Influence of Construction-Induced Effects and Post-Grouting on the Performance of Mud-Protected Bored Piles: A Numerical Investigation

Abstract

1. Introduction

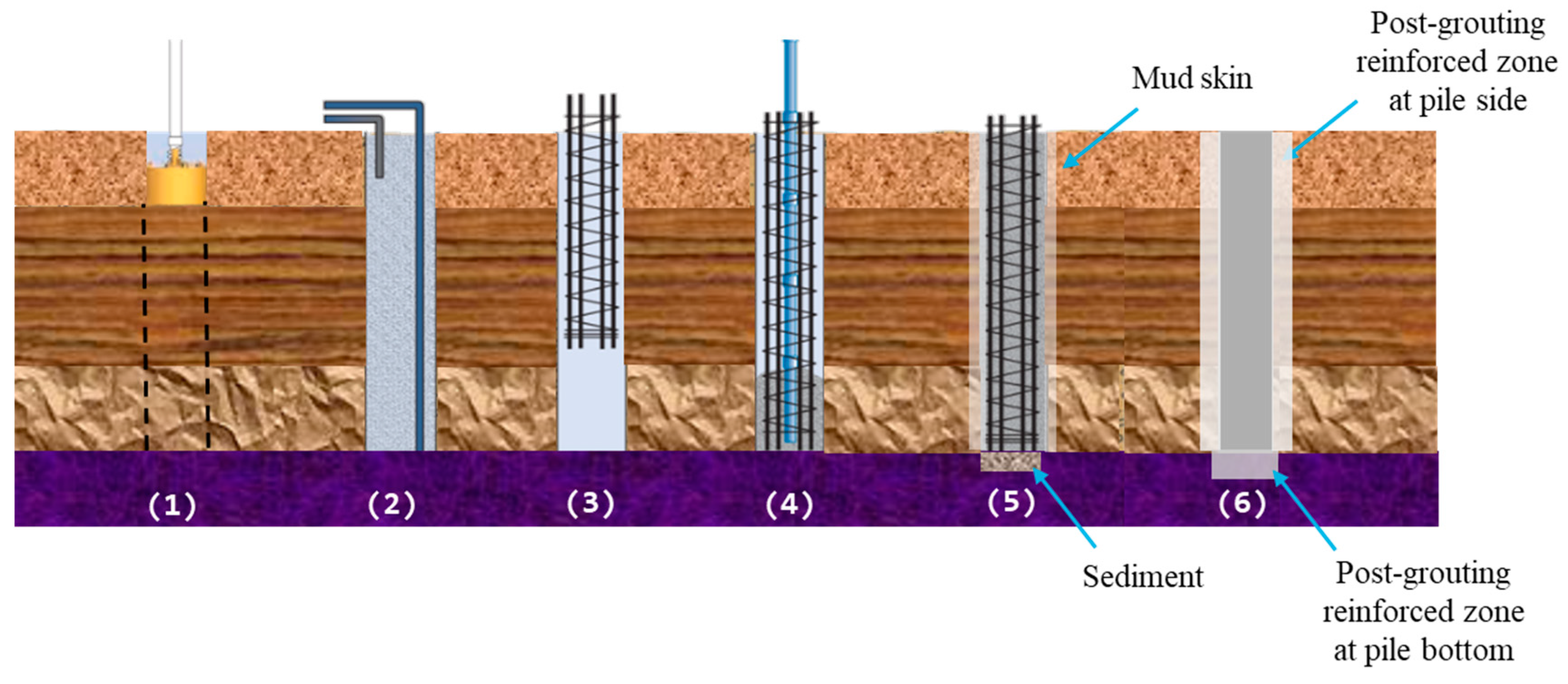

1.1. Conception of Mud-Protected Bored Pile

1.2. Previous Works

1.3. Objectives of Present Study

2. Presentation of the Site Condition

3. Numerical Model and Validation

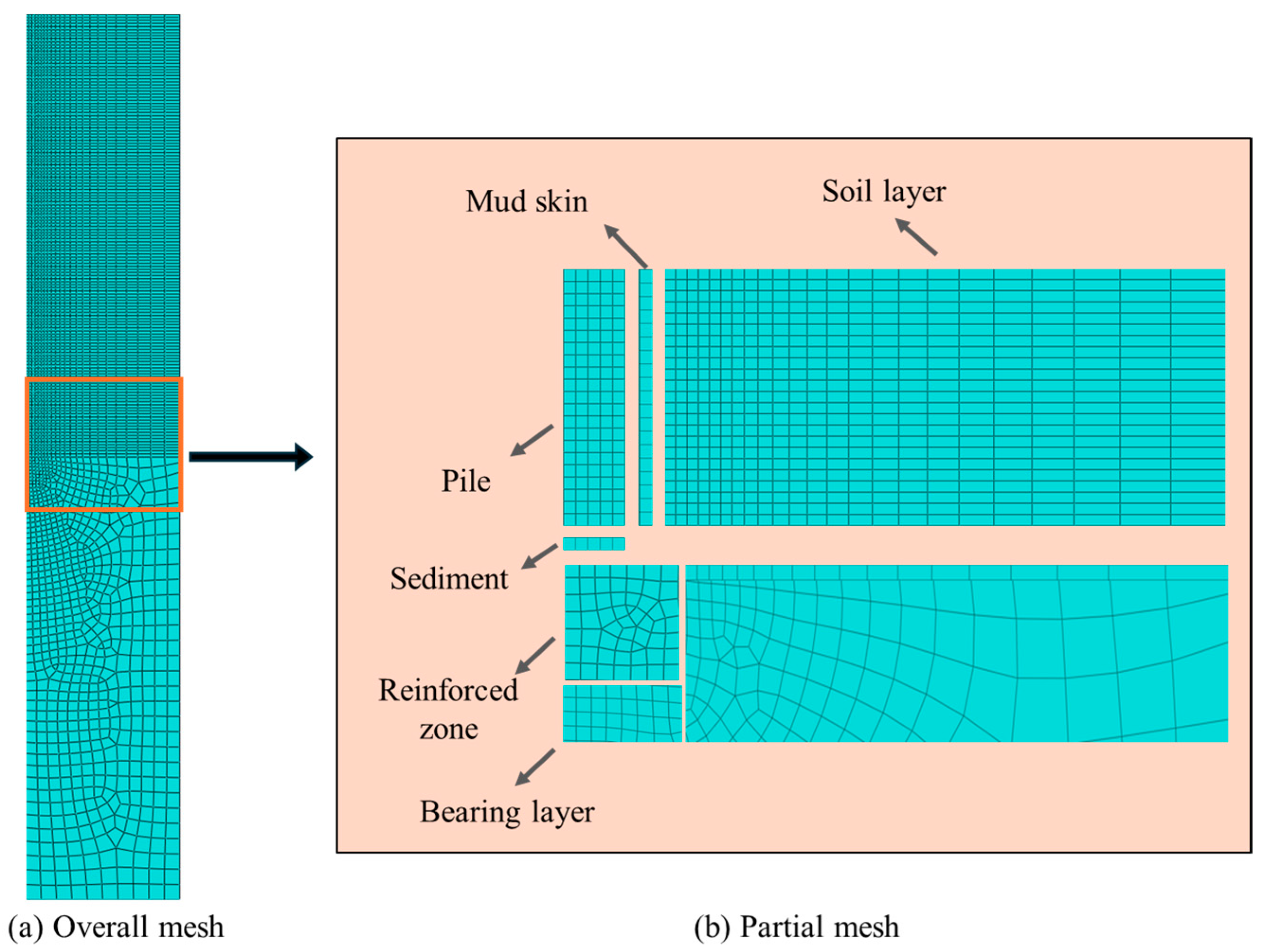

3.1. Numerical Model Configuration

3.1.1. Creation of a Numerical Model

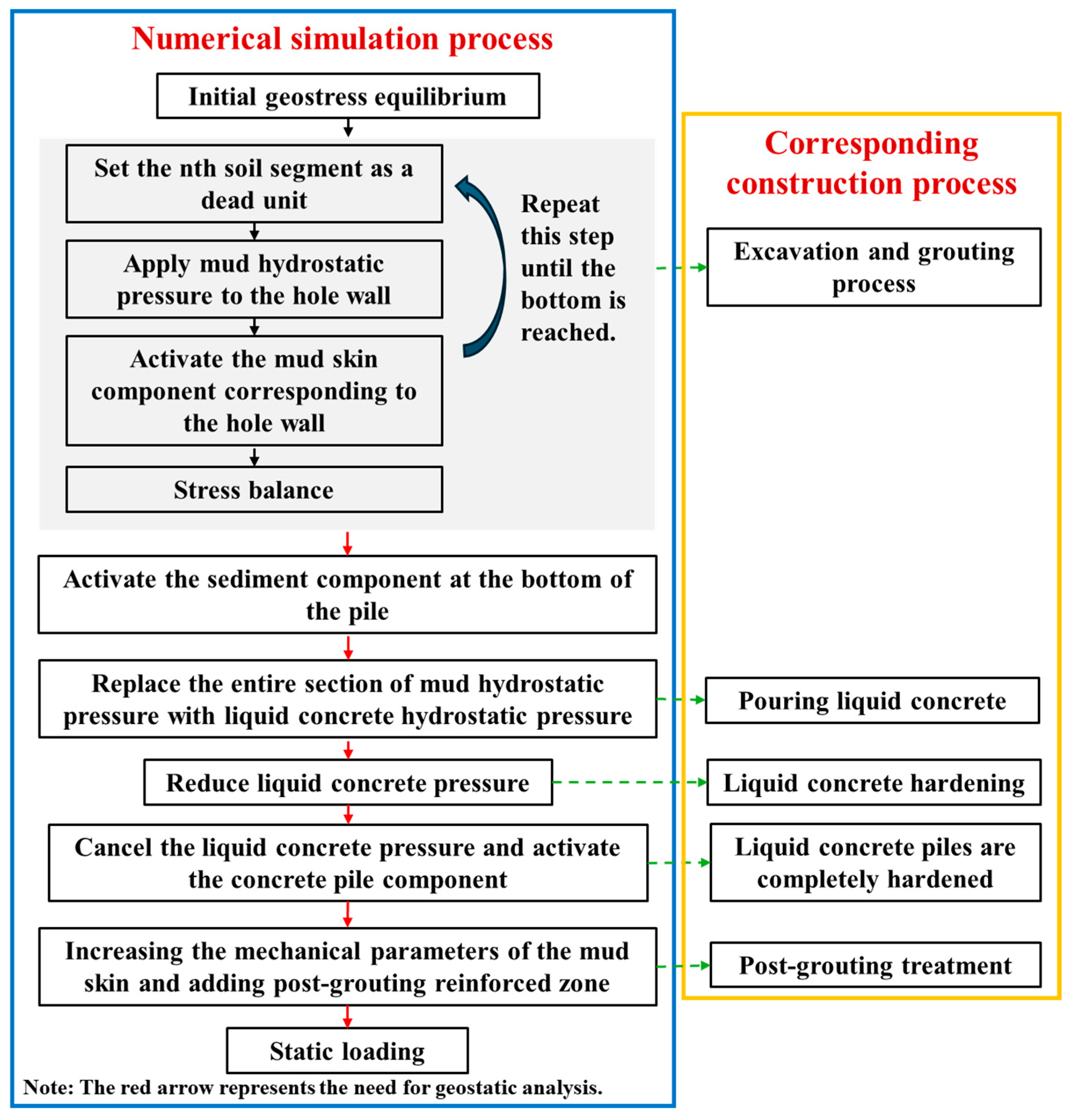

3.1.2. Numerical Simulation Process

- (1)

- Initial geostatic analysis: Calculate the inherent stress distribution in the soil.

- (2)

- Simulation of borehole excavation and mud protection: The soil elements to be excavated are progressively deactivated from top to bottom, and hydrostatic pressure is applied perpendicularly to the borehole wall to simulate the mud’s force on the wall. Due to the interaction between drilling mud and borehole wall, a mud skin forms around the pile, which is simulated by reducing the mechanical parameters of the mud skin elements. After each excavation step, a geostatic analysis is performed to determine the balanced stress distribution in soil and ensure that the system reaches equilibrium. After the excavation is completed, a sediment element is set at the pile bottom to simulate the accumulation of drilling debris and mud deposits.

- (3)

- Simulation of concrete pouring: The mud pressure on the borehole wall along the entire pile length is replaced with the pressure of liquid concrete. A sediment element is set at the pile bottom with significantly reduced mechanical parameters to simulate the effects of drilling debris and mud deposits. The expression is as follows [22]:

- where is the unit weight of liquid concrete, is the unit weight of mud, and z represents the pile depth. In this study, is set as 24 kN/m3, is set as 10.1 kN/m3, and represents the length of the pile.

- (4)

- Simulation of liquid concrete hardening: The pressure of the liquid concrete is reduced to simulate water loss and shrinkage during the hardening process, which leads to a decrease in pressure on the borehole wall (assuming the pressure value is , where is the coefficient of earth pressure at rest, is the unit weight of concrete after water loss, and z is the depth).

- (5)

- Simulation of completed concrete hardening: The pressure of the liquid concrete is removed, and the concrete pile elements are activated.

- (6)

- Post-grouting treatment: For the pile shaft, the improvement effect of grouting is simulated by increasing the mechanical parameters of the mud skin elements; at the pile bottom, the sediment element at the pile bottom is replaced with a cylindrical post-grouting reinforced zone with a height of 2 m and a diameter of 2 m, whose mechanical parameters are significantly improved.

- (7)

- Application of vertical loads: Vertical static loads are applied on top of the pile to calculate the corresponding settlement and derive bearing capacity.

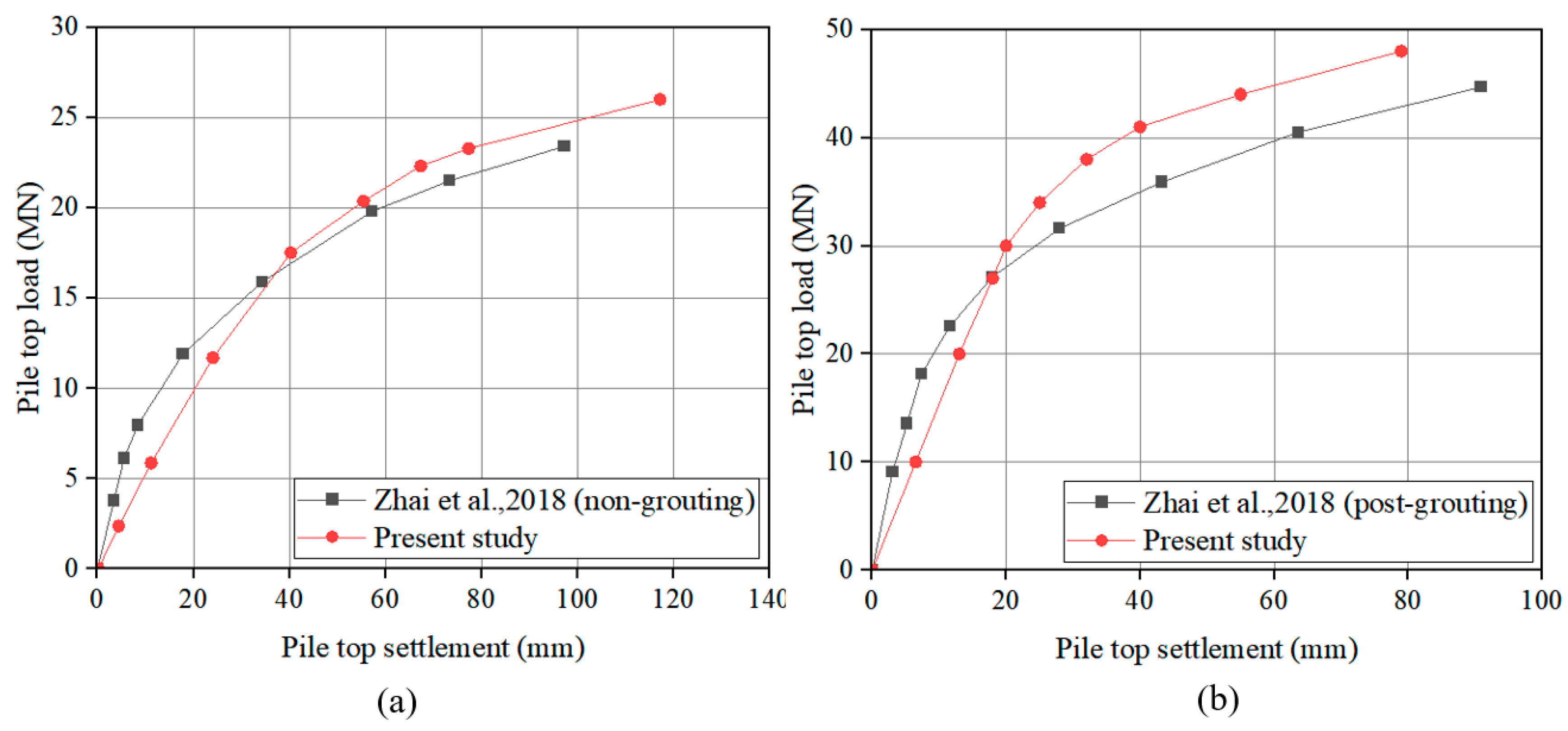

3.2. Validation of the Numerical Simulation Procedure

3.2.1. Comparison Against a Field Test Pile

3.2.2. Comparison Against Published Numerical Results

4. Effects of Construction-Induced Factors and Post-Grouting on Pile Performance

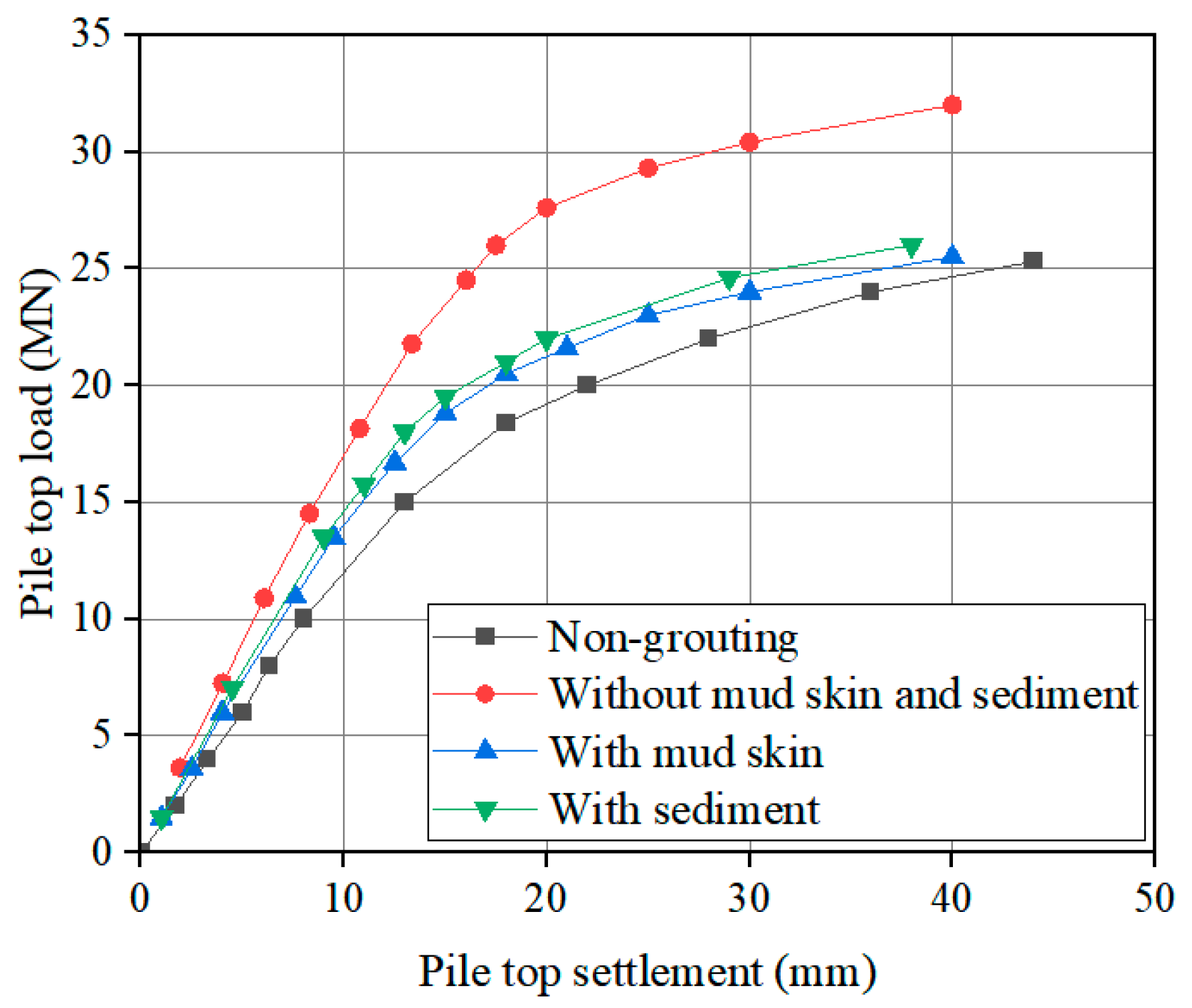

4.1. Effects of Mud Skin and Sediment on Pile Performance

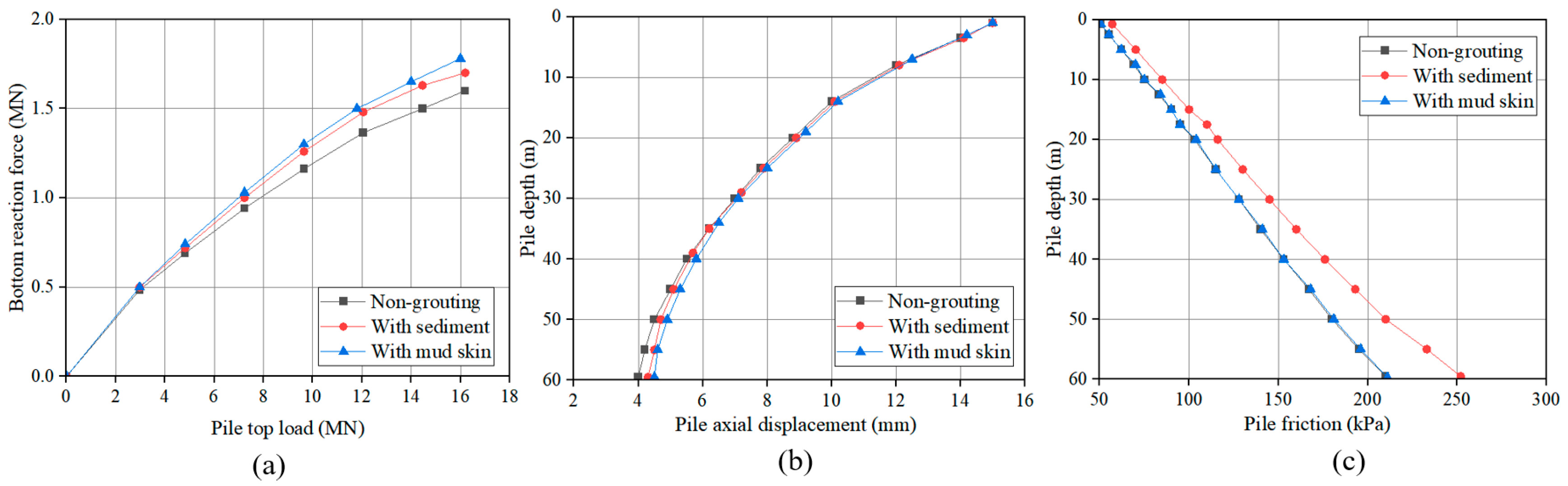

4.1.1. Effect of Mud Skin and Sediment on Load Transfer Mechanisms

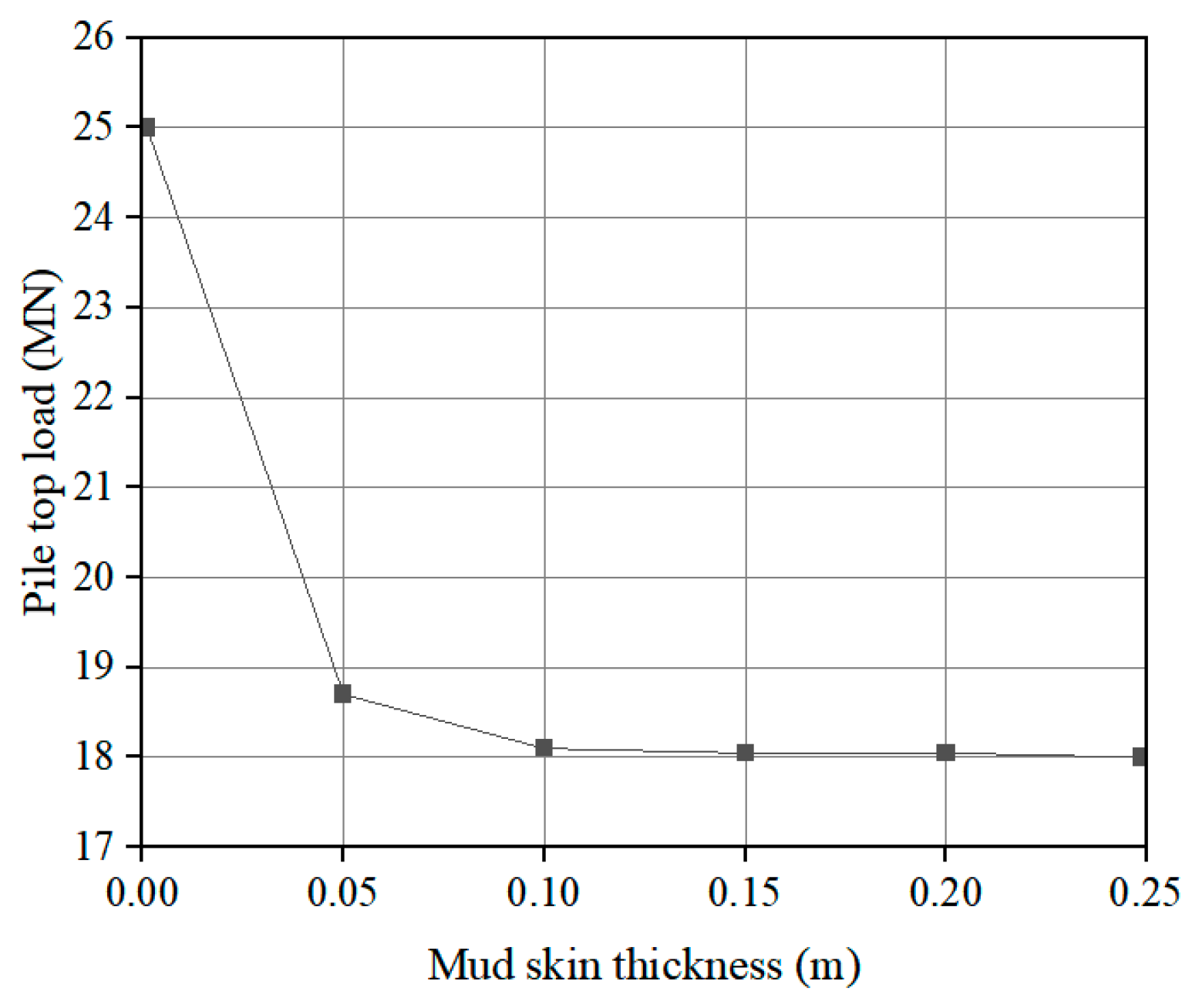

4.1.2. Parametric Analysis of Mud Skin Thickness

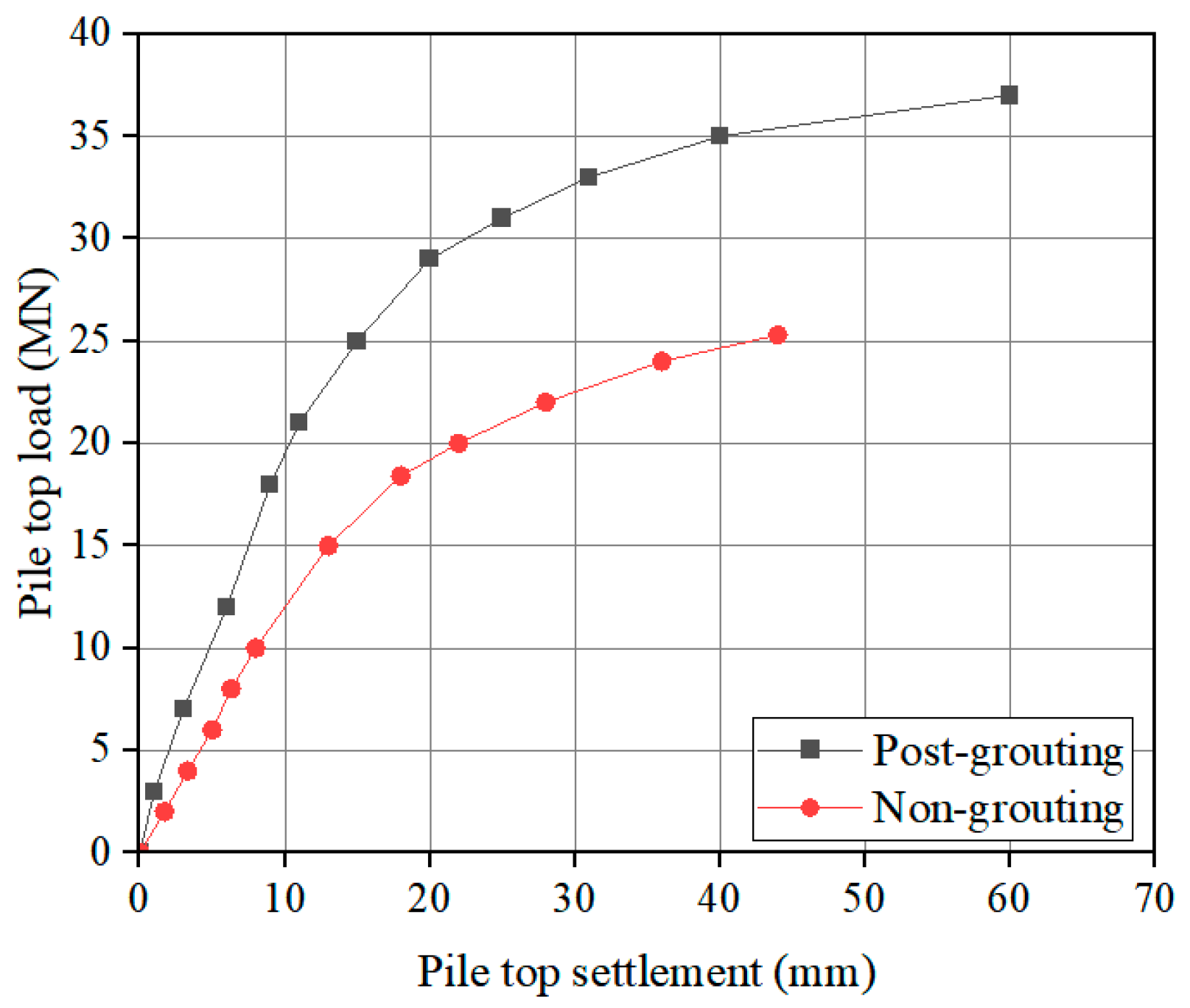

4.2. Effects of Post-Grouting on Pile Performance

4.2.1. Analysis of Bearing Capacity

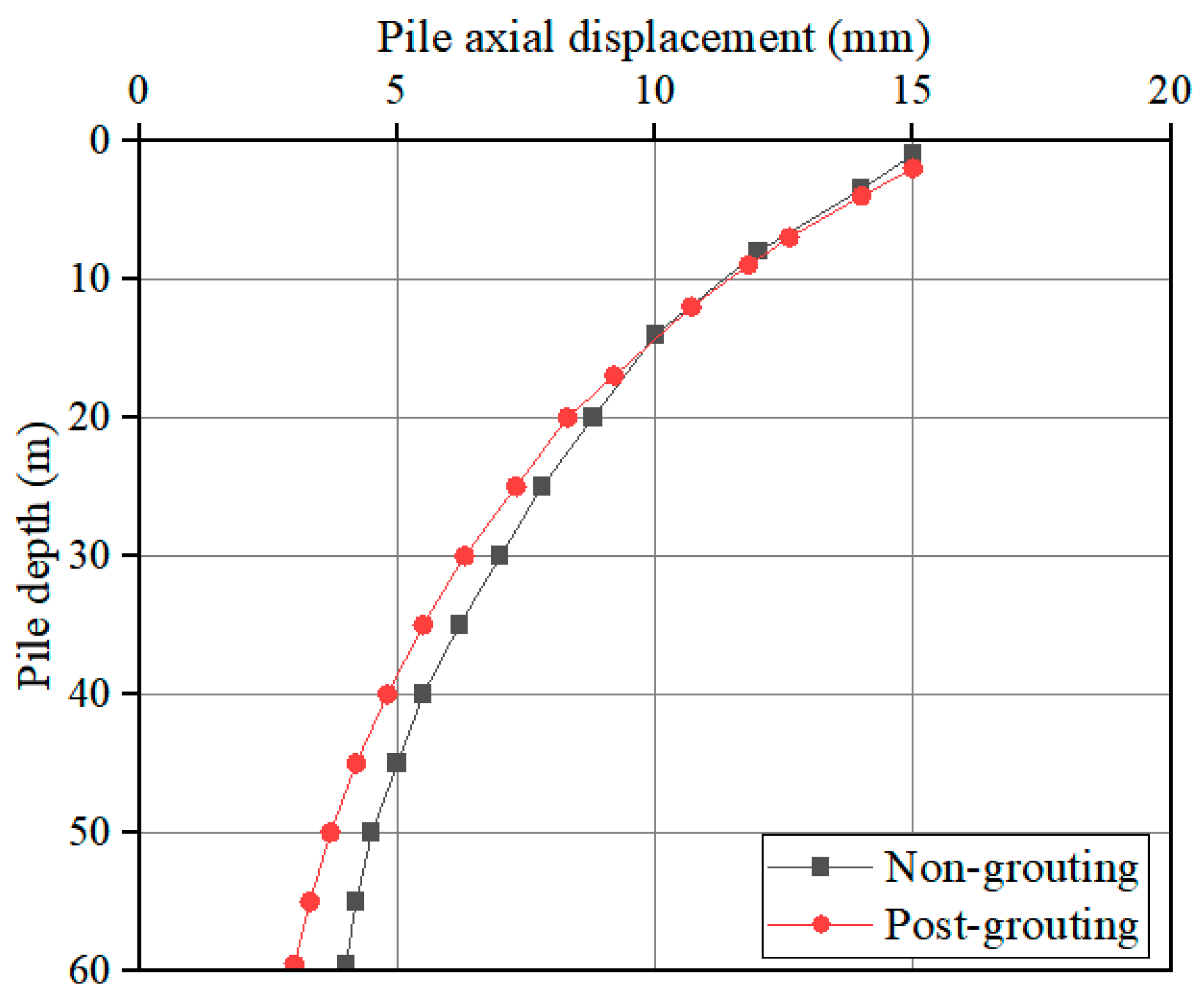

4.2.2. Analysis of Axial Displacement

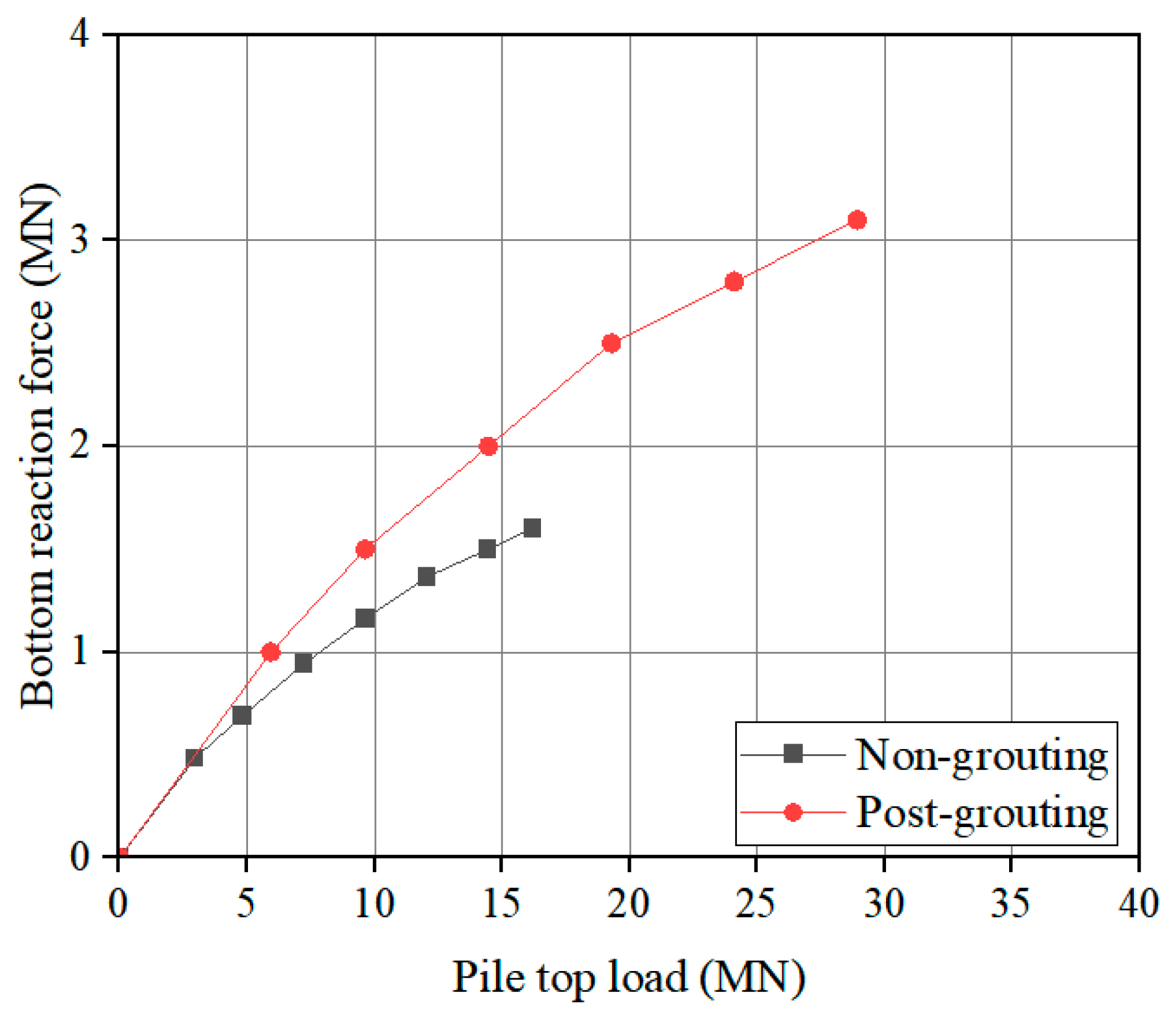

4.2.3. Analysis of Bottom Reaction Force

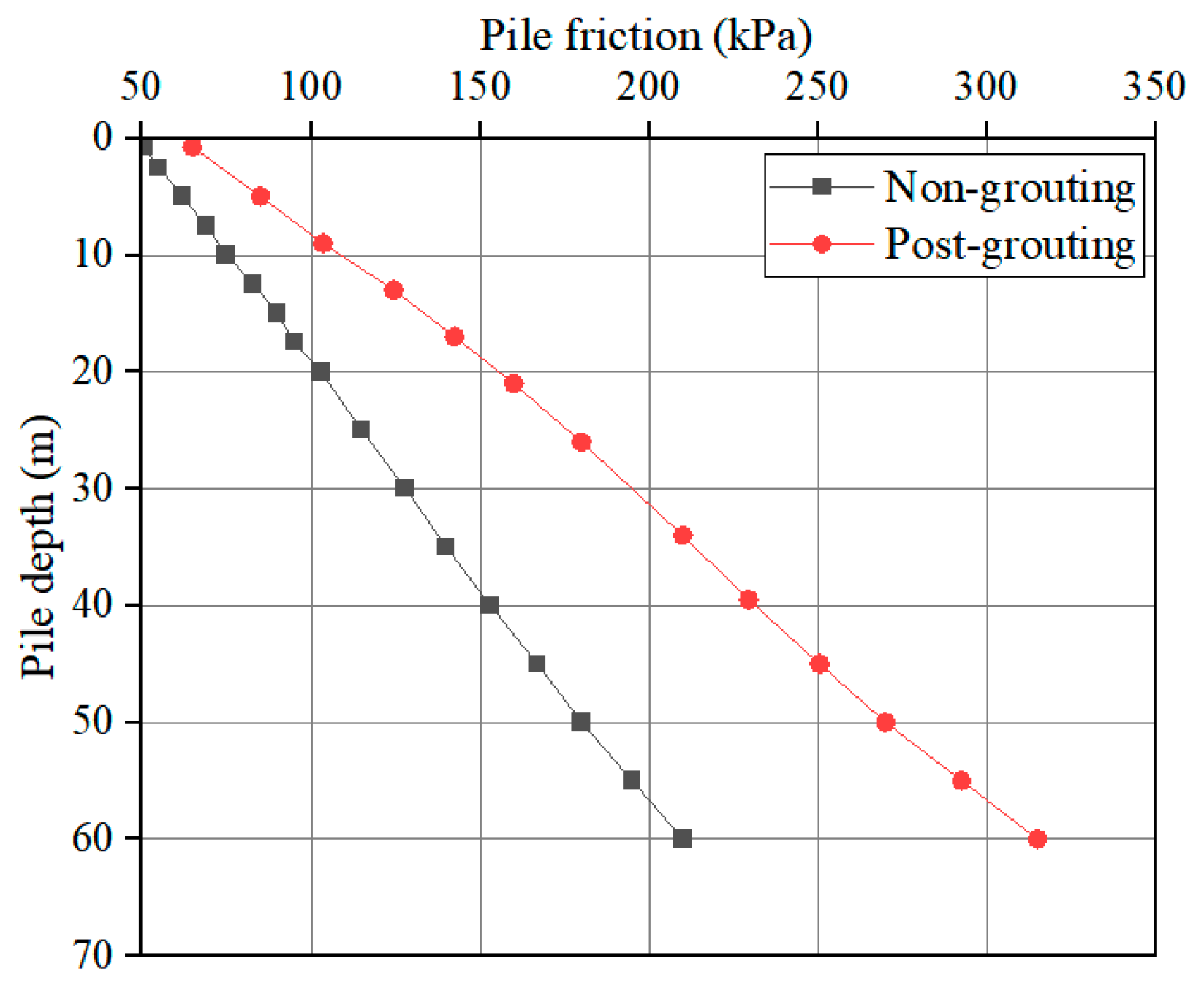

4.2.4. Analysis of Pile Friction

4.3. Discussion of Results

5. Influence of Post-Grouting Parameters on Pile Performance

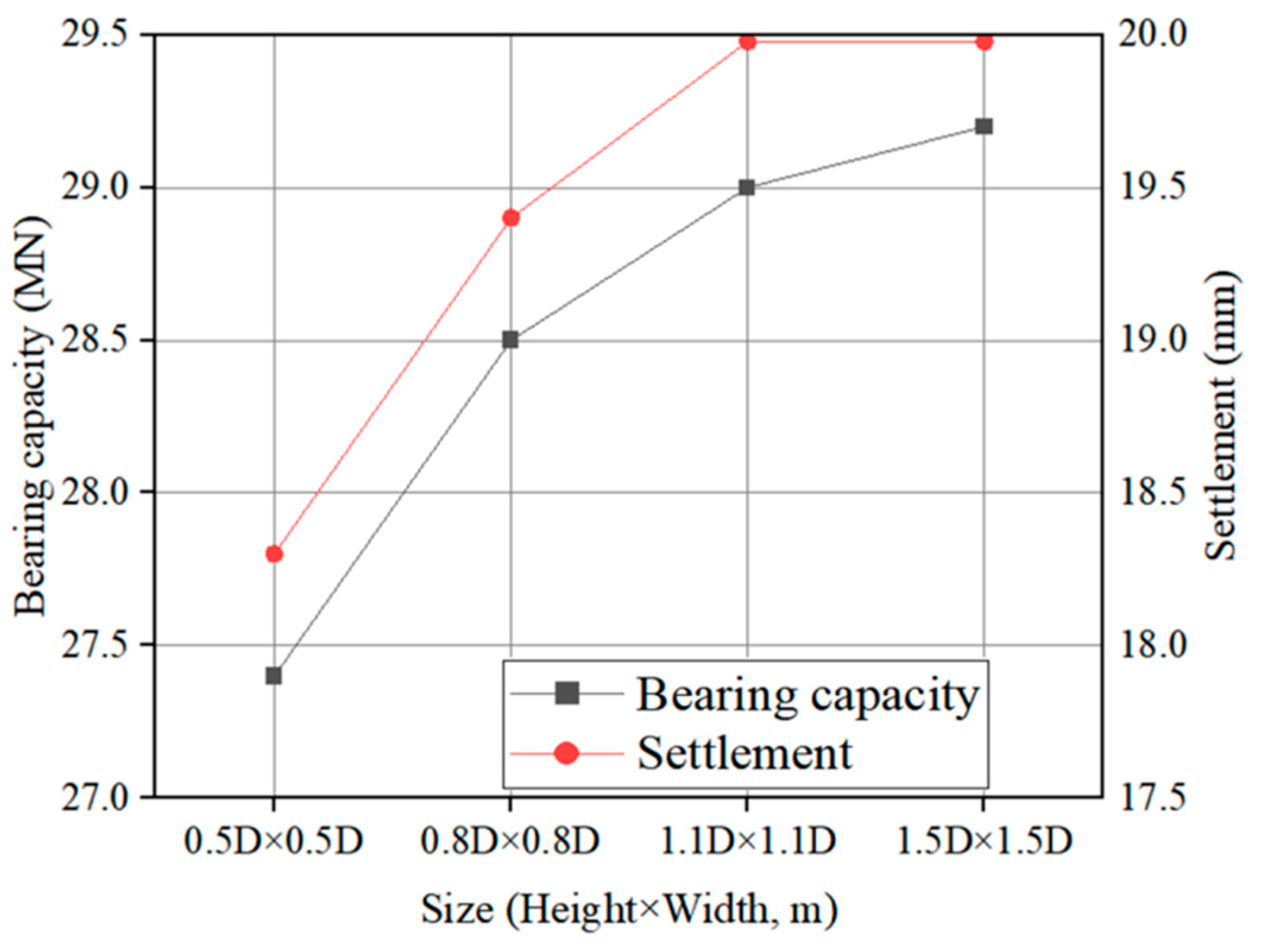

5.1. Effect of Pile Bottom Grouting Reinforced Zone Dimensions on Pile Performance

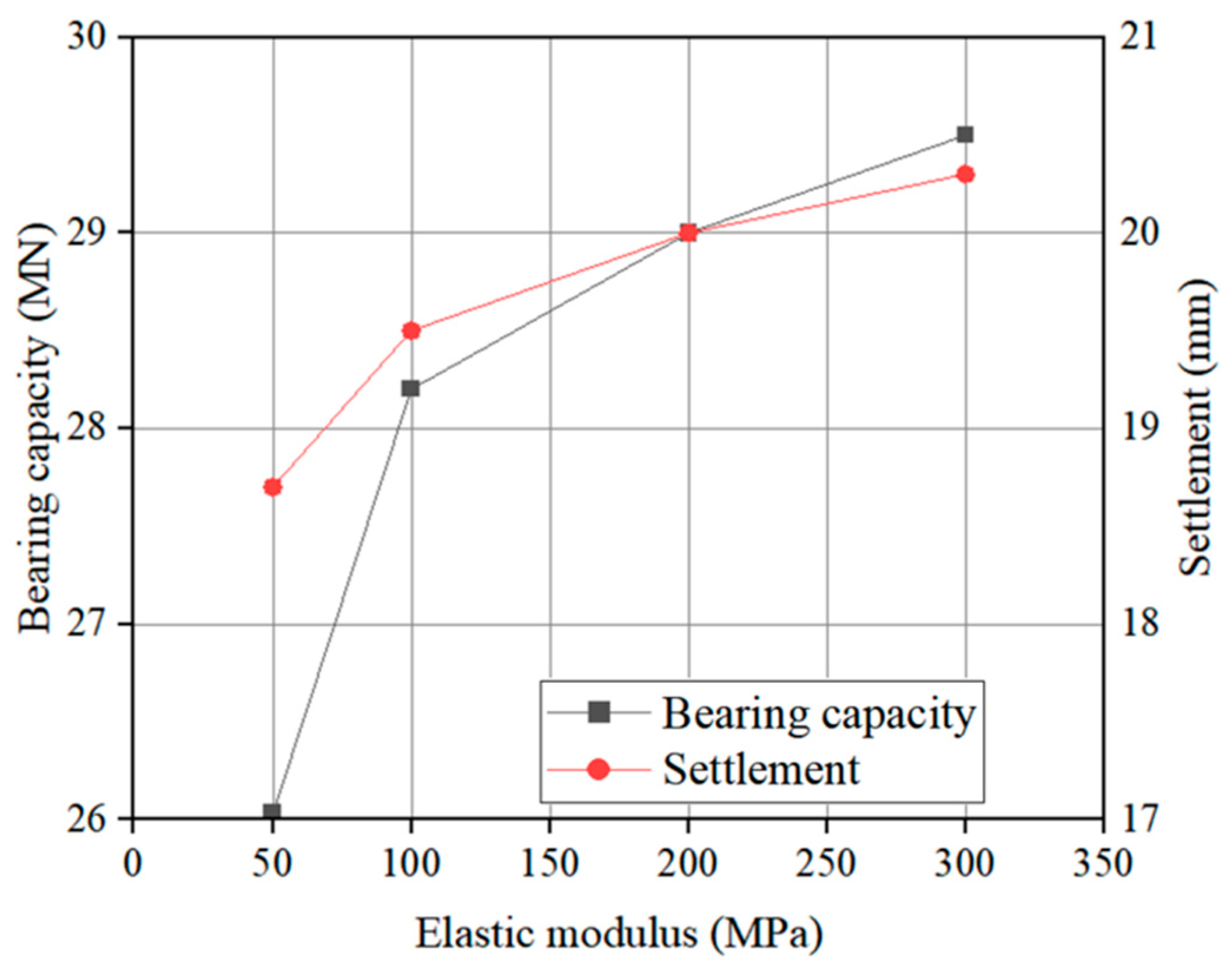

5.2. Effects of Elastic Modulus of Grouting Reinforced Zones on Pile Performance

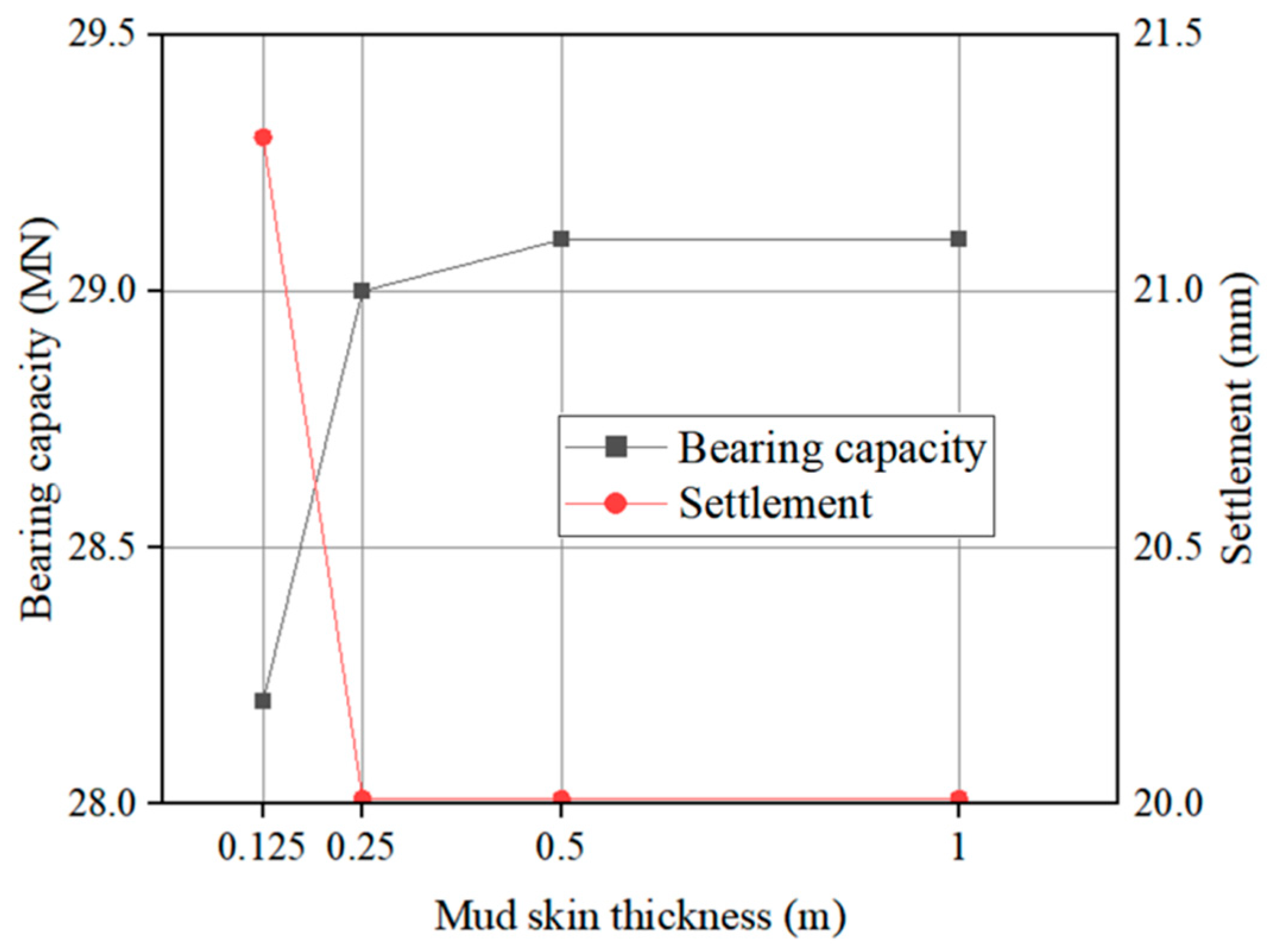

5.3. Effects of Pile Shaft Grouting Reinforced Zone Dimensions

6. Conclusions

- (1)

- For the case study, construction-induced effects significantly reduce pile bearing capacity, with mud skin and sediment individually leading to decreases of 28% and 24%, respectively, compared to ideal conditions. When both construction-induced effects are present, the bearing capacity decreases by 36%.

- (2)

- The parametric study on mud skin thickness reveals that beyond a certain minimal thickness, further increases in mud skin thickness have limited additional impact on the bearing capacity.

- (3)

- Post-grouting can effectively improve pile performance, increasing the bearing capacity by 81% compared to the non-grouting condition for the studied test pile. The load-settlement curves also show improved initial stiffness after post-grouting.

- (4)

- For the studied test pile, side friction dominates pile behavior, contributing approximately 90% of the total bearing capacity. The pile body exhibits significant elastic compression under loading, with pile compression between pile top and bottom reaching approximately 11~12 mm.

- (5)

- For the test pile studied, parametric analysis indicates that the grouted reinforcement zone at the pile bottom does not need to exceed 1.1 times the pile diameter. Additionally, reinforcement beyond the mud skin zone offers no further benefits to pile performance, and the elastic modulus of the reinforced zones shows diminishing returns beyond 200 MPa.

- (6)

- The findings from this research have significant practical implications for foundation engineering projects worldwide. While the test pile was located in Eastern China, the observed effects of construction-induced factors and post-grouting mechanisms are relevant to bored pile applications globally. The substantial reduction in bearing capacity due to mud skin and sediment highlights the universal importance of construction quality control in bored pile projects, regardless of geographical location. The optimal grouting zone dimensions identified in this study can serve as a reference for grouting design in similar soil conditions internationally, potentially leading to more cost-effective grouting practices.

- (1)

- The study assumes uniform mud skin thickness and properties along the pile shaft, while in practice, these may vary with depth.

- (2)

- The post-grouting reinforced zones were modeled with simplified cylindrical geometries, which may not fully represent the complex shapes that develop during actual grouting operations.

- (1)

- Probabilistic and reliability analysis to quantify uncertainties in input parameters (soil properties, mud skin characteristics, sediment conditions) and their propagation to bearing capacity predictions, providing confidence levels for performance estimations.

- (2)

- Investigation of grouting process parameters (pressure, volume, injection rate) and their relationship with the resulting reinforced zone characteristics across different soil conditions, which would provide more directly applicable guidance for post-grouting implementation.

- (3)

- Development of more realistic three-dimensional modeling approaches to better represent the complex geometry of grouting reinforced zones, which typically have irregular, water-drop shapes rather than the simplified cylindrical geometries used in this study.

- (4)

- Investigation of long-term settlement behavior and creep effects in post-grouted bored piles under various soil conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, H.; Ma, Y.; Yao, W.; Chen, C. Research on Bearing Capacity of Post-grouting Super-long Bored Pile. IOP Conf. Ser. Earth Environ. Sci. 2021, 634, 012111. [Google Scholar] [CrossRef]

- Wan, Z.; Dai, G.; Gong, W. Field study on post-grouting effects of cast-in-place bored piles in extra-thick fine sand layers. Acta Geotech. 2019, 14, 1357–1377. [Google Scholar] [CrossRef]

- Zhang, Z.-M.; Yu, J.; Zhang, G.-X.; Zhou, X.-M. Test study on the characteristics of mudcakes and in situ soils around bored piles. Can. Geotech. J. 2009, 46, 241–255. [Google Scholar] [CrossRef]

- Zhou, Z.; Yang, X.; Wang, H. Numerical simulation and bearing capacity analysis of post grouting reinforcement of bored pile based on CEL method. Found. Treat. 2023, 5, 305–311. [Google Scholar] [CrossRef]

- Cao, S.; Wang, Q.; Ma, J.; Xiao, Z.; Li, C.; Yang, Y.; Wang, J. Experimental Investigation of Vertical Bearing Characteristics of Composite Post-grouting Piles in Sandy Soil. Int. J. Civ. Eng. 2024, 22, 303–315. [Google Scholar] [CrossRef]

- Gao, Q.; Hu, Q.; Zhang, J.; Ren, Z.; Liu, C.; Liu, J.; Wang, S.; Cheng, G.; Zhang, R.; Ren, C. Experimental study on wall-protecting mud modification of super-long bored pile in the alluvial plain region of the Yellow River. Constr. Build. Mater. 2023, 368, 130395. [Google Scholar] [CrossRef]

- Lin, M.; Huang, X.; Han, D. Numerical simulation study on the influence of pile end sediment on the bearing performance of bored pile. Highway 2021, 66, 116–122. [Google Scholar]

- Zhai, D.; Zhou, F.; Zhou, J.; Zhu, R. Experimental study and numerical analysis on bearing characteristics of large diameter ultra long bored piles with post grouting on the tip and side. IOP Conf. Ser. Earth Environ. Sci. 2018, 189, 022024. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, C.; Wu, Y. Experimental Study on Post-Grouting Pile Vertical Bearing Performance Considering Different Grouting Methods and Parameters in Cohesive Soil. Appl. Sci. 2023, 13, 12175. [Google Scholar] [CrossRef]

- JGJ/T 403-2017; Technical Specification for Static Load Test of Building Foundation Piles. China Architecture & Building Press: Beijing, China, 2017.

- Dong, X. Research on the Vertical Bearing Mechanism of Pile end and Side Grouting Drilled Pile. Master’s thesis, Zhengzhou University, Zhengzhou, China, 2012. [Google Scholar]

- Gong, Y. Research on the Mechanism and Application of Post Grouting Technology in Drilled Pile Engineering. Master’s Thesis, Shijiazhuang Railway University, Shijiazhuang, China, 2016. [Google Scholar]

- Li, Y. Experimental Study on Vertical Bearing Performance of Post Grouting Bored Pile. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2022. [Google Scholar]

- JGJ 94-2008; Technical Specification for Building Pile Foundations. China Architecture & Building Press: Beijing, China, 2008.

- Huang, S.; Gong, W. Experimental study and finite element analysis on the bearing performance of large-diameter and ultra long piles after grouting. Rock Soil Mech. 2007, 297–301. [Google Scholar] [CrossRef]

- Huang, S.; Liu, P. Research on post grouting technology at the bottom of piles. Geol. Sci. Technol. Inf. 1999, S1, 73–75. [Google Scholar]

- Yu, X.; Pan, J.; Yang, N. Analysis of the influence of sediment at the bottom of piles and mud skin around piles on the vertical bearing capacity of large-diameter bored piles. Min. Metall. Eng. 2006, 6, 9–12. [Google Scholar]

- Zhang, Z.; Zhang, G.; Wu, Q. Experimental study on the properties of mud skin soil and soil between drilled piles. J. Geotech. Eng. 2006, 6, 695–699. [Google Scholar]

- Wang, S. Research on the Bearing Characteristics of Post Grouting of Large-Diameter and Ultra Long Bored Pile Ends. Master’s Thesis, Zhejiang University, Hangzhou, China, 2010. [Google Scholar]

- Jia, W.; Wang, L.; Li, J.; Chen, Y.; Li, T.; Huang, J. On-site clay mud modification for bored piles in a multi-layer soft ground. Constr. Build. Mater. 2024, 449, 138251. [Google Scholar] [CrossRef]

- Potyondy, J.G. Skin Friction between Various Soils and Construction Materials. Geotechnique 1961, 11, 339–353. [Google Scholar] [CrossRef]

- Yan, Y. The Influence of Pile Foundation in Lifecycle on Adjacent Existing Tunnel. Thesis, Tongji University, Shanghai, China, 2007. (In Chinese). Available online: https://kns.cnki.net/kcms2/article/abstract?v=RN_8baVbY4cUOCakC1mboQ4e2Z174dKB5mDisTNEsW633_tcSVvPtbw_HrcjOoL71dFST0cK7MD2jlDnf8kOdOFI01GFMxvAyhkgXtpboFs0h5eip8QdC3Jr7OGPEuZcmPejgvd8wh4Oby7j-iruZ4UwI_JpEjUgAYbgcrCeoOsluMJAJNGY6Q==uniplatform=NZKPTlanguage=CHS (accessed on 22 April 2025).

- Cheng, Y. Research on the Bearing Performance of the Super-Long and Large-Diameter Bored Pile. Ph.D. Thesis, Southeast University, Nanjing, China, 2005. [Google Scholar]

| (a) (MPa) | (a) (kN/m3) | (a) (kPa) | (a) (°) | Layer Thickness (m) | |

|---|---|---|---|---|---|

| Layer 1 (soft plastic to plastic silty clay) | 15 | 19.5 | 43 | 13.5 | 10 |

| Layer 2 (medium dense silt) | 25 | 19.8 | 40 | 15 | 20 |

| Layer 3 (hard plastic silty clay) | 35 | 19.7 | 43 | 13 | >50 |

| Material | Elastic Modulus (MPa) | Cohesion (kPa) | Internal Friction Angle (°) | Unit Weight (kN/m3) | Size (m) |

|---|---|---|---|---|---|

| Mud skin | 0.8(a) | 0.9(a) | 0.8(a) | 0.9(a) | Thickness: 0.25 |

| Sediment | 3 | 5 | 3 | 13 | Height: 0.2 Width: hole diameter |

| Post-grouting reinforced zone at pile bottom | 200 | 1.5(a) | 1.5(a) | 1.5(a) | Height: 2 Width: 2 |

| Test Scenario | Bearing Capacity (MN) | Settlement at Bearing Capacity (mm) |

|---|---|---|

| Ideal condition (without mud skin and sediment) | 25 | 15 |

| With mud skin only | 18 | 15 |

| With sediment only | 19 | 15 |

| Non-grouting | 16 | 15 |

| Size (Height × Width, m) | Bearing Capacity (MN) | Settlement (mm) |

|---|---|---|

| Non-grouting | 16 | 15 |

| 0.5D × 0.5D | 27.4 | 18.3 |

| 0.8D × 0.8D | 28.5 | 19.4 |

| 1.1D × 1.1D | 29 | 20 |

| 1.5D × 1.5D | 29.2 | 20 |

| Elastic Modulus (MPa) | Bearing Capacity (MN) | Settlement (mm) |

|---|---|---|

| Non-grouting | 16 | 15 |

| 50 | 26 | 18.7 |

| 100 | 28.2 | 19.5 |

| 200 | 29 | 20 |

| 300 | 29.5 | 20.2 |

| Thickness (m) | Bearing Capacity (MN) | Settlement (mm) |

|---|---|---|

| Non-grouting | 16 | 15 |

| 0.125 | 28.2 | 21.3 |

| 0.25 | 29 | 20 |

| 0.5 | 29.1 | 20 |

| 1 | 29.1 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mo, H.; Liao, H.; Guo, X.; Zhou, M. Influence of Construction-Induced Effects and Post-Grouting on the Performance of Mud-Protected Bored Piles: A Numerical Investigation. Buildings 2025, 15, 1457. https://doi.org/10.3390/buildings15091457

Mo H, Liao H, Guo X, Zhou M. Influence of Construction-Induced Effects and Post-Grouting on the Performance of Mud-Protected Bored Piles: A Numerical Investigation. Buildings. 2025; 15(9):1457. https://doi.org/10.3390/buildings15091457

Chicago/Turabian StyleMo, Hua, Haopeng Liao, Xiangfeng Guo, and Mi Zhou. 2025. "Influence of Construction-Induced Effects and Post-Grouting on the Performance of Mud-Protected Bored Piles: A Numerical Investigation" Buildings 15, no. 9: 1457. https://doi.org/10.3390/buildings15091457

APA StyleMo, H., Liao, H., Guo, X., & Zhou, M. (2025). Influence of Construction-Induced Effects and Post-Grouting on the Performance of Mud-Protected Bored Piles: A Numerical Investigation. Buildings, 15(9), 1457. https://doi.org/10.3390/buildings15091457