Abstract

There are two main themes in the research on the biodegradation of industrial materials by mycelial fungi. The challenge of reducing environmental pollution necessitates the creation of biodegradable polymers that allow microorganisms, including mycelial fungi, to degrade them to low-molecule soluble substances. Additionally, to minimize the biodegradation of industrial materials while they are operating in the environment, there is a need to produce fungi-resistant polymer compositions. The fungal resistance of industrial materials and products can be assessed using a specific set of mycelial fungi cultures. Test cultures selected for this purpose are supported in the All-Russian Collection of Microorganisms (VKM). This review addresses the principle of culture selection to assess the fungal resistance of industrial materials and evaluates the results of the tests using these cultures.

1. Introduction

Issues related to testing of the ability of microorganisms to damage industrial materials, both natural and artificial, are important and relevant not only for industrial biotechnology, but also for industry as a whole. At present, it is virtually impossible to put into operation a new industrial sample or product without appropriate testing.

Mycelial fungi are organisms that live everywhere: in the soil, air, and water, and on various materials. They are capable of causing significant damage to building structures and industrial materials [1,2]. Their destructive activities are facilitated by a well-developed enzyme system, excellent adaptive capacities, and a high growth rate [3]. These factors increase the ability of the fungi to adapt quickly to changes in the environment. The mycelial structure and the method of obtaining nutrition by absorbing solutions of organic substances allow them to rapidly colonise almost any surface. Using a rich and diverse set of constitutive and adaptive enzymes, fungi can degrade high-molecular compounds, including synthetic ones [4]. The production of organic acids also increases their destructive activity [5,6].

Direct biodegradation of industrial materials by fungi occurs when they themselves are a nutrient medium for micromycetes. If the nutrients required for fungal growth cannot be extracted from the industrial materials, they can come from the various contaminants that accumulate on the surface during the production, storage, and use of the materials. Further growth of the fungi can lead to the release of metabolic products. These substances can cause damage to industrial materials.

Micromycetes are capable of damaging almost all types of natural and synthetic materials [7,8]. However, the biodamage processes occur at different speeds, which depends on both the specifics of the materials and the aggressiveness of the fungi (biodegrading activity), and are able to develop in negative environmental conditions. Glass was, for a long period of time, thought to be an inert material capable of withstanding the influence of fungi. However, even under extreme conditions, some organisms can cause mechanical damage, reducing the optical properties and breaking the protective top layer of glass lenses [9]. Species of fungi that can develop at an extremely low humidity (less than 50%), such as Aspergillus tonophilus and A. penicillioides, are examples of fungi that can affect glass [10].

In order to assess which fungi should be used to check the resistance of a given material, it is necessary to find which fungal species are the most common and the most active in the degradation of polymers, fuels, synthetic fibres, etc. In turn, evaluation of the resistance of new industrial materials requires a defined set of fungal test cultures. An analysis of published articles and our own experimental experience in the estimation of fungal resistance of industrial materials and in studying the degradation of newly developed biodegradable polymers allowed us to reach the conclusion that both activities require the use of a specific set of test cultures of mycelial fungi to compare the results of different research and development activities.

2. Degradation of Some Industrial Materials by Fungi

Oil hydrocarbons are the main environmental pollutants from manufacturing plants, transport, shipping, and accidental oil spills. Numerous studies have shown that many polycyclic aromatic hydrocarbons are toxic to the environment. They can be biotoxic, phototoxic, genotoxic, and immunotoxic [11]. According to the IARC (International Agency for Research on Cancer), the first group of hazards (carcinogenic to humans) includes primarily benzopyrene, which is considered the most carcinogenic substance of this type. This group also includes engine exhaust, diesel, and mineral oils. Naphthalene and anthracene belong to Group 2B (possibly carcinogenic to humans) (https://monographs.iarc.who.int/list-of-classifications/, accessed on 27 December 2022.). Cleaning of the environment of such PAHs is a major issue, and fungi can play a part in this process.

Fungi affecting fuels, oils, and lubricants are well-known [12,13]. They mainly belong to Aspergillus, Penicillium, Fusarium, Hormoconis, Neosartorya, Paecilomyces, Talaromyces, Graphium, and Cunninghamella genera and are known for their ability to decompose crude oil and its components [14,15]. In particular, Cunninghamella elegans has demonstrated the ability to degrade fluoranthene [16], and Aspergillus terreus can degrade naphthalene and anthracene [17]. The strain Penicillium sp., isolated from Antarctic soil, can decompose acenaphthene at low temperatures [18].

Some of these fungi are used for bioremediation of the environment following polycyclic hydrocarbon pollution. Mycoremediation is becoming a popular bioremediation technique [4]. For example, it has been shown that fungi of the Aspergillus and Fusarium taxa isolated from the soil in an oil production area can be effectively used in bioaugmentation to remove hydrocarbon pollutants from oilfield wastewater in oil field areas [19]. Environmental factors (the mechanical and chemical composition of soil, temperature, and pH) influencing the bioremediation process with fungi are being actively studied [20].

However, there is a downside to these properties, as the same fungi can inflict damage to human economic activities by degrading the fuel used in many industries [21,22].

Aspergillus fumigatus is often isolated from aviation fuel and can be active destructors of petroleum products. In this environment, fungal spores are able to survive at temperatures of up to 80 °C [23]. Hormoconis resinae (syn. Cladosporium resinae, Amorphotheca resinae) has a very high decomposition potential for aviation fuel; it has been shown to cause a loss of 17.8–66.9% of base fuel mass in a 14-day incubation period at room temperature [24]. This microorganism, containing dark melanin pigment, is called a ‘kerosene fungus’. Another ‘kerosene fungus’ is Monascus floridanus, and is also capable of active growth in aviation fuel [25].

Spores of ‘kerosene fungi’ adapt well to extreme conditions, and they are smaller than the pores of fuel filters. When injected into the fuel tank, they germinate and produce a mycelium which damages the fuel system [26]. The activity of these fungi leads to damage to the pipelines and fuel storage tanks, as well as inefficient operation of aircraft engines [27,28].

It has been shown that biodegradation of fuel occurs due to microbial enzymatic oxidation of hydrocarbons, with the formation of organic acids with surface-active properties. For example, a system of extracellular enzymes of several Aspergillus species isolated from soils contaminated with crude oil were shown to effectively decompose hydrocarbons [14]. Aliphatic hydrocarbons are less biostable than aromatic hydrocarbons, and undergo oxidation more rapidly [29].

Fungal damage to paint coatings is another common case of biodegradation [30,31]. Various materials are used to produce such coatings, which differ in composition and chemical properties of the film-forming formers: bitumen and ether-cellulose varnishes; polyester and polyurethane varnishes; drying oils, oil varnishes and paints; and alkyd varnishes.

If the packaging of varnishes and paints is broken, predominantly waterborne materials are mainly affected by microorganisms. Once applied to products, virtually all paint coatings are subject to biodegradation by fungi. The biologically active substances produced by fungi can break down polyurethanes, converting plasticizers into different polymers, resulting in a loss of coating strength. This is detrimental to polymeric lacquers, as the coating becomes more permeable when exposed to the fungi, making it ineffective as a protective layer [32]. Mycological studies have shown that the fungi of the genera Aureobasidium, Alternaria, Aspergillus, Cladosporium, and Penicillium are the main destroyers of paint coatings [33,34].

The decomposition by micromycetes affects polymeric materials of various chemical compositions and structures, including synthetic plastics. The final disposal of these materials using chemical and physical methods is very expensive, and leads to the formation of persistent organic pollutants. Among these pollutants, furans and dioxins are known to be toxic products that are harmful to animals, humans, and ecosystems in general [35,36]. Therefore, the issue of microbial degradation of artificial polymers has been given very high priority in research. Biodegradation is also an environmentally friendly process that may contribute to solving the problem of plastic waste.

Extensive research has been carried out to determine the species composition of mycelial fungi capable of destroying polymeric materials of different compositions in nature. According to A.Y. Lugauskas and co-authors [37], there are more than 400 species of fungi known to destroy polymers, including Aspergillus amstelodami sensu lato, A. awamori, A. oryzae, Chaetomim globosum, Paecilomyces variotii, Penicillium cyclopium, P. chrysogenum, Scopulariopsis brevicaulis, Trichoderma virens, and T. viride.

By changing the conditions of the experiment, it is possible to determine how the degree of biodegradation is affected by material composition and environmental conditions. In addition, it is possible to establish which fungal taxa are the most common in the degradation of polymer composites. For example, in the humid marine climate, among the biodegradable fungi of polyethyracrylate polymer composites, the highest frequency of occurrence was recorded in the genera Aspergillus (41%) and Gliocladium (26%). Active destructors were found to be the fungi of genera Cladosporium, Penicillium, Chaetomium, and Fusarium [38]. Interestingly, the taxa of plastic-degrading fungi are generally similar, regardless of the region in which the process is studied. Depending on the ecological conditions, the main group of fungi may be joined by endemic taxa specific to a particular locality or habitat. For example, while researching plastic waste in the western South Atlantic [39], scientists found many Wallemia isolates, an obligate xerophyte commonly found in salt water. However, the typical group of dominant fungi consists mostly of Aspergillus and Cladosporium.

One of the difficult-to-decompose synthetic polymers for fungi are polyethylenes. The stability of different grades of polyethylene depends on the molecular weight distribution of the fractions, on the presence and composition of stabilizers, etc. Recent scientific publications have confirmed the ability of microscopic fungi in natural habitats to destroy polyethylene of both high and low density. Aspergillus oryzae is the most active decomposer of polyethylene [35,40,41], as well as strains of the species Penicilum oxalicum, P. chysogenum [35], P. simplicissimum [42], and others.

The most common disposable plastic among the various synthetic plastics is polyethylene terephthalate, which is a thermoplastic polymer resin of the polyester family. This transparent, durable, and lightweight plastic is widely used for packaging, including disposable drink bottles. The fungi of the genera Aspergillus, Fusarium, and Humicola [43] are involved in its degradation in nature.

Other types of polymeric materials are also destroyed by fungi. Polyurethanes are a versatile class of synthetic polymers used in a variety of products in medicine, the automotive industry, and other industries. Fungi are the main destroyers of polyurethanes in nature [44]. The micromycetes Alternaria, Aspergillus, Phoma, Penicilium, Plectosphaerella, Geomyces, Nectria, and others have been isolated from placed in soil polyurethane specimens when the fungi have access to other sources of nutrients. Geomyces pannorum was shown to have the highest frequency of occurrence in this polymer decomposition method [45].

However, there are fungi that can grow in nutrition media where polyurethane is the only source of carbon. Such strains have been found in Cladosporium cladosporioides sensu lato [46], Penicillium, Alternaria [47], and others.

Despite the very wide range of fungi involved in the biodegradation processes of various polymer materials, it is possible to name the taxa with a high frequency of occurrence. The genera of these fungi are shown in Table 1, and the character of impact and properties of industrial materials changing under the influence of fungi are also indicated.

Both our experience and numerous scientific publications point to the conclusion that fungi capable of breaking down polymeric materials belong to several dozen genera, but the most common are representatives of the genera Aspergillus, Penicillium, and Cladosporium. This is usually independent of the location of the research site.

For example, when studying Antarctic fungi at sites affected by various anthropogenic impacts (soil from a petroleum leakage site, including diesel fuel, gasoline, and aviation kerosene, and soil from a location near an incinerator that operates on diesel fuel, etc.) near the Russian research Antarctic stations Druzhnaya, Progress, Molodezhnaya, and others, we noted micromycetes whose numbers increased at a certain level of pollution due to their enzymatic potential to degrade hydrocarbons. Most of them belonged to the genera Aspergillus and Penicillium. From Antarctic soil polluted with oil products we isolated a strain of the species Penicillium restrictum [48]. In the Arctic, when studying fungal communities at the Polar Experimental Station in the Murmansk Region, mycologists also identified representatives of this species, categorizing them as “typical frequent” in oil-contaminated soil, while in the same undisturbed soil they are categorized as “typical rare” [49].

Table 1.

Degradation of some industrial materials by fungi.

Table 1.

Degradation of some industrial materials by fungi.

| Type of the Material | Fungal Action | Change in Properties during Biodestruction | Fungal Genera Most Actively Involved in Biodegradation | References |

|---|---|---|---|---|

| Fuels and lubricants, including petroleum fuels | Assimilation of hydrocarbons leading to degradation of the material | Viscosity reduction, change in acid number and oxidation stability | Aspergillus, Penicillium, Fusarium, Hormoconis (Amorphotheca), Monascus, Neosartorya, Paecilomyces, Talaromyces, Graphium, Cunninghamella | [14,15,25] |

| Lacquers and paint coatings | Oxidation, reduction, hydrolysis, esterification, decarboxylation | Change in density, color, viscosity reduction, formation of gases | Acremonium, Alternaria, Aspergillus, Aureobasidium, Cladosporium, Fusarium, Penicillium, Trichoderma, Pullularia | [33,34] |

| Polymer materials and their components | Oxidation, hydrolysis, esterification, acidification | Change in color, structure, tightness, strength | ||

| polyurethane | Aspergillus, Alternaria, Chaetomium, Cladosporium, Fusarium, Geomyces, Gliocladium, Nectria, Penicillium, Pestalotiopsis, Phoma, Trichoderma | [45,46,47,50,51,52,53,54] | ||

| polyethylene | Aspergillus, Aureobasidium, Cladosporium, Fusarium, Penicillium, Phanerochaete | [35,40,41,42,55,56,57] | ||

| polyethyleneterephthalate | Aspergillus, Fusarium, Humicola | [43] | ||

| polystyrene | Gloeophyllum striatum, Gloeophyllum trabeum | [58] |

3. Fungal Enzymes Involved in Plastic Degradation

There is evidence that biodegradation is an enzymatic process [59]. In the biodegradation process, plastics react with oxygen in the air, and then microorganisms release enzymes that decompose the plastic into simple substances, such as carbon dioxide and water [35]. The most common decomposition of plastic materials occurs in the process of co-oxydation, when, along with hard-to-reach substrates, fungi have access to other easily degradable substrates. However, there are fungi that have a pool of enzymes for the use of polymeric substances as the sole carbon source, though decomposition is slow in this case. This includes, for example, Aspergillus niger, which actually destroys polyurethane, but extremely slowly, so that visible signs of degradation do not appear until the 30th day [45].

Numerous studies shedding light on the assimilation mechanism of the ‘kerosene fungus’ Hormoconis resinae of n-alkanes, which are in aviation and automobile gasoline and diesel fuel, have been conducted [60]. H. resinae is thought to have a constitutive n-alkane oxidation system. The first step involves the entry of hydrocarbons into the cell by apparently active transport, although the mechanism of this process is not yet fully understood. Then, with the help of the enzymes alkane-monooxygenase, fatty alcoholoxygenase, and fatty aldehyde dehydrogenase, the process of alkane metabolism from hexadecane to hexadecanoic acid (palmitic acid) occurs, which, in turn, is involved in lipogenesis in fungal cells [27].

Microbial exposure to plastics can be carried out through enzymatic action, primarily of hydrolases such as ureases, proteases, and esterases. It is believed that biodegradation of polyester polyurethane may occur by hydrolysis of ester groups by esterase enzymes [61]. For example, from the biomass of Chaetomium globosum and Aspergillus terreus were isolated enzymes with esterase and urethane-hydrolase activities. The enzymes in these fungi were induced by adding liquid polyether polyurethane to the cultural medium, and it was found that a number of strains of the genera Curvularia, Fusarium, Aureobasidium, and Cladosporium can use polyurethane as their sole source of carbon. From the strain Curvularia senegalensis it was possible to isolate and purify an extracellular polyurethanease belonging to the esterase class, possessing high enzymatic activity [62]. Aspergillus flavus was also isolated from soil and found to have polyurethanolytic activity due to extracellular esterase. When it was developed on polyurethane, a 60% reduction in substrate weight was observed [63].

The endophyte Pestalotiopsis microspora, which is prone to horizontal gene transfer, degrades polyurethane both aerobically and in the absence of oxygen. It produces the enzyme polyurethanase, which belongs to the serine hydrolase family. The enzyme is extracellular and is synthesized by the fungus in a poor environment where polyurethane is the sole source of carbon [45].

There are studies confirming the involvement of hydrolases, such as lipases and cutinases, in the decomposition of various forms of plastic. Lipases can hydrolyse vegetable oils, triglycerides, and fatty acid methyl esters, while cutinases specifically hydrolyze ester bonds [64]. In Japan, a cutinase enzyme capable of decomposing polyethylene has been found in strains of the genus Paraphoma, and this enzyme is used with high efficiency in agriculture to decompose polyethylene films for soil mulching directly in the fields [65,66].

Hydrolases, such as proteases, may also be involved in the process of plastic degradation. In a study conducted on 22 strains of fungi capable of growth using polyurethane as a carbon source, it was shown with a high probability that the protease enzymatic activity was associated with plastic biodegradation [54].

Representatives of Penicillium simplicissimum are known to produce oxidases, such as laccase and manganese peroxidase, which decompose polyethylene [67]. P. pinophilum is a producer of a highly efficient specific depolymerase involved in the biodegradation of polyhydroxyalkanoates [61]. There are reports that non-ligninolytic fungi, such as Aspergillus niger, Pseudogymnoascus pannorum, and Cunninghamella elegans, involve the intracellular enzyme CytP450-dependent monooxygenase to degrade phenanthrene [68].

In general, it has been shown that fungal laccases and peroxidases involved in the decay of lignin by fungi are involved in the decomposition of polyethylene [69] and polyvinyl chloride, while esterases, such as cutinases and lipases, are successfully used by fungi in the biodegradation of polyethylene terephthalate and polyurethane [70].

Table 2 presents some of the enzymes found in fungi that are involved in the decomposition of plastic materials.

Table 2.

Fungal enzymes involved in plastic degradation.

4. Selection of Strains for Testing Industrial Samples for Biostability

In most countries, including the Russian Federation, mould resistance tests are carried out regularly for various materials and products, including industrial technical products, polymer materials, and coatings. The tests are carried out according to industry standards established for various types of materials and articles. Different sets of mycelial fungi, with indications of their species affiliation, are used in these tests. Despite the different composition and specificity of the objects studied, it is possible to distinguish fungi which are involved in the process of destruction of almost all industrial materials. These are used in biostability trials.

To select the strains for these tests, the following should be considered:

The test cultures should be sufficiently versatile. They are selected from eurytopic species that are ubiquitous and occupy different ecological niches. These fungi include Aspergillus, Penicillium, Trichoderma, Fusarium, and some other genera. Additionally, To standardise the testing process and be able to compare not only the experimental and control samples, but also data from different tests, the cultures should have an active and stable sporulation, allowing a standard suspension to be obtained for the application of fungal conidia to test surfaces. A large number of basidiomycetous fungi are involved in the process of breaking down plastics. For example, fungi of the genera Pleurotus, Phanerochaete, Trametes, and Bjerkandera form highly active peroxidases and laccases [3]. However, the use of these fungi for testing of polymeric material decomposition is difficult as these fungi do not have conidial sporulation, and it is not easy to prepare a standard suspension of them. Finally, the strains must also have a powerful enzymatic system, and the ability to degrade polymeric materials.

It should be taken into account that fungi of the same species, but different strains, may present varying levels of aggression towards degradable materials. The strain-biodestructors that are used to perform tests of industrial materials for degradation resistance are stored in the VKM (Table 3). For example, the strains Aspergillus terreus VKM F-1025, Aspergillus brasiliensis (formerly known as A. niger) VKM F-1119, Paecilomyces variotii VKM F-378, and Penicillium aurantiogriseum (syn. P. cyclopium) VKM F-245 have shown high efficiency in terms of degradation of the physical and chemical properties of hybrid composites based on chitosan and acrylic polymers [82,83]. Alternaria alternata strain VKM F-1120 has been used for 2-4-6-trinitrotoluene decomposition [84], and the Penicillium ochrochloron strain VKM F-2032, isolated from fluorolone materials, was protected by a USSR patent in 1977 as a biodegradant fungus which actively grows on polymeric coatings.

Table 3.

List of strains used in mold resistance tests in VKM.

Some of the strains currently in use in Russia are also being applied in other countries to assess the fungal resistance of various samples. The US Microbac Laboratory Services (http://ww.microbac.com/, accessed on 27 December 2022.) has published a list of tests, methods, and standards for testing industrial materials for resistance to fungal damage. In these tests, specific fungi from the American Type Culture Collection (ATCC) are used, and the identification numbers of the strains are included in each test. A number of the strains used are also stored in the VKM under the numbers VKM F-1119, VKM F-1115, VKM F-1117, and VKM F-1116, and are used in the Russian Governmental Standards to determine the mould resistance of industrial materials (Table 3).

International test ASTM G21-15 (standard practice for determining resistance of synthetic polymeric material to fungi) is a qualitative test that uses high concentrations of conidia from five different fungi species to determine the resistance of synthetic polymeric materials to fungal growth. The five strains of Aspergillus brasiliensis (formerly known as A. niger), Aureobasidium pullulans, Chaetomium globosum, Trichoderma virens (formerly known as T. viride), and Penicillium funiculosum (formerly known as P. pinophilum) are used as test cultures here. Approximately the same set of cultures is used in the International Standard ISO 846: 2019—(Plastics, Evaluation of the Action of Microorganisms). Method A of this test involves testing plastics for mould resistance. The difference between the two tests is that the latter uses the Aureobasidium pullulans strain instead of the Paecilomyces variotii strain.

In similar Russian tests in the study of biodegradation of polymeric materials and their components, nine cultures of fungi are being used. In addition, the strains of species Aspergillus sojae (formerly known as A. oryzae), Aspergillus terreus, Penicillium aurantiogriseum, and P. chrysogenum are being utilised. This is because the representatives of these species are active, and they are often the main biodestructors of polymeric composite materials [85,86,87].

The fund of VKM fungi-biodestructors is constantly being updated in the hopes of further development of methodological recommendations for assessing the biostability of materials.

Thus, the active role of the micromycetes Clonostachys rosea var. catenulata VKM F-3955, C. solani VKM F-3964, Thrichoderma harzianum VKM F-3962, and others in the biodegradation of polymers, particularly polyvinyl alcohol, polyurethane, and latexes based on acrylic acid used in construction as paintwork materials, has been shown in scientific studies [88]. Seventeen strains of soil micromycetes that are polymer biodestructors were accepted into the VKM collection based on the results of these studies.

The collection was enriched with a unique strain of Monascus floridanus (VKM F-4444), already mentioned as a ‘kerosene fungus’, which grows rapidly in aviation fuel and decomposes it at a high rate.

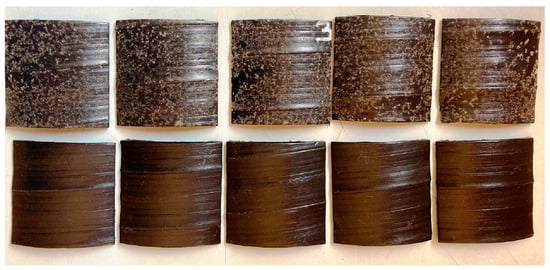

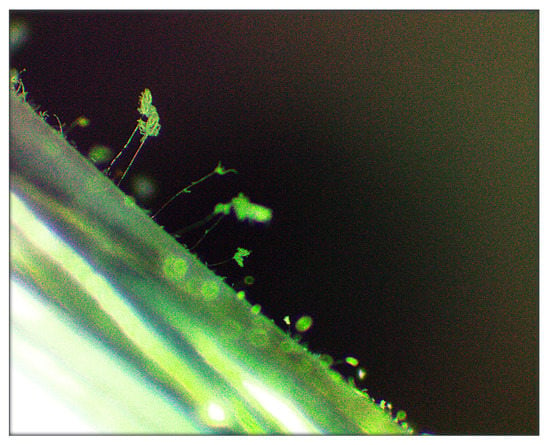

In the last five years, confirmation of the biological activity of a set of strains used in the All-Russian Collection of Microorganisms (VKM) was achieved with 663 samples of various polymer materials (mainly protective polyethylene and lacquer coatings) and products. It was found that the polymer composition influences resistance to biodamage; most of the investigated materials were resistant to the influence of fungi, but materials without such properties (unpublished data) have been also identified. Figure 1 shows the development of test cultures 28 days after the application of fungal spores on the polymer surface. In Figure 2, sporulation of a culture of Paecilomyces variotii VKM F-378 on a film of polyethylene coating is clearly visible. The results of VKM test cultures used in the development of biodegradable materials are presented below.

Figure 1.

Testing of the fungal resistance of paint and varnish coatings (bottom row-control). After 28 days of testing (temperature 30 °C, relative humidity more than 90%) on the surface of the material the growth of test-cultures in the form of a light-colored plaque, in particular Aspergillus terreus (VKM F-1025) is visible with the naked eye.

Figure 2.

Sporulation of test-culture Paecilomyces variotii VKM F-378 on the surface of the testing specimen of polyethylene film coating.

5. Application of Test Micromycetes from the VKM Collection for Investigations in the Field of Biodegradable Material Development

Another research field using mould fungi for testing is in the development of biodegradable polymer materials. One of the mandatory stages in the study of such materials is an exploration of their biodegradability. Tests of fungi resistance allow this ability to be unambiguously established.

In recent decades, interest in the creation of biodegradable polymer materials has increased due to the urgency of solving the problem of accumulation and disposal of polymeric wastes. Leading researchers around the world are developing more and more new formulations that could replace products made from synthetic and nondegradable, primarily oil-based polymers, for example, [89,90,91]. Such materials can be used as packaging containers, disposable tableware, mulching films, etc. One of the mandatory stages in the study of biodegradable materials is an exploration of their biodegradability. Previously, numerous authors have shown that this characteristic is essential in describing the properties of the obtained biodegradable compositions. It is therefore important to comprehensively investigate biodegradability using different methods, including tests of mould resistance using test cultures of polymers from VKM, assessing the mass loss of samples after exposure in soil for a certain period of time, fourier-transform infrared spectroscopy (FTIR), evaluating the change in structure by scanning electron microscopy (SEM), and so forth.

In order to be able to compare the results with other research, all the fungal resistance tests were carried out using a standard set of test organisms, consisting of nine strains used in the study of degradation of polymeric materials (Table 3), namely Chaetomium globosum VKM F-109, Penicillium chrysogenum VKM F-245, Penicillium aurantiogriseum VKM F-265, Paecilomyces variotii VKM F-378, Aspergillus terreus VKM F-1025, Penicillium pinophilum VKM F-1115, Trichoderma virens VKM F-1117, Aspergillus brasiliensis VKM F-1119, and Aspergillus sojae VKM F-2096. All tests were performed under standard conditions: the temperature was 30 °C, the relative humidity was over 90%, and the incubation time was up to 84 days.

In earlier studies [92,93,94], the authors obtained compositions based on low-density polyethylene (LDPE) with various polysaccharides (cellulose, ethyl cellulose, starch, chitin, chitosan) under conditions of shear deformation. The development of such compositions, allowing one to utilize large-tonnage synthetic polymers, led to a combination of the properties of both components; namely, good mechanical properties along with biodegradability. It has been shown that fungal resistance depends on the nature of the polysaccharide used and its availability in the composition. Compositions based on LDPE with starch and chitin [92] show minimal fungal resistance, while the introduction of poly(ethylene oxide) [93,94] and the creation of LDPE compositions with two different polysaccharides [95,96,97] intensified the growth of fungi. According to the existing system for assessing the intensity of their growth (six-point scale), these compositions received the maximum five points, as more than 25% of their surface was covered with fungal mycelium, which could be seen with the naked eye.

In further works, the authors developed compositions based on various polymers of natural origin (polysaccharides and polylactide (PLA)). Thus, in [97,98,99,100], the authors showed it is possible to obtain compositions based on PLA with various polysaccharides under the conditions of shear deformation and studied their properties, including biodegradability. PLA decomposes only under severe conditions (compost, sea water, etc.). However, the PLA-based compositions with polysaccharides exhibited low fungal resistance. In the study of PLA compositions with microcrystalline cellulose and ternary systems with poly(ethylene glycol) (PEG) [97], it was possible to identify fungal species that exhibited the maximum growth rate. Thus, after 21 days of testing, Aspergilus fungi were dominant, while on the 45th day of testing, conidial structures characteristic of Penicillium fungi were already clearly distinguishable. Rogovina et al. [98] showed that biodegradation proceeds most intensively in samples containing starch and PEG. Moreover, it was shown that after 84 days of testing in the case of a binary composition, almost 100% of the surface was covered with a dark grey layer caused by Aspergillus brasiliensis (VKM F-1119), while for the system with PEG, sample pigmentation indicated the dominant action of Aspergillus terreus (VKM F-1025).

Recent studies have been aimed at creating compositions based on LDPE, PLA, and starch [99,100]. According to tests of the fungal resistance of these systems, the same pattern was revealed; in compositions with a high content of polysaccharide starch, the biodegradation process proceeded more intensively (i.e., minimal fungal resistance was exhibited). More than 25% of the sample surface was covered by fungal mycelium that could be visualized by the naked eye.

Thus, studies conducted with the standard set of test cultures have made it possible to detect the patterns of destruction of various polymer compositions.

6. Conclusions

The creation of biodegradable polymer materials, as well as of protective compositions to reduce biodegradation of industrial products during operation, requires effective testing of materials for resistance to biodamage. The degree and nature of changes in the properties of the tested samples can be determined by the qualitative and quantitative composition of the metabolites of the microorganisms involved in the biodegradation process. Fungi have an important role in biodegradation processes, which is reflected in the creation of different tests governing the assessment process for mould resistance. A specific set of test cultures allows standardised research and, as a consequence, the ability to compare the results of studies of the fungal resistance of different materials. These fungi should have a constantly pronounced activity (aggressiveness) and be able to damage certain materials. The VKM is a member of the World Federation of Culture Collections (WFCC) and the largest collection of fungi in the Russian Federation and is, which preserves test-cultures and provides them to interested parties. Its capabilities allow us to ensure not only the viability but also the activity of the test cultures over a long period of time using modern preservation methods.

The VKM also constantly updates the list of active cultures with strains isolated directly from the foci of bio-damage materials and products. Changes in test cultures’ names related to the development of fungal taxonomy, data on the storage of these cultures in world collections, as well as the information of use of specific strains as research subject, are regularly monitored in VKM.

Author Contributions

Conceptualization, N.I. and G.K.; methodology, N.I. and G.K.; validation, G.K. and S.R.; investigation, N.I., G.K., K.A. and S.R.; writing—original draft preparation, G.K., S.R. and K.A.; writing—review and editing, N.I. and S.R.; visualization, G.K.; project administration, G.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research has received funding from the Ministry of Science and Higher Education of the Russian Federation under grant agreement № 075-15-2021-1051.

Data Availability Statement

Not applicable.

Acknowledgments

We acknowledge Svetlana Ozerskaya for her helpful scientifical imput.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Brambilla, A.; Sangiorgio, A. Mould growth in energy efficient buildings: Causes, health implications and strategies to mitigate the risk. Renew. Sustain. Energy Rev. 2020, 132, 110093. [Google Scholar] [CrossRef]

- Ali, S.S.; Elsamahy, T.; Al-Tohamy, R.; Zhu, D.; Mahmoud, Y.A.-G.; Koutra, E.; Metwally, M.A.; Kornaros, M.; Sun, J. Plastic wastes biodegradation: Mechanisms, challenges and future prospects. Sci. Total. Environ. 2021, 780, 146590. [Google Scholar] [CrossRef]

- Srikanth, M.; Sandeep, T.S.R.S.; Sucharitha, K.; Godi, S. Biodegradation of plastic polymers by fungi: A brief review. Bioresour. Bioprocess. 2022, 9, 42. [Google Scholar] [CrossRef]

- Tomer, A.; Singh, R.; Singh, S.K.; Dwivedi, S.A.; Reddy, C.U.; Keloth, M.R.A.; Rachel, R. Role of Fungi in Bioremediation and Environmental Sustainability. In Mycoremediation and Environmental Sustainability; Prasad, R., Nayak, S.C., Khawar, R.N., Dubey, N.K., Eds.; Springer: Cham, Switzerland, 2021; Volume 3, pp. 187–200. [Google Scholar] [CrossRef]

- Gutarowska, B.; Czyżowska, A. The ability of filamentous fungi to produce acids on indoor building materials. Ann. Microbiol. 2009, 59, 807–813. [Google Scholar] [CrossRef]

- Liao, J.; Jiang, J.; Xue, S.; Qingyu, C.; Wu, H.; Manikandan, R.; Hartley, W.; Huang, L. A novel acid-producing fungus isolated from bauxite residue: The potential to reduce the alkalinity. Geomicrobiol. J. 2018, 35, 840–847. [Google Scholar] [CrossRef]

- Cappitelli, F.; Sorlini, C. Microorganisms Attack Synthetic Polymers in Items Representing Our Cultural Heritage. Appl. Environ. Microbiol. 2008, 74, 564–569. [Google Scholar] [CrossRef]

- Dai, X.; Wang, H.; Ju, L.-K.; Cheng, G.; Cong, H.; Newby, B.-M.Z. Corrosion of aluminum alloy 2024 caused by Aspergillus niger. Int. Biodeterior. Biodegrad. 2016, 115, 1–10. [Google Scholar] [CrossRef]

- Ngo, C.C.; Nguyen, Q.H.; Nguyen, T.H.; Quach, N.T.; Dudhagara, P.; Vu, T.H.N.; Le, T.T.X.; Le, T.T.H.; Do, T.T.H.; Nguyen, V.D.; et al. Identification of Fungal Community Associated with Deterioration of Optical Observation Instruments of Museums in Northern Vietnam. Appl. Sci. 2021, 11, 5351. [Google Scholar] [CrossRef]

- Koval, E.Z.; Sidorenko, L.P. Mycodestructors of Industrial Materials; Naukova Dumka: Kiev, USSR, 1989; p. 189. (In Russian) [Google Scholar]

- Patel, A.B.; Shaikh, S.; Jain, K.R.; Desai, C.; Madamwar, D. Polycyclic Aromatic Hydrocarbons: Sources, Toxicity, and Remediation Approaches. Front. Microbiol. 2020, 11, 562813. [Google Scholar] [CrossRef]

- Rodríguez-Rodríguez, C.E.; Rodríguez, E.; Blanco, R.; Cordero, I.; Segura, D. Fungal contamination of stored automobile-fuels in a tropical environment. J. Environ. Sci. 2010, 22, 1595–1601. [Google Scholar] [CrossRef]

- Passman, F.J. Microbial contamination and its control in fuels and fuel systems since 1980–A review. Int. Biodeterior. Biodegrad. 2013, 81, 88–104. [Google Scholar] [CrossRef]

- Zhang, J.-H.; Xue, Q.-H.; Gao, H.; Ma, X.; Wang, P. Degradation of crude oil by fungal enzyme preparations from Aspergillus spp. for potential use in enhanced oil recovery. J. Chem. Technol. Biotechnol. 2016, 91, 865–875. [Google Scholar] [CrossRef]

- Al-Hawash, A.B.; Dragh, M.A.; Li, S.; Alhujaily, A.; Abbood, H.A.; Zhang, X.; Ma, F. Principles of microbial degradation of petroleum hydrocarbons in the environment. Egypt. J. Aquat. Res. 2018, 44, 71–76. [Google Scholar] [CrossRef]

- Mitra, S.; Pramanik, A.; Banerjee, S.; Haldar, S.; Gachhui, R.; Mukherjee, J. Enhanced Biotransformation of Fluoranthene by Intertidally Derived Cunninghamella elegans under Biofilm-Based and Niche-Mimicking Conditions. Appl. Environ. Microbiol. 2013, 79, 7922–7930. [Google Scholar] [CrossRef]

- Mohamed, I.A.; Neveen, M.K.; Mohamed, N.A.E.G. Biodegradation of some polycyclic aromatic hydrocarbons by Aspergillus terreus. Afr. J. Microbiol. Res. 2012, 6, 3783–3790. [Google Scholar] [CrossRef]

- Govarthanan, M.; Fuzisawa, S.; Hosogai, T.; Chang, Y.-C. Biodegradation of aliphatic and aromatic hydrocarbons using the filamentous fungus Penicillium sp. CHY-2 and characterization of its manganese peroxidase activity. RSC Adv. 2017, 7, 20716–20723. [Google Scholar] [CrossRef]

- Obire, O.; Aleruchi, O.; Wemedo, S. Fungi in Biodegradation of Polycyclic Aromatic Hydrocarbons in Oilfield Wastewater. Acta Sci. Microbiol. 2020, 3, 220–224. [Google Scholar] [CrossRef]

- Li, Q.; Liu, J.; Gadd, G.M. Fungal bioremediation of soil co-contaminated with petroleum hydrocarbons and toxic metals. Appl. Microbiol. Biotechnol. 2020, 104, 8999–9008. [Google Scholar] [CrossRef]

- Prenafeta-Boldú, F.X.; de Hoog, G.S.; Summerbell, R.C. Fungal communities in hydrocarbon degradation. In Microbial Communities Utilizing Hydrocarbons and Lipids: Members, Metagenomics and Ecophysiology Handbook of Hydrocarbon and Lipid Microbiology; McGenity, T.J., Ed.; Springer: Cham, Switzerland, 2018; pp. 1–36. [Google Scholar]

- Shapiro, T.; Chekanov, K.; Alexandrova, A.; Dolnikova, G.; Ivanova, E.; Lobakova, E. Revealing of Non-Cultivable Bacteria Associated with the Mycelium of Fungi in the Kerosene-Degrading Community Isolated from the Contaminated Jet Fuel. J. Fungi 2021, 7, 43. [Google Scholar] [CrossRef]

- Krivushina, A.A.; Startsev, V.O. Micromycetes-destructors of polymeric materials among extremophilic microorganisms (review). Trudy VIAM 2022, 1, 12. (In Russian) [Google Scholar] [CrossRef]

- Itah, A.Y.; Brooks, A.A.; Ogar, B.O.; Okure, A.B. Biodegradation of International Jet A-1 Aviation Fuel by Microorganisms Isolated from Aircraft Tank and Joint Hydrant Storage Systems. Bull. Environ. Contam. Toxicol. 2009, 83, 318–327. [Google Scholar] [CrossRef] [PubMed]

- Vasilyeva, A.A.; Chekunova, L.N.; Bilanenko, E.N.; Kachalkin, A.V.; Polyakova, A.V. Characterization of the strain Monascus floridanus P. F. Cannon & E. L. Barnard, isolated from aviation fuel. Microbiology 2012, 81, 244–250. [Google Scholar] [CrossRef]

- Semenov, S.A.; Gumargalieva, K.Z.; Zaikov, G.E. Process characteristics and peculiarities of damages of materials by microorganisms in the exploitation conditions. Vestnik MITHT 2008, 3, 3–23. (In Russian) [Google Scholar]

- Rafin, C.; Veignie, E. Hormoconis resinae, the kerosene fungus. In Taxonomy, Genomics and Ecophysiology of Hydrocarbon-Degrading Microbes; Springer: Berlin/Heidelberg, Germany, 2019; pp. 299–318. [Google Scholar]

- Singh, A.K. Industrial Cases of Microbial Induced Corrosion. In Microbially Induced Corrosion and its Mitigation; Springer: Singapore, 2020; pp. 81–106. [Google Scholar] [CrossRef]

- Shkilniuk, I.; Boichenko, S. Biological Risk of Aviation Fuel Supply. In Systems, Decision and Control in Energy I. Studies in Systems, Decision and Control; Babak, V., Isaienko, V., Zaporozhets, A., Eds.; Springer: Cham, Switzerland, 2020; Volume 298, pp. 179–199. [Google Scholar] [CrossRef]

- Maduka, C.M.; Igwilo, N.C. Microorganisms survive in paints. Cur. Anal. Biotechnol. 2019, 2, 1–5. [Google Scholar]

- Phulpoto, A.H.; Maitlo, M.A.; Kanhar, N.A. Culture-dependent to culture-independent approaches for the bioremediation of paints: A review. Int. J. Environ. Sci. Technol. 2021, 18, 241–262. [Google Scholar] [CrossRef]

- Ravikumar, H.R.; Rao, S.S.; Karigar, C.S. Biodegradation of paints: A current status. Indian J. Sci. Technol. 2012, 5, 1977–1987. [Google Scholar] [CrossRef]

- O’Neill, T.B. Succession and interrelationships of microorganisms on painted surfaces. Int. Biodeterior. 1988, 24, 373–379. [Google Scholar] [CrossRef]

- Shirakawa, M.A.; Loh, K.; John, V.M.; Silva, M.E.S.; Gaylarde, C.C. Biodeterioration of painted mortar surfaces in tropical urban and coastal situations: Comparison of four paint formulations. Int. Biodeterior. Biodegrad. 2011, 65, 669–674. [Google Scholar] [CrossRef]

- Ojha, N.; Pradhan, N.; Singh, S.; Barla, A.; Shrivastava, A.; Khatua, P.; Rai, V.; Bose, S. Evaluation of HDPE and LDPE degradation by fungus, implemented by statistical optimization. Sci. Rep. 2017, 7, 39515. [Google Scholar] [CrossRef]

- Kyaw, B.M.; Champakalakshmi, R.; Sakharkar, M.K.; Lim, C.S.; Sakharkar, K.R. Biodegradation of Low Density Polythene (LDPE) by Pseudomonas Species. Indian J. Microbiol. 2012, 52, 411–419. [Google Scholar] [CrossRef]

- Lugauskas, A.Y.; Mikulskene, A.I.; Shlyauzhene, D.Y. Catalog of Micromycetes—Biodestructors of Polymeric Materials; Nauka: Moscow, USSR, 1987; p. 344. (In Russian) [Google Scholar]

- Erofeev, V.T.; Smirnov, V.F.; Myshkin, A.V. The study of species composition of the mycoflora, selected surface samples proliferation composites in humid maritime climate. IOP Conf. Ser. Mater. Sci. Eng. 2019, 698, 022082. [Google Scholar] [CrossRef]

- Lacerda, A.L.D.F.; Proietti, M.C.; Secchi, E.R.; Taylor, J.D. Diverse groups of fungi are associated with plastics in the surface waters of the Western South Atlantic and the Antarctic Peninsula. Mol. Ecol. 2020, 29, 1903–1918. [Google Scholar] [CrossRef] [PubMed]

- Muhonja, C.N.; Makonde, H.; Magoma, G.; Imbuga, M. Biodegradability of polyethylene by bacteria and fungi from Dandora dumpsite Nairobi-Kenya. PLoS ONE 2018, 13, e0198446. [Google Scholar] [CrossRef] [PubMed]

- Ghatge, S.; Yang, Y.; Ahn, J.-H.; Hur, H.-G. Biodegradation of polyethylene: A brief review. Appl. Biol. Chem. 2020, 63, 27. [Google Scholar] [CrossRef]

- Yamada-Onodera, K.; Mukumoto, H.; Katsuyaya, Y.; Saiganji, A.; Tani, Y. Degradation of polyethylene by a fungus, Penicillium simplicissimum YK. Polym. Degrad. Stab. 2001, 72, 323–327. [Google Scholar] [CrossRef]

- Ahmaditabatabaei, S.; Kyazze, G.; Iqbal, H.M.N.; Keshavarz, T. Fungal Enzymes as Catalytic Tools for Polyethylene Terephthalate (PET) Degradation. J. Fungi 2021, 7, 931. [Google Scholar] [CrossRef] [PubMed]

- Zafar, U.; Houlden, A.; Robson, G.D. Fungal Communities Associated with the Biodegradation of Polyester Polyurethane Buried under Compost at Different Temperatures. Appl. Environ. Microbiol. 2013, 79, 7313–7324. [Google Scholar] [CrossRef]

- Russell, J.R.; Huang, J.; Anand, P.; Kucera, K.; Sandoval, A.G.; Dantzler, K.W.; Hickman, D.; Jee, J.; Kimovec, F.M.; Koppstein, D.; et al. Biodegradation of Polyester Polyurethane by Endophytic Fungi. Appl. Environ. Microbiol. 2011, 77, 6076–6084. [Google Scholar] [CrossRef]

- Álvarez-Barragán, J.; Domínguez-Malfavón, L.; Vargas-Suárez, M.; González-Hernández, R.; Aguilar-Osorio, G.; Loza-Tavera, H. Biodegradative Activities of Selected Environmental Fungi on a Polyester Polyurethane Varnish and Polyether Polyurethane Foams. Appl. Environ. Microbiol. 2016, 82, 5225–5235. [Google Scholar] [CrossRef]

- Magnin, A.; Hoornaert, L.; Pollet, E.; Laurichesse, S.; Phalip, V.; Avérous, L. Isolation and characterization of different promising fungi for biological waste management of polyurethanes. Microb. Biotechnol. 2019, 12, 544–555. [Google Scholar] [CrossRef]

- Kochkina, G.A.; Ivanushkina, N.E.; Lupachev, A.V.; Starodumova, I.P.; Vasilenko, O.V.; Ozerskaya, S.M. Diversity of mycelial fungi in natural and human-affected Antarctic soils. Polar Biol. 2019, 42, 47–64. [Google Scholar] [CrossRef]

- Korneikova, M.V.; Evdokimova, G.A.; Lebedeva, E.V. The complexes of microscopic fungi in cultivated soils polluted by oil products on the north of Kola Peninsula. Mykol. Phytopatol. 2011, 45, 249–256. (In Russian) [Google Scholar]

- Cosgrove, L.; McGeechan, P.L.; Robson, G.D.; Handley, P.S. Fungal Communities Associated with Degradation of Polyester Polyurethane in Soil. Appl. Environ. Microbiol. 2007, 73, 5817–5824. [Google Scholar] [CrossRef]

- Zhang, K.; Hu, J.; Yang, S.; Xu, W.; Wang, Z.; Zhuang, P.; Grossart, H.-P.; Luo, Z. Biodegradation of polyester polyurethane by the marine fungus Cladosporium halotolerans 6UPA1. J. Hazard. Mater. 2022, 437, 129406. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, I.N.; Maraqa, A.; Hameed, K.M.; Saadoun, I.M.; Maswadeh, H.M. Assessment of potential plastic-degrading fungi in Jordanian habitats. Turk. J. Biol. 2011, 35, 551–557. [Google Scholar] [CrossRef]

- Loredo-Treviño, A.; García, G.; Velasco-Téllez, A.; Rodríguez-Herrera, R.; Aguilar, C.N. Polyurethane foam as substrate for fungal strains. Adv. Biosci. Biotechnol. 2011, 2, 52–58. [Google Scholar] [CrossRef]

- Mahajan, N.; Gupta, P. New insights into the microbial degradation of polyurethanes. RSC Adv. 2015, 5, 41839–41854. [Google Scholar] [CrossRef]

- Danso, D.; Chow, J.; Streit, W.R. Plastics: Environmental and Biotechnological Perspectives on Microbial Degradation. Appl. Environ. Microbiol. 2019, 85, e01095-19. [Google Scholar] [CrossRef]

- Sen, S.K.; Raut, S. Microbial degradation of low density polyethylene (LDPE): A review. J. Environ. Chem. Eng. 2015, 3, 462–473. [Google Scholar] [CrossRef]

- Shah, A.; Hasan, F.; Hameed, A.; Akhter, J. Isolation of Fusarium sp. AF4 from sewage sludge, with the ability to adhere the surface of polyethylene. Afr. J. Microbiol. Res. 2009, 3, 658–663. [Google Scholar]

- Krueger, M.C.; Hofmann, U.; Moeder, M.; Schlosser, D. Potential of Wood-Rotting Fungi to Attack Polystyrene Sulfonate and Its Depolymerisation by Gloeophyllum trabeum via Hydroquinone-Driven Fenton Chemistry. PLoS ONE 2015, 10, e0131773. [Google Scholar] [CrossRef] [PubMed]

- Raaman, N.; Rajitha, N.; Jayshree, A.; Jegadeesh, R. Biodegradation of plastic by Aspergillus sp. isolated from polythene polluted sites around Chennai. J. Acad. Indus. Res. 2012, 1, 313–316. [Google Scholar]

- Cooney, J.J.; Proby, C.M. Fatty Acid Composition of Cladosporium resinae Grown on Glucose and on Hydrocarbons. J. Bacteriol. 1971, 108, 777. [Google Scholar] [CrossRef] [PubMed]

- Panagiotidou, E.; Konidaris, C.; Baklavaridis, A.; Zuburtikudis, I.; Achilias, D.; Mitlianga, P. A Simple Route for Purifying Extracellular Poly(3-hydroxybutyrate)-depolymerase from Penicillium pinophilum. Enzym. Res. 2014, 2014, 159809. [Google Scholar] [CrossRef]

- Howard, G.T. Biodegradation of polyurethane: A review. Int. Biodeterior. Biodegrad. 2002, 49, 245–252. [Google Scholar] [CrossRef]

- Mathur, G.; Prasad, R. Degradation of Polyurethane by Aspergillus flavus (ITCC 6051) Isolated from Soil. Appl. Biochem. Biotechnol. 2012, 167, 1595–1602. [Google Scholar] [CrossRef]

- Hadad, D.; Geresh, S.; Sivan, A. Biodegradation of polyethylene by the thermophilic bacterium Brevibacillus borstelensis. J. Appl. Microbiol. 2005, 98, 1093–1096. [Google Scholar] [CrossRef]

- Suzuki, K.; Noguchi, M.T.; Shinozaki, Y.; Koitabashi, M.; Sameshima-Yamashita, Y.; Yoshida, S.; Fujii, T.; Kitamoto, H.K. Purification, characterization, and cloning of the gene for a biodegradable plastic-degrading enzyme from Paraphoma-related fungal strain B47-9. Appl. Microbiol. Biotechnol. 2014, 98, 4457–4465. [Google Scholar] [CrossRef]

- Koitabashi, M.; Sameshima–Yamashita, Y.; Watanabe, T.; Shinozaki, Y.; Kitamoto, H. Phylloplane Fungal Enzyme Accelerate Decomposition of Biodegradable Plastic Film in Agricultural Settings. Jpn. Agric. Res. Quarterly: JARQ 2016, 50, 229–234. [Google Scholar] [CrossRef]

- Sowmya, H.V.; Ramalingappa; Krishnappa, M.; Thippeswamy, B. Degradation of polyethylene by Penicillium simplicissimum isolated from local dumpsite of Shivamogga district. Environ. Dev. Sustain. 2015, 17, 731–745. [Google Scholar] [CrossRef]

- Gupta, S.; Pathak, B. Mycoremediation of polycyclic aromatic hydrocarbons. In Abatement of Environmental Pollutants; Singh, P., Kumar, A., Borthakur, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 127–149. [Google Scholar] [CrossRef]

- Sowmya, H.V.; Ramalingappa; Krishnappa, M.; Thippeswamy, B. Degradation of polyethylene by Trichoderma harzianum—SEM, FTIR, and NMR analyses. Environ. Monit. Assess. 2014, 186, 6577–6586. [Google Scholar] [CrossRef] [PubMed]

- Temporiti, M.E.E.; Nicola, L.; Nielsen, E.; Tosi, S. Fungal Enzymes Involved in Plastics Biodegradation. Microorganisms 2022, 10, 1180. [Google Scholar] [CrossRef]

- Sudhakar, M.; Doble, M.; Murthy, P.S.; Venkatesan, R. Marine microbe-mediated biodegradation of low and high-density polyethylenes. Int. Biodeter. Biodegr. 2008, 61, 203–213. [Google Scholar] [CrossRef]

- Shimao, M. Biodegradation of plastics. Curr. Opin. Biotechnol. 2001, 12, 242–247. [Google Scholar] [CrossRef]

- Ronkvist, A.M.; Xie, W.; Lu, W.; Gross, R.A. Cutinase-Catalyzed Hydrolysis of Poly(ethylene terephthalate). Macromolecules 2009, 42, 5128–5138. [Google Scholar] [CrossRef]

- Maeda, H.; Yamagata, Y.; Abe, K.; Hasegawa, F.; Machida, M.; Ishioka, R.; Gomi, K.; Nakajima, T. Purification and characterization of a biodegradable plastic-degrading enzyme from Aspergillus oryzae. Appl. Microbiol. Biotechnol. 2005, 67, 778–788. [Google Scholar] [CrossRef] [PubMed]

- Tokiwa, Y.; Calabia, B.P.; Ugwu, C.U.; Aiba, S. Biodegradability of Plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef]

- Kim, H.; Kim, T.; Choi, S.; Jeon, H.; Oh, D.X.; Park, J.; Eom, Y.; Hwang, S.Y.; Koo, J.M. Remarkable elasticity and enzymatic degradation of bio-based poly(butylene adipate-co-furanoate): Replacing terephthalate. Green Chem. 2020, 22, 7778–7787. [Google Scholar] [CrossRef]

- Hoshino, A.; Isono, Y. Degradation of aliphatic polyester films by commercially available lipases with special reference to rapid and complete degradation of poly(L-lactide) film by lipase PL derived from Alcaligenes sp. Biodegradation 2002, 13, 141–147. [Google Scholar] [CrossRef]

- Mukherjee, S.; Kundu, P.P. Alkaline fungal degradation of oxidized polyethylene in black liquor: Studies on the effect of lignin peroxidases and manganese peroxidases. J. Appl. Polym. Sci. 2014, 131, 40738. [Google Scholar] [CrossRef]

- Wei, R.; Zimmermann, W. Microbial enzymes for the recycling of recalcitrant petroleum-based plastics: How far are we? Microb. Biotechnol. 2017, 10, 1308–1322. [Google Scholar] [CrossRef] [PubMed]

- Dhanraj, N.D.; Hatha, A.A.M.; Jisha, M.S. Biodegradation of petroleum based and bio-based plastics: Approaches to increase the rate of biodegradation. Arch. Microbiol. 2022, 204, 258. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, I.N.; Maraqa, A.; Hameed, K.M.; Saadoun, I.M.; Maswadeh, H.M.; Nakajima-Kambe, T. Polyester-polyurethane biodegradation by Alternaria solani, isolated from northern Jordan. Adv. Environ. Biol. 2009, 3, 162–170. [Google Scholar]

- Smirnov, V.F.; Glagoleva, A.A.; Mochalova, A.E.; Smirnova, L.A.; Smirnova, O.N.; Anikina, N.A. Effect of factors of the biological and physical nature on biodestruction and physical and chemical properties of compositions based on polyvinylchloride and natural polymers. Plast. Massy 2017, 7–8, 47. (In Russian) [Google Scholar] [CrossRef]

- Kalashnikov, I.N. Biodegradation of Composite Materials Based on Chitosan and Acrylic Polymers Caused by Micromycetes and Climatic Aging Factors. Ph.D. Thesis, Lobachevsky University, Nizhny Novgorod, Russia, 2013; p. 25. (In Russian). [Google Scholar]

- Myasoedova, N.M.; Kolomytseva, M.P.; Chernykh, A.M.; Baskunov, B.R.; Baboshin, M.A.; Kvesitadze, G.I.; Golovleva, L.A. Alternaria alternata F-1120: A new efficient destruction of 2, 4, 6-trinitroluene. Ann. Agrar. Sci. 2012, 10, 25–31. [Google Scholar]

- Antipova, T.V.; Zhelifonova, V.P.; Zaitsev, K.V.; Nedorezova, P.M.; Aladyshev, A.M.; Klyamkina, A.N.; Kostyuk, S.V.; Danilogorskaya, A.A.; Kozlovsky, A.G. Biodegradation of Poly-ε-caprolactones and Poly-l-lactides by Fungi. J. Polym. Environ. 2018, 26, 4350–4359. [Google Scholar] [CrossRef]

- Sakaeva, E.K.; Kulikova, V.Y.; Rudakova, V.L. Biodegradation of polymeric composite materials by microscopic fungi. Theor. Appl. Ecol. 2018, 4, 68–75. [Google Scholar] [CrossRef]

- Stawiński, W.; Wal, K. Microbial Degradation of Polymers. In Recent Advances in Microbial Degradation. Environmental and Microbial Biotechnology; Ahamed, M.I., Prasad, R., Eds.; Springer: Singapore, 2021; pp. 19–46. [Google Scholar] [CrossRef]

- Legonkova, O.A.; Selitskaya, O.V. Microbiological destruction of composite polymeric materials in soils. Eurasian Soil Sci. 2009, 42, 62–68. [Google Scholar] [CrossRef]

- Majid, I.; Thakur, M.; Nanda, V. Biodegradable packaging material. In Encyclopedia of Renewable and Sustainable Materials; Hashmi, S., Choudhury, I.A., Eds.; Elsevier Science Publishing Co. Inc.: Oxford, UK, 2018; Volume 2, p. 688. [Google Scholar]

- Iwata, T. Biodegradable and Bio-Based Polymers: Future Prospects of Eco-Friendly Plastics. Angew. Chem. Int. Ed. 2015, 54, 3210–3215. [Google Scholar] [CrossRef] [PubMed]

- Rogovina, S.Z. Biodegredable polymer composites based on synthetic and natural polymers of various classes. Polym. Sci. Ser. C 2016, 58, 62–73. [Google Scholar] [CrossRef]

- Rogovina, S.Z.; Aleksanyan, K.V.; Novikov, D.D.; Prut, E.V.; Rebrov, A.V. Synthesis and investigation of polyethylene blends with natural polysaccharides and their derivatives. Polym. Sci. Ser. A 2009, 51, 554–562. [Google Scholar] [CrossRef]

- Rogovina, S.Z.; Alexanyan, C.V.; Prut, E.V. Biodegradable blends based on chitin and chitosan: Production, structure, and properties. J. Appl. Polym. Sci. 2011, 121, 1850–1859. [Google Scholar] [CrossRef]

- Rogovina, S.; Aleksanyan, K.; Prut, E.; Gorenberg, A. Biodegradable blends of cellulose with synthetic polymers and some other polysaccharides. Eur. Polym. J. 2013, 49, 194–202. [Google Scholar] [CrossRef]

- Rogovina, S.; Aleksanyan, K.; Vladimirov, L.; Prut, E.; Ivanushkina, N.; Berlin, A. Development of Novel Biodegradable Polysaccharide-Based Composites and Investigation of Their Structure and Properties. J. Polym. Environ. 2018, 26, 1727–1736. [Google Scholar] [CrossRef]

- Rogovina, S.Z.; Aleksanyan, K.V.; Gorenberg, A.Y.; Ivanushkina, N.E.; Prut, E.V.; Berlin, A.A. Investigation of biodegradability of composites based on polyethylene and polysaccharides by some independent methods. Mendeleev Commun. 2018, 28, 105–107. [Google Scholar] [CrossRef]

- Rogovina, S.Z.; Aleksanyan, K.V.; Kosarev, A.A.; Ivanushkina, N.E.; Prut, E.V.; Berlin, A.A. Biodegradable polymer composites based on polylactide and cellulose. Polym. Sci. Ser. B 2016, 58, 38–46. [Google Scholar] [CrossRef]

- Rogovina, S.Z.; Aleksanyan, K.V.; Loginova, A.A.; Ivanushkina, N.E.; Vladimirov, L.V.; Prut, E.V.; Berlin, A.A. Influence of PEG on Mechanical Properties and Biodegradability of Composites Based on PLA and Starch. Starch/Stärke 2018, 70, 1700268. [Google Scholar] [CrossRef]

- Aleksanyan, K.V.; Rogovina, S.Z.; Ivanushkina, N.E. Novel biodegradable low-density polyethylene–poly(lactic acid)–starch ternary blends. Polym. Eng. Sci. 2021, 61, 802–809. [Google Scholar] [CrossRef]

- Aleksanyan, K.V.; Rogovina, S.Z.; Shakhov, A.M.; Ivanushkina, N.E. Effect of biodegradation conditions on morphology of ternary compositions of low density polyethylene with poly(lactic acid) and starch. Mendeleev Commun. 2022, 32, 558–560. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).