Stabilization of Different Soil Types Using a Hydraulic Binder

Abstract

1. Introduction

2. Materials and Methods

2.1. Component Materials

2.2. Methods

- Consistency testing;

- Proctor compaction test;

- UCS test;

- CBR test;

- ITS test.

2.2.1. Consistency

2.2.2. Proctor Compaction Test

2.2.3. CBR Test

2.2.4. UCS Test

2.2.5. ITS Test

3. Results and Discussion

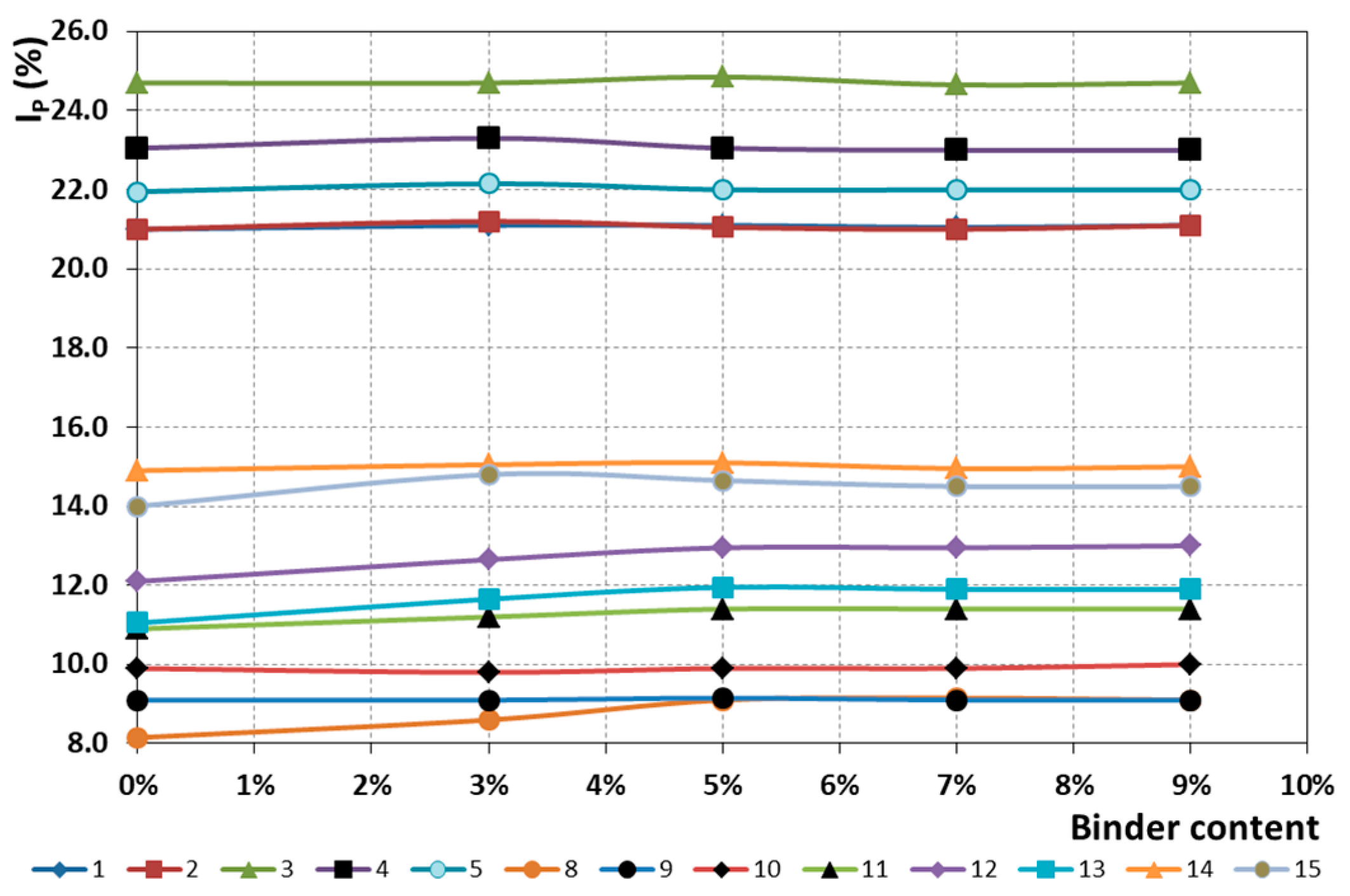

3.1. Consistency Limits

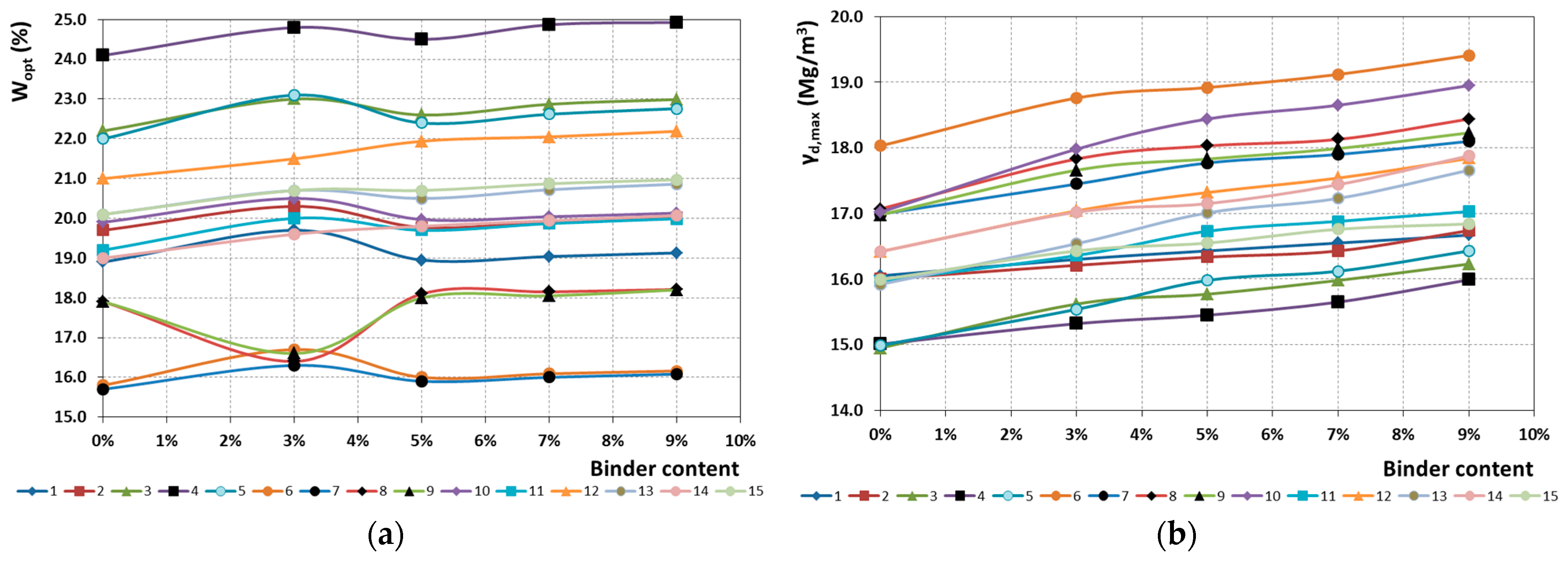

3.2. Compaction Characteristics (Proctor Compaction Test)

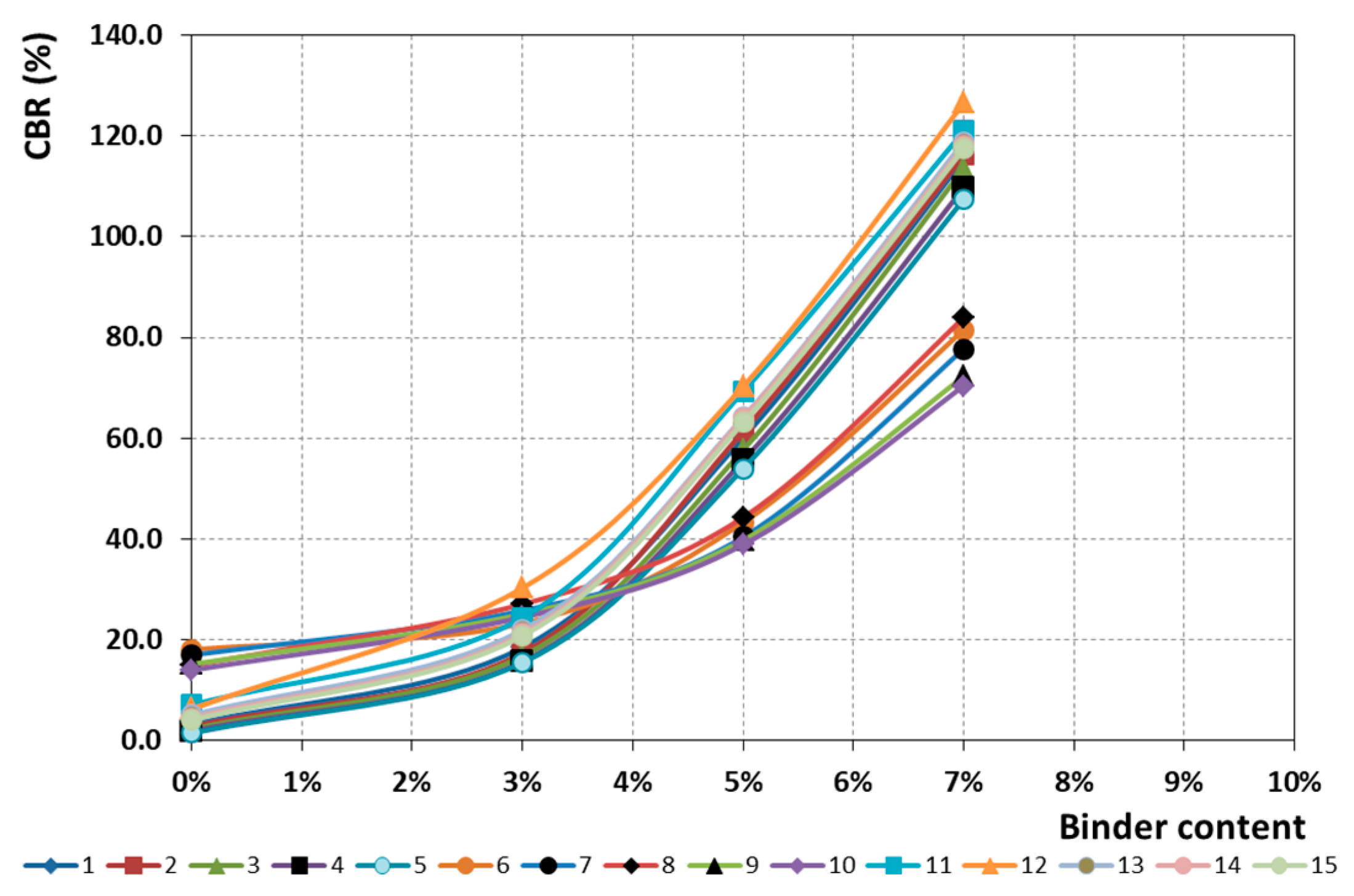

3.3. Bearing Capacity—California Bearing Ratio (CBR)

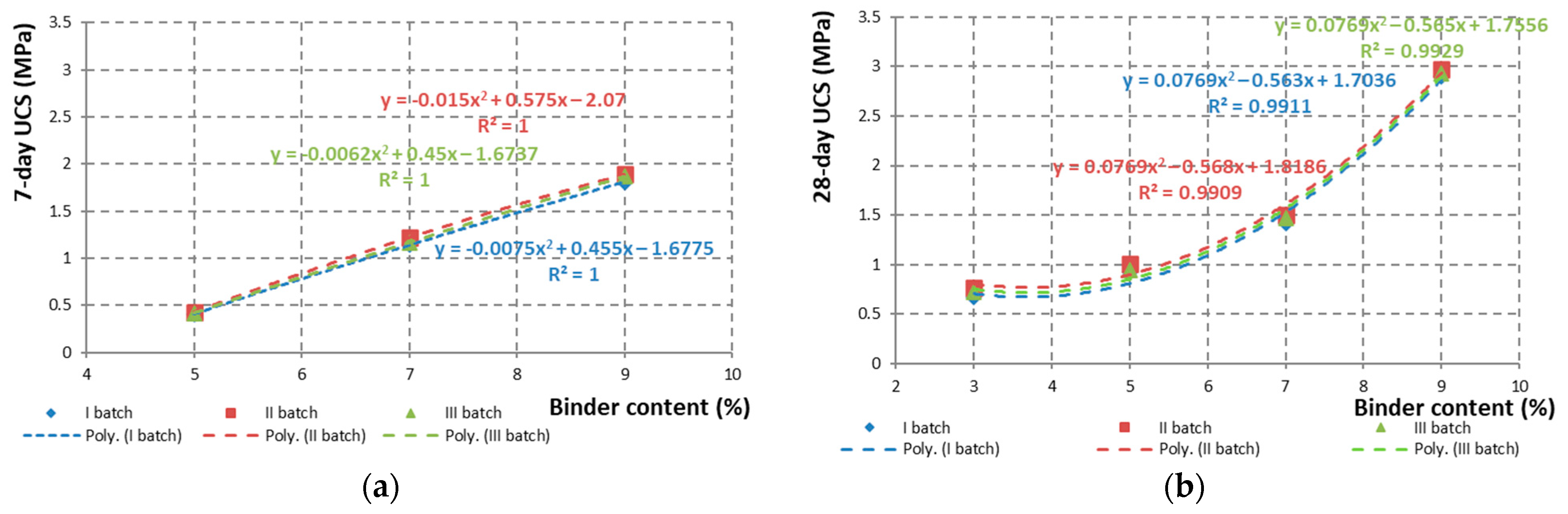

3.4. Unconfined Compressive Strength (UCS)

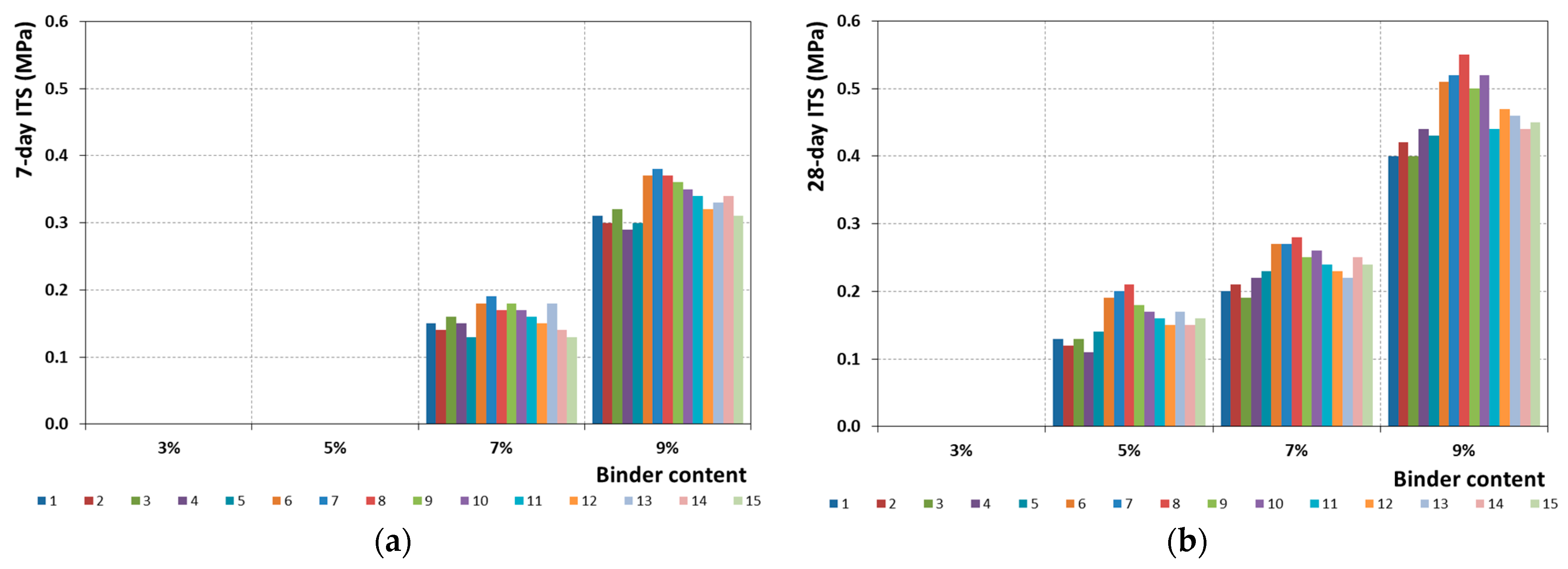

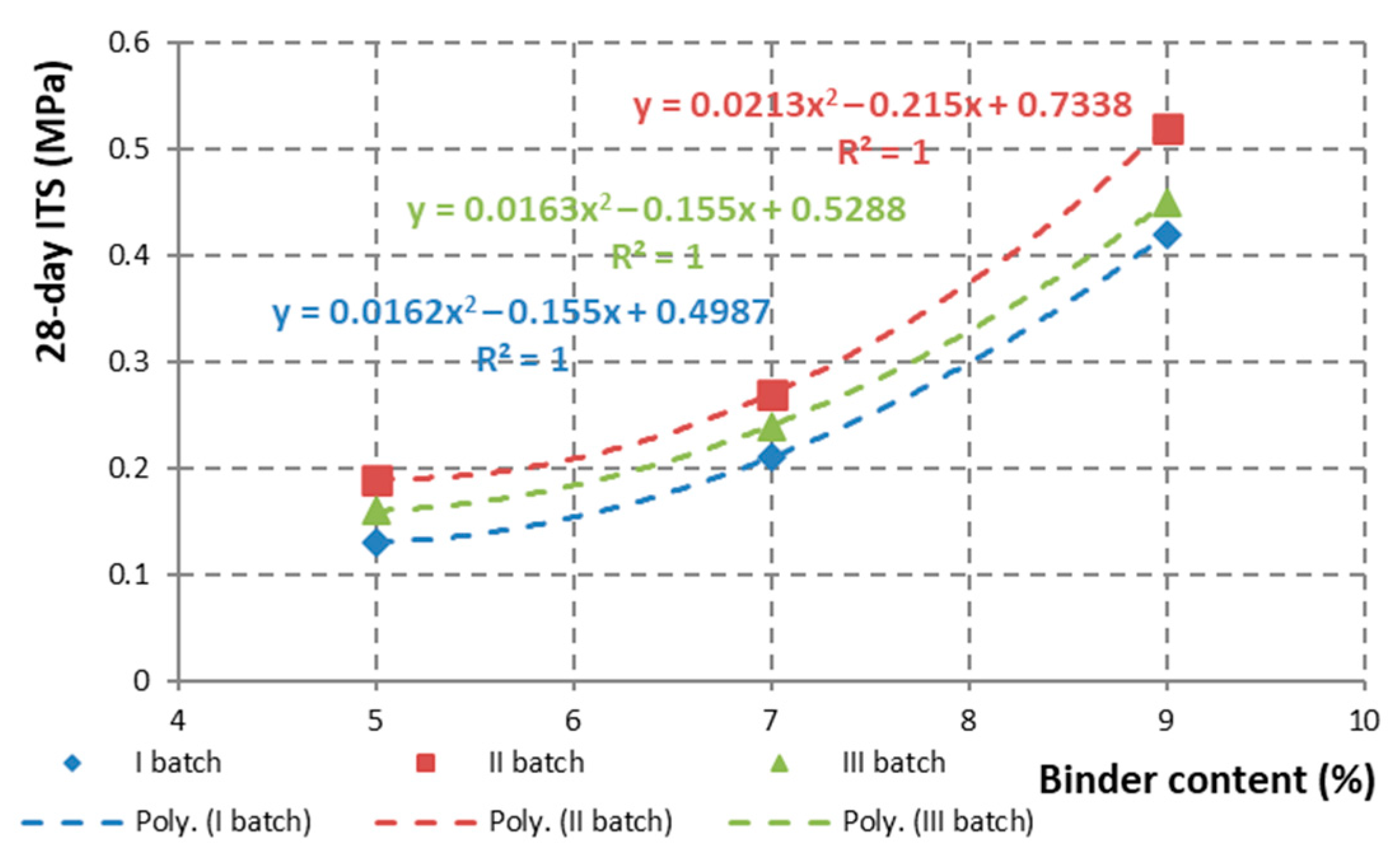

3.5. Indirect Tensile Strength (ITS)

3.6. Comparison of Obtained Results with Other Literature Data

4. Conclusions

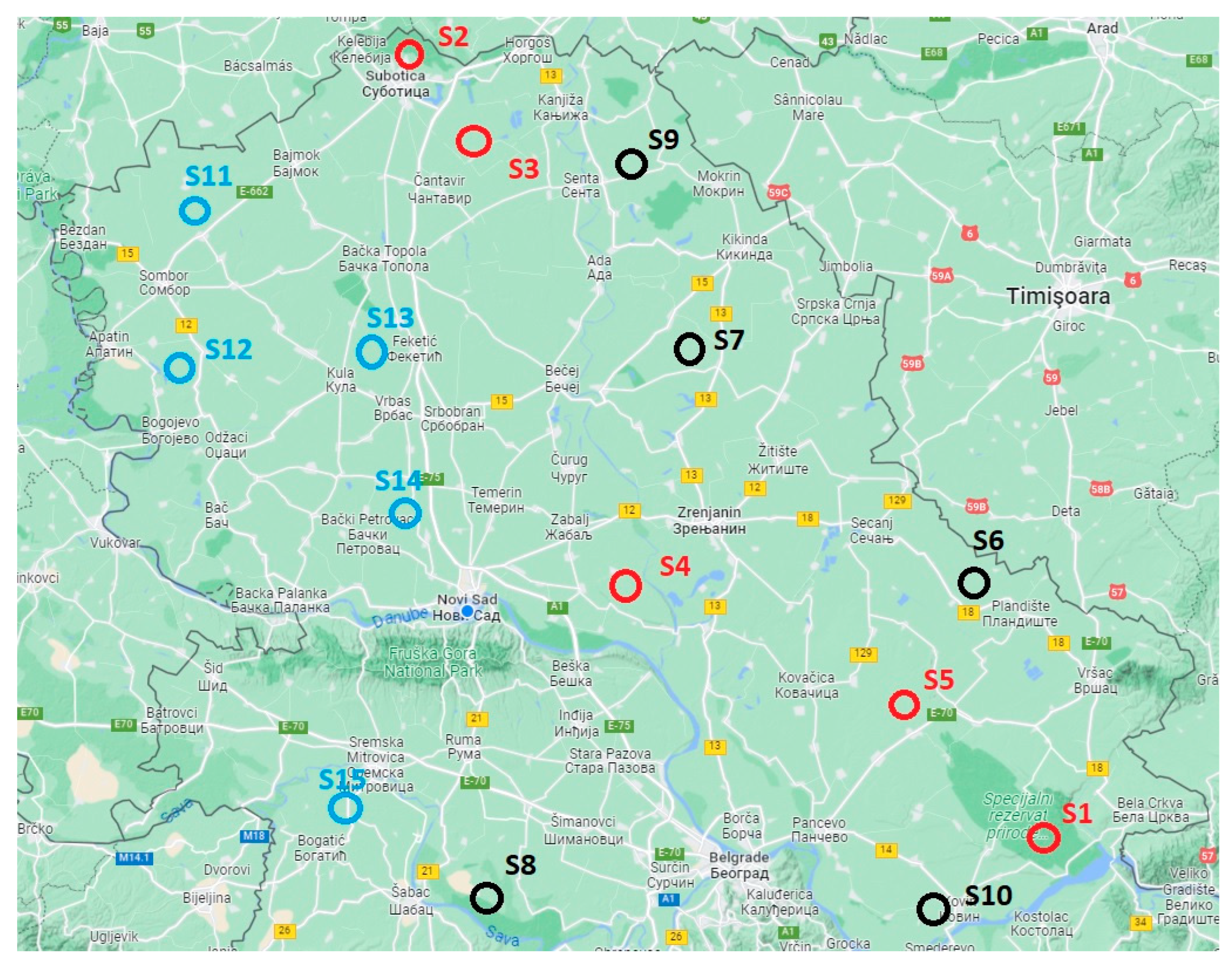

- The soil samples were classified into three groups (i.e., batches) according to the granulometric composition: (i) the dusty clay materials (cohesive soils), (ii) the sandy materials with much less clay particles (non-cohesive soils), and (iii) the clays of low plasticity or the so-called loess material (cohesive soils). Soil samples were sampled and examined in order to cover the entire area of Vojvodina and to obtain basic data on the possible stabilization of the soil subgrade, which is of great importance for planning the road network.

- Increasing the amount of binder did not significantly affect the consistency of the stabilized soils, but the results had a gradual growth trend.

- The Proctor’s compaction test results showed that increasing the amount of binder led to an increase in γd,max, and in most of cases an increase in Wopt, except for soil–binder specimens with a sandy component, where certain oscillations occurred in the results.

- The bearing capacity of the soil–binder specimens was evaluated by CBR, where specimens were tested only for pressing pistons up to 2.54 mm. The maximum CBR values with 5 and 7% had the mixtures with loess soils, and the minimum values belonged to the mixtures with sandy soils. With an increase in the binder content there was an increase in the bearing capacity of the stabilized soils. In the case of the specimens that had a binder addition of 9%, the CBR could not be determined, because the press could not apply enough pressure on those specimens, which confirmed that these materials had CBR > 300%, i.e., corresponding to the maximum limit of the press.

- USC values depended primarily on the curing time of the soil–binder specimens, then on the percentage of added hydraulic binder, and least on the type of used soil. The 7-day UCS values of the specimens containing 3% binder could not be determined, while with binder contents from 5 to 9%, a polynomial increase with very strong correlation (R2 = 1) in UCS was observed regardless of the applied soil type. With binder contents from 3 to 9%, a similar conclusion was observed in the 28-day UCS, again regardless of the applied soil type.

- The amount of binder had a dominant effect on the ITS of soil–binder specimens, followed by the length of specimen curing time, and the type of used soil, respectively. The ITS could not be determined for mixtures with 3 and 5% binder after 7 days of curing or for the mixture with 3% binder after 28 days of curing. Generally, ITS values increased with increasing binder content and increasing curing time of the mixture, and the highest ITS values were obtained for soil–binder mixtures that contained sandy components.

- Based on the presented results, stabilization can be recommended for different types of soils from a total of 15 different locations in Vojvodina with a hydraulic binder added in the amount of 3–9%, as well as their further usage as a subgrade. It is necessary to conduct additional soil stabilization tests with different amounts of hydraulic binder in order to obtain a more complete picture of the relevant data for the area where the construction of the specific road is planned and to determine the optimum binder content in that particular case.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yorulmaz, A.; Sivrikaya, O.; Uysal, F. Evaluation of the bearing capacity of poor subgrade soils stabilized with waste marble powder according to curing time and freeze-thaw cycles. Arab. J. Geosci. 2021, 14, 360. [Google Scholar] [CrossRef]

- IRC:SP:89; Guidelines for Soil and Granular Material Stabilization Using Cement, Lime and Fly Ash. Indian Road Congress: New Delhi, India, 2010.

- Wei, J.; Wei, J.; Huang, Q.; Sheikh Abidin, M.I.B.S.Z.; Zou, Z. Mechanism and Engineering Characteristics of Expansive Soil Reinforced by Industrial Solid Waste: A Review. Buildings 2023, 13, 1001. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Jiang, N.J.; Tang, C.S.; Hata, T.; Courcelles, B.; Dawoud, O.; Singh, D.N. Bio-mediated soil improvement: The way forward. Soil Use Manag. 2020, 36, 185–188. [Google Scholar] [CrossRef]

- Bhattacharja, S.; Bhatty, J.I.; Todres, H.A. Stabilization of Clay Soils by Portland Cement or Lime—A Critical Review of Literature. Portland Cem. Assoc. Res. Dev. Inf. 2003, 60, 124–133. [Google Scholar]

- Lebo, Ž.; Bačić, M.; Jurić Kaćunić, D.; Kovačević, M.S. Zagreb clay improved with various binders. Građevinar 2021, 73, 871–880. [Google Scholar] [CrossRef]

- Caselles, L.D.; Hot, J.; Roosz, C.; Cyr, M. Stabilization of soils containing sulfates by using alternative hydraulic binders. Appl. Geochem. 2020, 113, 104494. [Google Scholar] [CrossRef]

- Wang, L.; Roy, A.; Seals, R.; Metcalf, J. Stabilization of sulfate-containing soil by cementitious mixtures mechanical properties. Transp. Res. Rec. 2003, 1837, 12–19. [Google Scholar] [CrossRef]

- Kota, P.B.V.S.; Hazlett, D.; Perrin, L. Sulfate-bearing soils: Problems with calcium-based stabilizers. Transp. Res. Rec. 1996, 1546, 62–69. [Google Scholar] [CrossRef]

- Harris, P.; von Holdt, J.; Sebesta, S.; Scullion, T. Recommendations for stabilization of high-sulfate soils in Texas. Transp. Res. Rec. J. Transp. Res. Board 2006, 1952, 71–79. [Google Scholar] [CrossRef]

- Mishra, P.; Shukla, S.; Mittal, A. Stabilization of subgrade with expansive soil using agricultural and industrial By-products: A review. Mater. Today Proc. 2022, 65, 1418–1424. [Google Scholar] [CrossRef]

- Tanzadeh, R.; Vafaeian, M.; Fard, M.Y. The influence of lime powder on the behaviour of clay soil. Građevinar 2021, 73, 907–915. [Google Scholar] [CrossRef]

- Baldovino, J.A.; Moreira, E.B.; Teixeira, W.; Izzo, R.L.S.; Rose, J.L. Effects of lime addition on geotechnical properties of sedimentary soil in Curitiba, Brazil. J. Rock Mech. Geotech. Eng. 2018, 10, 188–194. [Google Scholar] [CrossRef]

- Ghobadi, M.H.; Abdilor, Y.; Babazadeh, R. Stabilization of clay soils using lime and effect of pH variations on shear strength parameters. Bull. Eng. Geol. Environ. 2014, 73, 611–619. [Google Scholar] [CrossRef]

- Negawo, W.J.; Di Emidio, G.; Bezuijen, A.; Verastegui Flores, R.D.; François, B. Lime-stabilisation of high plasticity swelling clay from Ethiopia. Eur. J. Environ. Civ. Eng. 2019, 23, 504–514. [Google Scholar] [CrossRef]

- Okonkwo, U.N.; Kennedy, C. The Effectiveness of Cement and Lime as Stabilizers for Subgrade Soils with High Plasticity and Swelling Potential. Saudi J. Civ. Eng. 2023, 7, 40–60. [Google Scholar] [CrossRef]

- Khemissa, M.; Mahamedi, A. Cement and lime mixture stabilization of an expansive overconsolidated clay. Appl. Clay Sci. 2014, 95, 104–110. [Google Scholar] [CrossRef]

- Rai, P.; Qiu, W.; Pei, H.; Chen, J.; Ai, X.; Liu, Y.; Ahmad, M. Effect of Fly Ash and Cement on the Engineering Characteristic of Stabilized Subgrade Soil: An Experimental Study. Hindawi Geofluids 2021, 2021, 1368194. [Google Scholar] [CrossRef]

- Makusa, G.P. Soil Stabilization Methods and Materials in Engineering Practice: State of the Art Review. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2012; pp. 1–35. [Google Scholar]

- Ahmad, A.; Sutanto, M.H.; binti Ahmad, N.R.; Bujang, M.; Mohamad, M.E. The Implementation of Industrial Byproduct in Malaysian Peat Improvement: A Sustainable Soil Stabilization Approach. Materials 2021, 14, 7315. [Google Scholar] [CrossRef]

- Barišić, I.; Netinger Grubeša, I.; Dokšanović, T.; Marković, B. Feasibility of Agricultural Biomass Fly Ash Usage for Soil Stabilisation of Road Works. Materials 2019, 12, 1375. [Google Scholar] [CrossRef]

- Hydraulically Treated Soils in Residential Construction. Available online: https://www.nhbc.co.uk/binaries/content/assets/nhbc/foundation/rr12-hydraulically-treated-soils-in-residential-construction.pdf (accessed on 20 July 2023).

- Wang, S.-L.; Baaj, H. Treatment of weak subgrade materials with cement and hydraulic road binder (HRB). Road Mater. Pavement Des. 2020, 22, 1756–1779. [Google Scholar] [CrossRef]

- General Use (GU) and Portland-Limestone (GUL) Cements. Available online: https://www.stmaryscement.com/Documents/Canada/CAC%20EPD%20(GU,%20GUL).pdf (accessed on 20 July 2023).

- Kushawa, U.; Yadav, R.K. Effect of Zeolite and Cement Addition on Properties of Granular Soil. Int. J. Res. Appl. Sci. Eng. Technol. 2018, 6, 783–788. [Google Scholar] [CrossRef]

- Chanarboni, H.A.; Lajevardi, S.H.; MolaAbasi, H.; Zeighami, E. The effect of zeolite and cement stabilization on the mechanical behavior of expansive soils. Constr. Build. Mater. 2020, 272, 121630. [Google Scholar] [CrossRef]

- Shirmohammadi, S.; Jahromi, S.G.; Payan, M.; Senetakis, K. Effect of Lime Stabilization and Partial Clinoptilolite Zeolite Replacement on the Behavior of a Silt-Sized Low-Plasticity Soil Subjected to Freezing–Thawing Cycles. Coatings 2021, 11, 994. [Google Scholar] [CrossRef]

- Akbari, H.R.; Sharafi, H.; Goodarzi, A.R. Effect of polypropylene fiber and nano-zeolite on stabilized soft soil under wet-dry cycles. Geotext. Geomembr. 2021, 49, 1470–1482. [Google Scholar] [CrossRef]

- Baker, M.B.; Abendeh, R.; Sharo, A.; Hanna, A. Stabilization of Sandy Soils by Bentonite Clay Slurry at Laboratory Bench and Pilot Scales. Coatings 2022, 12, 1922. [Google Scholar] [CrossRef]

- Hadžić, V.; Sekulić, P.; Vasin, J.; Nešić, L. Geological base of Vojvodina’s mantle of soil. Econ. Agric. 2005, 52, 429–438. [Google Scholar]

- SRPS U.B1.002; Testing of Soils—Classification of Soil and Soil Aggregate Mixtures for Highway Construction Purposes. Institute for Standardization of Serbia: Belgrade, Serbia, 1992.

- SRPS U.B1.001; General Classification of Soils for Engineering Purposes. Institute for Standardization of Serbia: Belgrade, Serbia, 1990.

- SRPS EN 17892-4; Geotechnical Investigation and Testing—Laboratory Testing of Soil-Part 4: Determination of Particle Size Distribution. Institute for Standardization of Serbia: Belgrade, Serbia, 2017.

- SRPS EN 196-3; Methods of Testing Cement-Part 3: Determination of Setting Times and Soundness. Institute for Standardization of Serbia: Belgrade, Serbia, 2017.

- SRPS EN 196-1; Methods of Testing Cement-Part 1: Determination of Strength. Institute for Standardization of Serbia: Belgrade, Serbia, 2017.

- SRPS EN 13282-2; Hydraulic Road Binders-Part 2: Normal Hardening Hydraulic Road Binders—Composition, Specifications and Conformity Criteria. Institute for Standardization of Serbia: Belgrade, Serbia, 2016.

- SRPS U.B1.020; Testing of Soils—Determination of Atterberg Limits. Institute for Standardization of Serbia: Belgrade, Serbia, 1980.

- SRPS EN 13286-2; Unbound and Hydraulically Bound Mixtures-Part 2: Test Methods for Laboratory Reference Density and Water Content—Proctor Compaction. Institute for Standardization of Serbia: Belgrade, Serbia, 2012.

- SRPS EN 13286-47; Unbound and Hydraulically Bound Mixtures-Part 47: Test Method for the Determination of California Bearing Ratio, Immediate Bearing Index and Linear Swelling. Institute for Standardization of Serbia: Belgrade, Serbia, 2012.

- SRPS EN 13286-41; Unbound and Hydraulically Bound Mixtures-Part 41: Test Method for the Determination of the Compressive Strength of Hydraulically Bound Mixtures. Institute for Standardization of Serbia: Belgrade, Serbia, 2012.

- SRPS EN 13286-42; Unbound and Hydraulically Bound Mixtures-Part 42: Test Method for the Determination of the Indirect Tensile Strength of Hydraulically Bound Mixtures. Institute for Standardization of Serbia: Belgrade, Serbia, 2012.

- SRPS U.E9.024; Highway Design and Construction—Construction of Pavement Base Courses Stabilized by Means of Portland Cement and Similar Chemicals—Technical Requirements. Institute for Standardization of Serbia: Belgrade, Serbia, 1980.

| Samples | Granulometric Composition (%) | Consistency (%) | AASHTO | USCS | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Clay | Dust | Sand | Gravel | WL | WP | IP | ||||

| I batch | S1 | 11.59 | 82.40 | 6.01 | - | 45.90 | 24.90 | 21.00 | A-7-6 | CL |

| S2 | 12.80 | 82.20 | 5.00 | - | 45.90 | 24.90 | 21.00 | A-7-6 | CL | |

| S3 | 16.70 | 81.30 | 2.00 | - | 55.70 | 31.00 | 24.70 | A-7-5 | MH | |

| S4 | 12.65 | 85.00 | 2.35 | - | 53.95 | 30.90 | 23.05 | A-7-5 | MH | |

| S5 | 10.90 | 86.00 | 3.10 | - | 54.85 | 32.90 | 21.95 | A-7-5 | MH | |

| II batch | S6 | 1.90 | 62.10 | 29.30 | 6.70 | - | - | - | A-4 | ML |

| S7 | 5.00 | 65.00 | 27.70 | 2.30 | - | - | - | A-4 | ML | |

| S8 | 5.50 | 72.00 | 22.50 | - | 29.05 | 20.90 | 8.15 | A-4 | CL | |

| S9 | 7.90 | 73.90 | 18.20 | - | 34.00 | 24.90 | 9.10 | A-4 | CL | |

| S10 | 7.90 | 76.80 | 15.30 | - | 36.90 | 27.00 | 9.90 | A-4 | CL | |

| III batch | S11 | 8.00 | 70.10 | 21.90 | - | 41.80 | 30.90 | 10.90 | A-2-7 | CL |

| S12 | 8.90 | 73.80 | 17.30 | - | 43.00 | 30.90 | 12.10 | A-7-5 | CL | |

| S13 | 5.10 | 82.90 | 12.00 | - | 40.05 | 29.00 | 11.05 | A-6 | CL | |

| S14 | 5.10 | 78.10 | 16.80 | - | 43.90 | 29.00 | 14.90 | A-7-6 | CL | |

| S15 | 5.90 | 77.90 | 16.20 | - | 44.00 | 30.00 | 14.00 | A-7-6 | CL | |

| Samples | Wopt (%) | γd,max (Mg/m3) | CBR (%) | |

|---|---|---|---|---|

| I batch | S1 | 18.90 | 1.605 | 3.2 |

| S2 | 19.70 | 1.600 | 2.8 | |

| S3 | 22.20 | 1.495 | 2.3 | |

| S4 | 24.10 | 1.501 | 1.9 | |

| S5 | 22.00 | 1.499 | 1.5 | |

| II batch | S6 | 15.80 | 1.803 | 18.1 |

| S7 | 15.70 | 1.699 | 17 | |

| S8 | 17.90 | 1.707 | 14.9 | |

| S9 | 17.90 | 1.698 | 15.2 | |

| S10 | 19.90 | 1.702 | 14 | |

| III batch | S11 | 19.20 | 1.597 | 7.1 |

| S12 | 21.00 | 1.642 | 6.3 | |

| S13 | 20.10 | 1.592 | 5.1 | |

| S14 | 19.00 | 1.642 | 4.5 | |

| S15 | 20.10 | 1.599 | 4.1 | |

| Property | Requirement | Obtained Value |

|---|---|---|

| Standard consistency, (%) | - | 37.5 |

| Initial setting time, (min) | ≥150 | 180 |

| Compressive strength after 2 days, (MPa) | - | 15.0 |

| Compressive strength after 28 days, (MPa) | ≥32.5, ≤52.5 | 48.0 |

| Soundness—Le Shatelier, (mm) | ≤10 | 0.7 |

| Fineness, mass fraction of the residue on the 90 µm sieve mesh, (%) | ≤15 | 13.0 |

| Tested Property | Hydraulic Binder Content (%) | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 3 | 5 | 7 | 9 | |||

| I batch of specimens (with S1–S5) | WL | (%) | 51.26 | 51.59 | 51.54 | 51.39 | 51.51 |

| σ (%) | 4.93 | 4.99 | 4.98 | 4.93 | 4.91 | ||

| Cv (%) | 9.62 | 9.68 | 9.67 | 9.60 | 9.53 | ||

| WP | (%) | 28.92 | 29.10 | 29.13 | 29.05 | 29.13 | |

| σ (%) | 3.76 | 3.81 | 3.80 | 3.78 | 3.78 | ||

| Cv (%) | 12.99 | 13.09 | 13.05 | 13.00 | 12.98 | ||

| IP | (%) | 22.34 | 22.49 | 22.41 | 22.34 | 22.38 | |

| σ (%) | 1.57 | 1.52 | 1.59 | 1.53 | 1.52 | ||

| Cv (%) | 7.01 | 6.76 | 7.09 | 6.84 | 6.77 | ||

| Wopt | (%) | 21.38 | 22.18 | 21.64 | 21.86 | 21.96 | |

| σ (%) | 2.09 | 2.13 | 2.26 | 2.37 | 2.36 | ||

| Cv (%) | 9.76 | 9.58 | 10.44 | 10.82 | 10.76 | ||

| γd.max | (Mg/m3) | 1.54 | 1.58 | 1.60 | 1.61 | 1.64 | |

| σ (Mg/m3) | 0.06 | 0.04 | 0.04 | 0.04 | 0.03 | ||

| Cv (%) | 3.71 | 2.74 | 2.53 | 2.23 | 1.89 | ||

| CBR | (%) | 2.34 | 16.78 | 57.76 | 112.40 | - | |

| σ (%) | 0.68 | 1.24 | 3.06 | 3.73 | - | ||

| Cv (%) | 29.08 | 7.39 | 5.30 | 3.32 | - | ||

| 7-day UCS | (MPa) | 0.00 | 0.00 | 0.41 | 1.14 | 1.81 | |

| σ (MPa) | 0.00 | 0.00 | 0.00 | 0.02 | 0.02 | ||

| Cv (%) | 0.00 | 0.00 | 1.18 | 2.10 | 1.27 | ||

| 28-day UCS | (MPa) | 0.00 | 0.67 | 0.92 | 1.42 | 2.90 | |

| σ (MPa) | 0.00 | 0.01 | 0.01 | 0.01 | 0.01 | ||

| Cv (%) | 0.00 | 1.71 | 1.24 | 0.81 | 0.39 | ||

| 7-day ITS | (MPa) | 0.00 | 0.00 | 0.00 | 0.15 | 0.30 | |

| σ (MPa) | 0.00 | 0.00 | 0.00 | 0.01 | 0.01 | ||

| Cv (%) | 0.00 | 0.00 | 0.00 | 7.81 | 3.75 | ||

| 28-day ITS | (MPa) | 0.00 | 0.00 | 0.13 | 0.21 | 0.42 | |

| σ (MPa) | 0.00 | 0.00 | 0.01 | 0.02 | 0.02 | ||

| Cv (%) | 0.00 | 0.00 | 9.05 | 7.53 | 4.28 | ||

| II batch of specimens (with S6–S10) | WL | (%) | 33.32 | 33.50 | 33.72 | 33.72 | 33.83 |

| σ (%) | 3.97 | 3.74 | 3.52 | 3.44 | 3.46 | ||

| Cv (%) | 11.91 | 11.15 | 10.44 | 10.21 | 10.24 | ||

| WP | (%) | 24.27 | 24.33 | 24.33 | 24.33 | 24.43 | |

| σ (%) | 3.10 | 3.15 | 3.15 | 3.10 | 3.06 | ||

| Cv (%) | 12.77 | 12.96 | 12.96 | 12.76 | 12.50 | ||

| IP | (%) | 9.05 | 9.17 | 9.38 | 9.38 | 9.40 | |

| σ (%) | 0.88 | 0.60 | 0.45 | 0.45 | 0.52 | ||

| Cv (%) | 9.68 | 6.58 | 4.78 | 4.78 | 5.53 | ||

| Wopt | (%) | 17.44 | 17.30 | 17.59 | 17.67 | 17.76 | |

| σ (%) | 1.75 | 1.80 | 1.69 | 1.68 | 1.69 | ||

| Cv (%) | 10.01 | 10.38 | 9.63 | 9.50 | 9.51 | ||

| γd.max | (Mg/m3) | 1.72 | 1.79 | 1.82 | 1.84 | 1.86 | |

| σ (Mg/m3) | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | ||

| Cv (%) | 2.64 | 2.79 | 2.64 | 2.81 | 2.93 | ||

| CBR | (%) | 15.84 | 25.16 | 41.34 | 77.16 | - | |

| σ (%) | 1.67 | 1.42 | 2.34 | 5.79 | - | ||

| Cv (%) | 10.53 | 5.65 | 5.65 | 7.50 | - | ||

| 7-day UCS | (MPa) | 0.00 | 0.00 | 0.43 | 1.22 | 1.89 | |

| σ (MPa) | 0.00 | 0.00 | 0.01 | 0.01 | 0.01 | ||

| Cv (%) | 0.00 | 1.00 | 2.00 | 3.00 | 4.00 | ||

| 28-day UCS | (MPa) | 0.00 | 0.77 | 1.01 | 1.50 | 2.97 | |

| σ (MPa) | 0.00 | 0.02 | 0.01 | 0.01 | 0.02 | ||

| Cv (%) | 0.00 | 1.00 | 2.00 | 3.00 | 4.00 | ||

| 7-day ITS | (MPa) | 0.00 | 0.00 | 0.00 | 0.18 | 0.37 | |

| σ (MPa) | 0.00 | 0.00 | 0.00 | 0.01 | 0.01 | ||

| Cv (%) | 0.00 | 1.00 | 2.00 | 3.00 | 4.00 | ||

| 28-day ITS | (MPa) | 0.00 | 0.00 | 0.19 | 0.27 | 0.52 | |

| σ (MPa) | 0.00 | 0.00 | 0.02 | 0.01 | 0.02 | ||

| Cv (%) | 0.00 | 1.00 | 2.00 | 3.00 | 4.00 | ||

| III batch of specimens (with S10–S15) | WL | (%) | 42.55 | 43.20 | 43.37 | 43.23 | 43.34 |

| σ (%) | 1.65 | 1.68 | 1.56 | 1.52 | 1.53 | ||

| Cv (%) | 3.89 | 3.89 | 3.59 | 3.52 | 3.52 | ||

| WP | (%) | 29.96 | 30.13 | 30.16 | 30.09 | 30.18 | |

| σ (%) | 0.95 | 0.94 | 0.99 | 0.97 | 0.98 | ||

| Cv (%) | 3.17 | 3.13 | 3.29 | 3.22 | 3.26 | ||

| IP | (%) | 12.59 | 13.07 | 13.21 | 13.14 | 13.16 | |

| σ (%) | 1.79 | 1.78 | 1.63 | 1.56 | 1.57 | ||

| Cv (%) | 14.20 | 13.58 | 12.31 | 11.87 | 11.95 | ||

| Wopt | (%) | 19.88 | 20.50 | 20.53 | 20.69 | 20.82 | |

| σ (%) | 0.80 | 0.73 | 0.90 | 0.88 | 0.89 | ||

| Cv (%) | 4.05 | 3.57 | 4.38 | 4.27 | 4.26 | ||

| γd.max | (Mg/m3) | 1.61 | 1.67 | 1.70 | 1.72 | 1.75 | |

| σ (Mg/m3) | 0.03 | 0.03 | 0.03 | 0.03 | 0.05 | ||

| Cv (%) | 1.57 | 1.97 | 1.84 | 1.99 | 2.76 | ||

| CBR | (%) | 5.42 | 23.74 | 66.16 | 120.30 | - | |

| σ (%) | 1.25 | 3.92 | 3.37 | 3.72 | - | ||

| Cv (%) | 23.13 | 16.53 | 5.09 | 3.09 | - | ||

| 7-day UCS | (MPa) | 0.00 | 0.00 | 0.42 | 1.17 | 1.87 | |

| σ (MPa) | 0.00 | 0.00 | 0.01 | 0.02 | 0.02 | ||

| Cv (%) | 0.00 | 0.00 | 2.81 | 1.35 | 0.81 | ||

| 28-day UCS | (MPa) | 0.00 | 0.72 | 0.95 | 1.47 | 2.93 | |

| σ (MPa) | 0.00 | 0.01 | 0.01 | 0.01 | 0.01 | ||

| Cv (%) | 0.00 | 2.05 | 1.20 | 0.78 | 0.39 | ||

| 7-day ITS | (MPa) | 0.00 | 0.00 | 0.00 | 0.15 | 0.33 | |

| σ (MPa) | 0.00 | 0.00 | 0.00 | 0.02 | 0.01 | ||

| Cv (%) | 0.00 | 0.00 | 0.00 | 12.65 | 3.98 | ||

| 28-day ITS | (MPa) | 0.00 | 0.00 | 0.16 | 0.24 | 0.45 | |

| σ (MPa) | 0.00 | 0.00 | 0.01 | 0.01 | 0.01 | ||

| Cv (%) | 0.00 | 0.00 | 5.30 | 4.83 | 2.88 | ||

| Layer | 7-Day UCS (MPa) | 28-Day UCS (MPa) |

|---|---|---|

| Base course and subbase course of the road pavement construction of highways and roads of classes I and II | 2–5.5 | 3–6.5 |

| Subbase course of the road pavement construction of class III and class IV roads | 1.5–4.5 | 2.5–6 |

| Papers | WL | WP | IP | Wopr | γd.max | CBR | 7-Day UCS | 28-Day UCS | 7-Day Its | 28-Day Its |

|---|---|---|---|---|---|---|---|---|---|---|

| [7] | - | - | - | - | - | - | 0.12–1.52 | 0.12–3.00 | - | - |

| [12] | 67.8–77.2 | 40.8–51.1 | 18.2–33.3 | 25.9–33.7 | 1.17–1.68 | 2.3–14.3 | 0.48–0.75 | 0.52–0.84 | - | - |

| [13] | 53.1 | 31.8 | 21.3 | 30–32.5 | 1.35 | - | - | 0.32–1.207 | - | 0.06–0.245 |

| [16] | 16.65–37.9 | 13.94–20.6 | 2.71–15.4 | 12.6–15.7 | 1.53–1.99 | 6.3–82.88 | 0.23–0.30 | 0.28–0.36 | - | - |

| [18] | 18.98–23.9 | 28.67–34.78 | 9.13–10.9 | 6.31–8.94 | 2.13–2.41 | 2.9–10.12 | 0.11–0.15 | 0.12–0.17 | - | - |

| [21] | 1.70–1.78 | 8.0–21.0 | 2.5–33.5 | - | 0.30–0.90 | - | - | |||

| Authors paper | 29.05–55.7 | 20.9–32.9 | 8.15–24.7 | 15.7–24.1 | 1.49–1.80 | 1.5–122 | 0.40–1.95 | 0.6–3.0 | 0.13–0.37 | 0.12–0.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kired, F.; Šešlija, M.; Milović, T.; Starčev-Ćurčin, A.; Bulatović, V.; Radović, N. Stabilization of Different Soil Types Using a Hydraulic Binder. Buildings 2023, 13, 2040. https://doi.org/10.3390/buildings13082040

Kired F, Šešlija M, Milović T, Starčev-Ćurčin A, Bulatović V, Radović N. Stabilization of Different Soil Types Using a Hydraulic Binder. Buildings. 2023; 13(8):2040. https://doi.org/10.3390/buildings13082040

Chicago/Turabian StyleKired, Fawzia, Miloš Šešlija, Tiana Milović, Anka Starčev-Ćurčin, Vesna Bulatović, and Nebojša Radović. 2023. "Stabilization of Different Soil Types Using a Hydraulic Binder" Buildings 13, no. 8: 2040. https://doi.org/10.3390/buildings13082040

APA StyleKired, F., Šešlija, M., Milović, T., Starčev-Ćurčin, A., Bulatović, V., & Radović, N. (2023). Stabilization of Different Soil Types Using a Hydraulic Binder. Buildings, 13(8), 2040. https://doi.org/10.3390/buildings13082040