Abstract

Plastics represent an integral part of our everyday lives, with various functions from packaging materials to insulation layers in our buildings. Pure expanded polystyrene (EPS) is a good example of a fully recyclable material. However, once polluted with other materials or substances, EPS becomes a serious environmental burden. In this work, waste EPS for the production of greener building composites with balanced properties and utility value was investigated. Natural aggregate (2/4 mm) was substituted with corresponding fractions of a thermoplastic alternative in portions of 25, 50, 75, and 100 vol.%. The comprehensive experimental investigation evaluated physical and mechanical properties, heat transport and accumulation, and water absorption characteristics. Due to the uniformly distributed plastic particles in the hardened cement-based matrix, the data revealed an important reduction in the dead weight of produced mortars, which also reduced thermal conductivity by up to 47%. On one hand, lightweight mortars showed partially reduced mechanical resistivity; on the other hand, the EPS bead-modified structure turned out to be effective in liquid water transport reduction.

1. Introduction

Plastics have become ubiquitous materials used worldwide as, e.g., thin but very tough shopping bags, parts of our cars, elements applied in buildings, and computer components [1]. Although plastics are relatively young materials, they experienced broad usage during the 20th century, and nowadays it is hard to imagine everyday life without them [2]. Plastics, in general, are products that come from the petroleum industry [3]. A very important representative of thermoplastic materials, polystyrene (PS), in particular in its expanded form (EPS), is considered in this work. EPS is well known and used as a packaging material because of its unique shock absorption capability and its reasonable ratio between strength and lightness [4]. The construction industry constitutes a field in which applications and sales of EPS are widespread. EPS, in its different densities, is used as an important part of all types of buildings, e.g., family houses, office buildings, shopping malls, etc., and as boards or particulate material (beads) it is a part of buildings’ envelopes, floors, roofs, foundations, soffits, etc., due to its low density, impact sound insulation and, in particular, excellent thermal-insulation function [5,6,7]. In its basic form, PS is a solid material that can be modified into an aerated product [2]. Styrene monomers are inflated with suitable gasses, such as pentane and hexane, and as a result, lightweight beads with a closed-cell structure composed of up to 98% air are created [8,9,10]. A very important advantage of polystyrene is its complete recyclability and ability to be used as a secondary material, which is an important benefit in view of the current emphasis on long-term sustainability and circularity. However, if polystyrene is polluted, for example, with other materials or substances, recycling is loaded with high economic costs, and a high quantity of this waste often ends up in sprawling landfills, or is used for energetic purposes (incinerated). Thus, serious environmental problems may be induced [11]. This is an alarming problem, especially in developing countries where rapid population growth is tied with increasing industrialization [12].

Lightweight concretes and mortars are irreplaceable in the construction industry because of their low weight, low thermal conductivity, good acoustic insulation function, fire resistance, etc. [13,14]. In particular, their low weight is a significant benefit allowing structures, such as beams, columns, etc., to be slimmed down, thus providing new technical solutions contributing to material and financial savings [13]. Lightweight concrete can be designed in several basic ways. First, the use of chemical additives (agents) causes the creation of air bubbles inside the fresh cement-based matrix and lightens the typically dense cement stone—the direct lightening method [15]. Further, the desired rate of composite lightening can be achieved by applying a uniform size of coarse aggregate while reducing the fine aggregate content. Such a product is called no-fine concrete [16,17]. The last option, the so-called indirect method, is the application of lightweight fillers, an alternative to traditionally used dense and compact aggregates such as siliceous, carbonate, and other bases. Among these materials are natural products, such as volcanic pumice and tuffs, and artificially prepared bulk materials, e.g., expanded clay, shale, perlite, and vermiculite [18,19,20,21,22]. However, the quarrying or artificial preparation of lightweight aggregates is connected to several questionable aspects. The excessive quarrying of natural high-valued resources (volcanic pumice and tuffs) results in the creation of serious environmental impacts affecting different areas, from the quality of underground water sources to species biodiversity [23,24]. Artificially manufactured aggregates are produced under high temperatures, thus consuming high energy to create a highly expanded structures [25]. These energy-related aspects have to be taken into account in view of the European Union energy transformation [26,27]. In this regard, their high potential makes plastics a reasonable alternative to the aforementioned natural and artificial lightweight aggregates due to their unique properties, like low rate of thermal conductivity [28].

In contrast to traditional lightweight aggregates, plastics do not usually suffer from the problem of high water absorption [29]. This negative phenomenon is closely related to the loss of workability of fresh composite mixes [28] and their subsequent modification with expensive chemical additives. Incorporating recycled and processed plastics, unsuitable for producing new polymer products, into building composites may be a promising way to reduce the negative landfill and incinerator-related issues facing our environment. In previous works, the impact of natural aggregate replacement using EPS was investigated only with a focus on specific properties of cement-based composites, such as mechanical performance [30,31,32], volume changes [3,33], and water transport [8,34,35]. In light of this, providing a comprehensive insight into the behavior of lightweight EPS-dosed composites is needed.

The construction industry represents an important consumer of natural resources and artificial materials. With regard to the high energy demands related to production and other negative environmental aspects, this paper aims to include waste EPS in traditional mortars to develop more sustainable building composites. A comprehensive experimental investigation revealed the high potential of fine-grained mortars with a balanced content of thermoplastic-based aggregate, offering a sufficient rate of strength in combination with improved thermal insulation function and reduced liquid water absorption.

2. Experimental Part

2.1. Raw Materials

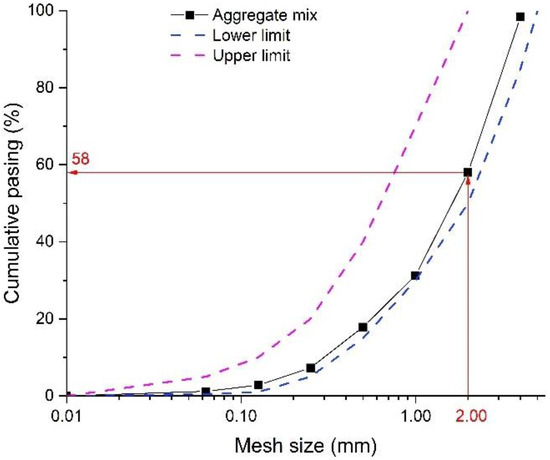

Locally available raw materials were used in order to minimize transport costs for long distances. Ordinary Portland cement of grade 32.5 (C 32.5) was applied with a rapid increase in strength and standard requirements according to EN 197-1 [36]. The oxide composition and main material properties provided by the manufacturer (Heidelberg Materials CZ, Corp., Czech Republic) are provided in Table 1 and Table 2. As a filler material, a blend of mined natural silica sand in the fraction 0/2 mm (N-A 0/2 mm)—LB MINERALS, Ltd., Horní Bříza, Czech Republic—and natural crushed fine silica aggregate in the fraction 2/4 mm (N-A 2/4 mm)—Kámen a písek, Ltd., Český Krumlov, Czech Republic—was used. The particle size distribution curve of the used aggregated blend is depicted in Figure 1. The cumulative particle size distribution curve fell within the highlighted lower and upper limit curves that indicate an optimal granulometry area suitable for the design of mixed cement bases, as indicated in EN 206-1 [37].

Table 1.

Chemical composition of the cement type.

Table 2.

Physical properties of cement used.

Figure 1.

Cumulative particle size distribution curve of aggregate mix.

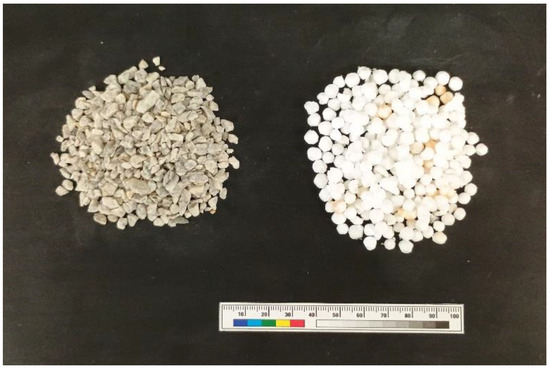

The coarser fraction of natural aggregate N-A 2/4 mm was substituted via detached beads of waste-expanded polystyrene of the same fraction (W-A 2/4 mm) up to 100 vol.% (see in Figure 2). Waste polystyrene particles produced from recycled EPS boards from thermal insulating layers of buildings’ envelopes, constituting a sustainable material source, were provided by the company Ecopolystyren, Ltd., Příbram, Czech Republic.

Figure 2.

Natural crushed silica fine aggregate (N-A 2/4 mm) and waste EPS beads (W-A 2/4 mm).

2.2. Filler Materials

The properties of fillers, which commonly occupy approx. 70–80% of the volume in cement-based composites [38], play an important role in the design of practical mortars. In this context, the physical characteristics of the natural aggregates and the waste alternative are summarized in Table 3.

Table 3.

Material characteristics of natural aggregates and waste replacement material.

In general, naturally mined and crushed aggregates have high bulk and specific densities. As reported in Table 3, the values of the bulk densities of the natural silica aggregates were found to be higher than 1200 and 1500 kg·m−3 in their loose and compacted states, respectively. On the contrary, the waste thermoplastic material with a closed-cell expanded structure showed around 150 times lower bulk density values. This observation points out the direct potential of waste alternatives in promoting the thermo-insulation function of produced composites and reducing dead weight. The water absorption of the N-A aggregates was found to be about 2% of their weight, which is a common value for natural dense aggregates [33]. In the W-A 2/4 mm filler, the value of 1.7 vol.% was obtained after 24 h of immersion in water as a result of the closed-cell structure and the surface hydrophobicity of the EPS beads [31,39,40]. The thermal transport and heat-storage-related properties of the natural N-A 2/4 mm material and the W-A filler, determined in loose and compacted states at 10, 30, and 60 s, are outlined in Table 4. No major differences in the measured properties of the individual aggregates were found after 30 s (N-A 2/4 mm) and 10 s (W-A 2/4 mm) of compaction. The commonly used dense natural aggregate reached thermal conductivities of 0.215 W·m−1·K−1 and 0.256 W·m−1·K−1 in its loose state and compacted state, respectively. In comparison with W-A 2/4 mm, thermal conductivity values were determined to decrease approx. 4 times. This observation directly confirmed the aforementioned assumption of the thermal-insulating effect related to the substitution of natural filler with the waste alternative.

Table 4.

Thermal performance of natural and waste aggregates in the fraction 2/4 mm.

2.3. Mixtures and Sampling

The compositions of all the produced mortar mixes are outlined in Table 5. The reference mix, labelled M-R, consists of Portland cement (C 32.5) and both types of natural aggregates, namely N-A 0/2 mm and N-A 2/4 mm. The initial water-to-binder ratio was set at 0.55. In other cases, in the mixes M-W 25 up to M-W 100, the natural aggregate N-A 2/4 mm was substituted with the expanded plastic beads of W-A 2/4 mm in volumetric ratios of 25, 50, 75, and 100%. One can observe a decreasing amount of batch water with an increasing portion of waste aggregate in the fresh mixes. The water content was adapted to the initial value of spreading of 160 × 160 ± 5 mm measured for M-R, with respect to the requirements listed in EN 1015-3 [41]. Waste-expanded polystyrene particles have a practically ideal spherical shape and dispose of low water absorption; they are capable of improving the workability of fresh composite mixes and, in an opposite way, decreasing the amount of batch water while maintaining the desired workability [42]. Fresh mortar mixes were blended according to EN 196-1 [43]. The mixing procedure is described in detail in Pokorný et al.’s study [44]. In total, 32 prismatic samples were made with a cross-sectional area of (40 × 40) mm2 and a length of 160 mm, and 14 cubes were made with a 70 mm edge. The test specimens were stored under standard conditions according to EN 12390-2 [45] and subjected to the experimental procedures after 28 days of curing.

Table 5.

Mixing proportions of prepared composite mixes.

2.4. Testing Procedures

The loose and compacted bulk densities of all fillers were measured in agreement with EN 1097-3 [46]. The device AccuPyc II 1340 (Micro-Metrics Co., Ltd., Lincoln, UK)—a helium pycnometer—was used to determine the specific density values. The relative standard deviation of eight independent measurements was calculated below 0.05%. The water absorption of the filling materials was measured according to EN 1097-6 [47]. The procedure of sieving analysis [48] for determining the cumulative particle size distribution curve of the aggregates was adopted according to EN 933-1. Among the physical properties measured on the hardened mortar specimens, bulk density, apparent density, and open porosity are considered. Bulk density values are expressed as the average of ten independent measurements (EN 1015-10 [49]), whereas the calculated expanded uncertainty was 3.0%. The apparent density values were obtained with the same apparatus described in the aforementioned case of specific density values. Open porosity values were calculated according to the approach described by Záleská et al. [50]. Measurements and calculations of flexural and compressive strengths were completed with respect to the requirements specified in EN 1015-11 [51]. The expanded uncertainty of both strength determinations was below 2%. More detailed descriptions of both these procedures are available in Pokorný et al.’s study [52]. The material properties related to one-dimensional water transport (details reported elsewhere [53]) via capillary forces through a porous system of siliceous materials were determined with respect to the standard EN 1015-18 [54]. Thermal–physical properties were measured with the device ISOMET 2114 (Applied Precision, Ltd., Bratislava, Slovakia), which operates on the transient measuring method. The experimental set and measuring accuracy of the method used are provided in Pokorný et al.’s work [55]. The digital microscope VHX 6000 (KEYENCE INTERNATIONAL, Corp., Mechelen, Belgium)—see more in Pokorný et al.’s work [44]—was used for microstructural observations of the produced mortars.

3. Results and Discussion

3.1. Physical Properties of Produced Mortars

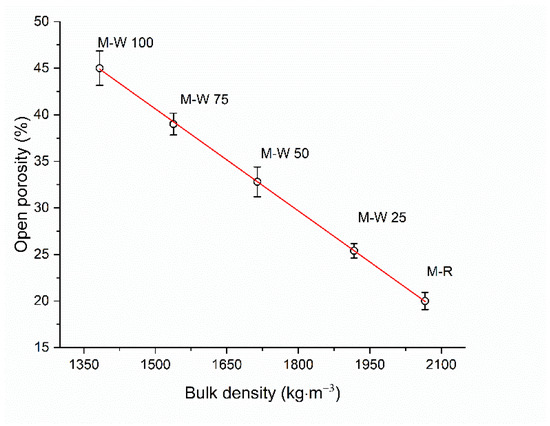

Bulk and apparent densities and porosity are summarized in Table 6. A gradual decrease in densities followed by a gradual increase in porosity were determined with the increasing content of the waste thermoplastic alternative in the hardened mortars. For example, the values of bulk density were found to be lower at 149, 352, 528, and a considerable 683 kg·m−3 for M-W 25, M-W 50, M-W 75, and M-W 100, respectively, in comparison with the reference sample (M-R). Thus, with 100 vol.% substitutions of N-A 2/4 mm with W-A 2/4 mm, it was possible to reduce the weight of the hardened mortars by up to one-third. Reducing the load of bearing structures is crucial in their subtle design and in decreasing the risk of earthquake-related damages to constructions [3,13]. No significant differences were determined for apparent density values. Only minor changes in the range of tens of kg·m−3 were obtained. Nevertheless, more noticeable changes were visible for calculated porosity values, which is in good correlation with previous works [3,56]. The lowest average porosity value of 20.0% for the reference material was recorded. In other cases, the porosity was detected to increase by approx. 5%, 13%, 19%, and even 25% with the increasing incorporation of EPS beads. Thus, the hardened mix without natural aggregate of the fraction 2/4 mm was 2.25 times lighter than M-R.

Table 6.

Physical properties of reference and waste-aggregate-dosed mortars.

The dependence of open porosity on the dry bulk density of hardened mortars is depicted in Figure 3. The linear character of the plotted data with a regression coefficient of ~0.997 was revealed. As shown in the reported data, including light polymeric waste into mixes instead of the corresponding fraction of natural aggregate resulted in a gradual increase in open porosity up to 45%, accompanied by a considerable decline in bulk density values under 1400 kg·m−3. Overall, dead weight plays an important role in the design of structures and their overall economy [39].

Figure 3.

Bulk density versus open porosity relationship obtained for reference (M-R) and M-W 25−100 mortars.

3.2. Strength Parameters: Flexural and Compressive Strength

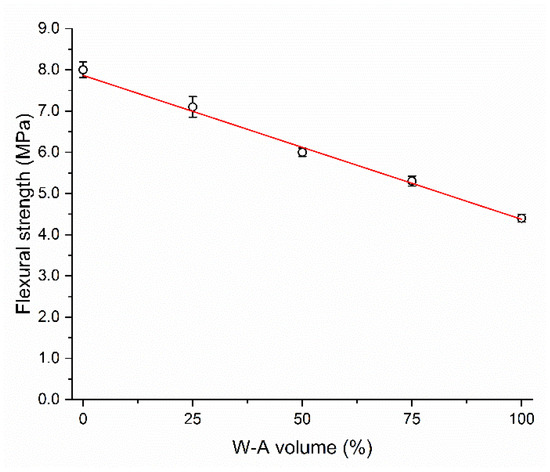

Strength-related properties are the most important for cement-based composites, particularly when a load-bearing function of concrete or mortar layers is expected. The mechanical properties of the W-A dose hardened the mortars, as depicted in Figure 4 and Figure 5. In line with the increasing porosity of the hardened mortars, the flexural strengths were found to gradually linearly (R2 = 0.993) decrease with the increasing content of waste aggregate. Thus, a minimum average flexural strength of 4.4 MPa was recorded for the material with a full volumetric content of W-A 2/4 mm. The rest of the tested hardened mortars, M-W 25–M-W 75, reached 0.9, 2.0, and 2.7 MPa lower strengths compared to the reference mortar (M-R). Similar results were also achieved in other works dealing with the addition of particulate plastic material into cement-based composites [56,57,58].

Figure 4.

Flexural strengths of reference and waste-expanded plastic-enriched mortars.

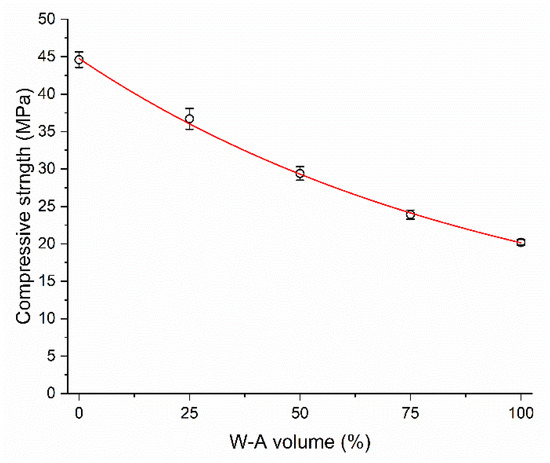

Figure 5.

Compressive strengths of reference and waste-expanded plastic-enriched mortars.

The compressive strength development is plotted in Figure 6. Again, the gradual linear (R2 = 0.999) decrease in strength with increased dosages of WA is shown. Compared with the dense reference material, the decrease in compressive strength values reached 7.9, 15.2, 20.7, and even 24.4% for samples M-W 25, M-W 50, M-W 75, and M-W 100. The observed trends fulfill the previous conclusions reported in works investigating the utilization of polymeric materials in cement-based composites [3,32,59]. Expanded thermoplastic materials are characterized by their soft matrixes filled with a high number of closed air pores. So, because of their small mechanical strength in the range of tens (in relation to the maximum of hundreds of kPa [60,61]), EPS beads represent a very fragile material that is susceptible to easy failure under loading in a hardened composite matrix [8,62]. However, even with the full volumetric replacement of the natural aggregate with a fraction of EPS beads at 2/4 mm, it was still possible to achieve mortars with 20 MPa of compressive strength. Such mortars still have sufficient bearing capacity [63]. In addition, Babu et al. reported that cement-based composites with an EPS content result in materials with higher strength properties compared with those filled with other artificial aggregates, like perlite or vermiculite [8].

Figure 6.

Thermal performance of control (M-R) and waste-filler-dosed mortars (M-W25–100).

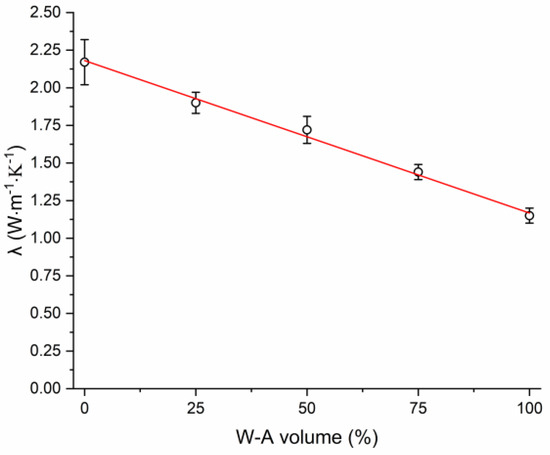

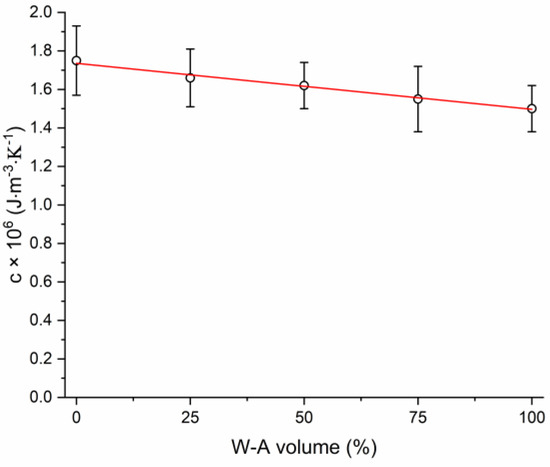

3.3. Thermal Performance

Hardened cement-based composites with reduced bulk density due to the utilization of alternative materials in their composition may bring benefits—not only in mitigating the dead load of structures, but also in improving their thermal performance, as visualized in Figure 6 (thermal transport) and Figure 7 (thermal energy accumulation). The substitution of traditionally used fine filler with the waste alternative caused a gradual linear (R2 = 0.992) decrease in the thermal conductivity values measured in hardened dried mortars. The highest-value thermal transport rate of 2.17 W·m−1·K−1 was observed for the reference sample (M-R). In other cases, for the mortars labelled M-W 25 to M-W 100, values gradually decreased by 12.4, 20.7, and 33.6, up to 47.0%. Accordingly, thermal conductivity decreased more than 1.0 W·m−1·K−1 for the material without the presence of natural filler N-A 2/4 mm. Such a thermal conductivity reduction can be achieved by assuming evenly distributed lightweight aggregate particles in hardened cement-based matrixes [64]. Demirboga and Kan reported that the thermal conductivity reduction can reach 43–70% depending on the lightness of the polystyrene aggregate concrete [65]. However, including soft plastic materials in the hardened matrixes of the designed mortars negatively influenced their thermal accumulation, as visualized in Figure 7. A linear decrease (R2 = 0.983) in the observed property was recorded. Nonetheless, the maximum loss of heat capacity was only 14.3% and, at the same time, a significant reduction in thermal conductivity was reached. An explanation of the role of EPS beads in the thermal performance of hardened mortars can be found in their 150 times lower bulk density compared with N-A 2/4 mm. Moreover, the air contained in the EPS closed-cell structures does not contribute to the heat accumulation in the hardened matrix, as proven by the data presented in Table 4.

Figure 7.

Volumetric heat capacity of control (M-R) and waste-filler-dosed mortars (M-W25–100).

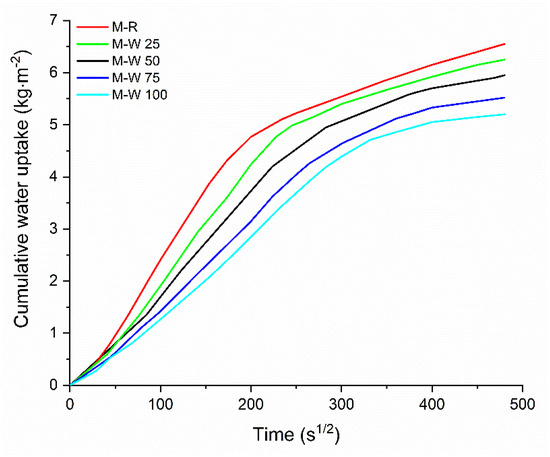

3.4. Water Transport

Concrete and mortar are, by their very nature, porous materials capable of absorbing water. The effect of the alternative thermoplastic aggregate on water-transport-related properties is outlined in Figure 8. As shown, plain mortars (M-R) are wettable hydrophilic materials for which the water absorption reaches the highest values [29]. This fact is also proven by the data listed in Table 7, where the M-R absorption coefficient (A) corresponds to 0.022 kg·m−2·s−1/2. With the increasing incorporation of EPS beads into the mortars, a gradual decrease in cumulative water uptake was observed. The obtained values of absorption coefficient were reduced by 13.6% (M-W 25), 22.7% (M-W 50), 36.4% (M-W 75), and 50.0% (M-W 100), with respect to the reference mortar. The capillary saturated water content (wcap) also decreased from 166.2 kg·m−3 (M-R) to 118.5 kg·m−3 for mortars with the full N-A 2/4 mm aggregate replacement. The apparent moisture diffusivity (Χapp) data correspond well with the measured absorption coefficient and capillary saturated water content developments. The reason for this decreasing water absorption tendency can be related to several factors. Expanded polystyrene beads have a closed-cell structure with minimal water absorption, as shown in Table 3. Another important factor influencing the water behavior of EPS beads is the hydrophobic surface of expanded polystyrene beads: they have water contact angle values between 99° and 102°. Therefore, EPS beads, due to their low surface energy, are non-wetting materials [42,66].

Figure 8.

Cumulative water uptake measured on samples of reference mortar (M-R) and W-A 2/4 mm dosed mortars.

Table 7.

Material properties related to liquid water transport.

Because of the reduced water transport capability of the produced W-A composites, it is expected that EPS bead-dosed concrete will be more durable against corrosion and chemical attack (like the penetration of salt solutions from winter roads and pavement maintenance [51]) than traditional dense aggregate-filled composites [13].

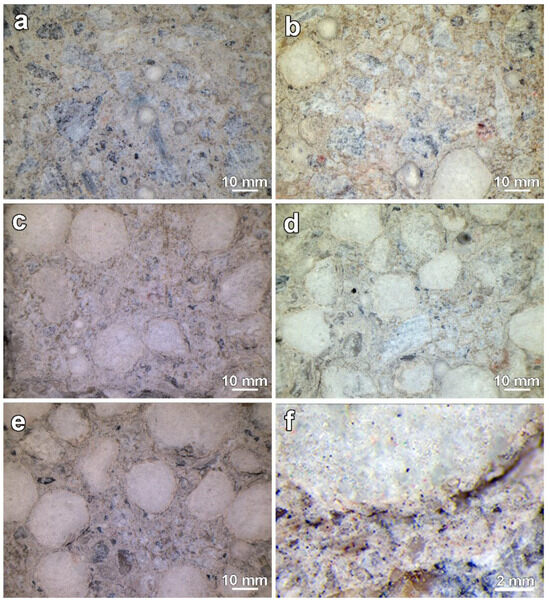

3.5. Microscopic Observation

Images of the produced alternative lightweight aggregate mortars, collected under a digital microscope, are displayed in Figure 9. As is evident, M-R displayed the densest structure with no visible large pores. In the case of the thermoplastic-modified mortars, it is possible to see homogenously distributed EPS beads in a cement matrix with visible cracking around the EPS beads. Figure 9f shows the detail of the W-A 2/4 mm particles embedded in a hardened matrix and the interface between the polymer beads and the siliceous-based surroundings is clearly visible (the so-called interfacial transition zone (ITZ)). The weak ITZ caused by the increased presence of pores resulted in the decreased mechanical resistance of the alternative aggregate-dosed mortars. Normal dense aggregate is stronger than cement-based matrixes. On the contrary, lightweight aggregates typically have low mechanical resistance and high porosity values [13,30,34]. The other explanation could be in relation to the generally smooth surface of polymeric materials. To improve the bonding of the cement matrix with the surface of the thermoplastic material, the application of supplementary cementitious materials, such as silica nanoparticles or fly ash, constitutes a promising approach [67,68].

Figure 9.

Series of images from the digital microscope: (a) reference mortar (M-R), (b) M-W 25, (c) M-W 50, (d) M-W 75, (e) M-W 100, and the interfacial transition zone between an EPS particle and cement matrix at higher magnification (f).

4. Conclusions

A comprehensive evaluation of technical properties, including the physical–mechanical characteristics, thermal performance, liquid water transport, and structural arrangement of waste-EPS-dosed mortars was provided in this research. New types of eco-friendly composites containing different amounts of expanded thermoplastic particulate material, which substituted only the rougher part of the dense natural silica aggregate in the fraction of 2/4 mm, were produced. The performed experimental tests on 28-day-aged mortar samples bring the following conclusions:

- The expanded thermoplastic alternative was found to be an approx. 150 times lighter filling material than the traditional aggregate. In this context, the closed-cell structure of EPS beads provides a very good thermal insulation function: 3.9 up to 4.4. times lower thermal conductivity, depending on the free bulk of compacted-state aggregate, was observed. Moreover, the unique closed structure of EPS beads is also responsible for very low water absorption (only 1.7 vol.%), which is an important benefit compared to siliceous lightweight aggregates with open porous structures.

- In light of the physical properties of the lightweight mortars, the full substitution of silica aggregate of the fraction 2/4 mm with EPS beads resulted in significant decrease in bulk density of the hardened samples by one-third, i.e., by more than 680 kg·m−3. Reducing the weight of building structures constitutes an important aspect in the slimming of bearing structures, and provides material and related financial savings.

- The soft character of the expanded alternative filler impacted the mechanical resistance of the lightweight hardened mortars. Accordingly, a linear decrease in flexural strength induced with increasing EPS content in the mixes was recorded. The initial strength of 8.0 MPa (M-R) was reduced to 4.4 MPa (M-W 100). In the context of compressive strength, the property reduction was not so steep. The maximum decrease was 24.4% for the M-W 100 sample. Strength properties can be improved by adjusting the interfacial transition zone. However, it is still possible to produce resistant composites without adding expensive additives and admixtures and maintain a compressive strength above 20 MPa sufficient for bearing structures.

- Including EPS beads into the compact siliceous skeleton of the produced hardened mortars significantly improved their thermal insulation function. The thermal conductivity linearly decreased with the increasing alternative aggregate content, with a maximum reduction of 47% (M-W 100). An explanation is given by the very low weight (150 times lighter) of W-A 2/4 mm compared to N-A 2/4 mm. On the other hand, the higher open porosity of the lightweight mortars led to a maximum heat accumulation of 14%.

- Filling mortars with expanded thermoplastic directly impacted the mitigation of liquid water absorption. The absorption coefficient, which was highest for the reference mortar (M-R), decreased by 36.4% with a 50% representation of W-A 2/4 mm, and even by 50% for samples with a full content of EPS in relation to fraction size.

The developed waste EPS bead-based concretes can find direct application in the construction industry in the form of precast façade panels with considerable thermal insulation function, reducing buildings’ energy demands. The discussed data also point to a significant strength-to-weight ratio of the produced composites which would be beneficial in reducing the dead weight of building structures. The final products, which contain high volumes of EPS beads, can be used in non-load bearing bases. On the other hand, it is still possible to produce composites with improved thermal insulation function while having a compressive strength higher than 20 MPa. Such composites for single or multi-story buildings represent products with high potential.

Author Contributions

Conceptualization, J.P.; methodology, R.Š.; software, L.Z. and J.P.; validation, R.Š.; formal analysis, L.Z.; investigation, L.Z.; resources, L.P.; data curation, L.Z.; writing—original draft preparation, J.P.; writing—review and editing, J.P. and R.Š.; visualization, L.Z.; supervision, J.P.; project administration, L.P.; funding acquisition, R.Š. and J.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Institute of Technology and Business, under project No. 03SVV2325, and the Czech Academy of Sciences, Institute of Theoretical and Applied Mechanics—RVO 68378297.

Data Availability Statement

The data presented in this study are available on demand.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- An Introduction to Plastics—Elias, Hans-Georg: 9783527296026—AbeBooks. Available online: https://www.abebooks.com/9783527296026/Introduction-Plastics-Elias-Hans-Georg-3527296026/plp (accessed on 19 February 2024).

- Almohana, A.I.; Abdulwahid, M.Y.; Galobardes, I.; Mushtaq, J.; Almojil, S.F. Producing Sustainable Concrete with Plastic Waste: A Review. Environ. Chall. 2022, 9, 100626. [Google Scholar] [CrossRef]

- Maghfouri, M.; Alimohammadi, V.; Gupta, R.; Saberian, M.; Azarsa, P.; Hashemi, M.; Asadi, I.; Roychand, R. Drying Shrinkage Properties of Expanded Polystyrene (EPS) Lightweight Aggregate Concrete: A Review. Case Stud. Constr. Mater. 2022, 16, e00919. [Google Scholar] [CrossRef]

- Enarevba, D.R.; Haapala, K.R. A Comparative Life Cycle Assessment of Expanded Polystyrene and Mycelium Packaging Box Inserts. Procedia CIRP 2023, 116, 654–659. [Google Scholar] [CrossRef]

- Fernando, P.L.N.; Jayasinghe, M.T.R.; Jayasinghe, C. Structural Feasibility of Expanded Polystyrene (EPS) Based Lightweight Concrete Sandwich Wall Panels. Constr. Build. Mater. 2017, 139, 45–51. [Google Scholar] [CrossRef]

- Sun, Y.; Li, C.; You, J.; Bu, C.; Yu, L.; Yan, Z.; Liu, X.; Zhang, Y.; Chen, X. An Investigation of the Properties of Expanded Polystyrene Concrete with Fibers Based on an Orthogonal Experimental Design. Materials 2022, 15, 1228. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Zhao, L.; Zhang, Y.; Han, H.; Zhou, L.; Wang, C. Optimizing the Composition Design of Cement-Based Expanded-Polystyrene (EPS) Exterior Wall Based on Thermal Insulation and Flame Retardance. Polymers 2022, 14, 5229. [Google Scholar] [CrossRef] [PubMed]

- Babu, D.S.; Ganesh Babu, K.; Tiong-Huan, W. Effect of Polystyrene Aggregate Size on Strength and Moisture Migration Characteristics of Lightweight Concrete. Cem. Concr. Compos. 2006, 28, 520–527. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Abdi, R.; Tabatabaei, M. Expanded Polystyrene Waste Application for Improving Biodiesel Environmental Performance Parameters from Life Cycle Assessment Point of View. Renew. Sustain. Energy Rev. 2017, 74, 278–298. [Google Scholar] [CrossRef]

- Assaad, J.; Chakar, E.; Zéhil, G.-P. Testing and Modeling the Behavior of Sandwich Lightweight Panels against Wind and Seismic Loads. Eng. Struct. 2018, 175, 457–466. [Google Scholar] [CrossRef]

- Poletto, M.; Dettenborn, J.; Zeni, M.; Zattera, A.J. Characterization of Composites Based on Expanded Polystyrene Wastes and Wood Flour. Waste Manag. 2011, 31, 779–784. [Google Scholar] [CrossRef]

- Damghani, A.M.; Savarypour, G.; Zand, E.; Deihimfard, R. Municipal Solid Waste Management in Tehran: Current Practices, Opportunities and Challenges. Waste Manag. 2008, 28, 929–934. [Google Scholar] [CrossRef] [PubMed]

- Sayadi, A.A.; Tapia, J.V.; Neitzert, T.R.; Clifton, G.C. Effects of Expanded Polystyrene (EPS) Particles on Fire Resistance, Thermal Conductivity and Compressive Strength of Foamed Concrete. Constr. Build. Mater. 2016, 112, 716–724. [Google Scholar] [CrossRef]

- Chinnu, S.N.; Minnu, S.N.; Bahurudeen, A.; Senthilkumar, R. Reuse of Industrial and Agricultural By-Products as Pozzolan and Aggregates in Lightweight Concrete. Constr. Build. Mater. 2021, 302, 124172. [Google Scholar] [CrossRef]

- Tittarelli, F.; Carsana, M.; Ruello, M.L. Effect of Hydrophobic Admixture and Recycled Aggregate on Physical–Mechanical Properties and Durability Aspects of No-Fines Concrete. Constr. Build. Mater. 2014, 66, 30–37. [Google Scholar] [CrossRef]

- Carsana, M.; Tittarelli, F.; Bertolini, L. Use of No-Fines Concrete as a Building Material: Strength, Durability Properties and Corrosion Protection of Embedded Steel. Cem. Concr. Res. 2013, 48, 64–73. [Google Scholar] [CrossRef]

- Bayuaji, R.; Ruki Biyanto, T. Deflection Prediction of No-Fines Lightweight Concrete Wall Using Neural Network Caused Dynamic Loads. Buildings 2018, 8, 62. [Google Scholar] [CrossRef]

- Granata, M.F. Pumice Powder as Filler of Self-Compacting Concrete. Constr. Build. Mater. 2015, 96, 581–590. [Google Scholar] [CrossRef]

- Kharun, M.; Klyuev, S.; Koroteev, D.; Chiadighikaobi, P.C.; Fediuk, R.; Olisov, A.; Vatin, N.; Alfimova, N. Heat Treatment of Basalt Fiber Reinforced Expanded Clay Concrete with Increased Strength for Cast-In-Situ Construction. Fibers 2020, 8, 67. [Google Scholar] [CrossRef]

- Záleská, M.; Pavlíková, M.; Vyšvařil, M.; Pavlík, Z. Effect of Aggregate and Binder Type on the Functional and Durability Parameters of Lightweight Repair Mortars. Sustainability 2021, 13, 11780. [Google Scholar] [CrossRef]

- Li, X.; Li, C.; Zhao, M.; Yang, H.; Zhou, S. Testing and Prediction of Shear Performance for Steel Fiber Reinforced Expanded-Shale Lightweight Concrete Beams without Web Reinforcements. Materials 2019, 12, 1594. [Google Scholar] [CrossRef] [PubMed]

- Gencel, O.; Gholampour, A.; Tokay, H.; Ozbakkaloglu, T. Replacement of Natural Sand with Expanded Vermiculite in Fly Ash-Based Geopolymer Mortars. Appl. Sci. 2021, 11, 1917. [Google Scholar] [CrossRef]

- Souza, B.A.; Sánchez, L.E. Biodiversity Offsets in Limestone Quarries: Investigation of Practices in Brazil. Resour. Policy 2018, 57, 213–223. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, T.; Liu, X. Index System to Evaluate the Quarries Ecological Restoration. Sustainability 2018, 10, 619. [Google Scholar] [CrossRef]

- Viana Rodrigues, A.; Roca Bragança, S. An Evaluation of the Increased Expansion of Clay Aggregates Fired at 1300 °C to Maximize Lightness for Non-Structural Concrete. Boletín De La Soc. Española De Cerámica Y Vidr. 2023, 62, 56–65. [Google Scholar] [CrossRef]

- Gonzalez-Torres, M.; Bertoldi, P.; Castellazzi, L.; Perez-Lombard, L. Review of EU Product Energy Efficiency Policies: What Have We Achieved in 40 Years? J. Clean. Prod. 2023, 421, 138442. [Google Scholar] [CrossRef]

- Dubský, Z.; Tichý, L. The Role of Narratives in the Discourse on Energy Security of the European Commission: The EU’s Transition in Energy Relations with Russia. Extr. Ind. Soc. 2024, 17, 101392. [Google Scholar] [CrossRef]

- Rides, M.; Morikawa, J.; Halldahl, L.; Hay, B.; Lobo, H.; Dawson, A.; Allen, C. Intercomparison of Thermal Conductivity and Thermal Diffusivity Methods for Plastics. Polym. Test. 2009, 28, 480–489. [Google Scholar] [CrossRef]

- Ganesh Babu, K.; Saradhi Babu, D. Performance of Fly Ash Concretes Containing Lightweight EPS Aggregates. Cem. Concr. Compos. 2004, 26, 605–611. [Google Scholar] [CrossRef]

- Bogas, J.; Gomes, A. Compressive Behavior and Failure Modes of Structural Lightweight Aggregate Concrete—Characterization and Strength Prediction. Mater. Des. 2013, 46, 832–841. [Google Scholar] [CrossRef]

- Liu, N.; Chen, B. Experimental Study of the Influence of EPS Particle Size on the Mechanical Properties of EPS Lightweight Concrete. Constr. Build. Mater. 2014, 68, 227–232. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, L.; Xu, J.; Chu, H.; Li, Y. Prediction of Compressive Strength and Elastic Modulus of Expanded Polystyrene Lightweight Concrete. Mag. Concr. Res. 2015, 67, 954–962. [Google Scholar] [CrossRef]

- Okechi, I.; Aguayo, F.; Torres, A. Coefficient of Thermal Expansion of Concrete Produced with Recycled Concrete Aggregates. J. Civ. Eng. Constr. 2022, 11, 65–74. [Google Scholar] [CrossRef]

- Herki, B.M.A. Combined Effects of Densified Polystyrene and Unprocessed Fly Ash on Concrete Engineering Properties. Buildings 2017, 7, 77. [Google Scholar] [CrossRef]

- Herki, B. Absorption Characteristics of Lightweight Concrete Containing Densified Polystyrene. Civ. Eng. J. 2017, 3, 594–609. [Google Scholar] [CrossRef]

- EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Comitee for Standardization (CEN): Brussels, Belgium, 2011.

- EN 206-1; Concrete—Part 1: Specification, Performance, Production and Conformity. European Comitee for Standardization (CEN): Brussels, Belgium, 2017.

- Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Lampropoulou, P.; Tsikouras, B.; Rigopoulos, I.; Hatzipanagiotou, K. Petrographic and Mechanical Characteristics of Concrete Produced by Different Type of Recycled Materials. Geosciences 2019, 9, 264. [Google Scholar] [CrossRef]

- Assaad, J.J.; Mikhael, C.; Hanna, R. Recycling of Waste Expanded Polystyrene Concrete in Lightweight Sandwich Panels and Structural Applications. Clean. Mater. 2022, 4, 100095. [Google Scholar] [CrossRef]

- Cai, S.; Zhang, B.; Cremaschi, L. Review of Moisture Behavior and Thermal Performance of Polystyrene Insulation in Building Applications. Build. Environ. 2017, 123, 50–65. [Google Scholar] [CrossRef]

- EN 1015-3; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar. European Comitee for Standardization (CEN): Brussels, Belgium, 2000.

- Petrella, A.; Di Mundo, R.; Notarnicola, M. Recycled Expanded Polystyrene as Lightweight Aggregate for Environmentally Sustainable Cement Conglomerates. Materials 2020, 13, 988. [Google Scholar] [CrossRef] [PubMed]

- EN 196-1; Method of Testing Cement—Part 1: Determination of Strength. European Comitee for Standardization (CEN): Brussels, Belgium, 2005.

- Pokorný, J.; Ševčík, R.; Šál, J.; Zárybnická, L. Lightweight Blended Building Waste in the Production of Innovative Cement-Based Composites for Sustainable Construction. Constr. Build. Mater. 2021, 299, 123933. [Google Scholar] [CrossRef]

- EN 12390-2; Testing of Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. European Comitee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 1097-3; Test of Mechanical and Physical Properties of Aggregate—Part 3: Determination of Loose Bulk Density and Voids. European Comitee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. European Comitee for Standardization (CEN): Brussels, Belgium, 2014.

- EN 933-1; Test of Geometrical Properties of Aggregate—Part 1: Determination of Particle Size Distribution—Sieving Method. European Comitee for Standardization (CEN): Brussels, Belgium, 2012.

- EN 1015-10; Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar. European Comitee for Standardization (CEN): Brussels, Belgium, 1999.

- Záleská, M.; Pavlik, Z.; Pavlíková, M.; Scheinherrova, L.; Pokorny, J.; Trnik, A.; Svora, P.; Fořt, J.; Jankovský, O.; Suchorab, Z.; et al. Biomass Ash-Based Mineral Admixture Prepared from Municipal Sewage Sludge and Its Application in Cement Composites. Clean Technol. Environ. Policy 2018, 20, 159–171. [Google Scholar] [CrossRef]

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Comitee for Standardization (CEN): Brussels, Belgium, 1999.

- Pokorný, J.; Ševčík, R.; Šál, J.; Zárybnická, L.; Žák, J. Lightweight Concretes with Improved Water and Water Vapor Transport for Remediation of Damp Induced Buildings. Materials 2021, 14, 5902. [Google Scholar] [CrossRef] [PubMed]

- Zárybnická, L.; Pokorný, J.; Machotová, J.; Ševčík, R.; Šál, J.; Viani, A. Study of Keto-Hydrazide Crosslinking Effect in Acrylic Latex Applied to Portland Cements with Respect to Physical Properties. Constr. Build. Mater. 2023, 375, 130897. [Google Scholar] [CrossRef]

- EN 1015-18; Methods of Test for Mortar for Masonry. Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar. European Comitee for Standardization (CEN): Brussels, Belgium, 2002.

- Pokorný, J.; Ševčík, R.; Šál, J.; Fiala, L.; Zárybnická, L.; Podolka, L. Bio-Based Aggregate in the Production of Advanced Thermal-Insulating Concrete with Improved Acoustic Performance. Constr. Build. Mater. 2022, 358, 129436. [Google Scholar] [CrossRef]

- Herki, B.; Khatib, J. Valorisation of Waste Expanded Polystyrene in Concrete Using a Novel Recycling Technique. Eur. J. Environ. Civ. Eng. 2016, 21, 1384–1402. [Google Scholar] [CrossRef]

- Záleská, M.; Pavlíková, M.; Pokorný, J.; Jankovský, O.; Pavlík, Z.; Černý, R. Structural, Mechanical and Hygrothermal Properties of Lightweight Concrete Based on the Application of Waste Plastics. Constr. Build. Mater. 2018, 180, 1–11. [Google Scholar] [CrossRef]

- Askar, M.K.; Al-Kamaki, Y.S.S.; Hassan, A. Utilizing Polyethylene Terephthalate PET in Concrete: A Review. Polymers 2023, 15, 3320. [Google Scholar] [CrossRef] [PubMed]

- Le Roy, R.; Parant, E.; Boulay, C. Taking into Account the Inclusions’ Size in Lightweight Concrete Compressive Strength Prediction. Cem. Concr. Res. 2005, 35, 770–775. [Google Scholar] [CrossRef]

- Goyal, S. Properties of expanded polystyrene (EPS) and its environmental effects. Adv. Appl. Math. Sci. 2021, 20, 2151–2162. [Google Scholar]

- Argalis, P.P.; Bumanis, G.; Bajare, D. Gypsum Composites with Modified Waste Expanded Polystyrene. J. Compos. Sci. 2023, 7, 203. [Google Scholar] [CrossRef]

- Suchorab, Z.; Franus, M.; Barnat-Hunek, D. Properties of Fibrous Concrete Made with Plastic Optical Fibers from E-Waste. Materials 2020, 13, 2414. [Google Scholar] [CrossRef] [PubMed]

- Masėnas, V.; Meškėnas, A.; Valivonis, J. Analysis of the Bearing Capacity of Reinforced Concrete Dapped-End Beams. Appl. Sci. 2023, 13, 5228. [Google Scholar] [CrossRef]

- Gomes, M.d.G.; Bogas, J.A.; Real, S.; Moret Rodrigues, A.; Machete, R. Thermal Performance Assessment of Lightweight Aggregate Concrete by Different Test Methods. Sustainability 2023, 15, 11105. [Google Scholar] [CrossRef]

- Demirboga, R.; Kan, A. Thermal Conductivity and Shrinkage Properties of Modified Waste Polystyrene Aggregate Concretes. Constr. Build. Mater. 2012, 35, 730–734. [Google Scholar] [CrossRef]

- Sethi, S.; Manik, G. Recent Progress in Super Hydrophobic/Hydrophilic Self-Cleaning Surfaces for Various Industrial Applications: A Review. Polym.-Plast. Technol. Eng. 2018, 57, 1932–1952. [Google Scholar] [CrossRef]

- Akinyemi, B.; Ojediran, J.; Oyewole, O.; Ayanwola, S. Eflcacy of Expanded Polystyrene as Fine Aggregate in Cement Mortars Modified with Latex Paint as an Alternative to Polymer Admixture. J. Mech. Behav. Mater. 2020, 29, 163–168. [Google Scholar] [CrossRef]

- Lakhiar, M.T.; Kong, S.Y.; Bai, Y.; Susilawati, S.; Zahidi, I.; Paul, S.C.; Raghunandan, M.E. Thermal and Mechanical Properties of Concrete Incorporating Silica Fume and Waste Rubber Powder. Polymers 2022, 14, 4858. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).