Abstract

It is thought that there is a low level of awareness of key competencies that drive material waste reduction at the construction stage of a project which has led to the low impact of waste minimization in the construction industry. This study, therefore, explores the key competencies for driving waste minimization at the construction stage of projects. Twenty-four (24) key factors that drive CW minimization at the construction stage of projects were derived from a thorough review of existing literature. The research adopted the quantitative approach whereby a questionnaire survey involving 53 construction professionals was conducted. Factor analysis was the statistical tool employed for the analysis of the data gathered. The findings of the study revealed four major competencies that drive CW minimization: Awareness Competency (AC), Managerial Competency (MC), Personnel Ability Competency (PAC), and Communication Competency (CC). The implementation of the key competencies from the findings of the study is highly recommended for the achievement of low waste in building projects. In view of this, it is recommended that government should enact legislative and fiscal measures to instill waste management habits in the construction industry. Several studies have investigated strategies or measures for CW minimization. However, this study focused on the knowledge and skills of construction stakeholders as the main component of waste minimization competencies.

1. Introduction

The construction sector is a major economic backbone of most countries. However, construction waste (CW) has been a principal problem in this sector for years. Ebekozien et al. [] defined CW as any inefficiency that results in the use of equipment, materials, or labor in the construction of a building. USEPA [] also defined CW as building and site improvement materials and other solid waste resulting from construction, remodeling, renovation, or repair operations. The Government of Hong Kong defined CW as anything which is generated because of construction works, then abandoned, regardless of whether it has been processed or stockpiled []. In a nutshell, CW could be defined as an activity or material that adds no value to any production in the construction stage of buildings.

Sharma [] indicated that waste could be classified either as unavoidable (or natural waste) or avoidable. If the cost of waste is higher than the cost to prevent it, it is classified as avoidable waste. If the necessary investment for its reduction is higher than the economy produced, it is classified as unavoidable waste []. Wu et al. [] grouped waste from the construction field into inert, non-inert, and hazardous categories. Large amounts of waste are generated in the construction sector as compared to other sectors. In 2017, 569 million tons of construction and demolition (C&D) waste was generated in the United States, and this amount of waste is more than twice the amount of municipal solid waste. However, demolition activities account for more than 90 percent of total waste generation, while the portion attributed to construction activities amounts to less than 10 percent []. In the European Union (EU), C&D waste accounted for 36.4% of all waste in 2016 []. In 2016, 66.2 million tons of non-hazardous C&D waste were reported in the UK and 59.6 million in England []. The Ghanaian construction industry has also experienced an enormous range of CW over the years []. According to Agyekum et al. [], there is a wide variation in wastage rates of between 5% and 27% of total materials purchased for construction projects in Ghana.

Research reveals that design decisions contribute more to materials waste generation on construction sites. In addition, materials waste can be produced during the construction and operation stages [,]. Project duration, project size, activities during project delivery, as well as worker numbers greatly influence waste generation. Tzourmaklioutou [] and Amudjie et al. [] postulated that mistakes, unplanned work delivery, redundant activity, movement, delayed or premature inputs, and products or services that do not meet customer needs comprise the causes of waste on construction sites. According to Agyekum et al. [] and Salgın [], the constructability of a project should be considered in the design process to prevent or reduce the generation of excessive waste.

CW has negative effects on the environment and economy, as well as impacting project costs. The high level of waste recorded at construction sites has led to a great demand for construction materials on construction sites. The stage of construction as well as the method of construction practice, influences waste generation in project delivery. This, therefore, tends to lead to devastating effects on the environment []. Construction players have roles to play in minimizing CW to bring value for money at the end of construction projects and protect the environment through the usage of circular principles such as the five (5) ‘Rs’ (reduction, re-use, recycle, repair, and recover).

Bajjou and Chafi [] defined waste minimization as “the understanding and changing of processes in order to reduce waste at source”. Rasanjali [] also stated that any procedure, method, or action that prevents or reduces waste at its source or facilitates reuse/recycling is considered waste minimization. It could be understood from the above literature that the concept of material waste minimization tackles waste at the initial stages of the construction activity. Jaillon et al. [] conducted a study to reveal the waste minimization potential of prefabrication usage compared to traditional construction and found that prefabrication provides benefits in waste minimization (approximately 52%) on sites. Mendis [] argued that there are two waste minimization strategies, i.e., planning and controlling. Lu and Yuan [] postulated five (5) waste minimization factors at the construction stage of projects, including minimizing waste by government legislation and through design, establishing an effective waste management system, use of low-waste technologies, and improving practitioners’ viewpoints toward waste reduction. Ding et al. [] developed a system dynamic model for waste minimization at the construction stage to simulate the environmental benefits of CW reduction. Some research shows the importance of workers’ positive attitudes toward CW minimization []. According to Salgın et al. [], the primary cause of waste during the construction stage of buildings is “improper workmanship and practices”. Tam and Tam [] examined a kind of reward system called the Stepwise Incentive System (SIS), and it was found that 23% less waste was generated when SIS was implemented in a case study project in Hong Kong. According to Khan et al. [], providing training and education among staff is an important factor in waste minimization. Despite the existence of these strategies, little impact has been felt on the construction industry as far as waste minimization is concerned. It is thought that there is a low level of awareness of key competencies that drive material waste reduction at the construction stage of a project, especially in the setting of a developing country. This study, therefore, explores the key competencies for driving waste minimization at the construction stage of projects in a typical developing country (i.e., Ghana).

2. Literature Review

2.1. The Concept of Competency

The concept of competency has been touched on by various literature works, with Taylor, McClelland, and Boyatzis spearheading it in the 20th century []. Competency is the collection of knowledge, skills, and attributes that are capable of influencing an individual’s performance []. The Iceberg Theory, as propounded by Spencer and Spencer [], viewed competency as an iceberg at sea level depicting a visible part and a hidden part. Knowledge and skill form the visible part, while interpersonal, motive/trait/concept, and value/moral forms the hidden part. Prifti et al. [] defined competency as a behavior that produces successful results through the combination of knowledge, skill, attitude, and value. Competency is a series of skills and traits needed by workers for effective work delivery.

2.2. Components of Waste Minimization Competencies

To ensure waste minimization in the construction industry, there is a need to explore the core competencies required by the construction players to ensure effectiveness. Na’im [] proposed leadership and organization, basic literacy, target management, and emotional intelligence as core competencies that could drive waste minimization. The Project Management Institute [] categorized competency under knowledge, performance, and personal competencies. This study focuses on skills and knowledge as the main components of waste minimization competencies. This reiterates the position of Spencer and Spencer [] on viewing competency as an iceberg showing forth a visible part (Skills and Knowledge) and a hidden part (Trait).

Ebekozien [] defined skill as the capacity to perform a task of a mental or physical nature in order to have a specified outcome. Skills could be easily identifiable or abstract. Zhao et al. [] and Geoghegan and Dulewiz [] asserted that the effectiveness of any project’s success depends on the leadership role of the construction professionals. Therefore, in focusing on key competencies that drive waste minimization at the construction stage of a project, leadership skill was targeted. Leadership skill encompasses self-awareness, emotional resilience, intuitiveness, interpersonal sensitivity, influence, motivation, and conscientiousness [] of the construction professional in waste reduction.

The construction manager or the head in charge of waste minimization at the construction site should be able to efficiently communicate with all parties involved in CW reduction on policies governing waste management to fulfill sustainability goals. According to Li et al. [], effective communication of organizational waste management policy mobilizes support for the minimization objectives. Wagstaff [] also postulated that working cooperatively with others as opposed to separately or competitively is a prerequisite for influencing a team to perform in a desirable manner. Effective communication, information sharing, early warning systems, and the early contribution of expertise on CW needs to be enhanced to prevent construction errors, reworks, and waste []. Developing and implementing a waste management plan contributes immensely to CW reduction at the construction stage of a project. It helps to identify the forms of waste and their sources and specifies mitigating measures for them. The plan reflects the peculiarities of the project in terms of the nature and amount of waste anticipated and prescribes ways of managing them [].

According to Tatham [], supply chain management skills involve the capacity to obtain suppliers’ highest commitment, achieve just-in-time delivery, and enable lean construction in order to avoid waste due to long storage or ordering unneeded materials. The just-in-time delivery approach enables the usage of material as and when needed. This reduces double handling and damage that erupts from long storage. Alvanchi et al. [] asserted that the implementation of a Material Logistics Plan (MLP) at construction sites is an efficient way to reduce CW. Logistics management involves effective planning of materials ordering and purchase, inbound, materials movement, and storage on construction sites []. Waste minimization requires adequate estimation of materials required at different stages of projects in an attempt to reduce the likelihood of materials over-ordering and subsequent leftover, which is a key cause of waste generation []. Bearing skills in logistics management ensures efficient waste reduction.

In a nutshell, potential key factors frequently used during the construction phase of building projects to drive CW minimization were derived from existing literature, and twenty-four (24) competencies were identified under two (2) components as knowledge and skill (see Table 1).

Table 1.

Potential Key Competencies that Drive Material Waste Minimization.

Li et al. [] defined knowledge as the awareness or understanding of facts, rules, principles, guidelines, concepts, theories, or processes needed to complete a task. Most wastes on construction sites happen due to a lack of planning and sequencing of construction activities. Pérez and Bastos Costa [] asserted that planning and scheduling is a critical factor in the quest to achieve sustainability; hence it needs to be well addressed and reflected in construction schedules to avoid any delays and wastage of materials. The recycled content, as well as the recyclability of construction material, enhances sustainability which eventually contributes to waste reduction. For instance, according to Senaratne et al. [], steel can be recycled from construction debris, which makes it a commonly recycled building material. Glass is a recyclable construction material, but its separation from a CW is difficult []. Using materials that can be recycled reduces the use of raw mater and embodied energy []. He further stated that recycling takes less energy than producing a whole new material. Health and Safety Management is critical when focusing on key competencies that drive waste minimization at the construction stage of a project. The construction manager needs to understand the health impact of on-site workers and the danger improper management of CW brings.

Accidents that normally happen from poor site waste management could be reduced through proper health and safety management []. Hwang and Ng [] postulated that construction managers should select parties for construction activities based on their knowledge of CW. In human resource management, practices such as organizing waste management and materials handling, vocational training for operatives, having a dedicated site team or specialist sub-contract package for on-site waste management, the appointment of labor solely for waste management, etc., could enhance the minimization of waste []. Modern construction methods, such as the use of prefabricated construction products and modular construction, contribute to CW minimization at the construction stage of a project. Prefabrication makes use of precast components and modules, modular construction technique, and other off-site technologies []. Modular construction also refers to factory-produced building units that are delivered and assembled on-site as building elements or volumetric components. The use of precast materials has the potential to reduce the amount of on-site damage and rework, thereby contributing to waste reduction output by up to 84% [].

In the construction phase of a project, standard material sizes could be opted for to reduce waste during trimming processes. Salgın [] states that choosing dimensionally coordinated building products with the building helps to avoid the required cut-offs in the construction stage to ensure CW minimization is provided. Mixing of concrete can also be done on-site to readily control the amount needed. These points are supported by Menegaki and Damigos [] with the claim that minimal CW during installation reduces the need for landfill space and provides cost savings. Sustainability is a concept that aims at protecting our environment, ensuring economic profitability, and creating social awareness []. Requisite knowledge of sustainable construction practices ensures effective waste reduction.

Other knowledge competencies cited by researchers include adherence to project design/drawings, waste auditing to monitor the environmental performance, and thorough review of the project specifications by contractors at the construction stage []. Hwang and Ng [] stated delegation and problem-solving as key skills that could drive CW minimization. Shi et al. [] also added continuing professional learning, on-site practical skill, and personnel quality as skills that should be possessed by construction professionals in waste minimization. Creative thinking, provision of direction to inspire others, and a personal commitment to pursuing an ethical solution to waste minimization are also skills that could drive material waste minimization if portrayed by construction site workers [,].

3. Research Methodology

This study sought to explore the key competencies for driving waste minimization at the construction stage of projects. A quantitative research approach was employed. This approach was thought to be essential because it enables the use of structured questionnaire surveys, which allow researchers to generalize their findings over a larger population [].

3.1. Survey Design and Administration

In order to assemble the requisite knowledge to realize the aim of this study, an appropriate methodology was used. Twenty-four (24) key factors that drive CW minimization at the construction stage of projects were derived from a comparative review of related literature. Questionnaires were adopted as an economical way to obtain the views of the respondents. According to Patra [], a questionnaire is a data collection instrument with a particular set of questions that have been formulated beforehand for which answers are expected from various respondents. Hence, a questionnaire survey employing closed-ended questions was conducted. The quantitative research approach allows information about a sample population to be generalized to a larger population. In the case of this study, this approach enabled the use of a structured questionnaire survey with interval Likert-type scales to measure data and the ability to analyze data obtained and be able to generalize findings to the larger construction professionals operating in the Ghanaian construction industry. Hence, the questionnaire is effective in achieving quantifiability and objectiveness [].

A pilot study was conducted to test the comprehensiveness and relevance of the questionnaire before it was distributed. The pilot study involved three (3) construction managers and a postgraduate researcher who was experienced in this research area. Based on feedback from the pilot study, the questionnaire was finalized. The questionnaire was structured into two main sections: Section A and Section B. Section A sought to investigate the profile of the respondents, such as their professional role, level of education, years of professional experience, and the number of years they have been involved in the integration of material waste minimization in building projects. Section B also looked at the key competencies that drive construction material waste minimization at the construction stage of projects. The respondents were asked to rank the level of importance of the twenty-four (24) variables identified on a Likert scale of 1–5 where 1 = not important, 2 = fairly important, 3 = quite important, 4 = important, and 5 = very important.

The questionnaires were administered to construction professionals working with large building construction firms in Ghana. These construction professionals included project/construction managers, quantity surveyors, architects, and site supervisors. Due to the difficulty in locating such large firms in Ghana, two sampling techniques (i.e., purposive and snowball) were employed in this study. To begin, the construction professionals’ knowledge concerning the key competencies driving waste minimization during the construction phase of buildings was ascertained through the use of the purposive sampling technique. The snowball sampling technique was employed to discover more respondents who were difficult for the researchers to locate through recommendations from the previously identified respondents.

In all, sixty-nine (69) questionnaires were administered. A total of fifty-three (53) responses were retrieved. The analysis of results revealed the professionals as people who have more than five years of experience in the Ghanaian construction industry.

3.2. Data Analyses

The data retrieved from the respondents were analyzed using the Statistical Package for Social Sciences (SPSS) version 26. The consistency of responses (i.e., reliability) of the data from the completed questionnaires was checked using Cronbach’s Alpha. The reliability analysis performed returned Cronbach Alpha values of 0.918, 0.864, 0.868, and 0.759 for the four components. These values represent high levels of internal consistency. The statistical tool employed for the data analysis was Factor Analysis. The choice of this analytical tool for the data analysis was to reduce the large number of variables into a more easily understood framework []. Factor Analysis uses mathematical procedures to simplify interrelated measures that seek to discover patterns in several variables. Since all the twenty variables/competencies seek to reduce waste during the construction phase of building projects, it was deemed necessary to simplify these interrelated competencies using the Factor Analysis []. Moreover, Factor Analysis was adopted to discover the correlation relationship among variables for the competencies driving waste minimization during the construction phase of building projects. Factor analysis also ascertains the correlation relationship among individual variables to determine which variables measure aspects of common variance [].

Data were collected from construction professionals knowledgeable of construction waste minimization and who have also been involved in material waste minimization integrated building projects before. These professionals included construction/project managers (52.8%), quantity surveyors (13.2%), architects (7.5%), and site supervisors (26.4%).

4. Results

Kaiser–Meyer–Olkin (KMO) and Bartlett’s tests were conducted to determine the adequacy and the reliability of using Factor Analysis as shown in Table 2. KMO determines the appropriateness of Factor Analysis, as well as the degree of inter-correlation among the variables []. Correlation among variables is also confirmed by the Bartlett test of sphericity. It provided the probability that the correlation matrix has a significant correlation among at least some of the variables, as shown in Table 2 []. KMOs in the range of 0.5–0.6, 0.6–0.7, 0.7–0.8, 0.8–0.9, and above 0.9 are considered poor, average, good, great, and superb, respectively []. 0.795 was obtained as the KMO for the factors. This, according to Field [] signifies great. Table 3 further presents the communalities for the key competencies that drive material waste minimization at the construction stage of projects.

Table 2.

KMO and Bartlett’s Test.

Table 3.

Communalities for Key Competencies that Drive Material Waste Minimization at the Construction Stage of Projects.

Component Detection and Extraction

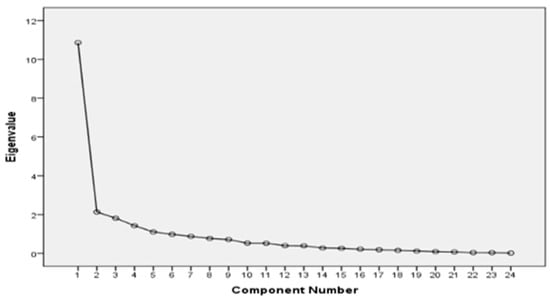

The total variance is explained in Table 4 with much emphasis on extraction sums of squared loadings as well as rotation sums of squared loadings. Per the Kaiser criterion, eigenvalues equal to or greater than one (1) in Principal Component Analysis ought to be retained. The significance of a variable is determined by the skewness of its eigenvalue towards 1.00. Based on the eigenvalues, four factors were generated, encapsulating the 24 variables. In total, 67.7% was the total variance explained by all the extracted components. The Cumulative Proportion of Variance Criterion stipulates that the components extracted should explain at least 50% of the variation in the data set. The test result of 67.7% agrees with the above statement (see Table 4). Using the factor loading of 0.50 as the cut-off point, four (4) components with eigenvalues more than 1.0 were extracted. This is indicated on the scree plot in Figure 1.

Table 4.

Total Variance Explained.

Figure 1.

Scree Plot.

Rotation improves the interpretation of the results of the principal component analysis []. It turns large loading factors into an absolute value for the variables to achieve a simple structure. The rotated component matrix indicating the groupings and the coefficients under each component is tabulated in Table 5.

Table 5.

Rotated Component Matrix on Competencies that Drive Material Waste Minimization at the Construction Stage of Projects.

5. Discussion of Results

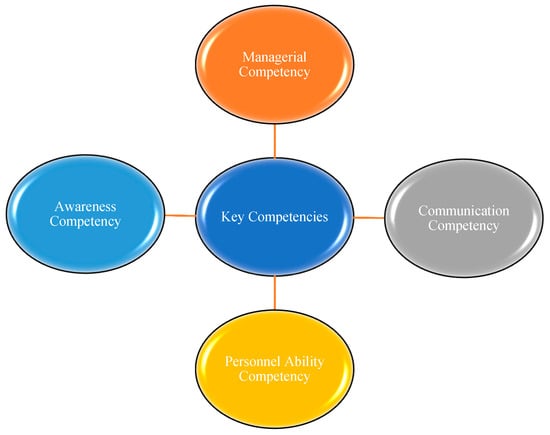

Four (4) components were retained to represent the twenty-four (24) listed competencies that drive CW minimization (Figure 2). Each component stands for variables with common attributes (Table 5). 67.650% of the variance and the entire data indicate the summation of the four (4) components in the Rotation Sums of Squared Loadings. The four new constructs formed through the factor analysis were labeled and discussed according to their level of importance in the following order, Awareness Competency (AC), accounting for 18.707%, Managerial Competency (MC), accounting for 18.403%, Personnel Ability Competency (PAC) accounting for 15.737, and Communication Competency (CC), accounting for 14.803% of the total variance.

Figure 2.

Conceptual Module on Key Competencies that Influence Material Waste Minimization at the Construction Stage of Projects.

5.1. Component 1: Awareness Competency (AC)

Component 1 comprises six (6) variables, which accounted for 18.707% of the total variance: Awareness of CW minimization practices (0.847), Construction sequencing and planning (0.782), Standardization and Implementation of Sustainable Construction Practices (0.705), Modern Construction Methods (0.697), Waste management plan implementation (0.526), and Teamwork (0.522). The figures in parentheses indicate the loading of each variable impact on the component. This component was named Awareness Competency (AC). AC is the understanding or knowledge of concepts needed to effectively complete an assignment. The finding is consistent with Saka et al. [], who asserted that the attitude and awareness of construction stakeholders on waste minimization are very critical for driving CW minimization. Ajayi [] agreed with the awareness competency by indicating the need for construction professionals to be aware of CW minimization practices, along with their commitment to ensuring low waste in construction projects. According to Saka et al. [], construction waste minimization practices refer to any technologies (e.g., cast in-situ, prefabrication, and recycling technologies), work procedures (e.g., on-site waste sorting), and other economic or managerial approaches (e.g., designing out waste, and waste disposal charging) that are relevant to construction waste management.

Additionally, construction work sequences should be carefully planned in order to avoid damage to previously completed works []. Hence, the elimination of errors leads to reworks which results in the generation of materials waste. Furthermore, [] stated the significance of adopting modern methods of construction or other low-waste technologies to improve the waste management performance of construction projects. Jaillon et al. [] argued that modern construction methods, such as the use of prefabricated materials, could minimize waste output by up to 84%. Nevertheless, the adoption of prefabrication and other offsite construction techniques on construction projects is minimal, thus making it practically impossible to reduce waste through such means []. The level of waste generated by the conventional construction method is relatively higher than that of prefabrication in the trades of concreting, fixing of reinforcements, plastering, and tiling []. Therefore, the wider use of modern construction methods would help reduce the generation of construction waste considerably [].

Sustainable construction has been part of efforts within the construction industry to fulfilling the sustainability agenda in recent years []. Hence, construction stakeholders need to be aware of the importance of implementing sustainable construction practices to CW minimization at the construction stage of projects. According to Pérez and Bastos Costa [], the lack of effective waste management plans also contributes to waste generation on construction sites. Therefore, there is a need to develop and implement waste management plans []. Teamwork as an awareness competency is also essential for driving CW minimization at the construction stage of projects. Project participants should work cooperatively with one another and not competitively in order to achieve the goal of waste minimization [].

5.2. Component 2: Managerial Competency (MC)

The second component was labeled as Managerial Competency (MC). It accounted for 18.403% of the total variance not explained by the first component. The seven (7) variables within (MC) include: Effective leadership (0.805), Health and Safety Management (0.757), Reuse and recycling of waste (0.739), Adherence to project design/drawings (0.599), Delegation (0.570), Human Resource Management (0.564), and Waste auditing to monitor environmental performance (0.555). MC simply refers to the process of planning, controlling, and directing activities to influence an individual’s performance in order to yield positive results. Ajayi et al. [] suggested that strict adherence to project drawings and ensuring fewer or no changes to the design during the construction processes could substantially reduce waste generation. Additionally, in attempts to ensure waste minimization at the construction stage of projects, the managerial competency of reusing and recycling waste is consistent with a number of studies []. Ajayi et al. [] revealed that the maximization of onsite reuse of materials and provision of waste skips for specific materials were key for driving CW minimization at the construction stage of projects.

The success of projects requires the construction industry to adequately prepare and coordinate their workforce or effectively manage their human resource towards reducing construction waste. Human resource management practices such as organizing waste management and materials handling vocational training for operatives, the appointment of labor solely for waste management, etc., could enhance CW minimization []. Furthermore, project managers should possess the ability to efficiently delegate tasks to other members of the organization or decision-making authorities to qualified subordinates []. Hwang and Ng [] also asserted that project managers should exhibit effective team leadership to bring the best out of their team members. Effective leadership in project execution geared toward waste management could reduce waste significantly.

The managerial competency of waste auditing to monitor environmental performance is also regarded as a useful strategy to minimize construction waste on-site. Information could be collected on different projects (both past and current) to enable a comparative analysis of waste management strategies employed and measurement of project waste performance. This will aid in determining the suitability of these strategies for distinct projects, and then further actions can be taken for similar projects []. Health and Safety Management is also revealed as a key MC for driving waste minimization at the construction stage of building projects. It is thought that the provisions of health and safety management for waste workers working in healthcare services can also be applied to the construction sector. Construction firms should include provisions for the continuous monitoring of workers’ health and safety in their health and safety management policies or plans to ensure that correct handling, treatment, storage, and disposal procedures are followed.

5.3. Component 3: Personnel Ability Competency (PAC)

This component accounted for 15.737 percent total variance not explained by the former components. It encompasses seven (7) variables: Problem-solving skills (0.774), Creative thinking (0.732), Professional learning (0.652), Onsite practical skill (0.591), Provision of direction to inspire others (0.552), Personnel quality (0.551), and Personnel commitment to pursuing an ethical solution to waste minimization (0.547). The figures in the bracket indicate the loading of each variable impact on the component. PAC refers to the capacity to accomplish things. It could be inherent or acquired through practice or training. Construction professionals should be able to generate fast solutions to problems arising from construction processes that could produce waste []. Ganiyu et al. [] posited that construction operators lack the requisite skills for the execution of CW minimization. Their lack of skill results in poor control of waste. Therefore, construction practitioners should have the capacity to demonstrate practical skills in carrying out construction activities in order to effectively minimize waste.

Furthermore, this study reveals creative thinking, professional learning, and personal quality as personal ability competencies for engendering CW minimization at the construction stage of building projects. This finding is consistent with Shi et al. [], who indicated that creative thinking, continuous professional learning, and personal quality were key competencies required of construction professionals in construction project management. Personal qualities capable of engendering CW minimization include the ability to work in a team, management, delivery of solutions to clients, ownership, interpersonal communication skills, and organization skills. Another PAC is personnel commitment to pursuing an ethical solution to waste minimization, where Ajayi [] indicated the need for a dedicated site team for onsite waste management.

5.4. Component 4: Communication Competency (CC)

The final component was labeled as Communication Competency (CC). It accounted for 14.803% of the total variance with four (4) variables loaded onto it: Supply Chain Management (SCM) skills (0.716), Effective communication (0.679), Material logistic plan implementation (0.646), and thorough review of the project specifications by contractors at the construction stage (0.616). CC refers to the adequacy and ease of flow of thought (communication) to others through various mediums (drawings, charts, phone calls) for effective work delivery. CC is exhibited in the area of proper requisition and supply of construction materials, effective collaboration among construction professionals and site workers, and clearer communication of project specifications. This indeed drives construction material waste minimization. Ajayi et al. [] posited that CW minimization requires adequate estimation of materials required at different stages of projects in an attempt to reduce the likelihood of materials over-ordering and subsequent leftovers, which is a key cause of waste generation. Effective SCM can help achieve Just-in-time delivery (JIT) or lean construction in order to avoid unnecessary waste as a result of over-ordering of materials or long storage []. The JIT delivery approach is different from the conventional way of material storage as the time that materials are stored on site is reduced and reduces the likelihood of the materials experiencing damage due to poor handling.

Effective communication is also one of the communication competencies for driving waste minimization at the construction stage of projects. Ajayi [] indicated that, in order to achieve low waste in construction projects, project participants should ensure the effective communication of site activities and other project information. Li et al. [] also raised the argument that organizational waste management policy should be communicated to the site workers in order to mobilize support in achieving the waste minimization objective. Additionally, Al-Hajj and Hamani [] posited that there have been several reports published by the Waste and Resources Action Programme in the UK where the emphasis has been laid on the importance of implementing a good material logistic plan (MLP) on-site for better waste reduction. Logistics management can help realize CW minimization by preventing double handling and ensuring the adequate handling of equipment to minimize damage to materials on site []. Moreover, Ajayi [] was in agreement with the communication competency of the thorough review of project specifications by contractors at the construction stage as one of the key competencies for driving CW minimization.

6. Implications of Findings and Study Limitations

Quality, time, cost, and waste, among others, are key performance indicators for measuring the success of projects. Therefore, waste management and the need to reduce the amount of waste generated in the construction industry have been the subject of several research studies []. Construction waste minimization yields a lot of benefits to the construction industry, including improved project performance, cost savings, environmental sustainability, and contributions to the national economy. Nevertheless, the level of awareness of key competencies that drive material waste minimization in construction projects is minimal. This study, therefore, explored the key competencies for driving waste minimization in projects focusing on the construction stage. The implementation of the key competencies from the findings of the study is highly recommended for the achievement of low waste in building projects. In view of this, it is recommended that government should enact legislative and fiscal measures to instill waste management habits in the construction industry. These measures include landfill tax, aggregates levy, compulsory site waste management plan (SWMP), and sustainable design assessment frameworks such as BREEAM, among others. Contractual provisions that penalize and reward waste generation and minimization, respectively, are also recommended.

The study’s exploration of the key competencies for driving construction waste minimization at the construction stage of building projects constitutes a new contribution to knowledge and practice. Several studies have investigated strategies or measures for CW minimization. However, this study focused on the knowledge and skills of construction stakeholders as the main component of waste minimization competencies. In attempts to engender waste minimization at the construction stage of building projects, construction firms, based on the findings of the study, could develop and implement waste management plans for site activities. They could also aim at increasing the awareness of their staff of the various competencies that drive CW minimization and provide them with the necessary training to improve their knowledge, skills, and personal qualities for the execution of CW minimization. According to Khan et al. [], providing training and education among staff is an important factor in waste minimization. Researchers could also employ the competencies identified in this study as empirical evidence to discuss waste minimization competencies implementation measures or for further deliberations.

In spite of the significant contributions of this study, the study has limitations which are usual for research studies. The study is limited in its geographical consideration and sample. It, therefore, is recommended that further studies be conducted by expanding the frontiers of the data collection to cover other developing countries and professionals, respectively. Furthermore, the study collected data on building projects only. Hence, competencies for waste minimization in other aspects of construction, such as civil engineering projects, were not explored. This limitation can be attributed to differences in construction methods and materials used between building and civil engineering projects. Future research could precisely be aimed at exploring competencies for minimizing waste in civil engineering projects, as this study covered only building projects. This would allow a comparison analysis of competencies for waste minimization in building and civil engineering projects. Additionally, further studies could be conducted to examine/judge the objectivity of the study’s findings. Another limitation of this study is its assessment of waste from a materials perspective. Apart from materials waste, time waste and waste of machinery are other forms of construction waste. The study only approached waste from a materials perspective, especially as the study was motivated by the need to improve the environmental performance of the construction industry.

7. Conclusions

The study sought to explore the key competencies for driving material waste minimization at the construction stage of building projects. Twenty-four (24) key factors that drive CW minimization at the construction stage of projects were derived from a thorough review of existing literature. The research adopted the quantitative approach, where a questionnaire survey involving fifty-three (53) construction professionals was conducted. Factor analysis was the statistical tool employed for the analysis of the data gathered. Kaiser–Meyer–Olkin (KMO) and Bartlett’s tests were conducted to determine the adequacy and the reliability of using Factor Analysis. The findings of the study revealed four major competencies that drive CW minimization: Awareness Competency (AC), Managerial Competency (MC), Personnel Ability Competency (PAC), and Communication Competency (CC). A deeper understanding of the competencies was obtained by looking at the causes and effects of material waste on construction projects.

The professionals within the building sector, especially in a developing country setting such as Ghana, need to be fully acquainted with Waste Minimization Competencies through Continuous Professional Development (CPD), such as seminars, refresher courses, and workshops. The awareness and the implementation of the various competencies that drive waste minimization shall ensure proper collaboration among construction stakeholders as well as a positive attitude towards waste minimization to enhance high productivity.

Author Contributions

Conceptualization, E.A.B. and K.A.; methodology, K.A. and V.M.A.K.; software, H.P.; validation, E.A.B., S.S.A. and H.P.; formal analysis, A.M.A.D. and S.S.A.; investigation, E.A.B.; resources, E.A.B.; data curation, K.A. and B.S.; writing—original draft preparation, B.S. and V.M.A.K.; writing—review and editing, E.A.B., A.M.A.D. and B.S.; visualization, E.A.B.; supervision, K.A.; project administration, E.A.B.; funding acquisition, E.A.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data presented in this study are available in this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ebekozien, A.; Samsurijan, M.S.; Aigbavboa, C.; Malek, N.M. Malaysia’s low-cost housing solid waste management in the era of COVID-19: The role of fourth industrial revolution technologies. Manag. Environ. Qual. Int. J. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- USEPA (United States Environmental Protection Agency). Construction Waste Management Section 01 74 19. 2007. Available online: https://www.epa.gov/sites/default/files/2014-03/documents/017419.pdf (accessed on 5 December 2022).

- Construction Waste. 2022. Available online: https://www.gov.hk/en/residents/environment/waste/management/constructionwaste.htm (accessed on 22 February 2023).

- Sharma, R. Mechanical properties, permeability and microstructure of concrete using construction and industrial waste. Int. J. Struct. Integr. 2022, 13, 1013–1040. [Google Scholar] [CrossRef]

- WRAP (Waste and Resources Action Programme). Efficient Construction Logistics; WRAP: Banbury, UK, 2007. [Google Scholar]

- Sustainable Management of Construction and Demolition Materials. 2022. Available online: https://www.epa.gov/smm/sustainable-management-construction-and-demolition-materials (accessed on 22 February 2023).

- EUROSTAT (Statistical Office of the European Union). Waste statistics. 2019. Available online: https://ec.europa.eu/eurostat/statisticsexplained/index.php?title=Waste_statisticsandoldid=447576 (accessed on 22 February 2023).

- DEFRA (Department for Environment, Food and Rural Affairs). UK Statistics on Waste. 2022. Available online: https://www.gov.uk/government/statistics/uk-waste-data/uk-statistics-on-waste (accessed on 22 February 2023).

- Agyekum, K.; Botchway, S.Y.; Adinyira, E.; Opoku, A. Environmental performance indicators for assessing sustainability of projects in the Ghanaian construction industry. Smart Sustain. Built Environ. 2021, 11, 918–950. [Google Scholar] [CrossRef]

- Agyekum, K.; Ayarkwa, J.; Adjei-Kumi, T. Minimizing materials wastage in construction-a lean construction approach. J. Eng. Appl. Sci. 2013, 5, 125–146. [Google Scholar]

- Akinade, O.; Oyedele, L.; Oyedele, A.; Delgado, J.M.D.; Bilal, M.; Akanbi, L.; Ajayi, A.; Owolabi, H. Design for deconstruction using a circular economy approach: Barriers and strategies for improvement. Prod. Plan. Control. 2019, 31, 829–840. [Google Scholar] [CrossRef]

- Tzourmaklioutou, D. Designing for deconstruction-The related factors. J. Civ. Eng. Archit. 2021, 15, 459–468. [Google Scholar]

- Amudjie, J.; Agyekum, K.; Adinyira, E.; Amos-Abanyie, S.; Kumah, V.M.A. Awareness and practice of the principles of circular economy among built environment professionals. Built Environ. Proj. Asset Manag. 2023, 13, 140–156. [Google Scholar] [CrossRef]

- Salgın, B. Design Approaches to Prevent/Reduce CandD Waste Generated through the Building Life Processes and a Model Suggestion. Ph.D. Thesis, Yıldız Technical University, Istanbul, Türkiye, 2015. [Google Scholar]

- Menegaki, M.; Damigos, D. A review on current situation and challenges of construction and demolition waste management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. Exploring the critical waste factors affecting construction projects. Eng. Constr. Arch. Manag. 2022, 29, 2268–2299. [Google Scholar] [CrossRef]

- Rasanjali, W.; Mendis, A.; Perera, B.; Disaratna, V. Implementing enterprise resource planning for lean waste minimisation: Challenges and proposed strategies. Smart Sustain. Built Environ. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef] [PubMed]

- Mendis, D.P. Contractual Obligations Analysis for Construction Waste Management. Master’s Thesis, The University of British Columbia, Okanagan, Canada, 2011. [Google Scholar]

- Lu, W.; Yuan, H. A framework for understanding waste management studies in construction. Waste Manag. 2011, 31, 1252–1260. [Google Scholar] [CrossRef] [PubMed]

- Ding, Z.; Yi, G.; Tam, V.W.; Huang, T. A system dynamics-based environmental performance simulation of construction waste reduction management in China. Waste Manag. 2016, 51, 130–141. [Google Scholar] [CrossRef]

- Kulatunga, U.; Amaratunga, D.; Haigh, R.; Rameezdeen, R. Attitudes and perceptions of construction workforce on construction waste in Sri Lanka. Manag. Environ. Qual. Int. J. 2006, 17, 57–72. [Google Scholar] [CrossRef]

- Salgın, B.; Coşgun, N.; Aydın İpekçi, C.N.; Tıkansak Karadayı, T. Turkish architects’ views on construction and demolition waste reduction in the design stage. Environ. Eng. Manag. J. 2020, 19, 439–452. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M. Waste reduction through incentives: A case study. Build. Res. Inf. 2008, 36, 37–43. [Google Scholar] [CrossRef]

- Khan, B.A.; Cheng, L.; Khan, A.A.; Ahmed, H. Healthcare waste management in Asian developing countries: A mini review. Waste Manag. Res. 2019, 37, 863–875. [Google Scholar] [CrossRef] [PubMed]

- Mansfield, R.S. Building competency models: Approaches for HR professionals. Hum. Resour. Manag. 1996, 35, 7–18. [Google Scholar] [CrossRef]

- De Lisi, R. Preparing the Next Generation: A Leadership Academy for Doctoral Students Focusing on Competencies and Competency Development. In Competencies for Effective Leadership; Gigliotti, R.A., Ed.; Emerald Publishing Limited: Bingley, UK, 2019; pp. 59–69. [Google Scholar] [CrossRef]

- Spencer, L.M.; Spencer, S.M. Competence at Work Models for Superior Performance; John Wiley and Sons: Hoboken, NJ, USA, 1993. [Google Scholar]

- Prifti, L.; Knigge, M.; Kienegger, H.; Krcmar, H. A Competency Model for “Industrie 4.0” Employees. In Proceedings of the 13th International Conference on Wirtschaftsinformatik, St. Gallen, Switzerland, 12–15 February 2017; pp. 46–60. [Google Scholar]

- Na’im, S.N.S.M.; Din, M.F.M.; Krishnan, S.; Taib, S.M.; Sairan, F.M. Waste Minimisation Governance through Standardised Recycling Rate in Higher Education Institutions in Malaysia. In Sustainability Management Strategies and Impact in Developing Countries (Community, Environment and Disaster Risk Management); Din, M.F.M., Alias, N.E., Hussein, N., Zaidi, N.S., Eds.; Emerald Publishing Limited: Bingley, UK, 2022; Volume 26, pp. 87–102. [Google Scholar] [CrossRef]

- Project Management Institute. A Guide to the Project Management Body of knowledge: PMBOK® Guide. 2008. Available online: https://www.works.gov.bh/English/ourstrategy/Project%20Management/Documents/Other%20PM%20Resources/PMBOKGuideFourthEdition_protected.pdf (accessed on 10 January 2023).

- Ebekozien, A.; Aigbavboa, C.O.; Thwala, W.D.D.; Aigbedion, M.I.; Ogbaini, I.F. An appraisal of generic skills for Nigerian built environment professionals in workplace: The unexplored approach. J. Eng. Des. Technol. 2021; ahead-of-print. [Google Scholar] [CrossRef]

- Zhao, X.; Hwang, B.G.; Lim, J. Job satisfaction of project managers in green construction projects: Constituents, barriers, and improvement strategies. J. Clean. Prod. 2020, 246, 118968. [Google Scholar] [CrossRef]

- Geoghegan, L.; Dulewicz, V. Do Project Managers’ Leadership Competencies Contribute to Project Success? Proj. Manag. J. 2008, 39, 58–67. [Google Scholar] [CrossRef]

- Li, Y.Y.; Chen, P.H.; Chew, D.A.S.; Teo, C.C.; Xu, Y.Q. Project Management Factors Affecting Green Building Projects: Case Study of Singapore. Appl. Mech. Mater. 2013, 357, 2346–2352. [Google Scholar] [CrossRef]

- Wagstaff, S.; Burton, J.; Zolkiewski, J. Should we cooperate? Game theory insights for servitization. J. Serv. Manag. 2021, 32, 835–859. [Google Scholar] [CrossRef]

- Ajayi, S. Design, Procurement and Construction Strategies for Minimizing Waste in Construction Projects. Ph.D. Thesis, University of the West of England, Bristol, UK, 2016. [Google Scholar]

- Tatham, P.; Wu, Y.; Kovács, G.; Butcher, T. Supply chain management skills to sense and seize opportunities. Int. J. Logist. Manag. 2017, 28, 266–289. [Google Scholar] [CrossRef]

- Alvanchi, A.; Baniassadi, F.; Shahsavari, M.; Kashani, H. Improving materials logistics plan in road construction projects using discrete event simulation. Eng. Constr. Arch. Manag. 2021, 28, 3144–3163. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Kadiri, K.O.; Akinade, O.O.; Bilal, M.; Owolabi, K.A.; Alaka, H.A. Competency-based measures for designing out construction waste: Task and contextual attributes. Eng. Constr. Archit. Manag. 2016, 24, 464–490. [Google Scholar] [CrossRef]

- Li, X.; Liu, L.; Wang, X.; Li, Y.; Wu, Q.; Qian, T. Towards evolutionary knowledge representation under the big data circumstance. Electron. Libr. 2021, 39, 392–410. [Google Scholar] [CrossRef]

- Al-Hajj, A.; Hamani, K. Material waste in the UAE construction industry: Main causes and minimization practices. Archit. Eng. Des. Manag. 2011, 7, 221–235. [Google Scholar] [CrossRef]

- Hwang, B.G.; Ng, W.J. Project management knowledge and skills for green construction: Overcoming challenges. Int. J. Proj. Manag. 2013, 31, 272–284. [Google Scholar] [CrossRef]

- Shi, L.; Ye, K.; Lu, W.; Hu, X. Improving the competence of construction management consultants to underpin sustainable construction in China. Habitat Int. 2014, 41, 236–242. [Google Scholar] [CrossRef]

- Pittri, H.; Agyekum, K.; Botchway, E.A.; Opoku, A.; Bimpli, I. Design for deconstruction (DfD) implementation among design professionals: Empirical evidence from Ghana. Int. J. Constr. Manag. 2023, 1–11. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Osmani, M.; Glass, J.; Price, A.D.F. Architects’ perspectives on construction waste reduction by design. Waste Manag. 2008, 28, 1147–1158. [Google Scholar] [CrossRef] [PubMed]

- Pérez, C.T.; Costa, D.B. Increasing production efficiency through the reduction of transportation activities and time using 4D BIM simulations. Eng. Constr. Arch. Manag. 2021, 28, 2222–2247. [Google Scholar] [CrossRef]

- Senaratne, S.; Mirza, O.; Lambrousis, G.; Fernandez-Soncini, A. Structural applicability of steel fibre-recycled aggregate concrete in construction. J. Eng. Des. Technol. 2018, 16, 959–972. [Google Scholar] [CrossRef]

- Asa, E.; Anna, A.S.; Baffoe-Twum, E. An investigation of mechanical behavior of concrete containing crushed waste glass. J. Eng. Des. Technol. 2019, 17, 1285–1303. [Google Scholar] [CrossRef]

- Salgin, B. Contribution of Dimensional Coordination to Construction Waste Reduction. Open Access J. Waste Manag. Xenobiotics 2019, 2, 000114. [Google Scholar] [CrossRef]

- Burrell, G.; Morgan, G. Sociological Paradigms and Organisational Analysis: Elements of the Sociology of Corporate Life; Routledge: Oxfordshire, UK, 2017. [Google Scholar]

- Patra, S. Questionnaire Design. In Methodological Issues in Management Research: Advances, Challenges, and the Way Ahead; Subudhi, R.N., Mishra, S., Eds.; Emerald Publishing Limited: Bingley, UK, 2019; pp. 53–78. [Google Scholar] [CrossRef]

- Taherdoost, H.A.M.E.D.; Sahibuddin, S.H.A.M.S.U.L.; Jalaliyoon, N.E.D.A. Exploratory factor analysis; concepts and theory. Adv. Appl. Pure Math. 2022, 27, 375–382. [Google Scholar]

- Karamizadeh, S.; Abdullah, S.M.; Manaf, A.A.; Zamani, M.; Hooman, A. An overview of principal component analysis. J. Signal Inf. Process. 2020, 4, 173–175. [Google Scholar] [CrossRef]

- Field, A. Discovering Statistics Using SPSS for Windows; Sage Publication: London, UK, 2005. [Google Scholar]

- Saka, A.B.; Olaore, F.O.; Olawumi, T.O. Post-contract material management and waste minimization. J. Eng. Des. Technol. 2019, 17, 793–807. [Google Scholar] [CrossRef]

- Muhwezi, L.; Chamuriho, L.M.; Lema, N.M. An investigation into materials wastes on building construction projects in Kampala-Uganda. Sch. J. Eng. Res. 2012, 1, 11–18. [Google Scholar]

- Ajayi, S.O.; Oyedele, L.O.; Bilal, M.; Akinade, O.O.; Alaka, H.A.; Owolabi, H.A. Critical management practices influencing on-site waste minimization in construction projects. Waste Manag. 2017, 59, 330–339. [Google Scholar] [CrossRef]

- Rushton, T. Modern methods of construction. J. Build. Surv. Apprais. Valuat. 2022, 10, 369–381. [Google Scholar]

- Ganiyu, S.A.; Oyedele, L.O.; Akinade, O.; Owolabi, H.; Akanbi, L.; Gbadamosi, A. BIM competencies for delivering waste-efficient building projects in a circular economy. Dev. Built Environ. 2020, 4, 100036. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. The potential effectiveness of lean construction principles in reducing construction process waste: An input-output model. J. Mech. Eng. Sci. 2018, 12, 4141–4160. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).