Abstract

Considering the current energy environment, both efficient and environmentally friendly solutions have to be developed for building construction. Bio-based building materials offer new perspectives through their insulating and natural humidity regulation capacities. Nevertheless, these materials are as complex as they are promising, and grey areas still remain regarding their behavior. Their water sorption and desorption curves recorded in experimental work demonstrate a hysteresis phenomenon and, although plausible hypotheses have been formulated in the literature, there is currently no consensus on its causes. Furthermore, it is important to emphasize that no reference considers the hydrophilic nature of the resource. Yet, this is a specificity of raw material coming from the plant world. In this context, this paper explores the microstructure and chemical composition of plant aggregates to propose a new explanation for the hysteresis. It is based on recent work demonstrating the existence of differentiated hydrogen bonds between the water sorption and desorption phase in cellulose. Obviously, hysteresis also has an origin at the molecular scale. Lastly, the hypothesis put forward here is supported by the swelling of bio-based materials that has been observed at high relative humidity, and this study aims to identify a link between the mechanics of bio-based materials and their hygroscopic behavior. A swelling/shrinking is macroscopically observed. Combining the fields of chemistry, physics, and civil engineering allowed us to demonstrate that it comes from a molecular-scale hydromechanical coupling. This is a major breakthrough in the understanding of bio-based composites.

1. Introduction

The study of bio-based materials is quite recent, and works on these promising materials have increased over the past 20 years. This is probably due to their multiple advantages: local availability of resources, recovery of agricultural waste, low grey energy, limited environmental impact, and improvement of energy efficiency or even indoor air quality [1]. Today, given the energy and climate upset facing humanity, large-scale development of these materials has become essential. Therefore, more and more authors are focusing on the experimental characterization of these materials, considering different binders and/or vegetal aggregates [1,2,3,4,5,6]. Those experimental data are fundamental. However, the literature is still limited concerning reflection on the phenomena underlying the macroscopic observables. So, this study aims to focus on the phenomenon of hysteresis. Although it is widely observed experimentally [2,3,4,5,6], its causes are still poorly understood. This article provides a new consideration of the microscopic origin of the phenomenon at the molecular level.

First, some specific characteristics of bio-based materials are recalled. In particular, experimental observations and recent results concerning these materials are highlighted. It is also stressed that, to date, there is no consensus on how hysteresis in bio-based materials can be understood and described. Then, the hydrogen bond is briefly defined in order to facilitate understanding of a recently conducted study on sorption-swelling coupling in nanoporous materials [7].

The results of this study are then applied to bio-based building materials. The interest and relevance of considering the hysteresis phenomenon differently are highlighted: first at the microscopic molecular scale so that the plant aggregate’s specific nature can be considered, and then by exploring, one by one, the macroscopic consequences found in the literature. They are explained with the new theory put forward. This article thus proposes a new explanation, supported by numerous arguments, of hysteresis and its consequences.

2. Focus on Bio-Based Building Materials and Their Specificities

2.1. Microstructure

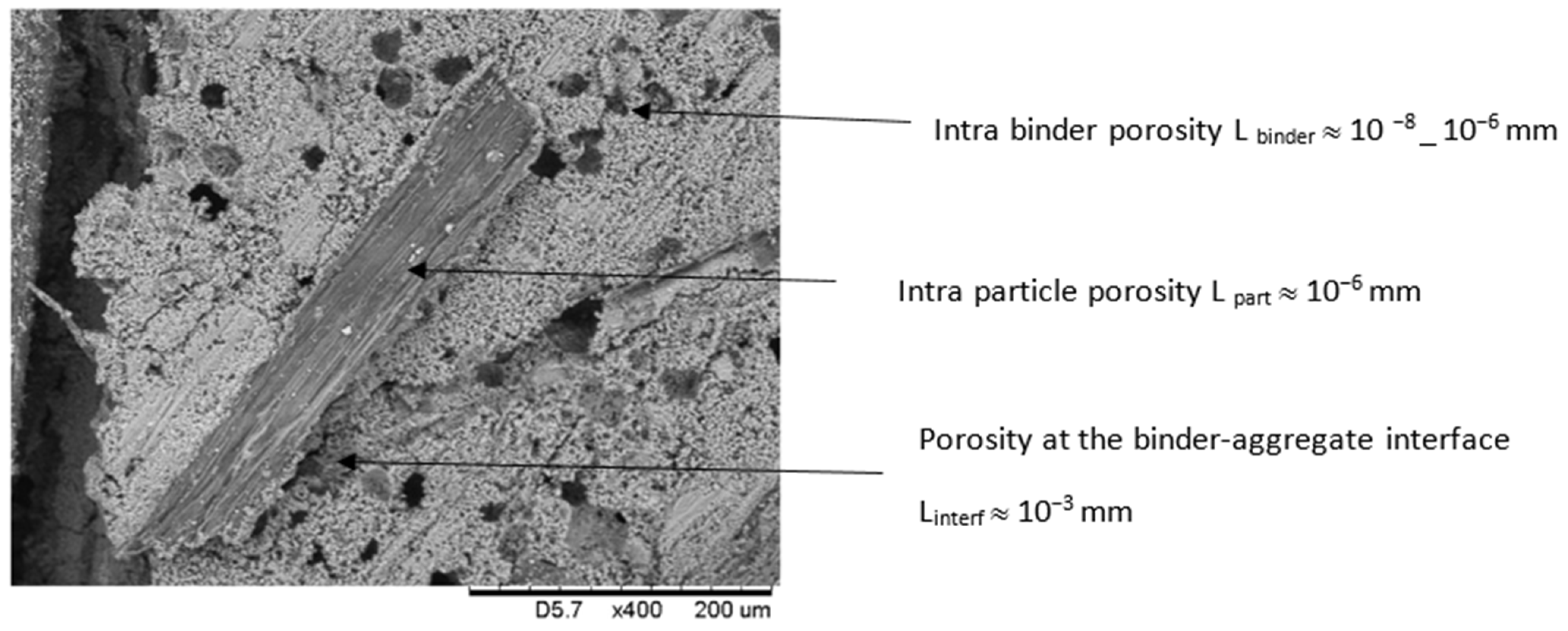

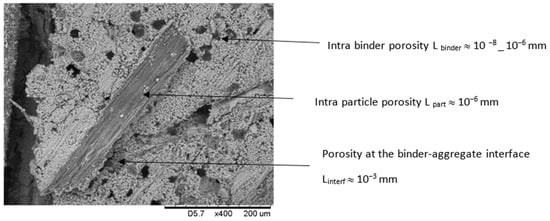

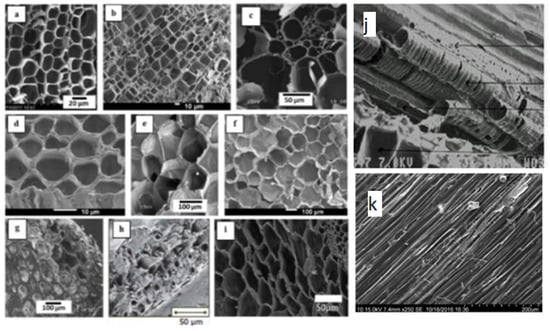

Bio-based building materials are made of agricultural by-products mixed with a binder (lime-based, metakaolin-based, clay, etc.). This leads to a microstructure that is both complex and variable, depending on the formulation, how the plant was grown, or even manufacturing [1,8]. A multi-scale porosity has also been underscored by several studies [4,9,10,11]. Bio-based and conventional materials have comparable intrinsic binder porosity due to the arrangement of hydrates and trapped air. However, the final porosity values for bio-based materials also include the additional contributions of inter-particulate and intra-particulate porosity and the porosity at the binder–aggregate interface (Figure 1).

Figure 1.

Multi-scale porosity of hemp concrete observed with SEM and Li order of magnitude [11].

Thus, this large, interconnected, and complex porosity allows the mass transfer of water within the microstructure.

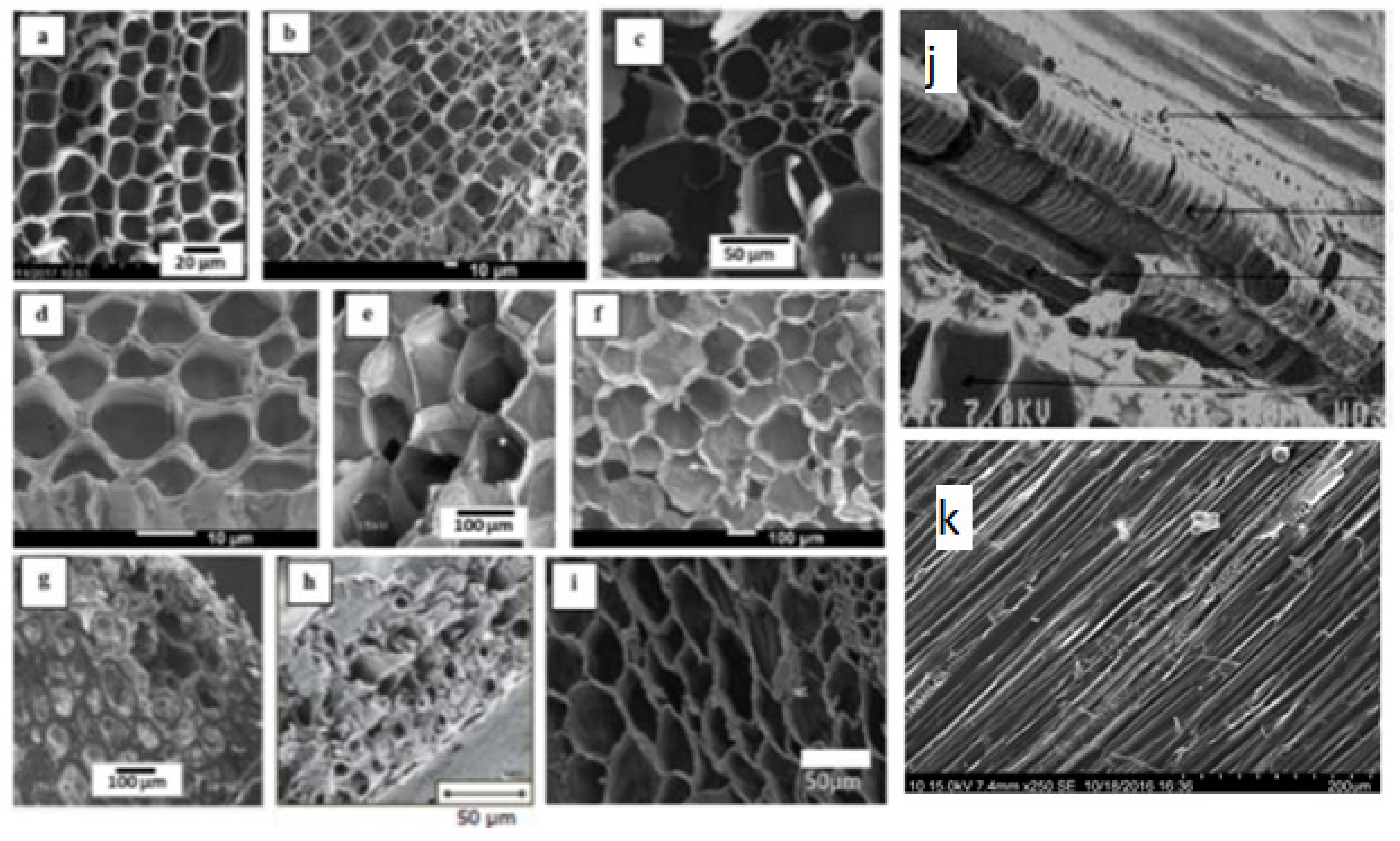

A large porosity can be observed more closely at the intra-particulate scale (Figure 2).

Figure 2.

SEM cross-sectional images of (a) hemp shiv, (b) flax shiv, (c) barley straw, (d) wheat straw, (e) I sunflower pith, (f) rape straw, (g) corn cob, (h) rice husk, and (i) miscanthus stem [12], and longitudinal (j) and transversal (k) images of hemp shiv [4].

These tubules allow the sap to circulate when the plant is growing. After drying, they fill with air, which causes intra-particle porosity, explaining, in particular, the insulating capacity of bio-based building materials. It is useful to note that a tubular morphology exists in a wide range of plant aggregates.

2.2. Hygroscopic Properties

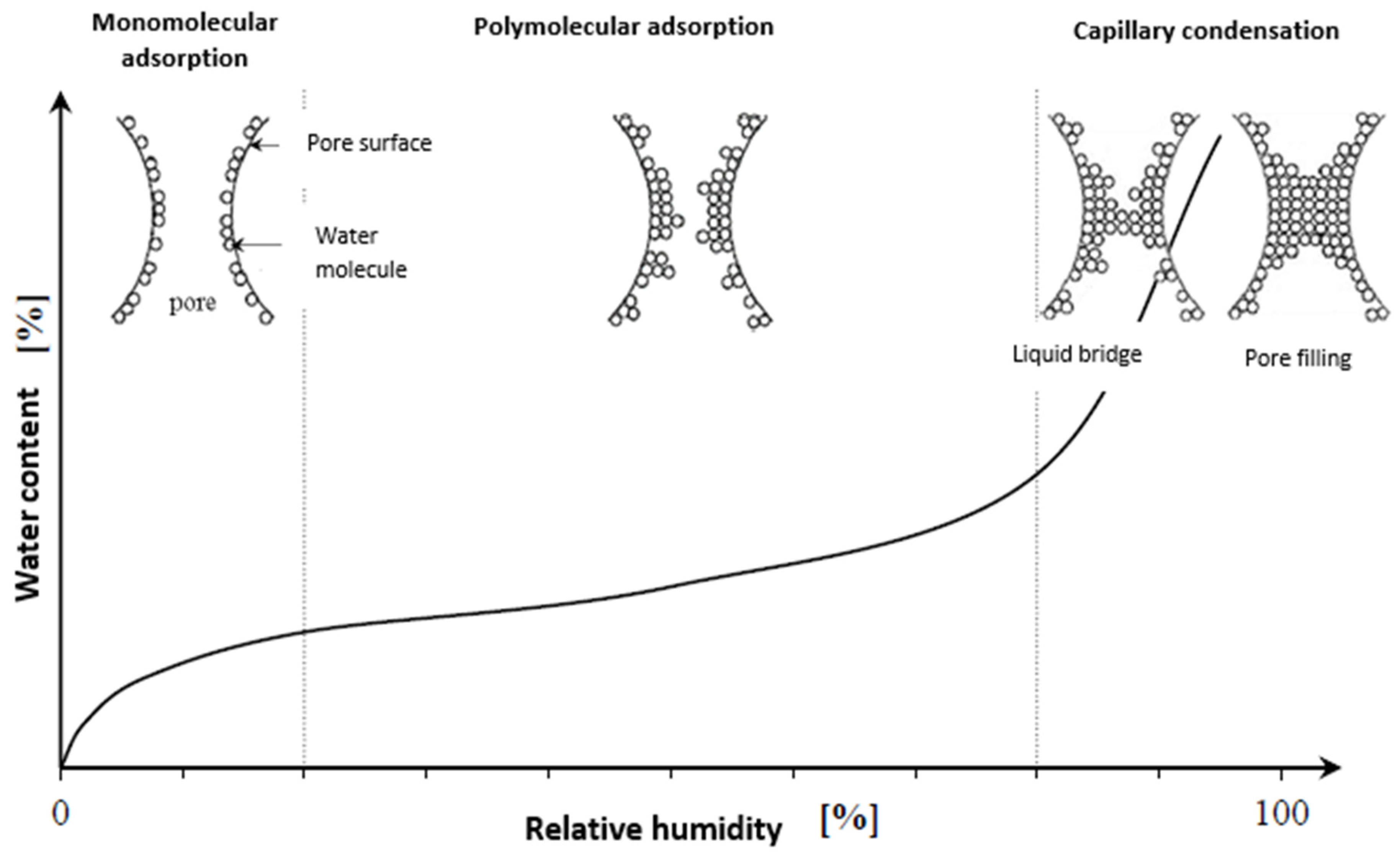

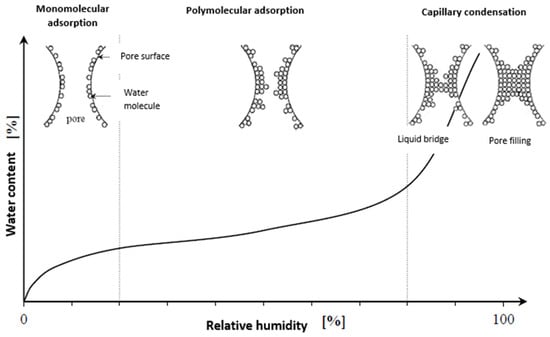

Hygroscopic material is able to fix and store water depending on moisture conditions. This capacity is governed by the pore size distribution [13]. According to many studies, both binder and plant particles are hygroscopic materials [4,8,10,14,15,16]. This means that they are able to adsorb excess water from the environment (in the form of vapor that condenses under certain conditions) and desorb this water when the environment is drier. This natural humidity regulation capacity is a major asset, as it contributes to healthier indoor conditions. Sorption effects are widely described in the literature by Van der Waals interactions between water and the pore walls. The type of binding that causes poly-molecular adsorption and capillary condensation is not specified. Thus, three different mechanisms schematically describe how water is adsorbed in the pore network of bio-based building materials (Figure 3) [17,18,19,20,21].

Figure 3.

Modes of water fixation in a pore [21].

Up to now, the nature of the solid skeleton surrounding the pores has not been differentiated. The same fixing modes are suggested for both the organic and the mineral parts of bio-based materials.

2.3. Chemical Composition

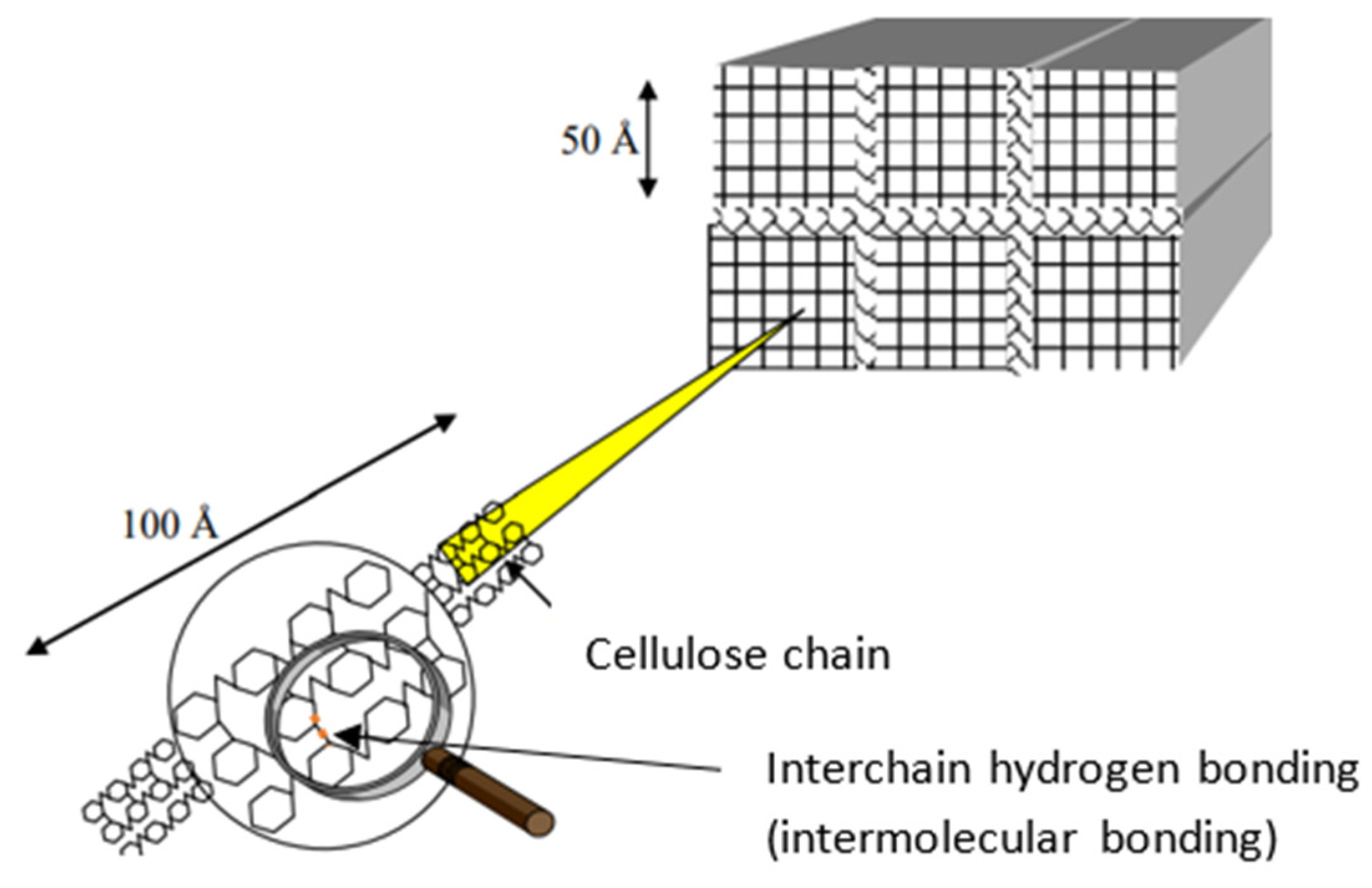

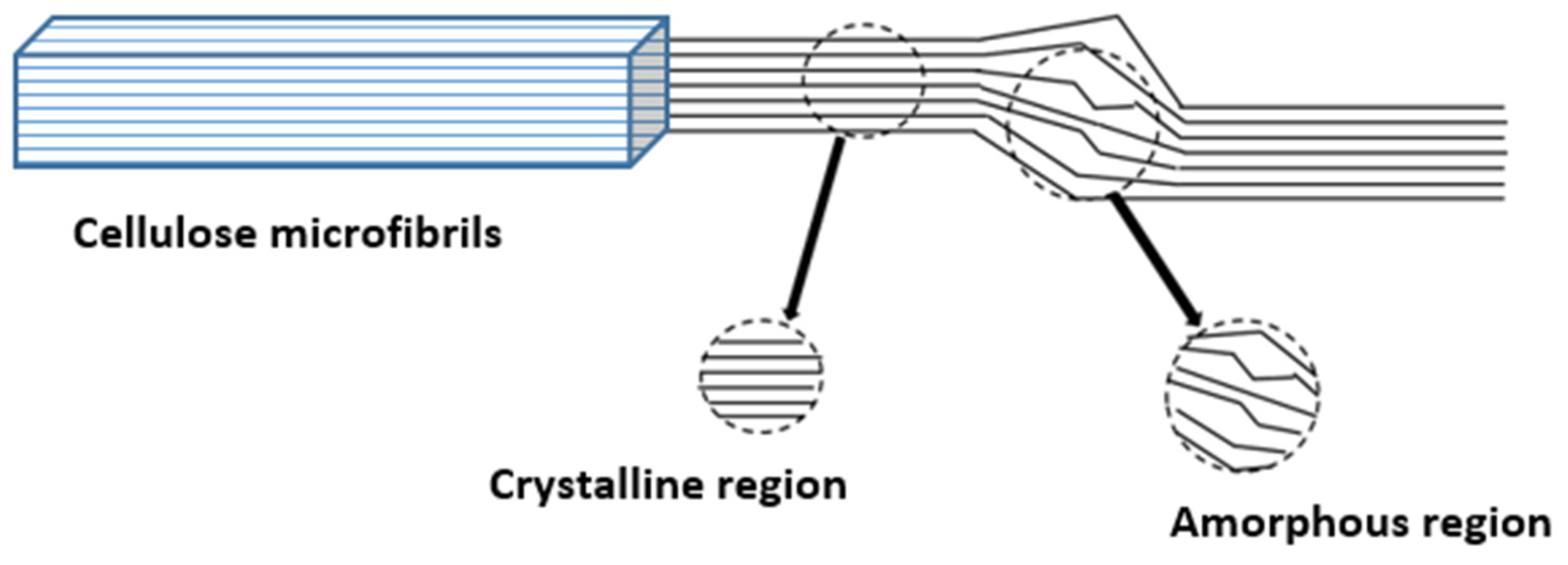

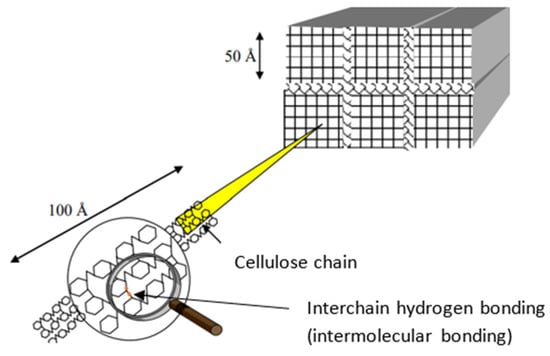

Bio-aggregates are mainly composed of cellulose, hemicellulose, and lignin [22,23,24,25]. Because cellulose is the major component [26,27], it is interesting to take a closer look at its microstructure. This bio-polymer is organized into chains of glucose. They are linked together by hydrogen bonds (interchain or intermolecular bonds) [7,28]. The cellulose chains are organized in the form of microfibrils, the arrangement of which determines the deformation capacity of the plant particle [29] (Figure 4).

Figure 4.

Cellulose microfibrils and inter-molecular hydrogen bonding [29].

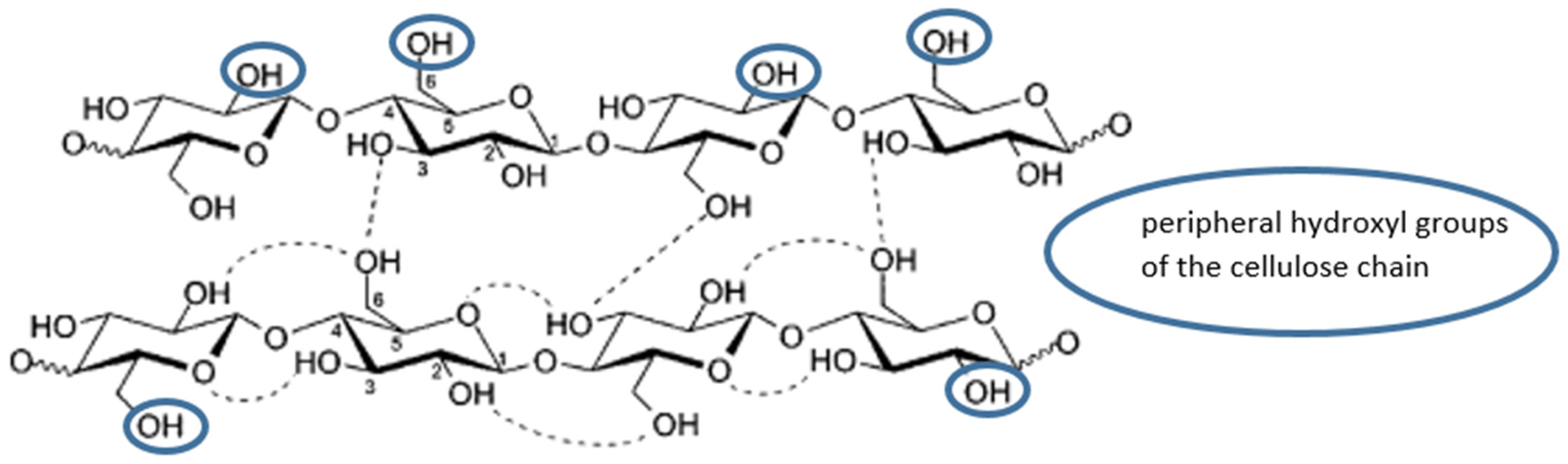

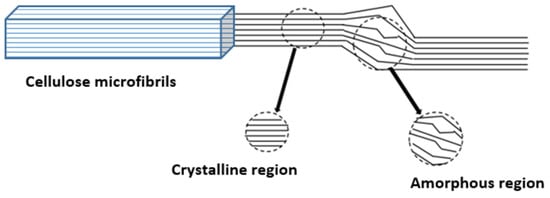

In reality, cellulose chains are not always perfectly aligned (crystalline part) and amorphous regions are present, especially in natural cellulose [30] (Figure 5). Some authors have indicated that cellulose is mainly crystalline in agro-resources [31], whereas dosages on hemp shiv have been shown to have very low crystallinity levels [32]. However, the sources agree that amorphous and crystalline zones coexist within plant walls. The proportion of each part is variable and depends on the harvesting zone, the method of extracting the fibers from the plant, and the treatments applied [33].

Figure 5.

Semi-crystallinity of cellulose, adapted from [34].

Cellulose chains have both intra- and inter-molecular hydrogen bonds. The hydroxyl groups on the surface of the chains are more accessible for creating hydrogen bonds with other molecules than those located inside (Figure 6).

Figure 6.

Intra- and inter-hydrogen bonds in cellulose (dotted lines), adapted from [35].

Thus, the reactivity of cellulose, i.e., its ability to create hydrogen bonds with its environment (with another cellulose molecule or a different molecule), is facilitated by its semi-crystallinity. This means that the steric hindrance is weaker in amorphous portions; space between cellulose chains increases the possibilities of hydrogen bonds with other potential molecules. Consequently, amorphous cellulose is a particularly favorable site for the creation of hydrogen bonds with its environment [36]. This is not the case for mineral or clay binders, as they do not contain cellulose [37,38,39,40].

2.4. Swelling and Shrinkage

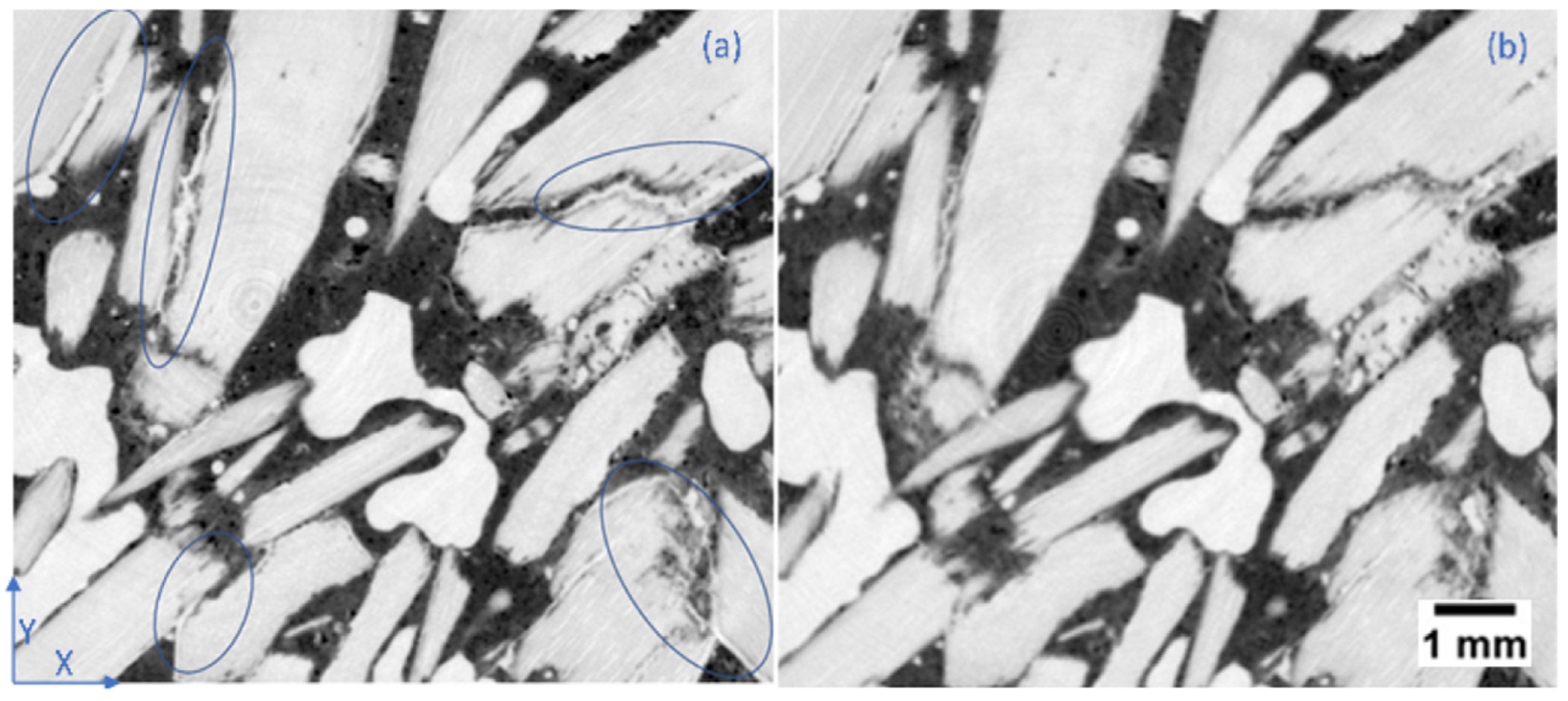

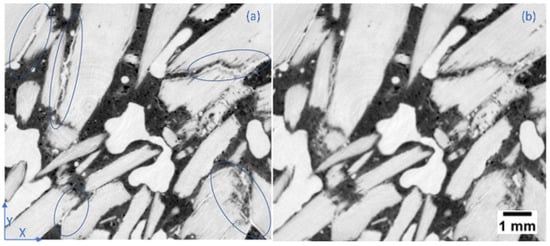

Cracking due to plastic shrinkage of composites is well known and is explained by mechanical stresses during drying [41,42]. Furthermore, other swelling and shrinkage phenomena have been reported in the literature, whether at a young age or after a period of accelerated aging [4,20,43]. This can be observed at the particulate scale under increasing or decreasing relative humidity conditions (Figure 7). The result is a significant change in the aggregate interface, which alters its porosity. This modification of microstructure in bio-materials is simply attributed to the presence of plant particles by the authors and has not been explained to date.

Figure 7.

X-ray tomography images of hemp concrete showing the swelling phenomenon (in the areas surrounded in blue) between dry and wet states ((a) 0% RH and (b) 85% RH) [4].

Swelling and shrinkage impact the porosity of bio-materials [20,44,45] and can therefore have effects on their thermal, hydric, and mechanical properties more or less in the long term.

2.5. Functional Properties with Age

According to recent studies, thermal and hygric properties of bio-based materials change with age [46,47]. Thus, whether aging is accelerated or not, several authors have shown that age reduces the adsorption and desorption rate and the water vapor permeability. However, some authors have indicated an increase with age in thermal conductivity, whereas others have shown the opposite [4,46].

2.6. Temperature Effects

The thermal conductivity of bio-based materials is temperature dependent [48]. Moreover, several studies have demonstrated the temperature dependence of sorption curves [6,16,49,50]. Thus, the effects of temperature on the sorption process have been promisingly modeled, but no explanation of this phenomenon has been proposed so far.

2.7. Local Kinetic Sorption

Recent work has highlighted the relevance of considering local sorption kinetics in bio-based materials, especially when coupled with hysteresis [51,52]. This was motivated by the observation that these materials take a long time to stabilize when the environment changes (more or less humid). The consideration of local kinetics is very relevant to describing the transformation of water from vapor to liquid (and vice versa). This has been experimentally validated. Thus, the fixation of liquid water in hemp concrete would be conditioned by a very slow diffusion of water molecules.

2.8. Sorption Hysteresis

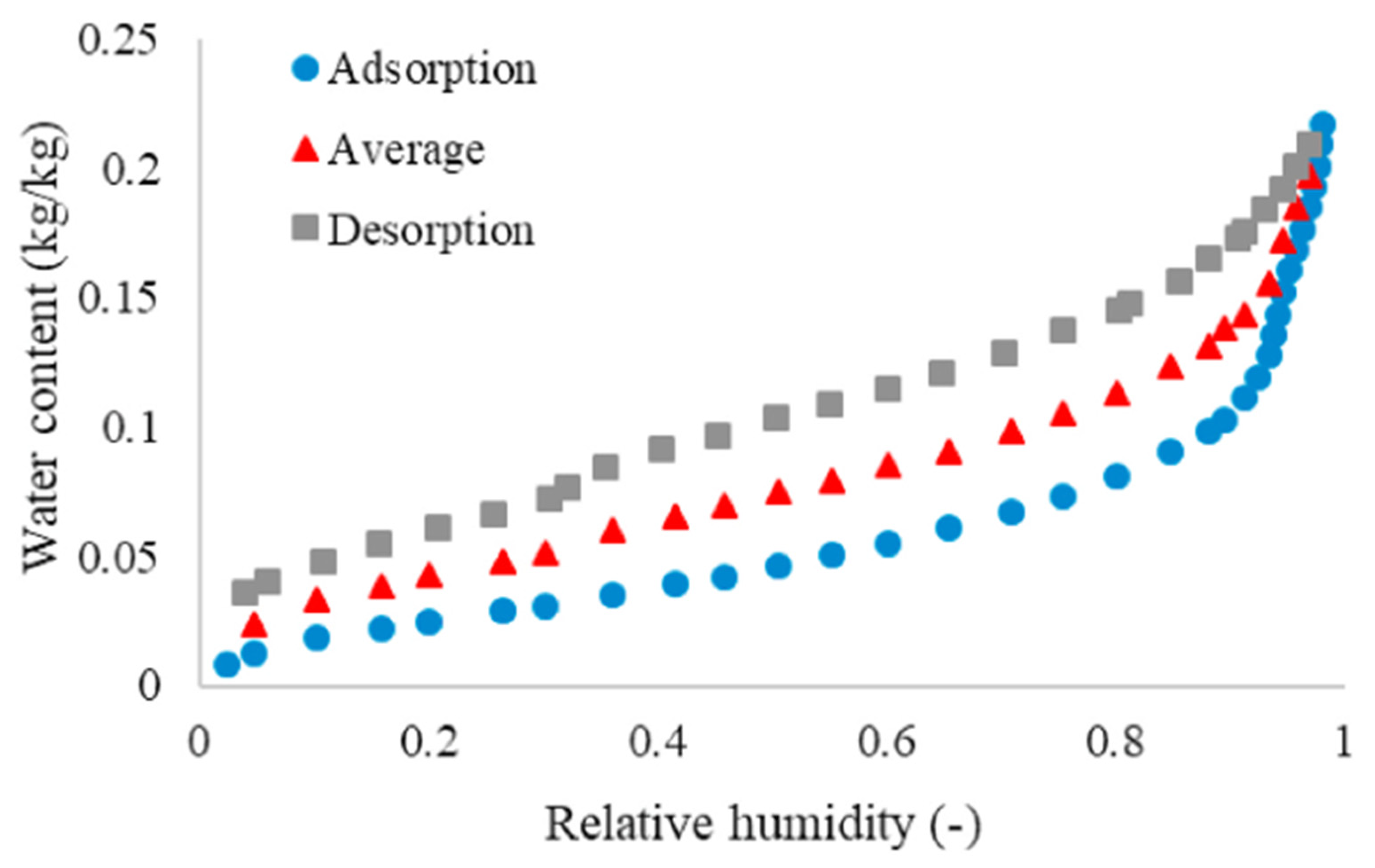

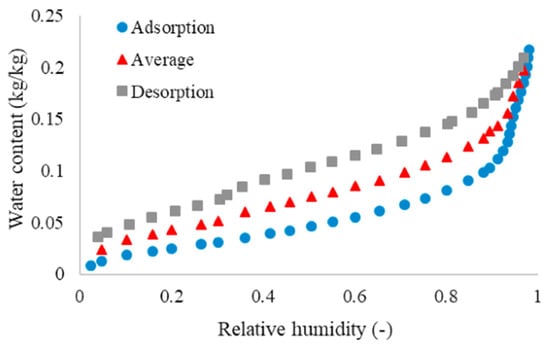

Sorption hysteresis observed on bio-based materials is widely reported in the literature [2,6,13,20,25,51,53,54,55,56,57,58]. At a given relative humidity, the eco-material does not have the same water content (after stabilization), depending on the sorption or desorption phase (Figure 8).

Figure 8.

Hysteresis in the case of hemp concrete [2].

This fundamental point must be considered to assess the hygrothermal behavior of bio-based walls. Thus, the following items have been experimentally demonstrated:

- The sorption mechanism is reversible since the original state is obtained at a dry state [57].

- Hysteresis is more pronounced for plant-based concrete materials than for aggregates [23,55,57,58].

- Aging reduces the rate of adsorption and desorption for hemp concrete [59].

- Temperature can influence hysteresis [6,60], or not [61].

- Swelling of the plant particles or fibers during hysteresis is irreversible [43,60].

- Hysteresis increases, whereas crystallinity decreases [60].

- Water content is always higher in the desorption than in the adsorption phase for the same relative humidity.

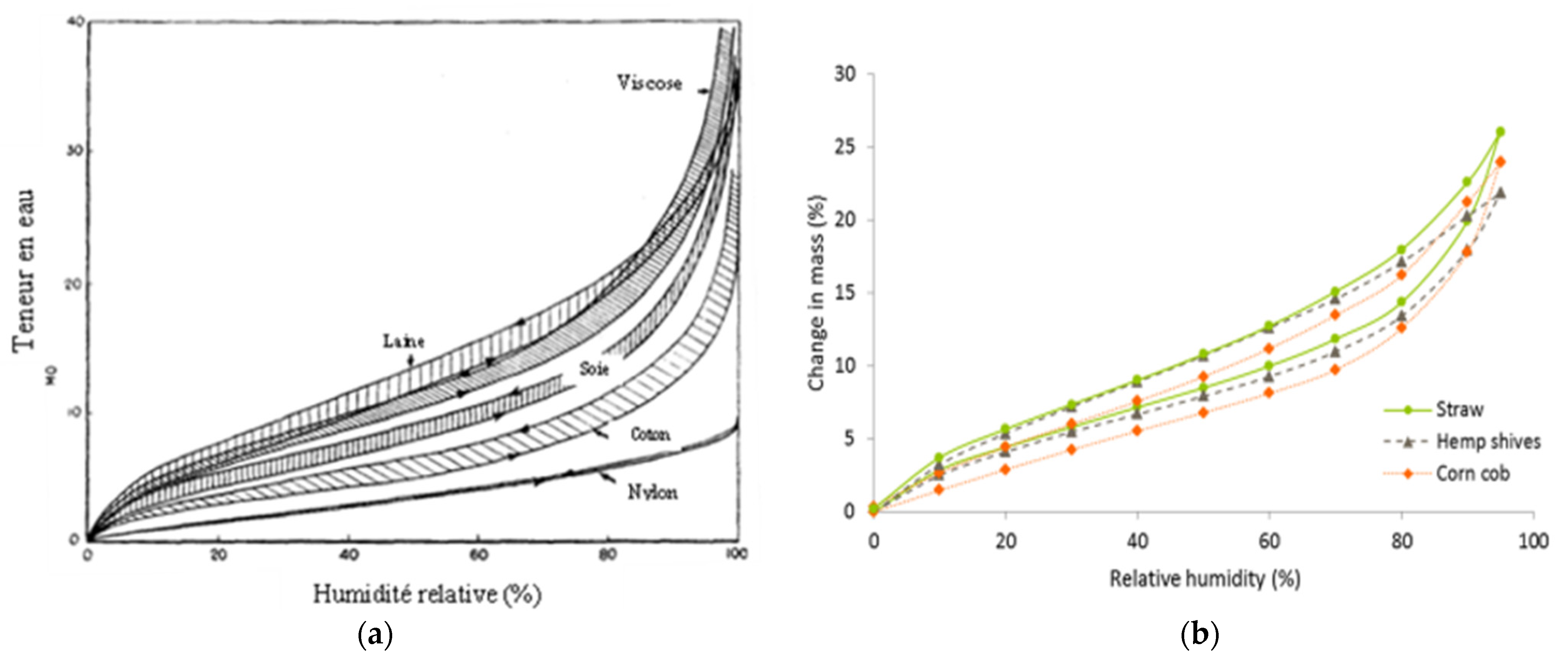

Moreover, the hysteresis phenomenon can be observed on binders alone, whether they are mineral or geo-sourced [3,13,62,63,64]. It can also be demonstrated on plant fibers or aggregates (Figure 9) used both in the textile and in the building industries [21,60].

Figure 9.

Hysteresis for a wide range of plant fibers and aggregates used in the textile industry (a) [60] or in the building industry (b) [5].

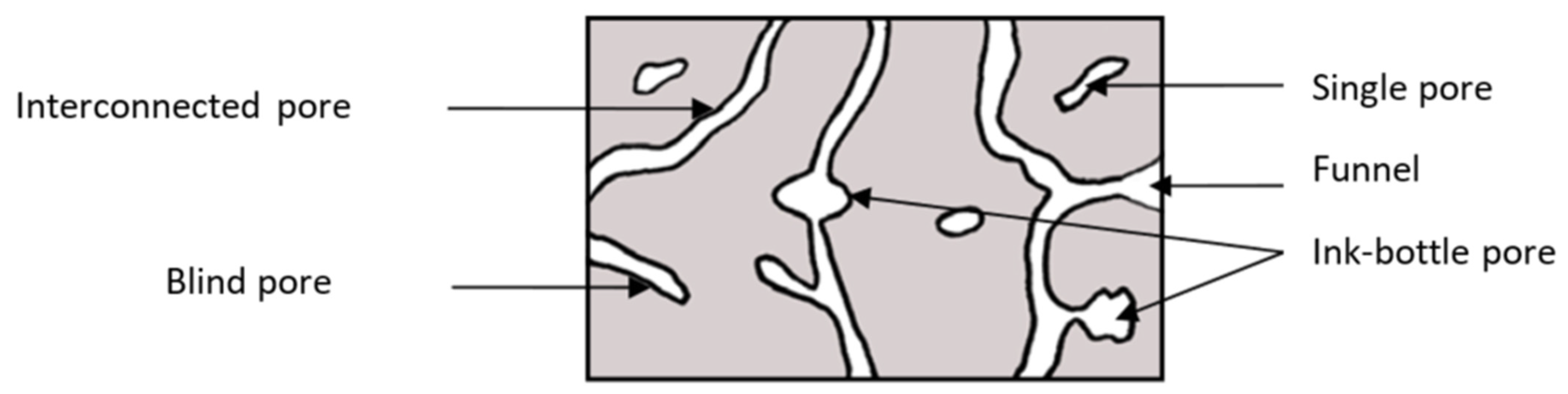

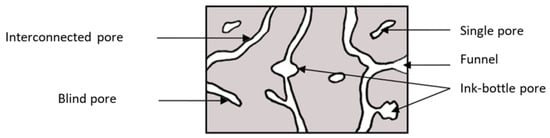

The offset between the sorption and desorption curves is commonly explained by an ink-bottle effect (Figure 10), capillary condensation, and/or the contact angle difference [17,20,55,57,64,65]. No distinction is made based on the nature of the material where hysteresis is observed.

Figure 10.

Schematic diagram of the porous network [17].

To date, the explanations remain open since there is no real consensus on this subject [54,66].

3. From Hydrogen Bonding to Hysteresis

3.1. Hydrogen Bonding

Hydrogen and Van der Waals bonds are modelled by dipole–dipole interactions [67,68]. Although they both result from electrostatic interaction, hydrogen bonds have a higher binding energy due to the strong polarization of the hydroxyl groups. On the other hand, a covalent bond results from the pooling of valence electrons between two atoms. It involves a chemical reaction that is not reversible. Consequently, the binding energies differ since they result from different phenomena (Table 1). Finally, the greater the binding energy, the more difficult it is to break the bond. Thus, hydrogen bonds can break or change form easily at ambient temperature (300 K) due to their low bonding energy [67]. Nevertheless, for the same type of bond, the binding energy may differ according to the nature of the atoms and molecules involved.

Table 1.

Order of size of different bonds [67].

It should be noted that Van der Waals interactions, mentioned to explain the first step of water fixation in bio-based materials (cf. Section 2.2), are about 10 times weaker than hydrogen bonds. Moreover, it is well known that water, a polar molecule, forms hydrogen bonds [69]. It establishes hydrogen bonds rather than Van der Waals bonds as far as possible. The two interactions are different and should not be confused [68].

In addition, cellulose is a host polymer concerning hydrogen bonding due to its hydroxyl groups [70]. Recent work highlights the potential of hydrogen bonding in porous molecular materials [71]: They condition the spatial organization of the microstructure [72].

3.2. Microscopic Understanding of Hysteresis

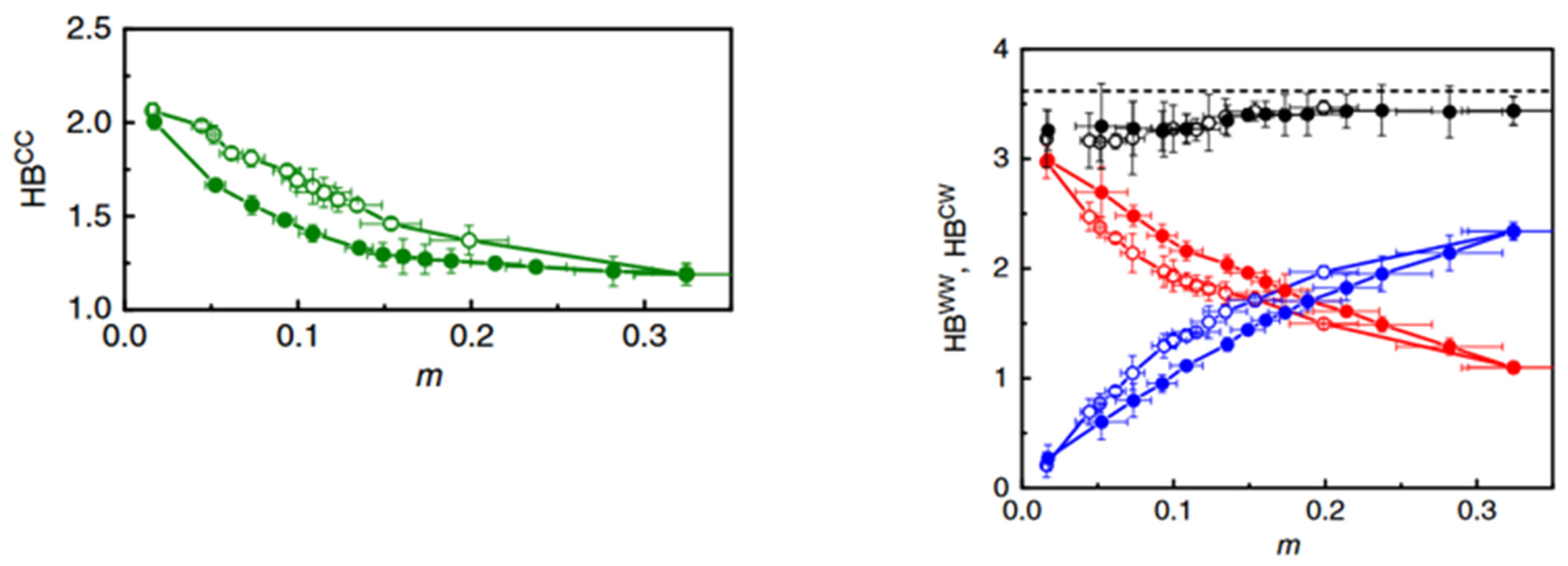

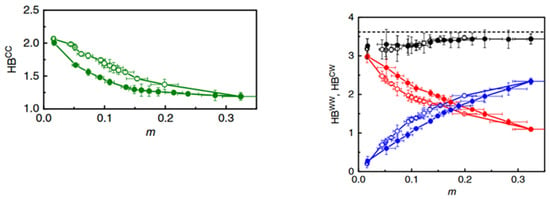

A recent study demonstrated a molecular-scale coupling mechanism to explain the sorption hysteresis and swelling of polymers such as cellulose [7]. The authors explained that three types of hydrogen bonds coexist within cellulose:

- Intermolecular hydrogen bonds between water molecules (HBWW);

- Intermolecular hydrogen bond between water molecules and cellulose (HBCW);

- Inter-chain hydrogen bonds in cellulose (HBCC).

The sequence of creation/breakage of these hydrogen bonds is conditioned by the phase observed: sorption or desorption.

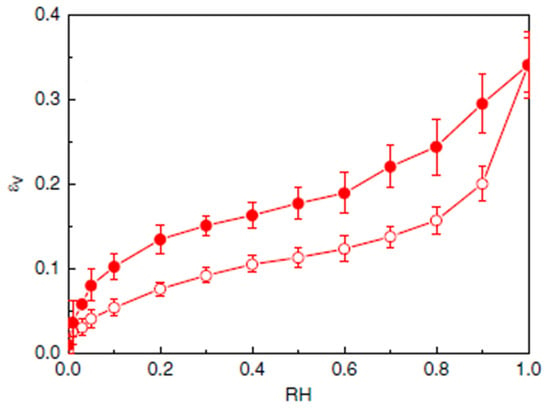

Water is first physisorbed (through HBCW) in the sorption phase (to the cellulose chains. The cellulose swells and the number of HBCC decreases with increasing water content. Consequently, the intermolecular bonds in cellulose (HBCC) break: More and more hydroxyl groups are accessible to form HBCW. Simultaneously, the number of HBWW increases, reflecting the formation of water clusters within the polymer pore space (Figure 11).

Figure 11.

Number of HBCC (on the left)/HBWW and HBCW versus moisture content (m) from Chen et al. [7].

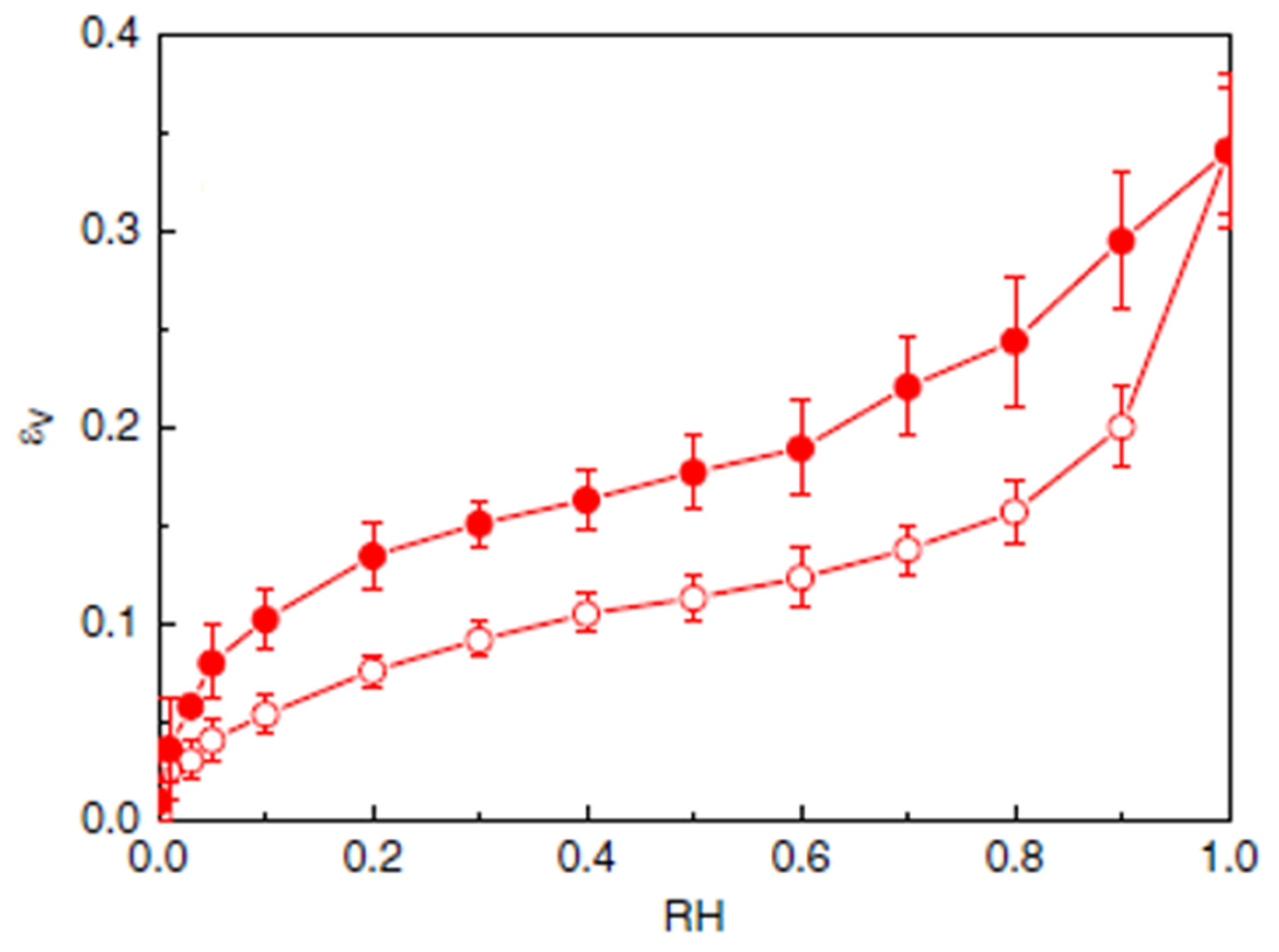

In the desorption phase, lower energy bonds break first. As HBCW is stronger than HBWW, water molecules are first removed from pore water clusters. Thus, there are more HBCW in the desorption than in the sorption phase for the same relative humidity since more “host sites” are accessible in the polymer. This microscopic phenomenon leads to an observable hysteresis in the sorption-induced swelling of cellulose (Figure 12).

Figure 12.

Hysteresis in sorption-induced swelling in the case of cellulose [7].

The existence of differentiated hydrogen bonds between the water sorption and desorption phases in amorphous cellulose has been clearly demonstrated. It causes macroscopic hysteresis within the polymer. This leads us to consider these results while analyzing the behavior of bio-based materials.

In addition, Chen et al. pointed out that the moisture content first increases rapidly (low relative humidity) and then less rapidly (higher relative humidity). This inflection point in the adsorption isotherm can be explained by an initial rapid and easy adsorption of water molecules into the initially available host sites of cellulose. Subsequently, the cellulose chains open up and more water molecules are adsorbed, but the process is slower. Finally, the authors indicated that the pore size prevents the phenomenon of capillary hysteresis in nanoporous media (with pores smaller than 2 nm). Thus, in cellulose, where the pores are smaller than 1 nm, capillary hysteresis cannot take place.

4. Discussion: New Insights into Hysteresis in Bio-Sourced Materials

4.1. A Necessary New Approach

The explanations for hysteresis provided in the literature are open to criticism. First, SEM images show that the plant aggregates have a tubular morphology. No pronounced narrowing or widening is visible. The hypothesis of ink-bottle-shaped pores is not justified at this scale. It is more relevant at the scale of the material due to a multi-scale complex and tortuous porosity. However, in the case of plant aggregates, the pore size is measured in tens of micrometers [73], so capillary hysteresis is founded.

Furthermore, covalent bonds cannot explain the sorption mechanism, since sorption is reversible. In contrast, it seems appropriate to regard weaker bonds as Van der Waals or hydrogen bonds to explain water sorption and desorption.

In addition, whether it is through the ink-bottle effect, the capillary condensation, and/or the contact angle difference, the hypotheses mentioned assume that the condensed state of the water is reached. However, capillary condensation occurs from 80% RH (cf. Figure 3). The sorption and desorption curves do not overlap, even at low relative humidity. Moreover, although the smallest pores can contain liquid water, they probably cannot account for the entire shift between the curves at low humidity values. Finally, no assumption made so far can explain other observables such as swelling, sorption kinetics, and temperature effects.

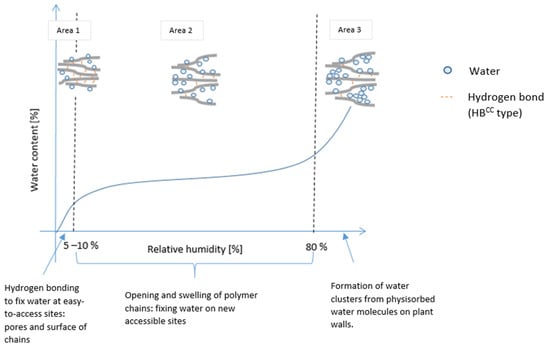

4.2. Hysteresis: From the Aggregate Scale to the Material One

- (i)

- A new water fixation mechanism

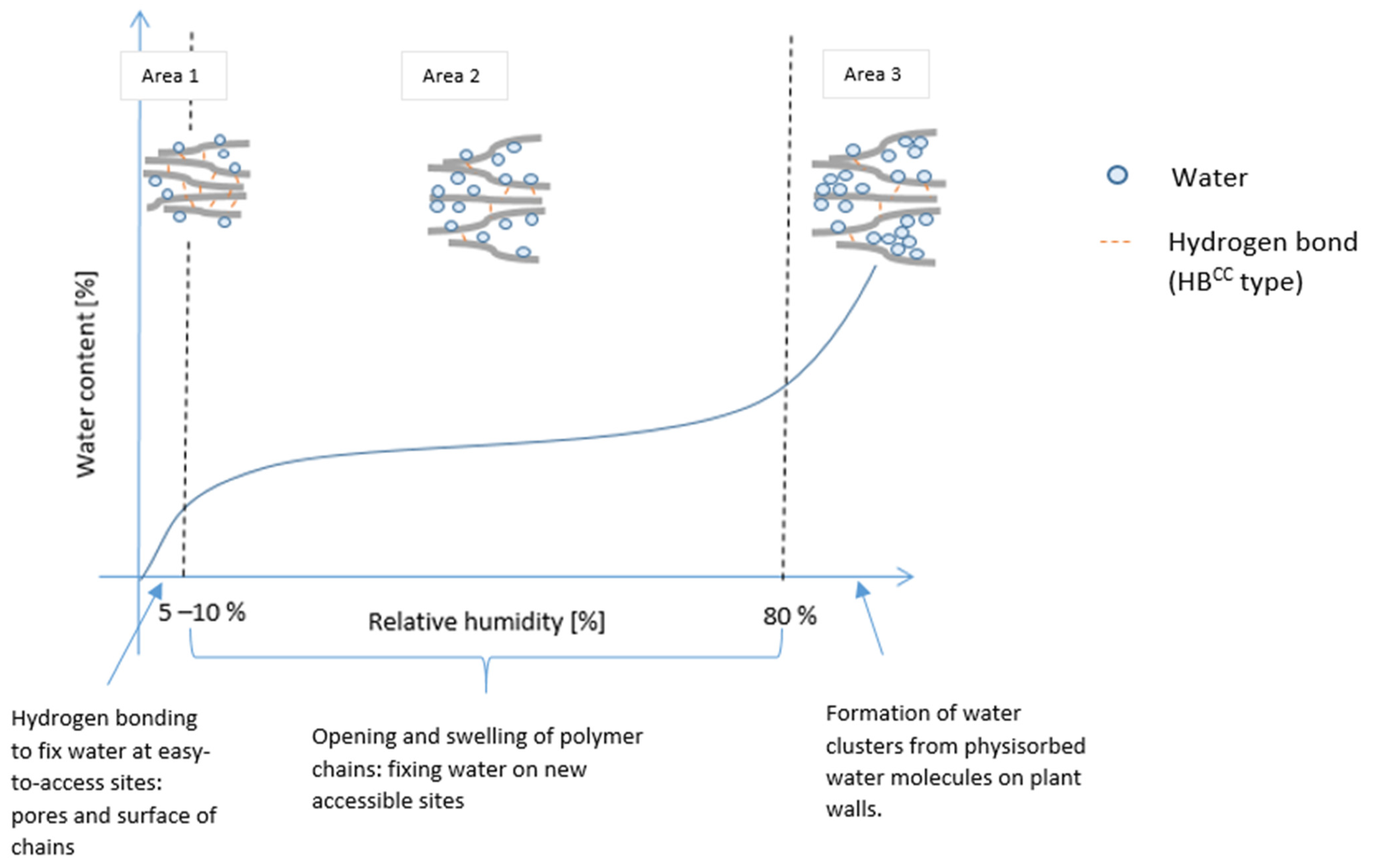

It is now possible to differentiate the modes of water fixation between the pore network of the plant aggregate and that of the material (vegetal concrete or lightened earth). This means that the plant aggregate’s lignocellulosic nature is considered. Nevertheless, as most sorption sites for hydrogen bonds have been found in the hemicellulose, followed by cellulose and lignin [74], this study does not consider the nature of the polymers in the plant aggregate. Only the scale of the plant particle and the material are differentiated. A new water fixation mechanism is thus proposed (Figure 13).

Figure 13.

Water fixation mechanism in bio-based materials at the molecular scale in plant particles.

The bonds involved in the process are likely to be hydrogen bonds, although Van Der Waals bonds (induced dipole) may occur at the margin. Only hydrogen bonds are considered here. Thus, different regions of the curve and the corresponding slopes show the existence of three processes with different kinetics:

- Area 1: Water fixation on a pore surface is relatively fast because the host sites are easily accessible: HBCW bonds form on polymer surface chains or in pores of an amorphous region, and then HBWW form easily until the initial pores are filled.

- Area 2: Polymer chains open up, freeing new host sites to create HBCW bonds. In parallel, HBCC bonds break.

- Area 3: At high relative humidity, hydrogen bonds mostly form between water molecules because many host sites are occupied on polymer chains. This leads to water clusters in the new pore spaces created by the swelling of the polymer chains. Because host sites are very accessible, the associated kinetics are quite fast, as in area 1.

- (ii)

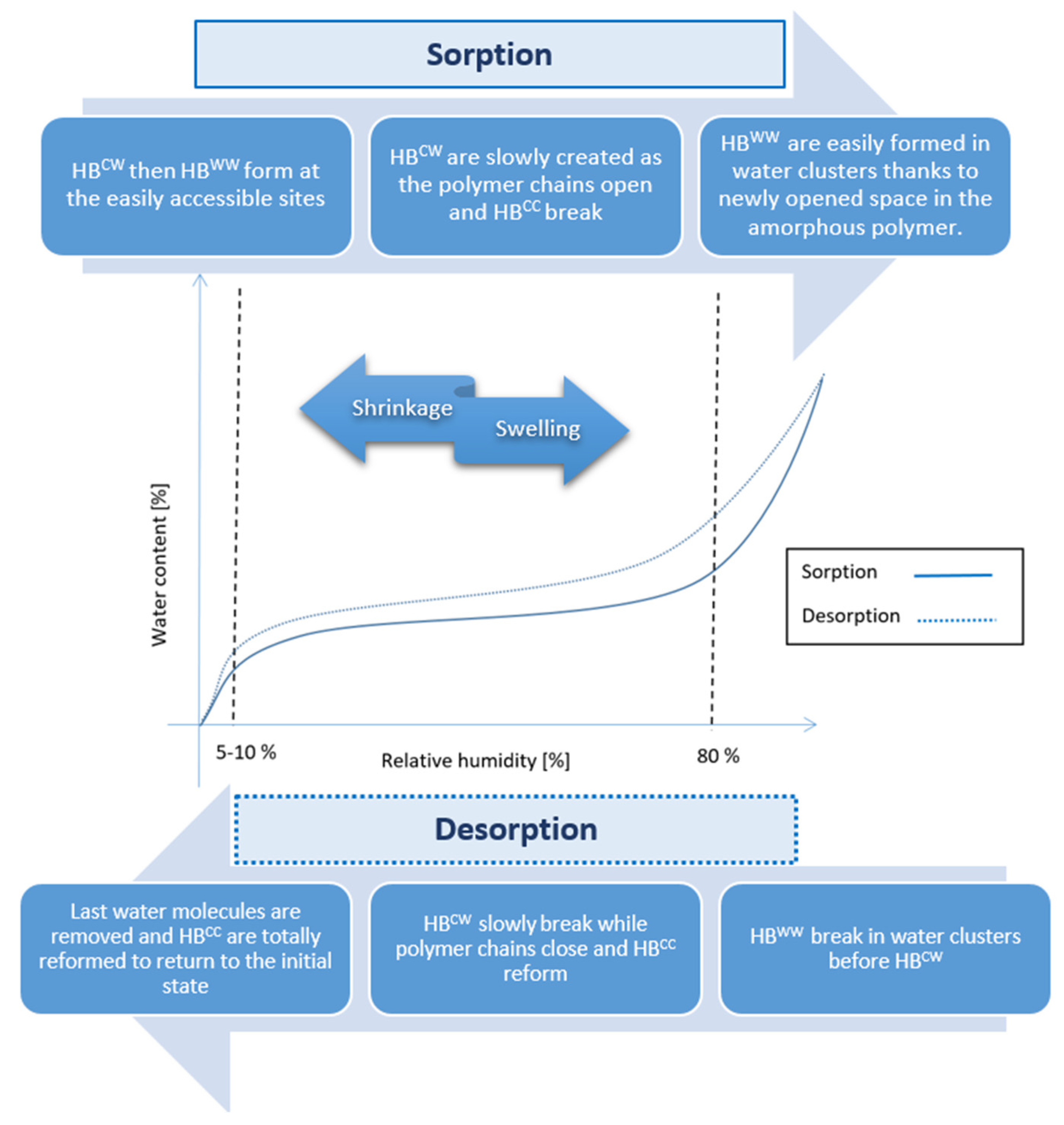

- A new description of hysteresis

Furthermore, from the results presented in Section 2.2, it is assumed that, when plant aggregate is subjected to an increase in relative humidity, more and more new “host sites” become available to create HBCW bonds. Those bonds are not broken at the same relative humidity level during the desorption phase. This is assumed to be the only cause of hysteresis at the particulate scale up to 80% RH. First, this phenomenon has been proven, and second, the microstructure of the plant aggregates is inconsistent with the other assumptions made in the literature so far.

In addition, the richer the plant aggregate is in amorphous polymers (cellulose, hemicellulose, and lignin), the likelier it is that the mechanism will occur.

In contrast, at the material level, the ink-bottle effect, capillary condensation, and/or the contact angle difference probably coexist—especially at high humidity when water is mostly liquid. Consequently, a new description of hysteresis in bio-based building material can be proposed (Figure 14).

Figure 14.

Hysteresis mechanism in bio-based building materials explained thanks to differentiated hydrogen bonds in plant particles.

4.3. Experimental Measurments

- (i)

- Protocol

Sunflower pith panels manufactured without binder were dried in an oven (under 60 °C) until stabilization of mass to ensure no adsorbed water remained in the aggregate. The dimensions of the particleboards were measured with a caliper in the dry state. The particleboards were then placed in an enclosure under 80% relative humidity until stabilization. The dimensions of the particleboards were measured again with a caliper in this humid state. This allowed the volumes of the panels to be compared in their dry and wet states.

- (ii)

- Dimension comparison

The results of the dry and wet measurements are presented in Table 2.

Table 2.

Comparison of particleboard dimensions (without binder) in dry and wet conditions.

Both observation and experimental measurements showed significant swelling of the sunflower pith panels. From the dry to wet state, the swelling observed was on average 6%. As these particleboards were made up entirely of particles, the swelling observed was clearly a process that took place in the sunflower pith. It was a macroscopic demonstration of the microscopic hydro-mechanical coupling within the aggregate. It is worth noticing that sunflower pith, as a bio-aggregate, is mainly composed of cellulose (cf. Section 2.3). The experimental measurements support the theory defended in this study.

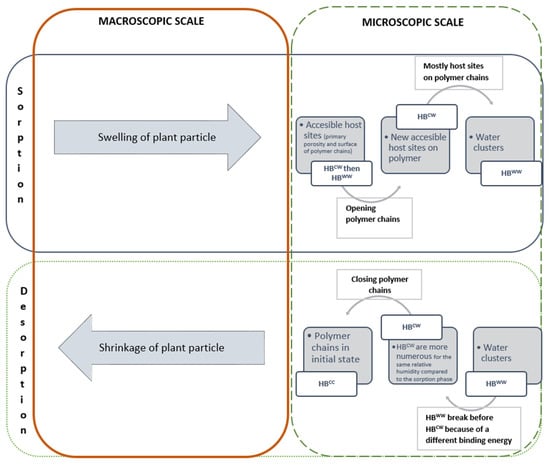

4.4. Macroscopic Effects

The theory put forward in the previous section is supported by a wide range of macroscopic observations. Thus, it is possible to connect and explain all of these points—raised in Section 2—through sorption–swelling coupling (Table 3).

Table 3.

Macroscopic observations of sorption–swelling coupling that causes hysteresis in bio-based building materials.

All of these elements allow us to establish the relevance of taking this recently demonstrated sorption–swelling coupling effect into account. It improves our understanding and description of hysteresis and its consequences in bio-based building materials.

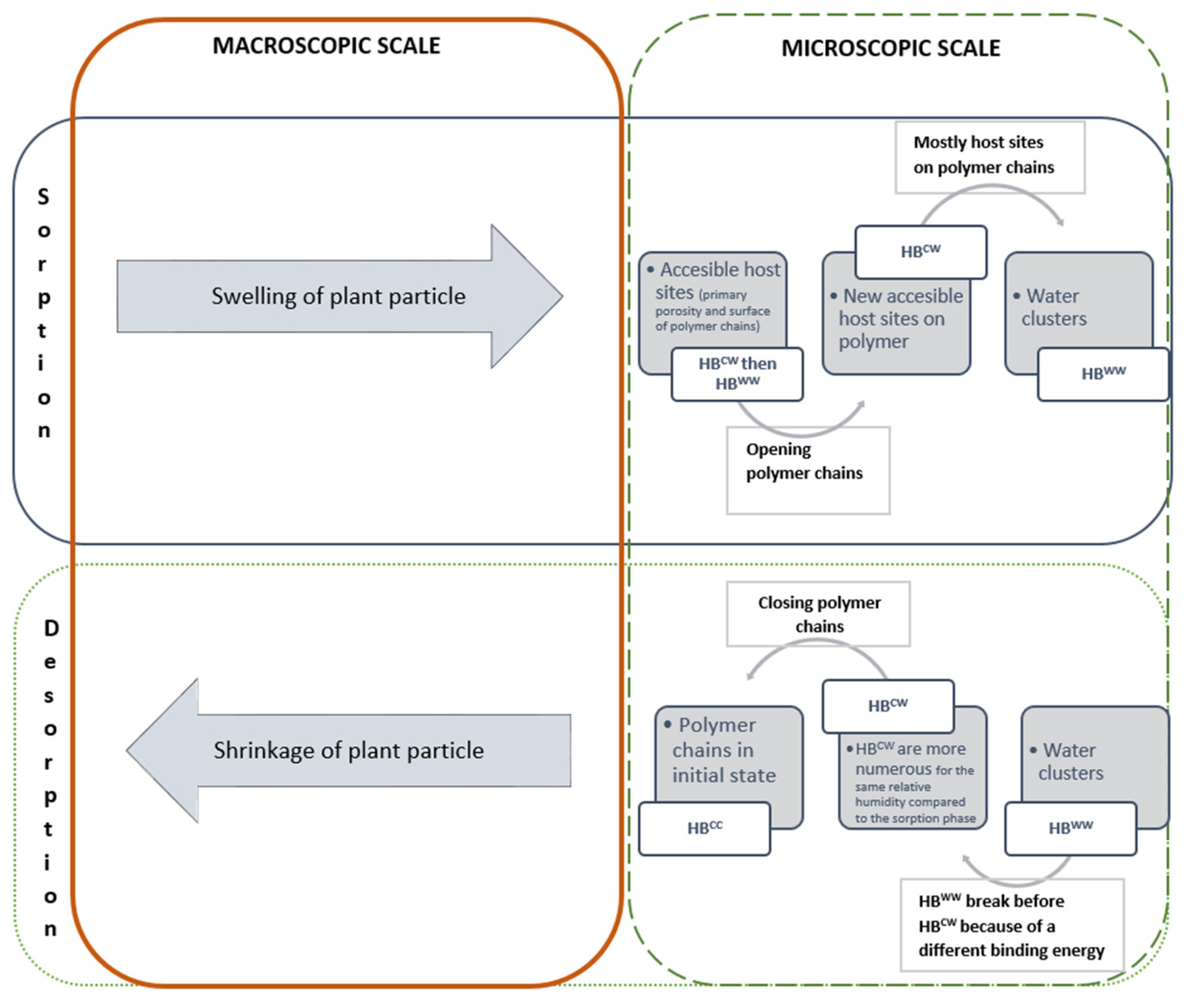

In view of all of the elements discussed above, a new multi-scale schematization of bio-based material behavior is proposed (Figure 15).

Figure 15.

Sorption–desorption of water: summary diagram of the reversible coupling process at the plant particle scale that causes hysteresis in bio-based building material.

This demonstrates the link between molecular-scale phenomena and their consequences at the macroscopic scale. It thus highlights the hydro-mechanical multi-scale coupling of these materials.

5. Conclusions

This study demonstrates the need to reconsider the description of water sorption in bio-based building materials. The explanations put forward in the literature are not to be totally discarded but are not sufficient. Indeed, recent work has shown how water adsorbed at the cellulose scale can induce both hysteresis and swelling of cellulose chains. The lignocellulosic nature of the plant aggregates incorporated should therefore be taken into account.

Thus, a new description of sorption hysteresis in the case of bio-based materials is proposed. It is based on the existence of hydrogen bonds that are differentiated between the water sorption and desorption phases in cellulose. These bonds are stronger than the Van der Waals bonds that have commonly been reported in the literature until now.

It is thus possible to better understand the hysteresis phenomenon widely observed in the literature for bio-based materials. A new scale of porosity that has been ignored so far is to be considered: nanoporosity (in the amorphous polymers constituting the plant aggregate). This molecular-scale hydro-mechanical coupling explains many observations at the macroscopic scale. We matched this new consideration with a set of macroscopic observables widely reported in the literature. The results were also confirmed by our own experimental measurements. This lends support to the new hypothesis suggested and shows how it is relevant.

Finally, this study opens up new perspectives:

(i) A better understanding of macroscopic swelling makes it possible to anticipate and to predict. It is important to leave a corresponding gap in the wall to avoid any disorder. In addition, swelling affects impact the porosity of the material and therefore probably affects its mechanical properties and durability.

(ii) It would be interesting to investigate whether, as in the case of hysteresis in electromagnetism, the area of the hysteresis curve provides additional information about the sorption/desorption phenomenon.

This article is the fruit of in-depth and well-argued reflection. It is based on experimental results as well as the collection and analysis of results coming from different scientific fields. It leads to a new theory being proposed to understand the hysteresis mechanism observed in bio-sourced materials. The experiment carried out on aggregate panels demonstrated that the theories put forward in literature are not sufficient to explain what is happening within the material. The ink-bottle effect is not very probable given the microstructural morphology of plant aggregates (cf. Section 4.1). A new theory considering the microscopic scale is necessary to describe hysteresis. The hydro-mechanical coupling taking place within cellulose chains has been exploited to propose a new vision. New schemes (cf. Figure 13, Figure 14 and Figure 15) of the water sorption and desorption phases within bio-sourced materials are provided. To date, plant aggregates were considered inert with respect to water absorption in the same way as conventional materials. This work therefore represents a significant advancement in the field of bio-sourced materials, since for the first time the lignocellulosic nature of the aggregate is taken into account. This means that new specific physicochemical phenomena need to be considered.

To conclude, this work combines the fields of chemistry, civil engineering, and applied physics in order to open new perspectives. This allowed for the removal of some grey areas in the hysteresis phenomenon, which remains a key factor when considering bio-based building materials. Our work underlines the interest of conducting interdisciplinary studies to understand the full complexity of bio-based materials.

Author Contributions

Conceptualization, S.R.L.; methodology, S.R.L.; software, S.R.L.; validation, S.R.L., V.S. and A.A.-C.; formal analysis, S.R.L.; investigation, S.R.L.; resources, S.R.L.; data curation, S.R.L.; writing—original draft preparation, S.R.L.; writing—review and editing, S.R.L.; visualization, S.R.L.; supervision, A.A.-C.; project administration, S.R.L.; funding acquisition, S.R.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lagouin, M.; Magniont, C.; Sénéchal, P.; Moonen, P.; Aubert, J.-E.; Laborel-préneron, A. Influence of types of binder and plant aggregates on hygrothermal and mechanical properties of vegetal concretes. Constr. Build. Mater. 2019, 222, 852–871. [Google Scholar] [CrossRef]

- Maaroufi, M.; Bennai, F.; Belarbi, R.; Abahri, K. Experimental and numerical highlighting of water vapor sorption hysteresis in the coupled heat and moisture transfers. J. Build. Eng. 2021, 40, 102321. [Google Scholar] [CrossRef]

- Issaadi, N. Effets De La Variabilité Des Propriétés De Matériaux Cimentaires Sur Les Transferts Hygrothermiques: Développement D’une Approche Probabiliste. Ph.D. Thesis, Laboratoire des Sciences de l’Ingénieur Pour l’Environnement, La Rochelle, France, 2015. [Google Scholar]

- Bennai, F.; El Hachem, C.; Abahri, K.; Belarbi, R. Microscopic hydric characterization of hemp concrete by X-ray microtomography and digital volume correlation. Constr. Build. Mater. 2018, 188, 983–994. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Magniont, C.; Aubert, J.-E. Characterization of Barley Straw, Hemp Shiv and Corn Cob as Resources for Bioaggregate Based Building Materials. Waste Biomass Valoriz. 2018, 9, 1095–1112. [Google Scholar] [CrossRef]

- Aït Oumeziane, Y.; Moissette, S.; Bart, M.; Lanos, C. Influence of temperature on sorption process in hemp concrete. Constr. Build. Mater. 2016, 106, 600–607. [Google Scholar] [CrossRef]

- Chen, M.; Coasne, B.; Guyer, R.; Derome, D.; Carmeliet, J. Role of hydrogen bonding in hysteresis observed in sorption-induced swelling of soft nanoporous polymers. Nat. Commun. 2018, 9, 3507. [Google Scholar] [CrossRef]

- Jami, T.; Karade, S.R.; Singh, L.P. A review of the properties of hemp concrete for green building applications. J. Clean. Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Delannoy, G.; Marceau, S.; Glé, P.; Gourlay, E.; Guéguen-Minerbe, M.; Diafi, D.; Nour, I.; Amziane, S.; Farcas, F. Performances des bétons de chanvre: Des propriétés microscopiques aux propriétés fonctionnelles. Acad. J. Civ. Eng. 2017, 35, 194–197. [Google Scholar] [CrossRef]

- Abbas, M.S.; Gourdon, E.; Glé, P.; McGregor, F.; Ferroukhi, M.Y.; Fabbri, A. Relationship between hygrothermal and acoustical behavior of hemp and sunflower composites. Build. Environ. 2021, 188, 107462. [Google Scholar] [CrossRef]

- Collet, F.; Chamoin, J.; Pretot, S.; Lanos, C. Comparison of the hygric behaviour of three hemp concretes. Energy Build. 2013, 62, 294–303. [Google Scholar] [CrossRef]

- Ratsimbazafy, H.H.; Laborel-Preneron, A.; Magniont, C.; Evon, P. A review of the multi-physical characteristics of plant aggregates and their effects on the properties of plant-based concrete. Recent Prog. Mater. 2021, 3, 2. [Google Scholar] [CrossRef]

- Maaroufi, M. Modélisation Des Transferts Hygrothermiques Dans Les Matériaux De Construction: Incidence de L’hystérésis. Ph.D. Thesis, Laboratoire des Sciences de l’Ingénieur Pour l’Environnement, La Rochelle, France, 2019. [Google Scholar]

- Mazhoud, B.; Collet, F.; Prétot, S.; Lanos, C. Effect of hemp content and clay stabilization on hygric and thermal properties of hemp-clay composites. Constr. Build. Mater. 2021, 300, 123878. [Google Scholar] [CrossRef]

- Babaee, M.; Castel, A. Water vapor sorption isotherms, pore structure, and moisture transport characteristics of alkali-activated and Portland cement-based binders. Cem. Concr. Res. 2018, 113, 99–120. [Google Scholar] [CrossRef]

- Promis, G.; Freitas Dutra, L.; Douzane, O.; Tran Le, A.D.; Langlet, T. Temperature-dependent sorption models for mass transfer throughout bio-based building materials. Constr. Build. Mater. 2019, 197, 513–525. [Google Scholar] [CrossRef]

- Collet, F. Caracterisation Hydrique Et Thermique De Materiaux De Genie Civil A Faibles Impacts Environnementaux. Ph.D. Thesis, L’institut National des Sciences Appliquées de Rennes, Rennes, France, 2004. [Google Scholar]

- Magniont, C. Contribution à la Formulation et à la Caractérisation d’un Écomatériau de Construction à Base D’agroressources. Ph.D. Thesis, University of Toulouse III-Paul Sabatier, Toulouse, France, 2010. [Google Scholar]

- Le Troëdec, M.; Rachini, A.; Peyratout, C.; Rossignol, S.; Max, E.; Kaftan, O.; Fery, A.; Smith, A. Influence of chemical treatments on adhesion properties of hemp fibres. J. Colloid Interface Sci. 2011, 356, 303–310. [Google Scholar] [CrossRef] [PubMed]

- Benmahiddine, F. Études des Transferts Couplés de Chaleur, D’air et D’humidité par des Techniques de Changement D’échelle (Microscopique-Macroscopique): Application à L’évaluation de la Performance Énergétique et la Durabilité Des Matériaux de Construction. Ph.D. Thesis, Laboratoire des Sciences de l’Ingénieur Pour l’Environnement, La Rochelle, France, 2020. [Google Scholar]

- Lagouin, M. Caractérisation et Optimisation Multiphysiques D’une Paroi Bicouche bio et Géosourcée. Ph.D. Thesis, University of Toulouse III-Paul Sabatier, Toulouse, France, 2020. [Google Scholar]

- Magniont, C.; Escadeillas, G. Chemical Composition of Bio-aggregates and Their Interactions with Mineral Binders. In Bio-Aggregates Based Building Materials: State-of-the-Art Report of the RILEM Technical Committee 236-BBM; Amziane, S., Collet, F., Eds.; RILEM State-of-the-Art Reports; Springer: Dordrecht, The Netherlands, 2017; pp. 1–37. ISBN 978-94-024-1031-0. [Google Scholar]

- Ratsimbazafy, H.H.; Laborel-Preneron, A.; Magniont, C.; Evon, P. Comprehensive Characterization of Agricultural By-Products for Bio-Aggregate Based Concrete. Constr. Technol. Archit. 2022, 1, 77–84. [Google Scholar]

- Stevulova, N.; Cigasova, J.; Schwarzova, I.; Sicakova, A.; Junak, J. Sustainable Bio-Aggregate-Based Composites Containing Hemp Hurds and Alternative Binder. Buildings 2018, 8, 25. [Google Scholar] [CrossRef]

- Amziane, S.; Collet, F. Bio-Aggregates Based Building Materials: State-of-the-Art Report of the RILEM Technical Committee 236-BBM; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 978-94-024-1031-0. [Google Scholar]

- Dujardin, N. Un Materiau Biosource de Choix: Les Fibres Naturelles. In Caractérisations et applications. In Proceedings of the 25th Journées Scientifiques de l’Environnement-L’économie Verte en Question, Créteil, France, 18 February 2014. [Google Scholar]

- Gehring, F. Étude du Comportement Mécanique et de L’endommagement de Composites Thermoplastiques Renforcés de Fibres Courtes de Chanvre: Approche Expérimentale et Modélisation; Université de Lorraine: Nancy, France, 2013. [Google Scholar]

- Gardner, K.H.; Blackwell, J. The hydrogen bonding in native cellulose. Biochim. Biophys. Acta BBA-Gen. Subj. 1974, 343, 232–237. [Google Scholar] [CrossRef]

- Perez, S. Structure et Morphologie de la Cellulose. 2000. Available online: https://www.researchgate.net/publication/281877184_Structure_et_morphologie_de_la_cellulose (accessed on 12 April 2023).

- Teeri, T.T. Crystalline cellulose degradation: New insight into the function of cellobiohydrolases. Trends Biotechnol. 1997, 15, 160–167. [Google Scholar] [CrossRef]

- Sofiane, A.; Laurent, A. Les Bétons de Granulats D’origine Végétale: Application au Béton de Chanvre; Lavoisier: Paris, France, 2013; ISBN 978-2-7462-8809-6. [Google Scholar]

- Mitra, G.B.; Mukherjee, P.S. X-ray diffraction study of fibrous polymers. I. Degree of paracrystallinity—A new parameter for characterizing fibrous polymers. Polymer 1980, 21, 1403–1409. [Google Scholar] [CrossRef]

- Frollini, E.; Leao, A.; Mattoso, L.; Rowell, R.; Han, J.; Rowell, J. Characterization and Factors Effecting Fiber Properties. Nat. Polym. Agrofibers Compos. 2000. [Google Scholar]

- Rebiere, J. Nouvelle Méthodologie Pour la Caractérisation de Distributions de Masses Molaires D’échantillons Cellulosiques Complexes; Institut National Polytechnique: Toulouse, France, 2017. [Google Scholar]

- Pinkert, A.; Marsh, K.; Pang, S.; Staiger, M. Ionic Liquids and Their Interaction with Cellulose. Chem. Rev. 2009, 109, 6712–6728. [Google Scholar] [CrossRef] [PubMed]

- Rabideau, B.D.; Ismail, A.E. Mechanisms of hydrogen bond formation between ionic liquids and cellulose and the influence of water content. Phys. Chem. Chem. Phys. 2015, 17, 5767–5775. [Google Scholar] [CrossRef] [PubMed]

- Troncoso, V.; Kouta, N.; Escadeillas, G.; Barragan, V.H.G. Réactivité Des Cendres Volcaniques Équatoriennes Dans Les Liants Minéraux. 2022. Available online: https://hal.science/hal-03879708 (accessed on 12 April 2023).

- Chabannes, M.; Nozahic, V.; Amziane, S. Design and multi-physical properties of a new insulating concrete using sunflower stem aggregates and eco-friendly binders. Mater. Struct. 2015, 48, 1815–1829. [Google Scholar] [CrossRef]

- Ouedraogo, K.A.J. Stabilisation de Matériaux de Construction Durables et Écologiques à Base de Terre Crue Par Des Liants organiques et/ou Minéraux à Faibles Impacts Environnementaux. Ph.D. Thesis, University of Toulouse III-Paul Sabatier, Toulouse, France, 2019. [Google Scholar]

- Guide des Bonnes Pratiques de la Construction en Terre Crue. Available online: https://www.rehabilitation-bati-ancien.fr/espace-documentaire/guide-des-bonnes-pratiques-la-construction-en-terre-crue (accessed on 12 April 2023).

- Garcia-Boivin, S. Retrait au Jeune Age du Beton: Developpement D’une Methode Experimentale et Contribution a L’analyse Physique du Retrait Endogene. 1999. Available online: https://trid.trb.org/view/960738 (accessed on 12 April 2023).

- Matthieu, M.S. Potentiel des Fibres Végétales Courtes Dans L’amélioration du Comportement Mécanique des Mortiers. Ph.D. Thesis, INSA de Toulouse, Toulouse, France, 2022. [Google Scholar]

- Achour, C.; Remond, S.; Belayachi, N. Mesure du gonflement-retrait des granulats végétaux par analyse d’image. Acad. J. Civ. Eng. 2022, 40, 104–107. [Google Scholar] [CrossRef]

- Marceau, S.; Glé, P.; Gourlay, E.; Gueguen-Minerbe, M.; Delannoy, G.; Amziane, S.; Farcas, F. Impact de vieillissements accélérés sur les propriétés de bétons de chanvre. Acad. J. Civ. Eng. 2016, 34, 712–719. [Google Scholar] [CrossRef]

- Delannoy, G. Durabilité du béton de chanvre soumis à des cycles d’humidification-séchage. Acad. J. Civ. Eng. 2018, 36, 400–407. [Google Scholar] [CrossRef]

- Benmahiddine, F.; Bennai, F.; Cherif, R.; Belarbi, R.; Tahakourt, A.; Abahri, K. Experimental investigation on the influence of immersion/drying cycles on the hygrothermal and mechanical properties of hemp concrete. J. Build. Eng. 2020, 32, 101758. [Google Scholar] [CrossRef]

- Delannoy, G.; Marceau, S.; Glé, P.; Gourlay, E.; Guéguen-Minerbe, M.; Amziane, S.; Farcas, F. Durability of hemp concretes exposed to accelerated environmental aging. Constr. Build. Mater. 2020, 252, 119043. [Google Scholar] [CrossRef]

- Bourdot, A.; Moussa, T.; Gacoin, A.; Maalouf, C.; Vazquez, P.; Thomachot-Schneider, C.; Bliard, C.; Merabtine, A.; Lachi, M.; Douzane, O.; et al. Characterization of a hemp-based agro-material: Influence of starch ratio and hemp shive size on physical, mechanical, and hygrothermal properties. Energy Build. 2017, 153, 501–512. [Google Scholar] [CrossRef]

- Rode, C.; Clorius, C.O. Modeling of Moisture Transport in Wood with Hysteresis and Temperature-Dependent Sorption Characteristics. Available online: https://web.ornl.gov/sci/buildings/conf-archive/2004%20B9%20papers/154_Rode.pdf (accessed on 12 April 2023).

- Le, A.D.T.; Samri, D.; Rahim, M.; Douzane, O.; Promis, G.; Langlet, T. Effect of Temperature-dependent Sorption Characteristics on The Hygrothermal Behavior of Hemp Concrete. Energy Procedia 2015, 78, 1449–1454. [Google Scholar] [CrossRef]

- Reuge, N.; Moissette, S.; Bart, M.; Collet, F.; Lanos, C. Modèle de cinétique locale de sorption couplé au phénomène d’hystérésis pour les matériaux biosourcés. Acad. J. Civ. Eng. 2018, 36, 43–46. [Google Scholar] [CrossRef]

- Reuge, N.; Collet, F.; Pretot, S.; Moissette, S.; Bart, M.; Lanos, C. Cinétique locale de sorption: Modélisation d’une paroi biosourcée. Acad. J. Civ. Eng. 2021, 38. [Google Scholar] [CrossRef]

- Yacine, A.O.; Bart, M.; Moissette, S.; Lanos, C.; Collet, F.; Pretot, S. Hysteresis phenomenon in hemp concrete. In Proceedings of the First International Conference on Bio-based Building Materials, Clermont-Ferrand, France, 22–24 June 2015. [Google Scholar]

- Nouri, M. Développement D’éléments en Biocomposite à Base de Fibre Végétale Pour la Réhabilitation Énergétique des Bâtiments. Ph.D. Thesis, Ecole centrale de Nantes, Nantes, France, 2020. [Google Scholar]

- Abbas, M.S. Caractérisations Multi-Physiques Des Mortiers Bio-Sourcés Isolants et Modélisation de Leurs Impacts Sur Les Transferts Hygrothermiques à L’échelle des Parois: Application Aux Bétons de Moelles Végétales. Ph.D. Thesis, Laboratoire de Tribologie et Dynamique des Systèmes, Lyon, France, 2021. [Google Scholar]

- Lelièvre, D. Simulation Numérique Des Transferts De Chaleur Et D’humidité Dans Une Paroi Multicouche De Bâtiment En Matériaux Biosourcés. Ph.D. Thesis, Université de Bretagne Sud, Lorient, France, 2015. [Google Scholar]

- Maalouf, C.; Moussa, T.; Umurigirwa, B.S.; Mai, T.H. Etude Des Isothermes De Sorption D’un Agromatériau À Base De Chanvre-Amidon. Available online: https://www.sft.asso.fr/Local/sft/dir/user-3775/documents/actes/Congres_2015/Communications/38383-fichier4.pdf (accessed on 12 April 2023).

- Abbas, M.S.; McGregor, F.; Fabbri, A.; Ferroukhi, M.Y. The use of pith in the formulation of lightweight bio-based composites: Impact on mechanical and hygrothermal properties. Constr. Build. Mater. 2020, 259, 120573. [Google Scholar] [CrossRef]

- Bennai, F.; Issaadi, N.; Abahri, K.; Belarbi, R.; Tahakourt, A. Experimental characterization of thermal and hygric properties of hemp concrete with consideration of the material age evolution. Heat Mass Transf. 2018, 54, 1189–1197. [Google Scholar] [CrossRef]

- Bhouri, N. Comportement Thermodynamique Et Dimensionnel Des Matériaux Textiles Soumis À Des Variations Des Conditions Climatiques. Ph.D. Thesis, Laboratoire d’Etude et de Recherche sur le Matériau Bois, Nancy, France, 2009. [Google Scholar]

- Fabbri, A.; McGregor, F. Impact of the determination of the sorption-desorption curves on the prediction of the hemp concrete hygrothermal behaviour. Constr. Build. Mater. 2017, 157, 108–116. [Google Scholar] [CrossRef]

- Soudani, L. Modelling and Experimental Validation of the Hygrothermal Performances of Earth as A Building Material. Ph.D. Thesis, Laboratoire de Tribologie et Dynamique des Systèmes, Lyon, France, 2016. [Google Scholar]

- Champiré, F. Étude expérimentale du comportement hydro-mécanique de la terre crue compactée pour la construction. Ph.D. Thesis, Université de Lyon, Lyon, France, 2017. [Google Scholar]

- Zhang, Z. Modelling Of Sorption Hysteresis and Its Effect on Moisture Transport within Cementitious Materials. Ph.D. Thesis, Université Paris-Est, Créteil, France, 2014. [Google Scholar]

- Oumeziane, Y.A. Evaluation Des Performances Hygrothermiques D’une Paroi Par Simulation Numérique: Application Aux Parois En Béton De Chanvre. Ph.D. Thesis, INSA de Rennes, Rennes, France, 2013. [Google Scholar]

- Derluyn, H.; Derome, D.; Carmeliet, J.; Stora, E.; Barbarulo, R. Hysteretic moisture behavior of concrete: Modeling and analysis. Cem. Concr. Res. 2012, 42, 1379–1388. [Google Scholar] [CrossRef]

- Cavillon, F. Caractérisation De La Liaison Hydrogène Dans Des Systèmes Moléculaires D’intérêt Biologique Par Diffusion De Neutrons. Ph.D. Thesis, Université des Sciences et Technologie de Lille-Lille I, Villeneuve-d’Ascq, France, 2004. [Google Scholar]

- Steiner, T.; Desiraju, G.R. Distinction between the weak hydrogen bond and the van der Waals interaction. Chem. Commun. 1998, 891–892. [Google Scholar] [CrossRef]

- Buckingham, A.D.; Del Bene, J.E.; McDowell, S.A.C. The hydrogen bond. Chem. Phys. Lett. 2008, 463, 1–10. [Google Scholar] [CrossRef]

- Spinu, M. Evaluation Des Paramètres Physiques Et Physico-Chimiques Qui Influencent L’accessibilité De La Cellulose. Ph.D. Thesis, École Nationale Supérieure des Mines de Paris, Paris, France, 2010. [Google Scholar]

- Mouchaham, G. Architectures Supramoléculaires À Structures Ouvertes Fondées Sur La Liaison Hydrogène: Élaboration, Caractérisation Structurale Et Propriétés De Sorption. Ph.D. Thesis, Toulouse 3, Toulouse, France, 2012. [Google Scholar]

- Kannam, S.K.; Oehme, D.P.; Doblin, M.S.; Gidley, M.J.; Bacic, A.; Downton, M.T. Hydrogen bonds and twist in cellulose microfibrils. Carbohydr. Polym. 2017, 175, 433–439. [Google Scholar] [CrossRef]

- Ratsimbazafy, H.H. Évaluation Du Potentiel De Co-Produits Agricoles Locaux Valorisables Dans Le Domaine Des Matériaux De Construction (Palomac). Ph.D. Thesis, Toulouse 3, Toulouse, France, 2022. [Google Scholar]

- Engelund, E.T.; Thygesen, L.G.; Svensson, S.; Hill, C.A.S. A critical discussion of the physics of wood–water interactions. Wood Sci. Technol. 2013, 47, 141–161. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).