Mechanical Behaviors of Inter-Module Connections and Assembled Joints in Modular Steel Buildings: A Comprehensive Review

Abstract

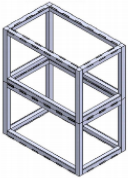

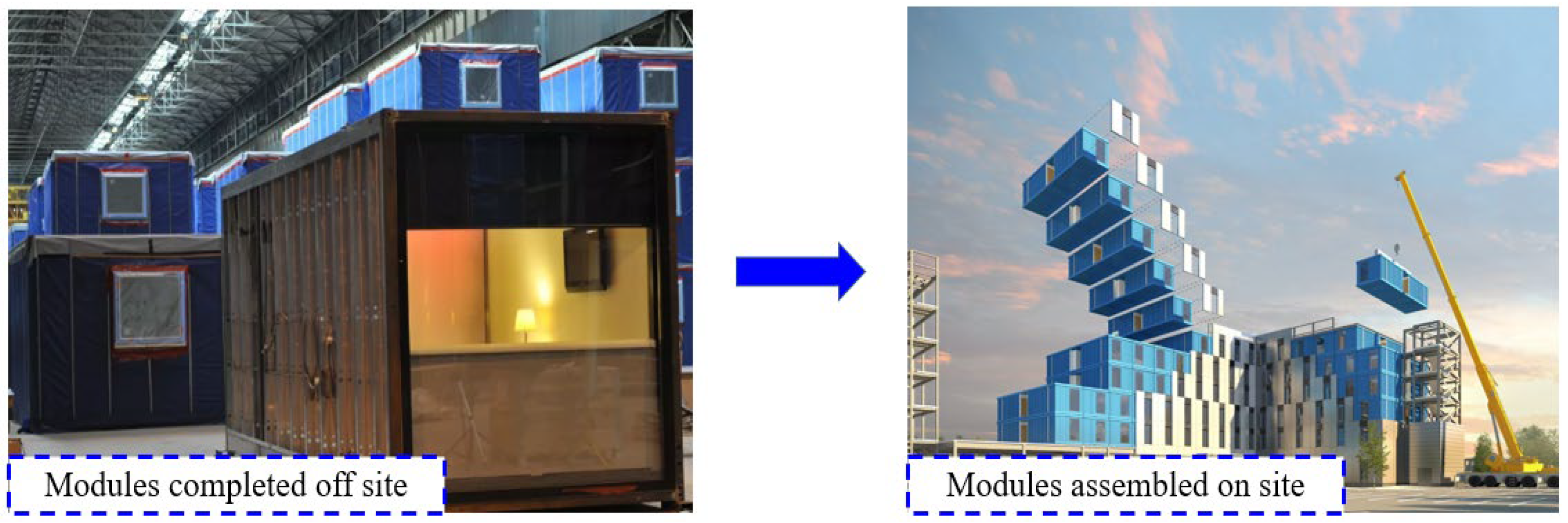

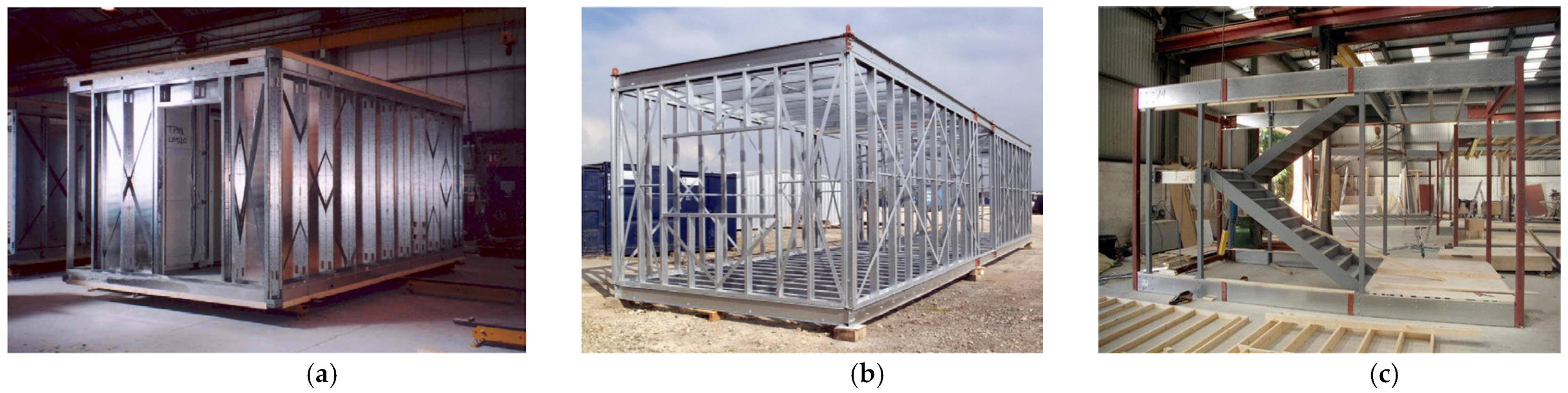

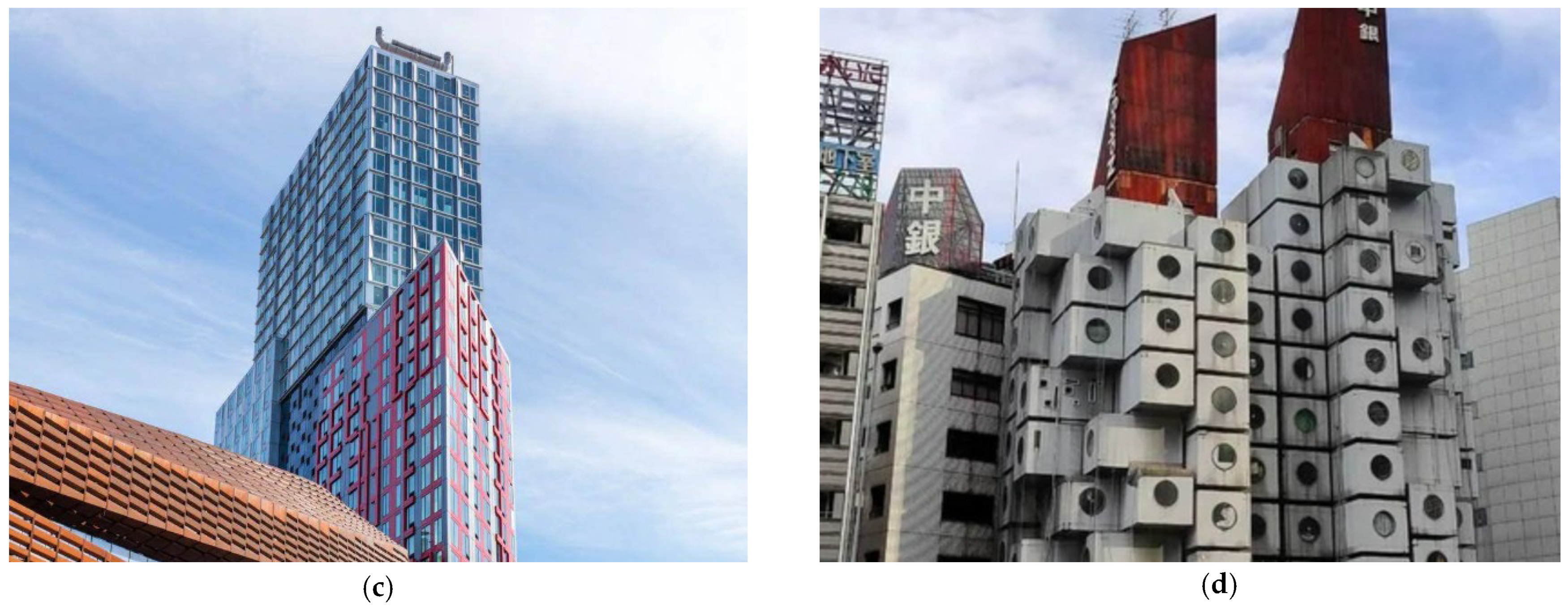

1. Introduction

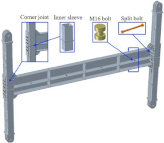

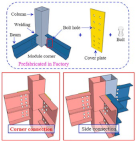

2. Connection Forms in Modular Steel Buildings

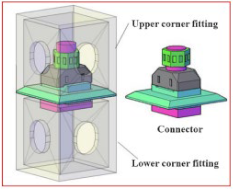

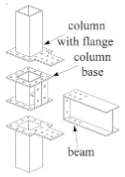

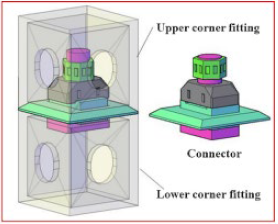

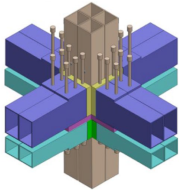

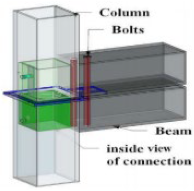

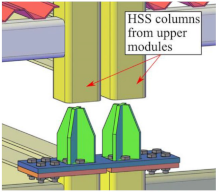

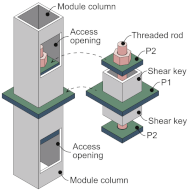

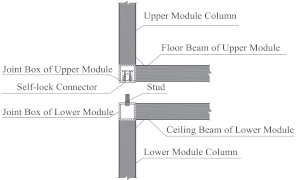

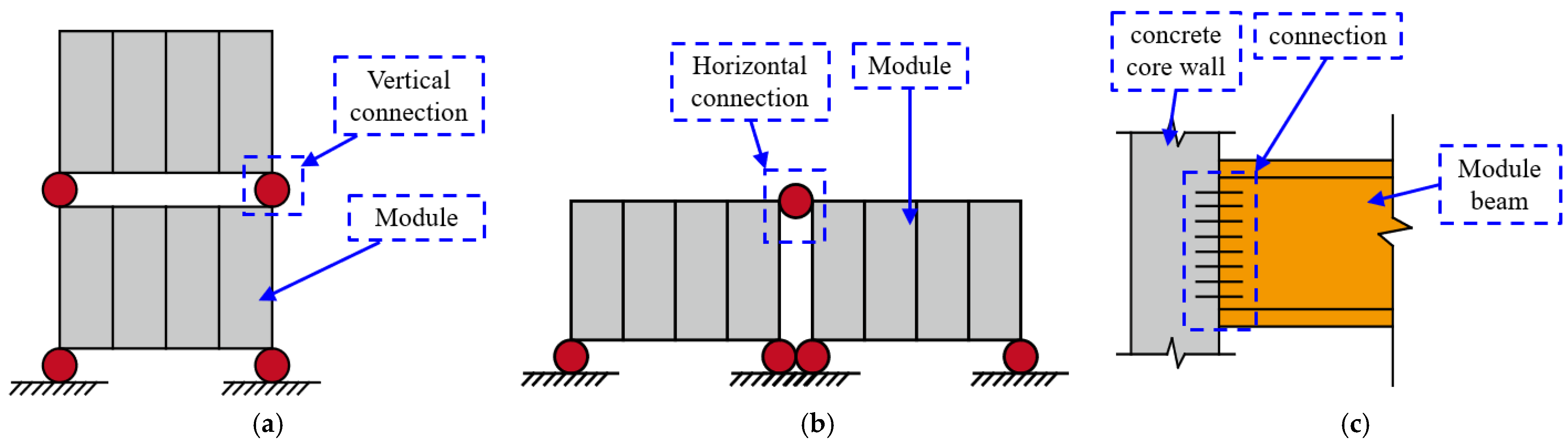

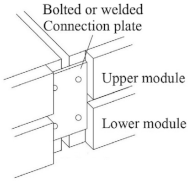

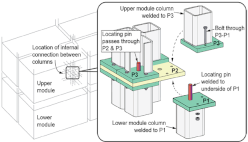

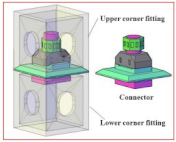

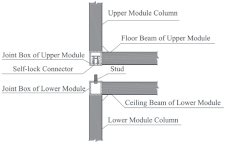

2.1. Vertical Module-to-Module Connections

| Connection Type | Illustration | Connection Type | Illustration |

|---|---|---|---|

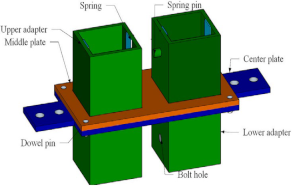

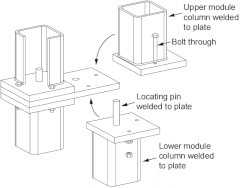

| VC1 Bolted connection [38] |  | VC2 Rotary and bolted connection [20,23] |  |

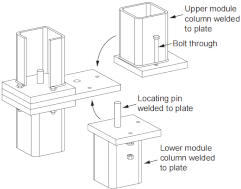

| VC3 Bolted connection [39] |  | VC4 Bolted connection [40,41] |  |

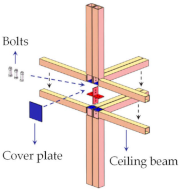

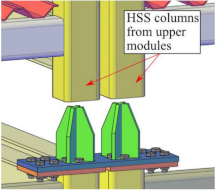

| VC5 Long beam bolted connection [42] |  | VC6 Bolted connection [43] |  |

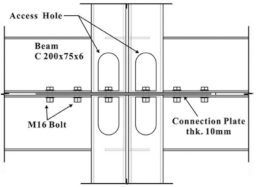

| VC7 Bolted connection [44] |  | VC8 Beam-to-beam bolted connection [45,46] |  |

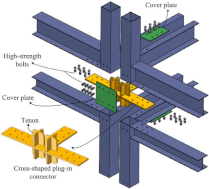

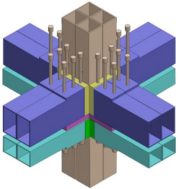

| VC9 Bolted connection [47] |  | VC10 Cross-shaped plug-in and bolted connection [48,49] |  |

| VC11 Bolted and splice connection [50] |  | VC12 Bolted and tenons connection [51] |  |

| VC13 Bolted connection [52] |  | VC14 Bolted connection [53] |  |

| VC15 Bolted and weld connection [54,55,56] |  | VC16 Bolted connection [57] |  |

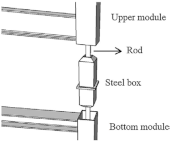

| VC17 Bolted and double beams laminated connection [26,27] |  | VC18 Post-tensioned connection [28] |  |

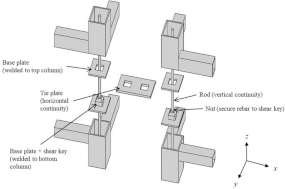

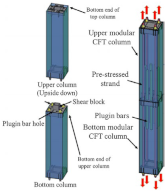

| VC19 Rod-base plate connection [29,30] |  | VC20 Prestressed connection [31] |  |

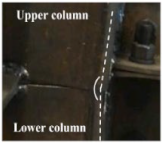

| VC21 Post-tensioned connection [32] |  | VC22 Post-tensioned connection [33,58,59] |  |

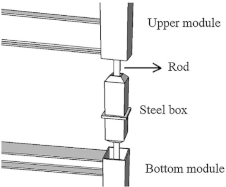

| VC23 sleeve connection [34] |  | VC24 Self-locking connection [35] |  |

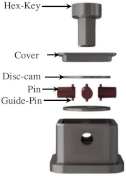

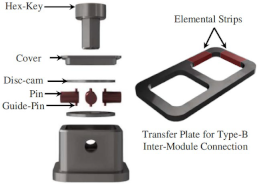

| VC25 Self-locking connection [36] |  | VC26 Interlocking connection [37] |  |

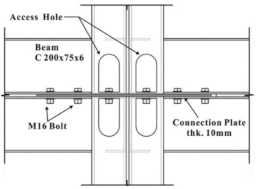

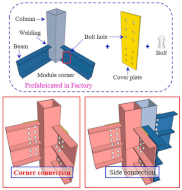

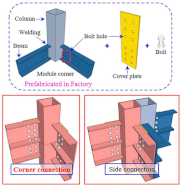

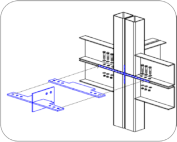

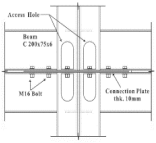

2.2. Horizontal Module-to-Module Connections

2.3. Module-to-Concrete Core Wall Connections

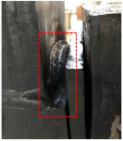

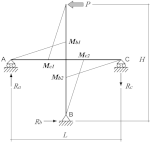

3. Load Transferring Path and Working Mechanisms

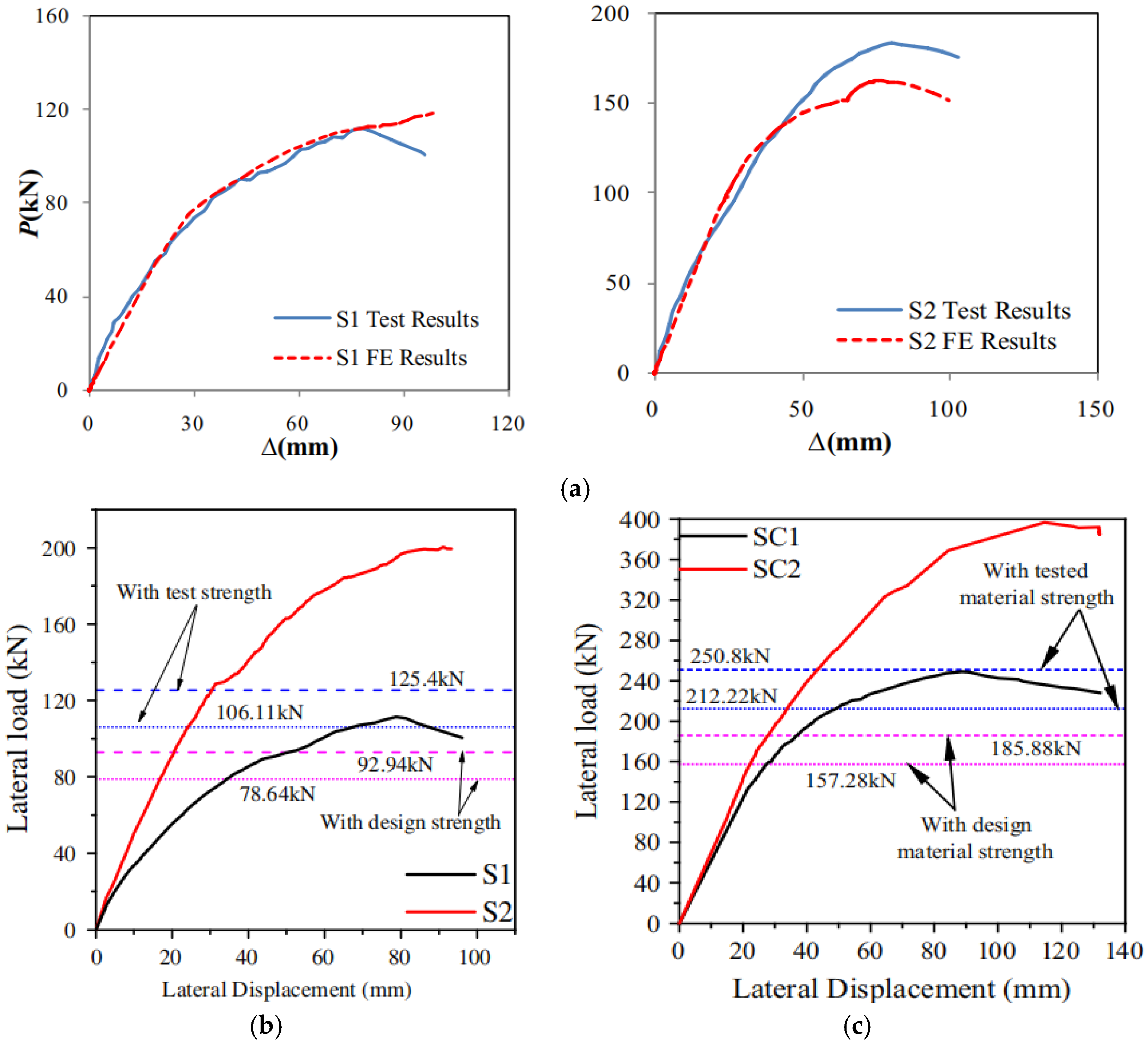

3.1. Mechanical Behaviors under Static Loading

3.2. Mechanical Behaviors under Cyclic Loading

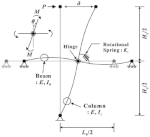

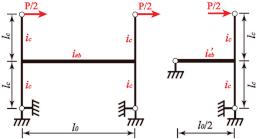

4. Simplified Analytical Models

4.1. Simplified Mechanical Models

4.2. Simplified Calculation Models

5. Prospects of Mechanical Connections in Modular Steel Buildings

6. Conclusions

- The structural forms of vertical and horizontal connections between modules were classified. Additionally, the connections between concrete and modules were summarized for high-rise modular steel buildings to provide a reference for subsequent research on the mechanical performance of high-rise modular steel buildings.

- Mechanical models and design formulas are the key to engineering applications. The load-bearing mechanisms of the joints used in module-to-module connections were summarized, and various design formulas were presented, providing a basis for the use of theoretical formulas related to inter-module connections.

- The existing simplified mechanical models of inter-module connections were systematically reviewed. Spring modelling methods, instead of connector methods, and "cartesian" connection units, instead of bolted connections, were summarized with the aim of improving the efficiency and accuracy of joint modelling. This provides a reference for the subsequent parametric analysis of inter-module connections.

- The methods of module-to-module connection were explored. Although many studies have been carried out on the joints used in inter-module connections, these joints do not allow for fully modular buildings, and their carrying capacity is not fully realized. Thus, this paper suggests two future research directions: self-locking connections and connections on double laminated beams.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Z.; Wang, J.; Liu, J.; Khan, K. Seismic behavior and moment transfer capacity of an innovative self-locking inter-module connection for modular steel building. Eng. Struct. 2021, 245, 112978. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.S.; Hao, H. Structural response of modular buildings—An overview. J. Build. Eng. 2018, 16, 45–56. [Google Scholar] [CrossRef]

- Ma, R.; Xia, J.; Chang, H.; Xu, B.; Zhang, L. Experimental and numerical investigation of mechanical properties on novel modular connections with superimposed beams. Eng. Struct. 2021, 232, 111858. [Google Scholar] [CrossRef]

- Gunawardena, T. Behaviour of Prefabricated Modular Buildings Subjected to Lateral Loads. Doctoral Thesis, The University of Melbourne, Melbourne, Australia, 2016. [Google Scholar]

- Xu, B.; Xia, J.; Chang, H.; Ma, R.; Zhang, L. A comprehensive experimental-numerical investigation on the bending response of laminated double channel beams in modular buildings. Eng. Struct. 2019, 200, 109737. [Google Scholar] [CrossRef]

- Lee, S.; Park, J.; Shon, S.; Kang, C. Seismic performance evaluation of the ceiling-bracket-type modular joint with various bracket parameters. J. Constr. Steel Res. 2018, 150, 298–325. [Google Scholar] [CrossRef]

- Nadeem, G.; Safiee, N.A.; Bakar, N.A.; Abd Karim, I.; Nasir, N.A. Connection design in modular steel construction: A review. Structures 2021, 33, 3239–3256. [Google Scholar] [CrossRef]

- Xu, B.; Xia, J.; Chang, H.; Ma, R.; Zhang, L. Flexural behaviour of pairs of laminated unequal channel beams with different interfacial connections in corner-supported modular steel buildings. Thin-Walled Struct. 2020, 154, 106792. [Google Scholar] [CrossRef]

- Chen, Z.; Khan, K.; Khan, A.; Javed, K.; Liu, J. Exploration of the multidirectional stability and response of prefabricated volumetric modular steel structures. J. Constr. Steel Res. 2021, 184, 106826. [Google Scholar] [CrossRef]

- Lawson, R.M.; Richards, J. Modular design for high-rise buildings. Proc. Inst. Civ. Eng.-Struct. Build. 2010, 163, 151–164. [Google Scholar] [CrossRef]

- Li, A.Q.; Zhou, T.; Miao, Z.W. State of the art of modular building system. Ind. Constr. 2018, 48, 132–139+150. [Google Scholar]

- Zhao, F.; Yu, Y.; Lin, S.; Ding, F. Evaluation of the working mechanisms and simplified models of endplate-type inter-module connections. Structures 2021, 32, 562–577. [Google Scholar] [CrossRef]

- Deng, E.F.; Zong, L.; Ding, Y.; Zhang, Z.; Zhang, J.F.; Shi, F.W.; Cai, L.M.; Gao, S.C. Seismic performance of mid-to-high rise modular steel construction—A critical review. Thin-Walled Struct. 2020, 155, 106924. [Google Scholar] [CrossRef]

- Lawson, R.M.; Ogden, R.G. ‘Hybrid’ light steel panel and modular systems. Thin-Walled Struct. 2008, 46, 720–730. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Review of bolted inter-module connections in modular steel buildings. J. Build. Eng. 2019, 23, 207–219. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings—A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Wang, Z.; Tsavdaridis, K.D. Optimality criteria-based minimum-weight design method for modular building systems subjected to generalised stiffness constraints: A comparative study. Eng. Struct. 2022, 251, 113472. [Google Scholar] [CrossRef]

- Davies, C. The Prefabricated Home; Reaktion Books: London, UK, 2005. [Google Scholar]

- Dai, X.M. Research on Seismic Behavior and Desgin Method of Self-Lock Plug-In Joints in Modular Steel Construction. Doctoral Thesis, Tianjin University, Tianjin, China, 2019. [Google Scholar]

- Chen, Z.; Liu, Y.; Zhong, X.; Liu, J. Rotational stiffness of inter-module connection in mid-rise modular steel buildings. Eng. Struct. 2019, 196, 109273. [Google Scholar] [CrossRef]

- Kurakawa, K. Kisho Kurakawa; Rizzoli Press: New York, NY, USA, 1988. [Google Scholar]

- Schmal, P.C.; Visscher, J.; Flagge, I.; Deutsches, A. Kisho Kurokawa: Metabolism and Sysbiosis; Jovis Verlag: Berlin, Germany, 2005. [Google Scholar]

- Chen, Z.; Wang, J.; Liu, J.; Cong, Z. Tensile and shear performance of rotary inter-module connection for modular steel buildings. J. Constr. Steel Res. 2020, 175, 106367. [Google Scholar] [CrossRef]

- Corfar, D.A.; Tsavdaridis, K.D. A comprehensive review and classification of inter-module connections for hot-rolled steel modular building systems. J. Build. Eng. 2022, 50, 104006. [Google Scholar] [CrossRef]

- Srisangeerthanan, S.; Hashemi, M.J.; Rajeev, P.; Gad, E.; Fernando, S. Review of performance requirements for inter-module connections in multi-story modular buildings. J. Build. Eng. 2020, 28, 101087. [Google Scholar] [CrossRef]

- Xu, B.; Xia, J.; Chang, H.; Ma, R.; Zhang, L. Evaluation of superimposed bending behaviour of laminated channel beams in modular steel buildings subjected to lateral load. Thin-Walled Struct. 2022, 175, 109234. [Google Scholar] [CrossRef]

- Xu, B.; Xia, J.; Chang, H.; Ma, R.; Zhang, L. Experimental and numerical investigation on the lateral force resistance of modular steel sub-frames with laminated double beam. J. Build. Eng. 2022, 46, 103666. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K.; Tallowin, F.J. Shear behaviour of post-tensioned inter-module connection for modular steel buildings. J. Constr. Steel Res. 2019, 162, 105707. [Google Scholar] [CrossRef]

- Chua, Y.S.; Liew, J.R.; Pang, S.D. Modelling of connections and lateral behavior of high-rise modular steel buildings. J. Constr. Steel Res. 2020, 166, 105901. [Google Scholar] [CrossRef]

- Chua, Y.S.; Dai Pang, S.; Liew, J.R.; Dai, Z. Robustness of inter-module connections and steel modular buildings under column loss scenarios. J. Build. Eng. 2022, 47, 103888. [Google Scholar] [CrossRef]

- Chen, Z.; Li, H.; Chen, A.; Yu, Y.; Wang, H. Research on pretensioned modular frame test and simulations. Eng. Struct. 2017, 151, 774–787. [Google Scholar] [CrossRef]

- Sanches, R.; Mercan, O.; Roberts, B. Experimental investigations of vertical post-tensioned connection for modular steel structures. Eng. Struct. 2018, 175, 776–789. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Lateral behaviour of modular steel building with simplified models of new inter-module connections. Eng. Struct. 2021, 236, 112103. [Google Scholar] [CrossRef]

- Dai, Z.; Cheong, T.C.; Dai Pang, S.; Liew, J.R. Experimental study of grouted sleeve connections under bending for steel modular buildings. Eng. Struct. 2021, 243, 112614. [Google Scholar] [CrossRef]

- Srisangeerthanan, S.; Hashemi, M.J.; Rajeev, P.; Gad, E.; Fernando, S. Development of an Innovative Boltless Connection for Multistory Modular Buildings. J. Struct. Eng. 2022, 148, 04022085. [Google Scholar] [CrossRef]

- Dai, X.M.; Zong, L.; Ding, Y.; Li, Z.X. Experimental study on seismic behavior of a novel plug-in self-lock joint for modular steel construction. Eng. Struct. 2019, 181, 143–164. [Google Scholar] [CrossRef]

- Sharafi, P.; Mortazavi, M.; Samali, B.; Ronagh, H. Interlocking system for enhancing the integrity of multi-storey modular buildings. Autom. Constr. 2018, 85, 263–272. [Google Scholar] [CrossRef]

- Liu, X.C.; Cui, F.Y.; Zhan, X.X.; Yu, C.; Jiang, Z.Q. Seismic performance of bolted connection of H-beam to HSS-column with web end-plate. J. Constr. Steel Res. 2019, 156, 167–181. [Google Scholar] [CrossRef]

- Choi, K.S.; Lee, H.C.; Kim, H.J. Influence of Analytical Models on the Seismic Response of Modular Structures. J. Korea Inst. Struct. Maint. Insp. 2016, 20, 74–85. [Google Scholar]

- Lee, S.; Park, J.; Kwak, E.; Shon, S.; Kang, C.; Choi, H. Verification of the Seismic Performance of a Rigidly Connected Modular System Depending on the Shape and Size of the Ceiling Bracket. Materials 2017, 10, 263. [Google Scholar] [CrossRef]

- Lee, S.S. Finite Element Modeling of Bolted Inter-Module Connections in Modular Steel Buildings. J. Korean Soc. Steel Constr. 2021, 33, 347–354. [Google Scholar] [CrossRef]

- Khan, K.; Yan, J.B. Finite Element Analysis on Seismic Behaviour of Novel Joint in Prefabricated Modular Steel Building. Int. J. Steel Struct. 2020, 20, 752–765. [Google Scholar] [CrossRef]

- Nadeem, G.; Safiee, N.A.; Abu Bakar, N.; Karim, I.A.; Nasir, N.A.M. Finite Element Analysis of Proposed Self-Locking Joint for Modular Steel Structures. Appl. Sci. 2021, 11, 9277. [Google Scholar] [CrossRef]

- Wang, Y.R.; Xia, J.W.; Ma, R.W. Experimental Study on the Flexural Behavior of an Innovative Modular Steel Building Connection with Installed Bolts in the Columns. Appl. Sci. 2019, 9, 3468. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, J.; Yu, Y.; Zhou, C.; Yan, R. Experimental study of an innovative modular steel building connection. J. Constr. Steel Res. 2017, 139, 69–82. [Google Scholar] [CrossRef]

- Chen, Z.H.; Liu, J.D.; Yu, Y.J. Experimental study on interior connections in modular steel buildings. Eng. Struct. 2017, 147, 625–638. [Google Scholar] [CrossRef]

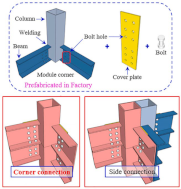

- Zhai, S.Y.; Lyu, Y.F.; Cao, K.; Li, G.Q.; Wang, W.Y.; Chen, C. Experimental study on bolted-cover plate corner connections for column-supported modular steel buildings. J. Constr. Steel Res. 2022, 189, 107060. [Google Scholar] [CrossRef]

- Xu, L.H.; Yang, X.L.; Zhang, G. Study on mechanical behavior of plug-in connection for a novel modular steel structure. Eng. Mech. 2022, 39, 1–10. [Google Scholar]

- Zhang, G.; Xu, L.-H.; Li, Z.-X. Development and seismic retrofit of an innovative modular steel structure connection using symmetrical self-centering haunch braces. Eng. Struct. 2021, 229, 111671. [Google Scholar] [CrossRef]

- Lyu, Y.F.; Li, G.Q.; Cao, K.; Zhai, S.Y.; Wang, Y.B.; Mao, L.; Ran, M.M. Bending behavior of splice connection for corner-supported steel modular buildings. Eng. Struct. 2022, 250, 113460. [Google Scholar] [CrossRef]

- Deng, E.F.; Yan, J.B.; Ding, Y.; Zong, L.; Li, Z.X.; Dai, X.M. Analytical and numerical studies on steel columns with novel connections in modular construction. Int. J. Steel Struct. 2017, 17, 1613–1626. [Google Scholar] [CrossRef]

- Styles, A.J.; Luo, F.J.; Bai, Y.; Murray-Parkes, J.B. Effects of joint rotational stiffness on structural reponses of multi-story modular buildings. In Proceedings of the International Conference on Smart Infrastructure and Construction (ICSIC), Cambridge, UK, 27–29 June 2016. [Google Scholar]

- Bazarchi, E.; Davaran, A.; Lamarche, C.; Roy, N.; Parent, S. Experimental and numerical investigation of a novel vertically unconstrained steel inter-modular connection. Thin-Walled Struct. 2023, 183, 110364. [Google Scholar] [CrossRef]

- Deng, E.F.; Zong, L.; Ding, Y. Mechanical properties of innovative connection for integrated modular steel construction. J. Tianjin Univ. Sci. Technol. 2018, 51, 702–710. [Google Scholar]

- Deng, E.F.; Lian, J.Y.; Liu, Z.; Zhang, G.C.; Wang, S.B.; Cao, D.B. Compressive Behavior of a Fully Prefabricated Liftable Connection for Modular Steel Construction. Buildings 2022, 12, 649. [Google Scholar] [CrossRef]

- Deng, E.F.; Zong, L.; Ding, Y.; Luo, Y.B. Seismic behavior and design of cruciform bolted module-to-module connection with various reinforcing details. Thin-Walled Struct. 2018, 133, 106–119. [Google Scholar] [CrossRef]

- Shi, F.; Wang, H.; Zong, L.; Ding, Y.; Su, J. Seismic behavior of high-rise modular steel constructions with various module layouts. J. Build. Eng. 2020, 31, 101396. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. New interlocking inter-module connection for modular steel buildings: Experimental and numerical studies. Eng. Struct. 2019, 198, 109465. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. New interlocking inter-module connection for modular steel buildings: Simplified structural behaviours. Eng. Struct. 2021, 227, 111409. [Google Scholar] [CrossRef]

- Nadeem, G.; Safiee, N.A.; Abu Bakar, N.; Karim, I.A.; Nasir, N.A.M. Evaluation of slip behaviour of self-locking modular steel connection. J. Constr. Steel Res. 2022, 197, 107467. [Google Scholar] [CrossRef]

- Zhong, X.; Chen, Z.; Liu, J.; Liu, Y.; Liu, X. Experimental research on the in-plane performance of discontinuous modular diaphragms. Thin-Walled Struct. 2022, 173, 108905. [Google Scholar] [CrossRef]

- Fathieh, A.; Mercan, O. Seismic evaluation of modular steel buildings. Eng. Struct. 2016, 122, 83–92. [Google Scholar] [CrossRef]

- Gorgolewski, M.T.; Grubb, P.J.; Lawson, R.M. Modular Construction Using Light Steel Framing: Design of Residential Buildings; The Steel Construction Institute: Berkshire, UK, 2001. [Google Scholar]

- Choi, Y.H.; Lee, H.C.; Kim, J.K. Seismic Performance Assessment of a Modular System with Composite Section. J. Korea Inst. Struct. Maint. Insp. 2017, 21, 69–77. [Google Scholar]

- Ping, T.Y.; Pan, W.; Mou, B. An innovative type of module-to-core wall connections for high- rise steel modular buildings. J. Build. Eng. 2022, 62, 105425. [Google Scholar] [CrossRef]

- Chen, Z.; Zhong, X.; Liu, Y.; Liu, J. Analytical and Design Method for the Global Stability of Modular Steel Buildings. Int. J. Steel Struct. 2021, 21, 1741–1758. [Google Scholar] [CrossRef]

- He XH, C.; Chan, T.M.; Chung, K.F. Effect of inter-module connections on progressive collapse behaviour of MiC structures. J. Constr. Steel Res. 2021, 185, 106823. [Google Scholar]

- Zhai, S.Y.; Lyu, Y.F.; Cao, K.; Li, G.Q.; Wang, W.Y.; Chen, C. Seismic behavior of an innovative bolted connection with dual-slot hole for modular steel buildings. Eng. Struct. 2023, 279, 115619. [Google Scholar] [CrossRef]

- Xu, B.; Xia, J.; Ma, R.; Chang, H.; Yang, C.; Zhang, L. Investigation on interfacial slipping response of laminated channel beams with bolt connections in modular steel buildings. J. Build. Eng. 2023, 63, 105441. [Google Scholar] [CrossRef]

- Ye, J.; Mojtabaei, S.M.; Hajirasouliha, I.; Shepherd, P.; Pilakoutas, K. Strength and deflection behaviour of cold-formed steel back-to-back channels. Eng. Struct. 2018, 177, 641–654. [Google Scholar] [CrossRef]

- Annan, C.; Youssef, M.; El Naggar, M. Experimental evaluation of the seismic performance of modular steel-braced frames. Eng. Struct. 2009, 13, 1435–1446. [Google Scholar] [CrossRef]

- Annan, C.D.; Youssef, M.A.; El Naggar, M.H. Seismic vulnerability assessment of modular steel buildings. J. Earthq. Eng. 2009, 13, 1065–1088. [Google Scholar] [CrossRef]

- Annan, C.D.; Youssef, M.A.; El Naggar, M.H. Seismic Overstrength in Braced Frames of Modular Steel Buildings. J. Earthq. Eng. 2008, 13, 1–21. [Google Scholar] [CrossRef]

- Li, G.Q.; Cao, K.; Lu, Y.; Jiang, J. Effective length factor of columns in non-sway modular steel buildings. Adv. Steel Constr. 2017, 13, 412–426. [Google Scholar]

- Peng, J.H.; Hou, C.; Shen, L.M. Numerical analysis of corner-supported composite modular buildings under wind actions. J. Constr. Steel Res. 2021, 187, 412–426. [Google Scholar] [CrossRef]

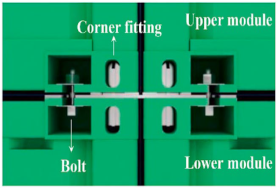

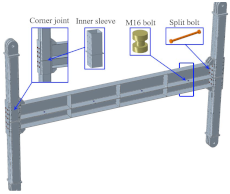

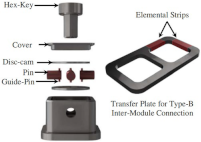

| Connection Type | Illustration | Connection Type | Illustration |

|---|---|---|---|

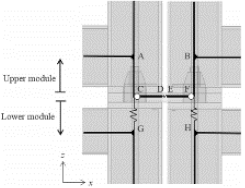

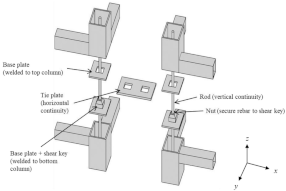

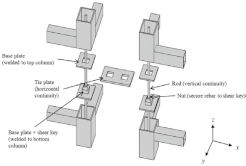

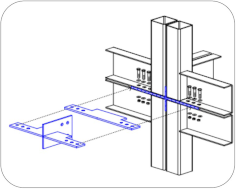

| HC1 Vertical plate connection [52] |  | HC2 End plate connection [60] |  |

| HC3 Tie plate connection [34] |  | HC4 End plate connection [33,58,59] |  |

| HC5 End plate connection [29,30] |  | HC6 End plate connection [61] |  |

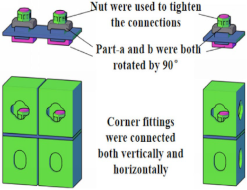

| HC7 End plate connection [39] |  | HC8 Bolted and welded plate connection [62,63] |  |

| HC9 End plate connection [35] |  | HC10 End plate and bolted connection [47] |  |

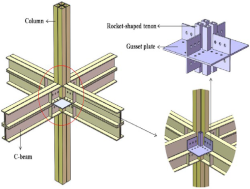

| HC11 Cover plate connection [54,55,56] |  | HC12 Tenon-gusset plate connection [42] |  |

| HC13 Straight and cross-shaped plate connection [40,41] |  | HC14 End plate connection [53] |  |

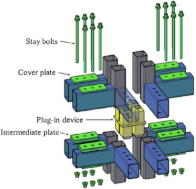

| HC15 Bolted and tenons connection [51] |  | HC16 Plug-in connection [45,46] |  |

| HC17 Cross-shaped plug-in and end plate connection [48,49] |  | HC18 Interlocking connection [37] |  |

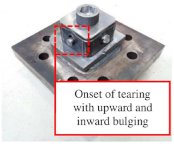

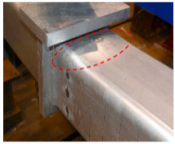

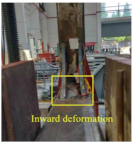

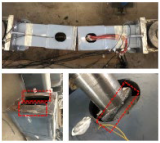

| Connection Type | Illustration and Testing of Mechanical Property | Deformation State and Failure Mode | |

|---|---|---|---|

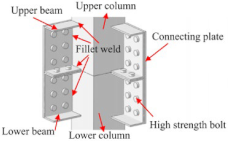

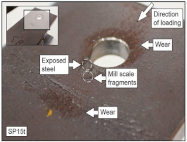

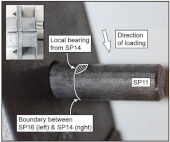

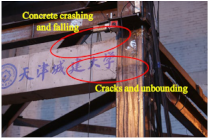

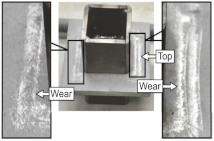

| 1 Lyu et al. [50] |  1. monotonic loading 2. Bending behavior |  |  |

| 2 Srisangeerthanan et al. [35] |  1. monotonic and cyclic loading 2. Tension, compression behavior |  |  |

| 3 Sanches et al. [32] |  1. cyclic loading 2. Bending behavior |  |  |

| 4 Dai et al. [34] |  1. monotonic loading 2. Bending behavior |  |  |

| 5 Wang et al. [44] |  1. monotonic loading 2. Bending behavior |  |  |

| 6 Lacey et al. [33,58] |  1. cyclic loading 2. Shear behavior |  |  |

| 7 Chen et al. [31] |  1. static loading 2. Moment transfer behavior |  |  |

| 8 Lacey et al. [28] |  1. monotonic loading 2. Shear behavior |  |  |

| 9 Chen et al. [20,23] |  1. monotonic loading 2. Tensile and shear behavior |  |  |

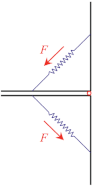

| Type | Detailed Model | Simplified Model | Main Calculation Formula |

|---|---|---|---|

| Lee et al. [40] |  |  | |

| Chen et al. [20] |  |  | |

| Dai et al. [36] |  |  | |

| Choi et al. [39] |  |  | |

| Deng et al. [54,55,56] |  |  | |

| Xu et al. [26,27] |  |  | |

| Zhai et al. [47] |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Xu, B.; Xia, J.; Chang, H.; Chen, X.; Ma, R. Mechanical Behaviors of Inter-Module Connections and Assembled Joints in Modular Steel Buildings: A Comprehensive Review. Buildings 2023, 13, 1727. https://doi.org/10.3390/buildings13071727

Yang C, Xu B, Xia J, Chang H, Chen X, Ma R. Mechanical Behaviors of Inter-Module Connections and Assembled Joints in Modular Steel Buildings: A Comprehensive Review. Buildings. 2023; 13(7):1727. https://doi.org/10.3390/buildings13071727

Chicago/Turabian StyleYang, Chen, Bo Xu, Junwu Xia, Hongfei Chang, Xiaomiao Chen, and Renwei Ma. 2023. "Mechanical Behaviors of Inter-Module Connections and Assembled Joints in Modular Steel Buildings: A Comprehensive Review" Buildings 13, no. 7: 1727. https://doi.org/10.3390/buildings13071727

APA StyleYang, C., Xu, B., Xia, J., Chang, H., Chen, X., & Ma, R. (2023). Mechanical Behaviors of Inter-Module Connections and Assembled Joints in Modular Steel Buildings: A Comprehensive Review. Buildings, 13(7), 1727. https://doi.org/10.3390/buildings13071727