Reinforcement of Insufficient Transverse Connectivity in Prestressed Concrete Box Girder Bridges Using Concrete-Filled Steel Tube Trusses and Diaphragms: A Comparative Study

Abstract

1. Introduction

2. Finite Element Model

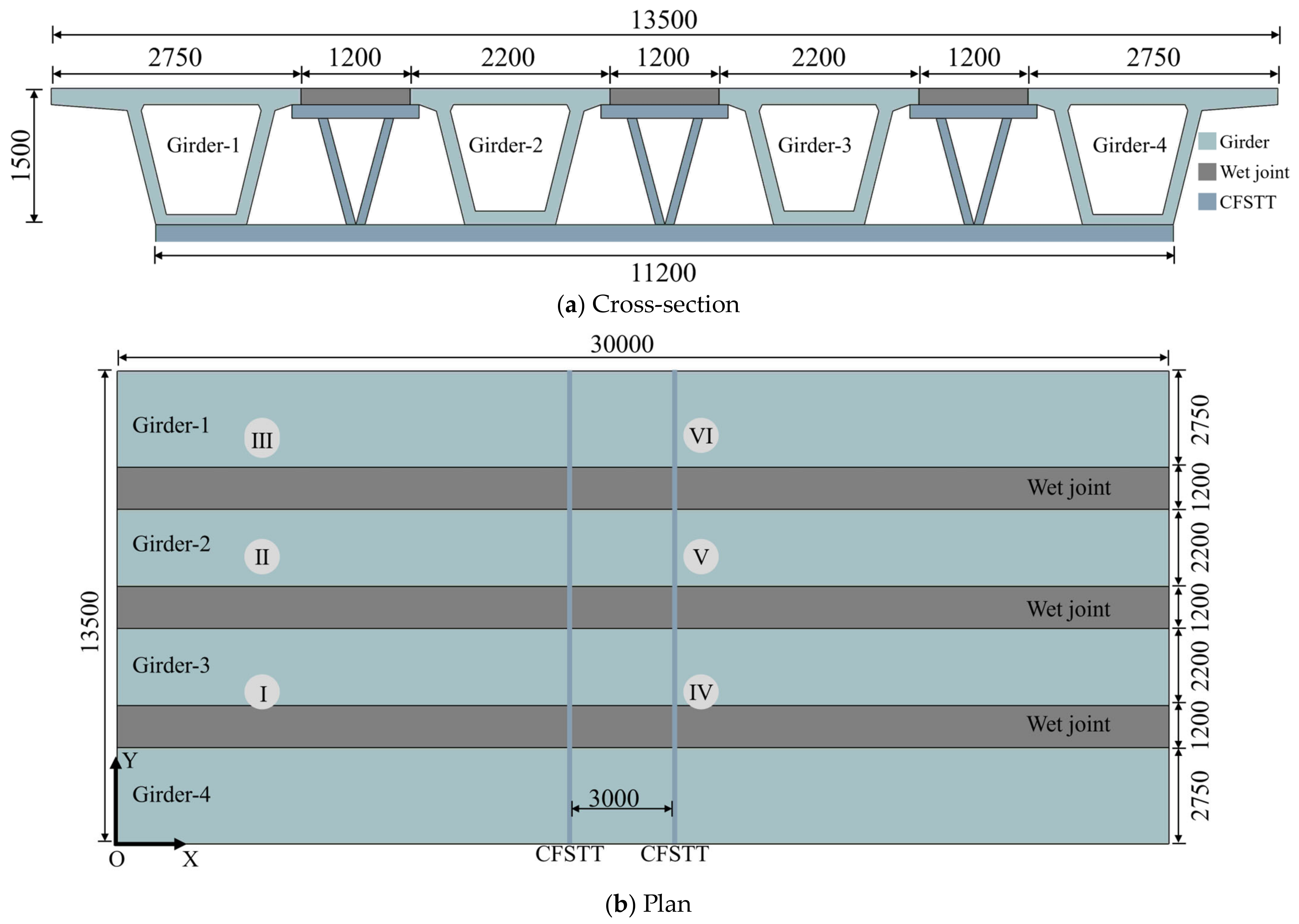

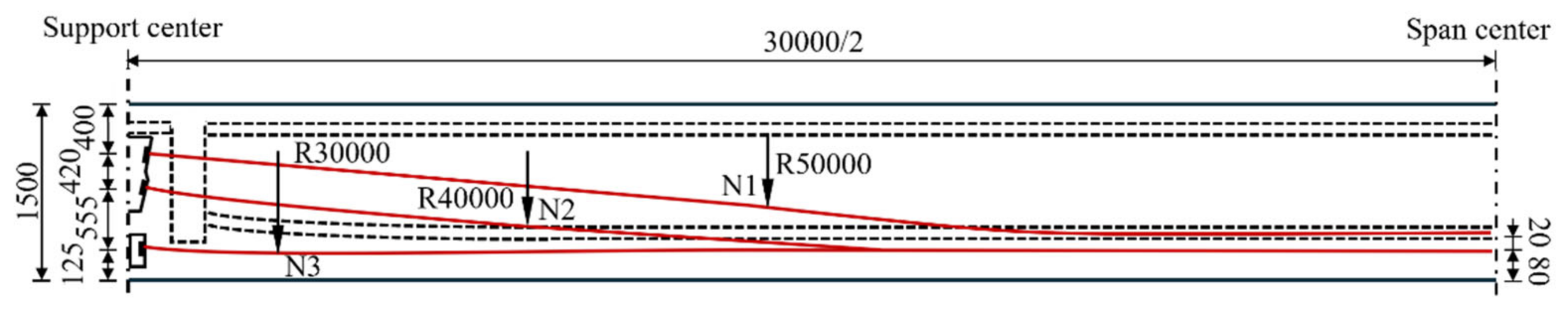

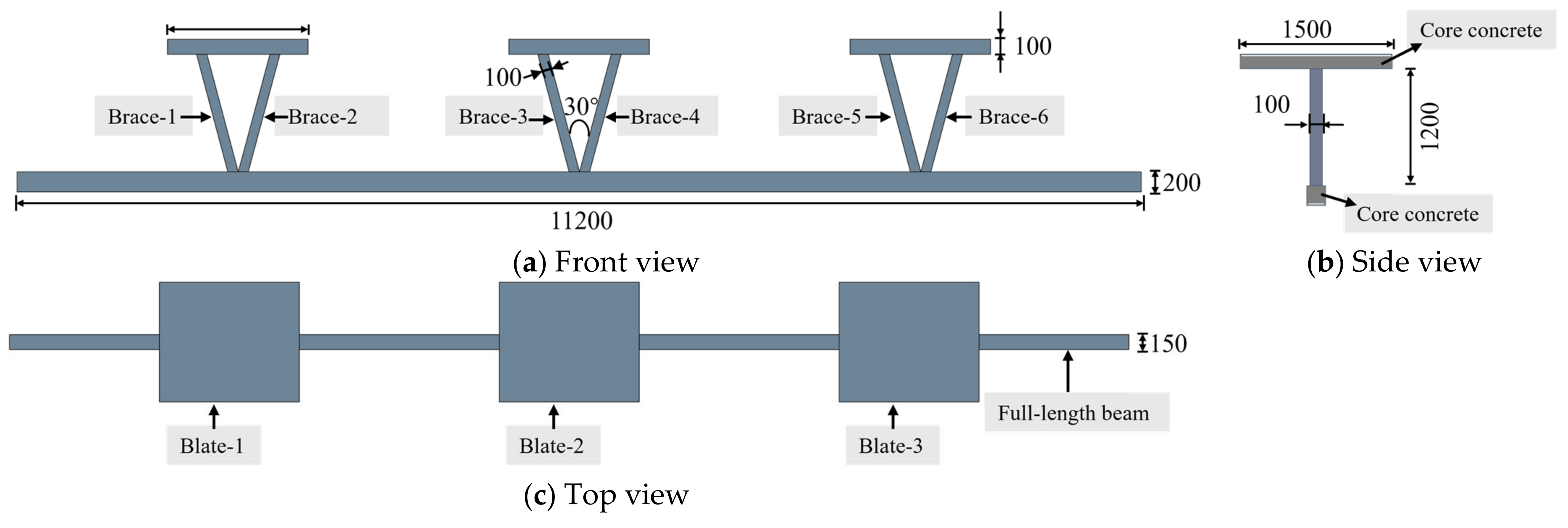

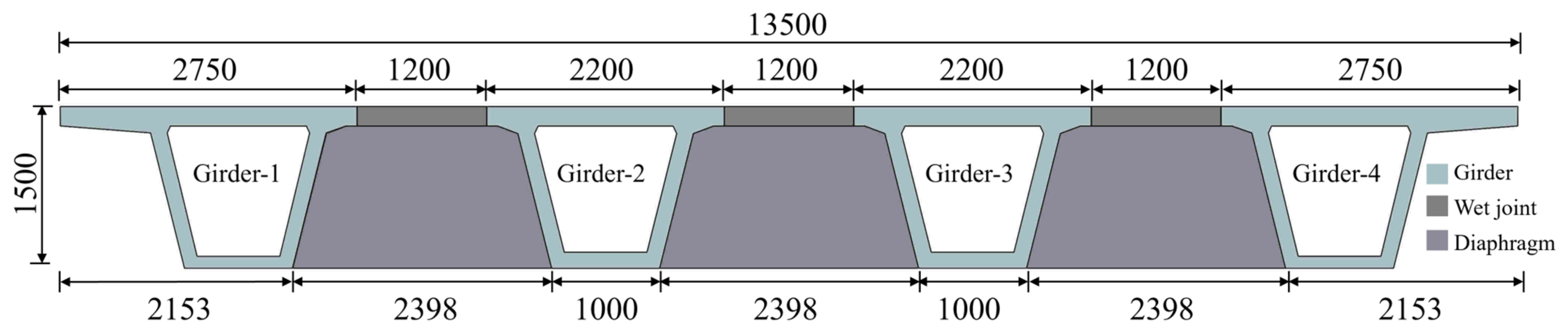

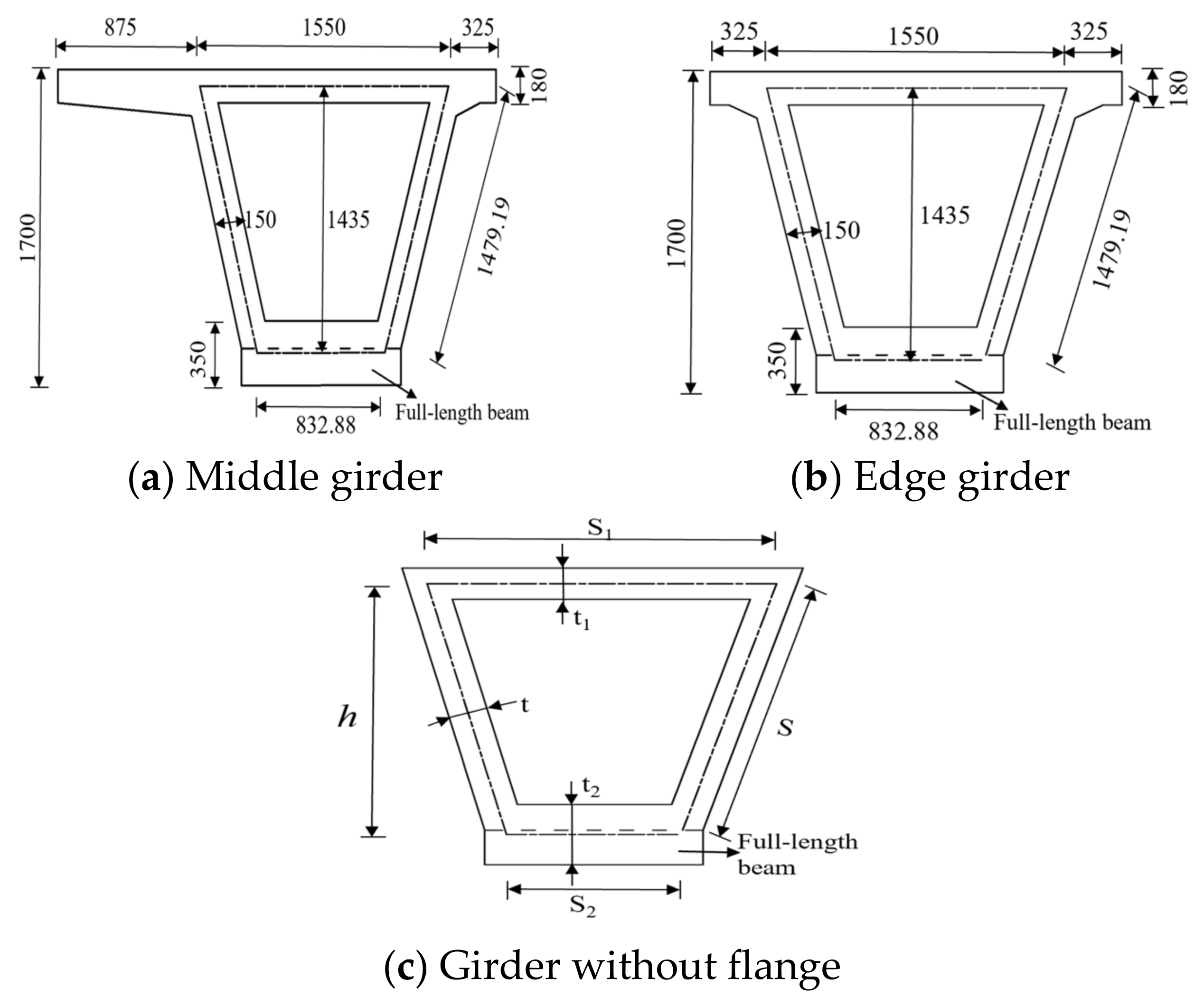

2.1. Geometric Description

2.2. Materials

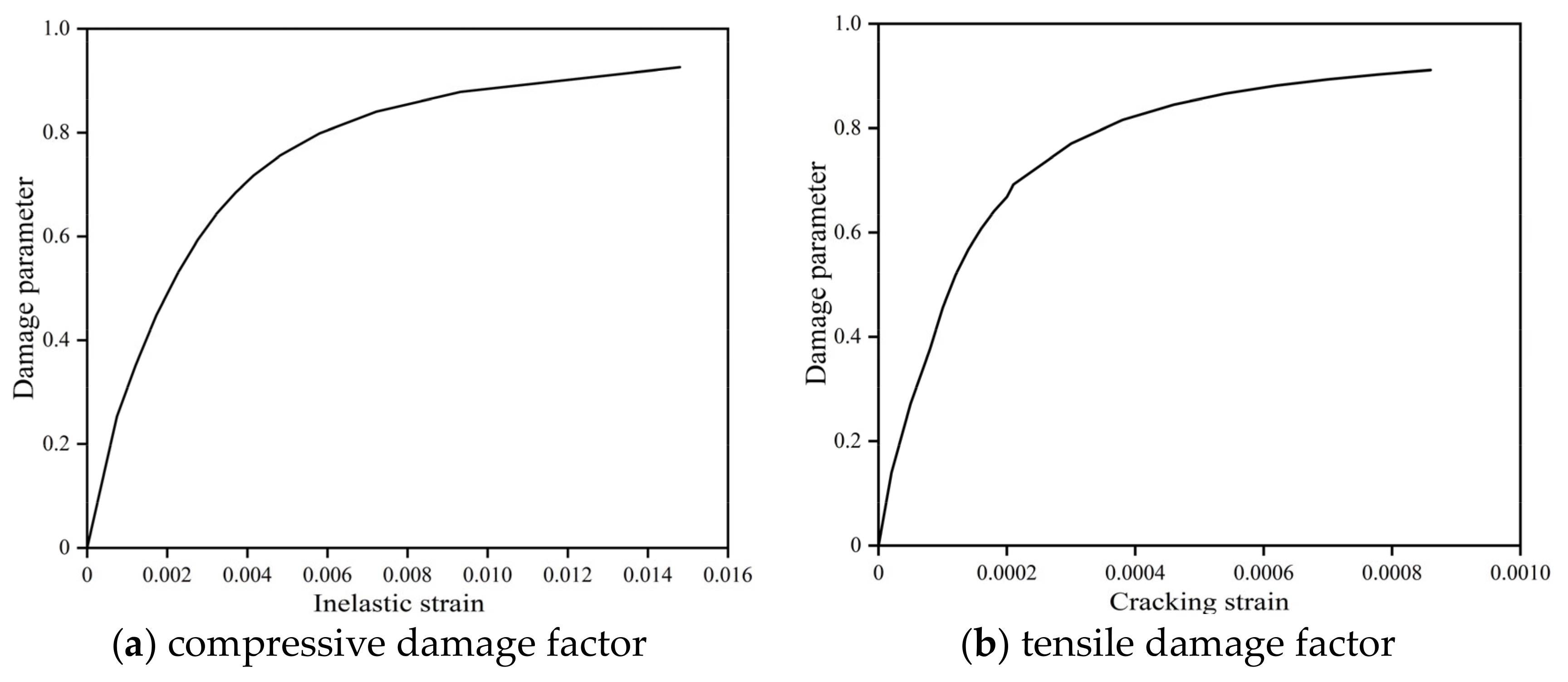

2.2.1. Concrete

2.2.2. Steel Bars and Steel Strands

2.2.3. CFSTTs and Diaphragms

2.3. Elements and Mesh

2.4. Contacts and Boundary Conditions

3. Calibration and Validation of the FE Model

3.1. Calibration of Models

3.1.1. Viscosity Coefficient

3.1.2. Dilation Angle

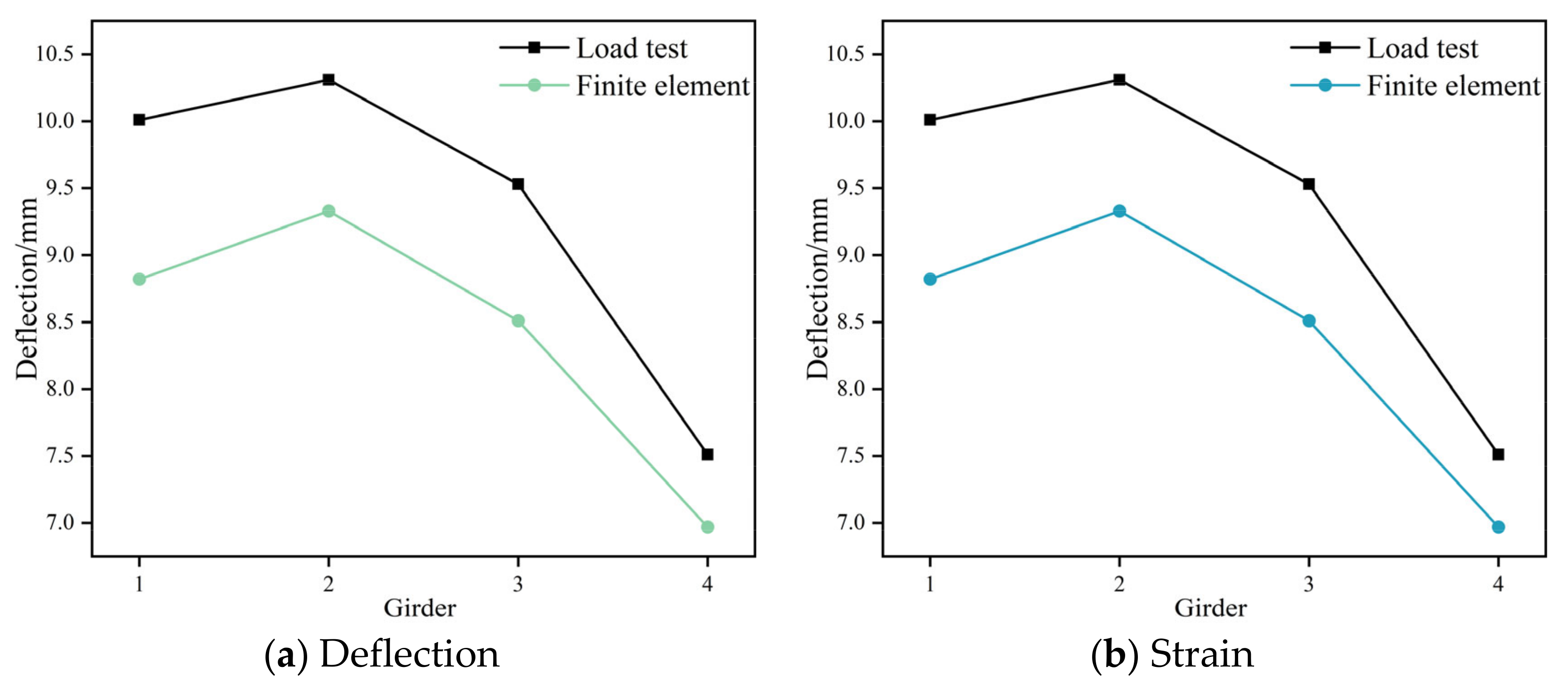

3.2. Validation of Models

4. Load Mode and Models

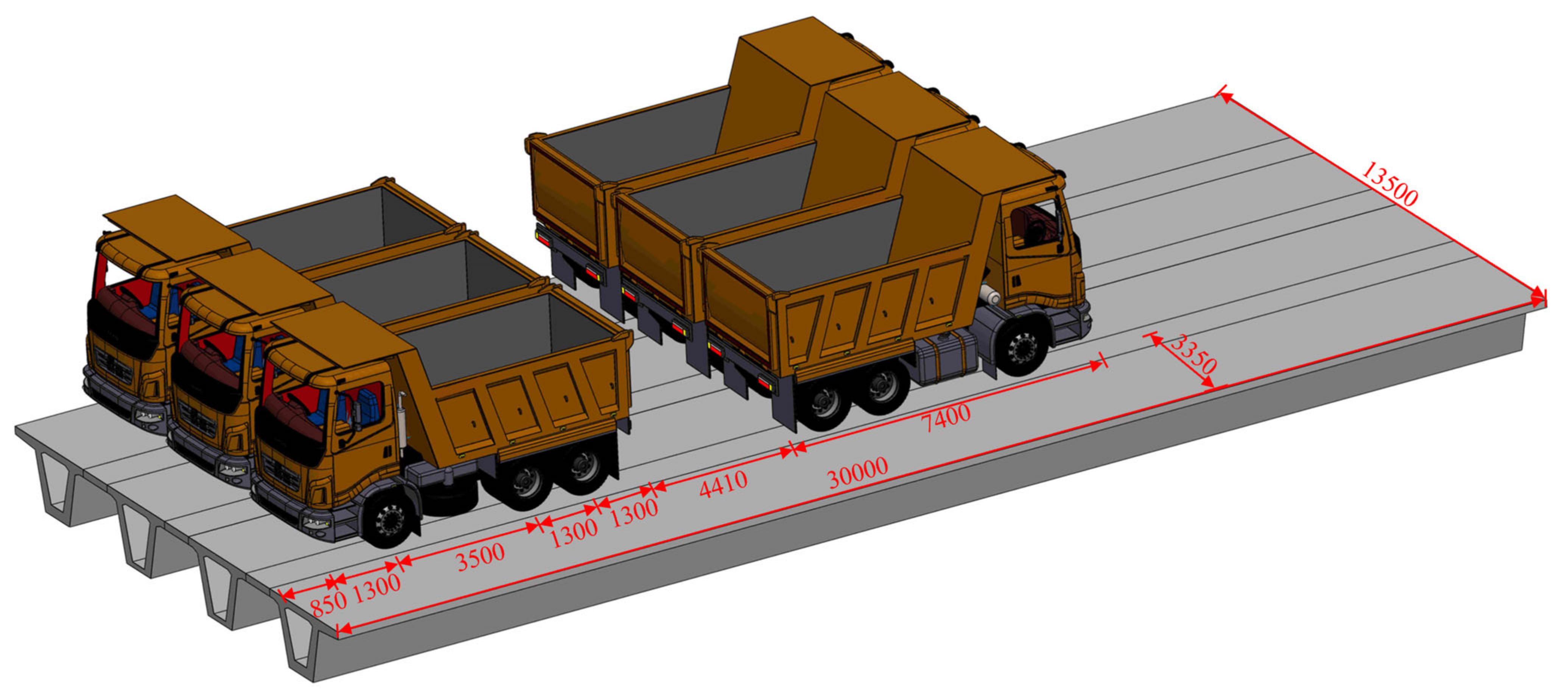

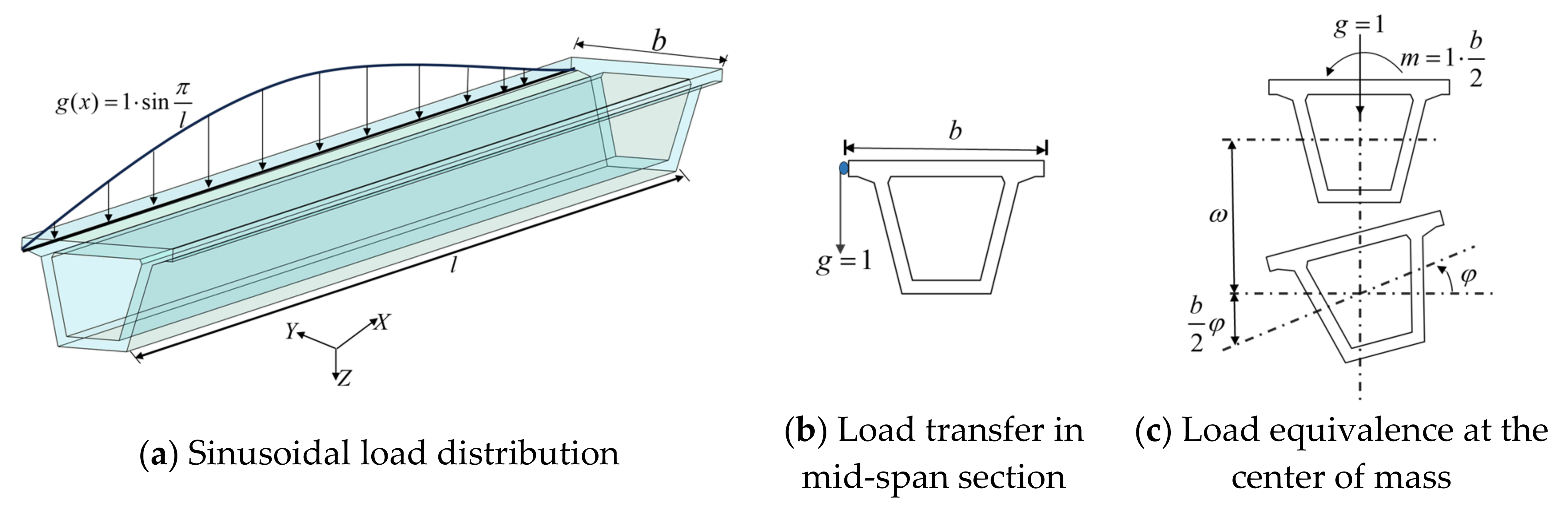

4.1. Load Mode

4.2. Finite Element Models

5. Results and Discussion

5.1. Deflection

5.2. Load Distribution

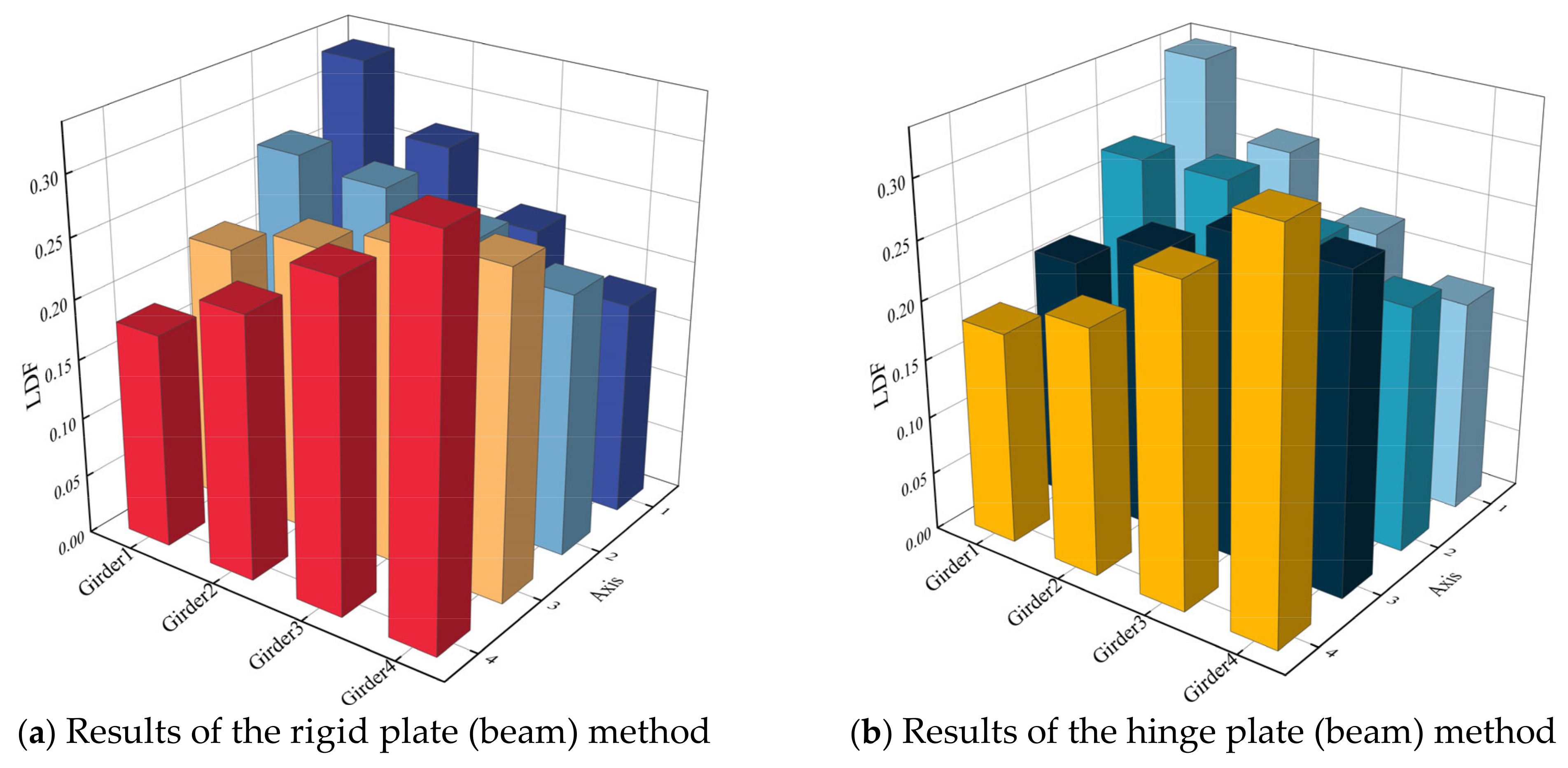

5.2.1. Theory of LDF

5.2.2. FE Method

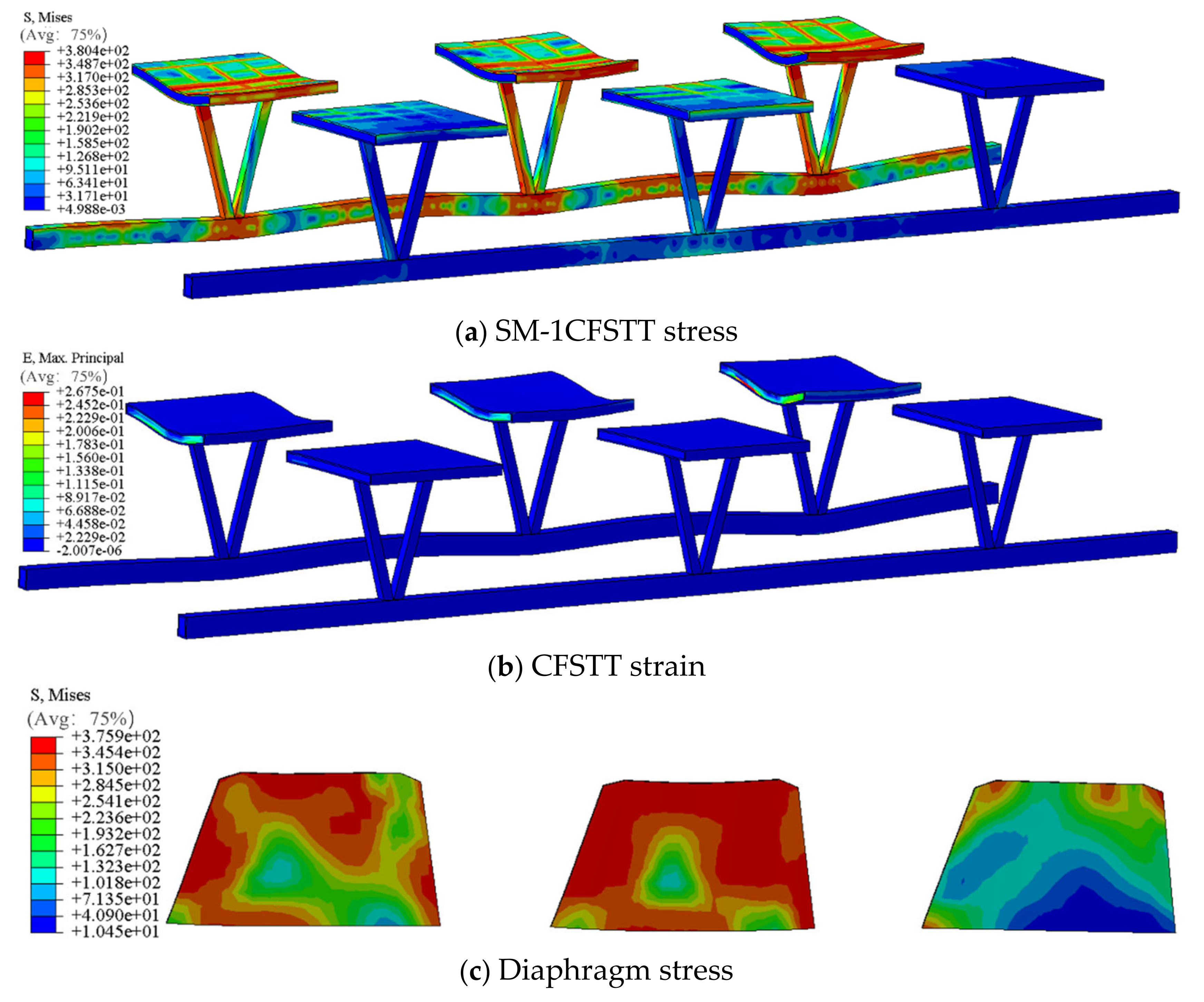

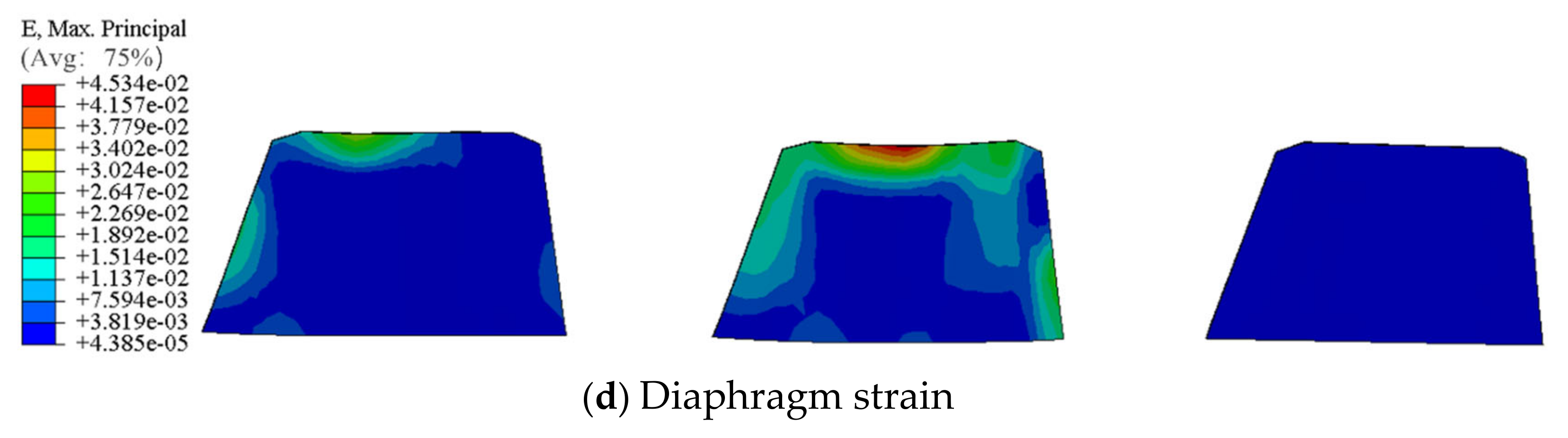

5.3. Maximum Stress and Strain

6. Conclusions

- (1)

- Both diaphragm and CFSTTs can improve the lateral connection and load distribution of PCB bridges, reducing the deflection of main girders. After reinforcement, the main girders tend to cooperate more effectively in load sharing. Comparatively, the CFSTT reinforcement method demonstrates better effectiveness than adding diaphragms, especially in significantly reducing main girder deflections by enhancing the strength of steel tube walls. When steel pipes with yield strength grades of 235 MPa and 420 MPa are used to fill concrete with compressive strength grades of 50 MPa, the maximum deflection of the main girders decreased by 15.32% and 24.55%, respectively. The maximum improvement in LDF for the main girders was 7.31% and 11.57%.

- (2)

- The reinforcement effect of steel diaphragms is superior to that of concrete diaphragms, and the reduction in deflection is proportional to the thickness of the diaphragms. When using concrete transverse diaphragms, the deflection reduction in Girder-1 was 8.72% and 18.82% for diaphragm thicknesses of 100 mm and 500 mm, respectively. When the thickness of steel diaphragms was 10 mm and 30 mm, the deflection of Girder-1 decreased by 12.73% and 21.8%, respectively.

- (3)

- Treating CFSTTs as a midspan diaphragm, there is little difference in the calculated LDF between the hinged plate (beam) method and the rigidly connected plate (beam) method under unit load. From the perspective of maximum stress and strain, CFSTTs have significant advantages in stress dispersion and deformation control compared with traditional diaphragms.

- (4)

- In addition, when selecting a reinforcement strategy, it is important not only to optimize the material properties of the reinforcement technology for optimal reinforcement results but also to comprehensively evaluate the economic impacts, practical challenges, and other factors associated with implementing the reinforcement program. The reinforcement effects of traffic loads and different load combinations need to be further studied.

- (5)

- By comparing strain and deflection values from load tests on a PCB bridge, the reliability of the finite element model is verified. Therefore, this finite element model can be used to effectively study the reinforcement effects of lateral reinforcement methods on PCB bridges.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Beam | The Unit Load Acts on the Axis of the Beam | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 1# | 0.001 | 0.02 | 294 | 283 | 234 | 209 |

| 0.04 | 329 | 274 | 222 | 176 | ||

| 0.003 | 0.02 | 299 | 263 | 230 | 208 | |

| 0.04 | 334 | 273 | 218 | 175 | ||

| 2# | 0.001 | 0.02 | 263 | 257 | 246 | 234 |

| 0.04 | 274 | 261 | 243 | 222 | ||

| 0.003 | 0.02 | 263 | 261 | 246 | 230 | |

| 0.04 | 273 | 266 | 243 | 218 | ||

| Beam | The Unit Load Acts on the Axis of the Beam | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| 1# | 0.02 | 300 | 263 | 227 | 210 |

| 0.04 | 341 | 273 | 208 | 178 | |

| 2# | 0.02 | 263 | 264 | 246 | 227 |

| 0.04 | 273 | 276 | 243 | 208 | |

References

- Sun, Y.; Xu, D.; Chen, B.; Xu, F.-Y.; Zhu, H.-P. Three-dimensional reinforcement design method and program realization for prestressed concrete box-girder bridges based on a specific spatial lattice grid model. Eng. Struct. 2018, 175, 822–846. [Google Scholar] [CrossRef]

- Duan, M.; Miao, J.; Wu, J.; Dong, F. Reliability Assessment Approach for Fire Resistance Performance of Prestressed Steel–Concrete Box Girder Bridges. Fire 2023, 6, 472. [Google Scholar] [CrossRef]

- Yuan, J.; Luo, L.; Zheng, Y.; Yu, S.; Shi, J.; Wang, J.; Shen, J. Analysis of The Working Performance of Large Curvature Prestressed Concrete Box Girder Bridges. Materials 2022, 15, 5414. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, Y.; Zhou, F.; Liu, Z. Effect of frame stiffness calculation method on the analysis of distortion effect of box girder. J. Southeast Univ. (Nat. Sci. Ed.) 2024, 54, 423–431. [Google Scholar]

- Li, Y.; Yu, Z.; Liu, Y. Experimental and Numerical Study of the Ultimate Flexural Capacity of a Full-Size Damaged Prestressed Concrete Box Girder Strengthened with Bonded Steel Plates. Materials 2023, 16, 2476. [Google Scholar] [CrossRef]

- Nettis, A.; Nettis, A.; Ruggieri, S.; Uva, G. Corrosion-induced fragility of existing prestressed concrete girder bridges under traffic loads. Eng. Struct. 2024, 314, 118302. [Google Scholar] [CrossRef]

- Cao, G.; Shen, J.; Yang, L.; Li, K.; Li, Z. Experimental and Modeling Study on Long-Term Deformation of Three-Span Prestressed Concrete Continuous Box-Girder Bridge Model after Cracking. J. Bridge Eng. 2024, 29. [Google Scholar] [CrossRef]

- Liu, H.; Li, J.; Zhang, J.; Pang, D. Decision Analysis of a Reinforcement Scheme for In-Service Prestressed Concrete Box Girder Bridges Based on AHP and Evaluation of the Reinforcement Effect. Buildings 2022, 12, 1771. [Google Scholar] [CrossRef]

- Hu, Z.; Li, X.; Shah, Y.I. Simplified Method for Lateral Distribution Factor of the Live Load of Prefabricated Concrete Box-Girder Bridges with Transverse Post-tensioning. KSCE J. Civ. Eng. 2022, 26, 3460–3470. [Google Scholar] [CrossRef]

- Li, L.; Ma, J.-Z. Effect of Intermediate Diaphragms on Decked Bulb-Tee Bridge System for Accelerated Construction. J. Bridge Eng. 2010, 15, 715–722. [Google Scholar] [CrossRef]

- Zhang, K.; Qi, T.; Li, D.; Xue, X.; Wu, F.; Liu, X. Research on innovative reinforcement of prestressed T-beam bridge. Int. J. Struct. Integr. 2021, 12, 922–937. [Google Scholar] [CrossRef]

- Shi, J.; Chen, Z. Research on the Rationality of Setting the Transverse Ribs of Large Cantilever Segmental Prefabricated Box Girders. Buildings 2023, 13, 1873. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.; Kang, Y.J. Improved design of intermediate diaphragm spacing in horizontally curved steel box bridges. J. Constr. Steel Res. 2022, 198, 107488. [Google Scholar] [CrossRef]

- Jeonghwa, L.; Seungjun, K.; Jong, Y.K. Effect of cross-sectional rigidity on intermediate diaphragm spacing of steel-box girder bridges. J. Constr. Steel Res. 2022, 188, 107006. [Google Scholar]

- Ahmad, I.W.; Ibrahim, I.S.; Padil, K.H.; Umar, S.; Lee, H.S.; Singh, J.K. Numerical analysis on the effect of the intermediate diaphragm on the concrete bridge to the acceleration and frequency under moving load. IOP Conf. Ser. Earth Environ. Sci. 2023, 1135, 012045. [Google Scholar]

- Tsiptsis, N.I.; Sapountzaki, E.O. Analysis of composite bridges with intermediate diaphragms & assessment of design guidelines. Comput. Struct. 2020, 234, 106252. [Google Scholar]

- Yang, C.-Q.; Du, W.-P.; Hou, P.; Zhu, F.-W.; Chen, Y.-J.; Ma, C.-J.; Pan, Y.; Zhang, H.-L. Adding composite truss to improve mechanical properties of reinforced concrete T-girder bridge. Adv. Struct. Eng. 2022, 25, 2058–2207. [Google Scholar] [CrossRef]

- Hou, P.; Yang, J.; Pan, Y.; Ma, C.-J.; Du, W.-P.; Yang, C.-Q.; Zhang, Y. Experimental and simulation studies on the mechanical performance of concrete T-Girder bridge strengthened with K-Brace composite trusses. Structures 2022, 43, 479–492. [Google Scholar] [CrossRef]

- Hou, P.; Yang, C.Q.; Yang, J.; Pan, Y.; Li, P.; Du, W.-P. Fatigue Life of Composite Truss Used to Strengthen the Prestressed Concrete Box Girder Bridge: A Case Study. J. Perform. Constr. Facil. 2024, 38, 04024032. [Google Scholar] [CrossRef]

- Chen, C.; Yang, C.-Q.; Zhang, K.; Wang, W.; Dong, L. Structural Behavior and Load Distribution Factor of a T-Girder Bridge with Various Truss Diaphragms. J. Bridge Eng. 2023, 28, 04023094. [Google Scholar] [CrossRef]

- Niu, Y.; Liu, B.; Zhao, Y.; Rong, S.; Huang, P. Diaphragm damage of precast concrete T-shape girder bridge: Analysis and strengthening. Open Civ. Eng. J. 2014, 8, 396–405. [Google Scholar] [CrossRef][Green Version]

- ABAQUS. User’s Manual, version 6.13; ABAQUS, Inc.: Providence, RI, USA, 2022. [Google Scholar]

- JTG D60-2004; General Code for Design of Highway Bridges and Culverts. The Ministry of Construction of the People’s Republic of China: Beijing, China, 2004.

- GB/T 50081-2002; Standard for Test Methods for Mechanical Properties of Ordinary Concrete. The Ministry of Construction of the People’s Republic of China: Beijing, China, 2002.

- Li, X. Parametric study on numerical simulation of missile punching test using concrete damaged plasticity (CDP) model. Int. J. Impact Eng. 2020, 144, 103652. [Google Scholar] [CrossRef]

- Lubliner, J.; Oliver, J.; Oller, S.; Oñate, E. Aplastic-damage Model for Concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Jia, Y.; Chiang, J.C.L. Finite Element Analysis of Punching Shear of Reinforced Concrete Slab–Column Connections with Shear Reinforcement. Appl. Sci. 2022, 12, 9584. [Google Scholar] [CrossRef]

- EC Standardization EN 1992-1-2; Design of Concrete Structures—Part 1-2: General Rules—Structural Fire Design. European Commission: Brussels, Belgium, 1992.

- GB 50010-2010; Code for Design of Concrete Structures. The Concrete Society: Surrey, UK, 2010.

- Hou, P.; Yang, C.-Q.; Yang, J.; Pan, Y. Study on the Mechanical Performance of the Xiuzhen River Bridge Strengthened Using K-brace Composite Trusses. KSCE J. Civ. Eng. 2024, 28, 860–872. [Google Scholar] [CrossRef]

- Chen, C.; Yang, C.-Q. Experimental and Simulation Studies on the Mechanical Performance of T-Girder Bridge Strengthened with Transverse Connection. J. Perform. Constr. Facil. 2019, 33, 04019055. [Google Scholar] [CrossRef]

- Chen, C.; Yang, C.-Q.; Pan, Y.; Zhang, H.-L.; De Backer, H. Simulation and design considerations 410 on transverse connection of prestressed concrete T-girder bridge. Int. J. Steel Struct. 2021, 21, 1182–1196. [Google Scholar] [CrossRef]

- Chen, C.; Yang, C.-Q.; Pan, Y.; Zhang, H.-L.; De Backer, H. Parameters analysis and design of 413 transverse connection strengthening prestressed concrete T-girder bridge. Struct. Concret. 2021, 22, 3385–3395. [Google Scholar] [CrossRef]

- Transportation, Ministry of Expertise, National Commission, etc. General Drawings of Highway Bridges (Plate Beam Series, Box Beam Series); China Communication Press: Beijing, China, 2014. [Google Scholar]

- Labib, S.N.; El-Salakawy, E.F. Finite-Element Analysis of Adjacent Concrete Box Girders Transversely Post-Tensioned at the Top Flanges Only. CivilEng 2022, 3, 165–183. [Google Scholar] [CrossRef]

- Li, X.; Hu, Z.; Shah, Y.I. Transverse Connection Performance of Prefabricated PC Box Girder Bridge with Transverse Prestress. Int. J. Civ. Eng. 2022, 20, 957–966. [Google Scholar] [CrossRef]

- Deng, Y.; Li, A.Q.; Zhang, Y.L.; Li, Y.H. Analysis on seismic performance of novel prefabricated pin-shaft concrete beam-column joints. J. Southeast Univ. 2022, 53, 461–470. [Google Scholar]

- Vu, Q.V.; Thai, D.K.; Kim, S.E. Effect of intermediate diaphragms on the load–carrying capacity of steel–concrete composite box girder bridges. Thin-Walled Struct. 2018, 122, 230–241. [Google Scholar] [CrossRef]

- Du, L.; Qi, J.; Cheng, Z.; Wang, J. Finite element modeling of UHPC slabs with dovetail joints and steel wire mesh using an innovative interfacial treating method. Structures 2022, 37, 745–755. [Google Scholar] [CrossRef]

- JTG/T J21-01-2015; Load Test Code for Highway Bridges. The Ministry of Construction of the People’s Republic of China: Beijing, China, 2015.

- Zu, J.-H. Research on the Influence of Beeline and Skew Multi-Shaped Beam Bridge’s Diaphragm Thickness to Its Static and Dynamic Performance. Master’s Thesis, Southwest Jiao Tong University, Chengdu, China, 2015. [Google Scholar]

- Highway Planning and Design Institute of the Ministry of Communications. Design Code for Highway Reinforced Concrete and Prestressed Concrete Bridge and Culvert JTJ023-85; China Communications Press: Beijing, China, 2002. [Google Scholar]

- AASHTO. Standard Specification for Highway Bridges; AASHTO: Washington, DC, USA, 2002. [Google Scholar]

- Armenàkas, E.A. Advanced Mechanics of Materials and Applied Elasticity; CRC Press: Boca Raton, FL, USA, 19 April 2016. [Google Scholar]

- Mahmoud, J.; Semih, E. Optimization of prestressed concrete bridge girder section using a modified harmony search algorithm. Structures 2022, 46, 625–636. [Google Scholar]

- Li, J.-W. Research on Transverse Load Distribution of Prestressed Concrete Small Box Girder Bridge. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2020. [Google Scholar]

- Zhang, J. Research on Transverse Distribution Coefficient of Bridge Load. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2011. [Google Scholar]

- Li, G.-H.; Shi, D. Calculation of Transverse Distribution of Highway Bridge Load; China Communications Press: Beijing, China, 1987. [Google Scholar]

- Yao, L. Bridge Engineering; People’s Communications Press: Beijing, China, 1985. [Google Scholar]

| Strength Grade | Tensile Strength (ftk)/MPa | Poisson’s Ratio () | Elasticity Modulus/MPa | Density/ kg/m3 |

|---|---|---|---|---|

| C30 | 2.20 | 0.2 | 3.00 × 104 | 2.2 × 103 |

| C40 | 2.39 | 0.2 | 3.25 × 105 | 2.2 × 103 |

| C50 | 2.51 | 0.2 | 3.45 × 104 | 2.2 × 103 |

| Type | Diameter/mm | Yield Strength (fy)/MPa | Elasticity Modulus/MPa | Ultimate Strength (fu)/MPa | Elongation/% |

|---|---|---|---|---|---|

| R1 | 20 | 335 | 2.0 × 105 | 455 | 7.5 |

| R2 | 12 | 335 | 2.0 × 105 | 455 | 7.5 |

| R3 | 10 | 300 | 2.1 × 105 | 420 | 10.0 |

| Type | Initial Angle | Area/mm2 | Length/mm | Radius of Curvature/mm |

|---|---|---|---|---|

| N1 | 6.843° | 405 | 30,760 | 50,000 |

| N2 | 6.843° | 405 | 30,810 | 40,000 |

| N3 | 1.909° | 550 | 30,660 | 30,000 |

| Nominal Diameter (Dn)/mm | Maximum Total Elongational (Agt)/%≥ | Channel Friction Coefficient | Channel Deviation Coefficient | Elasticity Modulus/MPa | /MPa |

|---|---|---|---|---|---|

| 15.24 | 3.5 | 0.25 | 0.0015 | 195,000 | 1860 |

| (°) | Average Strain Relative Error (%) | Average Deflection Relative Error (%) |

|---|---|---|

| 15 | 14.49 | 15.22 |

| 28 | 8.94 | 13.98 |

| 36 | 21.81 | 36.29 |

| 50 | 31.78 | 41.29 |

| Loading Point | I | II | III | IV | V | VI |

|---|---|---|---|---|---|---|

| X/mm | 5100 | 5100 | 5100 | 17,400 | 17,400 | 17,400 |

| Y/mm | 4050 | 7850 | 11,650 | 4050 | 7850 | 11,650 |

| Model ID | Description | Strengthening Method |

|---|---|---|

| CM-1 | Control model | Control model |

| SM-1 | C50-grade concrete filled in Q235-grade steel pipe walls | Use CFSTTs |

| SM-2 | C50-grade concrete filled in Q345-grade steel pipe walls | |

| SM-3 | C50-grade concrete filled in Q420-grade steel pipe walls | |

| SM-4 | C30-grade concrete filled in Q345-grade steel pipe walls | |

| SM-5 | C40-grade concrete filled in Q345-grade steel pipe walls | |

| SM-6 | 10 mm thick Q345-grade diaphragm | Use diaphragms |

| SM-7 | 20 mm thick Q345-grade diaphragm | |

| SM-8 | 30 mm thick Q345-grade diaphragm | |

| SM-9 | 100 mm thick C50-grade concrete diaphragm | |

| SM-10 | 300 mm thick C50-grade concrete diaphragm | |

| SM-11 | 500 mm thick C50-grade concrete diaphragm |

| = 0.001 | = 0.003 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.02 | 0.294 | 0.283 | 0.234 | 0.209 | 0.299 | 0.263 | 0.230 | 0.208 | |

| 0.04 | 0.329 | 0.274 | 0.222 | 0.176 | 0.334 | 0.273 | 0.218 | 0.175 | |

| First interpolation | = 0.0371 | 0.323 | 0.274 | 0.223 | 0.180 | 0.329 | 0.271 | 0.220 | 0.180 |

| Second interpolation | = 0.0013 | ||||||||

| = 0.0371 | 0.328 | 0.272 | 0.220 | 0.180 | |||||

| 0.02 | 0.300 | 0.263 | 0.227 | 0.210 | |

| 0.04 | 0.341 | 0.273 | 0.208 | 0.178 | |

| First interpolation | = 0.0371 | 0.335 | 0.272 | 0.211 | 0.182 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Yang, C.; Xu, F.; Li, J.; Jin, D. Reinforcement of Insufficient Transverse Connectivity in Prestressed Concrete Box Girder Bridges Using Concrete-Filled Steel Tube Trusses and Diaphragms: A Comparative Study. Buildings 2024, 14, 2466. https://doi.org/10.3390/buildings14082466

Li P, Yang C, Xu F, Li J, Jin D. Reinforcement of Insufficient Transverse Connectivity in Prestressed Concrete Box Girder Bridges Using Concrete-Filled Steel Tube Trusses and Diaphragms: A Comparative Study. Buildings. 2024; 14(8):2466. https://doi.org/10.3390/buildings14082466

Chicago/Turabian StyleLi, Peng, Caiqian Yang, Fu Xu, Junshi Li, and Dongzhao Jin. 2024. "Reinforcement of Insufficient Transverse Connectivity in Prestressed Concrete Box Girder Bridges Using Concrete-Filled Steel Tube Trusses and Diaphragms: A Comparative Study" Buildings 14, no. 8: 2466. https://doi.org/10.3390/buildings14082466

APA StyleLi, P., Yang, C., Xu, F., Li, J., & Jin, D. (2024). Reinforcement of Insufficient Transverse Connectivity in Prestressed Concrete Box Girder Bridges Using Concrete-Filled Steel Tube Trusses and Diaphragms: A Comparative Study. Buildings, 14(8), 2466. https://doi.org/10.3390/buildings14082466