Abstract

Reclaimed asphalt pavement (RAP) has been utilized as a potential partial substitute for virgin asphalt binder in asphalt mixtures. However, a primary concern with increasing RAP content in asphalt mixtures is the cracking potential, attributed to the aged RAP asphalt binder (RAP-binder). To address this, the use of petroleum-based and bio-derived recycling agents (RAs) in enhancing the cracking resistance of high-RAP asphalt mixtures has been explored. The objective of this study is to ascertain the effectiveness of six RAs in mitigating cracking in high-RAP asphalt mixtures. The RAs considered include petroleum-crude-oil-derived aromatic oil, soy oil, and four types of tall-oil-derived phytosterol (industrial by-product, intermediate, purified, and fatty acid-based). The RAs’ dosages were optimized, based on RAP-binder and unmodified asphalt binder properties, to produce target PG 70-22 asphalt binder when incorporated in asphalt mixtures containing 30% RAP. To assess the engineering performance of these 30%-RAP asphalt mixtures for each RA, a conventional asphalt mixture incorporating styrene-butadiene-styrene (SBS)-modified PG 70-22 asphalt binder without RAP or RAs was benchmarked for comparison. Mechanical tests performed included Hamburg wheel-track testing (HWTT), intermediate-temperature fracture tests (semi-circular bend, Illinois flexibility index, and IDEAL cracking tolerance), and thermal stress-restrained specimen tensile strength test to evaluate permanent deformation, intermediate-temperature cracking resistance, and low-temperature cracking resistance, respectively. Results showed that petroleum-crude-oil-derived aromatic oil and tall-oil-derived fatty-acid-based oil RAs were able to rejuvenate RAP-binder as measured by the cracking tests performed. Further, the use of these RAs did not adversely impact the asphalt mixtures’ permanent deformation performance.

1. Introduction

Asphalt mixture, a key material in flexible pavement construction, is facing increased costs, prompting pavement agencies to explore cost-effective alternatives without sacrificing performance [1,2,3]. A sustainable approach to this challenge is the utilization of reclaimed asphalt pavement (RAP) as a replacement part of the virgin materials which not only reduces material costs but also conserves natural resources, thus benefiting the environment. RAP materials have been utilized with virgin aggregates and asphalt binders in Louisiana and across the country for decades [4,5]; yet, there are many concerns related to the cracking performance when a high RAP level is used in asphalt mixtures. High RAP content was defined as 25% to 50% or higher according to the National Cooperative Highway Research Program (NCHRP) report 752 [6]. This is due to the aged RAP asphalt binder (RAP-binder) that is unable to be utilized as a straight replacement for virgin asphalt binder since it ages during service life resulting in alterations in its chemical properties [1,2,3]. Consequently, RAP-binders frequently include molecules with extremely large molecular weights that raise issues with durability and cracking [7]. Therefore, increased RAP contents in asphalt mixtures could have a negative impact on the cracking performance of asphalt pavements, which would ultimately drive up the cost of pavement maintenance and repairs [4].

In response, state agencies and Departments of Transportation (DOTs) have been exploring the use of recycling agents (RAs) that can rejuvenate high-RAP contents in asphalt mixtures without compromising pavement performance [8]. RAs can be categorized as softening or rejuvenating agents. Rejuvenating agents, primarily organic oils, are rich in maltenes that disperse the aged asphaltenes and rejuvenate the asphalt binder’s chemical and physical characteristics [9]. Softening agents, in contrast, primarily decrease the aged asphalt binder viscosity to yield suitable workability for mixing high RAP in asphalt mixtures; their role is predominantly focused on altering the physical characteristics of the RAP-binder [9]. Table 1 compiles a range of RAs from existing literature, detailing their results and impacts.

Table 1.

Summary of recycling agents’ effectiveness on RAP asphalt binder.

Results reported in the literature show discrepancies relative to the effectiveness of recycling agents on cracking performance, (Table 1). Specifically, the LaDOTD study reported that the addition of RAs resulted in reduction in cracking resistance as compared to similar asphalt mixtures with no RAs [9]. This study assessed the effectiveness of new RAs in improving mechanical properties, including cracking resistance, of asphalt mixture containing 30% RAP within the Louisiana balanced asphalt mixture design (BMD) framework [15]. Louisiana balanced mixture design (BMD) framework specifies a maximum Loaded Wheel tester (LWT) rut depth of 6.0 mm and a minimum semi-circular bend (SCB) Jc value of 0.6 Kj/m2 as a criterion for resisting permanent deformation and intermediate-temperature cracking, respectively [15].

2. Objectives and Scope

The objective of this study was to ascertain the effectiveness of RAs in mitigating cracking in asphalt mixtures containing 30% RAP content. Six types of RAs were considered, namely petroleum-crude-oil-derived aromatic oil, soy oil, and four types of tall-oil-derived phytosterol (industrial by-product, intermediate, purified, and fatty-acid-based). The six RAs were incorporated into asphalt mixtures containing 30%-RAP material (by total mixture weight). The RAs’ dosages were optimized, based on RAP-binder and virgin unmodified asphalt binder properties, to produce a target PG 70-22 asphalt binder when incorporated in asphalt mixtures containing 30% RAP. For reference and comparison, a control mixture was prepared that contained styrene-butadiene-styrene (SBS)-polymer-modified asphalt binders PG 70-22 without RAP or RAs (hereafter referred to as ‘Mix 70’). The target asphalt binder selected for this study is PG 70-22 as it meets Louisiana’s specification [15] for Level 2 design traffic volume (greater than 3 million ESALs). Mechanical tests performed included Hamburg wheel-track testing (HWTT), intermediate-temperature fracture tests (semi-circular bend ‘SCB-Jc’, Illinois flexibility index test ‘I-FIT’, IDEAL cracking tolerance ‘IDEAL-CT’), and TSRST test to evaluate permanent deformation, intermediate-temperature cracking resistance, and low-temperature cracking resistance, respectively. A flowchart of the research methodology followed is shown in Figure 1.

Figure 1.

Research methodology.

3. Materials

Table 2 presents the types, dosages, and classification of RAs used in this study. The six RAs evaluated include petroleum-crude-oil-derived aromatic oil, soy oil, and tall-oil-derived phytosterol (industrial by-product, intermediate, purified, and fatty-acid-based), Figure 2. Virgin unmodified asphalt binder PG 67-22 was used as a carrier for the RAs to be mixed with 30% RAP (RBR = 0.28) and virgin aggregates to produce asphalt mixtures with a target PG 70-22 asphalt binder. RBR is defined as the recycled binder ratio to the total asphalt binder in an asphalt mixture. It is noted that the dosage for each RA type was optimized based on RAP-binder, virgin unmodified asphalt binder properties, and RBR of 0.28 to produce target asphalt binders PG 70-22. In other words, the ultimate blend of unmodified asphalt binder PG 67-22, RA, and RAP-binder is expected to have a PG 70-22 asphalt binder if RBR is 0.28. Based on preliminary rheological testing, RA 2 (soy oil) was selected because of its ability to decrease asphalt binder stiffness [16,17,18]. Therefore, it was considered to quantify its effectiveness on improving cracking performance of asphalt mixtures containing 30% RAP. A control asphalt mixture containing SBS-modified asphalt binder PG 70-22 meeting Louisiana specifications [15] was included in this study as a conventional one for benchmarking.

Table 2.

Recycling agents used in this study.

Figure 2.

The six recycling agents utilized in this study.

RAP-binder was extracted following AASHTO T 164 standard [19] using trichloroethylene (TCE) solvent type. Figure 3a presents the Auto Centrifuge Extractor used for extracting asphalt binder. Following this extraction, removal of fillers and fines was performed using the Allegra X-14R centrifuge machine at 770 rotations per minute for 30 min, Figure 3b. An auto-evaporator was then utilized to condense most of the TCE out, Figure 3c. Abson distillation process was then followed for more separation of TCE from the extracted asphalt binder, then removal of the remaining TCE traces was conducted by introducing a carbon dioxide gas. The Abson method was conducted as stipulated by AASHTO R 59 standard [20]. Figure 3d shows the setup and the Abson Method. After extracting and recovering the RAP-binder, it was rheologically graded to be PG 100-16.

Figure 3.

Extracting and recovering asphalt binder; (a) Auto-centrifuge extractor, (b) Allegra X-14R centrifuge machine, (c) Auto-evaporator and condenser, and (d) Asphalt binder recovery setup by Abson method.

An asphlat binder blending tool was developed and used for predicting target asphalt binder performance grade based on equations introduced in NCHRP Report 452 [21]. The developed procedure followed in this study aimed to locate the critical temperatures at which an asphalt binder is expected to exhibit certain distresses according to AASHTO M320 standard [22]. Knowing the critical temperatures for the RAP-binder and target asphalt binder along with predetermined RBR, the modified asphalt binder rheological properties were interpolated and determined. The following subsections explain the procedure in detail.

At high-temperature grading, Equation (1) was derived based on meeting AASHTO M 320 standard [22] criteria, a minimum rutting factor (G*/sin (δ)) of 1.00 KPa and 2.20 KPa for original and short-term aged conditions, respectively (Equations (1) and (2)).

At high-temperature grading:

where:

- G* = complex shear modulus;

- δ = phase angle;

- Tc (high) = high-critical temperature;

- G1 = value of G*/sin (δ) at temperature T1;

- T1 = recommended to be the closest temperature to the criteria;

- a = slope of stiffness-temperature curve = Δ log (G*/sin (δ))/ΔT.

At intermediate temperature, Equation (3) was derived based on meeting AASHTO M 320 criteria, a maximum cracking factor (G*. Sin (δ)) of 5000 KPa for long-term aged condition.

where:

- Tc (Intermediate) = intermediate-critical temperature;

- G1 = value of G*. Sin (δ) at temperature T1;

- a = slope of stiffness-temperature curve = Δ log (G*. Sin (δ))/ΔT.

At low-temperature grading, asphalt binder was short- and long-term aged using RTFO and PAV and graded using the bending beam rheometer (BBR) test following AASHTO T 313 standard [23]. The BBR test is used to determine the asphalt binder’s creep stiffness (S) with time, Equation (4), and relaxation (m-value), Equation (5).

where:

- Tc (S) = critical low-temperature obtained at stiffness;

- Tc (m) = critical low-temperature obtained from m-value;

- S1 = the S-value at temperature T1;

- m1 = the m-value at temperature T1;

- T1 = recommended to be the closest temperature to the criteria;

- aS = slope of stiffness-temperature curve = Δ log (S)/ΔT;

- am = slope of m-value-temperature curve = Δm-value/ΔT.

Equations (6)–(9) were developed to compute the high-, intermediate-, and low-temperature gradings, respectively for the target asphalt binder,

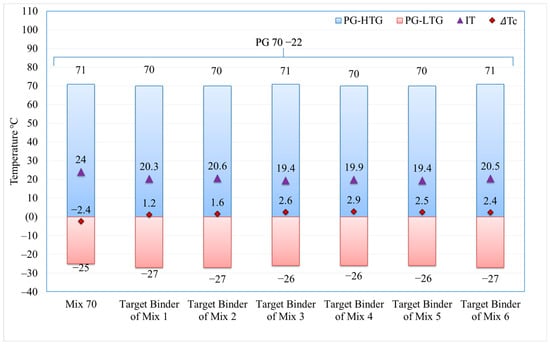

These calculations were included in a blending tool developed to ascertain the performance grade of the virgin binder mixed with RA. The dosages of an RA were selected to yield a PG 58-28 asphalt binder when blended with the unmodified PG 67-22 asphalt binder. The asphalt binder PG 58-28 was then blended with the RAP-binder (RBR = 0.28) to yield a target asphalt binder of PG 70-22. All asphalt mixtures had a similar target asphalt binder by optimizing the RAs’ dosages, Figure 4.

Figure 4.

The target asphalt binder performance grade for the studied mixtures. Note: PG: Asphalt binder Performance Grading; HTG: high-temperature grading; LTG: low-temperature grading; IT: intermediate-temperature; ∆Tc: difference in critical low-temperatures between stiffness and m-value.

4. Mixture Design

Seven Louisiana Level 2 (traffic volume greater than 3 million ESALs) asphalt mixtures with a nominal maximum aggregate size (NMAS) of 12.5 mm were designed and evaluated according to AASHTO R 35 standard [24], and LaDOTD specifications—Section 502 [15]. The aggregate’s types were #78 limestone, #11 limestone, and coarse sand (CS). It is noted that all mixtures were prepared to have similar volumetrics within the LaDOTD specifications’ tolerances [15].

Table 3 and Figure 5 present the job mix formula and aggregates’ gradations curves for the studied asphalt mixtures. It is worth noting that the mixtures evaluated are fine-sided, dense-graded, and have the same gradation. The design asphalt mixture binder and RAP-binder contents were 5.3% and 4.9%, respectively.

Table 3.

Asphalt mixtures job mix formulas.

Figure 5.

Aggregates gradation.

It is noted that RAs were first blended into virgin PG 67-22 unmodified asphalt binders at 165 °C using paddle agitation to obtain a PG 58-28 modified asphalt binder. However, the following steps were followed in the preparation of 30%-RAP asphalt mixtures to increase RAP-binder contribution [25]:

- After preparing the RAP materials in a separate pan, 5% water by weight to the RAP materials was added to the RAP pan and stirred for five minutes to ensure water was not collected at the bottom of the pan. Then, the pan was covered with aluminum paper and soaked overnight.

- The modified PG 58-28 asphalt binder was heated at the mixing temperature of 325 °F (163 °C) along with the mixing bucket and tools. Virgin aggregates were heated at 383 °F (195 °C) for 3 h.

- First, wet RAP materials were placed in the heated mixing bucket at room temperature. Then, superheated virgin aggregates were added on top of the wet RAP materials. Subsequently, mechanical mixing was initiated and continued until there was no steam and the dark color of the RAP materials disappeared. At this point, the virgin aggregates and RAP materials were homogeneous, with no observed separation between them.

- The mixing bucket containing the aggregates and RAP was placed in an oven until a mixing temperature of 325 °F (163 °C) was reached. The modified PG 58-28 asphalt binder was added to the mixing bucket containing the aggregates mixed with RAP materials and mixed thoroughly for four minutes.

- After the mixing process, short- and long-term aging procedures were followed as per the AASHTO R 30 standard [26]. Cylindrical specimens of the asphalt mixtures were then compacted to the specified specimen dimensions of mechanical tests considered, using a Superpave gyratory compactor (SGC)

5. Testing Methods

Table 4 shows the laboratory mechanical tests performed on the studied asphalt mixtures. All specimens were compacted to an air void level of 7% ± 0.5% and subjected to short- and long-term oven aging at 85 °C for 120 h following AASHTO R 30 standard, except for the HWTT specimens which were subjected to short-term aging only.

Table 4.

List of mechanical tests conducted on asphalt mixtures.

6. Laboratory Test Results and Discussion

A statistical analysis was performed on the laboratory test results using the analysis of variance (ANOVA) method, at a confidence level of 95, utilizing Statistical Analysis System (SAS) software version 9.4, SAS Institute, Inc. at Cary, NC, USA [32]. The statistical grouping are presented using the letters A, B, C, D, and so on. The highest mean was given to the letter A, and then the subsequent letters were in the proper sequence. If a designation has two letters, like A/B, it suggests that there is a slight difference between groups A and B as the mean is close to both and the mean difference is not noticeable.

7. Permanent Deformation

The HWTT rut depths at 20,000 passes for the assessed asphalt mixtures are shown in Figure 6. The HWTT test was carried out in compliance with the AASHTO T 324 standard [27]. The rut depth’s coefficient of variation (CoV) ranged from 7% to 22%, with an average of 12.9% overall. Louisiana DOTD (LaDOTD) specifies a maximum rut depth of 6.0 mm at 20,000 passes [15]. All mixtures evaluated did meet the maximum LWT rut depth requirement, Figure 6. However, the control mixture Mix 70 showed statistically higher rut depth as compared to other RAP mixtures evaluated. Further, Mix 4, containing RA 4, exhibited statistically better rutting resistance when compared to other RAP mixtures. These findings indicate that the addition of RAP materials could stiffen asphalt mixtures, even though a soft asphalt binder (PG 67-22) and RAs were used. It also implied that the use of RAs did not negatively impact the permanent deformation resistance. The studied asphalt mixtures exhibited a stripping inflection point of 20,000 passes, indicating that those mixtures were moisture-damage-resistant.

Figure 6.

HWTT rutting depths.

8. Cracking and Fracture Resistance

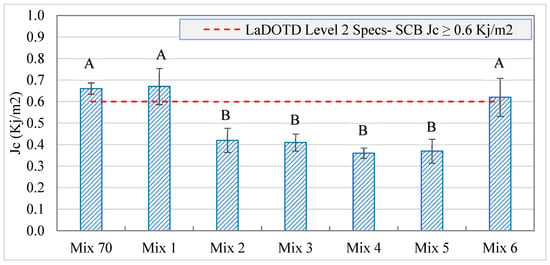

The critical strain energy release rate (Jc) values for the studied asphalt mixtures obtained from the SCB Jc test are shown in Figure 7. The SCB was carried out in compliance with ASTM D8044 standard [28]. The averaged CoV for the strain energy (per-unit thickness) varied from 4% to 14%, with an overall average of 11%. For an asphalt mixture to withstand cracking at moderate temperatures, a greater SCB Jc value is required. The LaDOTD specifies a “GO/NO-GO” minimum SCB Jc of 0.6 KJ/m2 for Level 2 mixtures [15]. Level 2 mixtures are designed for traffic volumes greater than 3 million ESALs [15]. Mix 1 and Mix 6 showed statistically similar SCB Jc values to Mix 70’s and met the threshold of LaDOTD Level 2 mixture design, Figure 7. Mixes 2 to 5 showed statistically lower SCB Jc values than Mix 70’s and failed to meet the threshold of LaDOTD Level 2 mixture design. This implied that only asphalt mixtures containing 30% RAP content (RBR of 0.28) and RAs 1 and 6 complied with the LaDOTD specifications in terms of cracking resistance. It is worth noting that Mix 4 and Mix 5 had lower effective asphalt binder content after aging than the remaining RAP mixtures, Table 3.

Figure 7.

SCB Test Results—Critical Stain Energy Release Rate, Jc.

The flexibility index (FI) findings from the Illinois flexibility index (I-Fit) test are shown in Figure 8. I-FIT was carried out in compliance with AASHTO T 393 standard [30]. The Illinois Center for Transportation’s modeling MATLAB software (IFIT_2017_v1.1) was used to conduct the analysis [33]. The FI’s CoV ranged from 4.2% to 23.3%, with an average of 14.2% overall. The better a mixture’s cracking resistance, the higher its FI value [34]. The Illinois DOT specifies a minimum FI value of 4.0 for hot mix asphalts [35]. RA1, RA2, and RA6 in the asphalt mixtures 1, 2, and 6 possessed similar FI values as compared to the control mixture Mix 70 and met the Illinois DOT minimum FI value of 4.0, [35]. Mix 3, Mix 4, and Mix 5 failed to comply with the specified threshold. It is noted that Mix 4 had the lowest FI value amongst the studied asphalt mixtures containing 30% RAP and RAs.

Figure 8.

I-FIT Test Results—Flexible Index.

Figure 9 presents the IDEAL cracking tolerance (IDEAL-CT) test results (CTindex) obtained for the studied asphalt mixtures. IDEAL-CT was conducted according to ASTM D8225 standard [29]. The CoV of CTindex values ranged from 4% to 21%, with an overall average of 14%. The NCHRP project 20-44/16 recommends a minimum CTindex value of 90 for hot mix asphalts (HMAs) [36]. The control mixture 70 showed a statistically significant higher CTindex value than the asphalt mixtures containing 30% RAP content and RAs, Figure 9. Mixes 1, 2, 3, and 6 complied with the recommendations of CTindex value, Figure 9. This observation could be attributed to the high loading rate (50 mm/min), which affected the slope of the post-peak region, resulting in a significant effect on the CTindex value. Mix 5 marginally met the CTindex value requirement of a minimum of 90. Mix 4 had the lowest CTindex value among the studied asphalt mixtures containing 30% RAP and RAs, similar to I-FIT test results, which align with the low effective asphalt binder content, Table 3.

Figure 9.

IDEAL CT Test Results—CT index.

Table 5 presents the statistical analysis ranking of the evaluated asphalt mixtures for each cracking test. It is noted that mixtures with the same ranking in a specific column (representing a cracking test) are considered statistically similar. As depicted in Table 5, the control mixture Mix 70 demonstrated the highest ranking among all the asphalt mixtures studied for each cracking test, closely followed by Mix 1 and Mix 6. This observation suggests that amongst the asphalt mixtures containing 30% RAP content and RAs, those with RA1 and RA6 exhibited the best cracking resistance. Conversely, Mix 4 consistently ranked as the least cracking-resistant mixture across all three cracking tests, as illustrated in Table 5, which could be attributed to the lower effective asphalt binder content in Mix 4 than the remaining mixtures, Table 3. Thus, RA 4 was not an effective RA (Table 2). These findings are aligned with research reported elsewhere for RA1 [37], RA2 [38], and RA 6 [39].

Table 5.

Cracking test results: statistical analysis and ranking.

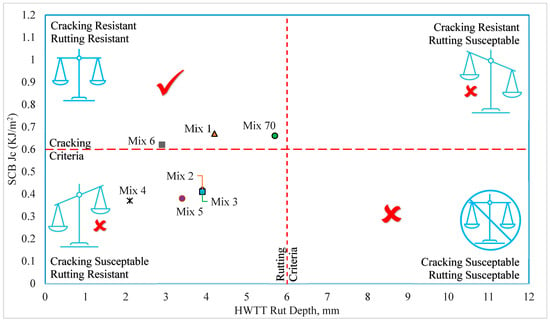

9. Louisiana DOTD Balance Mixture Design

Figure 10 explains the LaDOTD balanced mixture design (BMD) framework. In LaDOTD, every produced asphalt mixture is subjected to stress tests to balance between cracking (minimum SCB Jc value of 0.6 Kj/m2 for level 2 mixture design) and rutting (maximum HWTT rut depth of 6.0 mm for level 2 mixture design) [15]. The horizontal dashed line represents the minimum SCB Jc cracking threshold, however, the vertical one shows the maximum HWTT rut-depth threshold. The framework is divided into four quarters; the top-left one contains asphalt mixtures that complies with both HWTT rutting and SCB Jc cracking criteria. The quarters located top-right and bottom-left contain unbalanced asphalt mixtures where rutting and cracking performances are susceptible, respectively. Accordingly, the bottom-right quarter’s mixtures failed to meet both HWTT rutting and SCB Jc cracking criteria. As expected, the control mixture Mix 70 met Louisiana’s BMD criteria for Level 2. However, among the 30% RAP asphalt mixtures, Mix 1 and Mix 6 met the LaDOTD BMD; as such, RA 1 (petroleum crude oil-derived aromatic oil), and RA 6 (tall oil-derived fatty acid-based oil) were able to restore RAP-aged binder as measured by the SCB cracking tests performed, and are recommended to be used in LaDOTD when 30% RAP is incorporated in asphalt mixtures.

Figure 10.

Louisiana’s balanced mix design framework.

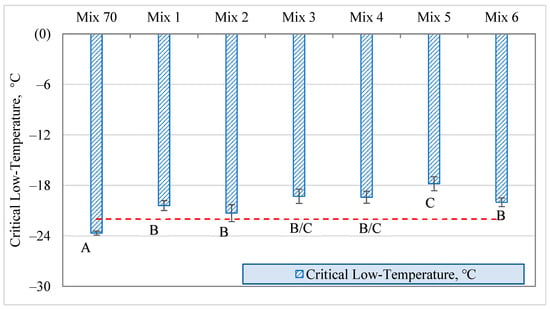

10. Low-Temperature Cracking Resistance

Figure 11 presents the critical low-temperature values computed from the thermal stress-restrained specimen tensile strength (TSRST) test. The AASHTO TP 10 standard [31] was followed when conducting the TSRST test. The CoV of critical low-temperature values ranged from 4.7% to 19.0%, with an overall average of 14.0%. The control mixture Mix 70 had the lowest critical low-temperature value among the evaluated asphalt mixtures, Figure 11. Mix 70 showed a critical low-temperature value as low as −23 °C, which complied with the low-temperature PG of asphalt binder used in this mixture (PG 70-22). However, the asphalt mixtures containing 30%-RAP and RAs showed slightly warmer critical low-temperature cracking values than −22 °C, even though their asphalt binders (blends of virgin unmodified asphalt binder, RAP-binder, and RA) had a low-temperature PG of −22 as marked by the red dashed line, Figure 11. All asphalt mixtures containing 30% RAP and RAs were considered to have statistically similar critical low-temperature values except for Mix 5, which showed a warmer value of −17.8 °C

Figure 11.

TSRST results—low-temperature cracking.

11. Summary and Conclusions

This study investigated the effectiveness of six recycling agents (RAs) in mitigating cracking in asphalt mixtures containing 30% RAP. The RAs considered included petroleum-crude-oil-derived aromatic oil, soy oil, and four categories of tall-oil-derived phytosterol (encompassing industrial byproduct, intermediate, purified, and fatty-acid-based types). Asphalt mixtures containing 30% RAP (RBR of 0.28) and RAs were evaluated and compared to the control asphalt mixture which contains SBS-polymer-modified asphalt binder PG 70-22, without RAP and RA. The RAs’ dosages were optimized using a developed tool to yield a target PG 70-22 asphalt binder when added to 30% RAP. Mechanical tests performed included Hamburg wheel-track testing, intermediate-temperature fracture tests (semi-circular bend, Illinois flexibility index, IDEAL cracking tolerance), and thermal stress-restrained specimen tensile strength test to evaluate permanent deformation, intermediate-temperature cracking resistance, and low-temperature cracking resistance, respectively. Based on results presented, several key conclusions delineating the effectiveness of the various RAs in the performance of 30%-RAP asphalt mixtures were drawn:

- The mixtures evaluated complied with the LaDOTD maximum HWTT rut depth requirement of 6.0 mm at 20,000 passes. The use of RAs did not negatively impact permanent deformation.

- Mixtures containing 30% RAP and RAs exhibited, as expected, lower rut depth than the control mixture due to the aged RAP-binder.

- Amongst RAs evaluated, RA1 (petroleum-crude-oil-derived aromatic oil) and RA6 (tall-oil-derived fatty-acid-based oil) were effective in mitigating cracking in asphalt mixtures containing 30% RAP as measured by the considered cracking tests.

- Asphalt mixtures containing 30% RAP and RAs showed slightly warmer critical low-temperature cracking values than −22 °C. All asphalt mixtures containing 30% RAP and RAs were considered to have statistically similar critical low-temperature values except for Mix 5, which showed a slightly warmer value.

- The RAs in 30%-RAP asphalt mixtures were optimized to have the same final target asphalt binder (PG 70-22); however, the results showed those RAs did not exhibit similar asphalt mixtures performances.

This study expanded the fundamental knowledge relative to the effectiveness of the new generation of recycling agents on improving cracking performance of asphalt mixtures containing 30% RAP. Future research recommendations include investigating additional recycling agents and conducting chemical and microstructure analyses to clarify the mechanism of RAs’ effectiveness. Functionality and skid resistance for these 30% RAP mixtures with this new generation of RAs are also recommended to be investigated.

Author Contributions

The authors confirm their contribution to the paper as follows: study conception and design: L.N.M. and I.E.; data collection and analysis: I.E., G.L.B., L.N.M. and S.C.J.; results’ interpretation: I.E., L.N.M. and S.C.III; draft manuscript preparation: I.E., J.L., L.N.M. and S.C.III. All authors have read and agreed to the published version of the manuscript.

Funding

This study is funded by the Louisiana DOTD under LTRC project 21-3B, New Generation of Recycling Agents for Durable and Sustainable Flexible Pavements. The authors would like to express their gratitude for this support.

Data Availability Statement

Data, models, and code generated or used during the study appear in the submitted article.

Acknowledgments

This study was a part of Louisiana Transportation Research Center project 21-3B titled New Generation of Recycling Agents for Durable and Sustainable Flexible Pavements Program. The authors would like to express their gratitude to the Louisiana Transportation Research Center for their support.

Conflicts of Interest

All sources of financial and technical support are listed in the acknowledgements section of the paper. The authors do not have any inherent commercial interests or other conflicts of interest related to this paper.

References

- Howard, I.L.; Cooley, L.A.; Doyle, J.D. Laboratory Testing and Economic Analysis of High RAP Warm Mixed Asphalt; Report No FHWA/MS-DOT-RD-09-200; Mississippi State University, Dept. of Civil Engineering: Starkville, MI, USA, 2009. [Google Scholar]

- Hansen, K.R.; Newcomb, D.E. Asphalt pavement mix production survey on reclaimed asphalt pavement, reclaimed asphalt shingles, and warm-mix asphalt usage: 2009–2010. Inf. Ser. 2011, 138, 21. [Google Scholar]

- Guo, M.; Liu, H.; Jiao, Y.; Mo, L.; Tan, Y.; Wang, D.; Liang, M. Effect of WMA-RAP technology on pavement performance of asphalt mixture: A state-of-the-art review. J. Clean. Prod. 2020, 266, 121704. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Elseifi, M.; Carpenter, S.H. Reclaimed Asphalt Pavement—A Literature Review; 0197-9191; Report No: FHWA-ICT-07-001; Illinois Center for Transportation: Urbana, IL, USA, 2007. [Google Scholar]

- Elnaml, I.; Mousa, M.; Hassan, M.M.; Idris, I.; Mohammad, L. Development of Cost-Effective High-Modulus Asphalt Concrete Mixtures Using Crumb Rubber and Local Construction Materials in Louisiana. Transp. Res. Rec. 2022, 2676, 274–286. [Google Scholar] [CrossRef]

- West, R.C.; Willis, J.R.; Marasteanu, M.O. Improved Mix Design, Evaluation, and Materials Management Practices for Hot Mix Asphalt with High Reclaimed Asphalt Pavement Content; 0309259134; Transportation Research Board: Washington, DC, USA, 2013. [Google Scholar]

- Martin, A.E.; Kaseer, F.; Arámbula-Mercado, E.; Bajaj, A.; Cucalon, L.G.; Yin, F.; Chowdhury, A.; Epps, J.; Glover, C.; Hajj, E.Y. Evaluating the Effects of Recycling Agents on Asphalt Mixtures with High RAS and RAP Binder Ratios; NCHRP Research Report 927; Transportation Research Board: Washington, DC, USA, 2020. [Google Scholar]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Mohammad, L.N.; Cooper, S.B., Jr.; Kim, M. Sustainable Materials for Pavement Infrastructure: Design and Performance of Asphalt Mixtures Containing Recycled Asphalt Shingles; Report No: FHWA/LA.17/594; Louisiana State University: Baton Rouge, LA, USA; Transportation Research Center: Baton Rouge, LA, USA, 2019. [Google Scholar]

- Ongel, A.; Hugener, M. Impact of rejuvenators on aging properties of bitumen. Constr. Build. Mater. 2015, 94, 467–474. [Google Scholar] [CrossRef]

- Yu, X.; Zaumanis, M.; Santos, S.D.; Poulikakos, L.D. Rheological, microscopic, and chemical characterization of the rejuvenating effect on asphalt binders. Fuel 2014, 135, 162–171. [Google Scholar] [CrossRef]

- Im, S.; Karki, P.; Zhou, F. Development of new mix design method for asphalt mixtures containing RAP and rejuvenators. Constr. Build. Mater. 2016, 115, 727–734. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Booshehrian, A.; Vahidi, S.; Austerman, A.J. Evaluating the effect of rejuvenators on the degree of blending and performance of high RAP, RAS, and RAP/RAS mixtures. Road Mater. Pavement Des. 2013, 14, 193–213. [Google Scholar] [CrossRef]

- Elnaml, I.; Liu, J.; Mohammad, L.N.; Cooper, S.B., III; Cooper, S.B., Jr. Use of the Iron Chloride Type of Lewis Acid Catalyst in High Reclaimed Asphalt Pavement Content Asphalt Mixtures. Transp. Res. Rec. 2023, 2678, 430–440. [Google Scholar] [CrossRef]

- Louisiana Department of Transportation and Development. Louisiana Standard Specifications for Roads and Bridges; Louisiana Department of Transportation and Development location: Baton Rouge, LA, USA, 2018. [Google Scholar]

- Seidel, J.C.; Haddock, J.E. Soy fatty acids as a sustainable modifier for asphalt binders. In Proceedings of the Alternative Binders for Sustainable Asphalt Pavements, Washington, DC, USA, 22 January 2012. [Google Scholar]

- Elkashef, M.; Podolsky, J.; Williams, R.C.; Cochran, E. Preliminary examination of soybean oil derived material as a potential rejuvenator through Superpave criteria and asphalt bitumen rheology. Constr. Build. Mater. 2017, 149, 826–836. [Google Scholar] [CrossRef]

- Portugal, A.C.X.; Lucena, L.C.d.F.L.; Lucena, A.E.d.F.L.; Beserra da Costa, D. Rheological performance of soybean in asphalt binder modification. Road Mater. Pavement Des. 2018, 19, 768–782. [Google Scholar] [CrossRef]

- AASHTO T 164; Standard Method of Test for Quantitative Extraction of Asphalt Binder from Asphalt Mixtures. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- AASHTO R 59; Standard Practice for Recovery of Asphalt Binder from Solution by Abson Method. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- McDaniel, R.S.; Soleymani, H.; Anderson, R.M.; Turner, P.; Peterson, R. Recommended use of reclaimed asphalt pavement in the Superpave mix design method. NCHRP Web Doc. 2000, 30, 15417. [Google Scholar]

- AASHTO M 320; Standard Specification for Performance-Graded Asphalt Binder. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2023.

- AASHTO T 313; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- AASHTO R 35; Standard Practice for Superpave Volumetric Design for Asphalt Mixtures. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- Cooper, S.B., Jr. Characterization of HMA Mixtures Containing High Recycled Asphalt Pavement Content with Crumb Rubber Additives; Louisiana State University and Agricultural & Mechanical College: Baton Rouge, LA, USA, 2008. [Google Scholar]

- AASHTO R 30; Standard Practice for Laboratory Conditioning of Asphalt Mixtures. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- AASHTO T 324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2023.

- ASTM D 8044; Standard Test Method for Evaluation of Asphalt Mixture Cracking Resistance Using the Semi-Circular Bend Test (SCB) at Intermediate Temperatures. American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2016.

- ASTM D 8225; Standard Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Temperature. American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2019.

- AASHTO T 393; Standard Method of Test for Determining the Fracture Potential of Asphalt Mixtures Using the Illinois Flexibility Index Test (I-FIT). American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- AASHTO TP 10; Standard Test Method for Thermal Stress Restrained Specimen Tensile Strength. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 1996.

- SAS Institute. Base SAS 9.4 Procedures Guide: Statistical Procedures; SAS Institute Inc.: Cary, NC, USA, 2013. [Google Scholar]

- Illinois Center for Transportation. Illinois Flexibility Index Test (I-FIT). Available online: https://ict.illinois.edu/research/tools/ifit-software (accessed on 15 July 2023).

- Al-Qadi, I.L.; Ozer, H.; Lambros, J. Development of the Illinois flexibility index test. Asphalt Mixtures 2019, 31, 01722468. [Google Scholar]

- Illinois department of transportation. Standard Specifications for Road and Bridge Construction; Illinois department of transportation: Springfield, IL, USA, 2022. [Google Scholar]

- Zhou, F.; Hu, S.; Newcomb, D. Development of a performance-related framework for production quality control with ideal cracking and rutting tests. Constr. Build. Mater. 2020, 261, 120549. [Google Scholar] [CrossRef]

- Mallick, R.B.; Tao, M.; O’Sullivan, K.A.; Frank, R. Use of 100% reclaimed asphalt pavement (RAP) material in asphalt pavement construction. In Proceedings of the 89th Conference of International Society of Asphalt Pavement, Nagoya, Japan, 1 August 2009. [Google Scholar]

- Neto, O.d.M.M.; Silva, I.M.; Lucena, L.C.d.F.L.; Lucena, L.d.F.L.; Mendonça, A.M.G.D.; de Lima, R.K.B. Viability of recycled asphalt mixtures with soybean oil sludge fatty acid. Constr. Build. Mater. 2022, 349, 128728. [Google Scholar] [CrossRef]

- Zhou, F. Balanced RAP–RAS–Recycling Agent Mix Design for Project-Specific Conditions. Innov. Asph. Mix. Des. Proced. 2018, 44, 01687983. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).