Abstract

In the last decade, an enormous amount of attention has been paid to piezoelectric harvesters due to their flexibility in design and the increasing need for small-scale energy generation. As a result, various energy review papers have been presented by many researchers to cover different aspects of piezoelectric-based energy harvesting, including piezo-materials, modeling approaches, and design points for various applications. Most of these papers have tried to shed light on recent progress in related interdisciplinary fields, and to pave the road for future prospects in the development of these technologies. However, there are some missing parts, overlaps, and even some contradictions in these review papers. In the present review of these review articles, recommendations for future research directions suggested by the review papers have been systematically summed up under one umbrella. In the final section, topics for missing review papers, concluding remarks on outlooks and possible research topics, as well as potentially misleading strategies, have been presented. The review papers have been evaluated based on their merits and subcategories and the authors’ choice papers have been presented for each section based on clear classification criteria.

1. Introduction

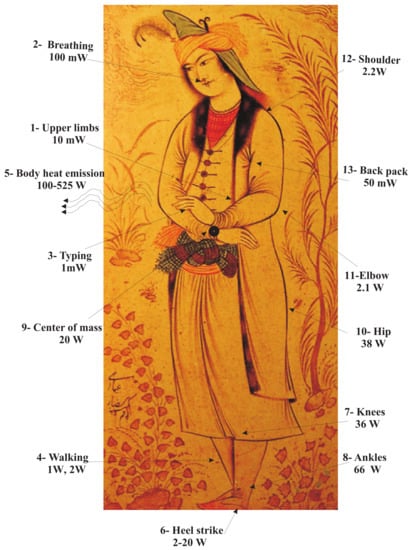

Due to recent developments in portable and wearable electronics, wireless electronic systems, implantable medical devices, energy-autonomous systems, monitoring systems, and MEMS/NEMS-based devices, the procedure of small-scale energy generation may lead to a revolution in the development of compact power technologies.

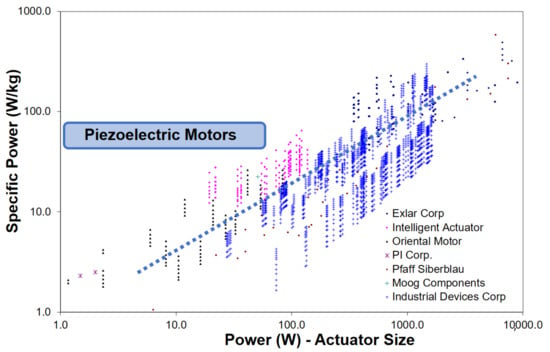

Figure 1 presents the output power density variation versus the actual motor power for 2000 commercial electromagnetic motors. Electromagnetic motors are superior for the production of power levels higher than 100 W. However, because the efficiency drops significantly below 100 W, piezoelectric devices with a power density that is insensitive to their size will replace battery-operated small portable electronic equipment below the 50 W level. It is not logical to compare these energy harvesting systems at the MW power level. Hence, it is necessary for researchers to determine their original piezo-harvesting target, which should basically involve the replacement of compact batteries—one of the main forms of toxic waste—in sustainable society [1].

Figure 1.

Comparison of the specific power with respect to the power [1].

Dutoit et al. [2] provided a comparison based on the density of the output power, and indicated that the power densities of fixed-energy density sources extensively drop after just 1 year of operation. Thus, they require maintenance and repair if possible. Designing an effective power normalization scheme, as well as strain cancelation due to multiple input vibration components; optimizing the minimum vibration level required for positive energy harvesting; and prototype testing to eliminate the proof mass are among the suggestions for future works.

The advantages of piezoelectric energy harnessing include the use of a simple structure without several additional components, the lack of a need for moving parts or mechanical constraints, environmental friendliness and ecological safety, portability, coupled operation with other renewable energies, the lack of a need for an external voltage source, compatibility with MEMS, easy fabrication with microelectronic devices, reasonable output power density, cost effectiveness, and scalability. Hence, piezo-materials are an excellent candidate to replace batteries, which have a short lifespan, for powering macro- to nanoscale electronic devices. Some disadvantages of piezo-harvesters are their high output impedance, producing relatively high output voltages at low electrical current, and rather large mechanical impedance.

The number of review papers on piezoelectric energy harvesting has extensively increased in the past decade. Due to the tremendous number of published review papers in this field, finding an appropriate review paper has become challenging. On the other hand, there are lots of overlaps, similarities, missing parts, and sometimes contradictions between different reviews. Therefore, the main motivation for the present paper was to present a systematic review of the review papers on piezoelectric energy harvesting. We tried to summarize all deficits, advantages, and missing parts of the existing review papers on piezo-energy harvesting systems.

An extensive search among database sources identified 91 review papers in diverse applications related to piezoelectric energy harvesting. As will be demonstrated later, such papers have presented different concluding remarks for the related areas of usage, materials, design approaches, and mathematical models. We tried to perform a very detailed search procedure with several keywords and search engines to cover all published review papers, as well as to find review papers without “piezo” directly mentioned in the title.

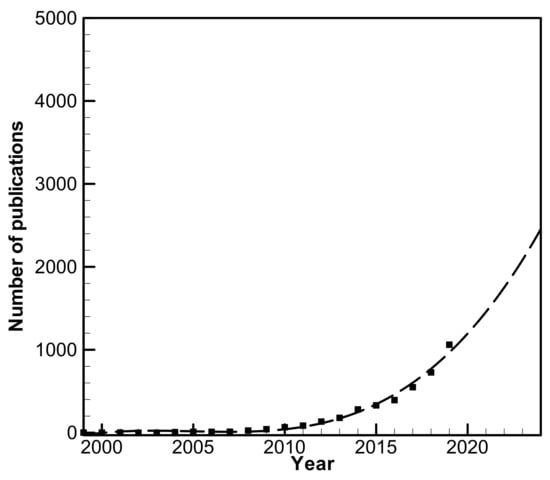

The statistics on publications during the last two decades, excluding conference papers, extracted using the keyword “piezo AND energy harvesting” from SCOPUS are shown in Figure 2. The results from SCOPUS included an overall total of 4435 documents, containing 874 open access papers, 130 book chapters, and 36 books. The national natural science foundation of China, the fundamental research funds for the central universities, and the national research foundation of Korea were the most frequent funding sponsors. The most common subject areas were engineering, material sciences, physics and astronomy, chemistry, and energy. An extrapolation, shown in the figure, anticipates the publication of about 2500 articles per year during the coming three years.

Figure 2.

Statistics and future estimation of publications on piezoelectric energy harvesting.

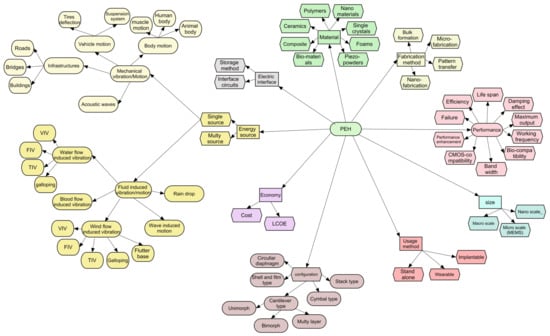

Due to the interdisciplinary nature of piezoelectric energy harvesting, predicting the behavior of piezo-generators is related to different thermo-electro-mechanical sciences, as well as material engineering. We have illustrated a systematic map of various aspects of piezo-energy harvesting in Figure 3. Different branches of connected sciences and applications include fabrication methods, hybrid systems, performance evaluation, size, utilization methods, configurations, modeling aspects, economic points, energy sources, optimization, the design of an electric interface, and the selection of proper materials. All sub-branches in the Figure will be discussed in subsections of the present paper.

Figure 3.

Strategic map of piezoelectric energy harvesting design aspects, modeling approaches, and applications.

A review article is not an omnibus of the paper collection. A review should be written in order to criticize and/or praise each paper. The evaluation of the review papers and their contributions to the field will be presented based on the following criteria:

- Having a solid evaluation philosophy used by the reviewer.

- Presenting non-general future research directions in the summary/conclusion of the paper.

- Paying attention to critical design aspects, such as the electromechanical coupling factor and actual resonance frequency.

- Many papers report on the harvesting energy around the resonance range. Though the typical noise vibration is in a much lower frequency range, researchers measure the amplified resonance response (even at a frequency higher than 1 kHz).

- If the harvested energy is lower than 1 mW, which is lower than the required electric energy to operate a typical energy harvesting electric circuit with a DC/DC converter (typically around 2–3 mW), it is somewhat difficult to describe the system as an energy harvesting device.

- The complete energy flow or exact efficiency from the input mechanical noise energy to the final electrical energy in a rechargeable battery via the piezoelectric transducer is an important part of the review from the applicational/industrial viewpoint.

- The number of sub-fields covered in the review paper.

- The provision of a sufficient theoretical background on piezoelectric energy harvesting, practical material selection, device design optimization, and energy harvesting electric circuits, to help readers avoid “Google syndrome” [3].

- The number of cited articles by each review paper has also been mentioned in a separate column in all tables. Since having a higher number of references is not a critical factor, we did not assign a score to this column. However, it may be helpful for readers to be aware of the number of reviewed papers in each article.

Our scoring strategy was as follows: 1 point for the number of conclusions reported, 1 point for the number of sub-categories covered, 2 points for paying attention to merits, and 1 point for reporting the minimum required energy output level. Details of scores for each part are presented in the tables inside brackets. Reviews with scores (rounded to two decimal places) less than 1.00, from 1.00 to less than 2.00, from 2.00 to less than 3.00, from 3.00 to less than 4.00, and from 4.00 to 5.00 have been labeled with E to A, respectively. It should be noted that the value of the minimum required output should be clearly addressed among the concluding remarks, conclusions, future directions, abstract, or introduction.

The outline of the paper is as follows. In the first section, the focus is on reviews about the design process, structure, material considerations, size effects, and mathematical modeling challenges. In the second part of the article, the main theme is evaluating applications of piezo-harvesters. The most common applications include vibrational energy sources, fluid-based harvesters, scavenging energy from ambient waste energies, and energy harnessing in biological applications. In the last section, a summary of future challenges, research directions, and missing review topics is presented.

2. Reviews with Non-Focused Topics

The papers discussed in this section are general review articles without a specific focal point. Safaei et al. [4] presented a review of energy harvesting using piezoelectric materials for the period from 2008 to 2018. This article is an update of their previous review [5], and covers lead-free piezo-materials, piezoelectric single crystals, high-temperature piezoelectricity, piezoelectric nanocomposites, piezoelectric foams, nonlinear and broadband transducers, and micro-electro-mechanical transducers. They also discussed several types of piezoelectric transducers, the mathematical modeling, energy conditioning circuitry, and applications such as fluid flow energy harvesters, windmill-style harvesters, flutter-style harvesters, /wearable devices, implantable devices, animal-based systems, infrastructure, vehicles, and multifunctional/multi-source energy harvesting systems. Several useful illustrations have been presented in the paper, which sum up different technologies in a unified framework. However, their brief recommendations for future horizons in the field, including the fabrication of piezoelectric nanofibers, piezoelectric thin films, printable piezoelectric materials, exploiting the internal resonance of structures, and the development of metamaterials and metastructures, may be extended to cover other aspects presented in Table 1.

Table 1.

Overall evaluation of review papers written about non-focused topics on piezoelectric energy harvesting. “Cons.” stands for conclusions. Numbers in brackets are scores for each item. Conclusions: 1: efficiency/performance improvement, 2: frequency tuning, 3: safety issues, 4: costs, hybrid harvesters, 5: non-linear models, 6: battery replacement, 7: miniaturization, 8: steady operation, 9: more efficient materials. Merits: 1: electromechanical coupling factor, 2: realistic resonance, 3: energy flow, 4: paying attention to the range of output power. Sub-categories: 1: microscale, 2: electrostatic, 3: magnetic induction, 4: electromagnetic radiation, 5: thermal energy, 6: circuit, 7: wearable device, 8: ambient fluid flow, 9: sensors, 10: material, 11: human-related, 12: vibration, 13: hybrid device, 14: modelling, 15: road and shoe, 16: fluids, 17: animal-related.

Taware and Deshmukh [6] briefly reviewed a number of studies in the field of piezoelectric energy harvesting. They mentioned the advantages and disadvantages of some piezoelectric materials. They examined cantilever-based piezoelectric energy harvesters, their related design points, and mathematical modeling. Anton and Sodano [5] reviewed some general topics published between 2003 to 2006, discussing efficiency improvement, configurations, circuitry and methods of power storage, implantable and wearable power supplies, harvesting from ambient fluid flows, micro-electro-mechanical systems, and self-powered sensors without a clear classification. They reported that future directions included the development of a complete self-powered device that includes a combination of a power harvester, storage, and application circuitry. Furthermore, they declared that the enhancement of energy generation and storage methods, along with decreasing the power requirements of electronic devices, may be a prime target for future studies. Sharma and Baredar [7] analyzed the current methods used to harvest energy from vibrations using a piezoelectric setup in the low-range frequency zone by analyzing piezoelectric material properties based on modeling and experimental investigations. They indicate that the disadvantages of piezo-harvesters are depolarization, sudden breaking of the piezo layer due to high brittleness and a poor coupling coefficient, the poor adhesive properties of PVDF material, and the relatively low electromagnetic coupling coefficient of PZT. They reported that the design of high-efficiency energy harvesters, the invention of new energy harvesting designs by exploring non-linear benefits, and the design of portable compact-size systems with integrated functions are forthcoming challenges.

Mateu and Moll [8] presented an overview of several methods to design an energy harvesting device for microelectronics, depending on the type of available energy. They summarized the power consumption of microelectronic devices and explained the working principals of piezoelectric, electrostatic, magnetic induction, and electromagnetic radiation-based generators. Calio et al. [9] reviewed the material properties of about 19 piezo-materials, the piezo-harvesters’ operating modes, resonant/non-resonant operations, the optimal shape of the beam, the frequency tuning, the rotational device configurations, the power density and bandwidth, and the conditioning circuitry. They tried to present a selection guide between piezoelectric materials based on the power output and the operating modes. They concluded that the resonant cantilever beam needs to be optimized and the harvester is still too complex to be fabricated but has great potential. This paper may be a good suggestion for beginners to start their research in the field of piezoelectric energy harvesting. Sun et al. [10] conducted a review of the applications of piezoelectric harvesters. However, they expressed everything in a nutshell. Such topics require closer considerations. Khaligh et al. [11] addressed piezoelectric and electromagnetic generators suitable for human-powered and vibration-based devices, including resonant, rotational, and hybrid devices. Brief information was been presented about hybrid generators using an imbalanced rotor, which requires more in-depth investigations in future reviews. Batra et al. [12] reviewed mathematical modeling and constitutive equations for piezo-materials, lumped parameter modeling, the mechanisms of piezoelectric energy conversion, and the operating principles of piezoelectric energy harvesters. There was also a very short review paper [13] that focused mainly on some points about the history of the piezoelectric effect, piezo-materials, and applications such as harvesting from footsteps and roads.

Although most of the aforementioned general review papers have more or less similar titles, they differ in terms of their scientific depth and the number of reviewed items. Some papers, such as [9], have focused on design strategies for piezoelectric energy harvesters. They have attempted to present a guide for the selection of piezoelectric materials as harvesters. Moreover, almost all the mentioned reviews suffer from weak classifications, stemming from the generality of their topics.

The results of the evaluation of generally-written review papers on piezoelectric energy harvesting have been presented in Table 1. The table contains different sub-categories, the range of output power, the number of reviewed articles, the merits, general conclusions, and some other information. The grade for each paper was computed based on the number of merits, the number of subcategories, the number of concluding remarks, and declaration of the minimum required output power.

3. Design and Fabrication

The design of piezoelectric energy harvesters is one of the most critical steps in attaining high-performance energy harvesting. We divided this section to three sub-sections, including the materials, structures, and electric interface circuits of PEHs.

3.1. Materials

The choice of a suitable piezoelectric material is a critical step in designing energy harvesters [14]. Thus, many of the review papers in the field of energy harvesters have addressed the topic of piezoelectric materials. Different performance metrics have been selected for comparing piezoelectric materials in diverse applications. In actuating and sensing applications, the piezoelectric strain and piezoelectric voltage constants are appropriate criteria. However, the electromechanical coupling factor, power density, mechanical stiffness, mechanical strength, manufacturability, and quality factor are the most important factors for energy harvesting. Furthermore, the operating temperature is important in material selection [15].

Li et al. [16] divided piezoelectric materials into four categories (ceramics, single crystals, polymers, and composites) based on their structural characteristics. They described the general properties of these four piezo-material categories, and compared some of the most important candidate materials from these categories in terms of the piezoelectric strain constant, piezoelectric voltage constant g, electromechanical coupling factor k, mechanical quality factor Q, and the dielectric constant e. They commented that piezoelectric ceramics and single crystals have much better piezoelectric properties than piezoelectric polymers, which is due to strong polarizations in their crystalline structures. On the other hand, piezoelectric ceramics and single crystals are more rigid and brittle then piezoelectric polymers. Both piezoelectric properties and mechanical properties are important in the selection of a certain piezoelectric material for a specific piezoelectric harvesting application. Other important parameters in selecting suitable materials are the application frequency, the available volume, and the form in which mechanical energy is fed into the system. In order to harvest the maximum amount of energy, the piezoelectric energy harvester should operate at its resonance frequency. However, in many cases, such as low-frequency applications, it is impractical to match the resonance frequency of the piezoelectric with the input frequency of the host structure. They demonstrated that for low-frequency applications in off-resonance conditions the piezoelectric element can be approximated as a parallel plate capacitor and for harvesting more electric energy the product of the piezoelectric strain constant and the piezoelectric voltage constant should be high. On the other hand, for near-resonance conditions, the optimum output power of the harvester is independent of piezoelectric properties of the piezo-element but the maximum output voltage depends on the piezoelectric strain constant. It is obvious that the selection of a suitable piezomaterial for a piezo-harvester depends on working conditions, and it makes the selection of piezo-material more complex. The energy density of piezoelectric materials was not reported. The focus was on macroscale piezomaterials and micro- and nono-scale materials were not covered.

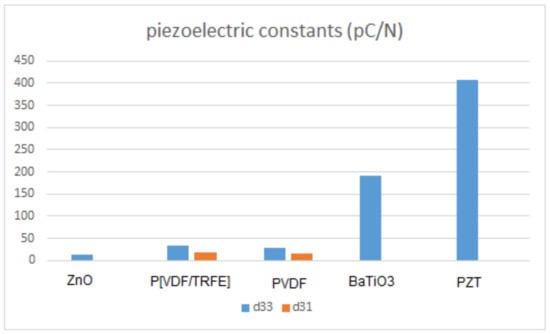

Narita and Fox [17] reviewed three categories including piezoelectric ceramics/ polymers, magnetostrictive alloys, and magnetoelectric multiferroic composites. Their review included a description of the properties of PZT, PVDF, and ZnO. They compared some of the piezoelectric materials based on their piezoelectric coefficients (Figure 4). They also remarked on some advantages and disadvantages of traditional piezoelectric ceramics, piezoelectric polymers, and composites. They focused on the characterization, fabrication, modeling, simulation, durability and reliability of piezo-devices. Based on their analysis, future directions include device size reduction, to make devices suitable for nanotechnology, as well as the optimization, and development of accurate multi-scale computational methods to link atomic, domain, grain, and macroscale behaviors. The investigation of temperature-dependent properties, the development of materials and structures capable of withstanding prolonged cyclic loading, studies of the duration of electro-magneto-mechanical properties, and fracture/fatigue studies are other recommendations for future research. The review did not report on some important mechanical and piezoelectric properties of the piezo-materials, such as the electromechanical coupling factor, the quality factor, and the mechanical strength and mechanical stiffness, and the materials were compared based on their piezoelectric coefficients and the output power of the energy harvesters.

Figure 4.

Piezoelectric coefficient range for some piezoelectric materials [17].

Safaei et al. [4] reviewed the recent progress in the field of piezoelectric ceramics, such as soft and hard PZTs, piezoelectric polymers including PVDF, piezoelectric single crystals, lead-free piezoelectrics, high temperature piezoelectrics, piezoelectric nanocomposites, and piezoelectric foams. They reported on the piezoelectric coefficient and the maximum output voltage for some of these materials without describing the geometry of the piezoelectric harvester. The brittleness of PZTs and the existence of health risks in PZT ceramics due to the toxicity of lead are the most important challenges of using PZTs, which motivates the development of lead-free flexible and high-performance piezoelectric materials. They concluded that the need for the enhancement of electromechanical, thermal, and biocompatible properties has led to the introduction of new piezoelectric materials, including new lead-free piezoelectrics, high-temperature piezoelectrics, piezoelectric foams, and piezoelectric nanocomposites. The paper explained many piezo-materials; however, it did not offer a systematic comparison between the piezoelectric materials in terms of their piezoelectric and mechanical properties. It seems that its main target was only to report the recent progresses in the field. Furthermore, the minimum required output power for the piezoelectric harvesters was not remarked upon.

Zaarour et al. [18] summarized the energy harvesting technologies developed based on piezoelectric polymeric fibers, inorganic piezoelectric fibers, and inorganic nanowire. The paper contains a review of piezoelectric fibers and nanowires with respect to the peak voltage, the peak current, the active area, and their advantages, without describing the working conditions and mechanical structure of the related piezoelectric energy harvester. Perhaps due to the lack of available data on properties of nano-scale piezoelectric materials, the paper does not present a comparison between the selected materials in terms of their piezoelectric and mechanical properties. The reported output powers are in the range of microwatts, which is not enough for the powering of real electronic systems and circuits. They concluded that standardizing the performance of the piezo-nanogenerator, developing effective packaging technology, the packaging of nano-piezo-harvesters, commercializing products for harsh environments, finding a suitable approach to enhance the electrical outputs, and augmenting the durability and the output stability are some future horizons.

Yuan et al. [19] introduced dielectric electroactive polymers as promising replacements for conventional piezoelectric materials. Electroactive polymers are lightweight, flexible, ductile, and manufactured at low cost, with high strength-to-weight ratio, low mechanical impedance, and the ability to endure large strains. Dielectric polymers require high voltage to realize energy cycles, which may lead to the breakdown of the device. Piezoelectric materials are employed in energy harvesters because of their compact configuration and compatibility. However, these materials have inherent limitations, including aging, depolarization, and brittleness. In comparison, electrostrictive polymers are promising candidates to replace piezoelectric materials in vibration energy harvesting cases. The challenge in the design of electroactive polymer energy harvesters is to develop systems that are capable of ensuring a constant initial voltage on the polymer at a small cost.

There are some other review papers which have focused on several issues in the field of piezoelectric materials. Piezoelectric polymers were reviewed in papers such as a review by Mishara et al. [20]. High-temperature single crystals are the subject of Priya’s paper, which presented a comparative study of the main high-temperature piezoelectric single crystals. Bio-piezoelectric materials were described by Liu et al. [21]. They have also reviewed micro- and nano-fabrication techniques for micro-/nanoscale energy harvesters. Useful information on micro-/nanoscale piezoelectric materials may be found in the work of Gosavi et al. [14]. They defined a systematic roadmap to select piezoelectric materials for micro and nanoscale energy harvesters. They pointed out that ZnO thin film is the most widely-used structure in micro- and nanoscale harvesters, and can be economically synthesized in arbitrary sizes and shapes. A detailed comparison between traditional macro materials and new micro/nano piezoelectric materials in terms of dielectric, mechanical and piezoelectric properties was performed by Bowen et al. [22]. They mentioned some points about high-temperature harvesting, related to the Curie temperature, light harvesting into chemical or electrical energy, and optimization algorithms. Their investigation contains parameters such as the pyroelectric coefficient (harvesting from temperature fluctuations), the electro-mechanical coupling factor, the mechanical quality factor, the constant-strain relative permittivity, the constant-stress relative permittivity, the piezoelectric coefficient, and the elastic constant of piezoelectric materials. For high-strain applications, they suggested polymeric or composite-based systems. Their suggested future directions are the understandingand development of new materials and the gaining of a strong scientific underpinning for the technology, as well as reliable measurements.

Most review papers have tried to compare piezoelectric materials and draw a roadmap for the selection of an appropriate material for energy harvesters. However, the choice of material is strictly dependent on type of the energy harvester; its working conditions; and the cost, accessibility, and ease of fabrication/synthesis of the piezoelectric material. For example, Ullah Khan and Ahmad [23], who have reviewed vibrational energy harvesters utilizing bridge oscillations, pointed out that the main selection criteria for piezoelectric vibrational energy harvesting are the dielectric constant, the Curie temperature, and the modulus of elasticity of the material.

Piezoelectric materials with a high elastic modulus can be an appropriate choice for high acceleration vibrations. However, piezoelectric materials such as lead lanthanum zirconate titanate, which has a high dielectric constant, perform very well in low-acceleration vibrational environments. Furthermore, due to the ease of the in situ fabrication of lead zirconate titanate (PZT) with the sol-gel technique, and its easy integration with other microfabrication processes, PZT has been largely utilized in most of these applications.

As another example, we can point out the selection of a desirable piezoelectric material for walking-energy-harvesting applications. Based on a review performed by Maghsoudi Nia et al. [24], this application required an incombustible, chemically resistant, low-price material, which should be unbreakable under harsh conditions. The mentioned criteria have made PVDF more suitable than PZT for the most piezoelectric devices harnessing energy from walking. Most of the review papers have contented themselves with reporting some of the electromechanical properties of piezoelectric materials, and providing scant information on the accessibility, relative cost, chemical properties, ease of fabrication, and suitable working conditions of different piezoelectrics. The lack of such information indicates the need for further research and also the necessity of more comprehensive and application-based reviews on piezoelectric materials.

The results of the evaluation of review papers on piezoelectric materials have been presented in Table 2. The table also contains different sub-categories, the range of output power, the number of reviewed articles, the merits, general conclusions, and some other descriptions. The rank of each paper was computed based on the number of merits, the number of subcategories, the number of concluding remarks, and a clear emphasis on the value of the minimum required output power.

Table 2.

Overall evaluation of review papers written on materials in piezoelectric energy harvesting. The numbers in brackets denote non-general future lines. “Cons.” stands for conclusions. Conclusions: 1: comparison of piezoelectric materials in terms of their important properties, 2: cost of piezoelectric materials, 3: selection strategies for piezoelectric materials, 4: increasing lifetime, endurance, size reduction, energy density, biocompatibility and manufacturability, 5: disadvantages and advantages of different types of piezo-materials, 6: the need for accurate modelling of piezoelectric materials; Merits: 1: piezoelectric coefficients, 2: coupling factors, 3: manufacturability, 4: mechanical strength, 5: guidelines for material selection, 6: paying attention to the range of output power or energy density, 7: stiffness, 8: quality factor; Sub-categories: 1: piezoelectric micro/macro fibers, 2: polymer nanofibers, 3: ceramic nanofibers, 4: piezoelectric nanowires, 5: micro-/nanofibers/wires composites, 6: piezoelectric polymers (PVDF, Pu, P(VDF-TrFE), cellular PP), 7: piezoelectric ceramics (PZT, PMM-PT, PMN-PZT …), 8: piezoelectric single crystals (Quartz …), 9: piezoelectric foams (PDMS piezoelectric, PET/EVA/PET piezoelectret, FEP piezoelectric), 10: piezoelectric powders, 11: piezoelectric composites (PVDF with nanofillers, non-piezoelectric polymer with BaTiO3), 12: bio materials.

As indicated in Table 1, with the exception of a few papers such as [16], other reviews suffer from a lack of reported data on mechanical piezoelectric materials, their fabrication methods, and other figures of merit in the selection of materials. Furthermore, with the exception of a few papers, such as [17], which has pointed out the energy required for powering the electronic devices, other papers have neglected to report the minimum required energy for an energy harvester.

3.2. Structure

All piezoelectric energy harvesters include a mechanical part (or transduction part) to convert the input mechanical energy into the electric charges in the piezoelectric element, and an electric part that maintains the electric charges and converts them into a suitable form of electric output, such as direct voltage. The design of the mechanical part of a piezoelectric energy harvester usually includes the determination of its size, configuration, working modes, and the selection of appropriate materials to enhance its performance characteristics, such as the output electric energy, the conversion efficiency and the working bandwidth. The size of the piezoelectric energy harvester may vary from the micro- and nanoscale (lower than 0.01 cm ) to the macroscale (75 cm) [2].

Based on the literature, piezoelectric energy harvesters can be classified according to various viewpoints. From the viewpoint of operating frequency, they may be categorized into two main sections: resonant-type devices that operate at or near their resonance frequency, and non-resonant systems that do not depend on any specific frequency. Piezoelectric energy harvesters may harvest energy from motions in a unique direction or from multiple directions. Accordingly, they may be single-directional or multi-directional harvesters. Furthermore, they can have a single or several vibration modes (multi-modal harvesters). From the viewpoint of governing dynamic models, piezoelectric harvesters may be linear or non-linear [27]. As indicated in Figure 3, their configuration can be classified as cantilever-type, stack-type, cymbal-type, circular-diaphragm-type, or the shell- and film-types.

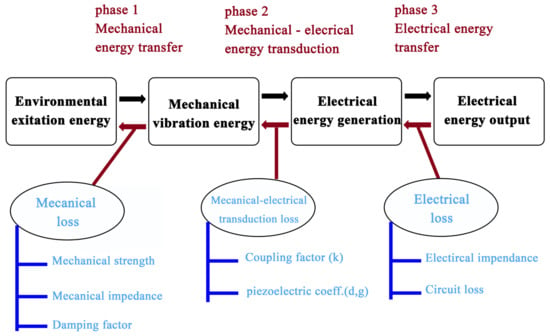

Uchino [28] started his review by mentioning the historical background of piezoelectric energy harvesting, and explaining several important misconceptions. He reviewed the different design approaches followed by mechanical, electrical, and MEMS engineers. He remarked that there are three major phases associated with piezoelectric energy harvesting: (i) mechanical–mechanical energy transfer, (ii) mechanical–electrical energy transduction, and (iii) electrical–electrical energy transfer, to accumulate the energy into a rechargeable battery. Figure 5 represents these three major phases. In order to provide comprehensive strategies on how to improve the efficiency of the harvesting system, step-by-step detailed energy flow analysis is essential. It was mentioned that the five important figures of merit in piezoelectrics are the piezoelectric strain constant d, the piezoelectric voltage constant g, the electromechanical coupling factor k, the mechanical quality factor , and the acoustic impedance Z. Furthermore, the energy transfer rates for piezoelectric energy harvesting systems with typical stiff cymbals and flexible piezoelectric transducers were evaluated for the three aforementioned phases/steps. Moreover, a hybrid energy harvesting device that operates under either magnetic and/or mechanical noises was introduced. It was concluded that remote signal transmission, energy accumulation in rechargeable batteries, discovering an ingenious idea for combining nano-devices in parallel, and enhancing energy density in medical applications represent important future research fields. It was declared that a clear future perspective for NEMS and MEMS piezoelectric harvesters is missing due to their low energy levels (on the order of pW to nW). We need to develop ingenious ideas concerning how to combine thousands of nanodevices in parallel and synchronously in phase. A description of the performance improvement techniques for non-resonant and resonant energy harvesters is missing in this article.

Figure 5.

Three major phases associated with piezoelectric energy harvesting [28].

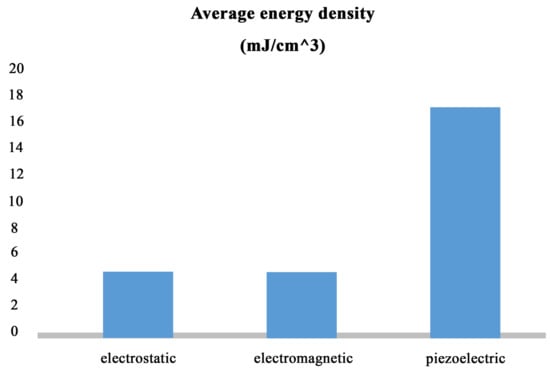

Priya [29] classified the energy harvesting approaches into two categories: (1) power harvesting for sensor networks using the MEMS/thin/thick-film approach, and (2) power harvesting for electronic devices using the bulk approach. His review article covered the latter category in more detail. He listed almost all the energy sources available in one’s surroundings which may be used for energy harvesting and commented that the selection of the energy harvester—as compared to other alternatives, such as batteries—depends on two main factors: cost effectiveness and reliability. Furthermore, he reported on the daily average power consumption for a wearable device, and of common household devices. Next, comparisons of the energy density for the three types of mechanical-to-electrical energy converters, including electrostatic, electromagnetic, and piezoelectric devices, were performed. The results are represented in Figure 6. He concluded that piezoelectric converters are a prominent choice for mechanical-to-electric energy conversion because the energy density is three times higher as compared to electrostatic and electromagnetic devices. He provided a review of piezo-harvesters appropriate for light-weight flexible systems with easy mounting, a large response, and low-frequency operation, called the low-profile piezo-transducer in on/off-resonance conditions. A good discussion of piezoelectric polymers, energy storage circuits, and microscale piezo-harvesting devices is available in the article. Priya mentioned that the electrical power generated by a piezoelectric energy harvester is inversely proportional to the damping ratio, which should be minimized through proper selection of the material and design. He also summarized the conditions leading to the appearance of maximum efficiency in low-profile piezoelectric energy harvesters. An interesting part of this paper is the description of the piezoelectric material selection procedure for on/off-resonance conditions. However, a description of performance improvement techniques for enhancing the system frequency response is missing from this article.

Figure 6.

Comparison of the energy density for the three types of mechanical-to-electrical energy converters [29].

Yang et al. [30] commented that from the perspective of applications, the output power of the harvester and its operational frequency bandwidth are the two metrics that are the most useful for product development engineers. They explained the material selection procedure for piezoelectric energy harvesters in off-resonant conditions and remarked as to why PZTs are still the most popular piezoelectric materials for energy harvesters. They stated that linear resonant harvesters are not suitable for the harvesting of energy from broadband or frequency-varying excitations, and in these conditions nonlinear energy harvesters have been proven to be able to exhibit a broadband performance. Therefore, researchers have explored monostable, bistable, and tristable systems and developed some frequency tuning approaches, such as multi-cantilever structures, bistable composite plate designs, and passive and active stiffness-tuning technologies. They commented, in regard to nonlinear energy harvesters, that keeping nonlinear harvesters in high-energy oscillation states, especially under weak excitations, is a difficult task. Especially in cases with zero initial conditions, nonlinear harvesters usually follow low-energy orbits, which results in small-amplitude voltage responses. Thus, maintaining the nonlinear PHE in high-energy states is a critical problem which can possibly arisewith active and passive control. Efficiently transferring and storing the generated broadband or random electric energy is another critical problem for nonlinear PHEs. Moreover, the authors reviewed different designs strategies, optimization techniques, and the harvesting of piezo-materials in applications such as shoes, pacemakers, tire pressure monitoring systems, and bridge and building monitoring systems. They declared that high energy conversion efficiency, ease of implementation, and miniaturization are the main advantages of such systems. However, the authors stated that the enhancement of the energy efficiency of piezo-based harvesters is still an open challenge. They also conducted a systematic performance comparison of some of these energy harvesters. They pointed out that a considerable gap exists between the achieved performance and the expected performance. Therefore, in situ testing, applying more realistic excitations and system-level investigations on piezo-harvesters integrated with power conditioning circuits, energy storage elements, sensors, and control circuits need to be investigated. This article focused on the mechanical part of energy harvesters and subjects such as the electric interface circuits of the harvesters and their energy flow analysis were not remarked upon.

There are some other review papers which have focused on several issues in the design of piezoelectric harvesters. Performance improvement techniques for PHEs and design optimization methods are hot topics covered by several reviews [16,27,31]. Manual and autonomous tuning systems aiming to widen the operating frequency bandwidth, as well as future plans in this field, were discussed by Ibrahim and Vahied [32]. A good review of PEH configurations, such as cantilever beam, discs, cymbals, diaphragms, circular diaphragms, shell-type designs, and ribbon geometries, may be found in [16]. Talib et al. [33] explained effective strategies and key factors in enhancing the performance of piezoelectric energy harvesters operating at low frequencies, including the selection of the piezoelectric material; the optimization of the shape, size, and structure; and the development of multi-modal, nonlinear, multi-directional, and hybrid energy harvesting systems. This review paper is suitable for beginners who want to get acquainted with piezoelectric materials and some designs of piezoelectric energy harvesters. They concluded that recent developments have been inclined towards the generation of more power from low-frequency and low-amplitude ambient vibrations with a reduced amount piezoelectric material required. Adding a single DOF system in the form of an extension beam or a spring to the piezoelectric beam is a remarkable piece of advice in relation to enhancing the power output. The authors showed that the multi-modal energy harvester exhibits a broader bandwidth as its multiple resonance peaks get closer.

3.3. Electric Interface Circuits

Brenes et al. [34] provided an overview of existing energy harvesting circuits and techniques for piezoelectric energy scavenging to distinguish between similar existing solutions that are different in practice. Such a categorization is helpful in order to ponder the advantages and drawbacks of each available item. Their review is unique since they classified the piezo-systems based on adaptive/non-adaptive control strategies, topologies, architectures, techniques on the one hand, and electromechanical models on the other hand. The best system was introduced with respect to the optimized power efficiency, the design complexity, the strength of coupling, the multi-stage load adaption, and the vibration frequency.

Issues such as the AC-DC conversion mechanism, the passive and active rectifications, start-up issues, harvester-specific interactions, voltage conditioning, DC-DC charge pumps, power regulation, and impedance matching were discussed by Szarka et al. [35] and Dell’Anna et al. [36]. Non-linear electronic interfaces for energy harvesting from mechanical vibrations were discussed in [37].

Table 3 and Table 4 gather together the results of evaluation of the review papers written on design methods and the power interface considerations, respectively. The table also contains different sub-categories, the range of output power, the number of reviewed articles, the merits, general conclusions, and some other descriptions. The ranking of each paper was computed based on the number of merits, the number of subcategories, the number of concluding remarks, and with a clear emphasis on value of the minimum required output power.

Table 3.

Overall evaluation of review papers on the design of piezoelectric energy harvesters. The numbers in brackets denote the number of non-general future lines. “Cons.” stands for conclusions. Conclusions: 1: Efficiency/performance improvement and optimization of PHEs; 2: widening the frequency bandwidth and frequency tuning of PHEs; 3: increasing life time and endurance of PHEs and their size reduction, packaging and manufacturability; 4: importance of electric interface circuits and storage circuits; 5: material selection strategy and material properties improvement: 6: necessity of standardizing the characterization methods of PHEs. Merits: 1: reporting the output power of PHEs, 2: coupling factors and operational mode, 3: including mathematical models, 4: matching the resonance frequency of PHEs with motivating frequencies, 5: paying attention to the energy conversion efficiencies. Sub-categories: mentioned in the text.

Table 4.

Overall evaluation of review papers written on power interfaces in piezoelectric energy harvesters. The numbers in brackets denote the number of non-general future lines. “Cons.” stands for conclusions. Conclusions: 1: Efficiency/performance improvement strategies, 2: challenges and future perspectives, 3: comparision of electric interface circuits, 4: electric impedance matching, 5: implementation easiness and load independency of interface circuits. Merits: 1: Energy flow analysis of PHEs, 2: practical implementation of electronic interfaces, 3: including mathematical models, 4: paying attention to electrical impedance matching, 5: paying attention to the energy consumption of electric interfaces, 6: analysis of energy conversion efficiency. Sub-categories: mentioned in the text.

The results of the evaluation of review papers on the design of piezoelectric energy harvesting have been presented in Table 3. The table also contains different sub-categories, the range of output power, the number of reviewed articles, the merits, general conclusions, and some other descriptions. The grade for each paper was computed based on the number of merits, the number of subcategories, the number of concluding remarks, and the declaration of the minimum required output power. Table 3 is designed to evaluate the review papers on the design of PHEs. The merits that were selected as the necessary considerations in the field of design of PHEs were—1: reporting the output power of PHEs, 2: reporting the coupling factors and operational modes, 3: including mathematical models, 4: attending to the motivating frequencies of PHEs, 5: attending to the mechanical and electrical energy conversion efficiencies. The quantitative evaluation of the papers was performed based on the number of merits which were followed by the article, number of sub-categories which were covered in the review and the number of conclusions. According to the table, with the exception of the first papers, the other papers neglected some merits such as the minimum required output power for the harvesters and energy flow analysis. Furthermore, most of the papers did not review some of the issues in the field. The examined subcategories in the field of design are—1: manual frequency tuning, 2: autonomous frequency tuning, 3: multi-frequency systems, 4: nonlinear systems, 5: frequency up-conversion approach, 6: systems with free moving mass, 7: bidirectional and three-directional systems, 8: amplification techniques, 9: piezoelectric materials and their selection criteria, 10: energy conversion efficiency, 11: low-profile piezoelectric harvesters, 12: geometric optimization, 13: mathematical modeling of PHEs, 14: design improvements for piezoelectric cantilevers, 15: piezoelectric cymbal, 16: piezoelectric stack configuration, 17: electrode optimization, 18: performance quantification and comparison strategies, 19: electronic interface and power storage circuits for PHEs, 20: hybrid energy harvesting mechanism.

The following sub-classes have been presented regarding power interface points 1: three phases in energy harvesting process, 2: mechanical-electrical energy transduction, 3: energy flow analysis, 4: electrical-to-electrical energy transfer, 5: electric impedance matching, 6: electromechanical models of PHEs, 7: requirements for power electronics, 8: stage topologies (1-, 2-, 3-, and 4-stage topologies), 9: nonadaptive control strategies, 10: adaptive control strategies, 11: optimized synchronized electric charge extraction (OSECE) architecture (including classical OSECE and SECPE), 12: synchronized electric charge extraction (SECE) architectures (including PSSECE, tunable SECE, N-SECE, tunable unipolar SECE, and FTSECE) 13: load adaptation architectures (including full bridge (FB), half bridge, and shunt techniques), 14: hybrid SECE (including SICE and SCSECE), 15: synchronized switch harvesting (SSH) architectures (including ESSH, DSSH, P-SSHI, SSHC, and tunable SSHI techniques). 16: performance comparison of harvesting circuits, 17: choice of an adequate circuit, 18: AC-DC conversion and rectification (including conversion with voltage conditioning, passive and active VM, direct AC–DC switch-mode converters, piezo-specific switched-inductor converters), 19: DC–DC conversion and rectification (including DC–DC charge pumps, DC–DC switch-mode converters) 20: startup issues, 21: power regulation techniques (including optimum resistance and complex impedance matching), 22: rectifiers for resonant PEHs.

3.4. MEMS/NEMS-Based Devices

A large number of reviews on piezo-harvesters have been devoted to the field of MEMS/NEMS piezoelectric harvesters. Micro- and nanoscale energy harvesters may be useful in the future for the easy powering or charging of mobile electronics, even in remote areas, without the need for large power storage elements. MEMS-type devices include cantilever, cymbal, and stack designs, whereas NEMS-type devices include wires, rods, fibers, belts, and tubes. The generation of output electric current using piezoelectric energy harvesters faces many limitations and difficulties. Some of these limitations are low output power, high electric impedance, crack propagation in most piezoelectric materials due to overloading, frequency matching of the harvester with vibrational energy sources, and the fabrication/integration of piezoelectrics at the micro-/nanoscale [38].

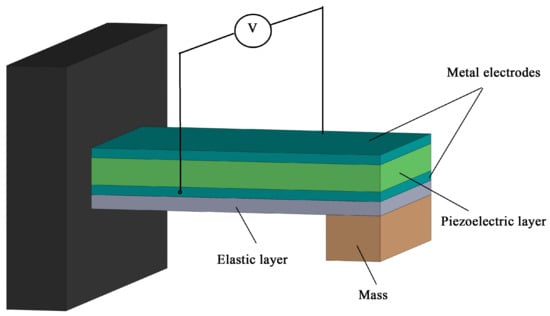

Kim et al. [39] commented that for the elimination of chemical batteries and complex wiring in microsystems, a fully assembled energy harvester the size of a US quarter dollar coin should be able to generate about 100 microW of continuous power from ambient vibrations. In addition, the cost of the device should be sufficiently low. Their article addresses two important questions: “how can one achieve self-powering when the power required is much larger than what can be achieved by MEMS-scale piezoelectric harvesters?” and “what is the best mechanism for converting mechanical energy into electrical energy at 3-mm dimensions?”. Furthermore, they noted that in order to harvest power robustly, the resonance bandwidth of piezoelectric cantilevers should be wide enough to accommodate the uncertain variance of ambient vibrations. Thus, the resonance bandwidth is a significant characteristic in order to trap enough energy in the harvester and should be accounted for in determining the performance of energy harvesters. MEMS technology is a cost-effective fabrication technology for PHEs if it can meet certain requirements for power density and bandwidth. Three major aspects required to make MEMS PEHs appropriate for use in real applications are the final cost of the PEH, the normalized power density, and the operational frequency range (including the bandwidth and center frequency). They added that piezoelectric MEMS energy harvesters most commonly have a unimorph cantilever configuration (Figure 7). The proof mass (M), shown in Figure 7, is used to adjust the resonant frequency to the available environmental frequency, which is normally below 100 Hz. Recently, integrated MEMS energy harvesters have been developed. When comparing MEMS PEHs, some essential merits such as the active area of the PEH, the active volume, resonant frequency, harvested power, and power densities in volume or area should be considered. They reviewed the challenges of piezo-harvesters, including the need for a high power density and wide bandwidth of operation in piezoelectric systems, as well as non-linear resonating beams for wide bandwidth resonance, and improvements in materials and structural design. They observed that the epitaxial growth and grain texturing of piezo-materials, embedded medical systems, lead-free piezoelectric MEMS-based materials, and materials with giant piezoelectric coefficient are active research fields. They presented an extensive comparison of thin-film piezo-systems from various sources and concluded that the state of the art of power density is still about one order smaller than what is needed for practical applications.

Figure 7.

Unimorph structure of a piezoelectric energy harvester that has one piezo-layer and a proof mass [39].

Toprak and Tigli [40] conducted a review on piezoelectric harvesters based on their size (nanoscale, microscale, mesoscale, and macroscale). They also presented interesting statistics showing that the number of publications between 2009 and 2014 on piezoelectric harvesting is more than twice the total number of publications about electromagnetic and electrostatic systems. They commented that the inherent reciprocal conversion capability is an important advantage of the piezoelectric energy harvesters, allowing them to have simpler architectures in comparison to their electromagnetic and electrostatic counterparts. They declared that bio-compatibility, the reconciliation with the CMOS technology, rectification and storage losses, and enhancing the operation bandwidth are the most challenging issues in regard to such systems. A discussion on the validity of the classical constitutive relations for piezo-materials at the nanoscale and a mention of the minimum required power output of PEHs are missing from this paper.

Todaro et al. [41] reviewed the current status of MEMS-based energy harvesters using piezoelectric thin films, and highlighted related approaches and strategies. They commented that such harvesters are compact and cost-effective, especially for harvesting energy from environmental vibrations. They remarked that two main challenges in this topic to achieve high-performance devices involve increasing the amount of generated power and the frequency bandwidth. They also introduced the theoretical principles and the main figures of merit for energy conversion in piezoelectric thin films. They compared most important thin-film piezo-materials based on the introduced figures of merit. Their recommendations for future research include the development of proper materials, new device architectures, and strategies involving bimorph and multimorph designs; exploiting them for their bandwidth and power density improvements; ensuring progress in synthesis and growth technologies for lead-free high quality piezoelectrics; the employment of new flexible materials with tailored mechanical properties for larger displacement and lower frequencies; and taking advantage of non-linear effects to obtain a wider bandwidth and a higher efficiency. Specification of the minimum required output power and attention to mechanical and electrical energy conversion efficiencies were missing from this review paper.

Dutoit et al. focused on design considerations for piezoelectric-based energy harvesters for MEMS-scale sensors. They stated that a power consumption of tens to hundreds of microW is predicted for sensor nodes and nowadays the milli-scale commercial node has an average power consumption of 6–300 microW [2]. With the reduction of power requirements for sensor nodes, the application of piezoelectric energy harvesters has become viable. They stated that power or energy sources can be divided into two groups: sources with a fixed energy density (e.g., batteries) and sources with a fixed power density (normally ambient energy harvesters). They suggested that the following information be made available in research papers to facilitate a relative comparison of PEH devices: device size, the maximum tip displacement at the maximum power output, the mechanical damping ratio, the electrical load, the device mass, and the input vibration characteristics. Furthermore, in this paper a fully coupled electromechanical model was developed to analyze the response of a piezoelectric energy harvester and the difference in optimization strategies of PEHs in on-resonant and off-resonant conditions were remarked upon.

Other review papers on MEMS PEHs have focused on several issues—ZnO nonorods and flexible substrates and ZnO-based nano-devices [42]; the comparison of existing piezoelectric micro generators (including impact-coupled, resonant and human-powered devices, and the cantilever-based setup) with electromagnetic and electrostatic mechanisms [43]; the description of micro- and nanodevice fabrication techniques, performance metrics, and device characterization [14]; hybrid electromagnetic-piezoelectric and triboelectric/piezoelectric MEMS-based harvesters and their privileges [44]; ZnO nanostructure-based photovoltaics; piezoelectric nano-generators, and the hybrid approach to the harvesting of energy [45]; the benefits, capacities, applications, challenges, and constraints of micro-power harvesting methods using thermoelectric, thermophotovoltaic, piezoelectric, and microbial fuel cells [38]; the use of nanostructured polymer-based piezoelectric and triboelectric materials as flexible, lightweight, easy/cheap-to-fabricate, lead-free, biocompatible, and robust harvesters [46]; theoretical and experimental characterization methods for predicting and determining the potential output of nano wire-based nanogenerators [47]; reviewing the research progress in the field of piezoelectric nanogenerators and describing their working mechanisms, modeling, and structural design [48]; and, finally, discussing the impact of composition, orientation, and microstructures on piezoelectric properties of perovskite thin films such as PbZr1-xTixO3 (PZT) in applications such as low-voltage radio frequency MEMS switches and resonators, actuators for millimeter-scale robotics, droplet ejectors, energy harvesters for unattended sensors, and medical imaging transducers [49].

Table 5 presents details of our evaluation of reviews on micro-/nanoscale energy harvesting. In summary, almost all review articles discussed some great challenges in the development of MEMS-/NEMS-based piezoelectric harvesters, such as the limited bandwidth and low output power. On the other hand, there are some competitive technologies such as electromagnetic, thermoelectric, and electrostatic energy harvesting that can be employed for scavenging environmental waste energy. Most of the comparative review papers have focused on the output power and coupling coefficient of the harvesting systems, and other important features such as the lifetime, capability of working in harsh environmental conditions, the cost level, commercial accessibility, and the technology readiness level (TRL) require more deep considerations.

Table 5.

Overall evaluation of review papers written on MEMS piezoelectric energy harvesters. The numbers in brackets denote the number of non-general future lines. “Cons.” stands for conclusions. Conclusions: 1: Suitable materials for MEMS/NEMS piezo harvesters; 2: synthesis and fabrication of MEMS/NEMS materials and structures; 3: hybrid materials and structures; 4: efficiency and performance of MEMS/NEMS harvesters and their improvement; 5: necessity of frequency bandwidth broadening and optimizations; 6: increasing life time, endurance, stability, and embedding abilities; 7: cost reduction, manufacturability and CMOS compatibility; 8: improvement of material properties and development of new architectures; 9: electronic interface circuits; 10: characterization of MEMS/NEMS devices and size effect. Merits: 1: Reports the output power or power density of MEMS/NEMS PHEs; 2: coupling factors and operational modes; 3: describes the fabrication techniques; 4: matching of the resonance frequency of PHEs with motivating frequencies, 5: pays attention to the minimum required output power, 6: CMOS compatibility, 7: energy flow analysis. Sub-categories: mentioned in the text.

Subcategories are 1: micro-/nanoscale materials (such as grain textured and epitaxial piezoelectric films, lead-free piezoelectric films, aluminum nitride piezoelectric film, piezoelectric nanopolymers, polymer-ceramic nanocomposite, electrospun P(VDF-TrFE) nanofibers, nylon nanowire, template-grown poly-L-lactic acid, electrospun poly-L-lactic acid nanofibers, ZnO-polymer nanocomposite, ZnO nano-rods, nanowire- and nanowire-composites, PZT thin films, piezo-polymer thin films, piezoelectric electroactive polymers); 2: nonlinear resonance-based energy harvesting structures; 3: energy conversion efficiency; 4: figure of merit for MEMS PHEs; 5: material synthesis and deposition (such as solution phase synthesis, thin film deposition, growth of polymer-based nanowires); 6: modes of operations for MEMS PHEs; 7: design configurations for MEMS PHEs (such as cantilever-based piezoelectric generators or other types of piezoelectric generators); 8: microscale PHEs; 9: substrate and electrodes and their impact on performance; 10: MEMS device performance parameters; 11: characterization of MEMS PHEs; 12: MEMS hybrid harvesters (which may include architectures of hybrid harvesters, mathematical models of PZT hybrid harvesters and PZT—tribo-electric hybrid harvesters); 13: nanoscale PHEs (including their working principles, design, fabrication and implementation of nano-generators, hybrid nano-generators, nano-rod arrays, flexible nano-generators, ZnO nano-PHEs, applications of nano-generators, flexoelectric enhancement at the nanometer scale, characterization of piezoelectric potential from piezoelectric NWs, prototypes of nanogenerators, prediction of the power output from piezoelectric NWs, vertically aligned nanowire arrays and their fabrication, laterally aligned nanowire arrays and their fabrication); 14: impact coupled devices; 15: human powered piezoelectric generation; 16: evolving technology of miniature power harvesters; 17: positive prospects of micro-scale electricity harvesters; 18: challenges and constraints of minute-scale energy harvesters; 19: CMOS compatibility; 20: characterization methods for MEMS/NEMS PHEs; 21: bandwidth of PHEs; 22: screening effect; 23: piezoelectric thin films; 24: Modelling of MEMS/NEMS PHEs; 25: application of MEMS/NEMS harvesters.

3.5. Modeling Approaches

Some review papers have focused on the modeling of PHEs to clarify the physical basis behind piezoelectric energy harvesting. There are few review papers that have totally focused on the evaluation of different modeling approaches for piezoelectric energy harvesting.

Erturk and Inman investigated mechanical [51] and mathematical [52] aspects of cantilevered piezoelectric energy harvesters to avoid the reuse of simple and incorrect older models in literature. They reviewed the general solution of the base excitation problem for transverse and longitudinal vibrations of a cantilevered Euler–Bernoulli beam. They proved that the classical single-degree-of-freedom (SODF) predictions may yield highly inaccurate results, and they are only appropriate for high tip-mass-to-beam-mass ratios. Damping due to internal friction (Kelvin–Voigt damping), damping related to the fluid medium, the base excitation as a forcing function, and the backward piezoelectric coupling in the beam equation are among the modeling parameters. The modeling of energy conversion efficiency is missing from the article.

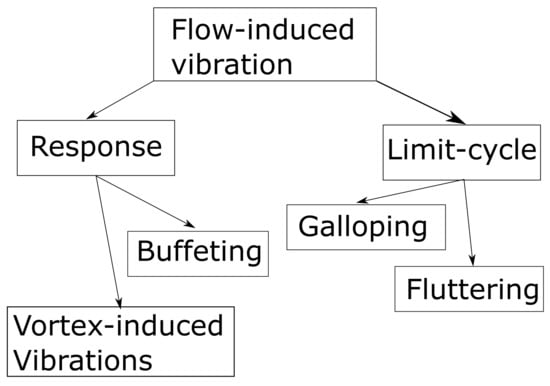

Zhao et al. [53] compared different modeling approaches for harvesting wind energy, including the single-degree-of-freedom, the single-mode, and multi-mode Euler-Bernoulli distributed-parameter models (ignored in Ref. [52]). They concluded that the distributed-parameter model has a more rational representation of aerodynamic forces, whereas the SDOF model more precisely predicts the cut-in wind speed and the electro-aeroelastic behavior. In addition, they performed a parametric study on the effect of the load resistance, wind exposure area, mass of the bluff body, and the length of the piezoelectric sheet on the cut-in wind speed, as well as the output power level of the GPEH. Again, the modeling of energy conversion efficiency is missing from the article.

Wei and Jing [54] presented a state-of-the-art review of the theory, modeling, and realization of piezoelectric, electromagnetic, and electrostatic energy harvesters. The linear inertia-based theory and the non-linear models have been described for the three mentioned vibration-to-electricity converters. They investigated some characteristics of the piezo-harvesters, such as their being unaffected from external/internal electromagnetic waves, their simple structure, depolarization, the brittleness of the bulk piezo-layer, the poor coupling in piezo-film, and their poor adhesion with the electrode materials. The development of new piezoelectric materials, the creation of new energy harvesting configurations by exploring non-linear benefits and the design of efficient energy harvesting interface circuits are among their suggestions as future prospects. They concluded that the non-linearity is an important and effective parameter in terms of performance enhancement. Theoretical modeling of non-linear systems while maintaining reliability and stability is a challenging task. The reviewed models were not compared in the paper.

Table 6 sums up the results of the evaluation of the review papers written about modeling approaches. The table also contains different sub-categories, the range of output power, the number of reviewed articles, the merits, general conclusions, and some other descriptions. The ranking of each paper was computed based on the number of merits, the number of subcategories, the number of concluding remarks, and with a clear emphasis on value of the minimum required output power.

Table 6.

Overall evaluation of review papers written on the modeling of piezoelectric energy harvesters. The numbers in brackets denote the number of non-general future lines. “Cons.” stands for conclusions. Conclusions: 1: Comparing the reviewed models; 2: the accuracy of the models and correction factors; 3: models constraints and limitations; 4: advantges and disadvantages of the models; 5: design consideration based on the modeling results. Merits: 1: Giving the mathematical background of the models; 2: considering the energy losses; 3: taking into account the resonance and off-resonance conditions; 4: efficiency modeling; 5: mentioning the constraints and limitations of the model; 6: mentioning the assumptions followed by the models; 7: comparison of the existing models. Sub-categories: 1: Energy conversion in PHEs with linear models; 2: energy conversion in PHEs with nonlinear models; 3: modeling efficiency and correction factors; 4: comparison of existing models for cantilever PHEs (SDOF models and distributed parameter modeling); 5: comparison of existing models for aeroelastic energy harvesting (models for flutter in airfoil sections, vortex-induced vibrations in circular cylinders, galloping in prismatic structures, VIV-/cylinder-based aeroelastic energy harvesters, galloping-based aeroelastic energy harvesters, wake galloping, SDOF models, Euler–Bernoulli distributed parameter model).

4. Applications

Piezo-materials can extract power directly from structural vibrations or other environmental mechanical waste energy sources in infrastructures (bridges, buildings), biomedical systems, healthcare, and medicine. They can also be used as a part of transducers, actuators, and surface acoustic wave devices. In this section, we tried to present a classified review of the contents of existing review papers that have focused on applications involving vibrational sources, waste energy harvesting, fluid-related sources, and biological applications.

4.1. Vibration

Vibration is the most common source of energy for piezoelectric harvesters, since there is no need to convert the input energy to the mechanical energy to produce electricity in piezo-materials. Furthermore, its abundance, accessibility, and ubiquity in the environment, in addition to multiple possible transduction types, have made it more attractive for energy-harvesting applications. The response of piezoelectric materials to the employed vibrations depends on their electromechanical properties such as the natural frequency, their geometry, the electromechanical coefficients, and the damping characteristics. The design strategies for such types of harvesters, performance enhancement methodologies, the behavior of the energy harvesters in harsh environments, their fatigue life and failure mode, and the conditioning electric circuits are some of the important issues that should be addressed in review papers.

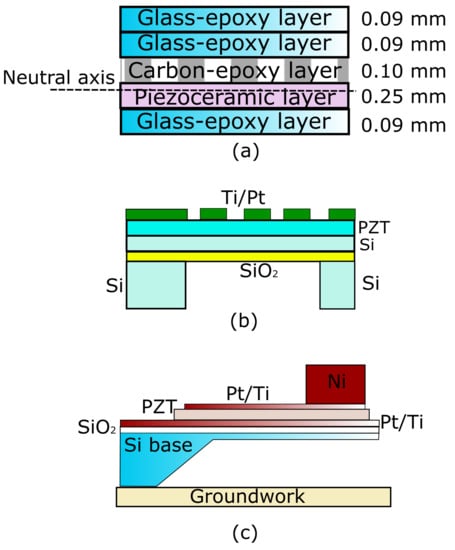

Sodano et al. [56], as one of the earliest reviewers of the field, discussed the future goals that must be achieved for power harvesting systems to find their way towards everyday use, and to generate sufficient energy to power the necessary electronic devices. They mentioned that the major limitations in the field of power harvesting revolve around the fact that the power generated by piezoelectric energy harvesters is far too small to power most electronic devices. Increasing the amount of energy generation, developing innovative methods for accumulating this energy, the use of rechargeable batteries, optimization of the power flow from a piezoelectric setup, minimizing the circuit losses, identifying the location of power harvesting and the excitation range, and proper tuning of the power harvesting device are their predictions for future prospects in regard to vibration-based piezo harvesters. Kim et al. [57] summarized the key ideas behind the performance evaluation of piezoelectric energy harvesters based on vibration, providing classifications, materials, and the mathematical modeling of vibrational energy harvesting devices. They listed 17 important electro-mechanical characteristics of PZT-5H, PZT-8, PVDF, and described various configurations such as the cantilever type, the cymbal type, the stack type, and the shell type. They advised that the future opportunities for research are the development of high coupling coefficients of piezoelectric materials, giving them the ability to sustain harsh vibrations and shocks, the sdevelopment of flexible and resilient piezoelectric materials, and designing efficient electronic circuitry for energy harvesters. Siddique et al. [58] provided a literature review on vibration-based micropower generation using electromagnetic and piezoelectric transduction systems and hybrid configurations. They reported some performance characteristics of piezoelectric energy harvesters with different materials and configurations. They claimed that most of the recent research has been devoted to modifications of the generator size, shape, and to introducing a power conditioning circuit to widen the frequency bandwidth of the system. Further research topics are the development of the MEMS-based energy harvesters from renewable resources and making miniature electric devices more reliable. Figure 8 presents three schematic views of microscale piezo-generators designed for vibration-based energy harvesting applications.

Figure 8.

(a) Geometry and position of the neutral axis of piezocomposite composed of layers of carbon/epoxy, PZT ceramic, and glass/epoxy [57]; (b) a MEMS-based piezo-generator in 3-3 mode [56]; (c) schematic diagram of cross sectional view of a fabricated vibration-based micro power generator [58].

Saadon and Sidek [59] presented a brief discussion of vibration-based MEMS piezoelectric energy harvesters. They summarized various designs of harvesters and reviewed experimental results presented in the 3 years before the date of publication of the paper. They focused on the working modes and maximum output power of MEMS piezoelectric energy harvesters.

Harb [60] reviewed a brief history of all energy harvesting methods, including the vibration-based, electromagnetic-based, thermal or radioactive-based, pressure-gradient-based, solar- and light-based, biological, and micro-water flow systems. However, it is advised that the different types of vibrations are the most available and the highest power provider sources. Review papers such as the one presented by Zhu et al. [61] are the result of the rapid increase inutilization of vibration-based micro-generators in powering the wireless sensor networks. They demonstrated an overall review of the principles and the operating strategies to increase the operational frequency range of vibration-based micro-generators. Harne and Wang [62] reported the major efforts and findings about common analytical frameworks and principal results for bi-stable electromechanical dynamics, and a wide variety of bi-stable energy harvesters. Based on their discussion, the remaining challenges of such systems are maintaining high-energy orbits, operation under stochastic vibratory conditions, designing coupled bi-stable harvesters, and defining proper performance metrics.

In summary, different configurations of piezoelectric cantilevers, their power output and performance enhancement strategies have been well covered by review papers. However, a systematic comparison of different configurations of piezoelectric energy harvesters, as well as their ability to sustain harsh vibrations and shocks, their fatigue life, their cost, and accessibility have not been considered by the reviews. Table 7 presents the results of our evaluation of the piezo-electric energy harvesters from vibrational sources. The table also contains different sub-categories, the range of output power, the number of reviewed articles, the merits, general conclusions, and some other descriptions. The ranking of each paper was computed based on the number of merits, the number of subcategories, the number of concluding remarks, and with a clear emphasis on the value of the minimum required output power.

Table 7.

Overall evaluation of review papers written on piezoelectric energy harvesting from vibration sources. “Cons.” stands for conclusions. Conclusions: 1: Efficiency/performance improvement, 2: frequency tuning, 3: safety issues, 4: costs, 5: hybrid harvesters, 6: non-linear models, 7: battery replacement, 8: miniaturization, 9: steady operation, 10: more efficient materials, 11: stochastic modeling. Merits: 1: Electromechanical coupling factor, 2: realistic resonance, 3: energy flow, 4: range of output. Sub-categories: 1: Circuits, 2: type of materials, 3: modeling, 4: noise level, 5: wearable, 6: frequency range, 7: MEMS.

4.2. Biological Sources

Biomechanical energy harvesting provides an important alternative to electrical energy for portable electronic devices. Hwang et al. [63] addressed the development of flexible piezoelectric energy-harvesting devices using high-quality perovskite thin films and innovative flexible fabrication processes. In addition, energy harvesting devices with thick and rigid substrates are unsuitable for responding to the movements of internal organs and muscles. The authors noted that the electric power harvested from the bending motion of a flexible thin film is sufficient to stimulate heart muscles. Furthermore, easy bendability, higher conversion efficiency, enhanced sensing capability at the nanoscale, self-energy generation and real-time diagnosis/therapy capabilities are among advantages of such systems. Ali et al. [64] discussed the possibilities of utilizing the piezo-based energy conversion from the source of muscle relaxation and contraction, body movement, blood circulation, lung and cardiac motion in applications such as pacemakers, blood pressure sensors, cardiac sensors, pulse sensors, deep brain simulations, biomimetic artificial hair cells, active pressure sensors, and active strain sensors. Piezoelectric materials containing nanowires, nanorods, nanotubes, nanoparticles, thin films, lead-based ceramics, lead-free ceramics, polymer-based materials, textured polycrystalline materials, and biological piezo-materials have been evaluated. They proposed several challenging problems such as the flexibility to fit into the shape of an organ, the proper management of power, the selection of a media for the electrical connection, enhancing the biological safety, designing the interface between the body tissue and the implanted piezo-material, efficient encapsulation, further miniaturization, and conducting related experiments on small/large animal and human cases.

Surmenev et al. [65] described novel techniques in the fabrication of hybrid piezoelectric polymer-based materials for biomedical energy harvesting applications such as detection of the motion rate of humans, the degradation of organic pollutants, and the sterilization of bacteria. They described the different methods that can be employed for the improvement of the piezoelectric response of polymeric materials and scaffolds. They also reviewed biomedical devices and sensors based on hybrid piezo-composites. Similarly to most other reviews, increasing performance is one of proposed future works. Others are the alignment of nanofiller particles inside the piezopolymer matrix, developing common standards for the consistent quantification and evaluation of the performance of various types of piezoelectric materials, and the investigation of the structural parameters.

The internal charging of implantable medical devices (IMD) is another important biological application of piezoelectric energy harvesting. Extending the lifespan of IMDs and size minimization have become the main challenges for their development. For such devices, energy from body movement, muscle contraction/relaxation, cardiac/lung motions, and blood circulation is used for powering medical devices. Zheng et al. [66] presented an overall review of piezoelectric energy devices in comparison to triboelectric harvesters with the source of body movement, muscle contraction/relaxation, cardiac/lung motions, and blood circulation. They proposed that future opportunities involve the fabrication of intelligent, flexible, stretchable, and fully biodegradable self-powered medical systems for monitoring biological signals, in vivo and in vitro treatment of various diseases, optimization of the output performance, the obtainment of higher sensitivity, elasticity, durability and biocompatibility, biodegradable transient electronics, the intelligent control of dynamic properties in vivo, improvement of operating lifetimes, and absorption efficiency.