Abstract

In a modern-day household, the most significant part of energy consumption is space heating. In this study, the effects of connection configurations on the heat transfer from the radiator are investigated. The difference between the current study and previous studies is that all possible valve connection configurations are investigated on the radiator, instead of only having water enter through one valve and outlet through another. The experimental results of heat transfer from the radiator in all connection configurations are presented. In addition, the temperature distributions on the radiator surface for each connection configuration are visualized using a thermal camera, and remarkable findings are presented. These images provide insights into the water flow distribution in the ducts of the radiator and the effects of the distribution on heat transfer. CFD simulations were conducted to analyze temperature and flow distributions for different connection configurations and revealed that two inlets from the bottom and two outlets from the top of the panel radiator have the best case in terms of temperature distribution. This study contributes to improving energy consumption efficiency for space heating by determining the heat transfer rate from the radiator in different valve connection configurations.

1. Introduction

According to the International Energy Agency, the energy demand increased by 2.2% worldwide, and the decrease in main energy resources clearly shows how important energy efficiency is in all areas of consumption. Therefore, the decrease in main energy resources has led researchers not only to seek alternative energy resources, but also to find more efficient energy consumption methods in all areas [].

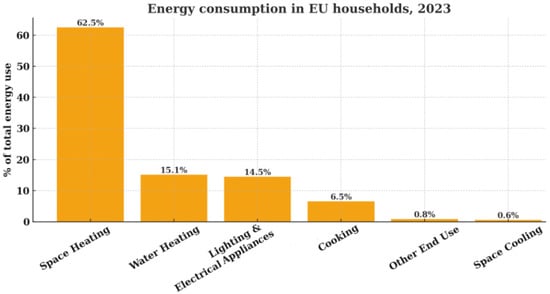

Energy consumption can be examined in sectors such as Transport, Industry, Household, Services, Agriculture and Forestry, and other sectors. If these sectors are examined according to total energy consumption in EU countries, transportation, industry, and household consumption are dominant. Household energy consumption holds 25.8% of the total energy consumed in EU countries in 2022, and 26.2% in 2023 []. Figure 1 displays the energy consumption report of Eurostat in 2023, where consumption areas in a household can be categorized into space heating, water heating, lighting and appliances, cooking, space cooling, and others. Space heating accounts for the highest rate of energy consumption in a household. In EU countries, 62.2% of the energy consumption in households in 2023 was for space heating []. These rates clearly show that the energy consumed for space heating is significant compared to other consumption areas.

Figure 1.

Energy consumption in EU households reported in the Eurostat report in 2023 [].

Aiming to increase energy efficiency in space heating and other energy consumption sectors, many studies have been carried out [,]. These improvements apply to heat sources, transport, and fitting elements in space heating systems, as well as heat emitters such as radiators []. Recent reviews showed that the panel radiators are one of the promising low-temperature heating devices in space heating that can stay up to date in the future, based on the surveyed researchers showing that the indoor air quality and thermal comfort remain improved [,].

Some recent studies focused on the heat transfer fluid used in panel radiators for cooling and space heating applications. Contreras and Filho [] added carbon nanotube nanoparticles with an ethylene glycol water mixture used in automobile radiators for cooling applications, and they showed that the heat transfer rate can be increased up to 4.6%. Çağlar [] reported that the air side heat transfer rate increased by 71% and the heat rate emission reached 45% for some cases when the Boron Nitride Water nanofluid was used on a type-11 panel radiator compared to water.

A lot of research has been done on panel radiators, which are the most widely used elements as heat emitters in space heating systems today, and increasing the energy efficiency of these radiators has been one of the most critical points for researchers. Analytical calculations, experimental studies, and CFD analysis are included in these studies [,].

For example, in the study conducted by Arslanturk and Ozguc [], an approximate analytical model was used to determine the optimum dimensions in central-heating radiator design. In this study, a radiator was considered as three separate one-dimensional fin problems. The temperature distribution on these fins and the rate of heat transfer from the radiator were analyzed analytically, and the optimum radiator geometry for maximum heat transfer was found. Thus, thermal and geometrical parameters affecting the radiator performance were presented.

Myhren and Holmberg [] analyzed the effects of different space heating methods on the thermal comfort properties of two different rooms with CFD analysis. The effects of high and medium temperature radiators on the vertical temperature gradients, air speed levels, and energy consumption in the modeled rooms were investigated.

Vosa et al. [] developed the first combined analytical model for room and radiator that can be used to directly calculate the heat transfer rate required to maintain a specific operative temperature. In this study, the efficiency of type-11 and type-22 panel radiators that were tested in a test chamber designed in accordance with EN 442-2 requirements was compared. In addition, the front and rear panel water inlet configurations were compared alongside the type-22 panel radiator in parallel and in series. Also, they evaluated the radiator performance in these two different flow directions by connecting the water inlet path to the front and rear panels in series or parallel configuration with the type-22 panel radiator.

Embaye et al. [] studied radiator flow pulsation to conserve energy without compromising the threshold of thermal comfort as defined by ASHRAE Standard 55 and EN ISO7730 [,,]. CFD modeling of the fixed and pulsed flow radiators was carried out and validated with published data, and then a CFD analysis of a room with these radiators was performed. Based on the results of this analysis, indoor spatial temperature and velocity distributions were investigated under both constant and pulsed flow conditions. As for the pulsed flow CFD simulations performed at different frequencies and flow rates, improvements were observed in heat transfer, indicating that pump power could be saved in pulsed flow compared to constant flow.

Aydar and Ekmekci [] obtained the thermal efficiency of a type-22 panel radiator with the Star-CCM+ CFD code for TBOE (top-bottom-opposite-end) and TBSE (top-bottom-same-end) connections. Thermal analyses were compared with commercial catalog values, and mass flow rate distributions in radiator channels for both connection configurations were examined in contrast.

In the study by Jančík and Bašta [], temperature patterns of two radiators connected to the BBOE (bottom-bottom-opposite-end) and TBOE were obtained by thermal imaging and compared over time. In addition, in this study, three different theoretical models derived from the energy balance equation and simulated in Matlab/Simulink were compared with the time-dependent experimental results.

In another study, Jančík and Bašta [] compared surface temperature patterns by using an infrared camera with two different inlet temperatures and various flow rates for the TBOE connection type-10 radiator.

Çalışır et al. [] investigated experimental heat transfer of the PCCP (panel-convector-convector-panel) radiator for TBSE, TBOE, and BBOE connection positions with different inlet temperatures and different flow rates.

In another study, Çalışır et al. [] investigated the heat transfer from the PCCP radiator in TBOE, TBSE, and BBOE connection configurations, not only experimentally, but also by performing a CFD analysis. Using CFD analysis, they examined the effects of water distribution within the water channels on the heat transfer from the radiator.

The presented study differs from others in that it aims to investigate heat transfer from a type-22, PCCP radiator not only with a single inlet and single outlet but also with all connection configurations. In this sense, experimental measurements were carried out for all combinations of connection configurations for the inlet and outlet, such as single, double, or triple; bottom or top; same or opposite. In addition, all combinations were visualized with a thermal camera to obtain the temperature distribution of the radiator surface, and the remarkable ones were identified. Those identified are then also investigated with the CFD technique to further understand flow and temperature distributions. In terms of results, the aim is to determine the most appropriate connection configuration to obtain the highest heat transfer from the radiator.

2. Method

The methodology of the present study involves both experimental and numerical investigations. Details are provided regarding the experimental setup, the measuring instruments employed, and the procedure used for data acquisition. Additionally, the numerical method used to further analyze the temperature distribution and flow patterns within the radiator is explained.

2.1. Experimental Study

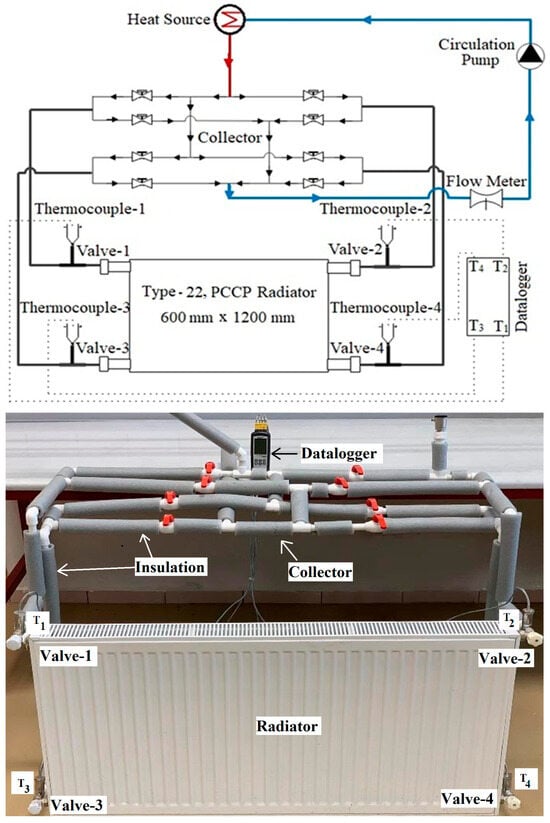

The experimental setup to determine the heat transfer from the type-22, PCCP radiator (Warmhaus, Bursa, Türkiye) (height: 600 mm–width: 1200 mm) is shown in Figure 2.

Figure 2.

Experimental setup.

Except for symmetrical conditions for inlet and outlet connections, 26 different connections were determined by considering all possibilities, such as single, double, or triple; bottom or top; same or opposite. The collector shown in Figure 2 was designed to enable experimentation with a total of 26 connection configurations. In this collector, it is observed that the hot water main line coming from the heat source is separated into four inner lines, and the cold water main line, which is the return line to the heat source, joins them. With this collector consisting of two main lines and eight internal lines, hot water from the heat source can be sent to and received from all four valves connected to the radiator at the same time. Therefore, with the valves on the designed collector, the water is easily directed to the valves connected to the radiator, eliminating the need to assemble different experimental setups for all connection configurations.

Each valve has a connection to the designed collector and the radiator through a three-way connector. Type-K immersion thermocouples are connected to the other end of these three-way connectors, which are placed between each valve and the collector. Thermocouples are connected to the Geratech DT-3891G data logger (Geratech, Shenzhen, China) with 0.1C resolution. These thermocouples measure the radiator inlet and outlet water temperature with an accuracy of ±0.75% according to ASTM E230-ANSI MC 96.1 [].

All immersion-type thermocouples are also linked to the data logger, so that the temperature of the water flowing through all the valves connected to the radiator can be obtained simultaneously. The water flow rate in the circuit is determined by the ultrasonic flow meter (RST TUF-2000H, Dimens, Hangzhou, China) with an accuracy of ±1% on the main line of the return to the heat source.

The experiments were carried out in a room conditioned at 20 °C, and the room temperature was controlled with a thermometer positioned in the center of the room, 0.75 m above the floor. Meanwhile, the radiator was positioned 0.11 m above the floor and 0.05 m between the back surface and the wall. These conditions were determined in accordance with EN 442-2 (British Standards 2014) [], and all experiments were carried out in steady state for 30 min as defined in this standard.

In each experiment, the inlet water to the radiator was heated to 45–50 °C by a heat source, and the total mass flow rate in the circuit was kept constant at 0.022 kg/s. Moreover, for each experiment, the radiator surface temperature distribution was visualized by a thermal camera. The governing equation used to calculate the heat transfer from the radiator for each connection configuration is Equation (2) derived from Equation (1). The data obtained in the experimental setup are used in Equation (2).

In this equation, shows the heat transfer from the radiator, [W], shows the mass flow rate measured by the ultrasonic flow meter on the return line of the water leaving the radiator to return the heat source, [kg/s], and shows the specific heat of water which is assumed constant 4180 J/kg.°C at 45 °C []. , the mean temperatures, calculated with Equation (3), show the mean of temperatures measured by thermocouples immersed in valves that provide water inlet to the radiator [°C]. Also, calculated with Equation (4) shows the mean of temperatures measured by thermocouples immersed in valves that provide water outlet from the radiator [°C].

In these equations, shows the inlet water temperature measured by the thermocouples immersed in the valves that provide water inlet to the radiator [°C], and shows the outlet water temperature measured by the thermocouples immersed in the valves that provide water outlet from the radiator [°C]. Note that the valves that provide water inlet to the radiator and water outlet from the radiator are different in each connection configuration. Experimental uncertainty is calculated using Equation (5) [].

where R is the calculated value using xi, which are directly measured quantities. In this equation is the uncertainty of R and are uncertainty of . This experimental uncertainty applies to Equation (2), therefore R = , The experimental uncertainty of the ultrasonic flow meter and thermocouples is given as 1% and 0.75%, respectively. The maximum value of the experimental uncertainty among 26 different experiments was calculated as (wQ/Q)max = 1.80%. An experimental study expanded with a thermal camera FLIR Systems ThermaCAM P25 with %2 temperature measurement sensitivity []. The measurement of thermal cameras was obtained by placing the camera in front of the panel radiator. The emissivity of the panel radiator surface is assumed as 0.05 according to the previous works [,].

2.2. Numerical Study

The numerical approach used in the present study includes CFD techniques and a mathematical model composed of a set of governing equations, which are the conservation of mass, momentum, and energy equations. The assumptions are (1) the problem is in steady state as described in the experimental study, (2) constant thermophysical properties for water, (3) turbulent flow, (4) flow is not compressible, and (5) there is no heat generation. The conservation of mass and momentum equations are given by Equations (6) and (7).

Here, ρ is density, u is velocity, p is pressure, μ is viscosity, δ is Kronecker delta, xi is coordinate direction, and is momentum source terms. In addition, is the Reynold stress term obtained through turbulence modeling with the chosen k- turbulence model for the present numerical approach. The conservation of energy equation is given by Equation (8).

where T is Temperature, is specific heat, and k is the thermal conductivity. The numerical approach used in the solution of the governing Equations (6)–(8) was the Finite Volume Method. This method is applied using the commercial software ANSYS Fluent 2023 R2. The coupling between conservation of momentum and mass equations is performed using a coupled linkage algorithm between velocity and pressure. Second-order Upwind differencing is used for the momentum equations for the conservation of energy equation. Convergence criteria set to for all the variables in the governing equations.

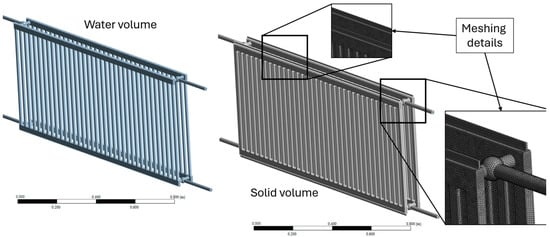

Figure 3 displays the geometric model suitable for CFD analysis. The water volume shows the extracted flow path of water that flows through the panel radiator, and the solid volume corresponds metal radiator surfaces.

Figure 3.

Extracted water volume, solid volume, and meshing details.

The boundary conditions of the specified problem are velocity inlet and pressure outlet for the valve inlet and outlet, respectively. The boundary condition for the energy equation is defined with a free convection heat transfer coefficient is calculated as h∞ = 3.5 W/m2K using Equation (9) [].

In this equation, Pr is the dimensionless Prandtl number, is the dimensionless Grashof number, where g is gravity, is the thermal expansion coefficient, is the surface temperature of the panel radiator, is ambient temperature, is characteristic length, and kinematic viscosity.

3. Results and Discussions

3.1. Experimental Results

The data obtained from the experiments for 26 different connection configurations are shown in Table 1, and these connection configurations are indicated as C1–C26. In this table, for each connection configuration, the valves that provide water inlet to the radiator, the valves that provide water outlet from the radiator, the water temperatures measured with thermocouples immersed in these valves, and the total mass flow rate in the circuit, which is measured with an ultrasonic flow meter, are shown. In addition, the heat transfer from the radiator, calculated using these data in Equation (2) for each connection configuration, is also shown in this table.

Table 1.

Experimental data.

In the connection configurations where the water inlet to the radiator is through one valve, the water outlet from the radiator is through one valve in C1–C6, two valves in C7–C12, and three valves in C13–C14.

In the connection configurations where the water inlet to the radiator is through two valves, the water outlet from the radiator is through one valve in C15–C20, and two valves in C21–C24.

In C25–C26, water inlet to the radiator is through three valves, and water outlet from the radiator is through one valve.

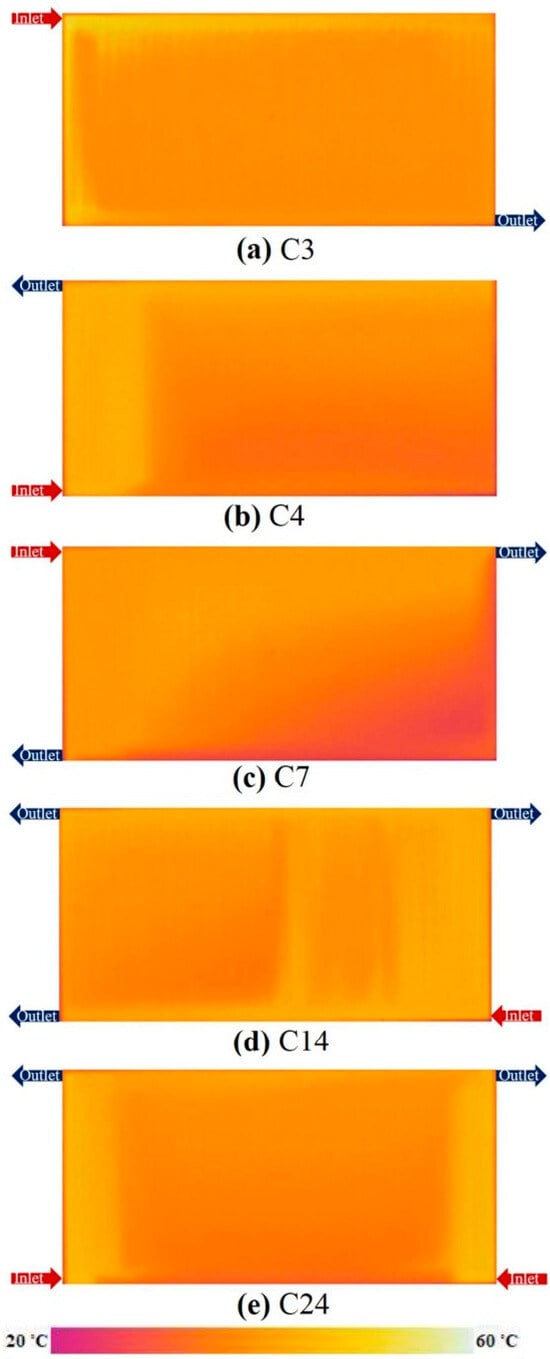

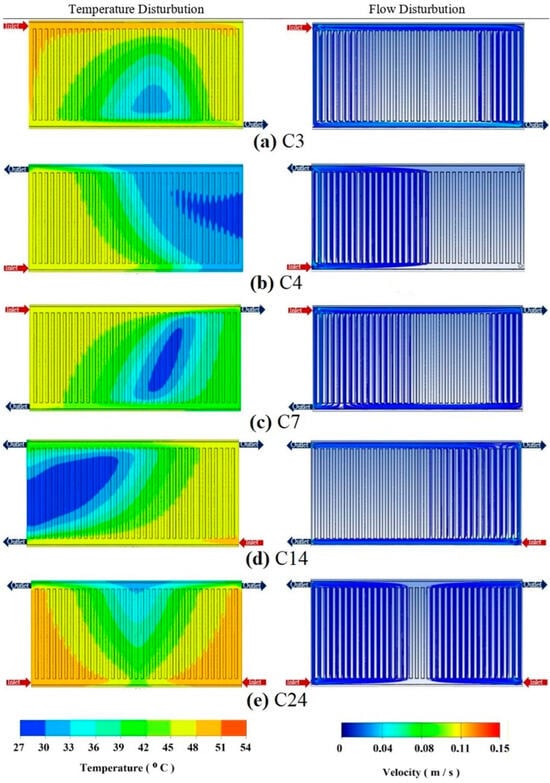

Some remarkable images of the radiator surface temperature distribution visualized by a thermal camera are presented in Figure 4a–e.

Figure 4.

Experimental temperature distribution on the radiator surface (a) in C3, (b) in C4, (c) in C7, (d) in C14, and (e) in C24.

The data in Table 1 showing the heat transfer obtained from the radiator in different connection configurations is discussed in this section.

When the heat transfer from the radiator is investigated in the connection configurations where the water inlet and outlet are through a single valve, it is observed that the highest heat transfer was obtained from C3. On the other hand, the lowest heat transfer was obtained from the C4. In addition, the water entering the radiator comes from the same valve in some connection configurations, as seen in C1, C2, and C3. It has been determined that the lowest heat transfer occurred in C1 compared to the other configurations, where the water outlet is provided by the valve connected to the top of the radiator. Moreover, if C4, C5, and C6, with the same water inlet valve, are compared, it is evident that the highest heat transfer from the radiator occurs in C6, in which the water outlet from the radiator is provided by the valve connected to the bottom of the radiator.

The highest heat transfer was achieved by C8 in connection configurations where the water inlet to the radiator is through a valve and the water outlet is through two valves. The lowest heat transfer was obtained from C10. If C7, C7 C8, and C9, which have the same valve as the water inlet to the radiator, and C9 which the water inlet to the radiator is from the same valve are compared among themselves, it is seen that the highest heat transfer from the radiator was obtained in C8. In this connection configuration, both valves that provide water outlets from the radiator are connected to the bottom of the radiator. Furthermore, if the C10, C11, and C12, where the water inlet to the radiator is from the same valve, are compared among themselves, it is seen that the lowest heat transfer from the radiator was obtained in C10. In this connection configuration, it should be noted that both valves that provide water outlets from the radiator are connected to the top of the radiator.

If the heat transfers from the radiator are compared in C13 and C14, the amount obtained in C13 was higher. In C14, the water inlet to the radiator is through a valve, and the water outlet from the radiator is through three valves. In C13, the water inlet is provided by a valve connected to the top of the radiator, while in C14, it is connected to the bottom of the radiator. Hence, in C13, the water outlet is provided by the two valves connected to the bottom of the radiator. In C14, the water outlet consists of a single valve at the bottom, and the other valve at the bottom serves as the water inlet into the radiator. This difference leads to higher heat transfer from the radiator in C13.

The heat transfer from the radiator is examined in connection configurations where the water inlet to the radiator is from two valves, and the water outlet is from one valve. It is seen that the highest heat transfer was obtained in C15. In this connection configuration, two valves at the top provide the water inlet to the radiator, and one valve at the bottom provides the water outlet. In C16, the connection is the exact opposite. It is determined that when comparing the heat transfer from the radiator in these two connection configurations, which are symmetrical to each other on the horizontal axis, the heat transfer from the radiator in C16 was less than one-third of that from C15. If the C17 and C18 wherein the water inlets to the radiator are from the same valves are compared, it is seen that the highest heat transfer from the radiator was obtained in C18. It should be noted that the valve that provides water outlet from the radiator is connected to the top of the radiator in C17 and to the bottom of the radiator in C18. Also, if C19 and C20, in which the water inlets to the radiator are from the same valves, are compared among themselves, it is seen that the highest heat transfer from the radiator was obtained in C20. In this comparison, it is clear that more heat transfer was obtained from the radiator in C20, where the valve providing the water outlet from the radiator is connected to the bottom of the radiator.

In the connection configurations in which the water inlet to the radiator is through two valves and the water outlet from the radiator is through two valves, it is evident that the highest heat transfer was obtained from C21. In this connection configuration, the valves, which provide water inlets and outlets, are positioned in a crosswise manner. In C22, another configuration of connection is considered where the water inlet to the radiator is via valves connected to both the bottom and top of the radiator on one side, and the water outlet is via valves on the opposite side of the radiator. In C22, the heat transfer from the radiator was approximately fifty percent of that in C21. In C23, water flows into the radiator from both valves connected at the top, and flows out from both valves connected at the bottom. Meanwhile, in C24, the connection is the symmetry of C23 on the horizontal axis. When comparing the heat transfer from the radiator in these two symmetrical connection configurations, it is noteworthy that much higher heat transfer was obtained in the C23, where the water outlet is from the valves connected to the bottom of the radiator.

Finally, when comparing heat transfer from the radiator in C25 and C26, which are two connection configurations where the water inlet to the radiator is through three valves and the water outlet from the radiator is through one valve, much higher heat transfer was obtained in C25. In C25, the water outlet from the radiator is provided from the valve connected to the bottom of the radiator.

Some of the remarkable images showing the temperature distribution on the radiator surface obtained by the thermal camera are examined in this section. In addition, these images exhibited in Figure 4 give clues about the flow distribution in the ducts of the radiator.

For example, in C3 where the highest heat transfer was obtained from the radiator, the temperature distribution is quite uniform as seen in Figure 4a, which shows the temperature distribution on the radiator surface. On the contrary, Figure 4b, which shows the temperature distribution on the radiator surface in C4, does not indicate a uniform temperature distribution and reveals that the temperature is higher on the side of the radiator where valve-1 and valve-3 are connected. Considering that the water inlet to the radiator is through valve-3 and the water outlet is through valve-1 connected to the top on the same side of the radiator in C4, it can be said that water flow was limited in the vertical ducts far from this side of the radiator, favoring ducts near this side. The non-uniform flow distribution in the vertical ducts caused the non-uniform temperature distribution on the radiator surface, and this led to less heat transfer from the radiator, as shown in Table 1.

Another remarkable image is seen in Figure 4c, which shows the temperature distribution on the radiator surface in C7. The radiator surface temperature around valve four is quite low. In this connection configuration, water is supplied to the radiator through valve-1, and the water outlet from the radiator is through valve-2 and valve-3. Therefore, no water passes through valve-4. Therefore, it can be concluded that the water flow in the ducts around valve-4, which was closed to flow, was significantly limited.

In Figure 4d, the temperature distribution on the radiator surface in C14 is shown, where the water inlet to the radiator is from valve-4, whereas the outlet is through valve-1, valve-2, and valve-3. In this figure, temperature differences on horizontal and vertical duct surfaces show that the water reached valve-2 through the vertical ducts close to valve-4, where the water inlet to the radiator is provided, and it also reached valve-3 through the horizontal duct near valve-4. On the other hand, water flow was insufficient in vertical ducts close to valve 1. In other words, the water outlet from valve-1 was less than that from the other valves.

Lastly, the temperature distribution on the radiator surface in C24 is shown in Figure 4e. In this figure, it is seen that the temperature is higher on several vertical duct surfaces close to the valves, on both edge sides of the radiator, compared to the central vertical duct surfaces. Considering that the water inlet to the radiator is from valve-3 and valve-4, connected to the bottom of the radiator, and the water outlet from the radiator is from valve-1 and valve-2, connected to the top of the radiator, it can be said that the water supplied to the radiator through valve-3 mostly left the radiator through valve-1, which is connected to the top of the radiator on the same side as valve-3. Likewise, it can be thought that the water supplied to the radiator through valve-4 mostly leaves the radiator through valve-2, which is connected to the top of the radiator on the same side as valve-4.

3.2. CFD Results

Figure 5

displays the numerical results obtained by the CFD solution. CFD results showed detailed information about temperature and flow distribution in the radiator. The temperature distribution remarkably changes depending on the inlet and outlet positioning. In C3, the flow distribution showed that most of the flow rates traverse the top and bottom borderlines and the left and right sides of the radiator. In C4, there are regions of nearly zero velocity for the left half of the radiator. In C7, there are regions of nearly zero velocity, but most of the radiator’s inner lines have flow. In C24, the figure shows that there are two flow trends: one between the left side inlet and outlet couple, and one between the right side inlet and outlet.

Figure 5.

CFD results for (a) C3, (b) C4, (c) C7, (d) C14, and (e) C24.

In C3, the flow predominantly follows the top and bottom borders as well as the left and right edges of the radiator, while a near-zero-velocity region is observed in the central area. In C4, near-zero-velocity zones are present across the entire right half of the radiator, indicating limited convective activity in that region. In C7, although some near-zero-velocity regions exist, a significant portion of the radiator’s inner section still maintains active flow. In C14, the flow tends to follow the top and left borders, with a near-zero-velocity region appearing on the left side of the radiator. In C24, the results reveal two distinct flow patterns: one between the left side inlet and outlet pair, and another between the corresponding pair on the right side. When comparing those connection configurations, it is seen that the C4 has the most areas with colder temperatures compared to the other connection configurations. This can be explained by examining the flow distribution: in C4, there are zero-velocity regions starting from the center and extending toward the right side of the radiator. Those cold regions are inactive in terms of convection heat transfer from hot water to radiator surfaces; therefore, half of the radiator is only heated by heat conduction from hot water to radiator surfaces far from the inlet/outlet. Similarly, when inspecting C24, there is a zero-velocity region in the middle of the radiator, in which the lowest temperatures are seen. In C3 and C7, there are zero-velocity regions, and their effect on the temperature distribution is not as severe as C4.

Table 2 presents the outlet water temperatures obtained from the CFD analysis results for each configuration, where the water inlet temperatures to the radiator are kept identical to the experimental conditions. This table also includes a comparison of the radiator water outlet temperatures obtained from CFD analyses for each configuration with the water outlet temperatures obtained from the experiments presented in Table 1.

Table 2.

CFD-water outlet temperature.

4. Conclusions

This study aims to experimentally determine the heat transfer obtained from a PCCP radiator operated with different connection configurations and to compare them to identify the most efficient result. Except for the symmetrical configurations, in all of the possible 26 different connection configurations, not only are the heat transfers from the radiator determined, but also thermal images showing the temperature distribution on the radiator surface are obtained. The remarkable cases are further analyzed. By visualizing the temperature distributions on the radiator surface, the effects of the connection configuration on the distribution of water flow within the horizontal and vertical ducts in the radiator are observed.

Among all connection configurations, the highest heat transfer from the radiator is obtained in C3. In this connection configuration, water inlet to the radiator was provided from valve-1, and water outlet from the radiator was provided from valve-4. This configuration is called TBOE. In addition, in C3, it is determined that the temperature distribution on the radiator surface is almost completely uniform. For connection configurations with low heat transfer from the radiator, the temperature distribution on the radiator surface is non-uniform.

The non-uniform temperature distribution on the radiator surface can be explained by limited flow in some radiator ducts. The low heat obtained from the radiator in these connection configurations is due to the surface area of the radiator used for heat transfer from the hot water to the ambient, being small compared to the connection configurations that have a uniform temperature distribution on the radiator surface. The uniform distribution of the water flow in the radiator ducts enables more effective use of the radiator surface area for heat transfer from the radiator to the ambient.

Another conclusion of the study is that when comparing heat transfer from the radiator by connection configurations, where the water inlets are from the same location, the heat transfer is higher in connection configurations with their water outlets through valves connected to the bottom of the radiator. This conclusion is recognized not only for the connection configurations, in which the water inlet to the radiator is through the same valves, but also for similar connection configurations, as in C25 and C26.

CFD results provided remarkable insights into understanding the relation between temperature and flow distribution in the radiator geometry. Among the evaluated connection configurations, C4 exhibited the most unfavorable thermal performance due to extensive zero-velocity regions, leading to large cold zones and inefficient convective heat transfer. In contrast, C3 and C7 also showed zero-velocity areas, but their impact on temperature distribution was less severe. These findings highlight the importance of an optimal connection configuration to ensure uniform flow and effective heat transfer throughout the radiator.

When the outlet water temperatures obtained from the CFD analysis and the experimental measurements are compared, the results are found to be consistent with each other. Compared to the experimental results, the highest deviation in the CFD analyses is observed in the C14 configuration at Valve-1, while another notable deviation is identified in the C7 configuration at Valve-2. It has been determined that these valves are located near the radiator ducts, where the flow velocity is very low or nearly zero, which has caused the deviation observed in the CFD analysis results.

Further studies are recommended to perform CFD analysis with the experimental conditions in this study in order to obtain more detailed and accurate data about the flow of water in the radiator ducts. In addition, it is recommended to investigate the effect of the connection configurations on the heat output and the temperature distribution on the radiator surface, focusing on radiators of different sizes than the one included in this study. Thus, the effect of the radiator size on the results can be discussed.

Author Contributions

Conceptualization, O.K.; methodology, O.K.; validation, M.C.Ö.; investigation, M.C.Ö.; data curation, O.K.; writing—original draft preparation, O.K.; writing—review and editing, O.K. and K.S.Y.; supervision, K.S.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been supported by Kocaeli University Scientific Research Projects Coordination Unit grant number #4764 and The APC was funded by Kocaeli University Scientific Research Projects Coordination Unit.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| BBOE | bottom–bottom-opposite-end |

| Thermal expansion coeff. [1/K] | |

| CFD | Computational Fluid Dynamics |

| cp | Specific heat of water [J/kg.°C] |

| C | Connection configuration |

| Temperature difference [°C] | |

| E | Energy [J] |

| EN | European Norm |

| EU | European Union |

| ith gravity [m/s2] | |

| Gr | Grashof number |

| h∞ | Convection coefficient [W/m2 °C] |

| k | Thermal conductivity [W/m °C] |

| m | mass [kg] |

| mass flow rate [kg/s] | |

| ν | Kinematic viscosity [m2/s] |

| Gradient operator [1/m] | |

| PCCP | Panel-Convector-Convector-Panel |

| Pr | Prandtl number |

| ρ | Density of water [kg/m3] |

| heat transfer from radiator [W] | |

| T | temperature [°C] |

| mean of inlet water temperatures [°C] | |

| mean of outlet water temperatures [°C] | |

| inlet water temperature [°C] | |

| outlet water temperature [°C] | |

| TBOE | top-bottom-opposite-end |

| TBSE | top-bottom-same-end |

| ith velocity component [m/s] |

References

- IEA. International Energy Agency—Global Energy Review. 2025. Available online: https://www.iea.org/reports/global-energy-review-2025 (accessed on 28 July 2025).

- European Union. European Commission, Eurostat, Energy Consumption in Households, Publication Office of the European Union. 2023. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Energy_consumption_in_households (accessed on 14 June 2025).

- Zhu, X.; Jamal, A.S.; Zhang, M.; Liu, B.; Shi, J. Energy consumption, carbon emissions and cost analysis of accelerated curing: A case study of hybrid alkali-activated cement. Renew. Sustain. Energy Rev. 2024, 210, 115206. [Google Scholar] [CrossRef]

- Cai, W.; Bu, K.; Zha, L.; Zhang, J.; Lai, D.; Bao, H. Energy consumption of plant factory with artificial light: Challenges and opportunities. Renew. Sustain. Energy Rev. 2024, 210, 115235. [Google Scholar] [CrossRef]

- Wang, S.; de Souza, C.B.; Golubchikov, O. Recent advances in decarbonising heating in rural China: A review. Renew. Sustain. Energy Rev. 2024, 210, 115282. [Google Scholar] [CrossRef]

- Puttige, A.R.; Feng, K.; Lu, W.; Olofsson, T. Are radiators ready for the challenges of the future: A review of advancements in radiators. E3S Web Conf. 2022, 356, 03024. [Google Scholar] [CrossRef]

- Hooshmand, S.M.; Zhang, H.; Javidanfar, H.; Zhai, Y.; Wagner, A. A review of local radiant heating systems and their effects on thermal comfort and sensation. Energy Build. 2023, 296, 113331. [Google Scholar] [CrossRef]

- Cardenas Contreras, E.M.; Bandarra Filho, E.P. Heat transfer performance of an automotive radiator with MWCNT nanofluid cooling in a high operating temperature range. Appl. Therm. Eng. 2022, 207, 118149. [Google Scholar] [CrossRef]

- Çağlar, A. Effects of using BN/water nanofluid on the thermal performance, energy saving, and power consumption of a panel radiator heating system. Case Stud. Therm. Eng. 2025, 69, 106024. [Google Scholar] [CrossRef]

- Calisir, T.; Baskaya, S. The influence of different geometrical dimensions of convectors on the heat transfer from panel radiators. SN Appl. Sci. 2021, 3, 284. [Google Scholar] [CrossRef]

- Gelis, K.; Akyurek, E.F. Entropy generation of different panel radiator types: Design of experiments using response surface methodology (RSM). J. Build. Eng. 2021, 41, 102369. [Google Scholar] [CrossRef]

- Arslanturk, C.; Ozguc, A.F. Optimization of a central-heating radiator. Appl. Energy 2006, 83, 1190–1197. [Google Scholar] [CrossRef]

- Myhren, J.A.; Holmberg, S. Flow patterns and thermal comfort in a room with panel, floor and wall heating. Energy Build. 2008, 40, 524–536. [Google Scholar] [CrossRef]

- Võsa, K.V.; Ferrantelli, A.; Kurnitski, J. A combined analytical model for increasing the accuracy of heat emission predictions in rooms heated by radiators. J. Build. Eng. 2019, 23, 291–300. [Google Scholar] [CrossRef]

- Embaye, M.; Al-Dadah, R.K.; Mahmoud, S. Numerical evaluation of indoor thermal comfort and energy saving by operating the heating panel radiator at different flow strategies. Energy Build. 2016, 121, 298–308. [Google Scholar] [CrossRef]

- ISO 2005 ISO 7730:2005; Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. Ergonomics of the Thermal Environment; International Organization for Standardization: Geneva, Switzerland, 2005.

- ASHRE. 2005 Ashrae Handbook Fundamentals I-P Edition Supported by ASHRAE Research. 2005. Available online: http://www.ashrae.org (accessed on 14 June 2025).

- ASHRAE/ANSI Standard 55-2010; Thermal Environmental Conditions for Human Occupancy. ASHRAE: Peachtree Corners, GA, USA, 2010.

- Aydar, E.; Ekmekci, I. Thermal efficiency estimation of the panel type radiators with CFD analysis. Isı Bilim. Tek. Derg. 2012, 32, 63–71. [Google Scholar]

- Jančík, L.; Bašta, J. Dynamic behavior of panel radiators—Thermographic investigation and computer modeling of heat-up. EPJ Web Conf. 2012, 25, 02008. [Google Scholar] [CrossRef]

- Jančík, L.; Bašta, J. Fluid flow in panel radiator under various conditions—Thermographic visualisation. EPJ Web Conf. 2012, 25, 01031. [Google Scholar] [CrossRef]

- Calisir, T.; Baskaya, S.; Yazar, H.O.; Yucedag, S. Experimental investigation of panel radiator heat output enhancement for efficient thermal use under actual operating conditions. EPJ Web Conf. 2015, 92, 02010. [Google Scholar] [CrossRef]

- Calisir, T.; Yazar, H.O.; Baskaya, S. Determination of the effects of different inlet-outlet locations and temperatures on PCCP panel radiator heat transfer and fluid flow characteristics. Int. J. Therm. Sci. 2017, 121, 322–335. [Google Scholar] [CrossRef]

- ASTM E230-ANSI MC 96.1; The American Society for Testing and Materials (ASTM) E230 Standard. ASTM: West Conshohocken, PA, USA, 1982.

- EN 442-2:2014; Radiators and Convectors—Part 2: Test Methods and Rating. European Committee for Standardization: Brussels, Belgium, 2014.

- Holman, J.P. Experimental Methods for Engineers; McGraw-Hill College: Columbus, OH, USA, 2012; p. 739. [Google Scholar]

- FLIR. ThermaCAMTM P50F and P25F? Data-Sheet. Available online: https://www.flir.com/en-eu/support-center/instruments2/what-are-the-key-features-of-thermacam-p50f-and-p25f/ (accessed on 27 October 2025).

- Shati, A.K.A.; Blakey, S.G.; Beck, S.B.M. The effect of surface roughness and emissivity on radiator output. Energy Build. 2011, 43, 400–406. [Google Scholar] [CrossRef]

- Beck, S.B.M.; Blakey, S.G.; Chung, M.C. The effect of wall emissivity on radiator heat output. Build. Serv. Eng. Res. Technol. 2001, 22, 185–194. [Google Scholar] [CrossRef]

- Holman, J.P. Heat Transfer, 10th ed.; McGraw-Hill Book Company: London, UK, 1992; p. 268. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).