Abstract

EPS module buildings are prefabricated, low-rise systems with high thermal insulation that are widely used in rural self-built houses in northern China, yet their indoor thermal environments often suffer from instability. This study experimentally verified the effectiveness of microcapsule phase change mortar (PCM plaster) in improving winter indoor temperatures of EPS module houses. In addition, based on simulation data from 350 design combinations across five representative cold-climate cities and four envelope design variables, the study provides quantitative design guidance for EPS module walls and PCM plaster in rural houses, offering a practical approach to improve indoor thermal stability that has not been previously reported. The main findings are as follows: (1) The thermal transmittance of EPS module walls is the dominant factor influencing indoor thermal performance. For climate adaptability, Type II walls are recommended for severely cold regions, while Type I walls are suitable for cold regions. The application of PCM plaster is not recommended in solar-rich cold regions such as Lhasa due to limited effectiveness. (2) Optimal PCM plaster parameters exist, with the phase change temperature recommended to be 2–4 °C higher than the average indoor operative temperature during the heating period. Specifically, 18 °C is optimal for Type I walls in Yinchuan, Beijing, and Dalian, while 15 °C is more appropriate for Type II walls in Shenyang and Harbin. The corresponding optimal thicknesses are 20 mm for Harbin, Shenyang, and Dalian; 30 mm for Yinchuan; and 40 mm for Beijing, achieving a balance between indoor temperature improvement and construction cost. (3) Operative temperature and discomfort hours are introduced to assess indoor thermal stability, especially in buildings with interior PCM plaster.

1. Introduction

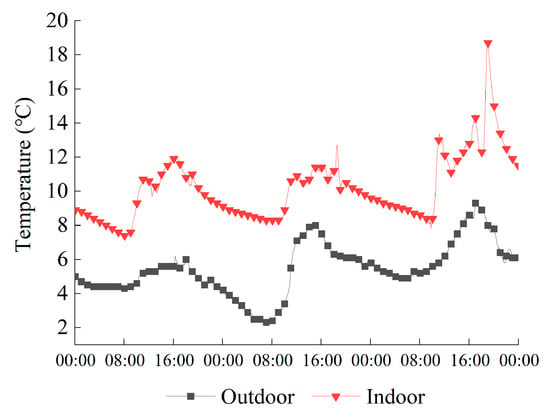

With the implementation of the dual carbon strategy, prefabricated buildings are bound to become the primary construction method in China [1]. EPS (Expanded Polystyrene) module buildings, due to their excellent insulation properties, strong seismic resistance, long durability, low construction costs, fast construction speed, and labor-saving advantages, have been widely applied in rural self-built houses in northern China [2]. Figure 1 presents a self-built EPS module rural residence in Liufen Village, Heze City, Shandong Province. The building features exterior walls constructed with EPS modules, a floor assembly comprising a 50 mm thick EPS insulation layer overlaid by a 100 mm concrete screed, and a roof structure consisting of a 100 mm cast-in-place concrete slab topped with a 60 mm EPS insulation layer. Indoor and outdoor bedroom temperatures were recorded from January 9 to 11, 2023 (Figure 2). During this period, the bedroom was unoccupied and no heating system was in operation, providing baseline data for evaluating the building’s thermal performance. The measured data indicates that, in the absence of indoor heating sources, the average indoor temperature was 10.2 °C, which is 4.7 °C higher than the outdoor temperature, demonstrating the good thermal insulation performance of the EPS module rural residence and its ability to effectively resist cold outdoor weather. The indoor daily temperature difference was 11.3 °C, with a maximum daytime temperature of 18.7 °C and a minimum nighttime temperature of 7.4 °C, which is lower than the design requirement of ≥14 °C for the indoor temperature of the rural residence [3]. The reason for this is that both the interior and exterior sides of the EPS module walls are composed of insulation panels, resulting in poor indoor heat storage capacity and significant indoor temperature fluctuations between day and night [2]. Therefore, in order to promote EPS module rural residences, it is essential to enhance their indoor heat storage capacity, improve thermal stability, and increase the indoor temperature at night to meet the requirements for continuous use throughout the day.

Figure 1.

EPS modular rural housing in Liufen village, Heze city. (a) Real view. (b) Construction site.

Figure 2.

Field measurement data of indoor and outdoor temperature in EPS modular rural housing of Liufen village.

The EPS module rural residences employ sandwich wall structures, with reinforced concrete cores sandwiched between insulation panels on both sides. The thermal insulation performance and air tightness of these envelope structures are far superior to those of traditional rural houses. However, these structures are unable to accommodate heavy heat storage interior walls, such as concrete or water tanks, to enhance the building’s thermal stability. Therefore, phase change materials (PCMs) have emerged as an effective solution to improve the poor indoor heat storage capacity of EPS module rural residences. Researchers both domestically and internationally have explored the use of encapsulated phase change materials in building applications from two main aspects: material development and structural optimization [4,5,6,7,8,9]. The research mainly focuses on the development of composite phase change building materials, such as form-stable phase change components and microencapsulated phase change mortars, with emphasis on material preparation and encapsulation techniques [10,11,12,13,14]. Zeng et al. (2009) [15] developed a shaped phase change floor encapsulating paraffin with high-density polyethylene material, which was applied in the ultra-low energy consumption demonstration building at Tsinghua University. The indoor temperature fluctuation was controlled within 6 °C throughout the day, marking the first engineering practice of composite phase change materials in China. Cunha et al. (2014) [16] researched and tested the heat storage capacity of phase change microcapsule concrete with a phase change temperature of 26 °C. The experimental results showed that the phase change microcapsule concrete walls exhibited good thermal inertia. Wen et al. (2022) [17] prepared phase change microcapsules of n-octadecane and their steel slag cement mortar, with experimental data indicating that the temperature difference between the inside and outside of the cement mortar was largest when the phase change microcapsule content was 15%, although the mechanical strength was lower than that of pure cement mortar. Research on the structural optimization of phase change building components, including walls, floors, and roofs, has mainly focused on factors such as phase change temperature, material thickness, structural layers, and spatial distribution. However, research on building envelope design, such as window–wall ratios and heat transfer coefficients, remains insufficient. Zhou et al. (2014) [18] explored the influence of phase change temperature, latent heat, thermal conductivity, and surface heat transfer coefficient on the thermal performance of phase change wall panels, pointing out that the optimal phase change temperature for interior walls is equal to the average indoor air temperature. Li et al. (2019) [19] studied the effect of phase change material thickness in phase change walls on the building’s thermal performance. The simulation results indicated that increasing the thickness of the phase change material reduces the temperature fluctuation amplitude on the interior surface of the envelope structure. Qiao et al. (2020) [20] and colleagues examined the effect of the location of phase change heat storage layers in different structural layers of exterior walls on indoor temperature. The experimental results showed that placing the phase change heat storage layer on the interior side of the building effectively reduced indoor temperature peaks. Meng et al. [21] and colleagues investigated the effect of four spatial distribution patterns of shaped phase change walls on indoor temperature stability. Simulation results revealed that not all distribution patterns effectively utilized the heat storage potential of the phase change walls.

In summary, phase change microcapsule mortar (referred to as phase change mortar) can be used as the plaster on the interior side of the building envelope in EPS module rural residences to improve indoor thermal stability. However, there is a lack of research on the optimization design of such building envelopes. This study first experimentally validates the effectiveness of phase change mortar in enhancing the indoor heat storage capacity of EPS module rural residences. Then, aiming to improve indoor temperature and thermal stability, a study on the optimization design of the EPS module rural residence building envelope is conducted, with variables including heat transfer coefficient of the building envelope, window–wall ratio, phase change temperature, and phase change mortar thickness. The research focuses on the application of phase change mortar in EPS module rural residences in cold and severe cold regions, providing quantitative recommendations for improving the indoor thermal performance of EPS module rural residences.

2. Experimental Exploration

The data from small-scale model testing can be used to verify the thermal performance of full-scale buildings [22]. Although small-scale models tend to heat up faster and reach higher peak temperatures than full-scale buildings [23], they are suitable for comparative studies. In this study, two scaled models—one with phase change mortar and one without—were tested to verify whether phase change mortar can effectively regulate indoor temperature in EPS module rural residences.

A small-scale physical model, constructed with the same building materials and assemblies as the full-scale building but at reduced spatial dimensions, offers a scientific approach to investigating thermal performance [22]. In this study, two 1:5 scaled models (Figure 3) representing a typical bedroom in rural residences were constructed. The dimensions of the typical room scaled model were 780 mm (width) × 960 mm (depth) × 600 mm (height), with a south-facing window of 420 mm × 300 mm. The building envelope used 120 mm thick expanded polystyrene (EPS) boards with a thermal conductivity of 0.33 W/(m·K), and the window used a transparent polycarbonate sheet with a heat transfer coefficient of 2.0 W/(m2·K). All model seams were sealed with structural adhesive. The phase change mortar was prepared by mixing paraffin phase change microcapsules with plaster mortar in a 1:3 ratio. The paraffin phase change microcapsules were made using high-purity straight-chain alkane paraffin as the core material and polymethyl methacrylate as the shell material. Differential scanning calorimetry (DSC) was used to test the latent heat of the prepared phase change mortar. The results indicated that the phase change temperature was 17.79 °C, with a latent heat of 72.461 J/g. The phase change mortar was applied to the interior surface of the experimental model’s external wall, while the control model’s interior wall was coated with cement mortar, both with a thickness of 10 mm.

Figure 3.

Experimental model and real picture.

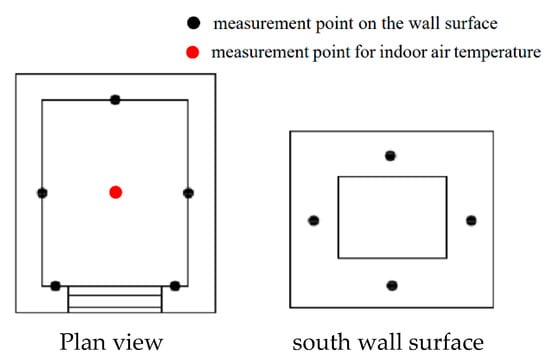

The wall surface and air temperatures of the two model sets were measured during the experiment. Four temperature measurement points were set on the interior wall of the model’s walls, and one temperature measurement point was placed on the floor. Additionally, one air temperature measurement point was located 300 mm above the floor. Data from each point were recorded every 5 min. The average temperature of the five wall surface measurement points was taken as the model’s wall surface temperature. The experimental data are shown in Figure 4. Compared to the control group, the wall surface temperature of the experimental group model increased by 0.35 °C. The average air temperature within the model remained unchanged, while the maximum temperature decreased by 4.3 °C, and the minimum temperature increased by 0.4 °C. The daily temperature fluctuation range was reduced by 4.7 °C. The experiment demonstrates that paraffin phase change mortar can increase indoor wall surface temperature and nighttime winter indoor temperature, reduce temperature fluctuations throughout the day, and improve indoor thermal stability without decreasing the average indoor temperature.

Figure 4.

Layout of temperature measurement points.

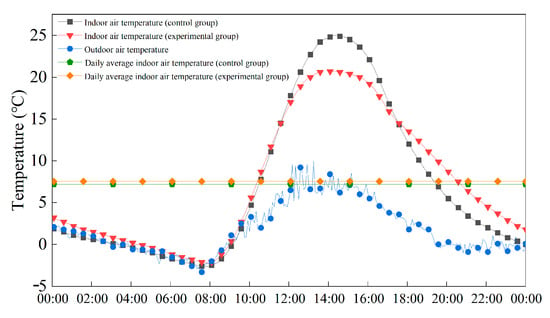

From January 1 to 3, 2024, under clear weather conditions, the inner wall surface temperatures and indoor air temperatures of the two models were continuously monitored in Jinan, with data collected at 10 min intervals. Figure 4 shows the positions of seven wall surfaces and one air temperature measurement point, with the latter located 300 mm above the floor. As shown in Figure 5, the experimental group exhibited a slight increase in average indoor air temperature and average wall surface temperature compared with the control group, by 0.35 °C and 0.42 °C, respectively. In contrast, the daily indoor air temperature fluctuation decreased by 4.7 °C, while the surface temperature differences between the south and north walls decreased by 6.4 °C and 6.5 °C, respectively. These findings indicate that paraffin microcapsule phase change mortar is effective in regulating indoor temperature and improving thermal stability. However, its influence on increasing the average indoor temperature is limited, as the total solar heat gain indoors remains constant, and the mortar primarily functions by redistributing the timing of the heat that is partially stored.

Figure 5.

Line charts of indoor and outdoor air temperature of control group and experimental group.

3. Numerical Simulation

3.1. Mathematic Model

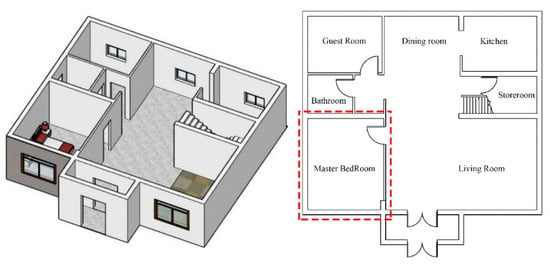

A survey was conducted on 27 EPS module rural residences in Shandong, Hebei, and other regions. The typical house type is a two-story residential building with a three-bay, three-deep layout. The south-facing bedroom is the most frequently used room throughout the day and has the longest occupancy time, making it the room with the least favorable indoor thermal stability. Therefore, the south-facing master bedroom was selected as the typical building space model for this study. The bedroom has a width of 4.8 m, a depth of 3.9 m, and a ceiling height of 3.3 m, with a total floor area of 18.72 m2 and a south-facing window, as shown in Figure 6. n winter, only solar radiation heat gain is considered for the bedroom, with no additional auxiliary heat sources inside the room.

Figure 6.

The plan of the first floor of the typical house type of a self-built agricultural house.

In rural houses, occupants often wear heavy clothing during winter due to frequent ingress and egress associated with daily life and work. According to relevant standards, the minimum indoor design temperature for rural residential buildings during the heating season is set at 14 °C [3]. The high thermal insulation and airtightness of EPS modular building envelopes make it possible for the indoor temperature to reach this design value relying solely on solar heat gain. Therefore, only solar heat gain through windows is considered, with no additional auxiliary heating. The negative effects of typical rural construction and the benefits of cast-in-place concrete within EPS modules and high-performance doors and windows are considered, with airtightness set at 1.7 h−1 at 50 Pa [24], based on average measurements in cold-climate city residential buildings.

In this study, the DesignBuilder V6.1.0.006 software was used to create a building model of the south-facing master bedroom (Figure 6). The temperature–enthalpy curve of the phase change mortar was defined, and the finite difference method was applied to calculate the impact of material phase change characteristics. In the model, phase change mortar was applied as a leveling layer on the interior sides of the walls and floor slabs.

3.2. Climate Variables

Solar energy availability and heating demand intensity are the key factors influencing the thermal regulation performance of phase change materials in rural houses without conventional heating systems. Therefore, this study focuses on regions with relatively abundant solar resources and moderately cold winters, where climatic conditions are not excessively severe. The selection of representative cities was conducted in two stages. In the first stage, Zone 1A (severe cold) was excluded due to its extremely high heating demand, which makes it unsuitable for rural houses without heating equipment. The candidate regions were thus restricted to Zones 1B and 1C (severe cold) and Zones 2A and 2B (cold) [25]. In the second stage, representative cities were selected based on the availability of solar resources [26]. Zones 1B, 1C, and 2B are generally characterized by relatively abundant solar radiation, and Harbin, Shenyang, and Beijing were chosen as representative cities, respectively. Zone 2A, which spans a wide geographical range with diverse solar conditions, was represented by Lhasa (extremely abundant resources), Yinchuan (abundant resources), and Dalian (relatively abundant resources). The climate characteristic data of the six representative cities are shown in Table 1.

Table 1.

The climate characteristics of typical representative cities.

3.3. Building Envelope Design Variables

This study investigates the impact of four building envelope design variables—heat transfer coefficient, window-to-wall ratio, phase change temperature, and phase change material thickness—on the indoor thermal environment of EPS module rural residences. Based on engineering practice, two types of wall heat transfer coefficient were defined in this study: The first type (Type I wall) uses a 60 mm thick EPS module on the exterior side, with a wall heat transfer coefficient of 0.128 W/(m2·K), and a triple-glazed, two-air cavity thermal-insulating aluminum alloy window, with a whole-window heat transfer coefficient of 2.0 W/(m2·K). The second type (Type II wall) uses a 160 mm thick EPS module on the exterior side, with an external wall heat transfer coefficient of 0.092 W/(m2·K), and a triple-glazed, two-air cavity argon-filled single LOW-E PVC window, with a whole-window heat transfer coefficient of 1.6 W/(m2·K). Both window types have a shading coefficient of 0.79. Table 2 shows the optimization design variables for the EPS module rural residence building envelope and their respective value ranges. The EPS modules corresponding to the two types of walls are shown in Figure 7.

Table 2.

Design variables and value range of envelope optimization.

Figure 7.

EPS straight plate wall cavity mold block with different thickness of Polystyrene plate.

3.4. Optimization Objectives

The operative temperature integrates environmental thermal and humidity parameters, such as air temperature, radiant temperature, and wind speed, and can comprehensively evaluate the influence of Phase Change Mortar (PCM) on the indoor air temperature and the radiant temperature of internal surfaces. According to the ASHRAE standard, the calculation formula for the indoor operative temperature is as follows:

In the formula: is indoor operative temperature; is average indoor air temperature; is average radiant temperature of indoor surfaces; is a function of relative wind speed, typically assumed to be 0.5. In this study, the DesignBuilder V6.1.0.006 software uses the above formula to calculate the indoor operative temperature.

Based on the indoor operative temperature, this study defines four optimization objectives during the heating period: the average temperature , the temperature difference ∆T on the winter solstice, the increase in comfort hours , and the indoor temperature improvement rate . represents the average hourly indoor operative temperature during the heating period; ∆T is the difference between the maximum indoor operative temperature and the minimum on the winter solstice day. The indoor design temperature for the EPS module rural residence is set at ≥14 °C. is the number of hours during the heating period when the indoor operative temperature is ≥14 °C, measured as the increase resulting from the use of Phase Change Mortar (PCM) compared to when PCM is not used.

Following the concept of heating/cooling degree days, this study defines discomfort hours H, where, for any hour when the indoor operative temperature is below 14 °C, the temperature difference from 14 °C is multiplied by 1 h, and this product is accumulated over the heating period [27], with the unit of measurement being K·h. The calculation for the indoor temperature improvement rate is given by Equation (2):

In the formula: is the indoor temperature improvement rate during the heating period (%); is the discomfort hours during the heating period without the use of Phase Change Mortar (PCM); is the discomfort hours during the heating period with the use of Phase Change Mortar (PCM).

4. Simulation Data Analysis

4.1. Correlation Analysis

This study conducted simulations for six cities—Beijing, Harbin, Shenyang, Dalian, Yinchuan, and Lhasa—covering a total of 350 combinations of four building envelope optimization design variables, thereby obtaining the indoor operative temperatures under 350 working conditions. Based on these datasets, SPSS 26.0 software was employed to analyze the correlations between climate variables, building envelope variables, and indoor operative temperature. The results indicate the following:

Wall thermal transmittance, phase change temperature, Phase Change Material (PCM) thickness, and representative city exert significant impacts on indoor operative temperature, with all significance (Sig.) values equal to 0.000.

The window-to-wall area ratio shows a relatively weaker influence on indoor operative temperature, with a significance (Sig.) value of 0.008.

4.2. Wall Thermal Transmittance

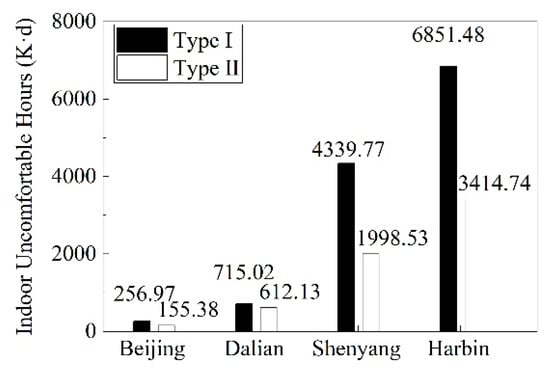

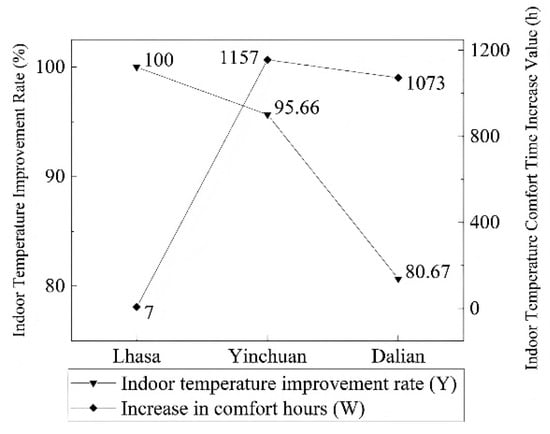

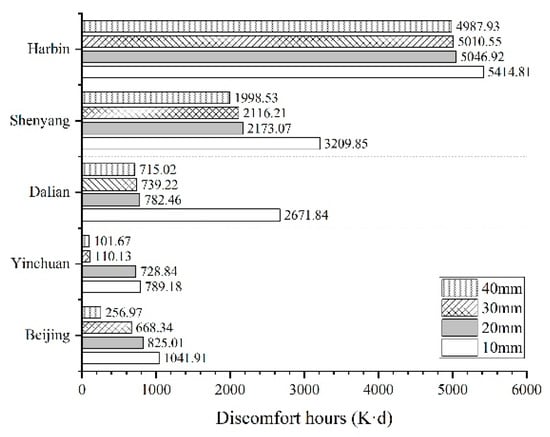

Beijing, Dalian, Shenyang, and Harbin belong to four building thermal design zones with relatively abundant solar resources. Figure 8 and Figure 9 present the variations in discomfort hours and indoor temperature improvement rate Y under two wall thermal transmittance conditions when Phase Change Mortar (PCM) is applied.

Figure 8.

Uncomfortable hours in different thermal climate zones.

Figure 9.

Room temperature improvement rate in different thermal climate zones.

For Harbin in Severe Cold Zone 1C and Shenyang in Severe Cold Zone 1B, the performance of Type II walls in terms of and is significantly better than that of Type I walls. Specifically, decreases by 3436.74 K·h and 2341.24 K·h, while Y increases by 23.48% and 25.94%, respectively. In contrast, for Beijing in Cold Zone 2B and Dalian in Cold Zone 2A, the differences in and between Type I and Type II building envelopes are less pronounced; decreases slightly, while Y decreases by 2.45% and 5.81%, respectively. Therefore, Type I walls are recommended for cold regions, while Type II walls are more suitable for severe cold regions.

4.3. Phase Change Temperature

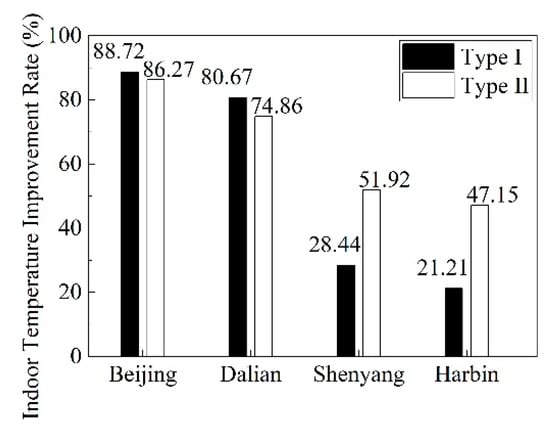

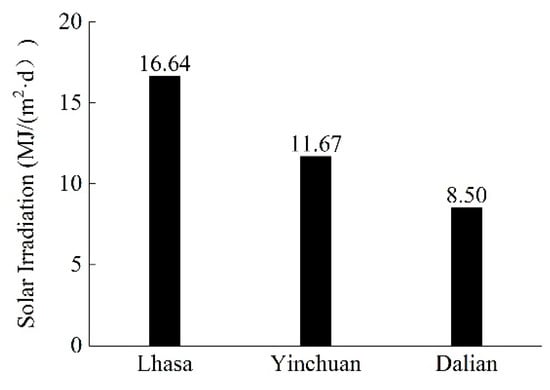

Lhasa, Yinchuan, and Dalian belong to three solar energy resource zones within Cold Zone 2A. The average daily solar radiation during the heating season is used to characterize the solar energy availability in these cities, as shown in Figure 10. Simulation results of applying Phase Change Mortar (PCM) to Type I walls in these cities are presented in Figure 11. The results indicate that Lhasa achieves the highest indoor temperature improvement rate of 100%, while exhibiting the lowest increase in comfort hours W of only 7 h.

Figure 10.

Average daily solar irradiation in heating season.

Figure 11.

Room temperature improvement rate and increase in comfort time.

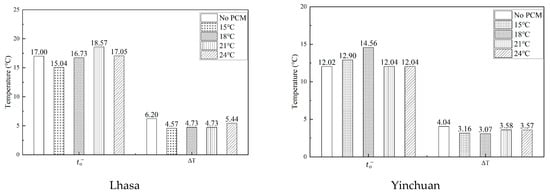

To further investigate this phenomenon, simulations were conducted with phase change temperature as the variable, assuming a PCM thickness of 10 mm and a window-to-wall ratio of 0.2. The study examined Type I walls in Lhasa, Yinchuan, Beijing, and Dalian, and Type II walls in Shenyang and Harbin. The variations in average operative temperature during the heating season () and the indoor operative temperature difference on the winter solstice (ΔT) are shown in Figure 12.

Figure 12.

The daily temperature difference ΔT and the average room temperature TA of the winter solstice room temperature in six regions with different phase transition temperatures.

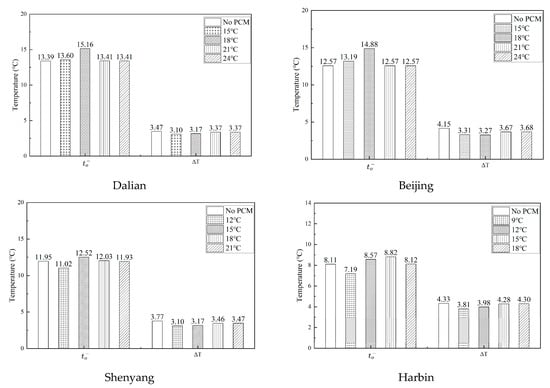

Considering both the average operative temperature and the temperature difference on the winter solstice (ΔT), the optimal phase change temperature of PCM for EPS module rural residences in Lhasa is 21 °C, in Yinchuan, Beijing, and Dalian is 18 °C, and in Shenyang and Harbin is 15 °C. As shown in Figure 13, the optimal phase change temperature is 2–4 °C higher than the corresponding .

Figure 13.

Mean value of optimal phase transition temperature and room temperature in heating period.

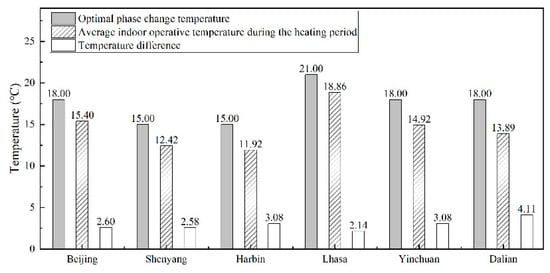

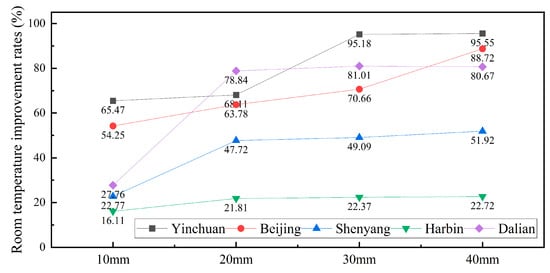

4.4. PCM Layer Thickness

Using PCM thickness as the variable, simulations were conducted under the optimal phase change temperature with a window-to-wall ratio of 0.2. PCM thicknesses of 10 mm, 20 mm, 30 mm, and 40 mm were tested for Type I building envelope walls in Beijing, Yinchuan, and Dalian, and for Type II walls in Harbin and Shenyang. The resulting degree-hours of discomfort () and indoor temperature improvement rate () of EPS module rural residences were analyzed.

Figure 14 presents for the five cities under different PCM thicknesses. The results show that is inversely related to PCM thickness. At certain PCM thicknesses, decreases significantly. Considering both performance and cost-effectiveness, the optimal PCM thickness is 20 mm for Harbin, Shenyang, and Dalian, 30 mm for Yinchuan, and 40 mm for Beijing.

Figure 14.

Discomfort hours at different phase transition thicknesses.

Figure 15 illustrates under varying PCM thicknesses across the five cities. The improvement rate increases as PCM thickness approaches its optimal value, with the maximum observed in Dalian at a thickness of 20 mm, where the improvement reaches 51.08%.

Figure 15.

Room temperature improvement rates of different thicknesses of phase change mortar.

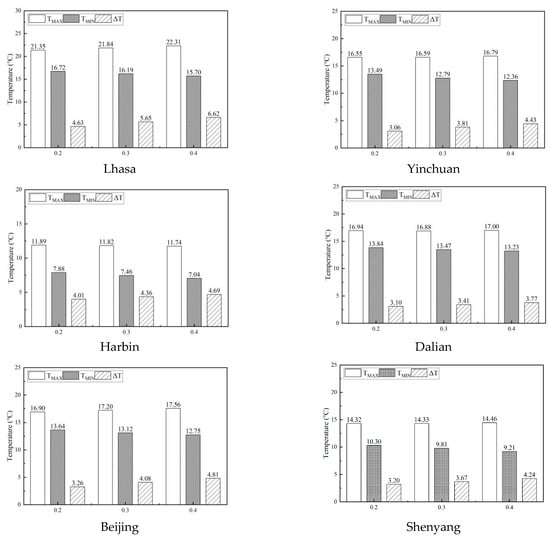

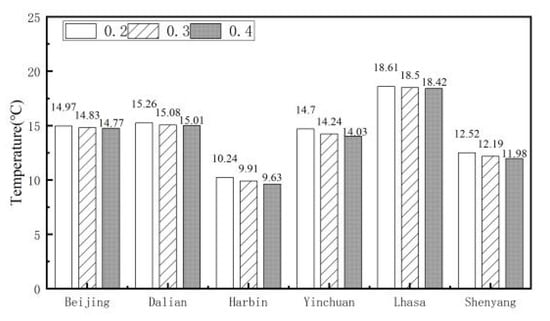

4.5. Window-to-Wall Ratio

Using the window-to-wall ratio as the variable, simulations were conducted under the optimal phase change temperature for ratios of 0.2, 0.3, and 0.4. The tested cases included Type I walls in Lhasa, Beijing, Dalian, and Yinchuan, and Type II walls in Harbin and Shenyang. The analyzed indicators included the indoor operative temperature difference on the winter solstice (ΔT), daily maximum temperature (), daily minimum temperature (), and daily average temperature, as shown in Figure 16 and Figure 17.

Figure 16.

ΔT, and on winter solstice in different WWR.

Figure 17.

Average room temperature on winter solstice in different WWR.

Figure 16 demonstrates that for all six cities, when the window-to-wall ratio is 0.4, ΔT reaches its maximum value, indicating the poorest thermal stability. The reason is that a larger window area allows for greater solar heat gain during the day, increasing , while also causing greater heat loss at night, reducing . This results in a larger ΔT and thus reduced indoor thermal stability.

Figure 17 shows that under the three window-to-wall ratio conditions, the range of variation in the daily average temperature on the winter solstice is only 0.19–0.67 °C, indicating that the effect of window-to-wall ratio on indoor temperature is relatively small. Therefore, the window-to-wall ratio has limited influence on the indoor operative temperature of EPS module rural residences. However, nighttime insulation measures for external windows in winter can effectively increase , thereby reducing daily indoor temperature fluctuations.

4.6. Results and Discussion

Jinan, similar to Beijing, belongs to cold climate zone 2B and benefits from relatively abundant solar resources. In the experimental study, the model adopted Type I EPS module exterior walls, a PCM plaster with a phase change temperature of 18 °C (measured 17.79 °C), and a window-to-wall ratio of 0.26. Considering the high cost of paraffin-based PCM microcapsules, the PCM layer thickness was restricted to 10 mm. On the experimental day, the measured average indoor air temperature was 7.55 °C, compared with the simulated value of 8.13 °C, resulting in a deviation of 7.1%, which demonstrates the accuracy of the numerical model.

The analysis indicates that severe indoor temperature fluctuations in well-insulated and airtight EPS module houses are mainly caused by the limited thermal mass of their special sandwich structure. By introducing PCM plaster as an interior finishing layer, the temporal distribution of solar heat can be modified. During periods of elevated indoor temperature, typically in the daytime, the PCM absorbs surplus solar heat and stores it as latent heat. As temperatures drop at night, the stored heat is gradually released, mitigating nighttime temperature fluctuations.

This study specifically focuses on the design variables of EPS modules and PCM plaster, including the thickness of the exterior insulation layer in EPS modules, as well as the phase change temperature and thickness of the PCM plaster. The objective is to explore how solar radiation transmitted through windows can be more effectively redistributed in EPS module rural houses without heating equipment. Although the window-to-wall ratio was included in the optimization process, the results indicate that its influence on indoor thermal stability is minimal compared with the effects of EPS module thermal transmittance, PCM phase change temperature, and PCM thickness.

It is worth noting that the present work only considers solar heat gains, whereas in real operation, kang systems, electric heating devices, and coal stoves also serve as important heating sources in rural houses. Accordingly, the optimization conclusions drawn here are specifically applicable to EPS module rural houses with PCM plaster under conditions without auxiliary heating equipment.

In addition, while most existing studies use indoor air temperature as the sole indicator of thermal stability [3], the application of PCM plaster also alters the dynamics of wall surface temperatures. Therefore, operative temperature was employed in this study as a more comprehensive evaluation index, accounting for both air and surface temperature variations. Inspired by the concept of heating degree days, a new metric, the “discomfort hours,” was defined to jointly integrate the dimensions of time and temperature, providing a more holistic assessment of indoor thermal conditions.

In summary, this study not only validates the effectiveness of PCM plaster in stabilizing indoor thermal environments of EPS module rural houses, but also introduces operative temperature and discomfort hours as innovative evaluation metrics, offering a more comprehensive framework for assessing thermal stability in cold-climate rural buildings.

5. Conclusions

The main conclusions regarding the optimization design of EPS module rural residence envelopes incorporating phase change microcapsule mortar are as follows:

(1) Climate adaptability of EPS modules and PCM plaster:

The thermal transmittance of EPS module walls is the key factor influencing indoor temperature in rural residences. Appropriate wall types should be selected according to climatic conditions: Type II walls are recommended for severely cold regions, while Type I walls are suitable for cold regions. The effectiveness of PCM plaster in improving indoor temperature is limited in solar-rich cold regions (e.g., Lhasa), where its application is not recommended.

(2) Optimization of PCM plaster design parameters:

An optimal phase change temperature and thickness exist for PCM plaster applied in EPS module rural residences. The optimal phase change temperature should be 2–4 °C higher than the average indoor operative temperature during the heating period. Specifically, 18 °C is recommended for Type I walls in Yinchuan, Beijing, and Dalian, while 15 °C is recommended for Type II walls in Shenyang and Harbin. Under these conditions, the optimal thicknesses are 20 mm for Harbin, Shenyang, and Dalian; 30 mm for Yinchuan; and 40 mm for Beijing. This optimization strategy balances indoor temperature improvement and construction cost, achieving more rational design.

Compared with the window-to-wall ratio, nighttime insulation measures for external windows in winter are more effective in enhancing the daily stability of indoor temperature.

(3) Innovative evaluation of indoor thermal stability

This study introduces operative temperature and discomfort hours as novel metrics to evaluate the thermal performance of EPS module rural houses, providing a more comprehensive framework for assessing indoor thermal stability in cold-climate rural buildings. This approach is particularly suitable for buildings using phase change materials on interior wall surfaces, such as PCM plaster.

Author Contributions

Conceptualization, Q.Y.; methodology, Q.Y. and K.W.; validation, Q.Y.; writing—original draft, L.K. and C.C.; writing—review and editing, Q.Y.; investigation, K.W. and C.C.; supervision, K.W.; software, C.C. and L.K.; visualization, C.C. and L.K.; resources, Q.Y.; project administration, K.W.; funding acquisition, K.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Research Results of Social Science Planning Project in Shandong Province: Research on Public Toilet Renovation Strategies in Shandong Region from the Perspective of Urban Renewal (23CWYJ23).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Nomenclature

| Abbreviations | |||

| DSC | Differential scanning calorimetry [-] | Indoor operative temperature [°C] | |

| EPS | Expanded polystyrene [-] | Average indoor air temperature [°C] | |

| PCM | Phase change material [-] | Average indoor operative temperature during the heating period [°C] | |

| SPSS | Statistical Product and Service Solutions [-] | Mean radiant temperature of indoor wall surfaces [°C] | |

| Window-to-Wall Ratio [-] | ∆T | Temperature difference, typically the daily difference between maximum and minimum operative temperatures [°C] | |

| Maximum operative temperature on the winter solstice [°C] | |||

| A function of relative wind speed, typically assumed to be 0.5 | Minimum operative temperature on the winter solstice [°C] | ||

| H | Cumulative discomfort degree-hours during the heating period [K·d] | Increase in comfortable hours, i.e., additional hours with to ≥ 14 °C compared to the case without PCM [ h] | |

| Cumulative discomfort degree-hours with PCM [K·d] | Y | Indoor temperature improvement rate during the heating period [%] | |

| Cumulative discomfort degree-hours without PCM [K·d] |

References

- Wang, J. China’s building “dual-carbon” pathway: Scientific issues and research recommendations. China Sci. Found. 2023, 37, 353–359. [Google Scholar]

- Pu, Y.; Ci, Q. EPS Module Concrete Shear Wall Structure System Rural House. Archit. Eng. Technol. Design. 2015, 33, 1706–1708. [Google Scholar]

- JGJ/T 267-2012; Technical Code for Passive Solar Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2012.

- Chen, J.; Kang, X. Numerical Simulation of Thermal Performance of Solar Phase-Change Heat Storage Ventilation Wall in Winter. Acta Energ. Sol. Sin. 2023, 44, 522–530. [Google Scholar]

- Harlé, T.; Hebert, R.L.; Nguyen, G.T.M.; Ledésert, B.A. A composite of cross-linked polyurethane as solid–solid phase change material and plaster for building application. Energy Build. 2022, 262, 111945. [Google Scholar] [CrossRef]

- Wang, J.; Li, H.; Lin, Z.; Chi, P. Preparation and Performance Analysis of Paraffin–Phenolic Resin–Cement Phase Change Mortar. J. Xiamen Univ. Technol. 2020, 28, 62–65. [Google Scholar]

- Li, D.; Tang, Y.; Zuo, X.; Zhao, X.; Zhang, X.; Yang, H. Preparation of hierarchical porous microspheres composite phase change material for thermal energy storage concrete in buildings. Appl. Clay Sci. 2023, 232, 106771. [Google Scholar] [CrossRef]

- Hu, Z.; Yang, C.; Guo, X.; Ge, F.; Wang, S. Thermal Performance Simulation of Low-Grade Water Jacket Phase Change Walls. J. Jiangsu Univ. Nat. Sci. Ed. 2023, 44, 242–248. [Google Scholar]

- Arivazhagan, R.; Geetha, N.B.; Sivasamy, P.; Kumaran, P.; Gnanamithra, M.K.; Sankar, S.; Loganathan, G.B.; Arivarasan, A. Review on performance assessment of phase change materials in buildings for thermal management through passive approach. Mater. Today Proc. 2020, 22, 419–431. [Google Scholar] [CrossRef]

- Fan, Z.; Zhao, Y.; Ding, Y.; Liu, X.; Jiang, D. Research Progress on the Application of Phase Change Energy Storage Materials in Building Walls. New Chem. Mater. 2022, 50, 225–228. [Google Scholar]

- Shi, C.; Wang, P.; Yang, L. Research Progress on the Modification of Paraffin-Based Phase Change Energy Storage Materials for Buildings. Prog. China Mater. 2022, 41, 607–616. [Google Scholar]

- Sarcinella, A.; Aguiar, J.L.B.; Jesus, C.; Frigione, M. Thermal properties of PEG-based form-stable Phase Change Materials (PCMs) incorporated in mortars for energy efficiency of buildings. J. Energy Storage 2023, 67, 107545. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Qian, W.; Li, D. Performance and temperature control simulation of fatty acid phase change energy storage panels. Energy Storage Sci. Technol. 2023, 12, 247–254. [Google Scholar]

- Jin, C.; Liu, Z.; Luo, T.; Jin, Q.; Tang, Y.; Cai, X. Research progress on composite phase change materials in the field of building energy conservation. New Chem. Mater. 2023, 51, 24–29. [Google Scholar]

- Zeng, R.; Wang, X.; Xiao, W.; Zhang, Y.; Di, H.; Zhang, Q. “Research and Demonstration of Renewable Energy and Building Integration Technology”—Subproject: Experimental Study on the Performance of Phase Change Heat Storage Floor. Constr. Sci. Technol. 2009, 24, 24–27. [Google Scholar]

- Cunha, S.; Aguiar, J.B.; Ferreira, V.M.; Tadeu, A. Influence of the Type of Phase Change Materials Microcapsules on the Properties of Lime-Gypsum Thermal Mortars. Adv. Eng. Mater. 2014, 16, 433–441. [Google Scholar] [CrossRef]

- Wen, Y. Study on Self-Insulation Performance and Microscopic Thermal Mechanism of Phase Change Microcapsule Modified Mortar. Master’s Thesis, Hebei University of Engineering, Handan, China, 2022. [Google Scholar]

- Zhou, D.; Shire, G.S.F.; Tian, Y. Parametric analysis of influencing factors in Phase Change Material Wallboard (PCMW). Appl. Energy 2014, 119, 33–42. [Google Scholar] [CrossRef]

- Li, Z.; Al-Rashed, A.A.A.A.; Rostamzadeh, M.; Kalbasi, R.; Shahsavaret, A.; Afrand, M. Heat transfer reduction in buildings by embedding phase change material in multi-layer walls: Effects of repositioning, thermophysical properties and thickness of PCM. Energy Convers. Manag. 2019, 195, 43–56. [Google Scholar] [CrossRef]

- Qiao, Y.; Bao, J.; Liu, Y.; Yang, L. Thermal performance of composite phase change layers in typical exterior wall structures. Build. Energy Effic. 2020, 48, 1–5. [Google Scholar]

- Meng, F.; Chu, Q.; Wang, S.; Gong, Y.; Hu, F.; Han, L. Influence of spatial distribution patterns of PCM-filled walls on heat transfer under periodic boundary conditions. Acta Energ. Sol. Sin. 2019, 40, 851–2856. [Google Scholar]

- Liu, X.; Xu, M. Thermal performance study of buildings and their corresponding scale models with identical constructions and geometrical similarity. J. Eng. Res. 2024, 12, 599–609. [Google Scholar] [CrossRef]

- Liu, X.; Guo, J.; Wang, J. Numerical and experimental studies on the energy performance of thermal mass windows. J. Build. Phys. 2019, 42, 692–721. [Google Scholar] [CrossRef]

- Ji, Y. Prediction Model of Air Infiltration for Building Envelopes in High Airtight Residential Buildings in Cold Regions. Master’s Thesis, Dalian University of Technology, Dalian, China, 2018. [Google Scholar]

- GB 50176-2016; Design Code for Thermal Insulation of Civil Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016.

- GB 50015-2019; Code for Design of Building Water Supply and Drainage. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Wang, W. Optimization Study on Thermal Performance of Solar Collection and Storage Components in Urban Residences of Solar-Rich regions. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2018. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).