw the following conclusions:

- (i)

- The life cycle GHG emissions of renewable diesel are much lower than those of low-sulfur diesel;

- (ii)

- The GHG emissions of all three fuels in 2035 are slightly lower than those in 2024;

- (iii)

- PM10 and PM2.5 emissions are comparable for low-sulfur diesel and renewable diesel produced from forestry residues in both 2024 and 2035;

- (iv)

- The life cycle emission trends of SOx, black carbon, and primary organic carbon are very similar to PM10 and PM2.5;

- (v)

- The product cost of renewable diesel would be USD 1.19/L and 1.11/L for the fuel derived from corn stover and forestry residue, with the biochar sell price at USD 100/t when considering on-site hydrogen production;

- (vi)

- The TCO of combination short-haul heavy-duty trucks fueled with renewable diesel is 10.3–14.8% higher than that of the trucks using low-sulfur diesel in Texas.

Author Contributions

Conceptualization, H.D. and R.R.K.; methodology, H.D.; validation, H.D. and R.R.K.; formal analysis, H.D.; investigation, H.D.; resources, R.R.K.; data curation, H.D.; writing—original draft preparation, H.D.; writing—review and editing, R.R.K.; visualization, H.D.; supervision, R.R.K.; project administration, R.R.K.; funding acquisition, R.R.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was primarily supported by the US DOT UTC Program Grant, Tran-SET, through Louisiana State University (#21HSPVAMU1), and partial support was received from the National Science Foundation CREST Center for Energy & Environmental Sustainability Phase II, NSF grant number 1914692.

Data Availability Statement

The intermediate data in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| GHG | Greenhouse gases |

| LCA | Life cycle assessment |

| TCO | Total cost of ownership |

| VOC | Volatile organic carbons |

| WTP | Well-to-pump |

| WTW | Well-to-wheels |

References

- Texas Population Projections Program. Available online: https://demographics.texas.gov/Projections/2024/ (accessed on 22 March 2025).

- Energy-Related CO2 Emission Data Tables. Available online: https://www.eia.gov/environment/emissions/state/ (accessed on 22 March 2025).

- Avinash, A.; Murugesan, A. Economic analysis of biodiesel production from waste cooking oil. Energy Sources B Econ. Plan. Policy 2017, 12, 890–894. [Google Scholar] [CrossRef]

- Miller, P.; Sultana, A.; Kumar, A. Optimum scale of feedstock processing for renewable diesel production. Biofuel Bioprod. Bior. 2012, 6, 188–204. [Google Scholar] [CrossRef]

- For the First Time 50% of California Diesel Fuel Is Replaced by Clean Fuels. Available online: https://ww2.arb.ca.gov/news/first-time-50-california-diesel-fuel-replaced-clean-fuels (accessed on 10 January 2024).

- Biodiesel Laws and Incentives in Texas. Available online: https://afdc.energy.gov/fuels/laws/BIOD?state=tx (accessed on 30 April 2025).

- Eccleston, C.H. Integrating a life-cycle assessment with NEPA: Does it make sense? Environ. Qual. Manag. 1999, 8, 43–48. [Google Scholar] [CrossRef]

- Lardon, L.; Hélias, A.; Sialve, B.; Steyer, J.-P.; Bernard, O. Life-cycle assessment of biodiesel production from microalgae. Environ. Sci. Technol. 2009, 43, 6475–6481. [Google Scholar] [CrossRef]

- Malça, J.; Freire, F. Life-cycle studies of biodiesel in Europe: A review addressing the variability of results and modeling issues. Renew. Sustain. Energy Rev. 2011, 15, 338–351. [Google Scholar] [CrossRef]

- Morais, S.; Mata, T.M.; Martins, A.A.; Pinto, G.A.; Costa, C.A. Simulation and life cycle assessment of process design alternatives for biodiesel production from waste vegetable oils. J. Clean. Prod. 2010, 18, 1251–1259. [Google Scholar] [CrossRef]

- Pradhan, A.; Shrestha, D.; McAloon, A.; Yee, W.; Haas, M.; Duffield, J.; Shapouri, H. Energy Life-Cycle Assessment of Soybean Biodiesel. 2009. Available online: https://ageconsearch.umn.edu/record/308486?v=pdf (accessed on 2 December 2023). [CrossRef]

- Hou, J.; Zhang, P.; Yuan, X.; Zheng, Y. Life cycle assessment of biodiesel from soybean, jatropha and microalgae in China conditions. Renew. Sustain. Energy Rev. 2011, 15, 5081–5091. [Google Scholar] [CrossRef]

- Krohn, B.J.; Fripp, M. A life cycle assessment of biodiesel derived from the “niche filling” energy crop camelina in the USA. Appl. Energy 2012, 92, 92–98. [Google Scholar] [CrossRef]

- Frank, E.D.; Elgowainy, A.; Han, J.; Wang, Z. Life cycle comparison of hydrothermal liquefaction and lipid extraction pathways to renewable diesel from algae. Mitig. Adapt. Strateg. Glob. Change 2013, 18, 137–158. [Google Scholar] [CrossRef]

- Wong, A.; Zhang, H.; Kumar, A. Life cycle assessment of renewable diesel production from lignocellulosic biomass. Int. J. Life Cycle Assess. 2016, 21, 1404–1424. [Google Scholar] [CrossRef]

- Summers, H.M.; Ledbetter, R.N.; McCurdy, A.T.; Morgan, M.R.; Seefeldt, L.C.; Jena, U.; Hoekman, S.K.; Quinn, J.C. Techno-economic feasibility and life cycle assessment of dairy effluent to renewable diesel via hydrothermal liquefaction. Bioresour. Technol. 2015, 196, 431–440. [Google Scholar] [CrossRef] [PubMed]

- Wong, A.; Zhang, H.; Kumar, A. Life cycle water footprint of hydrogenation-derived renewable diesel production from lignocellulosic biomass. Water Res. 2016, 102, 330–345. [Google Scholar] [CrossRef] [PubMed]

- Okeke, I.J.; Sahoo, K.; Kaliyan, N.; Mani, S. Life cycle assessment of renewable diesel production via anaerobic digestion and Fischer-Tropsch synthesis from miscanthus grown in strip-mined soils. J. Clean. Prod. 2020, 249, 119358. [Google Scholar] [CrossRef]

- Larnaudie, V.; Bule, M.; San, K.-Y.; Vadlani, P.V.; Mosby, J.; Elangovan, S.; Karanjikar, M.; Spatari, S. Life cycle environmental and cost evaluation of renewable diesel production. Fuel 2020, 279, 118429. [Google Scholar] [CrossRef]

- Huo, H.; Wang, M.; Bloyd, C.; Putsche, V. Life-cycle assessment of energy use and greenhouse gas emissions of soybean-derived biodiesel and renewable fuels. Environ. Sci. Technol. 2009, 43, 750–756. [Google Scholar] [CrossRef]

- Barla, R.J.; Anand, A.; Raghuvanshi, S.; Gupta, S. Life cycle assessment of renewable diesel production. In Renewable Diesel; Kumar, D., Singh, B., Gupta, S.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 65–86. [Google Scholar]

- Li, Y.; Xu, H.; Northrup, D.; Wang, M. Effects of soybean varieties on life-cycle greenhouse gas emissions of biodiesel and renewable diesel. Biofuel Bioprod. Bior. 2023, 17, 449–462. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.J. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Xu, H.; Ou, L.; Li, Y.; Hawkins, T.R.; Wang, M. Life cycle greenhouse gas emissions of biodiesel and renewable diesel production in the United States. Environ. Sci. Technol. 2022, 56, 7512–7521. [Google Scholar] [CrossRef] [PubMed]

- Cheah, K.W.; Yusup, S.; Singh, H.K.G.; Uemura, Y.; Lam, H.L. Process simulation and techno economic analysis of renewable diesel production via catalytic decarboxylation of rubber seed oil—A case study in Malaysia. J. Environ. Manag. 2017, 203, 950–961. [Google Scholar] [CrossRef]

- Hsu, K.H.; Wang, W.C.; Liu, Y.C. Experimental studies and techno-economic analysis of hydro-processed renewable diesel production in Taiwan. Energy 2018, 164, 99–111. [Google Scholar] [CrossRef]

- Juneja, A.; Murthy, G.S. Evaluating the potential of renewable diesel production from algae cultured on wastewater: Techno-economic analysis and life cycle assessment. AIMS Energy 2017, 5, 239–257. [Google Scholar] [CrossRef]

- Kantama, A.; Narataruksa, P.; Hunpinyo, P.; Prapainainar, C. Techno-economic assessment of a heat-integrated process for hydrogenated renewable diesel production from palm fatty acid distillate. Biomass Bioenerg. 2015, 83, 448–459. [Google Scholar] [CrossRef]

- Patel, M.; Kumar, A. Production of renewable diesel through the hydro-processing of lignocellulosic biomass-derived bio-oil: A review. Renew. Sustain. Energy Rev. 2016, 58, 1293–1307. [Google Scholar] [CrossRef]

- Patel, M.; Oyedun, A.O.; Kumar, A.; Gupta, R. What is the production cost of renewable diesel from woody biomass and agricultural residue based on experimentation? A comparative assessment. Fuel Process. Technol. 2019, 191, 79–92. [Google Scholar] [CrossRef]

- Ou, L.; Li, S.; Tao, L.; Phillips, S.; Hawkins, T.; Singh, A.; Snowden-Swan, L.; Cai, H. Techno-economic analysis and life-cycle analysis of renewable diesel fuels produced with waste feedstocks. ACS Sustain. Chem. Eng. 2021, 10, 382–393. [Google Scholar] [CrossRef]

- Lenders, E. Renewable Energy Potential in Texas and Business Opportunities for the Netherlands. 2017. Available online: https://nbso-texas.com/downloads/Report-renewable-energy.pdf (accessed on 1 December 2023).

- Nakagawa, Y.; Tamura, M.; Tomishige, K. Recent development of production technology of diesel- and jet-fuel-range hydrocarbons from inedible biomass. Fuel Process. Technol. 2019, 193, 404–422. [Google Scholar]

- TEXAS Bioenergy 2010 Status Report. Available online: https://texasagriculture.gov/Portals/0/Bioenergy/Texas%20Bioenergy%20Status%20Report%202010.pdf (accessed on 1 December 2023).

- Cai, H.; Burnham, A.; Wang, M.; Hang, W.; Vyas, A. The GREET Model Expansion for Well-to-Wheels Analysis of Heavy-Duty Vehicles; Argonne National Lab. (ANL): Argonne, IL, USA, 2015.

- Burnham, A. AFLEET: Assess the Impacts of Conventional and Alternative Fuel Vehicles; Argonne National Lab. (ANL): Argonne, IL, USA, 2021.

- Singh, D.; Subramanian, K.; Garg, M. Comprehensive review of combustion, performance and emissions characteristics of a compression ignition engine fueled with hydroprocessed renewable diesel. Renew. Sustain. Energy Rev. 2018, 81, 2947–2954. [Google Scholar] [CrossRef]

- Staples, T.; Xu, W.; Li, Y.; Carraway, B. Estimation of Woody Biomass Availability for Energy in Texas. 2008. Available online: https://books.google.com/books/about/Estimation_of_Woody_Biomass_Availability.html?id=9eJOAQAAMAAJ (accessed on 20 December 2023).

- Annual Crop Production. 2024. Available online: https://www.nass.usda.gov/Statistics_by_State/Texas/Publications/Current_News_Release/2024_Rls/spr-ann-crop-prod-2024.pdf (accessed on 1 November 2024).

- Graham, R.L.; Nelson, R.; Sheehan, J.; Perlack, R.D.; Wright, L.L. Current and potential US corn stover supplies. Agron. J. 2007, 99, 1–11. [Google Scholar] [CrossRef]

- An, H.; Wilhelm, W.E.; Searcy, S.W. A mathematical model to design a lignocellulosic biofuel supply chain system with a case study based on a region in Central Texas. Bioresour. Technol. 2011, 102, 7860–7870. [Google Scholar] [CrossRef]

- Biodiesel Plant List. Available online: https://biodieselmagazine.com/plants/list/biodiesel (accessed on 20 January 2025).

- Ethanol Plant List. Available online: https://ethanolproducer.com/plants/list/ethanol (accessed on 20 January 2025).

- Wright, M.M.; Daugaard, D.E.; Satrio, J.A.; Brown, R.C. Techno-economic analysis of biomass fast pyrolysis to transportation fuels. Fuel 2010, 89, S2–S10. [Google Scholar] [CrossRef]

- Brown, T.R.; Thilakaratne, R.; Brown, R.C.; Hu, G. Techno-economic analysis of biomass to transportation fuels and electricity via fast pyrolysis and hydro-processing. Fuel 2013, 106, 463–469. [Google Scholar] [CrossRef]

- Shemfe, M.B.; Gu, S.; Ranganathan, P. Techno-economic performance analysis of biofuel production and miniature electric power generation from biomass fast pyrolysis and bio-oil upgrading. Fuel 2015, 143, 361–372. [Google Scholar] [CrossRef]

- Leila, M.; Whalen, J.; Bergthorson, J. Strategic spatial and temporal design of renewable diesel and biojet fuel supply chains: Case study of California, USA. Energy 2018, 156, 181–195. [Google Scholar] [CrossRef]

- Alternative Fuel Price Report. Available online: https://afdc.energy.gov/fuels/prices.html (accessed on 31 January 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).