Abstract

This study focuses on improving pre-emptive risk recognition and safety checks to prevent workplace accidents. It underscores improvements by addressing existing research issues, suggesting potential enhancements through system development. Work approval procedures and workers’ prior risk awareness, through the confirmation of work safety standards in physically separated work areas, are fundamental methods of preventing serious accidents and creating a safe work environment. A key factor concerning worker safety is recognizing the potential accident risk factors (or hazards) in advance through practical job hazard analysis and consequently take risk-reduction measures in case the safety standards are not met. Despite the crucial significance of pre-awareness of work risks at the majority of construction sites, tools to enhance this awareness are currently limited. Furthermore, real-time detection of work risks and the implementation of risk reduction measures are contingent upon a monitoring environment and a robust safety culture. This study proposed construction worker location-tracking technology that recognizes personal identification (ID). A safety check system based on location tracking combining personal quick response code (QR code) recognition and computer vision technology to automatically identify workers’ personal identities and track their physical location was proposed. A real-time safety check system was implemented to classify automatically whether workers have confirmed hazards and to approve a work process in high-risk workplaces by supervisors. Location-tracking technology with ID recognition performed the following two safety management functions. First, if a construction worker does not pre-check the work risk information before entering the work zone, the geofencing technology automatically classifies workers as those who are not aware of job hazards. Secondly, the safety manager or supervisor entering the on-site work zone possesses the authority to halt work if the work environment fails to meet safety standards and can issue warnings regarding risky situations. Essential functions were validated through a case study involving preliminary testing within the development system. To assess the practical application of the system, virtual simulations were conducted using recorded videos from a construction site to replicate the two essential functions of the system. The system was constructed using an Apache server and Python code, and for testing purposes, the names of the workers were randomized.

1. Introduction

1.1. Risk Awareness

Identifying hazards and taking actions to mitigate them are typical safety processes applied across all industries [1]. The cornerstone of effective risk management lies in recognizing and communicating risk factors [2]. Currently, automatically performing safety checks to detect risks before driving a car is essential for accident prevention. Likewise, in the context of high-risk construction work, conducting a comprehensive safety review and having the capability to identify potential risk factors (or hazards) are crucial elements for safeguarding the safety and health of construction workers. Safety planning typically involves identifying all potential hazards and determining the corresponding safety measures [3]. To improve workers’ risk awareness, abundant experience, safety knowledge, safety education, and safety culture must be comprehensively considered. Risk-recognition capabilities have recently become more critical in domestic construction workplaces due to both rapid aging and a considerable increase in the number of foreign workers. Managing new or unfamiliar risks—in addition to addressing known hazards—through stringent safety compliance and enhancing the risk awareness of workers is a pivotal factor in accident prevention. Any lapses in safety design, safety inspection, and monitoring can elevate the risk of exposing workers to hazards in the construction environment [4].

The working environment at a construction site is dynamic, with various construction tasks being performed simultaneously each day, introducing new risk factors (or hazards) at unknown times and places. Safety supervisors, managers, and work team leaders at construction sites must always monitor potential risk factors [5]. Despite the importance of hazard identification and risk awareness, recent studies have demonstrated that a significant proportion of hazards remain unrecognized, exposing workers to workplace dangers [6]. Presently, effective communication is emphasized as a critical factor in preventing accidents at construction sites [7]. Real-time communication technology for work teams is an effective method to reduce accident risk factors significantly. In addition, an organization’s strict safety management can regulate unsafe workplace behaviors and conditions [8]. Therefore, inadequate safety supervision and deficient risk communication could result in workers being exposed to accidents. This exposure occurs because they are not fully aware of the workplace’s risk factors (hazards), with the risks not controlled. Real-time communication technology in construction workplaces is the key to overcoming such limitations of generalized risk assessments and safety checks.

1.2. Limitations of Job Hazard Analysis (JHA)

Occupational job hazard analysis (JHA) finds widespread application across various industries, including construction, aiming to enhance the overall quality and safety of projects. Job risk analysis (JRA) involves defining and identifying potential risks based on work processes. JHA is a technique centered on job tasks for proactively identifying hazards before they occur. It emphasizes the relationship between the worker, the task, the tools, and the work environment [9,10]. Various forms of risk assessment, such as JHA, preliminary hazard analysis (PHA), and failure mode and effects analysis (FMEA) serve as practical tools to strengthen the risk awareness of workers. Moreover, JHA, PHA, JRA, and FMEA all encompass risk reduction measures. JHA has been employed by safety experts for over 70 years. The results of JHA are formally documented during team meetings to ensure safe work execution; however, there is a deficiency in communicating risk information effectively to work participants. Given the daily changes in construction work sites, general work accident analysis information imposes limitations on safety checks for newly altered work risk factors [11]. Despite the advantages of risk mitigation using JHA, the limitations of using current work accident analysis tools are evident. The intricacy and time-consuming nature of JHA necessitate safety personnel to invest a substantial amount of time in acquiring JHA information and subsequently applying that knowledge to conduct the analysis [12]. Particularly in high-risk work scenarios at industrial sites, the analysis of work accidents for work permits and work safety confirmation is typically conducted through traditional documentation formats [13]. Document-type work-risk analysis forms are time consuming, and reflecting the potential hazards occurring in the workplace in real time is challenging. The most significant limitation of the JHA is that risk factors (or hazards) are not communicated or shared with workers in a real-time workplace.

1.3. Benefits of Location Tracking

In workplaces, various hazards are identified based on inspections. Through comprehensive unit inspections, it is more likely to observe hazards specific to that location [14]. The integration of location tracking information and JHA documents can offer numerous advantages. First, automated work approval procedures can be facilitated in high-risk workplaces. Second, if the corresponding JHA is not defined in the work area, the work can be stopped immediately. Location tracking technology based on computer vision can connect and interact with work participants using various types of information. Using location tracking and JHA information, the risk awareness regarding work hazards that workers may be required to remember or are careless about in the work area can be strengthened. Moreover, location-tracking-based JHA can identify workers who are unaware of risks, allowing for expanded safety management.

1.4. Objectives of the Study

This study proposed a location-based safety check system that officially grants work approval through real-time confirmation of work safety and supports to strengthen workers’ prior awareness of risks. On-site real-time work approval tools and risk-awareness support systems cannot completely prevent workers’ intentional violations. However, the number of worker violations can be significantly reduced through self-responsibility, mutual monitoring, and strict supervision. This study provides a safety check system for distinguishing between risk-unaware workers and risk-aware workers, and the real-time work approval (or work permit) method using location-tracking technology. Location-tracking technology identifies workers’ personal identifications (IDs) and provides JHA information on the relevant work area to individual workers. The proposed automatic safety check system performed the following two management functions. First, workers who did not pre-check for hazards in the work zone were automatically classified, and a warning was displayed in a red box to the crew. Secondly, relying on a pre-defined JHA, the safety manager or supervisor can make decisions regarding the approval or suspension of a job set to commence in the work zone. When work is halted, a risk warning is displayed in the work zone via closed-circuit television (CCTV), with the work stoppage promptly communicated to all work participants. The developed system underwent case studies for the two safety functions, evaluating their industrial applicability.

2. Research Methodology

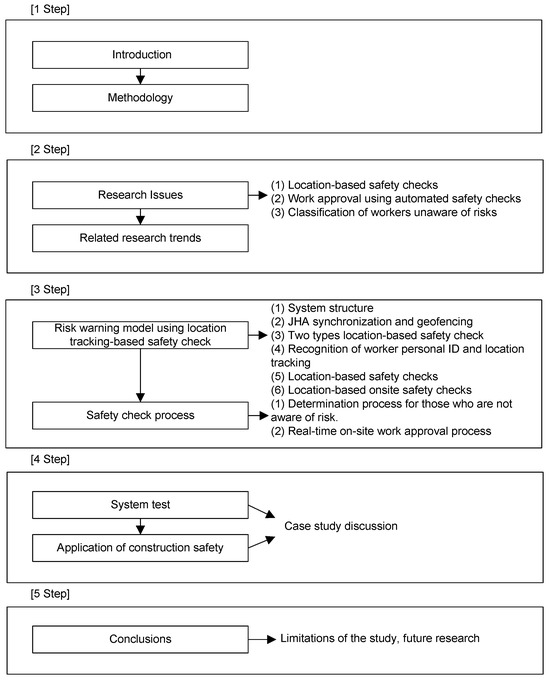

This study is organized into five categories. Category 1 encompasses the introduction and research methodology, detailing the study’s content, purpose, and methods. Category 2 discusses research issues, existing trends, differentiation from prior research, and outlines future research directions. Category 3 constitutes the core content, detailing the structure, model, function, types of safety checks, system processes, and more on the safety check system. Category 4 presents the simulation results from safety checks on construction sites, serving as confirmation of the basic functions of the development system and offering an application example. Finally, Category 5 outlines the main findings and conclusions of the study, acknowledging limitations and proposing future research plans.

The system underwent two development phases. The initial phase focused on integrating geofencing technology and personal identity recognition. In the subsequent phase, safety checks were synchronized based on individual worker location tracking. Depending on whether the safety check was conducted, a danger warning was issued.

Baseline testing was conducted through a case study, and discussions were held with three safety experts each possessing more than 10 years of experience. The outcomes of these discussions highlight the effectiveness of the system, its applicability in the field, and suggest directions for future research. Figure 1 presents a flowchart of the research methods.

Figure 1.

Study categories and flowchart.

3. Research Issues

The issue of this study was created based on the following two questions:

- How do we strengthen workers’ individual risk awareness?

- When work is stopped due to anticipated risk in hazardous work, is it possible to immediately share the hazardous situation with work participants?

3.1. Location-Based Safety Checks

Location-based safety inspections ensure the safety of workers and the entire construction site by monitoring potential hazards based on geographic location. Worker-location tracking technology using videos measures the effective working time of workers entering the workplace and provides various application methods through monitoring [15]. In case of location tracking, geofencing technology is a computer vision method that defines a virtual physical boundary in an image area and uses information on the entry and exit of humans or objects [16]. Geofencing technology can be used to create safe and dangerous zones within construction sites. When workers enter or leave predefined geofence areas, the system triggers warnings or hazard notifications to ensure compliance with safety standards. For construction equipment, entering a hazardous location and exceeding the speed limit automatically triggers a risk warning to facilitate hazard recognition. These video-based hazard warnings can communicate the necessary safety information in real time to workers, supervisors, and safety managers through communication channels such as text messages, emails, or app notifications. Owing to the various safety benefits of location tracking, wearable devices such as global positioning system (GPS), smart helmets, wristbands, Internet of Things (IoT) sensors, and mobile apps are continuously being developed [17].

Furthermore, a communication platform linked to location tracking facilitates rapid communication among workers, supervisors, and safety managers, thereby enabling an immediate response to safety issues. Owing to the rapid development of location tracking in the construction industry, the usability of the JHA increases to control risks. However, research results that enable real-time safety checks at construction work sites by combining location tracking and the JHA are still at their initial level.

3.2. Classification of Workers Unaware of Risks

The ability to recognize risks varies from worker to worker depending on prior education, risk recognition training, safety knowledge, and experience. Workers who are experienced have ample safety knowledge and may have a high hazard recognition ability. On the contrary, workers with limited experience or a lack of caution are prone to accidents. Previous research addressing the impact of “new” workers—i.e., those with minimal experience—has indicated that this group poses a significantly elevated risk of injuries [18]. Levitt and Samelson [19] found that 25% of injured construction workers had less than 2 months of work experience, while 6% had between 2 and 3 months of experience. According to the Health and Safety Executive of Great Britain, “adequate experience forms a significant component of competence.”

Low-risk awareness invariably leads to an increased probability of accidents. Studies indicate that workers are often unable to identify and manage over 55% of hazards on construction sites [20]. Consequently, workers can be classified as high- or low-risk based on their previous risk awareness, education, and training. Confirming the predefined risk factors (or hazards) and accident types in work areas where potential hazards are expected can prevent accidents beyond a certain level. On-site workplaces require a final inspection of risk factors (or hazards) that must be identified, and risk reduction measures can be determined. Only when the work participants are educated about the risks and are aware of them in advance do they become better aware of the actual risk and take risk reduction measures. Existing research shows that there exists no method to automatically provide workers with JHA information before work and distinguish in real time whether workers are aware of risk factors (hazards).

3.3. Work Approval using Automated Safety Checks

Failure to comply with safety checks before construction work can result in serious accidents or life-threatening consequences for workers and the public. Thorough safety inspections and checks play an important role in preventing accidents among construction site workers; however, safety checks can fail or be missed for various reasons. Typically, safety checks heavily depend on the manual use of paper documents. Manual observation is both inefficient and inaccurate, especially considering the large-sized, complex, and dynamic nature of construction sites [21]. Safety checks conducted manually are susceptible to errors as they heavily rely on human judgment and execution. Inspectors or workers might overlook potential hazards, omit safety precautions, or fail to identify safety criteria due to various human factors like fatigue, distraction, or lack of expertise. Safety checklists in various regulatory documents further impede experts from comprehending all rules, contributing to error-prone assessments of potential construction risks [13]. Construction sites are dynamic environments wherein the working conditions change constantly. Safety checks conducted at a single point in time may not account for changes occurring during subsequent project stages. Safety personnel may struggle to react swiftly to implement measures in response to evolving construction conditions and schedules [22]. Additionally, safety checks involving fatigue due to time constraints and human factors make it challenging to conduct a flawless safety inspection, hindering the identification of potential hazards. Both workers and safety managers need to carry out straightforward safety check procedures and leverage reliable risk-mitigation tools. The pre-work permit system is applied in high-risk workplaces [23]. In most industrial sites, the manual preparation of prior authorization systems poses difficulties in real-time sharing due to cost constraints related to communication technology.

The technical development direction of advanced safety management involves communicating work risks in real time and monitoring safety criteria. Based on the author’s existing research status and extensive technical surveys, current safety technology in computer vision is limited in terms of automated safety checks and work approval monitoring.

4. Related Research Trends

4.1. Location Tracking and Individual Human Recognition

In recent years, deep learning has revolutionized computer vision and has been widely used to monitor and position diverse visual scenes [24]. In the construction industry, location tracking technology has been used to ensure worker safety and improve productivity [25]. Knowing how construction workers travel on a job site provides a better view of their movement patterns and behaviors and enables a safer and more efficient construction job site [26]. Thus, tracking technology for multiple construction workers using location tracking at construction sites is an important research topic.

Ohay and Albert [26] addressed the problem of the image-based tracking of multiple workers using a single camera. The trajectory of a tracked object can be interrupted by worker overlap, occlusion, or inconsistency. It attempts to track a worker over successive image frames to resolve this issue. Manwoo and Ioannis [27] attempted to solve the worker duplication problem by tracking the positions in two-dimensional (2D) images from a single camera. Trajectories were created for all identified workers using video tracking. The tracking of workers that were obscured by overlapping workers in the video was automatically terminated. Workers whose recognition began again began video tracking by calculating the proximity distance. Manwoo and Ioannis [28] proposed a method for monitoring resource locations in crowded outdoor sites. The proposed method exploited the motion, shape, and color signals of construction workers to analyze their movements in the detection area. Two or more stereo camera systems tracked multiple workers simultaneously, thereby reducing errors in worker location tracking [29]. A study by Eirini et al. [30] found that it was extremely difficult for current computer vision technology to track multiple workers in complex construction workplaces; therefore, the location of numerous workers was determined by factors such as workers’ positions, physical characteristics, color, and height. Consequently, an advanced tracking method was proposed. Jinsun et al. [31] proposed a method to track the locations of multiple workers using a wireless network system. Bo and Zhenhua [32] used 15 visual tracking methods of computer vision technology, which have proven to exhibit excellent performance, to increase the accuracy of location tracking methods in 2D images. The tracking results outperformed the typical performance by evaluating the sequence overlap score, central error ratio, and trace length ratio. Heng et al. [33] focused on the safety technologies of radio frequency identification (RFID), GPS, ultra-wideband (UWB), vision analysis, wireless local area networks (WLAN), ultrasound, and infrared (IR) used in real-time location systems (RTLSs). The authors discussed this in terms of future safety and health possibilities.

Numerous studies on worker location tracking technology have been published, most of which aimed to improve the accuracy of location tracking and object recognition by multiple workers. At construction sites where multiple workers are present, tracking individual workers’ locations requires additional devices, such as RFID or wireless fidelity (WiFi) communications. Ran et al. [34] combined wireless network and video location tracking technologies to acquire an individual’s identity. Recognizing a worker’s personal ID with simultaneous location tracking offers excellent benefits and advantages in collecting individual and team productivity and health data [32]. Research on productivity and health data collection using location tracking is underway [35,36]. However, finding commercialized cases in the construction industry that recognize individual workers and track their physical locations in a multi-worker area is challenging. Research on this subject is currently ongoing [37]. Moreover, when multiple workers are present in a video, the problem of missing personal identities owing to video information duplication remains unresolved.

In summary, accurate location tracking of multiple workers and simultaneous recognition of personal ID can enable more communication within the workplace, which will provide more opportunities to improve productivity and ensure safety.

4.2. Automated Safety Checks

A safety check is a systematic procedure performed by an individual or organization to ensure that a particular environment, situation, process, or product is safe and protected from potential hazards. The status of research on safety checks is as follows:

Xuewei et al. [38] proposed a semantic approach to automate safety inspections using risk data in a building information model (BIM). This rule-based construction safety inspection method examined hazards during construction to ensure that the risk conditions were within the safety thresholds. Sijie et al. [39] fed into the BIM model of why, where, when, and what safety measures were needed to prevent fall-related accidents before construction commences. This study proposed a BIM platform that automatically suggested manual text-based safety checklists that were commonly applied in the field. David and Paul [40] proposed a safety check method using a barcode reader to prevent mistakes and omissions in worker safety checks. They aimed to provide immediate recognition of incorrect actions and feedback regarding failures. They demonstrated the effectiveness of automated systems in ensuring safety compliance by preventing workers from using equipment before barcode checks are complete. Sijie et al. [4] proposed a safety rule analysis algorithm for BIMs. If a fall-related hazard existed, BIM detected the accident risk and suggested preventive measures for the user. The BIM model was equipped with an automated safety inspection platform to provide safety check items to construction engineers and managers. Ying et al. [13] presented an ontological knowledge model for safety inspections. This study proposed a method for automatically extracting the content of safety inspections from construction regulations. They introduced a method for reducing manual risk-identification errors by quickly providing construction safety inspection items. Yuexiong et al. [41] proposed visual reasoning and question-answering (VQA) methods for detecting unsafe behaviors. The vision-and-language transformer model used construction images to identify unsafe behaviors and automatically checked for safety compliance. Sixteen safety rules and 2386 related construction images were used in the VQA model, and their usability in terms of inference speed was verified. Roshana et al. [42] proposed an automated safety rule checking (ASRC) system that automatically checks risk factors in fall risk areas by combining building information modeling and safety rules. This study integrated ASRC systems with BIM-based projects. In addition to the aforementioned research, numerous studies on various safety check methods are being conducted, and research efforts toward automation are ongoing.

4.3. Risk Recognition

Risk recognition refers to identifying and acknowledging potential risks or uncertainties that may affect the achievement of objectives, goals, or the success of a project, business, or any other endeavor. This is a crucial step in the risk management process, which involves assessing, analyzing, and responding to risks to mitigate their potential negative effects. Risk recognition technology detects unsafe behaviors in real time so that appropriate actions can be implemented immediately. Through deep learning, computer vision can prevent construction accidents by accurately recognizing unsafe conditions and unsafe worker behaviors. Computer vision (CV) technology can observe and record unsafe behaviors and recognize risks based on image data. Furthermore, computer vision analysis of digital images and videos automatically captures and identifies unsafe behavior in real time [43,44].

Recently, computer vision and deep learning have enabled motion monitoring in high-risk industries to improve field safety performance [31]. The main research directions using image-based technology are (1) object recognition of construction equipment, (2) work process monitoring, and (3) detection of safety defects and unsafe behaviors (e.g., hard hats and defects) [45]. Traditionally, the observation and identification of unsafe behaviors are performed manually by safety supervisors or managers. Certain studies conducted risk recognition using CV 2D image analysis technology.

Hong et al. [46] used CV to screen non-hardhat wearers. This method can identify worker violations such as not wearing a safety helmet or implementing safety measures in real time. Chi and Carlos [47] evaluated the safety of stereo vision cameras using object identification and tracking. They automated safety evaluations according to the safety regulations for earthmoving operations and surface mining activities. Yuan et al. [48] proposed a technology for tracking the location and movement of heavy equipment in real-time. This technology analyzed the direction of an excavator through three-dimensional (3D) measurements of its kinematic shape. This study enabled the advanced recognition of inappropriate spatial and temporal risks between equipment and workers by tracking movement. Bahaa et al., Qi et al., and Kishor et al. [49,50,51] used computer vision to detect whether a worker was wearing a hardhat based on captured images of a worksite. Weili et al. [52] proposed a computer vision framework for identifying unsafe behaviors and working conditions. Furthermore, Weili et al. [53] presented an example of using computer vision and neural network algorithms to recognize the relationships between workers and steel supports. The findings automatically identified unsafe behaviors and provided feedback to individuals regarding the likelihood of falling from heights. Weili et al. [54] suggested that many people practiced unsafe behavior by intentionally not wearing safety gear when working at a height. To address this problem, they developed an automated computer vision system using neural network models to determine whether workers wore safety gear when performing tasks at a height.

Seulki and Jungho [55] proposed a risk situation recognition method that combined image recognition technology and ontology reasoning. An ontology method was used to define the relationship between safety and risk situations required for mobile scaffolding construction. The ontology inferred the current work situation based on recognized objects and determined the safety compliance.

In the construction field, recent studies have explored the use of light detection and ranging (LiDAR) sensors to detect unsafe behaviors. Some studies have demonstrated risk recognition through LiDAR 3D image analysis. LiDAR sensors, which measure the depth of objects and people, are combined with ergonomic theory to identify worker behavior in real time [56]. Hongling et al., Yantao et al., and Sanguk et al. proposed the skeleton-based real-time identification of unsafe behavior by combining lidar sensor technology, construction safety knowledge, and ergonomic theory [57,58,59]. The proposed method recognized unsafe behaviors by simplifying dynamic motions into static postures that can be described using a few parameters. The tests proved the validity, efficiency, and accuracy of this method. Qian [21] proposed a technique to automatically check whether a scaffolding work platform complied with the safety regulations for 3D point cloud data. This technique detected the positions of vertical scaffold components from point-cloud data. The point cloud data for the detected scaffolding and guardrails were compared with safety regulation data to automatically check for safety regulation violations. Peilin et al. [60] introduced a method for detecting human behavior involving three actions: throwing (e.g., throwing a hammer, throwing a bottle), operating (e.g., turning on a switch, putting down a bottle), and crossing (e.g., crossing a railing, crossing obstacles). The outcomes were promising for monitoring the unsafe behavior of construction workers. Hongling et al. [61] proposed a 3D skeletal LiDAR-based behavior recognition method for fall accidents. This method automatically monitored the correct fastening of seatbelts in the field to ensure validity.

Most risk recognition studies use image-based computer vision or LiDAR sensor technologies. Risk recognition research trends are being actively studied to mitigate unsafe environments and behaviors.

4.4. Workers’ Risk Awareness and Perception

Risk perception refers to people’s beliefs, attitudes, judgments, and feelings toward risk and incorporates the broader social values, cultural values, and outlook that people adopt toward hazards. Risk management requires all managers and employees to identify hazards in their work environment [62]. Risk perception is the subjective interpretation of the level of risk associated with a particular situation, activity, or object. This includes people’s feelings and intuitive judgments regarding the potential harm or negative consequences of an action or event. Risk perception is influenced by beliefs, experiences, emotions, and physical conditions.

Susanne [63] examined the level of risk awareness of a group of experienced and unskilled workers in four workplace categories (obvious, minor, new, and hidden). The study found that the least experienced team discovered a minimum of four obvious, two minor, and five new hazards in their work area, but needed help to identify three hidden hazards. Given these findings, managers and workers should strengthen their risk awareness skills.

Gregory and Simon [62] found that the maximum risk identification levels were 0.899 (89.9%), 0.728 (72.8%), and 0.665 (66.5%) for construction projects in the nuclear industry, projects within the railway industry, and railway and construction projects, respectively. Research indicates that the level of risk identification in the construction industry is low. Workers in the construction industry must improve their level of risk identification compared with other industries. Susanne [63] suggested that risk awareness is necessary for all new and experienced workers. Alex et al. [64] conducted large-scale research on risk perception ability. The preliminary evidence indicated that construction workers perform poorly in terms of risk perception. The study reported that even if hazards were identified before work began, only 38% of the hazards on average were identified in the actual workplace. The authors argued that there was a need to improve workers’ risk awareness and encourage risk communication in the workplace. Alex et al. [6] described the effectiveness of hazard signs and warning facilities at construction sites. The study found that before introducing hazard signals, workers could only identify 46% of the hazards; however, after they were introduced, they recognized 77% of the hazards.

Idris [65] identified 13 factors hindering construction workers’ risk perception. The most frequently observed factors were as follows:

- Selective attention or inattention to certain types of hazards,

- A set of unexpected and unknown potential hazards,

- The perception that a particular hazard poses a low level of safety risk.

Furthermore, educational strategies to improve risk awareness increased risk identification levels from an average of 42% to 77%. Idris et al. [66] found that workers who spent more time researching safety hazards (i.e., search time) perceived a greater proportion of hazards. Safety training is undoubtedly one of the most effective initiatives for predicting construction hazards and improving safety awareness [67]. Workers who received more training, communication, and had higher levels of caution demonstrated superior risk perception performance. Consequently, research efforts to improve workers’ risk awareness and strengthen it are continuing.

4.5. Research Gap and Future Direction

Current research trends in location tracking primarily address challenges related to accurately tracking the physical location of workers and mitigating errors associated with human overlapping. The prevailing direction of research suggests that recognizing a person’s identity in location-tracking technology is considered less critical than enhancing tracking accuracy. The potential benefits and impacts of personal ID recognition in the safety field remain unclear. This study underscores that personal ID recognition technology during worker location tracking can effectively prevent accidents and enhance risk awareness in the workplace. The distinctive aspects of this study compared to previous research are summarized as follows:

- Existing research in safety checks predominantly aims for automation. This study, however, goes a step further by incorporating safety check automation, personal ID recognition, and JHA geofencing technology. This integrated approach not only automates safety checks, but also boosts an individual’s risk awareness, proving to be an effective means of communicating risk.

- In existing research, risk recognition technology typically analyzes images to identify risks associated with unsafe behavior and hazardous environments. In contrast, this study does not rely on automatic recognition of unsafe behavior and environments. Instead, it proactively shares information about risk factors, allowing safety managers, supervisors, and workers to recognize potential unsafe behaviors and environments in advance. Therefore, prior recognition and reinforcement of risks by workers is the goal and direction pursued by this study.

- The safety check technology, incorporating geofencing and ID recognition, as presented in this study, not only promptly enhances risk awareness, but also extends to encompass safety education content and accident prediction technology. Ongoing discussions and developments in these areas will continue.

5. Risk Warning Model Using a Location-Tracking-Based Safety Check

5.1. System Structure

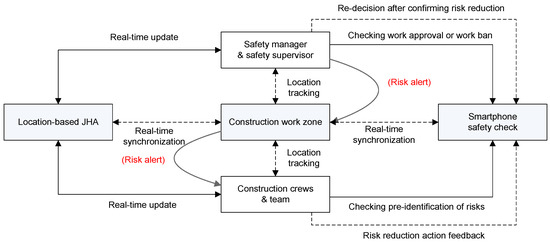

The proposed location-tracking-based safety check system immediately requests risk mitigation measures from the relevant work zone or worker if safety criteria are not met. The proposed system demands normal execution of a safety check if it is not appropriate or is missing. Furthermore, its system synchronizes with the JHA in the designated work zone and automatically transmits safety check items, including risk reduction, to workers entering the work zone. The JHA information in the work zone is updated simultaneously on the central computer system or individual smartphones, making it possible to update it when new work hazards are discovered.

Safety check items in the system distinguish between workers and safety supervisors.

First, if a worker does not check for potential hazards that may occur in the relevant work zone, the worker is marked with a red box. Next, the system asks relevant workers to confirm the workplace risk factors (or hazards). Workers must leave their current work zone to check for risk factors (or hazards). Only workers with confirmed risk factors (or hazards) in other work areas are changed from red to green boxes.

Second, the safety supervisor and manager can decide to stop work if the work environment falls short of necessary safety requirements. Work is stopped in the relevant work zone, and a notification of the work stoppage is automatically displayed, with the translucent red zone on a computer monitor. When work is stopped and risk reduction measures are implemented, the safety supervisor grants work approval again, and the translucent red display on the work zone disappears. In certain cases, a safety check is yet to be performed by the safety supervisor or manager in the designated work zone. Because the hazards in the relevant work zone have not been officially confirmed, a warning notification without work approval can be issued with a semi-transparent red sign for the relevant work zone when work starts. Figure 2 illustrates the basic concept of the monitoring and warning functions of the designated location-tracking-based safety check system.

Figure 2.

Risk reduction model and warning using location-based JHA.

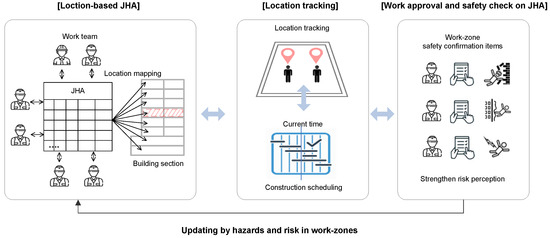

5.2. JHA Synchronization and Geofencing

Hazards identified in work processes, including risk mitigation, must be documented and made available to workers in the field. When the work zone and JHA are synchronized, workers entering the work zone are automatically provided with the JHA information. This is an advanced new tool because the JHA in the work zone is linked to the geofencing location. Consequently, the JHA automatically provides safety check items to reduce the risk of workers in the corresponding work zone. This process offers a valuable opportunity to immediately eliminate or reduce practical risks that may arise at construction sites. In addition, individual smartphones can update the work area’s risk factors (or hazards) anytime and anywhere. The purposes of combining the JHA with geofencing are summarized as follows:

- A safety supervisor or manager with a confirmed individual identity enters the work zone to perform a safety check at the start of the work and obtain official work approval.

- The workers’ risk perception is strengthened by automatically providing JHA information before performing work.

- New risk factors (or hazards) that may occur in the workplace are continuously updated.

Figure 3 illustrates the various ways to utilize safety checks by combining JHA information and geofencing technology.

Figure 3.

Combining JHA and geofencing work zone.

5.3. Two Types Location-Based Safety Check

From a time-based perspective, safety checks are preliminary checks before work, real-time on-site checks during work, and checks after the work is completed. This study experiments with two types of pre-checks: before work and on-site checks during work. The basic process of a location-tracking-based safety check system is to inspect work hazards, report hazards, and record safety improvements. The system operates as a plan-do-check-action system as follows.

- Plan and Update: Plan of work area JHA and updating.

- Do: Geofencing settings, individual ID recognition, location tracking, and assigning the safety check.

- Check: Perception risk factors (or hazards) by prior check, on-site check in the work zone.

- Action/Monitoring: Warning of non-conformity to safety standards when two types of safety checks are not confirmed/executed or are insufficient of safety criteria.

Figure 4 illustrates the plan, do check, and action (PDCA) diagram for a location-based safety check.

Figure 4.

PDCA diagram for location-based safety checks.

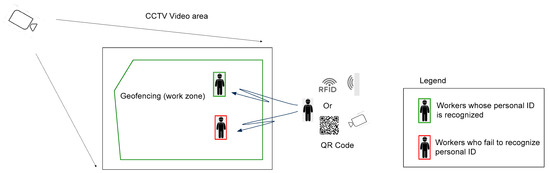

5.4. Recognition of Worker Personal ID and Location Tracking

The CCTV image represents the work area, and the imaginary line represents the work zone. The geofencing of the work zone can be freely set, and the personal ID begins to be recognized outside the CCTV footage. The worker transmits an individual ID to the main system of the central computer using a QR code or RFID. The QR or RFID technology containing a worker’s ID displays the name of the first worker entering the CCTV video. If a worker enters the work area without confirming a personal QR code or RFID, he or she is immediately marked with a red box. Figure 5 illustrates the concept of displaying a green box or red box, depending on whether a personal ID is recognized in the work zone of the CCTV footage.

Figure 5.

Recognition of personal ID and location tracking.

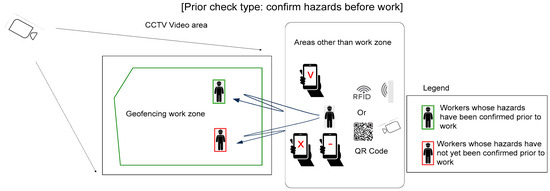

5.5. Location-Based Safety Checks

The preliminary safety check aims to check and recognize the potential risks of the current work in advance. Workers are required to check the JHA before entering the work zone or starting work. There may be more time for workers to check the JHA in the corresponding work zone. Therefore, the worker could better confirm the hazards with sufficient time before entering the work zone. If a worker enters the work zone without checking the JHA, the system classifies the worker as a potential risk worker whose hazards are not self-recognized or failed cognitively. The worker is immediately marked with a red box and receives a warning to check. Consequently, through this alert, the worker has their red box canceled by confirming their JHA. Figure 6 illustrates the classification of workers who did not carry out a prior check.

Figure 6.

Diagram of classification of risk-unaware workers with prior safety check.

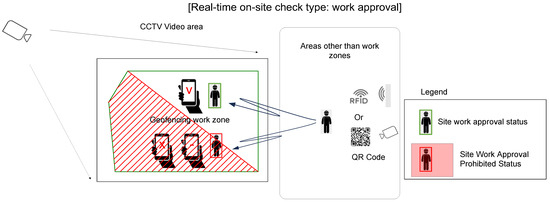

5.6. Location-Based Onsite Safety Checks

The purpose of location-based on-site safety checks is for safety managers or supervisors to check for potential risk factors (or hazards) prior to the current work and provide official work approval or work bans. Therefore, the safety manager or supervisor enters the work zone and checks with the JHA to approve the work. The work is approved if the safety manager or supervisor checks the JHA and determines that the risk-reduction measures satisfy the safety criteria. Work is stopped if the safety manager or supervisor determines that the work environment and worker safety criteria are insufficient. At this time, the system displays the safety manager or supervisor in a red box, as well as a warning for the relevant work zone with a red area. This warning indicates that risk-reduction measures or risk elimination must be implemented in the relevant work zone. When managers or supervisors verify that they meet the safety criteria and approve the work, the red zone is automatically canceled. Figure 7 illustrates a diagram of a work stoppage and risk warning using an on-site safety check.

Figure 7.

On-site safety check for work stop by safety manager or supervisor.

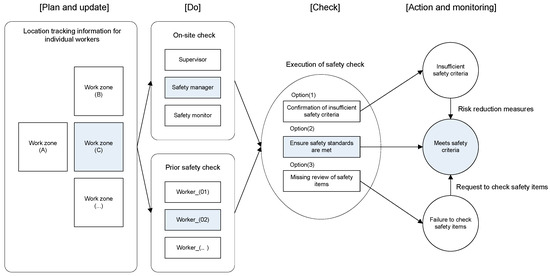

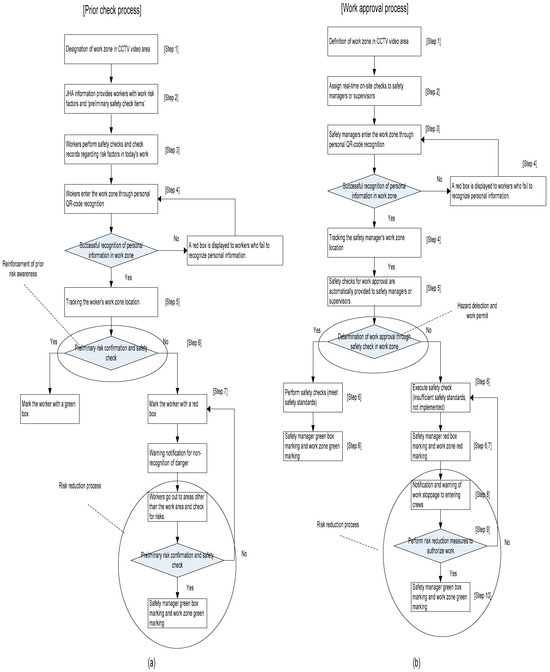

6. Safety Check Process

6.1. Determination Process for Those Who Are Not Aware of Risk

In the work zone, the hazards and risk reduction measures for the current work are defined by the JHA. Workers can be made aware of these risks by checking the JHA in advance. Risk recognition is valid in all cases, before and after entering the work area. However, workers require sufficient time to check the detailed risk factors (or hazards). Thus, it would be more effective to check before entering the work zone—that is, before starting work. If a worker does not perform a risk check before entering the work zone, the system individually warns the worker of the risk by displaying a red box when the worker enters the work zone. The operating sequence of the system that automatically distinguishes whether the worker has previously confirmed or omitted a pre-check in the geofencing work zone is as follows.

Step 1: Setting up a geofencing ‘work zone’ within the CCTV video area.

Step 2: Risk factors (or hazards) for work and ‘preliminary safety check items’ are provided to the relevant workers based on the JHA defined in the work zone before they perform the work.

Step 3: Before starting work or entering the work zone, workers perform safety checks regarding the risk factors (or hazards) of their current work.

Step 4: Workers who have completed the preliminary risk confirmation enter the work zone. The QR code is assigned to an individual construction worker, or the RFID device recognizes the ID of the individual worker.

Step 5: The personal ID of workers entering the CCTV video work area is recognized, and the worker’s location is continuously tracked.

Step 6: The system marks the worker in a green or red box according to the status of the preliminary safety check items given to each worker, whether they meet the safety standards, lack the safety criteria, or do not implement the safety standards.

Step 7: Warning notifications are issued to workers who must implement safety checks. Workers must immediately leave the work area to check for risk factors (or hazards). Workers who have confirmed risk factors (or hazards) through risk warning messages are changed to a green box when they reenter the work zone.

Figure 8a illustrates the system process for classifying risk-unrecognized workers.

Figure 8.

System process of prior safety check (a) and on-site check (b).

6.2. Real-Time On-Site Work Approval Process

In high-risk work, the start of the work must be approved through a safety inspection by a safety manager or supervisor. The on-site checking system can replace traditional work approval procedures with manual documents. This method is highly reliable because real-time onsite checks by workers cannot be performed outside the corresponding work zone. The on-site check button on a smartphone is only activated when the computer vision system recognizes the ID of the supervisor or manager. Supervisors or managers who enter the work zone check the work safety environment and the job preparations of the workers. If they do not meet the safety criteria, the work zone is marked in translucent red by the on-site check button. If work approval is denied and work is stopped, the participant must perform risk-reduction measures and request work approval again from the supervisor. After conducting the risk reduction measures, the supervisor confirms that the safety standards are met, and then puts on-site checks in normal and immediately changes the current work zone from red to transparent. The operating sequence of the real-time warning and notification method for the permission or prohibition of work is as follows.

Step 1: A ‘work zone’ is set up within the CCTV video area.

Step 2: Real-time on-site safety checks are allocated to safety managers or supervisors for work approval.

Step 3: Supervisor or manager IDs are recognized through QR codes or RFID devices assigned to individuals.

Step 4: The location of the safety manager or supervisor entering the work zone is tracked. If a manager’s ID recognition fails, a QR code or RFID recognition request is sent to the manager’s smartphone via a recognition failure notification.

Step 5: Safety checks for work approval are automatically provided to safety managers or supervisors entering the ‘work zone’ via smartphones.

Step 6: The safety manager or supervisor is marked with a green or red box depending on whether the status of the on-site safety check items assigned to him or her is suitable, insufficient, or not implemented.

Step 7: The system monitor displays the work zone in translucent red in cases of inadequate safety level or non-executed safety checks.

Step 8: If work approval is not obtained from the safety manager or supervisor, the work is stopped, and work stoppage warnings and notifications are issued.

Step 9: The work zone requests work approval again after risk reduction measures are implemented or risk removal by the work participants.

Step 10: When relevant work hazards are reduced or eliminated, the safety manager or supervisor grants work approval.

The work zone displays changes from translucent red to transparent. And the red box of the supervisor or safety manager changes to a green box.

Figure 8b illustrates the work approval process using onsite checking.

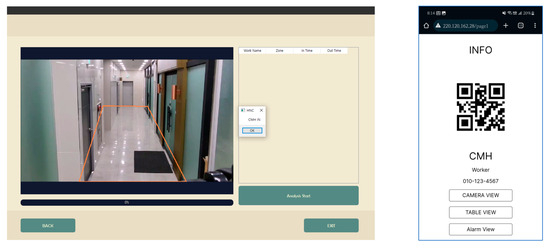

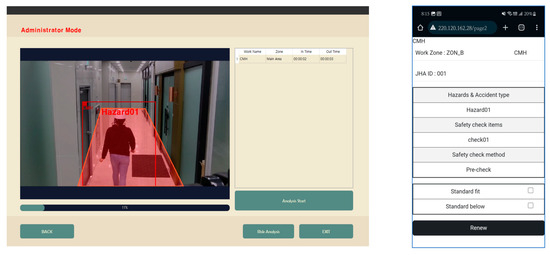

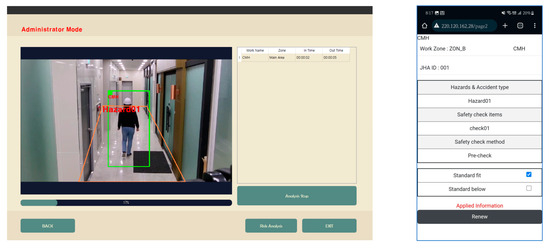

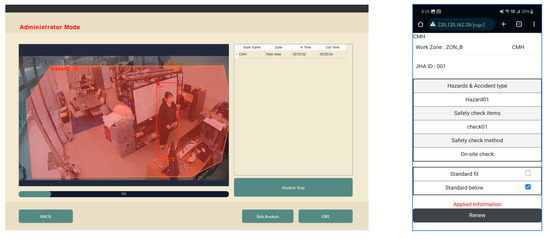

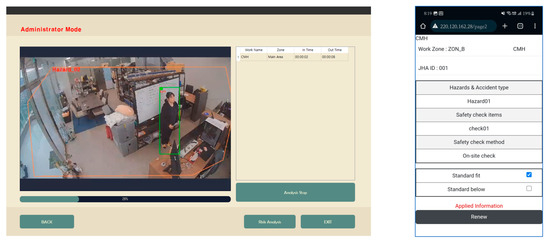

7. System Test

A basic test of the proposed system was conducted in an indoor office. There was no content for the worker’s safety check items, but process verification of the type of safety check was performed. The personal ID was confirmed by recognizing the user’s QR code, and the user’s location tracking time was automatically recorded. The tests verified the basic functions in two ways: preliminary safety and real-time on-site checks. Figure 9, Figure 10, Figure 11, Figure 12 and Figure 13 show photographs captured to check the basic functions of the system.

Figure 9.

Set up geofencing and scan QR code.

Figure 10.

Warning for users who did not perform a prior check.

Figure 11.

A green box is displayed for users whose prior check was performed.

Figure 12.

Warning displayed on monitor due to work stop.

Figure 13.

Normal work performance screen based on work approval.

- The QR code was placed and geofencing was set up on the video footage. Users scan QR codes to transmit personal information to the main computer.

- 2.

- Non-execution of a prior check: A user who has not previously confirmed the JHA sent to the smartphone enters the geofencing area. The user is marked with a red box.

- 3.

- Confirmation that the safety standards of the prior check are met: When a user who has performed a pre-check enters a geofencing area, a green box is displayed.

- 4.

- Insufficient safety criteria in on-site real-time checks: When the user is at the work site, and if the work safety environment is insufficient, the user decides to stop work through the smartphone. The warning screen appears as translucent red.

- 5.

- Meeting safety standards through on-site checks: The user decides to approve work when they confirm that the work environment is safe. Once the work approval is transited, the work zone on the monitor screen changes to a normal transparent area.

8. Application of Construction Safety

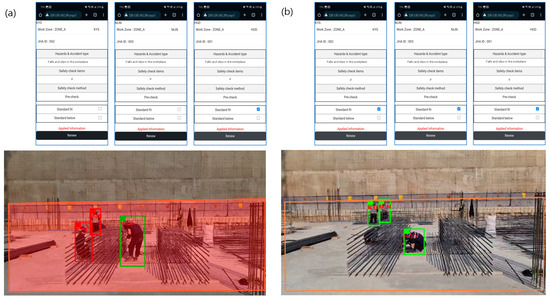

8.1. Prior Safety Check

A safety check simulation of the system was applied to rebar assembly work in reinforced concrete construction and the erection of steel columns in steel construction at construction sites. Each JHA was documented before rebar assembly and steel column erection work. The JHA was matched to the geofencing work zone and a safety checklist based on the JHA was delivered to the relevant worker via a smartphone.

The first simulation case study was an example of classifying workers who were unaware of risks according to the presence or absence of a status that previously confirmed the risk factors (or hazards) of being stabbed by a rebar, colliding with a work tool, or falling in the workplace while assembling the rebar.

Table 1 presents the JHA for rebar assembly operations. The potential risk factors (or hazards) and risk priority number (RPN) that may occur during the rebar assembly stage were defined. The RPN value was calculated based on severity and frequency. The JHA contained risk-reduction and safety-check items for each risk factor (or hazard).

Table 1.

JHA for rebar assembly work on the ground.

Workers must check the risk factors (or hazards) and safety checkpoints of the prepared JHA before entering the work zone. Therefore, the prior recognition of risk factors (or hazards) in rebar assembly work was determined by the presence or absence of JHA confirmation. Figure 14 illustrates the automatic classification of the green and red boxes depending on whether the risk factor (or hazard) (Table 1. (d). Falling or slipping at a rebar assembly workshop) was checked in advance by the corresponding works. In Figure 14a, KYS and MJN are marked with a red box because they were not pre-checked, and HGD is marked with a green box because it was pre-checked. In Figure 14b, KYS and MJN were changed to green boxes because they performed the duty of pre-checking after the red notification warning.

Figure 14.

Case of distinguishing between confirmed and unconfirmed risk factors (d) of Table 1.

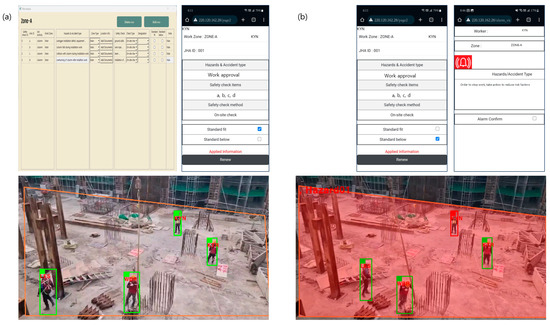

8.2. On-Site Safety Check

The second case study was an example of work approval and stoppage for steel-column erection work. Table 2 lists the JHA values for the steel erection operations. Four representative risk factors (or hazards), RPN, and risk reduction measures were documented in steel-frame erection work. If risk factors (or hazards) were discovered during the steel-frame erection work, or if safety measures did not meet the standards, the supervisor decided to stop work. Figure 15b shows an example where a supervisor decides to stop work after detecting a work risk factor item (d: wire ropes that were not inspected regularly) and issues a risk warning. The supervisor used a smartphone to check the work environment, which did not meet the safety criteria. The supervisor in the CCTV video immediately changed to a red box, and the work zone was marked with an opaque red warning sign. Figure 15 illustrates a simulation example of (a) work approval and (b) work stoppage for steel-frame erection.

Table 2.

JHA for steel erection work.

Figure 15.

Case of work approval through supervisor checking safety criteria (a) and case of steel frame erection work stoppage (b).

8.3. Case Study Discussion

Case studies were undertaken on two fronts. Firstly, a random work zone was established inside a building to verify the functionalities of preliminary safety checks and real-time safety checks. Workers who executed the safety check correctly were represented in a green box, while those with insufficient safety checks were indicated in a red box or red area. The experiment yielded successful results. Secondly, work scenarios at real construction sites were recorded, and worker IDs were randomly assigned based on the recorded data. If a random worker performed the safety check improperly, it was marked as a red box, and if a random worker performed the safety check normally, it was marked as a green box.

This process entails administrators manually inputting worker information. When the manager directly inputs whether a worker has completed the safety check, the system automatically displays the results using green boxes for those who have completed it and red boxes for those who have not. This case study validates the effectiveness of the location-based safety check system in enhancing workers’ risk awareness. Additionally, the system uses real-time safety checks to suggest that real-time record management and risk sharing are possible beyond the limits of formal safety checks. However, because case studies are very formal and based on strict controls, the free format of risk communication and the effectiveness of risk situations remain to be improved. The developed safety check system does not ensure safety for all types of accidents and operations within the industry. It can be used as a tool for accident prevention by combining JHA and the work location of individual workers, limited to the work site where JHA is performed. Three safety experts with over 10 years of experience validated the functionality of this system. They not only furnished formal documents on risk analysis, such as JHA and FMEA, but also proposed various risk reduction methods, including LMRA (Last Minute Risk Assessment) that enable immediate risk recognition and risk response. The need to expand the location-based safety check system was also discussed.

9. Conclusions

The risk reduction approach in this study involves proactive risk assessment and preemptive risk warnings. These two risk reduction measures were identified through system testing. The case study aimed to enhance workers’ risk perception and awareness by introducing a location-tracking-based safety check system. Additionally, it provided formal avenues for risk reduction through a work approval process for high-risk tasks. The safety check system validated two fundamental functions. First, the system alerted workers about potential hazards before commencing work, providing an optimal opportunity to be reminded of risk factors (or hazards) when engaging in hazardous tasks. Second, when a supervisor identified a risk factor (hazard) at a work site, a danger warning was issued to the work zone through a stop-work order. Implementing stop-work orders contributes to maintaining safe work environments. The outcomes of this study serve as an effective tool for accident prevention in high-risk workplaces.

Nevertheless, construction sites demand network-based simultaneous management methods employing multiple monitors and computers. The proposed system was implemented in an area designated as a work zone. Construction sites perform multiple tasks daily and simultaneously at multiple workplaces. Although case studies are limited in their ability to monitor multiple sites, the system experimentally tested the basic functions of safety checks in one work zone and monitoring was successfully completed. The preliminary safety check and on-site check methods of the system can be applied to monitor various situations and check safety standards at construction sites.

Despite the innovative method of location tracking-based safety checks proposed in this study, the accuracy and efficiency of ID recognition technology in cases of multiple workers remains challenging and should be focused on in future studies. Because this study was limited to two types of safety checks, follow-up research will propose more efficient risk communication technologies that do not require a specific format for safety checks. Furthermore, because safety management at industrial sites involves many safety check items and communication in a free format between various participants, this study showed that the use of standardized and formalized safety checks was very limited.

The ultimate direction of technological improvement achieved through this research is an efficient communication environment for real-time ID recognition and safety checks for multiple workers. This study derived basic results on risk communication at construction sites and is expected to be widely applied in safety management through the integration of information technology.

Author Contributions

Conceptualization, Y.H. and J.C.; methodology, J.C.; validation, Y.H.; formal analysis, J.C.; investigation, Y.H.; resources, Y.H. and J.C.; data curation, Y.H.; writing—original draft preparation, Y.H.; writing—review and editing, J.C.; visualization, Y.H.; supervision, J.C.; project administration, J.C.; funding acquisition, Y.H. and J.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (No. 2021R1F1A1062639).

Data Availability Statement

The data presented in this study are available on request from the corresponding author. Restrict commercial use of the data.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mohammed, I.I.; Osama, I.; Ibrahim, A.R.; Shamsuddin, K.; Ali, A. Hazard identification and risk assessment with controls (Hirac) in oil industry—A proposed approach. Mater. Proc. 2021, 44, 4898–4902. [Google Scholar] [CrossRef]

- Jukka, H.; Iris, K.; Urho, P.; Veli-Matti, V.; Markku, T. Risk management processes in supplier networks. Int. J. Prod. Econ. 2004, 90, 1. [Google Scholar] [CrossRef]

- Damrong, C.; Bonaventura, H.W.H.; Chotchai, C.; Steve, R. 4D CAD-safety: Visualizing project scheduling and safety planning. Constr. Innov. 2005, 5, 99–114. [Google Scholar] [CrossRef]

- Sijie, Z.; Jochen, T.; Jin-Kook, L.; Charles, M.E.; Manu, V. Building Information Modeling (BIM) and Safety: Automatic Safety Checking of Construction Models and Schedules. Autom. Constr. 2013, 29, 183–195. [Google Scholar] [CrossRef]

- Jeewoong, P.; Kyungki, K.; Yong, K.C. Framework of Automated Construction-Safety Monitoring Using Cloud-Enabled BIM and BLE Mobile Tracking Sensors. J. Constr. Eng. Manag. 2016, 143, 2. [Google Scholar] [CrossRef]

- Alex, A.; Matthew, R.H.; Brian, K.; Ao, C.; Mani, G.F. Enhancing construction hazard recognition with high-fidelity augmented virtuality. J. Constr. Eng. Manag. 2014, 140, 7. [Google Scholar] [CrossRef]

- Helen, L.; Payam, P.; David, O. Talking Safety: Health and Safety Communication and Safety Climate in Subcontracted Construction Workgroups. J. Constr. Eng. Manag. 2019, 145, 5. [Google Scholar] [CrossRef]

- Nini, X.; Yuchun, T.; Dezhi, L.; Ao, P. Safety Behavior among Construction Workers: Influences of Personality and Leadership. J. Constr. Eng. Manag. 2021, 147, 4. [Google Scholar] [CrossRef]

- Nai-Wen, C.; Ken-Yu, L.; Shang-Hsien, H. Using ontology-based text classification to assist Job Hazard Analysis. Adv. Eng. Inform. 2014, 28, 381–394. [Google Scholar] [CrossRef]

- U.S. Department of Labor. Job Hazard Analysis; OSHA 3071; OSHA: Washington, DC, USA, 2002. [Google Scholar]

- Idris, J.; Khashayar, A.; Hariharan, R.; Kevin, H.; Alex, A. Real-time vision-based worker localization & hazard detection for construction. Autom. Constr. 2021, 121, 103448. [Google Scholar] [CrossRef]

- Sijie, Z.; Frank, B.; Jochen, T. Ontology-based semantic modeling of construction safety knowledge: Towards automated safety planning for job hazard analysis (JHA). Autom. Constr. 2015, 52, 29–41. [Google Scholar] [CrossRef]

- Ying, L.; Qiming, L.; Zhipeng, Z.; Yongliang, D. Ontology-based knowledge modeling for automated construction safety checking. Saf. Sci. 2015, 79, 11–18. [Google Scholar] [CrossRef]

- Rajkumar, I.; Subash, K.; Raj, P.T.; Manikandan, R.; Ramaganesh, M. Job safety hazard identification and risk analysis in the foundry division of a gear manufacturing industry. Mater. Proc. 2012, 46, 7783–7788. [Google Scholar] [CrossRef]

- Yuganthini, P.; Vigneswari, A.; Jancy, S.; AntoPraveena, M.D. Activity Tracking of Employees in Industries using Computer Vision. In Proceedings of the 2021 5th International Conference on Trends in Electronics and Informatics (ICOEI), Tirunelveli, India, 3–5 June 2021. [Google Scholar] [CrossRef]

- Leonardo, C.; Rosalia, C.; Davide, D.B.; Michele, O. A geofencing-based methodology for speed limit regulation and user safety in e-scooter sharing systems. J. Intell. Transp. Syst. 2023, 1–16. [Google Scholar] [CrossRef]

- Chukwuma, N.; Ibukun, A.; JeeWoong, P.; Alex, A. Wearable Sensing Devices: Towards the Development of a Personalized System for Construction Safety and Health Risk Mitigation. Sensors 2021, 21, 682. [Google Scholar] [CrossRef]

- Vladimir, M.; Igor, P.; Jasmina, D.; Goran, Ć.; Milan, T.; Dragana, B. Construction Workers Injury Risk Assessment in Relation to their Experience and Age. Procedia Eng. 2015, 117, 525–533. [Google Scholar] [CrossRef]

- Levitt, R.; Samelson, M.N. Construction Safety Management; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1993. [Google Scholar]

- Alex, A.; Matthew, R.H.; Michael, S.; Brian, K. Empirical measurement and improvement of hazard recognition skill. Saf. Sci. 2017, 93, 1–8. [Google Scholar] [CrossRef]

- Qian, W. Automatic checks from 3D point cloud data for safety regulation compliance for scaffold work platforms. Autom. Constr. 2019, 104, 38–51. [Google Scholar] [CrossRef]

- Han-Hsiang, W.; Frank, B. Ontology-based representation and reasoning framework for supporting job hazard analysis. J. Comput. Civ. Eng. 2011, 25, 442–456. [Google Scholar] [CrossRef]

- Jongjin, J. A Study on the Preparation of Criteria for Selection of High-Risk Workers in the Construction Industry. Master’s Thesis, Kyung Hee University, Gyeonggi-do, Republic of Korea, 2022. [Google Scholar]

- Shuai, L.; Shichen, H.; Shuai, W.; Khan, M.; Paolo, B.; Javier, D.S. Visual tracking in complex scenes: A location fusion mechanism based on the combination of multiple visual cognition flows. Inf. Fusion 2023, 96, 281–296. [Google Scholar] [CrossRef]

- Bo, X.; Hairong, X.; Jingwen, W.; Yuan, C. Vision-based method for tracking workers by integrating deep learning instance segmentation in off-site construction. Autom. Constr. 2022, 136, 104148. [Google Scholar] [CrossRef]

- Ohay, A.; Albert, Y.C. Tracking multiple construction workers through deep learning and the gradient based method with re-matching based on multi-object tracking accuracy. Autom. Constr. 2020, 119, 103308. [Google Scholar] [CrossRef]

- Manwoo, P.; Ioannis, B. Continuous localization of construction workers via integration of detection and tracking. Autom. Constr. 2016, 72, 129–142. [Google Scholar] [CrossRef]

- Manwoo, P.; Ioannis, B. Construction worker detection in video frames for initializing vision trackers. Autom. Constr. 2012, 28, 15–25. [Google Scholar] [CrossRef]

- Yongju, L.; Manwoo, P. 3D tracking of multiple onsite workers based on stereo vision. Autom. Constr. 2019, 98, 146–159. [Google Scholar] [CrossRef]

- Eirini, K.; Joan, L.; Ioannis, B. Adaptive computer vision-based 2D tracking of workers in complex environments. Autom. Constr. 2019, 103, pp. 168–184. [Google Scholar] [CrossRef]

- Jinsun, L.; Ki-Il, S.; Hanglo, L. Real-Time Location Tracking of Multiple Construction Laborers. Sensors 2016, 16, 11. [Google Scholar] [CrossRef]

- Bo, X.; Zhenhua, Z. Two-dimensional visual tracking in construction scenarios: A comparative study. J. Comput. Civ. Eng. 2018, 32, 3. [Google Scholar] [CrossRef]

- Heng, L.; Greg, C.; Johnny, K.W.W.; Martin, S. Real-time locating systems applications in construction. Autom. Constr. 2016, 63, 37–47. [Google Scholar] [CrossRef]

- Ran, W.; Peter, E.D.L.; Weili, F.; Hanbin, L.; Shuangjie, X. Recognizing people’s identity in construction sites with computer vision: A spatial and temporal attention pooling network. Adv. Eng. Inform. 2019, 42, 100981. [Google Scholar] [CrossRef]

- Lipi, M.; Soungho, C.; Yaowen, Y. Identifying productive working patterns at construction sites using BLE sensor networks. Dev. Built Environ. 2020, 4, 100025. [Google Scholar] [CrossRef]

- Sungjoo, H.; Joonoh, S.; Houtan, J.; Sanghyun, L. Feasibility analysis of heart rate monitoring of construction workers using a photoplethysmography (PPG) sensor embedded in a wristband-type activity tracker. Autom. Constr. 2016, 71, 372–381. [Google Scholar] [CrossRef]

- Nazi, S.; Sanaz, S.; Carol, K.H.H.; Fariba, M.K. Real-time locating systems and safety in construction sites: A literature review. Saf. Sci. 2019, 117, 229–242. [Google Scholar] [CrossRef]

- Xuewei, L.; Dujuan, Y.; Jingfeng, Y.; Alex, D.; Xuan, L. BIM-enabled semantic web for automated safety checks in subway construction. Autom. Constr. 2022, 141, 104454. [Google Scholar] [CrossRef]

- Sijie, Z.; Jinkook, L.; Manu, V.; Jochen, T.; Charles, M.E. A Framework for Automatic Safety Checking of Building Information Models. In Proceedings of the Construction Research Congress, Lafayette, IN, USA, 21–23 May 2012. [Google Scholar] [CrossRef]

- David, T.G.; Paul, H.P.Y. IT-assisted equipment safety checks system to improve compliance: A case study at a distribution center. Saf. Sci. 2013, 60, 77–86. [Google Scholar] [CrossRef]

- Yuexiong, D.; Muyang, L.; Xiaowei, L. Safety compliance checking of construction behaviors using visual question answering. Autom. Constr. 2022, 144, 104580. [Google Scholar] [CrossRef]

- Roshana, T.; Muhammad, H.Z.; Abdul, H.N. Integration of Automated Safety Rule Checking (ASRC) System for Safety Planning BIM-Based Projects in Malaysia. Procedia Soc. Behav. Sci. 2016, 222, 103–110. [Google Scholar] [CrossRef][Green Version]

- Weili, F.; Peter, E.D.L.; Hanbin, L.; Lieyun, D. Computer vision for behaviour-based safety in construction: A review and future directions. Adv. Eng. Inform. 2020, 43, 100980. [Google Scholar] [CrossRef]

- Wenyao, L.; Qingfeng, M.; Zhen, L.; Xin, H. Applications of Computer Vision in Monitoring the Unsafe Behavior of Construction Workers: Current Status and Challenges. Buildings 2021, 11, 9. [Google Scholar] [CrossRef]

- Kareem, M.; Tarek, H. Review of image-based analysis and applications in construction. Autom. Constr. 2021, 122, 14. [Google Scholar] [CrossRef]

- Hong, Z.; Xuzhong, Y.; Heng, L.; HongFeng, F. Real-Time Alarming, Monitoring, and Locating for Non-Hard-Hat Use in Construction. J. Constr. Eng. Manag. 2019, 145, 3. [Google Scholar] [CrossRef]

- Chi, S.H.; Carlos, H.C. Image-Based Safety Assessment: Automated Spatial Safety Risk Identification of Earthmoving and Surface Mining Activities. J. Constr. Eng. Manag. 2011, 138, 341–351. [Google Scholar] [CrossRef]

- Yuan, C.X.; Li, S.; Cai, H.B. Vision-Based Excavator Detection and Tracking Using Hybrid Kinematic Shapes and Key Nodes. J. Comput. Civ. Eng. 2016, 31, 1. [Google Scholar] [CrossRef]

- Bahaa, E.M.; Mohamad, A.; Hiam, K. Automated hardhat detection for construction safety applications. Procedia Eng. 2017, 196, 895–902. [Google Scholar] [CrossRef]

- Qi, F.; Heng, L.; Xiaochun, L.; Lieyun, D.; Hanbin, L.; Timothy, M.R.; Wangpeng, A. Detecting non-hardhat-use by a deep learning method from far-field surveillance videos. Autom. Constr. 2018, 85, 1–9. [Google Scholar] [CrossRef]

- Kishor, S.; Pramen, P.S.; Dinesh, B.; Evangelos, A.Y. Hard-hat detection for construction safety visualization. J. Constr. Eng. 2015, 2015, 1. [Google Scholar] [CrossRef]

- Weili, F.; Lieyun, D.; Peter, E.D.L.; Hanbin, L.; Heng, L.; Feniosky, P.M.; Botao, Z.; Cheng, Z. Computer vision applications in construction safety assurance. Autom. Constr. 2020, 110, 10. [Google Scholar] [CrossRef]

- Weili, F.; Botao, Z.; Neng, Z.; Peter, E.D.L.; Hanbin, L.; Jiayue, X.; Shuangjie, X. A deep learning-based approach for mitigating falls from height with computer vision: Convolutional neural network. Adv. Eng. Inform. 2019, 39, 170–177. [Google Scholar] [CrossRef]

- Weili, F.; Lieyun, D.; Hanbin, L.; Peter, E.D.L. Falls from heights: A computer vision-based approach for safety harness detection. Autom. Constr. 2018, 91, 53–61. [Google Scholar] [CrossRef]

- Seulki, L.; Jungho, Y. Ontological inference process using AI-based object recognition for hazard awareness in construction sites. Autom. Constr. 2023, 153, 104961. [Google Scholar] [CrossRef]

- Kenji, K.; Jun, M.; Emanuele, M. A PorTable 3D LIDAR-based System for Long-term and Wide-area People Behavior Measurement. IJARS 2019, 16, 2. [Google Scholar] [CrossRef]

- Hongling, G.; Yantao, Y.; Qinghua, D.; Martin, S. Image-and-Skeleton-Based Parameterized Approach to Real-Time Identification of Construction Workers’ Unsafe Behaviors. JCEM 2018, 144, 6. [Google Scholar] [CrossRef]

- Yantao, Y.; Hongling, G.; Qinghua, D.; Heng, L.; Martin, S. An experimental study of real-time identification of construction workers’ unsafe behaviors. Autom. Constr. 2017, 82, 193–206. [Google Scholar] [CrossRef]

- Sanguk, H.; Sanghyun, L. A vision-based motion capture and recognition framework for behavior-based safety management. Autom. Constr. 2013, 35, 131–141. [Google Scholar] [CrossRef]

- Peilin, L.; Fan, W.; Shuhua, X.; Liangjie, G. Study on the Interaction Behaviors Identification of Construction Workers Based on ST-GCN and YOLO. Sensors 2023, 23, 14. [Google Scholar] [CrossRef]

- Hongling, G.; Zhitian, Z.; Run, Y.Y.S.; Heng, L. Action Recognition Based on 3D Skeleton and LSTM for the Monitoring of Construction Workers’ Safety Harness Usage. J. Constr. Eng. Manag. 2023, 149, 4. [Google Scholar] [CrossRef]

- Gregory, C.; Simon, D.S. Safety hazard identification on construction projects. J. Constr. Eng. Manag. 2006, 132, 197–205. [Google Scholar] [CrossRef]

- Susanne, B. Workplace hazard identification and management: The case of an underground mining operation. Saf. Sci. 2013, 57, 129–137. [Google Scholar] [CrossRef]

- Alex, A.; Matthew, R.H.; Brian, M.K. Enhancing construction hazard recognition and communication with energy-based cognitive mnemonics and safety meeting maturity model: Multiple baseline study. J. Constr. Eng. Manag. 2014, 140, 2. [Google Scholar] [CrossRef]

- Idris, J. Personalized Hazard Recognition Training for Construction Workers. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2016. [Google Scholar]

- Idris, J.; Alex, A.; Kevin, H.; Roger, A. Are visual search patterns predictive of hazard recognition performance? Empirical investigation using eye-tracking technology. J. Constr. Eng. Manag. 2019, 145, 1. [Google Scholar] [CrossRef]

- Loosemore, M.; Malouf, N. Safety training and positive safety attitude formation in the Australian construction industry. Saf. Sci. 2019, 113, 233–243. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).