Abstract

Polyester-fiber-reinforced cement-stabilized concrete is widely adopted to prevent the shrinkage cracking in pavement engineering. However, the effects of fiber length and content on the dry shrinkage and temperature shrinkage are not clear. The relationship between shrinkage resistance and strength is also discussed scantily. Hence, five types of polyester fiber length (1 cm, 3 cm, 5 cm, 7 cm, and 9 cm) and six types of polyester fiber content (0.1‰, 0.3‰, 0.5‰, 0.7‰, 0.9‰, and 1.1‰) were selected to prepare the fiber-reinforced cement-stabilized concrete. The dry shrinkage coefficients and temperature shrinkage coefficients were used to evaluate the shrinkage resistance. Moreover, the relationships among these shrinkage coefficients, compressive strength, and splitting strength at different curing ages were investigated to realize the prediction of shrinkage resistance of polyester-fiber-reinforced cement-stabilized concrete. This study aimed to seek the optimal fiber characteristics and conveniently evaluate the shrinkage resistance for the polyester-fiber-reinforced cement-stabilized concrete. Results show that: increasing the content of polyester fiber can significantly improve the shrinkage resistance of cement-stabilized concrete, especially for the temperature shrinkage. The fiber length should not be too long, especially for dry shrinkage. The optimum fiber content and fiber length is 0.7‰ and 5 cm for the dry shrinkage resistance and 0.7‰ and 9 cm for the temperature shrinkage resistance. There was higher correlation between compressive strengths and shrinkage coefficients, while the correlation between splitting strength and shrinkage coefficients was not obvious.

1. Introduction

Reinforced cement-based concrete is widely adopted in the civil construction [1,2]. In pavement engineering, the cement-stabilized concrete (i.e., cement-stabilized macadam) is used in base or subbase of highway structure considering the advantages in high-strength, strong-integrity, and low-price [3,4]. However, owing to the characteristics of dry shrinkage and temperature shrinkage, the cement-stabilized concrete usually results in shrinkage cracks, resulting from the changing of temperature and moisture content [5,6]. These cracks will quickly extend to the whole base and reflect to the asphalt pavement, which is one of the main diseases of asphalt pavement in China [7]. Therefore, how to effectively control the shrinkage cracks of cement-stabilized concrete is the key issue to solve the damage of asphalt pavement.

At present, there are two main ways to inhibit the shrinkage cracks of cement-stabilized concrete: (a) optimizing aggregate gradation to reduce cement content without compromising mechanical strength [8,9] and (b) adding fibers (e.g., polyester fiber, polypropylene fiber, steel fiber, basalt fiber, glass fiber, etc.) into cement-stabilized concrete [10,11]. However, owing to the reduction in the quality of aggregates in recent years, it is difficult to reduce the cement content while ensuring the mechanical strength of cement-stabilized concrete much of the time. Hence, the fiber used in cement-stabilized concrete received more concerns [12,13].

In previous studies, the effects of fibers on the mechanical strength of cement-stabilized concrete were widely investigated [14,15,16,17,18]. The results indicated that the fibers could improve the compressive strength, splitting strength, and compressive resilient modulus to a certain extent. However, owing to result uncertainty, experimental complexity, and time cost, the shrinkage resistance of cement-stabilized concrete was usually indirectly evaluated through the splitting strength (i.e., indirect tensile strength) or bending strength. This indirect evaluation method could not provide enough accuracy and was difficult to investigate the temperature shrinkage [19,20]. Only a few studies directly analyzed the shrinkage resistance of cement-stabilized concrete. Zhang et al. [21,22,23] analyzed the change law of shrinkage performance of cement-stabilized concrete using different polypropylene fiber contents via parametric tests. Liu et al. [1,24] revealed the effects of polyester fiber characteristics (content and diameter) and curing ages on dry shrinkage of cement-stabilized concrete via water loss rate and shrinkage coefficient. Tan et al. [25] demonstrated the feasibility of PVA fiber for improving the deformation characteristics of cement-stabilized concrete by means of the dry shrinkage test, temperature shrinkage test, freeze–thaw bending test, and fatigue test.

Although various fibers have respective advantages, the polyester fiber and polypropylene fiber became the most popular choices considering the price factor [26]. Moreover, previous studies [1,21,22,23,24,25] indicated that the polyester fiber could provide more effective effects on the mechanical strength and shrinkage resistance of cement-stabilized concrete, owing to the advantages in better chemical stability, erosion resistance, and ductility and wide sources. However, some important issues on the polyester fiber adopted in cement-stabilized concrete were not addressed in previous studies. For example: the effects on the temperature shrinkage are missing; the effects of polyester fiber length are less discussed; and the relationship between shrinkage and strength is not clear. Hence, the objective of this study is as follows:

- ●

- Investigating the effects of content and length of polyester fiber on the both dry shrinkage and temperature shrinkage of cement-stabilized concrete;

- ●

- Establishing the relationship between shrinkage (drying and thermal) and strength (compressive and splitting) of cement-stabilized concrete.

Based on the above, six types of polyester fiber content (0.1‰, 0.3‰, 0.5‰, 0.7‰, 0.9‰, and 1.1‰) and five types of polyester fiber length (1 cm, 3 cm, 5 cm, 7 cm, and 9 cm) were selected to investigate their effects on the dry shrinkage and temperature shrinkage of cement-stabilized concrete via dry shrinkage coefficient and temperature contraction coefficient. Moreover, the relationship among dry shrinkage, temperature shrinkage, mechanical strength, and polyester length characteristics was established.

2. Materials and Methods

2.1. Materials

Monofilament bundle polyester fiber, Shanlv P. O. 32.5 cement, and limestone aggregates were adopted to prepare the cement-stabilized concrete, of which the technical parameters are presented in Table 1, Table 2, and Table 3, respectively. The polyester fiber is shown in Figure 1. The aggregate gradation is listed in Table 4.

Table 1.

Technical parameters of polyester fiber.

Table 2.

Technical parameters of cement.

Table 3.

Technical parameters of aggregates.

Figure 1.

Polyester fiber.

Table 4.

Aggregate gradation.

2.2. Methods

- (1)

- Experiment methods

In this study, the coefficient of dry shrinkage and the coefficient of temperature shrinkage were used to evaluate the shrinkage resistance of cement-stabilized concrete. The compressive strength and the splitting strength were used to evaluate the strength characteristics. Cuboid samples with L 400 mm × W 100 mm × H 100 mm were prepared for the drying and temperature shrinkage experiments. Cylinder samples with Φ150 mm × H 150 mm were prepared for the strength experiments. Six specimens were measured for each condition. All the experiments were implemented according to the Chinese testing standard “Testing methods of Cement and Concrete for Highway Engineering (JTG 3420-2020)” [27].

The main process of the dry shrinkage test was as follows.

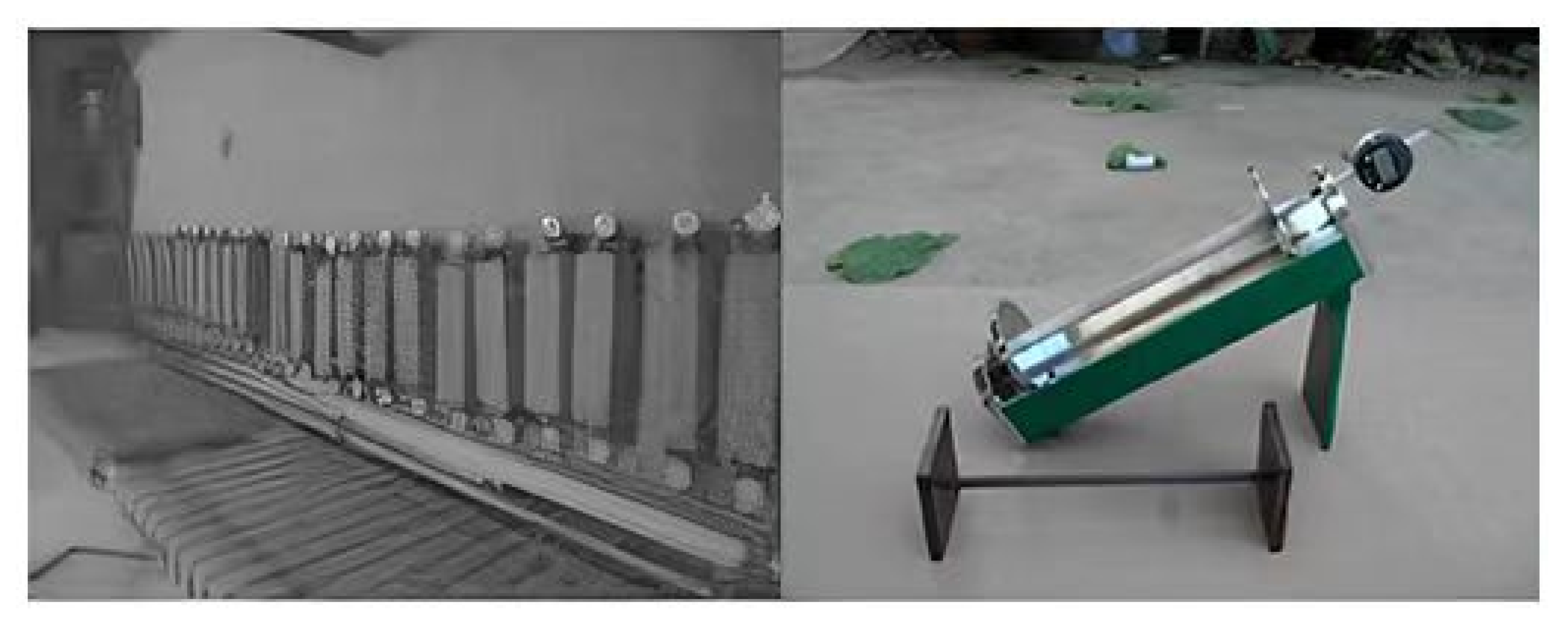

Step 1: The samples were installed into the dry shrinkage test racks. The experiments of dry shrinkage are illustrated in Figure 2. The initial reading of the dial indicator should be recorded.

Figure 2.

Experiment of dry shrinkage.

Step 2: The mass and deformation of the samples were recorded every day for the first 7 days and were recorded every 3 days during the 8th day to the 30th day. The temperature and relative humidity of the laboratory should be 17~25 °C and more than 50% during the whole testing process, respectively.

Step 3: The dry shrinkage coefficient was adopted to evaluate the dry shrinkage resistance and can be calculated via Equation (1).

where αd is the dry shrinkage coefficient; ε is the dry shrinkage strain (%); ω is the water loss rate (%); mi and mi+1 is the weighing mass (g) of the sample in the ith and (i + 1)th testing, respectively; Xi,j and Xi+1,j is the reading (mm) of the jth dial gauge in the ith and (i + 1)th test, respectively; l is the length (mm) of the sample; mp is the mass (g) of the sample after drying.

The main process of the temperature shrinkage test was as follows.

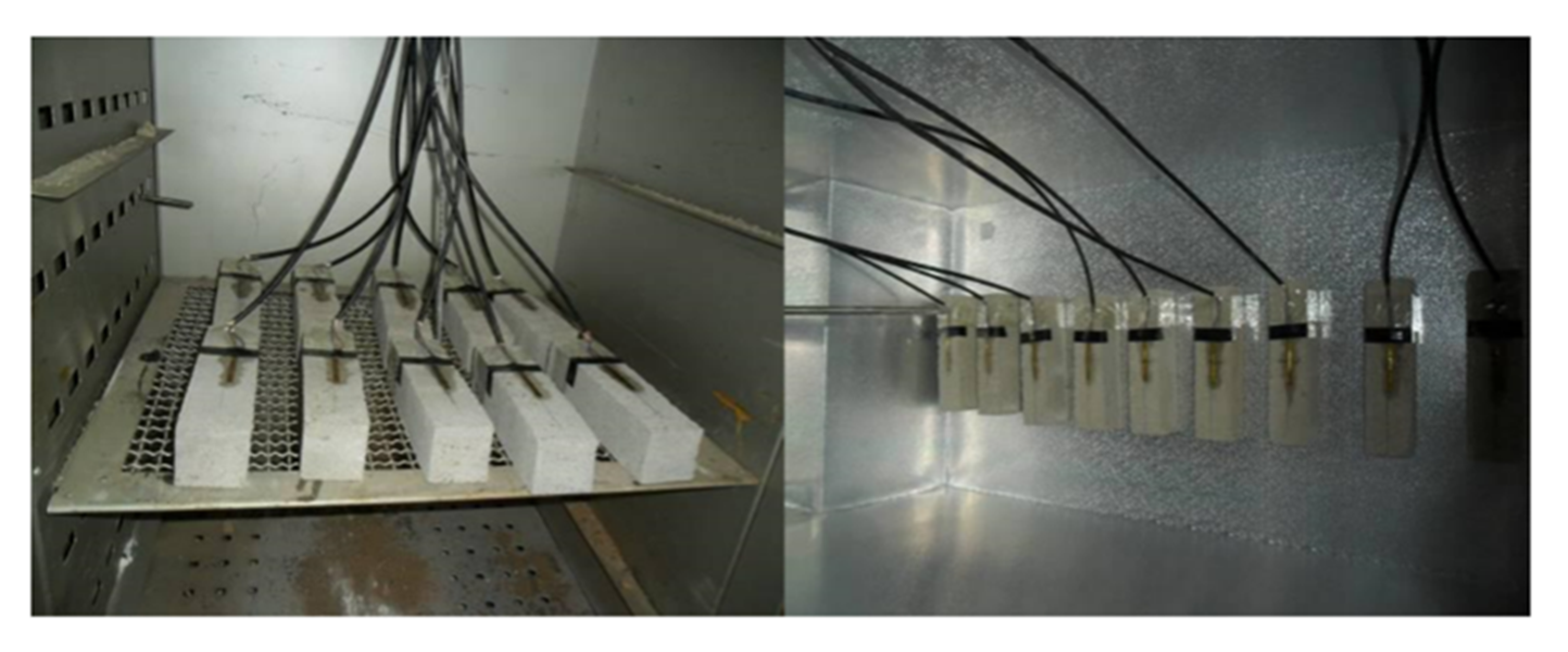

Step 1: The samples were dried for 10~12 h at 105 °C and placed into the programmable temperature chamber. The strain gages were affixed on the samples. The experiments of temperature shrinkage are illustrated in Figure 3.

Figure 3.

Experiment of temperature shrinkage.

Step 2: The deformations of the samples from 40 °C to −10 °C were recorded every 10 °C. When reaching one temperature grade, the samples should be kept temperature for 3 h. Subsequently, the reading of the strain gages must be finished within 5 min.

Step 3: The temperature shrinkage coefficient was adopted to evaluate the temperature shrinkage resistance and can be calculated via Equation (2).

where αt is the temperature shrinkage coefficient; li and li+1 is the reading (mm) of the dial gauge in the ith and (i + 1)th temperature range, respectively; ti and ti+1 is the initial temperature (°C) in the ith and (i + 1)th temperature range, respectively; L0 is the initial length (mm) of the sample, it should be explained that L0 must be measured before the experiment because the temperature shrinkage deformation is very small relative to the length of the sample; βs is the linear expansion coefficient.

- (2)

- Preparation of polyester-fiber-reinforced cement-stabilized concrete

Because the polyester fiber was filiform, it is easy to adhere with fine aggregates, mineral powder, and cement, leading to the nonuniform distribution of polyester fiber in cement-stabilized concrete. In order to avoid this situation, the following process was adopted to prepare the cement-stabilized concrete.

Step 1: Coarse aggregates and fine aggregates were mixed for 30 s in the concrete mixer;

Step 2: Polyester fibers were added into the aggregate mixtures and mixed 30 s in the concrete mixer;

Step 3: Cement and mineral powder were added into the aggregate mixtures with fibers and mixed for 30 s in the concrete mixer;

Step 4: According to the optimum moisture content, the water was added into the mixtures obtained by (c) and mixed for 180 s in the concrete mixer;

Step 5: The samples of polyester-fiber-reinforced cement-stabilized concrete can be manufactured via the static pressure method according to the Chinese testing standard “Testing methods of Cement and Concrete for Highway Engineering (JTG 3420-2020)” [27].

3. Crack Resistance

The detailed data of dry and temperature shrinkage coefficients can be found in Supplementary Materials.

3.1. Dry Shrinkage

3.1.1. Effect of Fiber Content

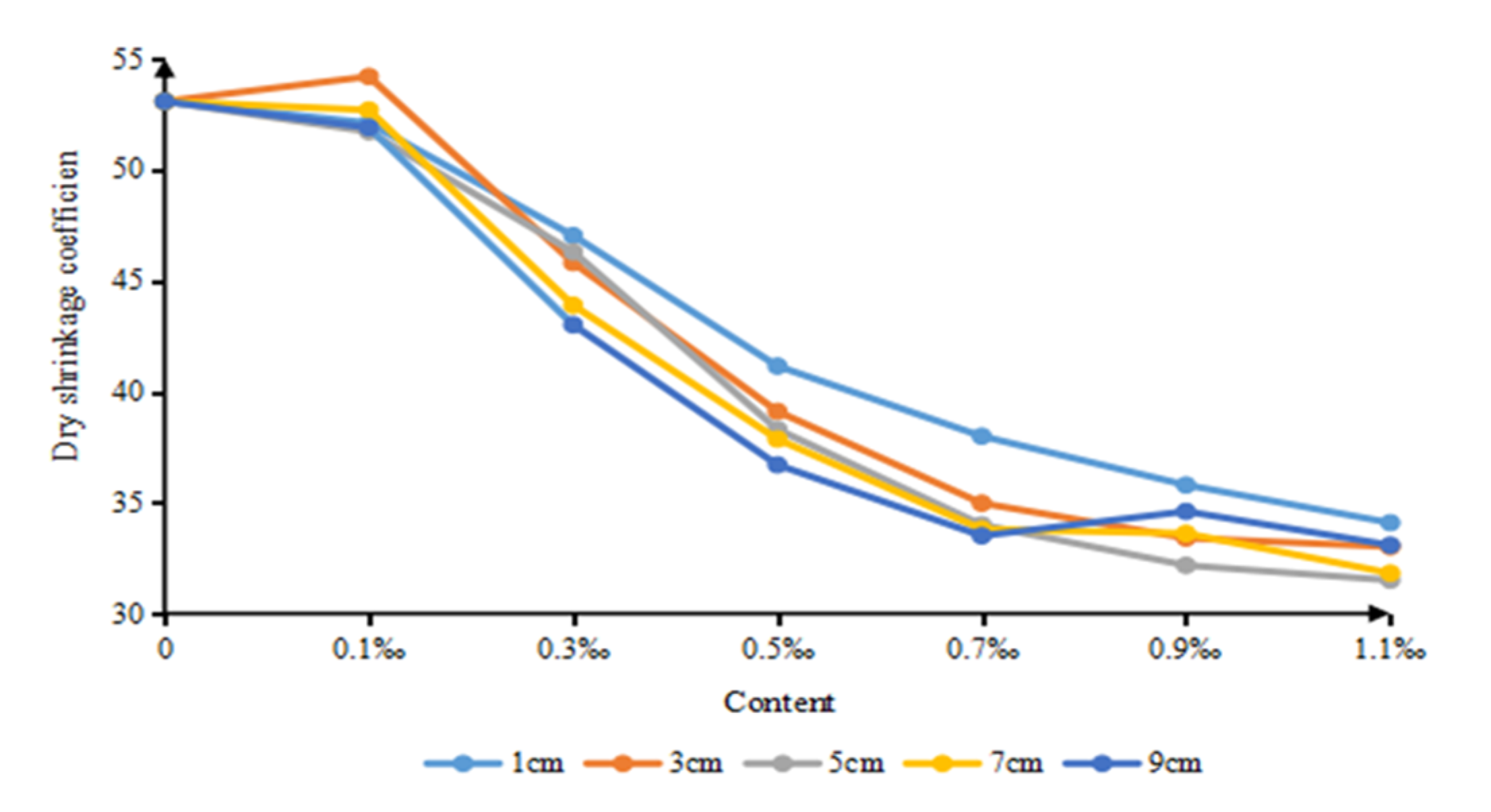

The effects of fiber content on the dry shrinkage coefficient are shown in Figure 4.

Figure 4.

Effects of fiber content on the dry shrinkage coefficient.

It can be seen from Figure 4 that the addition of polyester fiber obviously reduced the dry shrinkage coefficients of cement-stabilized concrete in general, and the fiber content had a great influence on the dry shrinkage. The dry shrinkage of cement-stabilized concrete was mainly the evaporation of its internal water. When polyester fiber mate-rial was added to cement-stabilized concrete, due to the existence of fiber material in the surface material, the water loss was reduced and the water migration was difficult, so that the capillary tension formed by capillary water loss shrinkage was reduced. Relying on the interfacial adhesion and mechanical meshing force between the fiber material and the cement base, the tensile strain energy of the material to resist cracking was improved.

However, when the fiber content was less than 0.1‰, the polyester fiber had little effect on the dry shrinkage. When the fiber content exceeded 0.1‰, the dry shrinkage coefficients decreased as the fiber content under the same fiber length increased, especially ranging from 0.1‰ to 0.7‰. The dry shrinkage coefficient decreased by 5.6% and 1.5% on average for every 0.1‰ increase in fiber content, when the fiber content increased from 0.1‰ to 0.7‰ and from 0.7‰ to 1.1‰, respectively. This was because polyester fiber can effectively reduce the dry shrinkage under the action of tension in the dry shrinkage process of cement-stabilized concrete. When fiber content was low, the fiber could not form an effective connection to resist the shrinkage crack, so as to present little impact on dry shrinkage of cement-stabilized concrete. When fiber content constantly increased the formation system between fibers, a good force transmission was generated, and so, the dry shrinkage coefficient of cement-stabilized concrete was greatly reduced. In addition, when the fiber content was less than 0.1‰ and the fiber length was 3 cm, the dry shrinkage coefficients increased with the increase in fiber content. It may have been caused by a test error. According to the Chinese test standard ‘Testing methods of Cement and Concrete for Highway Engineering (JTG 3420-2020)’ [27], the allowable error of dry shrinkage test is 15%. The data fluctuation here was only 2.11% and far less than the allowable error, which can prove the reliability of the data presented in Figure 4.

However, the above trends were affected by the fiber length, especially when the fiber content ranged from 0.7‰ to 1.1‰. When the fiber content increased from 0.1‰ to 0.7‰, the dry shrinkage coefficient of cement-stabilized concrete decreased by 4.1%, 4.9%, 5.1%, 5.2%, and 5.3% on average for every 0.1‰ increase in fiber content, respectively, in the case of the fiber length of 1 cm, 3 cm, 5 cm, 7 cm, and 9 cm. These reduction rates were 2.6%, 1.4%, 1.8%, 1.5%, and 0.3% when the fiber content ranged from 0.7‰ to 1.1‰.

3.1.2. Effect of Fiber Length

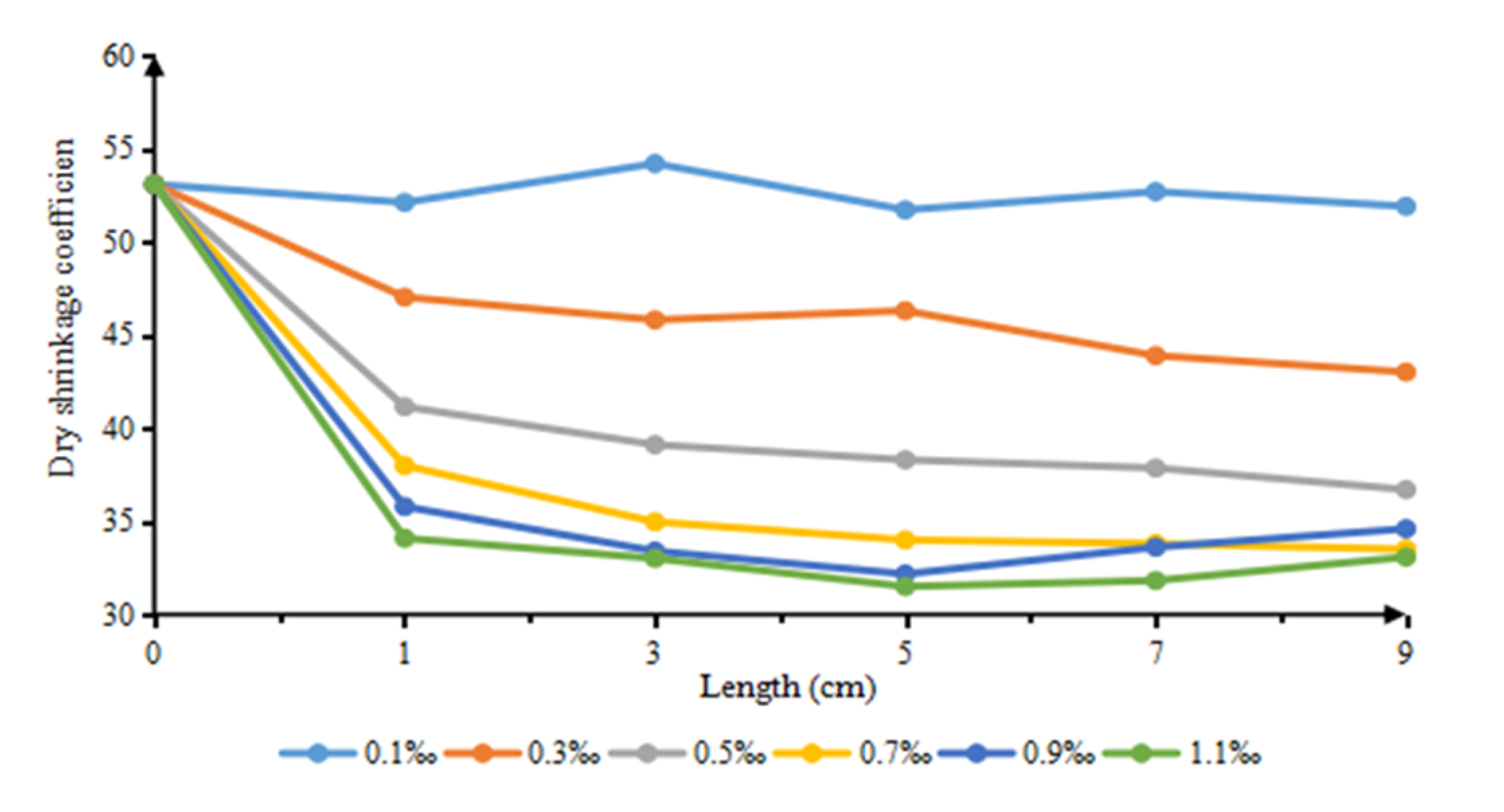

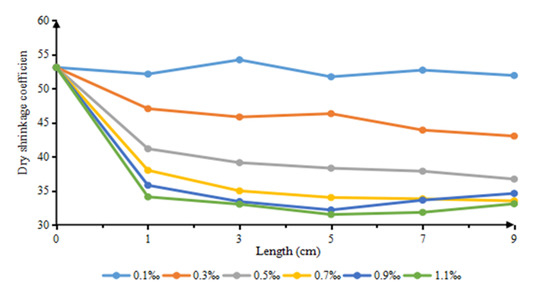

The effects of fiber length on the dry shrinkage coefficient are shown in Figure 5.

Figure 5.

Effects of fiber length on the dry shrinkage coefficient.

As shown in Figure 5, compared to the fiber content, fiber length had little effect on the dry shrinkage of cement-stabilized concrete when the fiber length exceeded 1 cm. When the fiber length was lower than 1 cm, the dry shrinkage coefficients decreased by 1.83%, 11.40%, 22.50%, 28.46%, 32.61%, and 35.81% on average, respectively, in the case of the fiber content of 0.1‰, 0.3‰, 0.5‰, 0.7‰, 0.9‰, and 1.1‰. When the fiber length exceeded 1 cm, these reduction rates were 1.07%, 1.35%, and 1.48% on average, respectively, in the case of the fiber content of 0.3‰, 0.5‰, and 0.7‰. Particularly, when the fiber content was 0.9‰ and 1.1‰, the shrinkage coefficient decreased first and then increased with the increase in fiber length. When the fiber length was 5 cm, the shrinkage coefficient reached the minimum. It showed that the increasing polyester fiber length can improve the shrinkage resistance, but increasing the extent of the length has a reasonable scope. This is because overlong fiber goes against its dispersion, so that the fiber reunites in the cement-stabilized concrete and cannot play the role in improving shrinkage resistance, especially when the fiber content is relatively large.

3.2. Temperature Shrinkage

3.2.1. Effect of Fiber Content

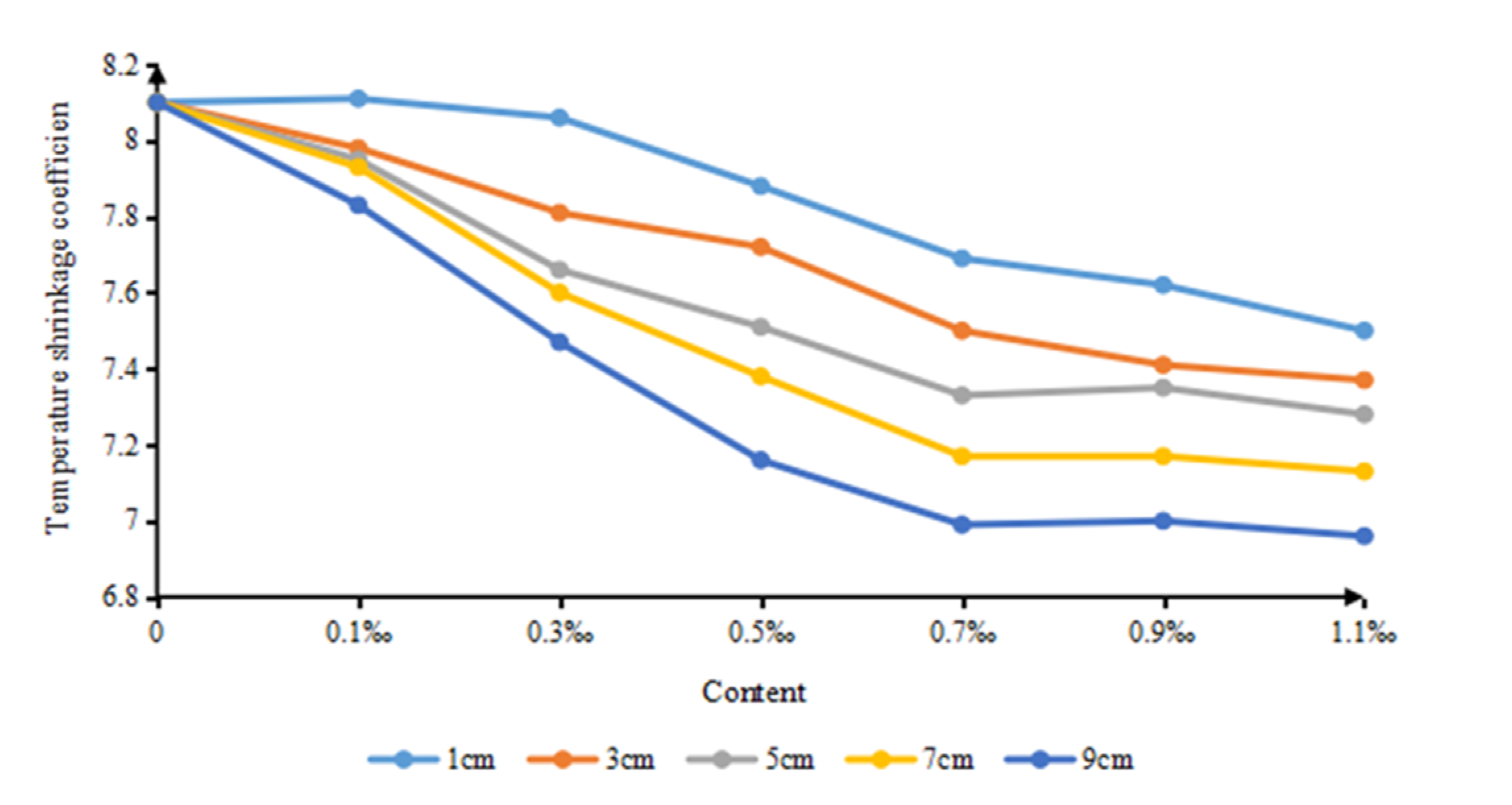

The effects of fiber content on temperature shrinkage coefficient are shown in Figure 6.

Figure 6.

Effects of fiber content on the temperature shrinkage coefficient.

It can be seen from Figure 6 that the addition of polyester fiber generally reduced the temperature shrinkage coefficients of cement-stabilized concrete, and the fiber content had a great influence on the temperature shrinkage. The temperature shrinkage of fiber-reinforced cement-stabilized concrete was determined by the combined effect of cement-stabilized concrete matrix and fibers. When the volume change of the composite material was affected by temperature, polyester fiber inhibited the expansion or shrinkage of cement-stabilized concrete, because the thermal expansion coefficient of polyester fiber was lower than that of cement-stabilized concrete. The expansion and shrinkage of the composite material decreased, which reduced its temperature shrinkage coefficient and improved the crack resistance of cement-stabilized concrete.

Under the same fiber length, the temperature shrinkage coefficient of cement-stabilized concrete decreased with the increase in fiber content. When the fiber content increased from 0.0‰ to 0.7‰, the temperature shrinkage coefficient decreased by 1.67% on average for every 0.1‰ increase in fiber content. This trend was more significant with the increase in fiber length. When the fiber content was less than 0.7‰, the temperature shrinkage coefficient decreased by 0.7%, 1.06%, 1.19%, 1.64%, and 1.96% on average for every 0.1‰ increase, respectively, in the case of the fiber length of 1 cm, 3 cm, 5 cm, 7 cm, and 9 cm. When the fiber content exceeded 0.7‰, the effect of fiber content on the temperature shrinkage coefficient was weakened. The temperature shrinkage coefficient decreased by only 0.14% on average for every 0.1‰ increase in fiber content.

3.2.2. Effect of Fiber Length

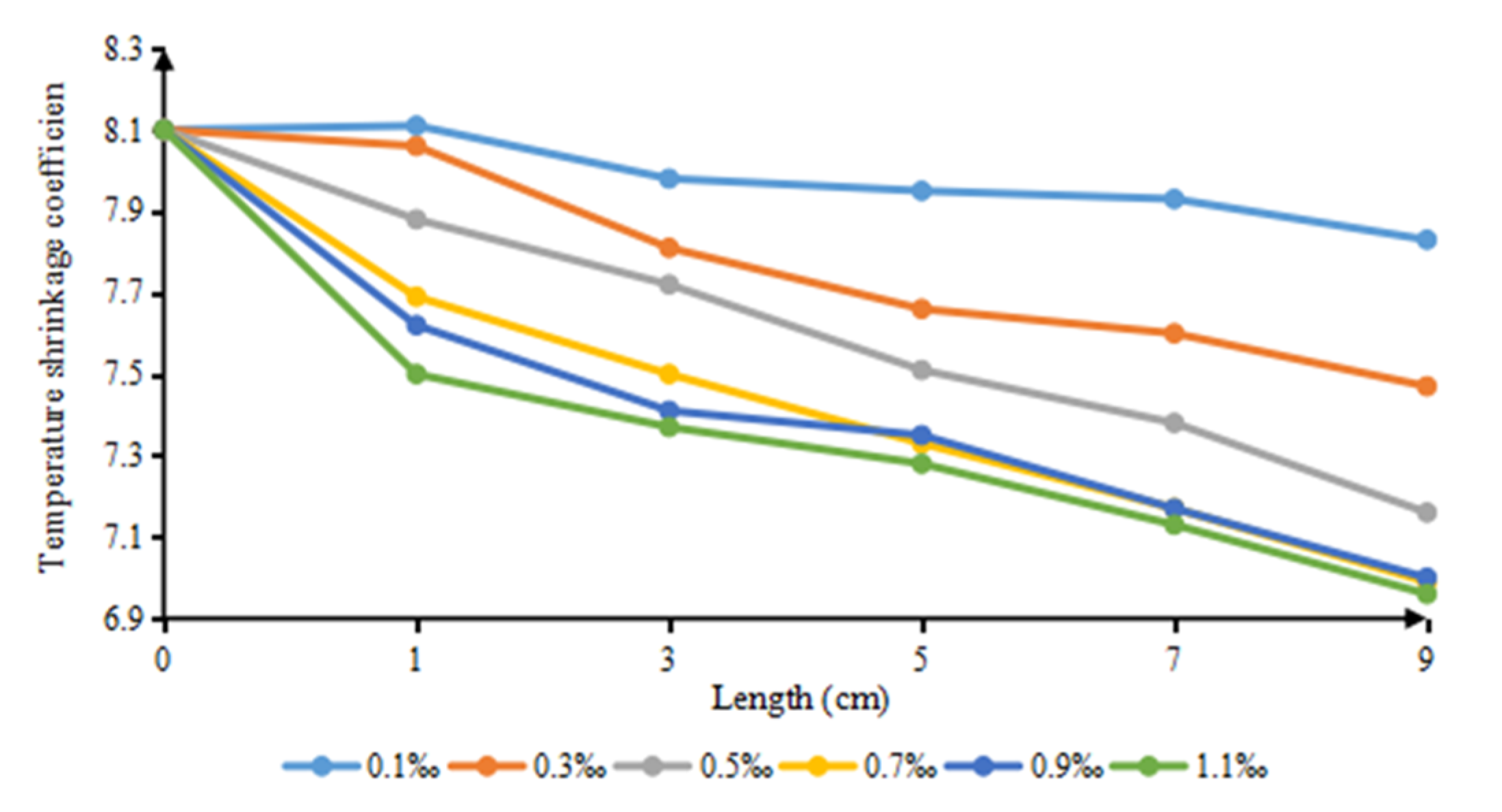

The effects of fiber content on temperature shrinkage coefficient are shown in Figure 7.

Figure 7.

Effects of fiber length on the temperature shrinkage coefficient.

It can be seen from Figure 7 that the increase in polyester fiber length generally reduced the temperature shrinkage coefficients of cement-stabilized concrete. When the fiber content was constant, the temperature shrinkage coefficient decreased by 1.19% on average for every 1 cm increase in fiber length. When the fiber length was lower than 1 cm, the reduction rates of the temperature shrinkage coefficient were accelerated with the increase in fiber length. When the fiber length was less than 1 cm, the temperature shrinkage coefficient decreased by −0.12%, 0.49%, 2.72%, 5.06%, 5.93%, and 7.41% on average for every 1 cm increase in fiber length, respectively, in the case of the fiber content of 0.1‰, 0.3‰, 0.5‰, 0.7‰, 0.9‰, and 1.1‰. When the fiber length exceeded 1 cm, the reduction rates of the temperature shrinkage coefficients had less difference in the case of different fiber contents. The temperature shrinkage coefficient decreased by 0.4% on average for every 1 cm increase in fiber length. In addition, different from the dry shrinkage, the increase in fiber length did not reflect a negative effect on the temperature shrinkage.

4. Relationship between Shrinkage and Strength

In order to establish the relationship of shrinkage and strength of the polyester-fiber-reinforced cement-stabilized concrete, the unconfined compressive strength and splitting strength at different curing ages were measured, as presented in Table 5 and Table 6.

Table 5.

Experiment results of unconfined compressive strength.

Table 6.

Experiment results of splitting strength.

As shown in Table 5 and Table 6, when the fiber content was lower than 0.1‰, the effect of fiber length on compressive strength was not significant, while the splitting strength increased with the fiber length. When the fiber content ranged from 0.1‰ to 0.3‰, the compressive strength and splitting strength both increased with the fiber length. It showed that the fiber can improve the strength of cement-stabilized concrete, especially for the splitting strength. When the fiber content ranged from 0.5‰ to 0.7‰, the compressive strengths and splitting strengths at different curing ages first increased and then decreased with the increase in fiber length, especially either for splitting strength or at early curing age (7-day). It implies that overlong fiber will have a negative impact on the strength. The optimal fiber length was 5–7 cm. When the fiber content exceeded 0.9‰, the compressive strengths and splitting strengths at different curing ages all decreased with the increase in fiber length, indicating that overmuch fiber is bad for the strength improvement of polyester-fiber-reinforced cement-stabilized concrete.

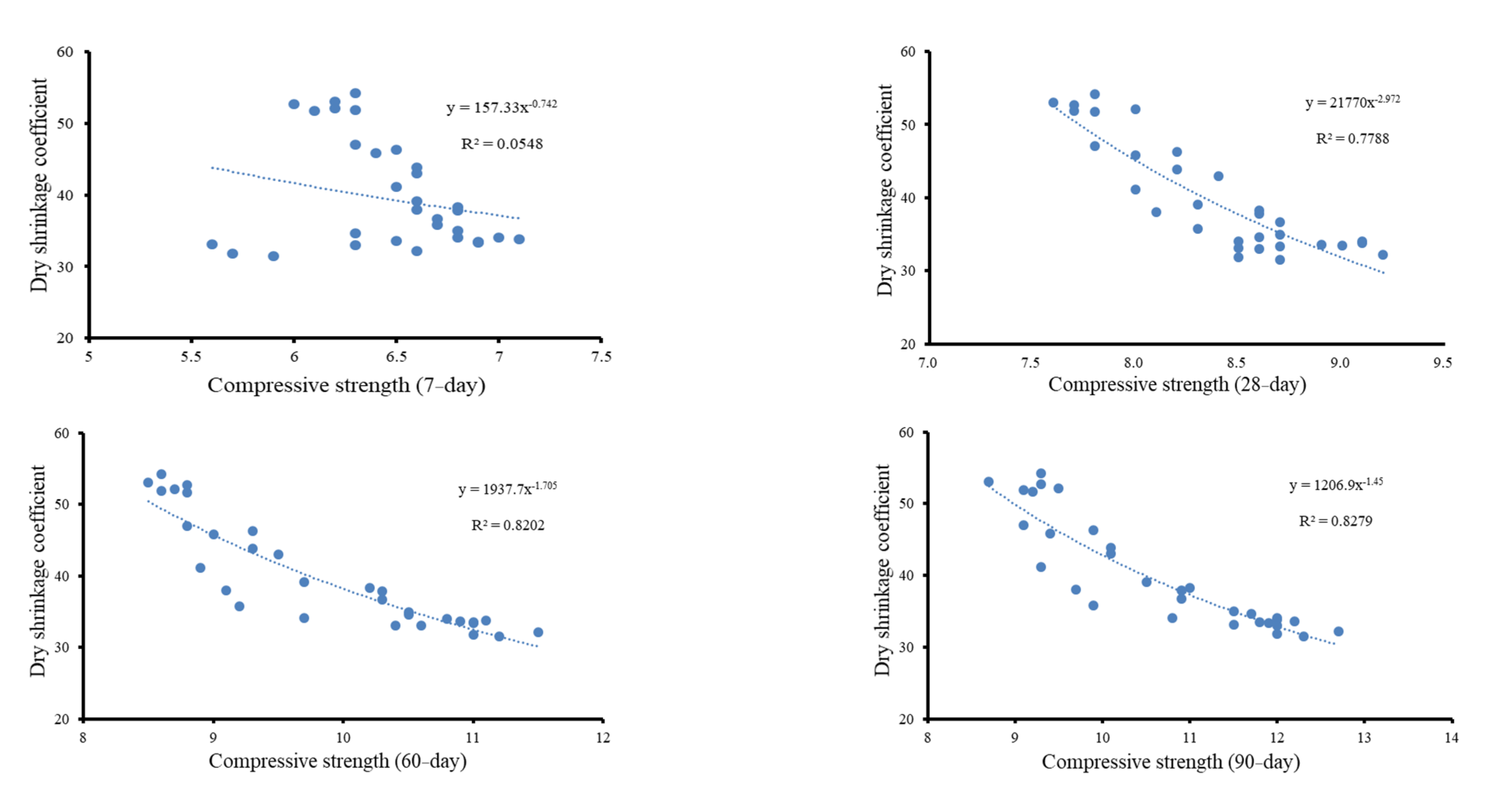

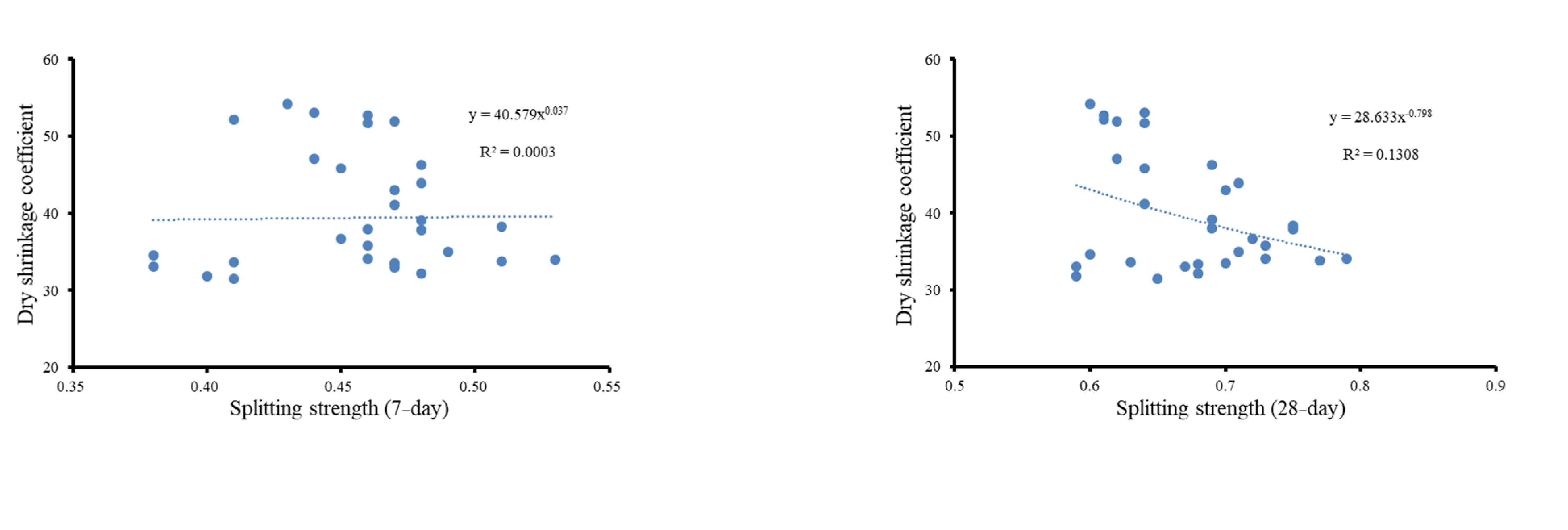

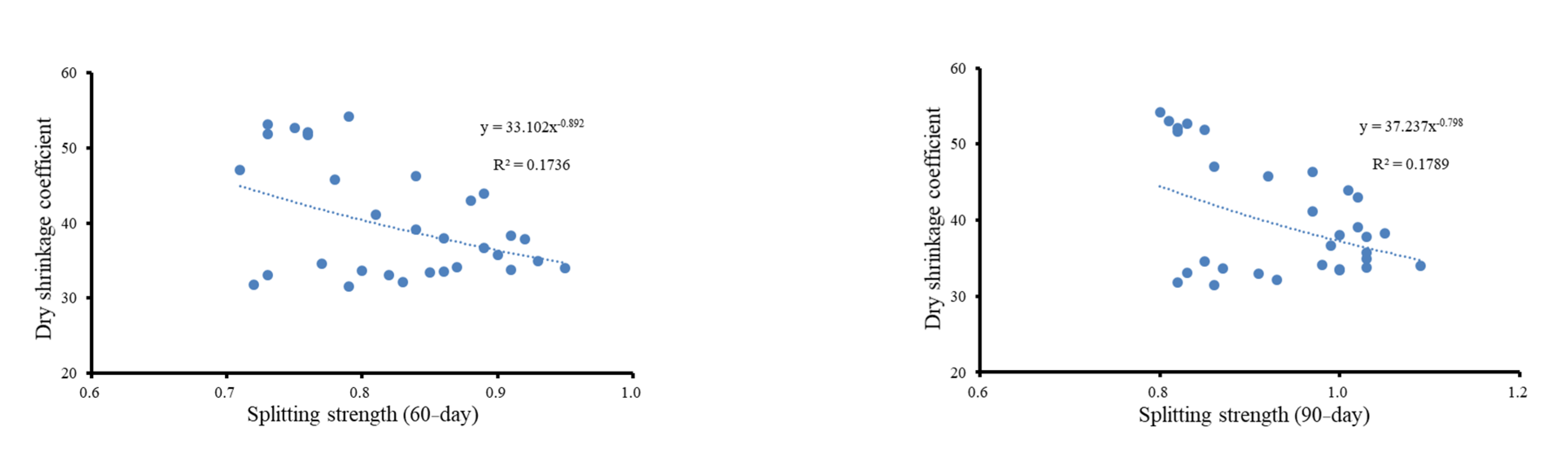

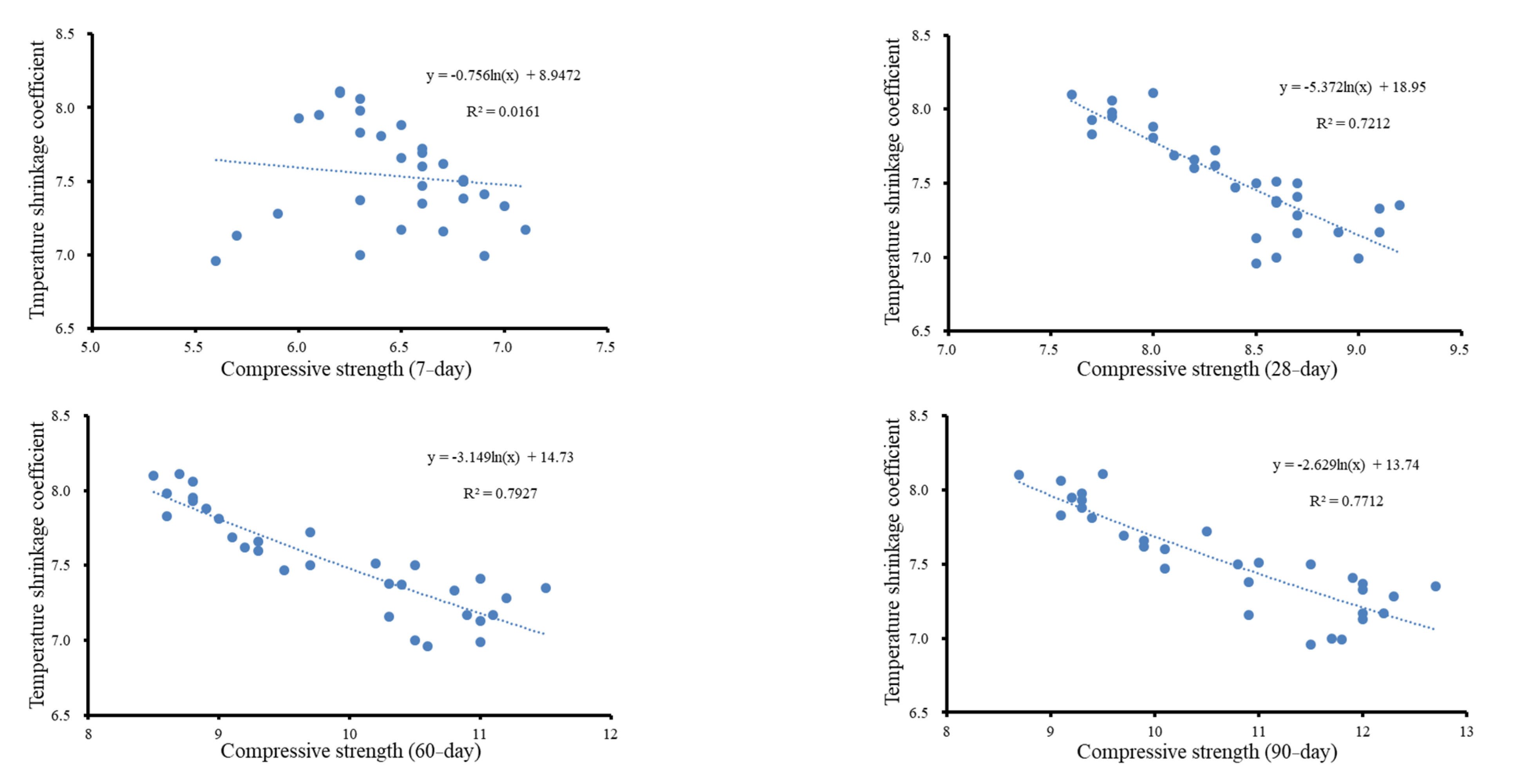

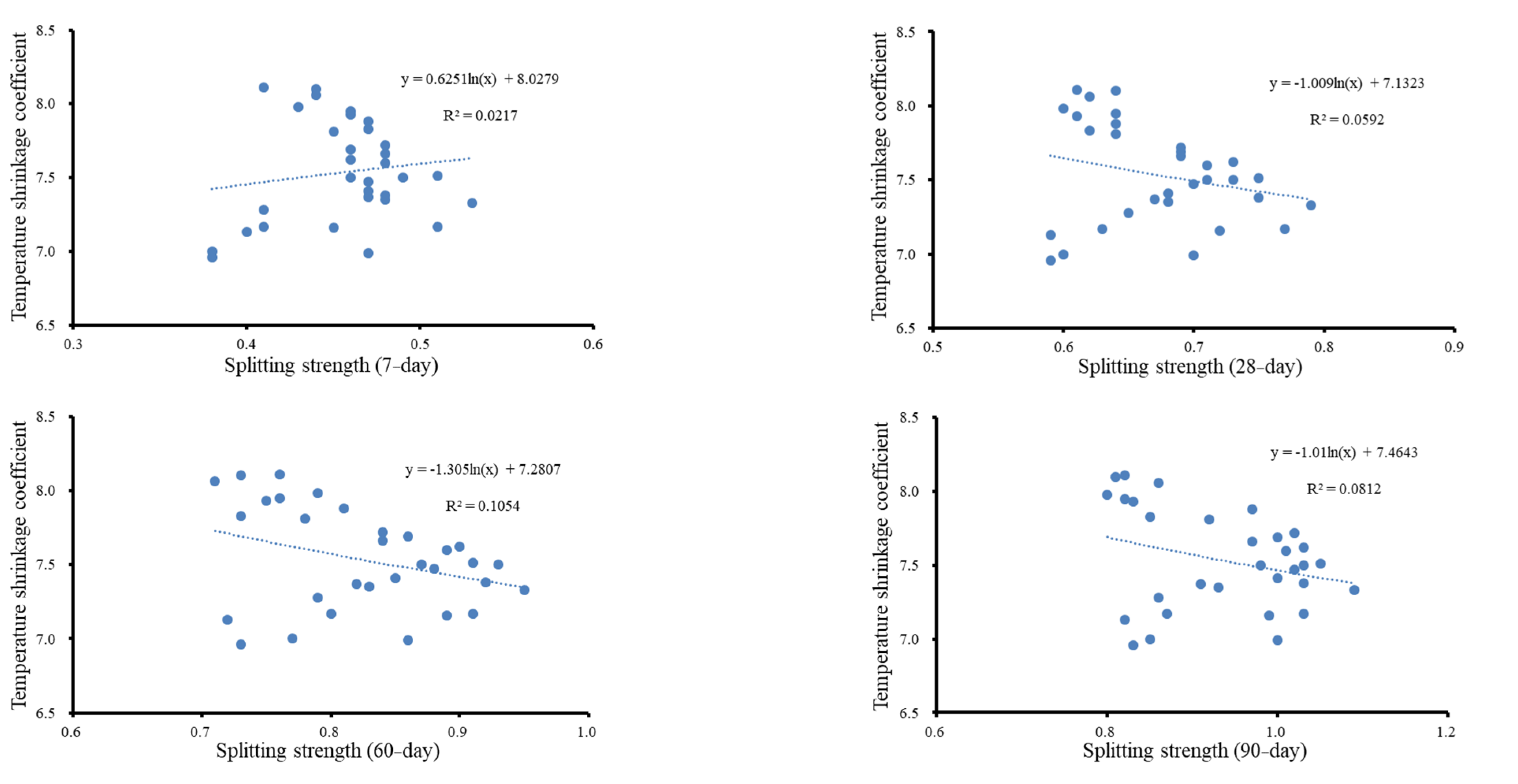

The relationships between compressive strengths and dry shrinkage coefficients, between splitting strengths and dry shrinkage coefficients, between compressive strengths and temperature shrinkage coefficients, and between splitting strengths and temperature shrinkage coefficients are shown in Figure 8, Figure 9, Figure 10, and Figure 11, respectively.

Figure 8.

Relationships between compressive strengths and dry shrinkage coefficients.

Figure 9.

Relationships between splitting strengths and dry shrinkage coefficients.

Figure 10.

Relationships between compressive strengths and temperature shrinkage coefficients.

Figure 11.

Relationships between splitting strengths and temperature shrinkage coefficients.

As shown in Figure 8, Figure 9, Figure 10 and Figure 11, splitting strengths at different curing ages had less correlation to the dry shrinkage coefficients and temperature shrinkage coefficients. The values of R2 were all less than 0.18. In contrast, there was a higher correlation between compressive strengths and shrinkage coefficients. Particularly when the curing age was larger than the 28-day period, the values of R2 were all more than 0.72. It implies that the dry and temperature shrinkage coefficients can be predicted via compressive strength. Considering the complicacy of the experimental process of the dry shrinkage and temperature shrinkage, the shrinkage prediction based on compressive strength is beneficial to evaluate the shrinkage resistance of fiber-reinforced cement-stabilized concrete in practical engineering. In addition, although the value of R2 increased as the curing age increased, overlong curing time is unfavorable for engineering applications. Hence, the compressive strength at the curing age of the 28-day period can be selected to predict the shrinkage resistance. The prediction frame of dry shrinkage coefficient αd and temperature shrinkage coefficient αt can be expressed as Equations (3) and (4), respectively.

where C is the compressive strength (MPa), ad, bd, at, and bt are all fitting parameters.

5. Conclusions

The effects of polyester fiber content and length on the dry shrinkage coefficients and temperature shrinkage coefficients of polyester-fiber-reinforced cement-stabilized concrete were explored. Moreover, the relationship between shrinkage and strength was established to indirectly evaluate the dry and temperature shrinkage resistance of polyester-fiber-reinforced cement-stabilized concrete.

- ●

- The dry shrinkage resistance was improved with the increase in polyester fiber content. When the fiber content exceeded 0.7‰, the modification effect became weaker. Overlong fiber was not good for improving dry shrinkage resistance. When the fiber length was longer than 1 cm, the positive effects of polyester fiber on the dry shrinkage resistance were obviously reduced. When the fiber length exceeded 5 cm, the polyester fiber had a negative effect on the dry shrinkage resistance. The optimum fiber content and fiber length for the dry shrinkage resistance was 0.7‰ and 5 cm.

- ●

- The temperature shrinkage resistance was improved with the increase in polyester fiber content and length. Similar to the dry shrinkage resistance, when the fiber content exceeded 0.7‰, the modification effect on the temperature shrinkage resistance became weaker. The difference was that the increase in fiber length did not cause a negative effect on the temperature shrinkage resistance. The influence of polyester fiber on the dry shrinkage was generally more significant than the temperature shrinkage. The optimum fiber content and fiber length for the temperature shrinkage resistance were 0.7‰ and 9 cm.

- ●

- Different from the cement-stabilized concrete without polyester fiber, there was a weak relationship between splitting strength and shrinkage, while the compressive strength presented more correlation. The prediction equations based on the compressive strength at the curing age of the 28-day period was put forward to predict the dry shrinkage coefficients and temperature shrinkage coefficients of polyester-fiber-reinforced cement-stabilized concrete.

In addition, considering the complexity of service conditions of engineering structures, the shrinkage characteristics of polyester-fiber-reinforced cement-stabilized concrete after special environmental action (e.g., sulfate corrosion, freeze–thawing, etc.) will be investigated in our future work.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/buildings13041027/s1, Table S1: Results of dry shrinkage coefficients and temperature shrinkage coefficients.

Author Contributions

Conceptualization, J.W. and J.R.; methodology, L.Z. and J.R.; validation, L.Z. and J.R.; formal analysis, L.Z.; investigation, M.L., J.C., Z.Z., H.Z. and L.Z.; resources, Z.Z.; data curation, J.W., M.L. and J.C.; writing—original draft preparation, J.W., M.L., J.C., Z.Z., H.Z., L.Z. and J.R.; writing—review and editing, H.Z. and J.R.; visualization, H.Z., L.Z. and J.R.; supervision, J.R., H.Z. and L.Z.; project administration, J.R., H.Z. and L.Z.; funding acquisition, J.R. and H.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 51808326, and by the Natural Science Foundation of Shandong Province, grant number ZR2022ME198.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in the article and the Supplementary Materials.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C. Characterization of eco-friendly steel fiber-reinforced concrete containing waste coconut shell as coarse aggregates and fly ash as partial cement replacement. Struct. Concrete. 2020, 21, 437–447. [Google Scholar] [CrossRef]

- Prakash, R.; Raman, S.N.; Divyah, N.; Subramanian, C.; Vijayaprabha, C.; Praveenkumar, S. Fresh and mechanical characteristics of roselle fibre reinforced self-compacting concrete incorporating fly ash and metakaolin. Constr. Build. Mater. 2021, 290, 123209. [Google Scholar] [CrossRef]

- Shi, C.; Li, J.; Sun, S.; Han, H. Research on Pavement Performance of Cement-Stabilized Municipal Solid Waste Incineration Bottom Ash Base. Materials 2022, 15, 8614. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Liu, Z.; Sha, A. Water reducing agent effects on the engineering performance of cement stabilized aggregates. Sci. Iran. 2018, 25, 2404–2412. [Google Scholar] [CrossRef]

- Li, X.; Lv, X.; Wang, W.; Liu, J.; Yu, M.; You, Z. Crack resistance of waste cooking oil modified cement stabilized macadam. J. Clean. Prod. 2020, 243, 118525. [Google Scholar] [CrossRef]

- Ji, X.; Li, X.; Hou, Y.; Wang, T. Mechanical Properties and Crack Resistances of Cement-Stabilized Crushed Pebbles Produced via Vibration Compaction Method. J. Test. Eval. 2020, 48, 3057–3072. [Google Scholar] [CrossRef]

- Ren, J.; Xu, Y.; Zhao, Z.; Chen, J.; Cheng, Y.; Huang, J.; Yang, C.; Wang, J. Fatigue prediction of semi-flexible composite mixture based on damage evolution. Constr. Build. Mater. 2022, 318, 126004. [Google Scholar] [CrossRef]

- You, L.; Yue, Y.; Yan, K.; Zhou, Y. Characteristics of cement-stabilized macadam containing surface-treated recycled aggregates. Road. Mater. Pavement 2021, 22, 2029–2043. [Google Scholar] [CrossRef]

- Li, Y.; Ma, S.; Chen, G.; Wang, S. Mechanical properties and durability of cement-stabilised macadam incorporating waste foundry sand. Int. J. Pavement Eng. 2021, 2021, 1–15. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, P.; Cai, Y.; Jin, Z.; Moshtagh, E. Cracking resistance and mechanical properties of basalt fibers reinforced cement-stabilized macadam. Compos. Part. B-Eng. 2019, 165, 312–334. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, X.; Zhang, Q.; Liang, N.; Xiang, Y.; Qin, M. Crack Resistance and Mechanical Properties of Polyvinyl Alcohol Fiber-Reinforced Cement-Stabilized Macadam Base. Adv. Civ. Eng. 2020, 2020, 6564076. [Google Scholar] [CrossRef]

- Zhao, C.; Liang, N.; Zhu, X.; Yuan, L.; Zhou, B. Fiber-Reinforced Cement-Stabilized Macadam with Various Polyvinyl Alcohol Fiber Contents and Lengths. J. Mater. Civil. Eng. 2020, 32, 04020312. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Wang, J.; Wang, C.; Guan, J.; Zhang, L.; Wang, X.; Hu, X.; Zhang, Y.; Chen, H.; et al. Study on Road Performance of Cement-Stabilized Recycled Aggregate Base with Fiber and Rubber. Adv. Civ. Eng. 2022, 2022, 4321781. [Google Scholar] [CrossRef]

- Du, Q.; Pan, T.; Lv, J.; Zhou, J.; Ma, Q.; Sun, Q. Mechanical Properties of Sandstone Cement-Stabilized Macadam. Appl. Sci. 2019, 9, 3460. [Google Scholar] [CrossRef]

- Mou, G.; Shen, A.; Lyu, Z.; Wang, L.; Guo, Y.; Wei, Z.; Yin, L. Effect of early strength anti-cracking materials on drying shrinkage of recycled cement stabilized macadam. Int. J. Pavement Eng. 2022. Available online: https://doi.org/10.1080/10298436.2022.2039922 (accessed on 28 March 2023). [CrossRef]

- Wang, L.; Shen, A.; Lyu, Z.; Guo, Y.; He, Z.; Mou, G.; Wei, Z. Rapid regeneration cement-stabilized macadam: Preparation, mechanical properties, and dry shrinkage performance. Constr. Build. Mater. 2022, 341, 127901. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, P.; Song, Z.; Wang, Y.; Gong, C. Experimental Investigation of the Performance of Corn Straw Fiber Cement-Stabilized Macadam. Materials 2023, 16, 294. [Google Scholar] [CrossRef]

- Estabragh, A.; Namdar, P.; Javadi, A. Behavior of Cement-Stabilized Clay Reinforced with Nylon Fiber. Geosynth. Int. 2012, 19, 85–92. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.; Wei, H. Investigation of Flexural Properties of Cement-Stabilized Macadam Reinforced with Polypropylene Fiber. J. Mater. Civil. Eng. 2010, 22, 1282–1287. [Google Scholar] [CrossRef]

- Ma, Y.; Gu, J.; Li, Y.; Li, Y. The bending fatigue performance of cement-stabilized aggregate reinforced with polypropylene filament fiber. Constr. Build. Mater. 2015, 83, 230–236. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q. Effect of polypropylene fibre on mechanical and shrinkage properties of cement-stabilised macadam. Int. J. Pavement Eng. 2009, 10, 435–445. [Google Scholar]

- Zhang, P.; Li, Q. Experimental Study on Shrinkage Properties of Cement-stabilized Macadam Reinforced with Polypropylene Fiber. J. Reinf. Plast. Comp. 2010, 29, 1851–1860. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, C.; Li, Q.; Zhang, T. Effect of Polypropylene Fiber on Fracture Properties of Cement Treated Crushed Rock. Compos. Part. B-Eng. 2013, 55, 48–54. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, D.; Wei, X.; Wang, L. Impact of Fiber Diameter on-Road Performance of Cement-Stabilized Macadam. Balt. J. Road Bridge Eng. 2017, 12, 12–20. [Google Scholar] [CrossRef]

- Tan, S.; Wang, C.; Zheng, Q.; Chen, F.; Huang, Y. Durability Performance of PVA Fiber Cement-Stabilized Macadam. Sustainability 2022, 14, 16953. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C. Fibre reinforced concrete containing waste coconut shell aggregate, fly ash and polypropylene fibre. Rev. Fac. Ing.-Univ. Ant. 2020, 94, 33–42. [Google Scholar] [CrossRef]

- JTG 3420-2020; Testing Methods of Cement and Concrete for Highway Engineering. Ministry of Transport of the People’s Public of China: Beijing, China, 2020.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).