Abstract

Digitalization in the construction industry has transformed efficiency and coordination, with Building Information Modeling (BIM) emerging as a central enabling technology. However, despite its potential, BIM usage during the implementation phase of Swedish construction projects remains limited. Using the Technology–Organization–Environment (TOE) framework, this study combines a systematic literature review with a quantitative survey of 220 professionals. The data were analyzed using descriptive statistics, correlation analysis, factor analysis, and ordinal logistic regression. The results show that technological and organizational barriers are present to a moderate extent, but they manifest as distinct and separate dimensions. In contrast, the most significant barriers to actual BIM adoption lie within the environmental domain. Specifically, the absence of clear external requirements, policies, and incentives is strongly and negatively associated with BIM implementation. The study concludes that although contractors demonstrate internal technical readiness, external systemic support is crucial for scaling up BIM in practice. These insights carry important implications for industry stakeholders and policymakers aiming to accelerate the digital transformation of the construction industry.

1. Introduction

The digital transformation of the construction industry has significantly reshaped the conditions for planning, design and production over the past two decades. Among the most influential technologies driving this shift is Building Information Modeling (BIM), which seeks to streamline information management and enhance coordination throughout the construction process. BIM has demonstrated considerable potential to improve quality, reduce costs, and foster collaboration among stakeholders in construction projects [,]. Nevertheless, its application during the production phase in the Swedish construction industry remains limited [].

Previous research has identified several barriers to BIM implementation in the Swedish construction industry, including inadequate training, insufficient client requirements, high investment costs, and organizational resistance [,]. However, these studies have primarily focused on the design phase or broader organizational perspectives. Few have systematically examined the specific barriers encountered during the production phase, particularly the operational barriers faced on-site. This study addresses that gap by applying a structured framework to investigate production-specific barriers to BIM adoption.

A deeper understanding is needed of the practical barriers that arise on construction sites, where time constraints, complex workflows, and limited digital support systems often impede effective BIM utilization []. To explore these barriers in a systematic manner, this study employs the Technology–Organization–Environment (TOE) framework—a well-established analytical framework for identifying and categorizing factors that influence technology adoption []. It distinguishes three main dimensions: technological factors (e.g., technical compatibility, usability), organizational factors (e.g., resources, management, culture) and environmental factors (e.g., industry pressures, regulations, client requirements).

While the TOE framework has been applied in previous studies on technology adoption in construction, such as analyses of digital strategies [], IT systems, and organizational change [,], it has not been extensively used to examine barriers to BIM implementation during the practical stage of construction production, especially from the perspective of contractors working on-site. Existing research linking TOE to BIM tends to focus on the design phase, organizational decision-making, or general technology acceptance [], and rarely captures the lived experiences from the production environment, where BIM encounters operational and collaborative barriers. By integrating the TOE framework with a qualitative approach, this study aims to fill that gap and contribute new insights into how technological, organizational, and environmental factors influence BIM adoption in the production phase.

The purpose of this study is to investigate the barriers that influence Swedish construction contractors’ adoption of BIM during the production phase, using the Technology–Organization–Environment (TOE) framework as a guiding structure. Within this context, the following research questions have been formulated to define the scope of the study:

- How do contractors perceive the influence of technological elements, such as software tools, technical expertise, and system compatibility, on the execution of BIM in construction production?

- What organizational barriers, such as management support, internal workflows, and availability of skilled personnel, limit contractors’ capacity to implement BIM in the production phase?

- In what ways do external factors, such as industry standards, client expectations, and digital maturity of project partners, affect BIM utilization in contractor-led construction projects?

- How do technological, organizational, and environmental barriers interact, and in what ways does this interplay contribute to the complexity of BIM implementation in real-world construction setting?

2. Background

This section explains further the discussion of barriers when implementing BIM, the research gap, and summarizes common BIM utilization in the construction production.

2.1. The Swedish Context: BIM for Construction Production

The construction industry plays a vital role in Sweden’s economy, labor market, and built environment, employing hundreds of thousands of individuals. Yet, it faces several persistent challenges, including productivity, high resource consumption, fragmented workflows and limited collaboration among stakeholders [,]. These issues are particularly distinct during the production phase, the on-site execution of construction projects, which is often marked by tight schedules, budget constraints, complex logistics, and frequent changes in personnel and contractors [,]. To address these challenges, digitalization has emerged as a key driver of improved efficiency, quality and sustainability within the sector. At the heart of this digital transformation is Building Information Modeling (BIM), an approach and process, that facilitates model-based information management and coordination throughout the entire lifecycle of a building [,]. BIM offers significant advantages, including enhanced planning, reduced errors, accelerated decision-making, and more streamlined construction processes, especially during the production phase, where resources are actively deployed. Despite its potential, BIM has yet to achieve widespread adoption in Swedish construction production, particularly among small and medium-sized enterprises.

Overall, the adoption of digital technologies in the construction industry remains limited, particularly among regional construction companies, which often hinder broader technological advancement within the sector []. Consequently, many companies continue to rely on traditional methods. According to sources [,], the use of BIM is unevenly distributed across the industry. Larger companies and clients tend to lead the way in digitalization; while contractors, subcontractors, and on-site teams frequently lack the necessary conditions to fully integrate BIM into their daily operations. Common barriers include inadequate digital skills, poor integration of technology into existing workflows, limited support from management, and the absence of clear client requirements or incentives to adopt new tools [,].

Sweden has launched several national initiatives at the national level aimed at accelerating the digital transformation in the construction industry. One of the most comprehensive efforts is the strategic innovation program Smart Built Environment, which seeks to foster a sustainable and digitally integrated built environment sector through research, standardization and collaboration []. Public authorities, such as the Swedish National Board of Housing, Building and Planning, have also introduced new regulations, such as climate declarations that indirectly increase the demand for improved information management and digital tools [].

Despite these efforts, substantial barriers continue to hinder the implementation of digital tools in construction production environments. Research suggests that there is often a lack of systematic understanding of how various types of barriers: technical, organizational and environmental, interact within the context of construction production, particularly from the perspective of contractors [,]. By focusing on the use of BIM during the production phase and examining these barriers through the lens of the TOE (Technology–Organization–Environment) framework, this study offers new insight into the factors that influence contractors’ ability to effectively harness the potential of digitalization in practice.

2.2. BIM as Enabler of Digitalization in Building Projects

Beyond enhancing efficiency and coordination, the integration of Building Information Modeling (BIM) offers significant benefits for improving quality and promoting sustainability in construction projects. BIM is increasingly linked to sustainability objectives within the industry. Numerous studies highlight its potential to support both environmental and social sustainability by facilitating life cycle assessments, optimizing resource use, and improving transparency in stakeholder communication [,,]. In construction projects, BIM proves valuable for analyzing data related to energy efficiency and sustainability. It enables visualization and modeling of a building’s design and performance by supporting assessments of energy consumption, carbon emissions, and pollution levels in green buildings []. According to [], BIM has been developed and promoted as a tool for integrating all design-related information. However, a major challenge remains there are still a shortage of qualified professionals with the necessary expertise and experience to fully leverage its capabilities [].

Furthermore, BIM has demonstrated clear advantages in enhancing project quality, managing and storing lifecycle data, optimizing collaboration, and improving planning and scheduling during the construction phase of green buildings []. According to [], several barriers hinder the effective use of BIM in this context. These include the non-uniform data format, limited system interoperability, unclear data ownership, inadequate BIM training, and general reluctance to adopt the technology.

Because BIM is predominantly focused on traditional facility design rather than sustainability-oriented features, designers and operators often rely on a range of heterogeneous software systems to compensate for its limitations. This reliance on multiple tools introduces significant challenges related to interoperability and data integrity []. As the authors [] point out, this issue is particularly pronounced in the Architecture, Engineering, and Construction (AEC) industry, which is highly fragmented. Different disciplines use distinct tools and produce various models that may function well independently but are difficult to integrate with third-party systems, complicating collaboration and data exchange across project stakeholders.

In the Swedish context, sustainability has become a central focus of the national digitalization agenda, where BIM is regarded not merely as a technical tool, but as a strategic enabler of sustainable practices in procurement, planning and production [,]. Socio-cultural expectations for sustainable development, combined with policy incentives and environmental declarations, further strengthen BIM’s role in aligning construction project with long-term sustainability goals [,]. Among the most significant contributions of digitalization to the construction industry, particularly in the realm of sustainability, is the improved access to information, the way it is exchanged, and the transparency it enables [].

2.3. BIM in Construction Production: Applications and Research Gaps in the Current Literature

Over the past decade, BIM has emerged as one of the most pivotal digital tools for streamlining and coordinating construction projects. Research indicates that BIM enhances information management, boosts productivity, reduces construction errors, and improves control over time, cost and quality, particularly during the planning and design phase [,]. Despite its proven benefits, BIM remains significantly underutilized during the implementation phase of construction. Nevertheless, numerous studies highlight its considerable potential in this stage as well [,].

In the production phase, BIM can be applied to a wide range of tasks, including digital planning of work sequences, quantity take-off, clash detection, 4D simulations, safety planning, resource logistics and support for quality assurance and progress tracking [,]. Additionally, BIM can be integrated with sensors, schedules, machine data and geographic information systems (GIS) to provide real-time support for site management. However, realizing these applications requires both robust technical infrastructure and effective collaboration among project stakeholders.

Several overview studies indicate that BIM implementation in the production phase is largely driven by technology-centric approaches, emphasizing software capabilities, technical interoperability, and system development [,]. However, within the field of Information Systems (IS), an information system is understood to comprise both a technical subsystem, which includes the processes, tasks, and technological components necessary for system operation, and a social subsystem, which encompasses the structure of the work system, the workforce, and their attitudes, knowledge, skills, values, and interpersonal relationships []. Consequently, recognizing the interdependence between social and technical elements within organizational systems is essential for the successful adoption and implementation of information systems [].

The concept of a sociotechnical system was originally introduced to describe systems characterized by complex interactions among machines, humans, and the environmental context of work systems []. At the heart of Socio-Technical Systems (STS) theory lies the principle of jointly optimizing both the technical subsystem, comprising tools, technologies, and processes, and the social subsystem, which includes people, organizational culture, and structural arrangements, to improve overall organizational performance and employee well-being []. Thus, the social subsystem is shaped by institutional arrangements such as formal work settings, communication channels, and authority structures. It also encompasses norms, values, role expectations, and behavioral patterns that influence how individuals, managers, employees, and stakeholders act within the organizational environment [].

According to [], there is a growing shift away from viewing BIM solely as a technology-centric tool toward a socio-technical perspective. In this view, BIM facilitates effective and efficient collaboration between people and information through structured processes and supporting technologies [,]. By emphasizing the interplay of people, information, processes, and technology, this perspective underscores that BIM is not merely software, it is a holistic system integrating both social and technical dimensions []. BIM also serves as a platform that integrates various tools, enhancing planning, design, construction, and facility management by enabling the visualization of buildings within a simulated environment. Its capabilities extend well beyond the design and construction phases, offering the ability to create and manage detailed 3D models and fostering improved coordination and communication among project teams. Ultimately, this leads to more efficient workflows and cost-effective project delivery [].

Social barriers related to the “people” and the “structure” dimensions of the BIM socio-technical system have been identified as one of the most significant barriers to the widespread adoption of BIM []. Moreover, few studies systematically examine technical, organizational and environmental barriers in an integrated manner. For instance, several articles highlight issues such as software incompatibility or the absence of clear client requirements, they rarely explore how these factors interact within the context of construction production [,]. There is also a gap in research focusing on small and medium-sized contractors, despite their dominant role in the execution phase of construction projects []. The authors of [] argue that, given the highly collaborative, heterogeneous, and project-specific nature of the construction work environment, a successful BIM process can only be achieved through deliberate negotiation of intervention strategies that align with the diverse goals of multiple end users.

There is a clear lack of studies examining how production actors, particularly contractors, perceive and utilize BIM in practice [,]. As a result, there remains limited insight into the specific barriers and enabling conditions present in site-based environments, where time pressures, entrenched work practices, and varying levels of digital maturity influence implementation outcomes. In response to this gap, the present study adopts an actor-oriented approach combined with a theoretical analysis based on the TOE framework. By focusing on contractors’ experiences during the production phase, this study seeks to identify practical barriers to adoption and thereby contributes to a deeper understanding of how the potential of digitalization can be effectively harnessed on construction sites.

Table 1 outlines common applications of BIM in construction production, grouped into four thematic areas: production planning and 4D simulation, quantity take-up and logistics, collision control and safety, and quality and follow-up. These applications illustrate how BIM can enhance efficiency, accuracy, and safety during the implementation phase, provided that the necessary technical, organizational, and external conditions are in place.

Table 1.

Thematic Categorization of BIM Applications in Construction Production.

The categorization of barriers into four thematic areas: technological, organizational, environmental, and economic, is grounded in the well-established TOE framework [], which outlines three core domains influencing technology adoption. However, empirical research in the construction sector has consistently highlighted financial and resource-related constraints as a distinct group of barriers, particularly affecting small and medium-sized contractors [,,,]. These economic challenges are not always adequately captured within the traditional TOE dimensions. Therefore, they are not included as a complementary fourth category to more accurately reflect the industry-specific conditions that shape BIM implementation in production environments.

2.4. Barriers to BIM Implementation in the Construction Industry

Although BIM is widely recognized as a key technology for advancing the digitalization of the construction industry, substantial barriers continue to hinder its broad and effective adoption. Globally, BIM has demonstrated potential to enhance quality, efficiency, information management and coordination in construction projects. However, its implementation remains uneven and is often influenced by a combination of technical, organizational and external factors. In many cases, practical challenges emerge during the transition from design to production, where BIM is inconsistently applied or frequently not integrated with established workflows and practices [,,].

In Sweden, the structural conditions for digitalization are relatively favorable. Nevertheless, BIM usage still varies significantly across company types, professional roles and project phases. As noted by [], BIM is employed far more extensively during planning and design than in production phase, where contractors often face barriers such as low internal demand, limited management support, insufficient collaboration requirements and constrained resources for training and technology development. A report by [] highlights that small and medium-sized contractors frequently lack the capacity to implement BIM at scale, resulting in a disconnect between strategic digitalization ambitions and operational execution on construction sites. Importantly, these barriers are not solely technical or economic. Several studies emphasize that organizational structures, entrenched work practices, and a limited culture of change represent equally significant obstacles to BIM adoption in production environments [,]. In the context of BIM implementation, ref. [] identified a comprehensive set of barriers, categorizing them into fifteen distinct areas: cost, expertise, legal frameworks, interoperability, awareness, organizational culture, processes, management, market demand, project scale, technology, skills, training, contractual arrangements, and BIM standards. Further, the author of [], highlighted in a review five particularly impactful barriers: (1) traditional methods of contracting, (2) social and habitual resistance to change, (3) lack of awareness about BIM, (4) unavailability of proper training on BIM, and (5) lack of BIM experts. Similarly, ref. [] classified BIM implementation into five overarching categories, technology, cost, management, personnel, and legal.

- -

- Technological factors refer to limitations associated with BIM tools themselves, such as immature or underdeveloped software, lack of standardized protocols, and insufficient interoperability.

- -

- Costrelated factors include expenses associated with acquiring BIM software and hardware, ongoing service fees, and the costs of training and upskilling personnel.

- -

- Management factors encompass organizational and processrelated challenges. These include negative attitudes toward BIM adoption, absence of successful reference cases and management standards, the fragmented nature of the construction industry, unsuitable business models, and limited cooperation among industry stakeholders.

- -

- Personnel factors highlight the shortage of skilled professionals with practical BIM experience. The widespread and effective use of BIM requires substantial investment in training and education to build a competent workforce.

- -

- Legal factors stem from the underdeveloped contractual and regulatory landscape. Issues such as software imperfections can lead to legal and insurance complications, including potential litigation.

A study [] highlights that personnel-related barriers were ranked as the most significant, while legal barriers were considered the least impactful. Similar conclusions have been drawn in other research, which suggests that most BIM implementation barriers are linked to organizational dynamics and human factors as the training of employees [,]. Also, findings by [] showed that emphasized that key obstacles to BIM adoption include the need for substantial cultural change within organizations, lack of senior management support, insufficient knowledge of BIM implementation strategies, limited staff experience and skills, and the necessity to modify existing workflows to align with new digital requirements. These findings suggest that companies face greater internal resistance to BIM implementation than individual projects do, underscoring the importance of organizational readiness and leadership commitment in driving successful adoption.

In summary, numerous global studies have identified key barriers to BIM implementation. These include the absence of common standards, limited interoperability between different BIM tools, high software complexity, and fragmented data and information flows [,]. Additional recurring challenges include insufficient training, high implementation costs, legal liability uncertainties, and low digital maturity among the project stakeholders [,]. At the systemic level, weak or ambiguous client requirements, low level of standardization, and a lack of incentives within the procurement frameworks further contribute to BIM being deprioritized during the implementation phase [,].

To address these fragmentation issues, new delivery models such as Integrated Project Delivery (IPD) have been proposed since a well-structured delivery approach is vital for construction project success. Research highlights that early stakeholder involvement and a collaborative environment significantly boost performance [,]. IPD is a modern method that enhances efficiency by promoting teamwork, sharing accurate data, and leveraging new technologies. IPD improves cost, time, and quality outcomes by aligning team incentives, sharing risks and rewards, and enabling fast information exchange through multiparty contracts []. Studies show that IPD outperforms traditional methods in areas like quality, change management, and communication [].

Integrated Project Delivery (IPD) also supports the implementation of Building Information Modeling (BIM). According to the American Institute of Architects [], IPD facilitates the adoption of BIM by promoting collaborative workflows []. Ref. [] highlights the importance of collaborative practices in optimizing BIM for sustainability. The contractual framework of IPD enhances BIM integration, particularly in achieving green building objectives. By fostering trust, encouraging early stakeholder involvement, and promoting collaboration, IPD helps overcome common barriers to BIM adoption [].

Moreover, BIM can serve as a powerful tool for advancing social sustainability in green building projects. It can promote equal opportunities through inclusive design processes; raise awareness that encourages alternative consumption habits; support broad participation by involving diverse groups in decision-making; and strengthen community cohesion through integrated planning and engagement [].

In summary, these models aim to promote more collaborative and transparent processes that support BIM integration across all project phases [,]. This literature review identifies 18 recurring barriers to BIM implementation (see Table 2), organized into four thematic categories: technical, organizational, economic, and industry and culture-based obstacles. Together, these barriers underscore the multifaceted nature of BIM adoption, particularly in the production phase, and highlight the need for coordinated effort across multiple levels, including system integration and workforce training, governance, requirements setting and change management. Table 2 provides an overview of the main barriers identified in the literature on BIM implementation in practice, especially for contractors operating in the production phase.

Table 2.

Thematic Overview of Challenges to BIM Implementation in the Construction Industry.

Barriers to BIM implementation vary significantly across countries, as each nation approaches these challenges from distinct perspectives shaped by its unique socio-economic, regulatory, and technological context []. Differences in time periods, regional practices, and even individual construction projects can result in varying limiting factors []. Moreover, a clear digital divide exists in BIM adoption, both between small and medium-sized enterprises (SMEs) and large firms, and between developed and developing countries. This divide reflects disparities in resources, technical capacity, and institutional support, which influence the pace and effectiveness of BIM implementation [].

3. Materials and Methods

3.1. Research Approach and Design

The purpose of this study is to examine the factors that hinder BIM implementation during execution phase of construction production, with a particular focus on contractors’ experiences within the Swedish construction industry. To support a comprehensive and in-depth analysis, the study employs a mixed-methods approach, combining a systematic literature review, a quantitative survey, and semi-structured interviews (see Figure 1). This methodological triangulation enhances the validity and reliability of the findings by integrating multiple data sources and perspectives [,].

Figure 1.

Research methodology.

The literature review aimed to map existing research on BIM usage in construction production, with a particular emphasis on implementation barriers, stakeholder perspectives and the Swedish context. Systematic searches were conducted using the databases Scopus, Web of Science and Google Scholar. Search strings included combination such as (“BIM” OR “Building Information Modeling”) AND (“construction production” OR “contractor” OR “construction phase”) AND (“barriers” OR “adoption” OR “implementation”). Only peer-reviewed articles published between 2012 and 2024 were considered. Google Scholar was used to identify industry reports and grey literature with practical significance [].

Primary data collection was conducted through a quantitative survey targeting professionals involved in Swedish construction production. The respondent group included site managers, supervisors, project managers and BIM coordinators with hands-on experience using BIM in the production phase. The survey was structured using the TOE framework [], which served as the analytical foundation. Three core dimensions were operationalized:

- Technological factors, e.g., software support, system integration, technical expertise.

- Organizational factors, e.g., management support, internal procedures, skills development.

- Environmental factors, e.g., customer requirements, industry practices, legal and procurement-related aspects.

Each survey item was presented as a statement and measured using a five-point Likert scale (1 = strongly disagree, 5 = strongly agree). The scale items and phrasing were adapted from previously validated instruments in technology adoption research [,].

The survey underwent pilot testing with two senior researchers specializing in digital transformation. They evaluated the survey for clarity, content validity, and theoretical alignment. Based on their feedback, revisions were made to the wording, logical flow, and question order. This process aligns with the established best practice for survey design and validation [].

The final version of the survey was distributed digitally via email and professional networks, including industry forums and LinkedIn groups. A purposive sampling strategy was employed to ensure participation from individuals with relevant expertise and experience. The sample included professionals from both small and large construction companies across various regions of Sweden.

To enrich the analysis, the survey was complemented by semi-structured interviews with key industry stakeholders. The interviews were conducted by telephone and targeted individuals with strategic or operational responsibility for digital practices in the production phase. The interview questions were guided by the TOE framework and aimed to capture context-specific insights into barriers and opportunities associated with BIM adoption consisted with recommendation from previous studies [,]. Although the semi-structured interviews were not analyzed using a separate coding scheme, they played a vital interpretive role within the study’s mixed-methods design. Specifically, the interview responses served as a qualitative triangulation tool to enrich the interpretation of the survey findings, in accordance with established practices in construction digitalization research in construction []. The interviews provided contextual insights into how and why certain barriers were encountered in practice, particularly those related to management support, unclear role definitions, and external regulatory uncertainty. This qualitative input deepened the understanding of the quantitative results without constituting a standalone dataset.

The analysis of the questionnaire responses was designed to directly address the study’s four research questions, with a particular focus on the three dimensions of the TOE framework: technological, organizational and environmental barriers. To achieve this, a combination of descriptive statistics, reliability testing, correlation analysis, group comparisons, factor analysis, and regression analysis was employed.

To answer research question 1, concerning the impact of technological factors on BIM usage in the production phase, descriptive statistics were used to analyze responses to each item within technological barrier category (T1–T5). Means and standard deviations were calculated to provide an overview of how these barriers are perceived. Cronbach’s alpha was calculated to assess the internal consistency of the items within this dimension. To explore the relationship between technological barriers and actual BIM usage, Spearman correlation was conducted between each technological barrier and the item measuring frequency of use (Q6). Additionally, ANOVA or Kruskal–Wallis tests were performed to determine whether perceptions of technological barriers differ across professional roles (Q1) or company sizes (Q3).

To address research question 2, which focuses on organizational barriers, the same statistical procedures used for technological factors were applied to items O1–O5. Descriptive statistics, Cronbach’s alpha for internal consistency, and Spearman correlation tests with BIM usage (Q6) were conducted. To examine whether perceptions of organizational barriers vary based on background variables such as professional role, company size, or level of experience, group comparisons were performed using ANOVA or non-parametric equivalents.

For research question 3, which investigates environmental factors, descriptive statistics were used to analyze response patterns for items E1–E6. Internal reliability within this dimension was assessed using Cronbach’s alpha. To determine whether perceived environmental barriers differ across geographical regions (Q5) or project types (Q4), group comparisons were conducted using ANOVA or Kruskal–Wallis tests. Additionally, Spearman correlation analyses were performed between each environmental item and BIM usage (Q6).

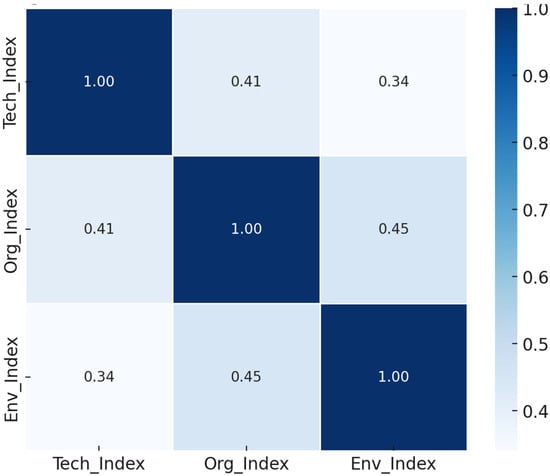

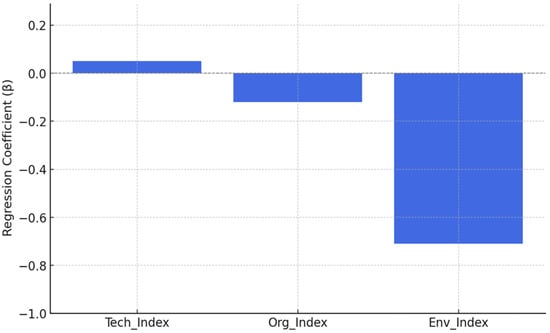

To address research question 4, which explores how technological, organizational, and environmental barriers interact to create complexity in BIM implementation, a multi-step analytical approach was employed. First, an exploratory factor analysis (using PCA with varimax rotation) was conducted to assess whether the survey items align with the TOE framework, i.e., whether they cluster into technological, organizational, and environmental dimensions, or whether alternative groupings emerge. Next, the relationships among the three TOE dimensions were examined through correlation analysis to explore potential interdependencies. Finally, an ordinal logistic regression analysis was performed, with self-reported BIM usage (Q6) as the dependent variable and the composite indices for each TOE dimension as independent variables. The objective was to identify which categories of barriers most significantly influence low levels of BIM adoption in practice. While technological and organizational challenges were evident, they did not fully account for the variation in BIM usage. Instead, external systemic factors—such as regulatory requirements and client-driven demands appeared to function as critical gatekeepers in the implementation process.

All analyses were conducted using the statistical software programs SPSS 30 and R 4.5.0. A significant level of p < 0.05 was applied throughout. For the TOE indices, mean values were calculated for each group of items (T1–T5 for technological, O1–O5 for organizational, and E1–E6 for environmental factors). The Likert scale responses (1–5) were treated as interval data for descriptive statistics and index construction, while non-parametric methods were also employed where appropriate to ensure robustness. By combining insights from the literature review with data from the questionnaire survey, this study enabled a comprehensive analysis of the potential of Big Data to support sustainability in the construction industry. This methodological approach integrates theoretical perspectives with empirical evidence, providing a solid foundation for future research and practical development in the field [,].

3.2. Survey Design Grounded in the TOE Framework

To examine the factors that hinder BIM usage in construction production in Sweden, a survey instrument (see Supplementary Material S1) was developed based on the well-established TOE framework []. The TOE model is widely used to explain technology adoption in industrial and technically complex settings [,]. It is particularly relevant to the construction industry, where the effect of digitalization remains unevenly distributed, especially in the production phase, and are shaped by both internal and external influences [,].

The TOE framework categorizes the key factors affecting organizational technology adoption into three overarching domains:

- Technological factors: including system compatibility, usability and technical availability.

- Organizational factors: such as management support, internal procedures and training.

- Environmental factors: encompassing external customer requirements, legislation, industry practices and policies.

To ensure a strong alignment between theoretical constructs and empirical data, each survey item was explicitly designed to reflect one of the three dimensions in the TOE framework. Questions related to technological factors addressed issues such as technical deficiencies, low user-friendliness, and limited access to digital support []. Items under organizational factors focused on management prioritization of BIM, availability of training, and the distribution of responsibilities related to BIM functions [,]. Environmental factors were explored through questions on the perceived influence of client requirements, the absence of structured collaboration with external stakeholders, and the clarity and application of national and EU-level guidelines in production settings [,]. This approach enabled the operationalization of theoretical concepts into practical, experience-based survey questions grounded in industry realities.

The final survey instrument consisted of 21 statements organized into three thematic blocks:

- 5 technological barriers (T1–T5).

- 5 organizational barriers (O1–O5).

- 6 environmental barriers (E1–E6).

In addition to the core survey items, background questions were included to capture respondents’ professional roles, level of experience, company size, project type, geographic region of work, and self-assessed frequency of BIM use in the production phase.

Each item was rated on a five-point Likert scale (1 = strongly disagree, 5 = strongly agree), enabling quantitative analysis of both individual indicators and composite index values for each TOE dimension. The estimated completion time was 5–7 min.

Although BIM has demonstrated potential to streamline information flows, reduce construction errors, and enhance coordination, its adoption in the production phase remains limited [,]. By applying the TOE model, a structured approach is created to identify both technical, organizational, and external barriers that affect implementation in practice.

Linking each survey item to the TOE dimensions enables a robust, theoretically grounded analysis of how contractors perceive barriers to BIM use in the execution phase of construction. This structure also facilitates the identification of systematic patterns across the three domains, technology, organization and the environment, and thereby supporting the study’s four research questions.

To ensure reliability and validity, the survey instrument, a two-step review process was conducted. First, face validity was evaluated through expert reviews involving academic researchers and industry professionals with extensive experience in BIM. Based on their feedback, several items were revised for clarity and relevance. Second, internal consistency was assessed using Cronbach’s alpha for each TOE dimension. While the technological and organizational constructs yielded relatively low alpha values, suggesting heterogeneity within these dimensions, the environmental index demonstrated acceptable internal consistency. These findings are further elaborated in the Results and Limitations sections.

3.3. Data Collection and Selection Strategy

This study explores the barriers to BIM implementation in construction production, with a particular emphasis on contractors’ experiences and perceptions within the Swedish construction industry. To ensure high validity and generalizability, a strategic and systematic data collection method was employed. This study targets Swedish construction companies of varying sizes and project types, aiming to capture the full spectrum of how BIM-related barriers are encountered in practice [,].

Construction production is one of the most complex and resource-intensive phases of the building process and remains significantly less digitalized compared to the planning and design stages []. Yet, BIM is widely recognized as a key technology for enhancing information flow, coordination, and quality during implementation []. By focusing on contractors in Sweden, this study offers context-specific insights into how technical, organizational, and environmental factors interact with national policy frameworks, industry norms, and varying levels of digital maturity [].

The sample consists of professionals involved in construction production who have direct or indirect experience with BIM-related tasks, including site managers, supervisors, project managers, production engineers, and BIM coordinators. These roles span various operational levels and carry differing responsibilities related to planning, coordination, and digital work practices. By incorporating multiple professional perspectives, the study offers a comprehensive view of the barriers to BIM adoption, both from practical and strategic standpoints, which is essential for understanding why BIM usage often remains confined to the design phase and fails to be fully integrated into production workflows [,]. Though, as stated by [,,], project delivery methods may have impacts on the contractor involvement in BIM implementation and hence impact on the project result and its success.

Participant selection was conducted through purposive sampling, with recruitment carried out via professional networks, industry platforms, and direct outreach to companies across different regions of Sweden. Potential respondents were identified through industry contacts and networks, including organizations such as Byggföretagen and the strategic innovation program Smart Built Environment. Additional recruitment was conducted through industry-specific forums and social media platforms targeting professionals in the construction sector.

It is important to note that subcontractors are underrepresented in this study, which primarily reflects the perspectives of main contractors. Future research should aim to include subcontractors to better capture their unique barriers and opportunities related to BIM use in the production phase.

The questionnaire was distributed to 385 professionals in Swedish construction production, including site managers, project managers, production engineers, foremen, and BIM coordinators. In total, 220 responses were received, yielding a response rate of 57%.

As previously outlined, the sample was focused on contractors actively engaged in construction production, including site managers, supervisors, project managers, production engineers and BIM coordinators. These roles span different operational levels and offer direct insight into both technical and organizational challenges. Respondents reported varying levels of BIM experience, ranging from less than one year to over ten years, with the majority indicating between three and seven years of practical use. This diversity in experience and role enhances the representativeness of the sample and strengthens the generalizability of the findings.

BIM managers were not included as a separate category, as in many small and medium-sized projects in Sweden, BIM management responsibilities are often integrated into the BIM coordinator role or distributed across the project team. By incorporating multiple contractor-level roles, the study provides a broad and nuanced understanding of the barriers to BIM adoption, both from practical and strategic perspectives, which is essential for explaining why BIM use frequently stalls at the design stage and is not fully embedded in production workflows [,].

Data collection was conducted through a digital questionnaire survey, complemented by semi-structured interviews with key industry professionals. The survey was distributed via email and professional networks, while the interviews were conducted through video conferencing or telephone calls. The purpose of the interviews was to deepen the understanding of the respondents’ experiences and enhance the analytical depth of the survey findings. To strengthen the representativeness of the sample and clarify respondents’ levels of expertise, the survey included questions specifically targeting practical BIM experience during the construction phase. While 89% of respondents reported having participated in at least one project where BIM was used in production, only 66% indicated having direct access to the BIM model on site. This reveals that formal project involvement does not necessarily equate to full system access or hands-on use, a distinction that is critical when interpreting perceived barriers.

To explore this further, BIM experience was analyzed across professional roles. Site managers and BIM coordinators were most likely to report both extensive project experience (more than five years) and frequent access to BIM models. In contrast, supervisors and production engineers often participated in BIM-enabled projects but lacked full model access or editing rights. Respondents categorized as “Other”, including cost estimators and logistics planners, typically reported the least experience and lowest levels of access. These differences suggest that perceptions of BIM-related barriers are shaped not only by professional role but also by the degree of practical engagement with the model. This underscores the importance of distinguishing between individuals with decision-making authority and technical responsibility for BIM, and those involved in production processes who may operate at a distance from the digital tools. The findings highlight the need for future research to more clearly differentiate types of BIM involvement (e.g., viewer-only vs. editor access) to better understand how technical and organizational barriers are experienced in practice.

3.4. Ethical Considerations in Data Collection

This study investigates barriers to BIM usage in construction production using the TOE framework as its theoretical foundation. It was conducted in accordance with established research ethics guidelines, the EU General Data Protection Regulation (GDPR) [] and the Swedish Research Council’s guidelines for good research practice []. Prior to participation, respondents were informed about the study’s purpose, research design, data handling procedures, and their rights as participants. They were made aware that participation was voluntary and that they could withdraw at any time without providing a reason []. To safeguard participant privacy, no personally identifiable information, such as names, contact details, or company affiliations, was collected. All survey responses were analyzed in aggregate form, ensuring that individual participants or organizations could not be identified in the presentation of results. Informed consent was obtained at the point of survey distribution, where respondents actively agreed to the terms and conditions before proceeding []. Although direct identifiers (e.g., names, email addresses) were not collected, the study acknowledged that combinations of role, company size, and geographical region could potentially lead to indirect identification. To mitigate this risk, all data were analyzed and reported exclusively in aggregated form, in compliance with GDPR principles of data minimization and privacy protection.

Given that several survey items addressed potentially sensitive topics, such as organizational support, technical limitations, and external pressures, the questions were carefully phrased to focus on general experiences rather than company-specific shortcomings, thereby reducing the likelihood of respondents feeling exposed [].

All data were stored in a secure digital environment with restricted access limited to the responsible research team. Upon completion of the analysis phase, the data will be permanently deleted in accordance with GDPR’s principles of storage minimization and purpose limitation [].

This study is independent and free from commercial or political affiliations. Participants were informed that the research is conducted for non-profit purposes and that the results will not be used for marketing or internal company evaluations. By adhering to these ethical principles, the study ensures respect for participants’ rights, integrity, and autonomy, while maintaining the credibility and transparency of the research process [].

3.5. Measurement Scales and Statistical Analysis Methods

To examine how technological, organizational and environmental factors influence the use of BIM in construction production, a survey study was conducted using a five-point Likert scale (1 = strongly disagree, 5 = strongly agree). Likert scales are widely recognized in quantitative research and are particularly effective for capturing subjective perceptions, attitudes, and perceived barriers []. The use of a consistent scale enables both nuanced analysis of individual responses and systematic comparisons across different respondent groups and barrier types within the three dimensions of the TOE framework: technology, organization and environment. Descriptive statistics were first employed to map response patterns within each question group: T1–T5 (technical factors), O1–O5 (organizational factors) and E1–E6 (environmental factors). For each item, the mean, standard deviation and frequency distribution were calculated. These results were visualized using tables and charts, forming the foundation for further interpretation. To assess the internal consistency within each TOE dimension, Cronbach’s alpha was calculated. Values above 0.7 were considered indicators of good internal reliability [].

Next, Spearman’s rank correlation analysis was conducted to explore the relationship between perceived barriers in each TOE category and the self-reported frequency of BIM use in production (question Q6). Spearman’s rho is particularly suitable for ordinal data and allows for the identification of nonlinear associations between variables [,]. Additionally, one-way analysis of variance (ANOVA) or the non-parametric Kruskal–Wallis test when assumptions of normality and homogeneity of variance were not met, was used to examine differences between respondent groups. These tests were applied to determine whether, for example, site managers and project managers, or employees from small versus large companies, perceive BIM-related barriers differently. A significance level of p < 0.05 was used throughout the analysis.

To uncover underlying patterns in how respondents perceive BIM-related barriers, an exploratory factor analysis (Principal Component Analysis, PCA) with varimax rotation was performed. The aim was to determine whether the 16 survey indicators could be grouped into broader latent constructs. This method was chosen because the survey items were conceptually related but not independent. Factor analysis reduces the large set of observed indicators into latent constructs, enabling both data reduction and construct validation. It allows us to test whether the empirical grouping of items aligns with the theoretical TOE framework, thereby strengthening the study’s internal validity. The results revealed a natural clustering of items into three distinct factors that closely align with the TOE framework: (1) technical/practical barrier, (2) organizational structure barrier, and (3) external/regulatory barrier.

To further examine how these barrier categories interact and influence BIM usage in practice, an ordinal logistic regression analysis was conducted. In this model, self-reported BIM use (Q6) was treated as the dependent variable, while the composite index scores for each TOE dimension served as independent variables. This regression method was selected due to the ordinal nature of the BIM usage variable, which is ranked but not continuous. It allows for interpretation of the likelihood of increased BIM use based on the intensity of perceived barriers []. Ordinal regression is appropriate because the dependent variable was measured on a five-point Likert scale, which represents an inherent order but not equal distances between categories. Unlike linear regression, this method accommodates the ordinal nature of the data and enables interpretation of the likelihood of higher BIM adoption levels given different intensities of perceived barriers.

Indexes for each TOE dimension were constructed by calculating the mean of the respective question group (T1–T5, O1–O5, E1–E6). Although Likert scales are technically ordinal, it is widely accepted practice to treat them as interval scales for index construction and certain statistical analyses [].

To maintain a systematic connection between the study’s purpose and its research questions, each analysis step was anchored in the TOE framework. The first research question, which explores how technological factors such as system compatibility, hardware availability, and usability affect BIM usage, was addressed using descriptive statistics, Cronbach’s alpha, Spearman correlations and group comparisons. The second research question, focused on organizational barriers to implementation, was examined using similar methods, with particular attention to differences across roles and company sizes. The third research question, concerning external influences such as industry standards and client expectations, was analyzed through responses to items E1–E6, including correlation with BIM usage and comparisons across project types and geographic regions. The fourth and final research question, which investigates how barriers interact and contribute to implementation complexity, was addressed through PCA, index-level correlation analysis, and ordinal logistic regression.

Together, this analytical framework provides a robust, theory-driven, and multi-layered approach to understanding both isolated and interrelated barriers to BIM implementation in Swedish construction production. By integrating the TOE dimensions with clearly defined analytical procedures, the study ensures that its findings are both statistically sound and directly aligned with its research objectives. Importantly, the results raise critical questions about the applicability of the TOE framework in the context of construction production. The assumption of equal relevance among technological, organizational, and environmental factors may not fully reflect the realities of a project-based, fragmented industry where external mandates and procurement systems heavily influence implementation decisions. Future research may benefit from expanding the framework to incorporate institutional and market-level drivers that more accurately capture the dynamics of BIM adoption in practice.

4. Results

4.1. Professional Roles, Experience and BIM Use Among Respondents

To establish a foundational understanding of the respondents’ background, a descriptive analysis was carried out on their professional roles, experience and use of BIM in construction production. The findings are presented numerically in Table 3 and illustrated visually in Figure 2.

Table 3.

Descriptive statistics of respondents’ professional roles, experience, and BIM use in construction production.

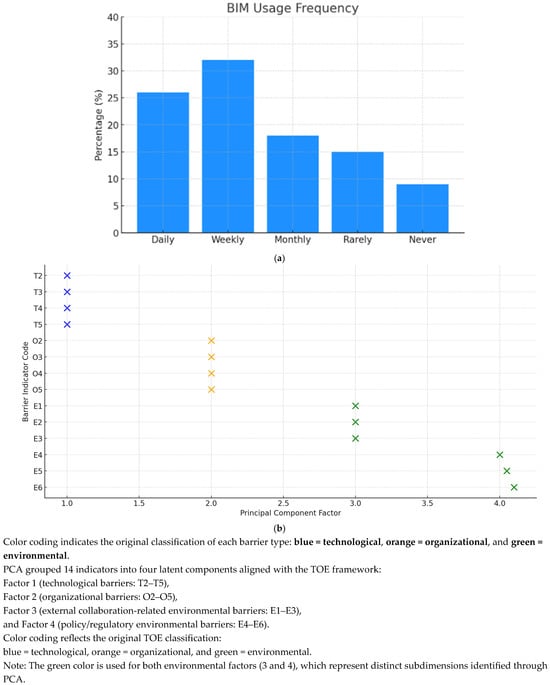

Figure 2.

(a) Frequency of BIM Use in Construction Production. (b) PCA-based grouping of BIM barrier indicators aligned with the TOE framework.

As shown in the table, site managers (26%) represent the largest professional group in the sample, followed closely by project managers (23%) and production engineers (19%). These roles are pivotal to the practical execution of construction production, encompassing responsibilities such as planning, managing and coordinating activities on site. Their predominance in the sample aligns with the study’s objective to explore BIM implementation from a production-oriented contractor perspective [,]. Supervisors account for a substantial portion of the respondents (17%). and, given their close collaboration with both tradespeople and project management, they offer valuable insights into the practical applicability of BIM. BIM coordinators and digital coordinators make up 10% of the sample, contributing a crucial digital and strategic dimension that complements previous research on digital roles in construction projects [].

To establish a clear context for the respondent selection, survey responses to questions Q1–Q6 were analyzed. These questions addressed professional role, industry experience, company size, project type, geographical location and frequency of BIM use in construction production. This background analysis provides a crucial foundation for interpreting the study’s broader findings. Regarding industry experience, the data reveal that most respondents possess substantial professional expertise: 33% have 6–10 years of experience, 27% have 11–20 years, and 20% have over 20 years in the field. Only 6% have less than two years of experience. This indicates that the vast majority bring deep practical insight into production-related barriers and digitalization issues [].

In terms of company size, 43% of respondents are employed by medium-sized companies (50–249 employees), 39% by large companies (250+ employees), and 18% by small companies (1–49 employees). This distribution enables meaningful comparisons of BIM-related barriers across different organizational scales, considering variations in resources and operational complexity [,]. The analysis of project types (Q4) shows a diverse range of construction environments: 28% of respondents primarily work on residential projects, 21% on public buildings, 18% in infrastructure, and 17% in commercial construction. Additionally, 16% report on involvement in mixed project environments. This diversity enhances the generalizability of the study’s findings.

The respondents are geographically distributed across Sweden (Q5), with the majority located in southern Sweden (48%), followed by central Sweden (30%) and northern Sweden (12%). An additional 10% work nationally or across multiple regions. This distribution mirrors the actual regional concentration of construction activity in Sweden, where the southern region, particularly in the housing sector, dominates production. Given that nearly half of the respondents are based in southern Sweden, the findings may reflect region-specific conditions related to digital maturity and policy frameworks. While regional differences were not the focus of this study, they represent a valuable avenue for future research.

BIM usage in production (Q6) varies in frequency: 26% of respondents use BIM daily, 32% weekly, 18% monthly, 15% rarely, and 9% never. As illustrated in Figure 2, more than 75% of respondents engage with BIM in production on a regular basis. This indicates that the sample includes both highly experienced users and those with limited exposure, thereby enhancing the study’s ability to identify barriers across different levels of BIM adoption [,].

Overall, this background analysis demonstrates that the respondent sample is broad and well-distributed across professional role, experience level, company size, project type, geographic regions, and BIM usage. It comprises professionals with direct, hands-on experience in construction production and reflects the real-world diversity of the Swedish construction industry. The relatively high frequency of BIM use further reinforces the relevance of this study and provides a strong foundation for examining perceived obstacles in practice.

4.2. Technological Barriers to the Use of BIM in Construction Production

To explore respondents’ perceptions of technological barriers to BIM use in construction production, a comprehensive analysis was conducted. This included descriptive statistics, reliability testing with Cronbach’s alpha, Spearman correlations with general attitude towards BIM (O1), and group comparisons based on frequency of use. The five indicators T1–T5 represent core technological barriers such as software compatibility, technical infrastructure, limited access to models, user-friendliness, and availability of technical support. These factors have also been noted in previous studies as significant barriers to BIM adoption in production settings [,].

The descriptive analysis of the technological indicators (T1–T5) reveals that respondents generally perceive technological barriers as moderately prevalent, though experiences vary depending on the specific type of barrier (see Table 4). The highest average score was recorded for T3: Problems accessing BIM models on the construction site (M = 3.13; SD = 1.37). This indicates that many respondents still encounter difficulties in accessing updated and properly integrated models in field environments, an issue that is critical for operational efficiency and coordination during production. The second highest score was observed for T2: Limitations in technical infrastructure (M = 3.10; SD = 1.36), suggesting that factors such as network stability, hardware availability, and system capacity continue to hinder BIM implementation in some organizations. These limitations may include, for example, poor internet connectivity on construction sites, insufficient mobile devices for model access, or incompatible technical systems that obstruct seamless use of BIM tools.

Table 4.

Descriptive Statistics of Technological Barriers (T1–T5).

The lowest mean was observed for T5: Insufficient technical support (M = 2.92; SD = 1.40), indicating that while access to support services and technical assistance is perceived as a barrier, it is less prominent than more structural or infrastructure-related challenges. However, the relatively high standard deviations across all indicators suggest considerable variation in how respondents experience technological barriers. This variability is likely influenced by contextual factors such as company size, project complexity, and prior with digital tools.

Overall, the results presented in Table 4 indicate that technological barriers should not be viewed as a uniform issue, but rather as a complex and multifaceted challenge. Some barriers appear to be more widespread, while others are highly context dependent. These findings align with previous research that underscore the importance of differentiating between various types of technical barriers, such as system compatibility, on-site functionality, and user support, when examining barriers to BIM implementation in construction production [,].

To evaluate whether the five technological indicators (T1–T5) collectively represent a coherent underlying dimension, namely a unified technological barrier index, Cronbach’s alpha was calculated. The resulting value of 0.10 is notably low and falls well below the commonly accepted threshold of 0.70 for satisfactory internal reliability []. This outcome suggests that the indicators do not exhibit sufficient covariance to be interpreted as manifestations of a single latent construct. Instead, they appear to capture distinct and independent aspects of technological barriers. In practical terms, this means that each indicator, such as limited model access (T3), technical infrastructure (T2) or lack of technical support (T5), should be treated as a standalone barrier rather than as a subcomponent of a unified barrier framework. The very low, and in some cases negative, Cronbach’s alpha values further reinforce the conclusion that the five technological (and organizational) indicators do not form a unidimensional construct. This implies that each type of barrier may be perceived independently, reflecting the nuanced and context-specific nature of BIM-related barriers in construction production.

This interpretation is also supported by the results in Table 4, where both the mean values and standard deviations vary significantly across indicators, highlighting the diverse ways in which respondents experience these barriers.

The finding is methodologically important, as it supports the decision to analyze each indicator individually rather than as part combined technological index. It also underscores the complexity highlighted in previous studies regarding technology-related barriers in the construction industry, where technical challenges are seldom uniform. Instead, they are shaped by contextual factors such as project environment, technical competence and system selection [,]. Rather than conceptualizing technology as a singular barrier, future analyses should differentiate between specific types of technological obstacles, such as system compatibility, hardware limitations, and access to technical support, in order to more accurately reflect the diversity and practical relevance of these barriers within construction production.

To examine whether the perceptions of technological barriers are associated with the respondents’ overall attitude towards BIM use, a series of Spearman correlations analyses were conducted between each technological indicator (T1–T5) and the variable O1, which measures general BIM attitude. As shown in Table 5, the results consistently revealed very low and statistically non-significant correlations. The values ranged from weakly positive to weakly negative, with all absolute coefficient below 0.10 (|ρ| < 0.10), indicating no clear direction or systematic relationships. This lack of correlation suggests that respondents who report strong technological barriers, such as limited model access (T3) or inadequate technical infrastructure (T2), do not necessarily hold more negative attitudes towards BIM. Likewise, a generally positive attitude towards BIM does not appear to correspond with a reduced perception of technical challenges. These findings imply that perceived technological barriers and attitudes toward BIM are analytically distinct dimensions, not easily connected through simple linear associations. One possible interpretation is that general attitudes towards BIM are shaped by factors beyond the immediate technical context. Previous research has shown that elements like organizational support structures, educational background, prior experience with digital projects and management commitment may exert a stronger influence on individuals’ attitudes towards new technology than the technical limitations themselves [,]. It is also plausible that technical barriers are viewed as a routine aspect of digitalization and therefore do not significantly affect attitudes, particularly among respondents who are already familiar with digital tools.

Table 5.

Spearman Correlations Between Technological Barriers (T1–T5) and General BIM Attitude (Q6).

Overall, the results presented in Table 5 indicate that there is no direct linear relationship between technical experiences and general attitude towards BIM. This suggests that technological barriers should be examined independently from attitudinal factors. To gain a deeper understanding of how attitudes toward BIM are formed, future analyses should incorporate additional explanatory variables, such as organizational culture, policy expectations, and prior experience with digital technologies.

To explore how the perceptions of technological barriers vary according to the extent of actual BIM use, a comparative analysis was conducted across five user groups: respondents who reported using BIM daily, weekly, monthly, rarely or never. The results, presented in Table 6, reveal clear and systematic patterns in the reported technological barriers (T1–T5) across these groups.

Table 6.

Mean Ratings of Technological Barriers (T1–T5) by BIM Usage Frequency.

Daily BIM users consistently reported higher levels of perceived technological barriers compared to less frequent users. The differences were especially pronounced for T1: Lack of compatibility between systems and software, and T3: Problems accessing models on the construction site, both of which were rated as more problematic by frequent users. These findings suggest that increased BIM usage tends to heighten awareness of technical challenges, rather than diminishing them through familiarity or routine. In contrast, respondents who rarely or never use BIM reported lower levels of perceived technological barriers. This pattern likely reflects limited exposure rather than the actual absence of problems, if the tools are not actively used, their limitations remain unexperienced. Similar trends have been observed in previous research, where technological constraints were more frequently reported by practitioners engaged in hands-on work than by staff operating at a strategic or managerial level [,].

This finding is methodologically significant, as it suggests that technological barriers are not solely linked to the implementation of BIM but also emerge as usage-related challenges. In other words, these barriers are primarily encountered in day-to-day operational work rather than during theoretical planning or strategic discussions. The visual summary in Figure 1 reinforces this interpretation, showing that average ratings for indicators T1–T5 increase with the frequency of BIM use.

Overall, the results in Table 6 indicate that perceptions of technological barriers are strongly shaped by practical experience. This implies that individuals who are more advanced in their digital implementation journey do not necessarily experience fewer obstacles, rather, they may be more attuned to the limitations of the systems they use. These insights carry important implications for the design of strategies: promoting the adoption of BIM tools is not sufficient on its own, ongoing support is essential to address the challenges that arise as usage intensifies.

In conclusion, the analysis demonstrates that technological barriers to BIM use in construction production should not be viewed as a uniform or monolithic phenomenon. Findings from the descriptive statistics, the reliability testing, the correlation analysis, and group comparisons consistently reveal that various technological barriers, such as system incompatibility, inadequate infrastructure, limited model access, and lack of technical support, are experienced differently across user groups and exhibit distinct characteristics.

The very low reliability score (Cronbach’s alpha = 0.10) clearly indicates that the indicators do not constitute a coherent latent construct and should therefore be examined individually. This heterogeneity in the barrier structure is further supported by the varying estimates across the indicators in Table 4, suggesting that certain technological barriers (e.g., field functionality) are more prevalent than others (e.g., technical support). Consequently, constructing a general BIM barrier index risks obscuring meaningful distinctions between different types of technological challenges.

Moreover, the correlation analysis (Table 5) revealed that there are no significant relationships between perceived technical barriers and the respondents’ overall attitude towards BIM. This suggests that these two dimensions are analytically distinct: it is entirely possible for individuals to hold a positive view of BIM conceptually while simultaneously encountering practical technical limitations in their daily work, and vice versa. This finding underscores the importance of not overestimating the explanatory power of attitudes when assessing actual technology use in production contexts.

The group comparison in Table 6 further revealed that respondents who use BIM daily reported higher levels of technological barriers than those who rarely or never engaged with the technology. This finding suggests that some barriers only become apparent during operational use, highlighting that implementation barriers often emerge through practical application rather than during initial planning. It challenges the assumption that barriers diminish with experience and instead emphasizes the need for continuous support and adaptation beyond the point of implementation.

Overall, the results demonstrate that technological barriers in construction production are complex, varied, and highly dependent on usage. To ensure the effective and sustainable application of BIM in practice, targeted interventions are needed to address each type of barrier individually. These may include improving system compatibility, enhancing technical infrastructure, developing mobile solutions for on-site access, and providing fast, user-centered technical support. Without such tailored adaptations, the practical utility of BIM may remain constrained, regardless of its theoretical appeal.

The analysis clearly shows that technological barriers to BIM use in production should not be treated as a uniform phenomenon. The technical challenges vary both in perceived severity and in relation to usage frequency. The low internal reliability among indicators and the absence of significant correlations with general BIM attitudes suggest that each barrier must be examined and addressed independently. The fact that daily users report higher levels of perceived barriers underscores the importance of technical standardization, interoperability solutions, and responsive support systems to enable effective and enduring BIM integration in construction production.

4.3. Organizational Barriers to the Use of BIM in Construction Production

To identify key organizational barriers to BIM use in production, five indicators (O1–O5) were analyzed, focusing on management, resource allocation, communication, division of responsibilities, and corporate culture. These dimensions have been recognized in prior research as crucial factors that can impede the progress of digitalization within the construction industry [,,].

The descriptive analysis of the organizational barriers (O1–O5) reveals that they are perceived as moderately prevalent among respondents, with average scores ranging from 2.89 to 3.06 (see Table 7). This suggests that while organizational barriers are present across many projects, they are not viewed as overwhelming or structurally dominant in day-to-day operations. However, the variation in mean values and standard deviations indicates that certain barriers are encountered more frequently and perceived as more severe than others. The most prominent barrier was O2: Insufficient resources for BIM (M = 3.06; SD = 1.47), highlighting that many organizations continue to struggle with inadequate staffing, limited time, and constrained financial resources for the full implementation and maintenance of BIM processes. This challenge is particularly acute in smaller companies or project-driven environments, where digital initiatives often take a back seat to immediate delivery demands. Previous studies have similarly identified resource limitations as a key factor contributing to the slow pace of technology integration in the construction industry [,].

Table 7.

Descriptive Statistics of Organizational Barriers (O1–O5).

The second highest-rated barrier was O3: Insufficient communication within the organization (M = 3.04; SD = 1.45), indicating that internal coordination, role clarity, and information flow remain significant challenges. Given that BIM implementation requires collaboration across multiple internal functions, including technology, project management and production, communication deficiencies can result in fragmented digital processes and diminished effectiveness. This finding aligns with previous research emphasizing that organizational integration is a critical factor in realizing the full value of BIM [,].

The lowest mean score was recorded for O4: Weak digital leadership (M = 2.89; SD = 1.43), though this still reflects a clear presence of the barrier. While not rated as severely as resource constraints or communication issues, the wide variation in responses suggests that some organizations face substantial challenges related to management commitment to digital initiatives. This is concerning, as leadership support is consistently identified in digital transformation literature as a key driver of successful implementation [,].

The relatively high standard deviation for all indicators suggests that the experience of organizational barriers varies significantly between organizations. These differences are likely influenced by contextual factors such as company size, project complexity, geographical distribution, and client type. Prior studies have shown that organizational structures and levels of digital maturity in the construction industry are highly context-dependent [], supporting the interpretation for these variations as a reflection of the sector’s fragmented nature.

Overall, the results in Table 7 clearly indicate that organizational barriers are a present but unevenly distributed challenge within Swedish construction production. The three most critical areas, resource availability, communication gaps, and leadership commitment, should be prioritized when developing organizational strategies aimed at fostering more effective and embedded BIM implementation.

To assess whether indicators O1–O5 reflect a common underlying construct, namely a collective measure of organizational barriers to BIM adoption, internal consistency was calculated using Cronbach’s alpha. The analysis yielded a very low and negative value (α = −0.075), indicating a lack of covariation among the indicators and, in some cases, even opposing response patterns.