Abstract

Expanded polystyrene (EPS), a lightweight thermoplastic polymer widely used in packaging and insulation, has become a growing environmental concern due to its non-biodegradable nature and escalating global consumption. Although EPS waste shows potential in construction applications, previous studies have primarily incorporated it into mortars, concrete, or soil–cement mixtures, often relying on the addition of cement to improve its mechanical performance. This approach compromises sustainability and has generally overlooked the role of microstructural interactions in the behavior of soil–EPS waste mixes without cement. This study differs from prior works by exploring the mechanical and microstructural properties of soil–EPS waste mixtures without cementitious binders under different compaction energies. Experimental tests were carried out for the technical characterization of soils, ground EPS waste, and mixtures of soil and different contents of EPS waste (0%, 20%, 30%, and 40% of the total apparent volume of the composite), using different compaction energies (Intermediate and Modified Proctor). The mixtures were subjected to Unconfined Compressive Strength (UCS), California Bearing Ratio (CBR), and direct shear strength tests, in addition to physical and microstructural characterization. The results indicated that both soil type and compaction energy influenced the engineering behavior of the mixtures. The clayey soil exhibited superior mechanical performance, while the sandy soil showed reductions in all mechanical properties. The UCS values of the clayey soil with the addition of EPS did not change significantly (297 kPa to 286 kPa at intermediate energy and 514 kPa to 505 kPa at modified energy), while for the sandy soil, there was a decrease in values (from 167 kPa to 46 kPa at intermediate energy and from 291 kPa to 104 kPa at modified energy). In the CBR tests, only the 20% and 30% addition of EPS to the clayey soil, using the Modified Proctor energy, showed an increase (from 18% to 20% for both percentages). This behavior was primarily attributed to adhesion mechanisms at the soil–EPS waste interface, with friction playing a secondary role, thereby suggesting that clayey soils may offer better mechanical response. The lower dry density of these mixtures compared to compacted natural soils presents a technical benefit for use as backfill in areas with low bearing capacity, where minimizing the load from the fill material is critical.

1. Introduction

Expanded polystyrene (EPS) is a lightweight thermoplastic polymer derived from petroleum, composed mainly of styrene expanded with pentane gas. In mass terms, EPS granules consist of approximately 98% air and 2% raw material [1]. It is chemically inert, non-toxic, and characterized by low density, hydrophobic behavior, and high resistance to chemical agents [2,3]. EPS and extruded polystyrene (XPS) are widely used in construction, mainly as insulation materials and lightweight fills, mainly due to their low density, which is about 100 times lower than that of natural soils [4,5].

The global consumption of EPS reached around 7 million tons in 2019 and is expected to increase to 8.5 million tons by 2025 [6]. The large volume of EPS waste, mainly from packaging and household appliances, represents a major environmental concern due to its non-biodegradable nature and visual impact on urban environments [7,8]. Recycling strategies have been developed to mitigate this problem, including mechanical recycling, in which EPS is ground into small beads or larger granules [9].

Some researchers have studied the behavior of soil–EPS mixtures in different applications and test scenarios [6,10,11,12,13,14,15,16,17,18,19]. These studies have mainly combined soil and EPS with cement or other cementitious binders to impart structural stability to the composite, as cement acts as a binding agent that promotes adhesion between the soil particles and EPS grains, resulting in a more rigid and mechanically resistant matrix. For example, Nobari et al. [20] observed that increasing the cement content by 4–6%, along with increasing the EPS beads up to 10% in volume, significantly enhances the compressive strength and shear modulus of soils. Abdelrahman [21] and Gao et al. [22] evaluated soil–EPS mixtures stabilized with cement and found that cement increased strength and stiffness but compromised the environmental sustainability of the composites due to the high environmental footprint associated with cement production.

In contrast, Silveira et al. [23] and Abdelrahman et al. [24] investigated uncemented soil–EPS waste mixtures and reported varied mechanical performances, depending on soil type, EPS density, and compaction effort. Haseeb et al. [25] demonstrated that clay mixtures treated with shredded EPS exhibit a substantial weight reduction (up to 22%), making them well-suited for lightweight fill applications. Moreover, Öztürk [6] verified that the incorporation of distinct sizes of EPS influences the mechanical behavior of lightweight soils; while both sizes reduced dry density, the finer EPS yielded higher Unconfined Compressive Strength than the coarser EPS under equivalent content levels. From an environmental perspective, Monkul and Özhan [26] discussed the potential role of solid waste disposal facilities as sources of microplastics by examining their geotechnical properties and assessing the risk of microplastic migration from landfills into surrounding soils.

Despite these contributions, previous research has generally quantified engineering properties without examining the microstructural mechanisms responsible for strength development. While most previous studies focused on cement-stabilized soil–EPS waste mixtures, few have systematically examined the combined effects of EPS content, soil type, and compaction energy on the mechanical and microstructural behavior of uncemented composites. This represents a relevant research gap, particularly in terms of sustainable applications in tropical regions. The present study aims to fill this gap by investigating the mechanical and microstructural behavior of tropical soils mixed with milled EPS waste under different compaction energies. The research is motivated both by environmental concerns, regarding reducing EPS disposal and the use of non-renewable soils, and by scientific interest in understanding particle-level interactions within soil–EPS waste mixtures, which are objectives in line with Sustainable Development Goals (SDGs) 9 (Industry, innovation and infrastructure), 11 (Sustainable cities and communities) and 12 (Responsible consumption and production) [27].

This study attempts to explain the mechanisms of interaction between the soil particles and the EPS waste, responsible for mobilizing the strength of the mixture in each of the test modalities included in the experimental program.

The specific objectives of this study are as follows:

- To evaluate the influence of EPS content, soil type, and compaction energy on the mechanical behavior of soil–EPS waste mixtures through UCS, CBR, and direct shear tests;

- To analyze the microstructural mechanisms governing the mechanical response using microscopy techniques;

- To assess the potential of soil–EPS waste mixtures as sustainable materials for geotechnical and pavement applications.

2. Materials and Methods

2.1. Materials

2.1.1. Soils

The soil samples used in this research were collected from two borrow sites (young residual gneiss soil, called Vila Secundino soil, and mature residual gneiss soil, called BR-120 soil). Both soils represent, respectively, the horizons C and B of the weathering profiles of the respective borrow sites.

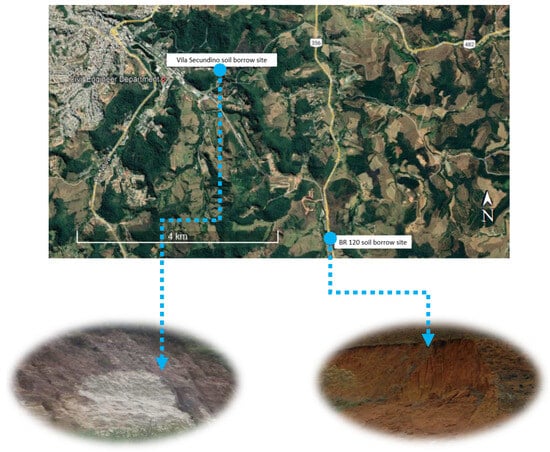

The borrow sites where the soil samples were collected are located in the micro-region of Viçosa, in the Zona da Mata region, state of Minas Gerais (MG), Brazil, with coordinates 20°45′48″ S; 42°51′29.50″ W and 20°47′30″ S; 42°50′17.50″ W, respectively (Figure 1).

Figure 1.

Location and details of the soil borrow sites selected to collect the soils.

These soil samples were collected following the recommendations of PRO 003 [28]. They were stored and transported in properly sealed plastic bags. The procedures for reducing and preparing the soil samples for the tests followed, respectively, the guidelines provided by the technical standards NBR 16915 [29] and NBR 6457 [30].

The tests carried out to geotechnically characterize the soils were as follows:

- Particle size analysis, according to NBR 7181 [31];

- Atterberg limits, according to NBR 6459 [32] and NBR 7180 [33];

- Specific gravity of solids, according to NBR 6458 [34].

Soil samples were classified according to the Unified Soil Classification (USC) and Transportation Research Board (TRB) systems, using the guidelines of D2487-17 [35] and M145-91 [36], respectively. Soils were also classified according to the MCT methodology (Miniature, Compacted, Tropical), using the guidelines of CLA 259 [37]. For this purpose, the Mini-MCV and mass loss by immersion tests were carried out, according to the guidelines of the ME 258 [38] test method.

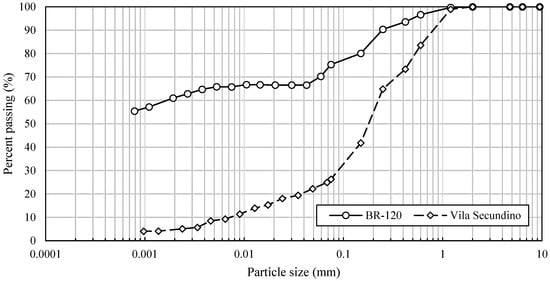

The results of the geotechnical characterization are presented in Table 1. BR-120 soil has a high percentage of fines, with a predominance of the clay fraction. Texturally, this sample was classified as sandy-silty clay. Vila Secundino soil has a predominance of the sand fraction, mainly medium sand, being considered a silty-clayey sand. Figure 2 presents the particle size distribution curves of the soil samples studied in this research.

Table 1.

Test results of the geotechnical characterization of the soils.

Figure 2.

Particle size distribution curve of the soil samples.

According to the USC, the BR-120 soil was classified as a highly compressible silt (MH) and the Vila Secundino soil as a clayey sand (SC). In the TRB system, BR-120 was classified as a plastic clay [A-7-5 (20)], unsuitable for subgrade use, while Vila Secundino was grouped as A-2-4 (0), suitable for subgrade applications.

Under the MCT classification, BR-120 was identified as a clayey lateritic soil (LG′), typical of B-horizon materials, such as latosols and podzolic soils, with potential behavior similar to sandy lateritic soils (LA′). Vila Secundino was classified as a non-lateritic sandy soil (NA′), composed mainly of quartz sands and fines, typical of saprolitic soils derived from granites and gneisses, suitable for pavement layers.

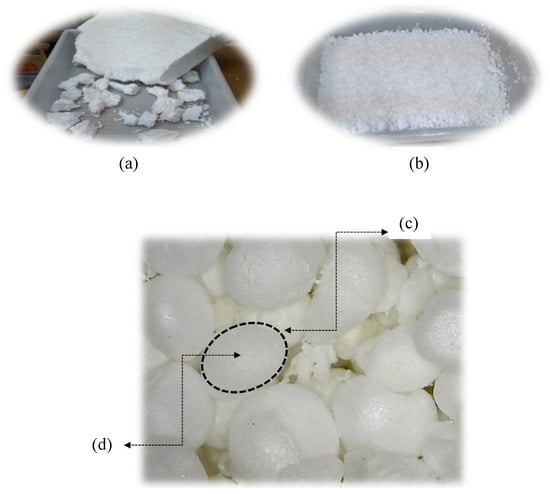

2.1.2. EPS Waste

The EPS waste was collected, in the shape of prismatic blocks, in a waste recycling unit in the city of Viçosa, Minas Gerais (Figure 3a). Later, it was milled and conformed to a standard particle size (Figure 3b). This aimed to ensure the geometric uniformity of the soil–EPS waste mixtures, hereinafter referred to as soil–EPS mixtures. Optical microscopy images showed that the EPS particles essentially had a smooth surface texture (Figure 3c) and a rounded morphology (Figure 3d).

Figure 3.

EPS waste details when collected (a) and after milling (b); and image of milled EPS waste sample obtained via optical microscopy, showing the rounded morphology (c) and smooth surface texture (d) of a representative particle.

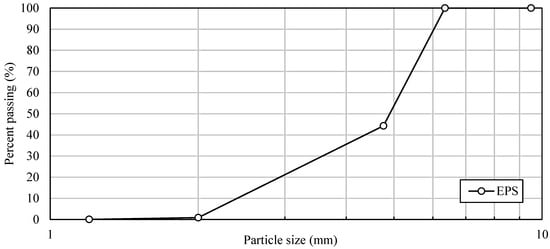

The analysis of the particle size of the EPS waste, carried out according to NBR 17054 [39], after being milled showed that the EPS particles are bigger than 1.2 mm (Figure 4). This means that the milled EPS waste particles are greater than the particles of the investigated soils. Table 2 shows the percentages of fractions (sand and gravel sizes) of the milled EPS waste.

Figure 4.

Particle size distribution curve of the milled EPS waste.

Table 2.

Milled EPS waste’s particle size data.

2.1.3. Soil–EPS Mixtures

The research included the analysis of mechanical properties of soil–EPS mixtures (Figure 5) compacted in the following volumetric proportions (soil-waste): 100–0%, 80–20%, 70–30%, and 60–40%.

Figure 5.

Milled EPS waste mixed with soil samples from BR-120 (a) and Vila Secundino (b).

2.2. Methods

2.2.1. Unit Mass of Soils and Milled EPS Waste

The unit mass test was carried out on the soils and on the milled EPS waste, according to NBR 16972 [40], to determine the mix ratio corresponding to the volume proportions considered in this study for the soil–EPS mixtures. Thus, in the preparation of the soil–EPS mixtures for the following tests, the values obtained in this test were used to obtain the correct proportion of the soil–EPS mixture in the desired apparent volume.

2.2.2. Compaction Test

Compaction tests in the soils and soil–EPS mixtures were carried out, following NBR 7182 [41], using the Intermediate and Modified Proctor compaction energies to determine the optimal compaction parameters (maximum dry unit weight and optimum moisture content).

2.2.3. Unconfined Compressive Strength (UCS) Test

The Unconfined Compressive Strength (UCS) tests were performed according to the technical standard NBR 12770 [42]. The cylindrical samples were compacted at the optimal moisture content of the respective compaction curve of the soil and soil–EPS mixtures at Intermediate and Modified Proctor energies. The UCS tests were performed on three replicate specimens for each mixture and compaction energy, assuming a maximum coefficient of variation (CV) of 10%. Cylindrical specimens with 10 cm in diameter and 12.7 cm in height were molded directly in standard Proctor cylinders to ensure consistent compaction conditions. No curing or rest period was applied; the specimens were tested immediately after molding.

2.2.4. California Bearing Ratio (CBR) Test

The CBR (California Bearing Ratio) tests were performed following the technical standard NBR 9895 [43]. The samples were compacted at the optimum moisture content using Intermediate and Modified Proctor energies. The CBR tests were carried out on three to five specimens per mixture and compaction energy, following standard procedures, assuming a maximum CV of 10%. The specimens were molded in CBR cylinders and soaked prior to testing, in order to determine both penetration resistance (CBR index) and swelling. Table 3 shows the threshold values of the CBR index and swelling required for the intended materials to compose the layers of asphalt pavements.

Table 3.

Minimum CBR index and maximum swelling values for asphalt pavement layers, according to DNIT [44] recommendations.

2.2.5. Direct Shear Strength Test

The Direct Shear Strength tests were performed according to the technical standard D 3080 (ASTM, 2011) [45]. The samples were compacted at the optimum moisture content of the compaction curve of the soil and soil–EPS mixtures, at Intermediate and Modified Proctor energies.

The compacted samples of soils and soil–EPS mixtures were first compacted in CBR cylinders. From these, test specimens with dimensions of 10 cm × 10 cm were prepared for direct shear tests. After water saturation, the specimens were consolidated, and the consolidation data were used to determine the rupture velocity. The rupture velocity adopted met all requirements for the materials studied in this research and all external loading conditions (consolidation stress).

Consolidation stresses of 100 kPa, 200 kPa and 400 kPa were assumed. Two test repetitions were carried out for each of these stresses. The coefficient R2 determined for the linear failure envelope was greater than 0.90.

2.2.6. Scanning Electron Microscopy

The samples of the soil–EPS waste mixtures were subjected to scanning electron microscopy (SEM) analyses to investigate the microstructural characteristics, aiming to correlate the mechanical results with the microstructures formed in soil–EPS waste mixtures. A small sample of the material was extracted from the central region of the specimen and placed on a SEM stub using carbon double-sided adhesive tape to ensure proper fixation and electrical conductivity during imaging. The sample surface was then sputter-coated with gold to enhance electrical conductivity, protect the sample, and improve the image quality. The sample was then placed in the SEM equipment. The samples were sputter-coated with gold using Quorum equipment, specifically model Q150R S. The SEM analysis was conducted using JEOL equipment, specifically model JSM-6010LA.

3. Results and Discussion

3.1. Unit Mass of the Materials

Table 4 shows the respective unit mass values of the soils and milled EPS waste. Moreover, the equations used to convert the apparent volume of EPS (VEPS) to the dry mass of EPS (Mass EPS) as a function of dry soil mass (Mass dry soil) are described below. Table 5 shows the conversions of the volumetric proportions of EPS in relation to the soils. These percentages fall within the typical EPS content range reported in previous studies, such as those by Ojuri and Ademola [46], Faraj and Omar [47], Mei, Xiang, and Huang [48], and Mei, Huang, and Xiang [49].

Table 4.

Unit mass of the materials.

Table 5.

Proportions by volume and mass of the EPS waste.

- Typical equation

- BR-120 soil

- Vila Secundino soil

3.2. Compaction Results

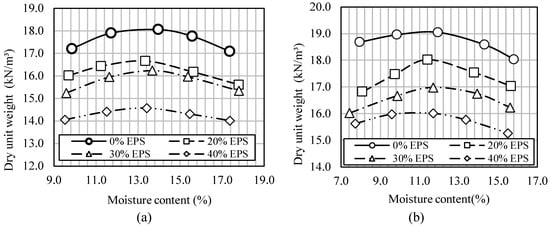

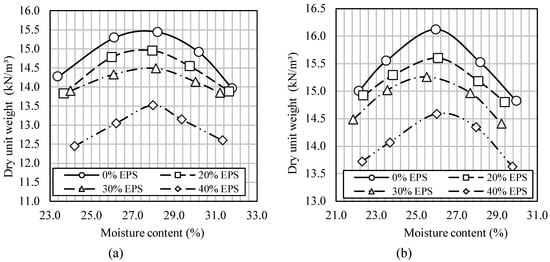

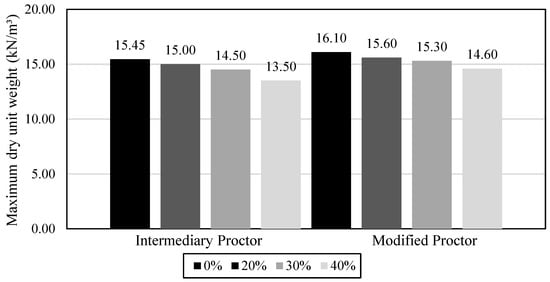

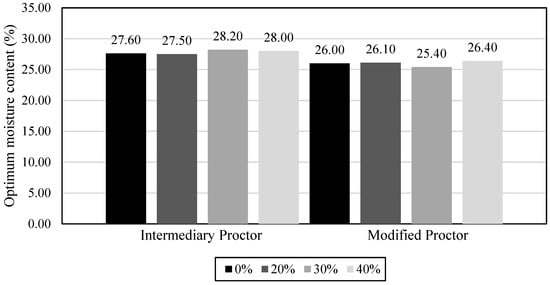

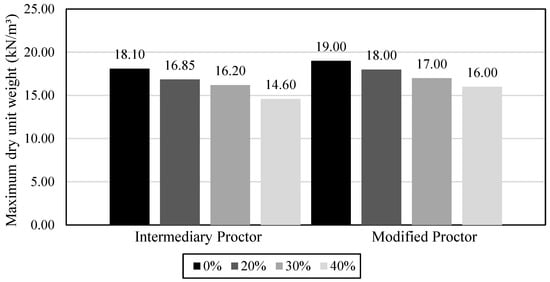

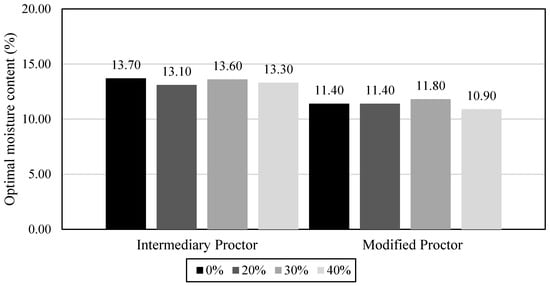

Figure 6 and Figure 7 show the compaction curves for the BR-120 and Vila Secundino soils, both in their natural state (0% in the apparent volume of EPS waste) and in mixtures of 20%, 30%, and 40% in the apparent volume of milled EPS waste, using Intermediate and Modified Proctor energies. The optimal compaction parameters (maximum dry unit weight and optimal moisture content) are shown in Figure 8, Figure 9, Figure 10 and Figure 11.

Figure 6.

Compaction curves of the soil and soil–EPS mixtures in Intermediate Proctor energy: (a) BR-120 soil and (b) Vila Secundino soil.

Figure 7.

Compaction curves of the soil and soil–EPS mixtures in Modified Proctor energy: (a) BR-120 soil and (b) Vila Secundino soil.

Figure 8.

Maximum dry unit weight of BR-120 soil and its mixtures with EPS waste.

Figure 9.

Optimal moisture content of BR-120 soil and its mixtures with EPS waste.

Figure 10.

Maximum dry unit weight of Vila Secundino soil and its mixtures with EPS waste.

Figure 11.

Optimal moisture content of Vila Secundino soil and its mixtures with EPS waste.

In both soils, the addition of milled EPS waste led to an overall reduction in dry unit weight, regardless of the compaction energy, as evidenced by the gradually lowering positioning of the compaction curves with increasing EPS content. This behavior results from the progressive replacement of denser soil particles by lightweight EPS.

A general trend of dry unit weight increasing with higher compaction energy was noted for all mixtures. The roles of compaction energy in modifying the compaction curve (MDD and OMC) and, consequently, the mechanical indices (UCS and CBR) are well established in soil mechanics. Increasing compaction effort normally promotes particle rearrangement, reduces void ratio and raises the maximum dry density, which in turn tends to improve bearing capacity and compressive strength [50,51].

A correlation between dry density and mechanical strength was observed mainly for the sandy soil. As EPS content increased, the dry density, and both UCS and CBR values, decreased markedly, due to the reduced particle interlock and the increased void ratio, consistent with the results reported in previous studies [48,52,53]. For the clayey soil, however, this correlation was weaker. Despite the reduction in density, the cohesive matrix of the clay promoted adhesion around EPS particles, maintaining part of the load transfer and mitigating the loss of strength, as noted by Utkarsh [54].

A similar pattern was not found for the optimum moisture content of compaction, which was less susceptible to the incorporation of waste with negligible variations. It can be concluded that the incorporation of EPS waste does not change the water demand of the system during compaction. The water demand to promote the rearrangement of the soil–EPS system particles is essentially the same as for the soil particles. These patterns (reduction in maximum dry unit weight and little significant change in optimum moisture content) have also been confirmed in other works with soil–EPS mixtures [23,24].

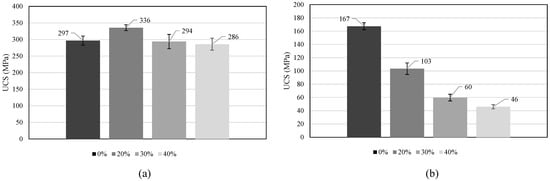

3.3. Unconfined Compressive Strength (UCS) Results

The Unconfined Compressive Strength (UCS) values of the BR-120 and Vila Secundino soils and their soil–EPS mixtures at Intermediate and Modified Proctor energies are shown in Figure 12 and Figure 13, respectively. The CV values of the repetitions were between 2.2% and 7.7%, and were, therefore, within the pre-established limit (CV ≤ 10%).

Figure 12.

Unconfined Compressive Strength (UCS) of the soils and soil–EPS mixtures at the Intermediate Proctor energy: (a) BR-120 soil and (b) Vila Secundino soil.

Figure 13.

Unconfined Compressive Strength (UCS) of the soils and soil–EPS mixtures at the Modified Proctor energy: (a) BR-120 soil and (b) Vila Secundino soil.

A statistical analysis was conducted to verify the significance of the variations in the UCS between the different volumetric contents of EPS waste for each soil type and compaction energy. The Shapiro–Wilk test confirmed that all data sets followed a normal distribution (p > 0.05) and Levene’s test indicated the homogeneity of variances among groups (p > 0.05). Therefore, one-way analysis of variance (ANOVA) and Tukey’s post hoc tests were applied.

For the BR-120 soil under Intermediate Proctor energy, the ANOVA test revealed significant differences among mixtures (F = 6.61, p = 0.015). According to Tukey’s test, the mixture containing 20% EPS presented a significantly higher UCS value (336 kPa) than the natural soil (297 kPa) and the other mixtures. Under Modified Proctor energy, however, no significant differences were observed among the groups (p = 0.082), suggesting that the higher compaction energy mitigated the influence of EPS content on strength. The mixture containing 30% EPS showed p = 0.056 in Tukey’s test, a more significant value than the natural soil sample (514 kPa), and close to the threshold for statistical significance, indicating an increase in the UCS with the addition of 30% EPS (561 kPa).

For the Vila Secundino soil, the ANOVA results were highly significant for both compaction energies (p < 0.001). Tukey’s test indicated a progressive and significant decrease in UCS with increasing EPS content, with the natural soil showing the highest strength, followed by 20%, 30%, and 40% EPS in soil–EPS mixtures. This trend is consistent with the predominance of frictional behavior and reduced interparticle interlock in sandy soils when replaced by smooth, rounded EPS grains.

Overall, these findings confirm that the mechanical response of the mixtures depends strongly on the soil type. Clayey soils exhibit stable or even improved strength at 20% and 30% EPS contents, whereas sandy soils experience a substantial reduction in compressive strength with EPS incorporation, regardless of compaction energy.

Analyzing the particularities of the test in which the strength is mobilized by the axial compression of the specimen without lateral confinement, it appears that the interaction between the particles under the condition of free transverse deformation to the load axis is the main factor for the mobilization of this strength, as previously reported by Zhuang and Zhao [55]. This interaction is determined by the contributions of the strength components via adhesion and via friction at the contact points between the particles of the soil–EPS mixture.

The BR-120 soil has a clayey granulometry and, therefore, consists mainly of smaller particles. Although the number of contacts between the particles has decreased due to the partial replacement of smaller particles (present in the finer, removed soil) by larger particles (present in the more granular EPS waste), it is assumed that there is still a considerable number of contacts between the individual particles of the mixture and thus also a considerable number of interactions between the soil particles and the EPS waste particles.

Considering that EPS has a relevant stiffness [5], the concentrated stresses acting at the points of contact between the particles are reduced when considering the structural configuration of the arrangement of soil particles BR-120–EPS waste. As reported by these authors, the EPS particles can help to absorb the internal stresses generated by the axial compressive load and promote their redistribution to the soil particles to an extent less than or equal to that transmitted in the internal structure of the pure soil (without the addition of EPS). It is therefore assumed that the loss of structural performance caused by the reduction in the number of contacts between the particles is compensated for by this mechanism of redistribution of internal stresses.

EPS particles essentially have a smooth surface texture and a rounded morphology. Despite their granular shape (Table 2), it is assumed that the frictional interaction between the particles of EPS and clay soil is limited [53], resulting in an equally restricted contribution of the frictional strength component in mobilizing the stiffness and compressive strength of the mixture under the action of the axial compressive stress that characterizes the test.

It is assumed, therefore, that the adhesion strength component appears to be the main mechanism for the mechanical response of the mixture to the stress state that characterizes the test. It restricts the deformability to compression of the mixture and, consequently, demands a higher level of compressive stress to overcome this constraint and to drive the internal structure of the soil–EPS system to failure [56].

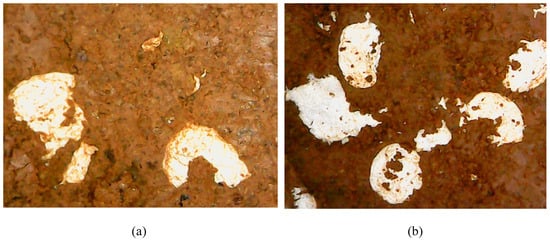

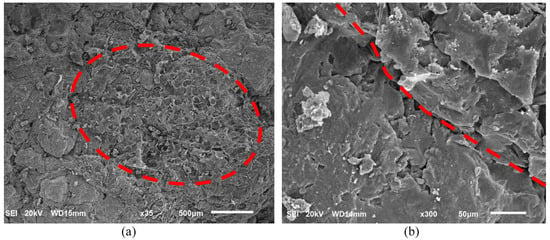

The rounder and smoother surface of the EPS particles and the cohesive character of the clay particles mean interfacial adhesion is favored between these particles. This adhesion is multiplied at the various contact points between the particles, which favor the transfer of internal stresses to the stiffer EPS particles and thus favor their redistribution to a level lower or equivalent to that of the system without EPS. It has been experimentally proven that the EPS particles are “trapped” in the compacted soil mass due to the cohesive character of the soil constituting the mixture, as shown in Figure 14. The good level of interfacial adhesion between the soil particles and the EPS waste can also be seen in detail in the SEM images, in Figure 15. Therefore, the assumption that stress redistribution mitigates the effect of fewer particle contacts is supported by the images in Figure 14 and Figure 15, which show EPS particles to be well encapsulated by the soil matrix, suggesting efficient stress transfer through the composite structure.

Figure 14.

Images of compacted samples of the clayey soil–EPS mixture obtained via optical microscopy, with details of the “trapping” through the interfacial adhesion of EPS particles in the cohesive soil mass (BR-120 soil) with 30% in the volumetric proportion of EPS: (a) Modified Proctor and (b) Intermediate Proctor.

Figure 15.

Images obtained via SEM showing the EPS particle (delimited by a red dashed line) surrounded by the soil mass (BR-120 soil) with 30% in the volumetric proportion of EPS in Modified Proctor Energy: (a) ×25 magnification and (b) ×300 magnification.

The Vila Secundino soil, with sandy granulometry, showed a significant reduction in its UCS due to the inclusion of EPS waste. In this case, due to the granulometric characteristics of both materials, which are essentially granular, and considering that a “finer” granular material (sandy soil) has been partially replaced by a “thicker” granular material (EPS waste), it is considered that in this configuration there is a lower number of contacts between the particles and, consequently, there are concentrated stresses of greater magnitudes, since there are fewer transmission points for the internal stresses generated by the external compressive load.

Due to its granular characteristics, it is also unlikely that the interaction between its particles can lead to adhesion and, thus, to a contribution of this strength component to the mechanical response of the mixture. It can therefore be assumed that the frictional strength component dominates the interaction between the granular particles of both materials and determines their stiffness and compressive strength, as reported by Zhu et al. [57]. However, the rounder and smoother surface of the EPS particles reduces the degree of interlocking and interfacial friction between the particles, thus favoring the relative movement between the soil and EPS particles under the action of internal stress.

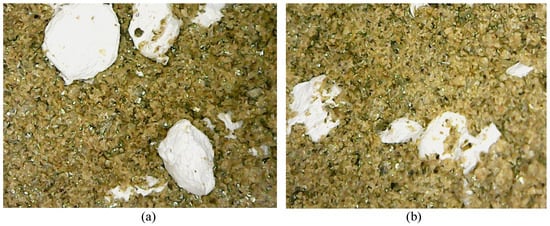

It has been experimentally proven that the EPS particles “float” in the compacted granular soil mass, being loose in this mass as a result of the aforementioned lack of interaction (Figure 16). Without sufficient interfacial interactions through adhesion and/or friction, the transfer of internal stresses to the EPS particles is, therefore, inefficient, preventing their redistribution and, consequently, causing a negative effect in the form of a loss of the strength of the sandy soil combined with the waste.

Figure 16.

Images of compacted samples of the sandy soil–EPS mixture obtained via optical microscopy with details of the “float” of EPS particles in the granular soil mass (Vila Secundino soil) with 30% in the volumetric proportion of EPS: (a) Intermediate Proctor and (b) Modified Proctor.

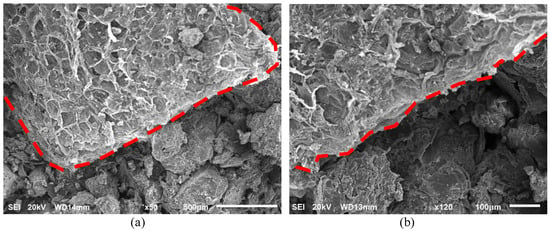

The inefficient interaction between the sandy soil particles and the EPS particles turns these interfaces into points of weakness in the mixture, where the mixture ruptures at stress levels much lower than those of pure, compacted soil. The lack of interaction is also evident in the scanning electron microscopy (SEM) images (Figure 17), which show the physical separation zone between the Vila Secundino soil particles and the EPS waste particles.

Figure 17.

Images obtained via SEM showing the EPS particle (delimited by a red dashed line) in contact with individual soil particles (Vila Secundino soil) with 30% in the volumetric proportion of EPS in Modified Proctor Energy: (a) ×50 magnification and (b) ×120 magnification.

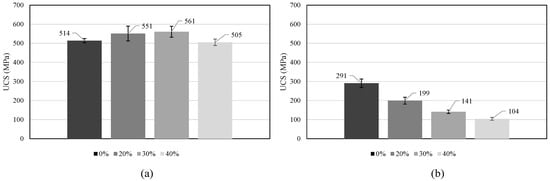

3.4. California Bearing Ratio (CBR) Results

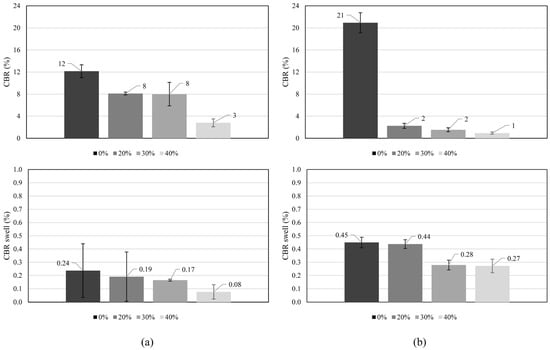

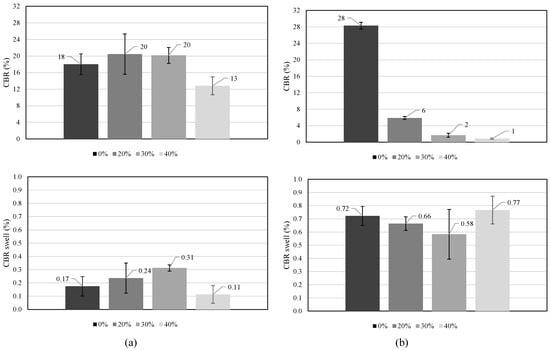

The CBR index and swelling values of the BR-120 and Vila Secundino soils, and their soil–EPS mixtures at Intermediate and Modified Proctor energies, are shown in Figure 18 and Figure 19, respectively. The CV values of the repetitions were between 5.8% and 8.9%, and, thus, were within the specified limit (CV ≤ 10%).

Figure 18.

CBR index and swelling of the soils and soil–EPS mixtures at Intermediate Proctor energy: (a) BR-120 soil and (b) Vila Secundino soil.

Figure 19.

CBR index and swelling of the soils and soil–EPS mixtures at Modified Proctor energy: (a) BR-120 soil and (b) Vila Secundino soil.

The CBR represents the material’s resistance to penetration by a rigid piston, reflecting the internal shear stress developed during the punching mechanism. For the BR-120 soil, this strength is primarily governed by the interfacial adhesion between the soil matrix and the EPS particles. Nevertheless, the load bearing of the mixture is strongly dependent on the level of compaction energy applied.

At Intermediate Proctor energy, the interfacial bonding between the soil and the EPS grains was insufficient to preserve the equilibrium of the punched system relative to that of the natural compacted soil, leading to lower CBR values. Statistical analysis confirmed these differences (F = 31.71, p < 0.001). The natural soil exhibited significantly higher CBR values than all soil–EPS mixtures, with the 40% EPS mixture showing the lowest performance. This reduction is attributed to the replacement of dense soil particles by low density EPS particles, which decreases dry unit weight and the number of interparticle contacts responsible for shear transfer.

When the Modified Proctor energy was applied, the deficiencies in the adhesion mechanism were partially compensated for. The higher compaction effort promoted closer contact between the soil and EPS particles, enhancing stress transfer and confinement. The ANOVA results indicated significant differences among mixtures (F = 5.64, p = 0.0095), although Tukey’s test showed that mixtures containing 20% and 30% EPS did not differ statistically from the natural soil and could maintain adequate bearing capacity. Additionally, the densification of the EPS particles under elevated compaction pressures increases their stiffness, reducing the deformation during loading and increasing resistance to the CBR piston penetration.

For the Vila Secundino soil, the results followed the same trend under both compaction energies, showing a pronounced and statistically significant reduction in CBR with increasing EPS content (p < 0.001). The natural soil presented the highest CBR, followed by 20%, 30%, and 40% EPS mixtures. The absence of effective adhesion and frictional interaction at the soil–EPS interface limited the mobilization of shear strength, producing weak zones within the composite.

In summary, the CBR of soil–EPS mixtures decreases systematically with increasing EPS content, particularly in Vila Secundino (sandy) soil where frictional resistance predominates. In contrast, for BR-120 (clayey) soil compacted at higher energy, 20% and 30% EPS contents can achieve CBR values, which are comparable to those of natural soil. These findings highlight the potential of such mixtures for use in lightweight geotechnical fills and low-bearing-capacity pavement layers, where reduced density and adequate performance are desirable.

For both clayey (BR-120) and sandy (Vila Secundino) soils, no significant differences in swelling were found with EPS incorporation (0–40%) under either compaction energy. BR-120 clayey soil showed consistent swelling behavior across all EPS contents (Intermediate: F = 2.894, p = 0.089 and Modified: F = 3.125, p = 0.072). Vila Secundino (sandy) soil also demonstrated no significant swelling variations (Intermediate: F = 1.892, p = 0.187 and Modified: F = 2.345, p = 0.124).

All data sets followed normal distribution (Shapiro–Wilk p > 0.05) with homogeneous variances (Levene’s p > 0.05). Tukey’s HSD tests confirmed no pairwise significant differences between EPS percentages. These results demonstrate that EPS waste incorporation does not increase swelling potential in tropical soils, supporting the technical feasibility of these sustainable composites in geotechnical applications where controlled expansion is required.

Taking into account the technical requirements (Table 3) established by the DNIT [44], Table 6 shows a summary of the possible applications of the materials in the structural layers of asphalt pavements.

Table 6.

Applicability of the materials investigated, according to the requirements of DNIT [44], in structural layers of asphalt pavements.

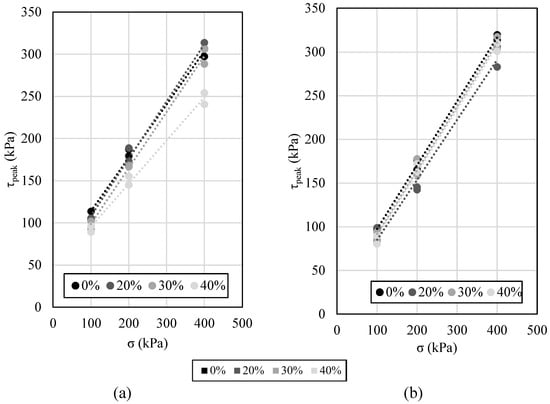

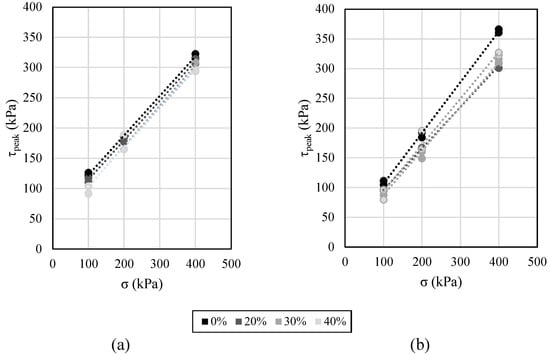

3.5. Direct Shear Strength Results

The peak shear strength (τpeak) envelopes of the BR-120 and Vila Secundino soils, and their respective soil–EPS mixtures compacted at Intermediate and Modified Proctor energies, are shown in Figure 20 and Figure 21, respectively. The corresponding shear strength parameters (cohesive intercept and internal friction angle) are shown in Table 7.

Figure 20.

Peak shear strength (τpeak) envelopes of soils and soil–EPS mixtures compacted at Intermediate Proctor energy: (a) BR-120 soil and (b) Vila Secundino soil.

Figure 21.

Peak shear strength (τpeak) envelopes of soils and soil–EPS mixtures compacted at Modified Proctor energy: (a) BR-120 soil and (b) Vila Secundino soil.

Table 7.

Peak shear strength parameters of soils (BR-120 and Vila Secundino) and their soil–EPS mixtures compacted at Intermediate and Modified Proctor energies.

In the BR-120 soil, mainly clayey, the addition of EPS waste is physically equivalent to the inclusion of round, smooth granular material into its composition, reducing its cohesive strength component and slightly increasing its frictional strength portion. This pattern is even more pronounced at lower compaction energies (Intermediate Proctor energy). This highlights the influence of the level of compaction on the development of soil–EPS interfacial interaction mechanisms, which are responsible for the strength of the mixture when sheared.

In Vila Secundino soil, the addition of EPS waste is be physically equivalent to the addition of round, smooth granular material, reducing its cohesive contribution (which is already reduced due to the intrinsically granular nature of the material) and reducing the friction at the contact points between the soil and waste particles (at least due to the round, smooth surface of the EPS particles).

In contrast to the mechanical responses offered by the sandy soil–EPS mixture in the previous tests (UCS and CBR), the direct shear test did not show any sudden changes in terms of the shear response of the material. The shear strength envelopes and the corresponding shear strength parameters compared to the compacted pure sandy soil did not show any abrupt variations in their quantified strength properties.

For the direct shear test, the confinement of the mixture by the consolidation stress (perpendicular to the shear plane) is presented as a basic boundary condition to prevent the material from being subjected to similar constraints to those in UCS and CBR tests, where there is no confinement. This condition triggered the abrupt loss of the strength of the sandy mixture. In the case of sandy materials, confinement therefore appears to be an essential boundary condition for assessing the technical feasibility of the engineered product.

Despite the experimental finding of a reduction in either the cohesive component or the frictional component, the shear strength envelopes representing the combined action of these components in mobilizing shear strength show the existence of soil–EPS mixtures with specific compaction energies and specific volumetric compositions that exhibit equivalent or even better mechanical performances than pure soil for the particular type of direct shear test.

4. Conclusions

This work presented an experimental program for the evaluation of the effects of expanded polystyrene (EPS) waste incorporation into different types of soils, aiming to evaluate its influence on the mechanical and microstructural properties, and its potential applications in geotechnical engineering. Based on the experimental results of this work, the following can be concluded:

- The addition of EPS waste to the soils reduced the dry density of the mixtures compared to that of pure soils, indicating a possible technical advantage when used in earthworks that will be laid on materials with low bearing capacity and stiffness.

- The mechanical response of the soil–EPS mixture essentially depended on the granulometric characteristics of the soil; for the particularities of the study, the clayey soil had a better overall mechanical response than the sandy soil when the EPS waste was incorporated.

- Upon the UCS test on clayey soil at Intermediate Proctor energy, an increase was observed only at 20% EPS content (336 kPa) compared to in pure soil (297 kPa). At Modified Proctor energy, increases were observed at 20% (551 kPa) and 30% (561 kPa) EPS contents compared to in pure soil (514 kPa). For the sandy soil, there was a more significant decrease in the UCS values for both energies studied up to 40% EPS, from 167 kPa to 46 kPa for the Intermediate Proctor energy, and from 291 kPa to 104 kPa for the Modified Proctor energy.

- In the CBR tests conducted on clayey soil, a decreasing trend was observed as the EPS content increased, with values dropping from 12% for the natural soil to 3% for the mixture containing 40% EPS under Intermediate Proctor compaction energy. Under Modified Proctor energy, a reduction was observed only at 40% EPS (CBR of 13%), while the mixtures with 20% and 30% EPS both exhibited higher CBR values (20%) compared to the natural soil (18%). For the sandy soil, a pronounced reduction in CBR values was observed for both compaction energies, decreasing from 21% (natural soil) to 1% (40% EPS) under Intermediate Proctor energy, and from 30% to 1% under Modified Proctor energy.

- The direct shear tests indicated that the addition of EPS reduced the peak shear strength parameters of the mixtures. The cohesion decreased by approximately 20% to 30%, and the friction angle showed a slight reduction as EPS content increased from 0% to 40%.

- The different mechanical responses of soil–EPS mixtures can be explained by the adhesion and friction mechanisms at the interface between soil and EPS waste particles.

- The scenarios studied in this research indicate that there is an optimal range for the addition of EPS waste (20% to 30% of the volume) that allows an improvement in or equivalence of the mechanical properties of the mixture compared to pure clay soil, especially under compressive and punching loads.

Future research is recommended to focus on investigating the long-term performance of EPS waste–soil mixtures, particularly under varying environmental conditions and extended loading periods. Further study is also recommended to obtain quantitative data on the frictional behavior of EPS grains compared to that of soil particles, and on their deformation and stiffening under compaction, in order to better substantiate the mechanisms hypothesized in this study. Detailed mineralogical analyses of the soils were beyond the scope of this work but could provide further insight into particle–EPS interactions. In addition, further exploration into the influence of different types and sizes of EPS particles on the mechanical and microstructural mechanisms of various soil types would provide valuable insights for optimizing the use of these sustainable composites in different construction applications. Finally, future studies should quantify the potential environmental impacts of incorporating EPS waste into geotechnical works, particularly regarding the long-term stability and possible release of microplastics under varying field conditions.

Author Contributions

Conceptualization, G.F.d.S., H.N.P., T.O.d.S. and K.H.d.P.R.; methodology, G.F.d.S. and H.N.P.; validation, G.F.d.S., H.N.P., T.O.d.S., G.H.N. and K.H.d.P.R.; formal analysis, G.F.d.S., H.N.P., G.H.N. and K.H.d.P.R.; investigation, G.F.d.S.; resources, G.F.d.S. and H.N.P.; data curation, G.F.d.S.; writing—original draft preparation, G.F.d.S.; writing—review and editing, H.N.P., T.O.d.S., G.H.N. and K.H.d.P.R.; visualization, H.N.P., G.H.N. and K.H.d.P.R.; supervision, H.N.P. and T.O.d.S.; and project administration, H.N.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors thank the support provided by the Civil Engineering Department “http://www.dec.ufv.br/” (accessed on 3 November 2025), Nucleus of Microscopy and Microanalysis “https://nmm.ufv.br/” (accessed on 3 November 2025), and the Department of Physics “https://www.dpf.ufv.br/” (accessed 3 November 2025) of the Federal University of Viçosa.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tamut, T.; Prabhu, R.; Venkataramana, K.; Yaragal, S. Partial Replacement of Coarse Aggregates by Expanded Polystyrene Beads in Concrete. Int. J. Res. Eng. Technol. 2014, 3, 238–241. [Google Scholar] [CrossRef]

- Ferrándiz-Mas, V.; García-Alcocel, E. Physical and Mechanical Characterization of Portland Cement Mortars Made with Expanded Polystyrene Particles Addition (EPS). Mater. Constr. 2012, 62, 547–566. [Google Scholar] [CrossRef]

- Oliveira, C.T.; Luna, M.M.M.; Campos, L.M.S. Understanding the Brazilian Expanded Polystyrene Supply Chain and Its Reverse Logistics towards Circular Economy. J. Clean. Prod. 2019, 235, 562–573. [Google Scholar] [CrossRef]

- Avesani Neto, J.O.; Rodrigues, D. Instrumented Load Tests and Layered Elastic Theory Analysis of a Large-Scale EPS Block Embankment. Transp. Geotech. 2021, 26, 100442. [Google Scholar] [CrossRef]

- Avesani Neto, J.O.; Bueno, B.S. Laboratory Research on EPS Blocks Used in Geotechnical Engineering. Soils Rocks 2012, 35, 169–180. [Google Scholar] [CrossRef]

- Öztürk, M. Strength Characteristics of Lightweight Soil with Waste Modified Expanded Polystyrene Particles. Constr. Build. Mater. 2024, 442, 137635. [Google Scholar] [CrossRef]

- Chaukura, N.; Gwenzi, W.; Bunhu, T.; Ruziwa, D.T.; Pumure, I. Potential Uses and Value-Added Products Derived from Waste Polystyrene in Developing Countries: A Review. Resour. Conserv. Recycl. 2016, 107, 157–165. [Google Scholar] [CrossRef]

- Modyela, B.T.; Madyira, D.M.; Tebeta, R.T. A Study on Expanded Polystyrene Solid Waste Management for Value-Added Products. In Proceedings of the 2022 IEEE 13th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 25–27 May 2022; pp. 192–195. [Google Scholar]

- Tkalčić, D.; Vukadin, J.; Milovanović, B.; Banjad Pečur, I. Performance Assessment of Mechanically Recycled EPS. Materials 2025, 18, 4547. [Google Scholar] [CrossRef]

- Jamshidi Chenari, R.; Karimpour Fard, M.; Pourghaffar Maghfarati, S.; Pishgar, F.; Lemos Machado, S. An Investigation on the Geotechnical Properties of Sand–EPS Mixture Using Large Oedometer Apparatus. Constr. Build. Mater. 2016, 113, 773–782. [Google Scholar] [CrossRef]

- Xiao, Y.; He, X.; Liu, H. New Lightweight Geomaterials: Biocemented Sand Mixed with Expanded Polystyrene Beads. Sci. China Technol. Sci. 2017, 60, 1118–1120. [Google Scholar] [CrossRef]

- Gao, H.; Bu, C.; Wang, Z.; Shen, Y.; Chen, G. Dynamic Characteristics of Expanded Polystyrene Composite Soil under Traffic Loadings Considering Initial Consolidation State. Soil Dyn. Earthq. Eng. 2017, 102, 86–98. [Google Scholar] [CrossRef]

- Samir El-kady, M. Soft Clay Treatment Using Geo-Foam Beads and Bypass Cement Dust. Civ. Eng. Res. J. 2018, 7, 555701. [Google Scholar] [CrossRef]

- Syahril; Somantri, A.K.; Febriansya, A. The Effect of EPS Addition to Soil Stabilized with Fly Ash as Lightweight Fill Materials for Embankment Construction. J. Phys. Conf. Ser. 2019, 1364, 012077. [Google Scholar] [CrossRef]

- Khajeh, A.; Jamshidi Chenari, R.; Payan, M. A Review of the Studies on Soil-EPS Composites: Beads and Blocks. Geotech. Geol. Eng. 2020, 38, 3363–3383. [Google Scholar] [CrossRef]

- Rauf, I.; Samang, L.; Harianto, T.; Arsyad, A. Compressive Strength of Lightweight Geocomposit Soil-Eps Stabilized with Palm Oil-Tea Fly Ash. IOP Conf. Ser. Earth Environ. Sci. 2020, 419, 012077. [Google Scholar] [CrossRef]

- Rauf, I.; Samang, L.; Harianto, T.; Arsyad, A. Correlation of UCS and CBR on Lightweight Geocomposite of Soil-EPS Stabilized by Waste of Buton Asphalt. Mater. Sci. Forum 2020, 998, 311–316. [Google Scholar] [CrossRef]

- Marfuah, N.; Harianto, T.; Muhiddin, A.B.; Irmawaty, R. Strength Characteristic of Lightweight Modular Block (LMB) Element Using Stabilized Dredged Soil-EPS. Civ. Eng. J. 2023, 9, 699–713. [Google Scholar] [CrossRef]

- Shen, Z.; Zhao, Y.; Shu, F.; Shen, G.; Wang, Z.; Gao, H. Meso-Scale Deformation and Strength Mobilization Mechanisms of EPS Composite Soil. Constr. Build. Mater. 2024, 411, 134394. [Google Scholar] [CrossRef]

- Zendehdel Nobari, A.; Saeedi Azizkandi, A.; Javadi, A.A.; Mohebbi, H.R. Experimental Study of the Static and Dynamic Characteristics of Lightweight EPS Composite Soils Treated with Cement. J. Mater. Civ. Eng. 2024, 36. [Google Scholar] [CrossRef]

- Abdelrahman, G.E. Lightweight Fill Using Clay, EPS-Beads and Cement. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering, Alexandria, Egypt, 5–9 October 2009. [Google Scholar]

- Gao, H.; Chen, Y.; Liu, H.; Liu, J.; Chu, J. Creep Behavior of EPS Composite Soil. Sci. China Technol. Sci. 2012, 55, 3070–3080. [Google Scholar] [CrossRef]

- Silveira, M.V.; Calheiros, A.V.; Casagrande, M.D.T. Applicability of the Expanded Polystyrene as a Soil Improvement Tool. J. Mater. Civ. Eng. 2018, 30. [Google Scholar] [CrossRef]

- Abdelrahman, G.; Mohamed, H.; Ahmed, H. New Replacement Formations on Expansive Soils Using Recycled EPS Beads. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013; pp. 3167–3170. [Google Scholar]

- Haseeb, M.; Maqsood, Z.; Baqir, M.; Sarwar, S.; Alshameri, B.; Hassan, W.; Haider, A.; Wenli, L.; Alam, M.; Xie, J.; et al. Sustainable Fill Solutions: Recycling EPS Waste in Shredded EPS-Clayed Soil Composites for Improved Mechanical and Compaction Behaviour. Transp. Geotech. 2025, 54, 101614. [Google Scholar] [CrossRef]

- Monkul, M.M.; Özhan, H.O. Microplastic Contamination in Soils: A Review from Geotechnical Engineering View. Polymers 2021, 13, 4129. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. Department of Economic and Social Affairs. Sustainable Development. 2025. Available online: https://sdgs.un.org/2030agenda (accessed on 3 November 2025).

- DNER PRO 003/94; Collection of Deformed Soil Samples. Departamento Nacional de Estradas de Rodagem: Brasília, Brazil, 1994; p. 4. (In Portuguese)

- ABNT NBR 16915; Aggregates—Sampling. ABNT (Associação Brasileira de Normas Técnicas): São Paulo, Brazil, 2021; pp. 1–8.

- ABNT NBR 6457; Soil Samples—Preparation for Compaction and Characterization Tests. ABNT (Associação Brasileira de Normas Técnicas): Rio de Janeiro, Brazil, 2016.

- ABNT NBR 7181; Soil—Grain Size Analysis. ABNT (Associação Brasileira de Normas Técnicas): São Paulo, Brazil, 2016; pp. 1–12.

- ABNT NBR 6459; Soil—Liquid Limit Determination. ABNT (Associação Brasileira de Normas Técnicas): São Paulo, Brazil, 2016.

- ABNT NBR 7180; Soil—Plasticity Limit Determination. ABNT (Associação Brasileira de Normas Técnicas): São Paulo, Brazil, 2016.

- ABNT NBR 6458; Gravel Grains Retained on the 4.8 Mm Mesh Sieve—Determination of the Bulk Specific Gravity, of the Apparent Specific Gravity and of Water Absorption. ABNT (Associação Brasileira de Normas Técnicas): São Paulo, Brazil, 2016.

- ASTM D2487–17; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017.

- AASHTO M145–91; Standard Specification for Classification of Soils and Soil—Aggregate Mixtures for Highway Construction Purposes. American Society for Testing and Materials (ASTM International): West Conshohocken, PA, USA, 2017.

- DNIT 259/2023; Soils—Classification of Tropical Fine Soils for Road Purposes Using Compacted Test Specimens in Miniature Equipment—Classification. Brazil’s National Department of Transport Infrastructure (DNIT): Brasília, Brazil, 2023; pp. 1–8.

- DNIT 258/2023—ME; Soils—Compaction in Miniature Equipment—Mini—MCV Tests and Mass Loss by Immersion—Test Method. Brazil’s National Department of Transport Infrastructure (DNIT): Brasília, Brazil, 2023; pp. 1–22.

- ABNT NBR 17054; Aggregates—Determination of Particle Size Composition—Test Method. ABNT (Associação Brasileira de Normas Técnicas): São Paulo, Brazil, 2022; pp. 1–5.

- ABNT NBR 16972; Aggregates—Determination of Unit Mass and Void Ratio. ABNT (Associação Brasileira de Normas Técnicas): São Paulo, Brazil, 2021; pp. 1–6.

- ABNT NBR 7182; Compaction Test—Procedures. ABNT (Associação Brasileira de Normas Técnicas): São Paulo, Brazil, 2020.

- ABNT NBR 12770; Soil—Determination of the Unconfined Compressive Strength of Cohesive Soil. ABNT (Associação Brasileira de Normas Técnicas): São Paulo, Brazil, 2022.

- ABNT NBR 9895; Soil—California Bearing Ratio (CBR)—Testing Method. ABNT (Associação Brasileira de Normas Técnicas): São Paulo, Brazil, 2016; p. 14.

- DNIT. Pavement Manual, 3rd ed.; Institute of Highway Research: Rio de Janeiro, Brazil, 2006. (In Portuguese) [Google Scholar]

- ASTM D3080-11: Standard Test Method for Direct Shear Test of Soils under Consolidated Drained Conditions; ASTM International: West Conshohocken, PA, USA, 2011.

- Ojuri, O.O.; Ademola, S.A. Compaction and Strength Characteristics of Modified Waste Expanded Polystyrene (EPS) Mixed with a Standard Sand. In Proceedings of the Geo-China 2016, Shandong, China, 25–27 July 2016; American Society of Civil Engineers: Reston, VA, USA, 2016; pp. 85–92. [Google Scholar]

- Faraj, A.S.; Omar, E.A. Experimental Study on Geotechnical Properties of Clay Soil with Adding Expanded Polystyrene Material. Tobruk Univ. J. Eng. Sci. 2023, 4, 1–15. [Google Scholar] [CrossRef]

- Mei, L.; Xiang, D.; Huang, Y. Research on the Mechanical Properties of EPS Lightweight Soil Mixed with Slag. PLoS ONE 2024, 19, e0297372. [Google Scholar] [CrossRef]

- Mei, L.; Huang, Y.; Xiang, D. Research on the Mechanical Properties of EPS Lightweight Soil Mixed with Fly Ash. Polymer 2024, 16, 3517. [Google Scholar] [CrossRef]

- Das, A. Analysis of Pavement Structures; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Craig, J. Craig’s Soil Mechanics, 9th ed.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Jiang, P.; Zheng, W.; Zhou, L.; Li, N.; Wang, W. Laboratory Characterization of Soft Clay Mixed with EPS, Lime, Fly Ash, and Sodium Silicate. Bull. Eng. Geol. Environ. 2023, 82, 302. [Google Scholar] [CrossRef]

- Abbasimaedeh, P.; Ghanbari, A.; O’Kelly, B.C.; Tavanafar, M.; Irdmoosa, K.G. Geomechanical Behaviour of Uncemented Expanded Polystyrene (EPS) Beads–Clayey Soil Mixtures as Lightweight Fill. Geotechnics 2021, 1, 38–58. [Google Scholar] [CrossRef]

- Utkarsh; Jain, P.K. A Review on Innovative Approaches to Expansive Soil Stabilization: Focussing on EPS Beads, Sand, and Jute. Sci. Eng. Compos. Mater. 2024, 31, 20240005. [Google Scholar] [CrossRef]

- Zhuang, X.; Zhao, J. Experimental Study of the Dynamic Characteristics and Microscopic Mechanism of Lightweight Soil Modified with Expanded Polystyrene and Sisal Fibre. Appl. Sci. 2023, 13, 11502. [Google Scholar] [CrossRef]

- Tao, H.; Zheng, W.; Zhou, X.; Zhou, L.; Li, C.; Yu, Y.; Jiang, P. Study on Dynamic Modulus and Damping Characteristics of Modified Expanded Polystyrene Lightweight Soil under Cyclic Load. Polymer 2023, 15, 1865. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Wen, K.; Tong, R.; Li, M. Dynamic Shear Strength Characteristics of Lightweight Sand-EPS Soil. Sustainability 2022, 14, 7397. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).