Preparation and Properties of Double Liquid Grouting Materials (DLGMs) Used for the Regenerated Roof of a Coal Mine

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Design and Preparation of Grouting Materials

2.2.1. Preparation of Slurry A

2.2.2. Preparation and Optimization of Slurry C

2.3. Test Method

3. Results and Discussion

3.1. Influence of Raw Material Composition on the Performance of Slurry A

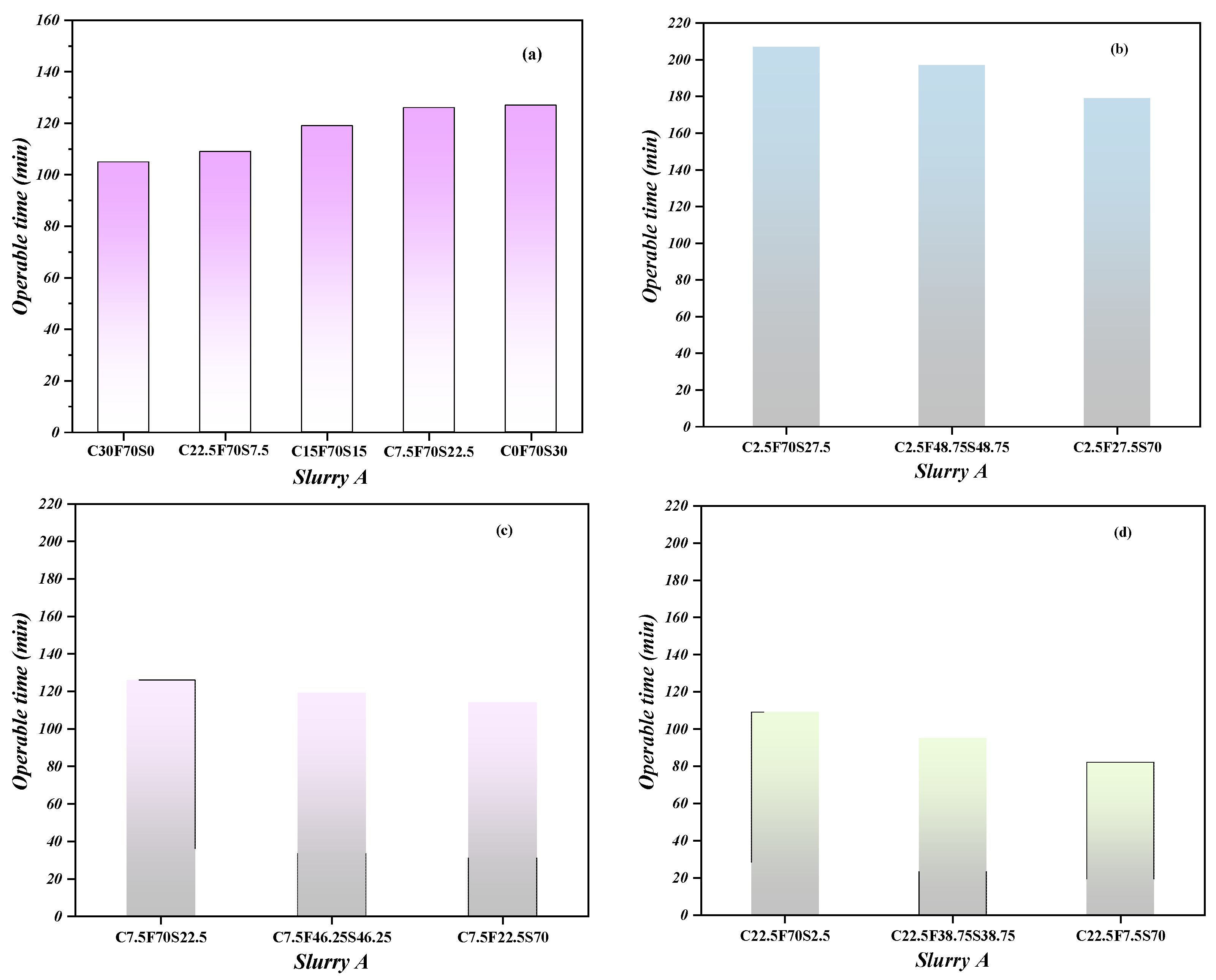

3.1.1. The Operable Time of Slurry

3.1.2. Viscosity of the Slurry

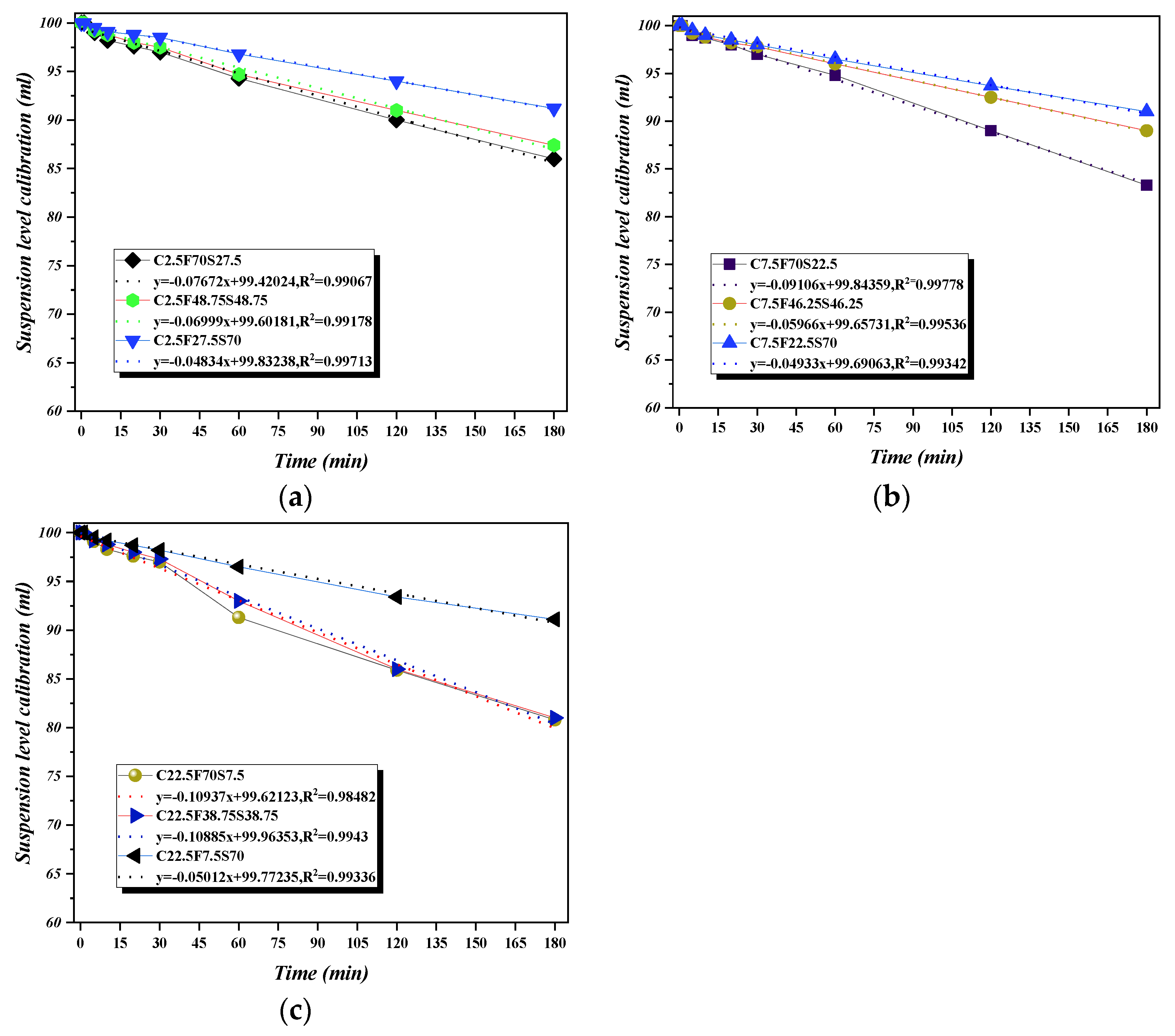

3.1.3. Stability of Slurry

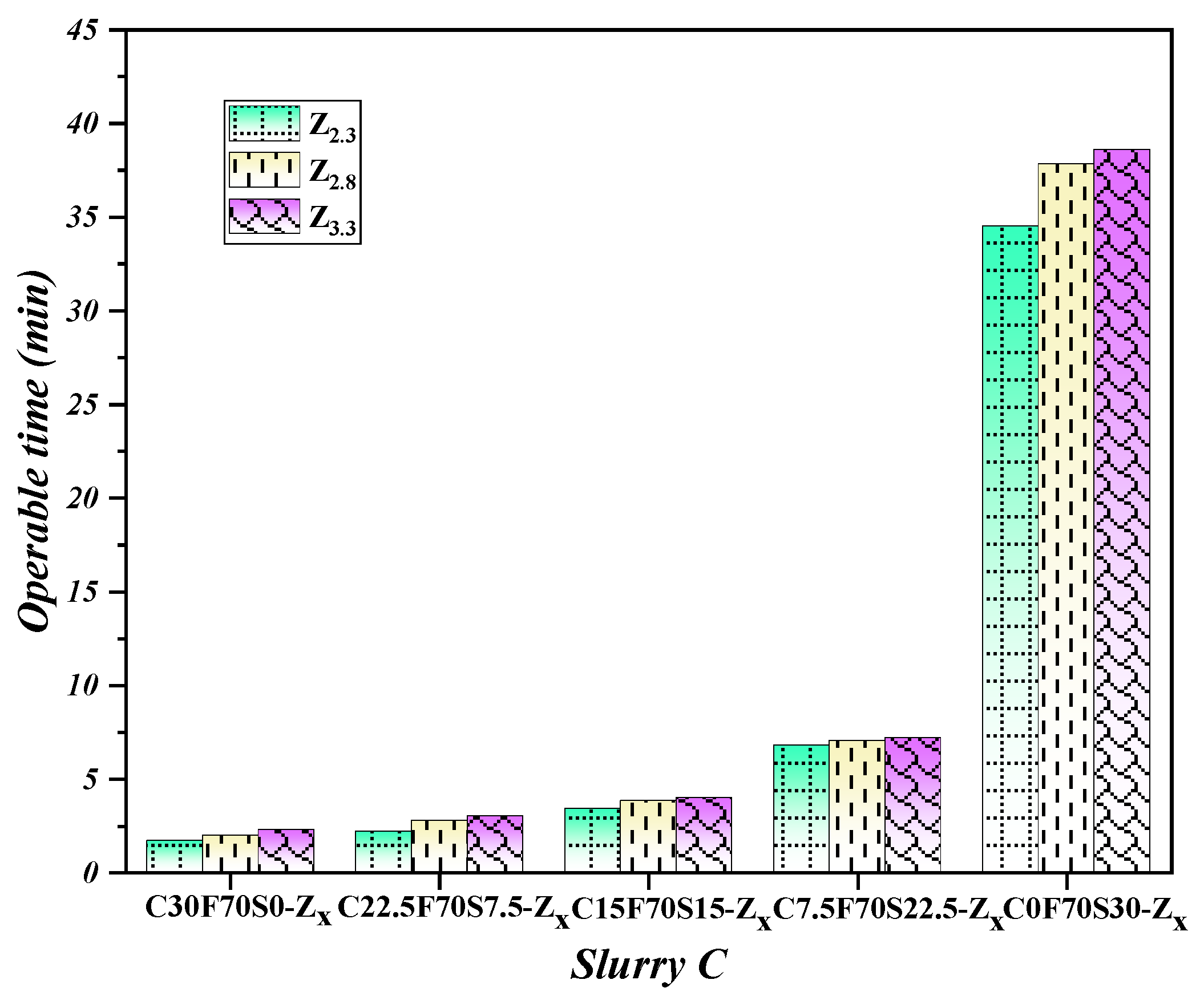

3.2. Effect of Raw Material Composition and Sodium Silicate Modulus on the Operable Time of Slurry C

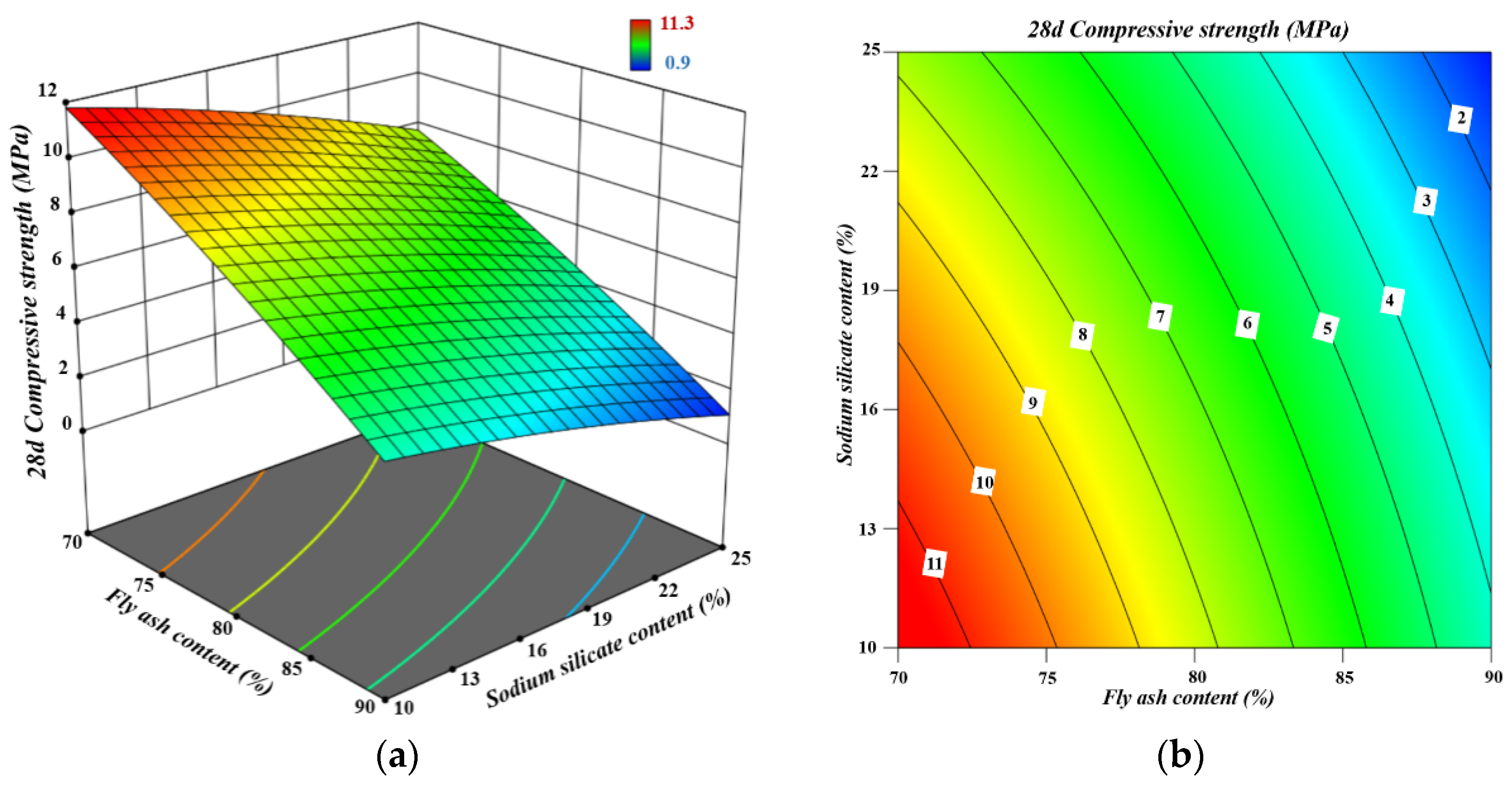

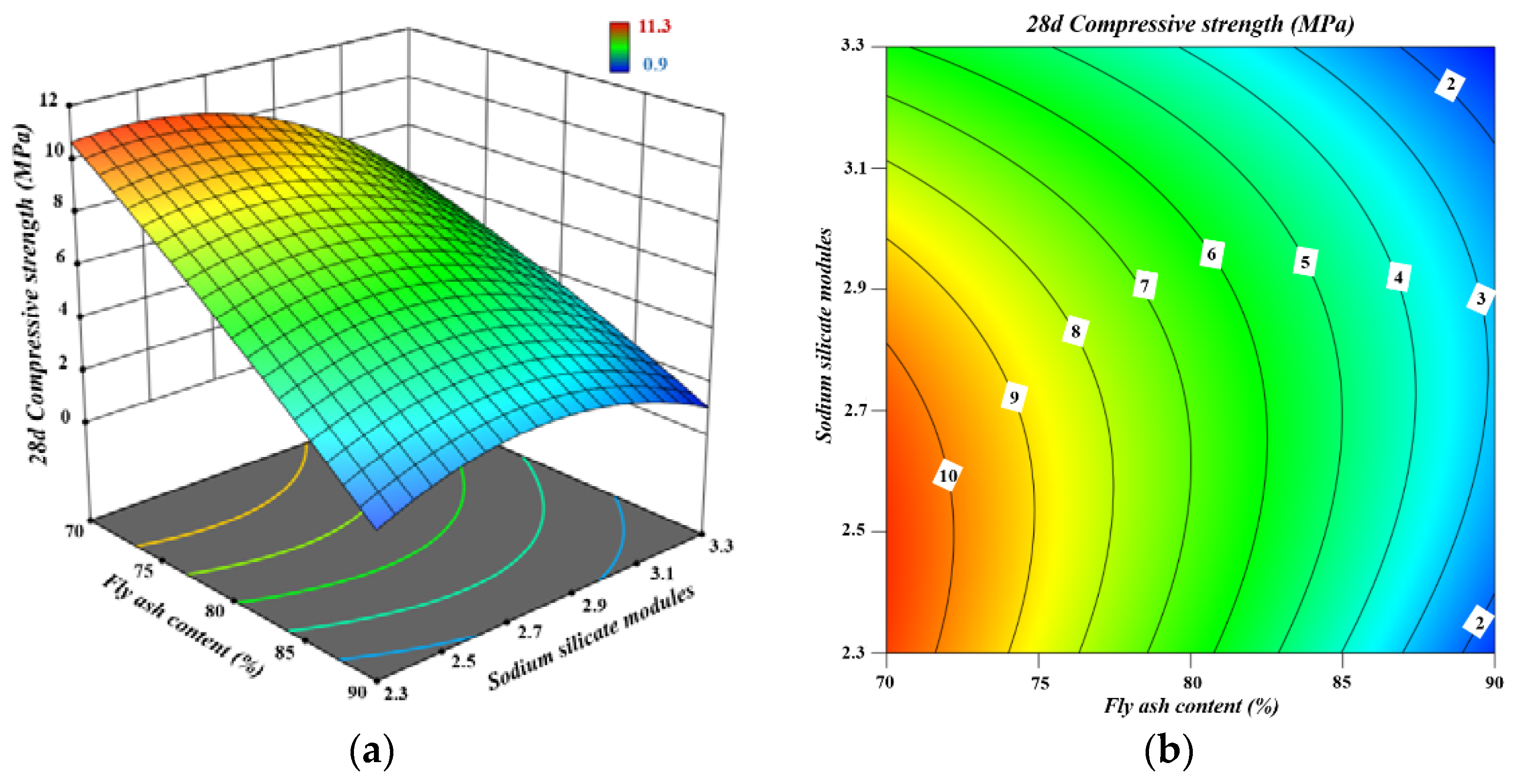

3.3. The Effect of Interaction on the Mechanical Properties of the DLGMs

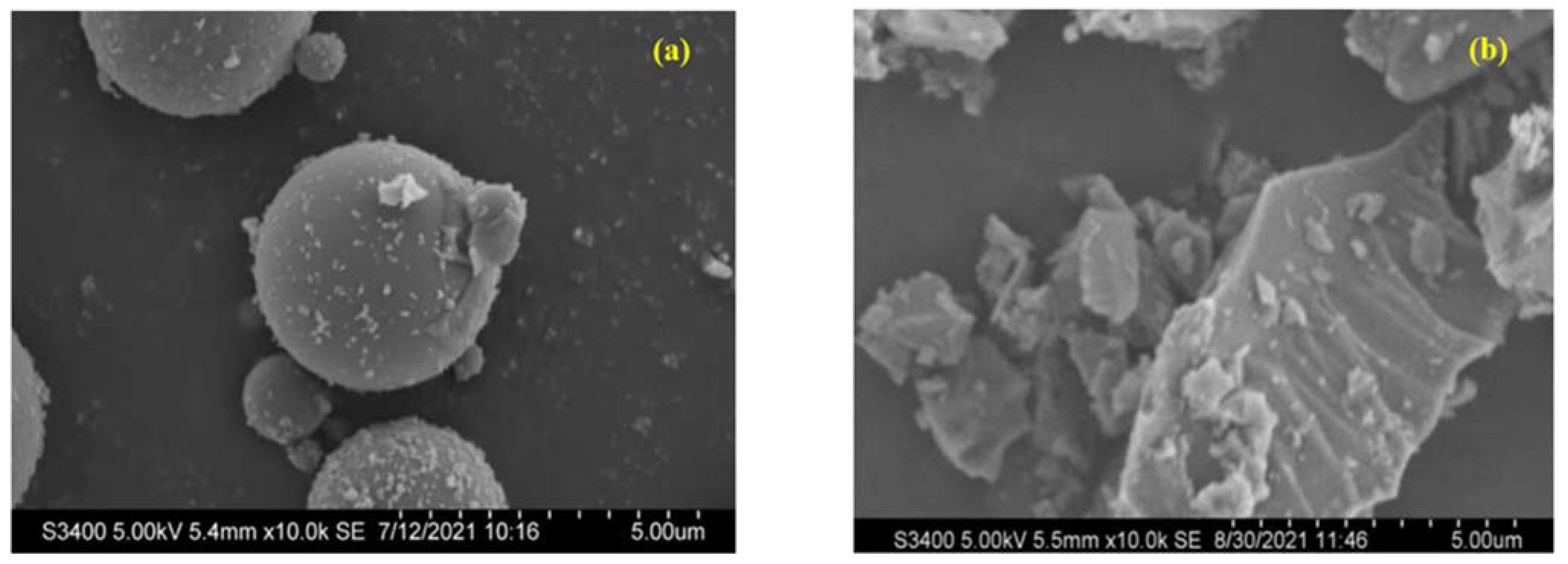

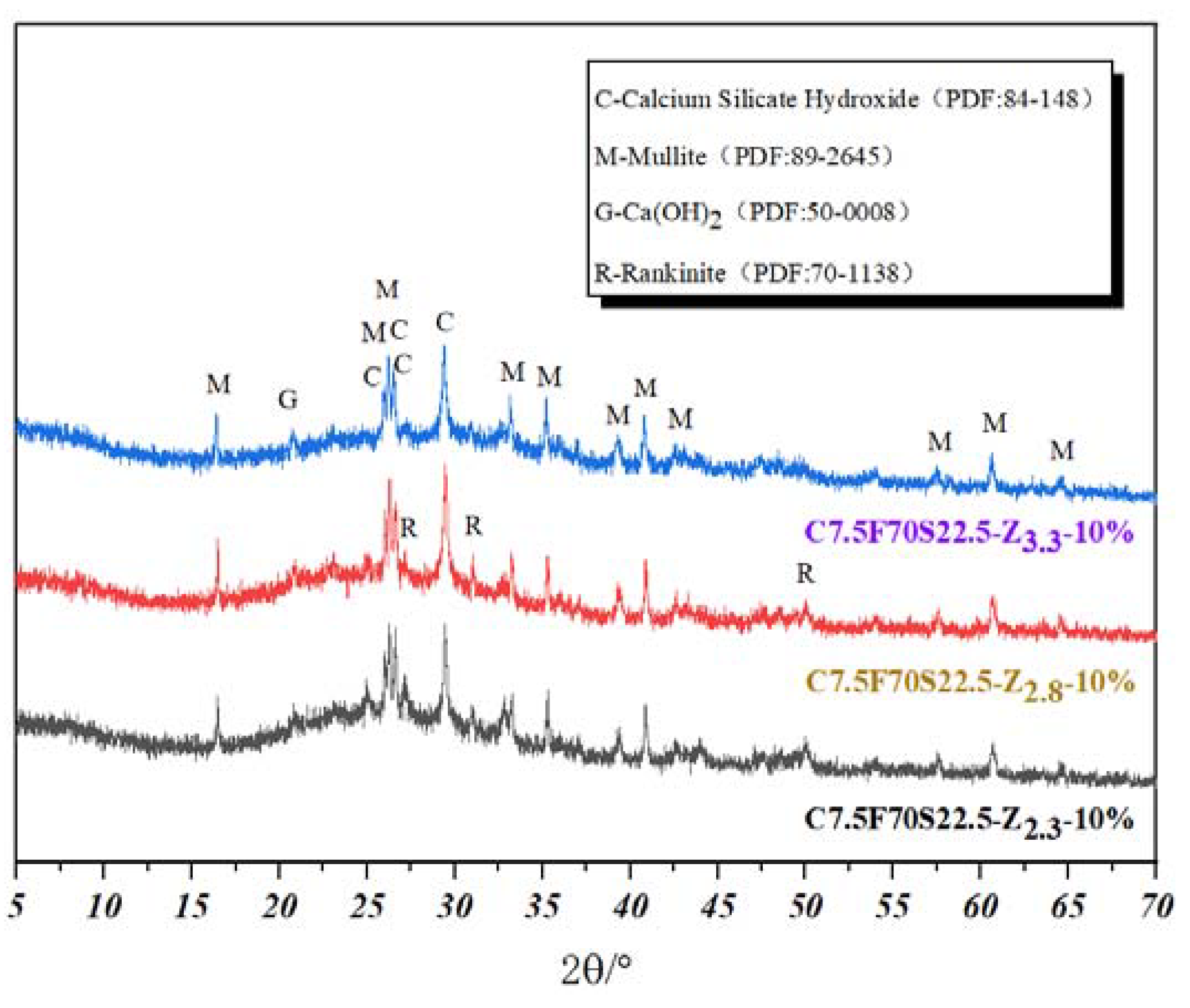

4. Composition and Microstructure of Hardened Slurry A and Slurry C

5. Conclusions

- (1)

- Slurry A was prepared with fly ash, slag, and ordinary Portland cement. Compared to the C7.5F70S22.5 group, when the cement content was 7.5%, the operable time and settlement rate of the C7.5F22.5S70 group were reduced by 9.5% and 45.8%, respectively. The viscosity of the C7.5F70S22.5 group was 7.9% lower than that of the C7.5F22.5S70 group. However, compared to the C22.5F70S7.5 group, when the cement content was increased to 22.5%, the operable time and settlement rate of the C22.5F7.5S70 group were reduced by 24.8% and 54.2%, respectively and the viscosity of the C22.5F70S7.5 group was reduced by 18.3% compared to that of the C22.5F7.5S70 group.

- (2)

- Slurry C acquired a fast setting time by the addition of sodium silicate (slurry B) to slurry A. The relative content of the cement and the sodium silicate modulus was the main factor affecting the operable time of slurry C. Compared to the C30F70S0-Z3.3 group, the operable time of the C0F70S30-Z3.3 group increased by approximately 36 min. Due to the reduction in the modulus of sodium silicate, compared to the C0F70S30-Z3.3 group, the operable time of the C0F70S30-Z2.3 group decreased by 10.6%.

- (3)

- The design parameters of the DLGMs were optimized based on the response surface method. The regression model and response surface could well reflect the influence of multiple factors on the properties of the DLGMs. When the fly ash content, sodium silicate modulus, and sodium silicate content were 70–75%, 2.3–2.7, and 10–13%, respectively, the properties of the DLGMs were excellent. When the mass percentage of cement, fly ash, and slag in slurry A was 7.5%:70%:22.5%, and the sodium silicate modulus and content in slurry B were 2.8 and 10%, respectively, the 28-day compressive strength of the DLGM mortar could reach up to 11.3 MPa. To obtain higher compressive strength of the DLGMs, it is recommended to choose the ratio above. This is the best ratio for the DLGMs. According to the variance analysis of the response surface model, the influence of the experimental design on the 28-day compressive strength of the DLGM mortar is in the order, from strong to weak, of fly ash content, sodium silicate content, and sodium silicate modulus.

- (4)

- After mixing different moduli of sodium silicate into the C7.5F70S22.5 group, the characteristic peak intensity of the Ca(OH)2 revealed a significant reduction, and a broader amorphous peak appeared in the range of 20° to 35°. With the decrease in the sodium silicate modulus, the amorphous peak became more obvious, indicating that amorphous phases were produced in the system. The SEM results showed that the microstructure of the C7.5F70S22.5-Z2.3 and the C7.5F70S22.5-Z2.8 groups was denser than that of the C7.5F70S22.5-Z3.3 groups. Compared to the C7.5F70S22.5-Z2.3 group, the distribution of the reaction products in the C7.5F70S22.5-Z2.8 group was more uniform.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, C.; Zhang, J.; Li, M.; He, Z.; Wang, Y.; Lan, Y. Effect mechanism of strata breakage evolution on stope deformation in extra-thick coal seams. Alex. Eng. J. 2022, 61, 5003–5020. [Google Scholar] [CrossRef]

- Pan, C.; Xia, B.; Zuo, Y.; Yu, B.; Ou, C. Mechanism and control technology of strong ground pressure behaviour induced by high-position hard roofs in extra-thick coal seam mining. Int. J. Min. Sci. Technol. 2022, 32, 499–511. [Google Scholar] [CrossRef]

- Lv, H.; Cheng, Z.; Liu, F. Study on the mechanism of a new fully mechanical mining method for extremely thick coal seam. Int. J. Rock Mech. Min. Sci. 2021, 142, 104788. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Y.; Pang, S.; Wang, X.; He, J.; Zhang, J.; Rodriguez-Dono, A. Mining footprint of the underground longwall caving extraction method: A case study of a typical industrial coal area in China. J. Hazard. Mater. 2022, 425, 127762. [Google Scholar] [CrossRef]

- Çelik, A.; Özçelik, Y. Investigation of the efficiency of longwall top coal caving method applied by forming a face in horizontal thickness of the seam in steeply inclined thick coal seams by using a physical model. Int. J. Rock Mech. Min. Sci. 2021, 148, 104917. [Google Scholar] [CrossRef]

- Tu, S.-H.; Yong, Y.; Zhen, Y.; Ma, X.-T.; Qi, W. Research situation and prospect of fully mechanized mining technology in thick coal seams in China. Procedia Earth Planet. Sci. 2009, 1, 35–40. [Google Scholar] [CrossRef]

- Pan, D.; Hong, K.; Fu, H.; Zhou, J.; Zhang, N.; Lu, G. Influence characteristics and mechanism of fragmental size of broken coal mass on the injection regularity of silica sol grouting. Constr. Build. Mater. 2021, 269, 121251. [Google Scholar] [CrossRef]

- Shimada, H.; Hamanaka, A.; Sasaoka, T.; Matsui, K. Behaviour of grouting material used for floor reinforcement in underground mines. Int. J. Surf. Min. Reclam. Environ. 2014, 28, 133–148. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Hoang, N.-D. Groutability prediction of microfine cement based soil improvement using evolutionary LS-SVM inference model. J. Civ. Eng. Manag. 2014, 20, 839–848. [Google Scholar] [CrossRef]

- Hesse, J.C.; Schedel, M.; Diedel, R.; Sass, I. Influence of swelling and non-swelling clays on the thermal properties of grouting materials for borehole heat exchangers. Appl. Clay Sci. 2021, 210, 106154. [Google Scholar] [CrossRef]

- Guo, L.; Zhou, M.; Wang, X.; Li, C.; Jia, H. Preparation of coal gangue-slag-fly ash geopolymer grouting materials. Constr. Build. Mater. 2022, 328, 126997. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, Z.; Tang, X.; Gui, Z.; Liu, F. Synthesis and characterization of one-part alkali-activated grouting materials based on granulated blast furnace slag, uncalcined coal gangue and microscopic fly ash sinking beads. Constr. Build. Mater. 2022, 345, 128254. [Google Scholar] [CrossRef]

- Li, B.; Zhang, J.; Liu, Y.; Qu, L.; Liu, Q.; Sun, Y.; Xu, G. Interfacial porosity model and modification mechanism of broken coal grouting: A theoretical and experimental study. Surf. Interfaces 2022, 33, 102286. [Google Scholar] [CrossRef]

- Li, G.; Sun, Y.; Qi, C. Machine learning-based constitutive models for cement-grouted coal specimens under shearing. Int. J. Min. Sci. Technol. 2021, 31, 813–823. [Google Scholar] [CrossRef]

- Wu, T.; Gao, Y.; Zhou, Y. Application of a novel grouting material for prereinforcement of shield tunnelling adjacent to existing piles in a soft soil area. Tunn. Undergr. Space Technol. 2022, 128, 104646. [Google Scholar] [CrossRef]

- Gao, Y.; Jing, H.; Fu, G.; Zhao, Z.; Shi, X. Studies on combined effects of graphene oxide-fly ash hybrid on the workability, mechanical performance and pore structures of cementitious grouting under high W/C ratio. Constr. Build. Mater. 2021, 281, 122578. [Google Scholar] [CrossRef]

- Cui, Y.; Tan, Z.; An, C. Research and application of multi-functional acrylic resin grouting material. Constr. Build. Mater. 2022, 359, 129381. [Google Scholar] [CrossRef]

- Thumrongvut, J.; Seangatith, S.; Phetchuay, C.; Suksiripattanapong, C. Comparative experimental study of sustainable reinforced Portland cement concrete and geopolymer concrete beams using rice husk ash. Sustainability 2022, 14, 9856. [Google Scholar] [CrossRef]

- Phoo-Ngernkham, T.; Hanjitsuwan, S.; Dethan, S.; Thumrongvut, J.; Suksiripattanapong, C.; Damrongwiriyanupap, N.; Chindaprasirt, P.; Hatanaka, S. Shear bond strength of FA-PC geopoylmer under different sand to binder ratios and sodium hydroxide concentrations. Int. J. Geomate 2018, 42, 52–57. [Google Scholar] [CrossRef]

- Jiao, Z.; Li, X.; Yu, Q.; Yao, Q.; Guan, X.; Hu, P. Chloride resistance of class C/class F fly ash-based geopolymer mortars with different strength grades. Case Stud. Constr. Mater. 2023, 18, e01811. [Google Scholar] [CrossRef]

- Sun, X.; Liu, H.; Tian, Z.; Ma, Y.; Wang, Z.; Fan, H. Feasibility and economic evaluation of grouting materials containing binary and ternary industrial waste. Constr. Build. Mater. 2021, 274, 122021. [Google Scholar] [CrossRef]

- Güllü, H.; Cevik, A.; Al-Ezzi, K.M.; Gülsan, M.E. On the rheology of using geopolymer for grouting: A comparative study with cement-based grout included fly ash and cold bonded fly ash. Constr. Build. Mater. 2019, 196, 594–610. [Google Scholar] [CrossRef]

- Jin, J.; Zhang, G.; Qin, Z.; Liu, T.; Shi, J.; Zuo, S. Viscosity enhancement of self-consolidating cement-tailings grout by biomass fly ash vs. chemical admixtures. Constr. Build. Mater. 2022, 340, 127802. [Google Scholar] [CrossRef]

- Do, T.M.; Kim, H.-K.; Kim, M.-J.; Kim, Y.-S. Utilization of controlled low strength material (CLSM) as a novel grout for geothermal systems: Laboratory and field experiments. J. Build. Eng. 2020, 29, 101110. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, G.H.; Yuan, Y.F. Basic properties and engineering application of bentonite-cement-water glass grouting. KSCE J. Civ. Eng. 2020, 24, 2742–2750. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Zhang, B.; Hou, D.; Li, H.; Li, L.; Wang, J.; Lin, C. A preliminary investigation of the properties of potassium magnesium phosphate cement-based grouts mixed with fly ash, water glass and bentonite. Constr. Build. Mater. 2020, 237, 117501. [Google Scholar] [CrossRef]

- Sha, F.; Li, S.C.; Lin, C.J.; Liu, R.T.; Zhang, Q.S.; Yang, L.; Li, Z.F. Research on penetration grouting diffusion experiment and reinforcement mechanism for sandy soil porous media. Rock Soil Mech. 2019, 40, 4259–4269. [Google Scholar] [CrossRef]

- Lee, J.; Bang, C.; Mok, Y.; Joh, S. Numerical and experimental analysis of penetration grouting in jointed rock masses. Int. J. Rock Mech. Min. Sci. 2000, 37, 1027–1037. [Google Scholar] [CrossRef]

- Sha, F.; Li, H.; Pan, D.; Liu, H.; Zhang, X. Development of steel slag composite grouts for underground engineering. J. Mater. Res. Technol. 2020, 9, 2793–2809. [Google Scholar] [CrossRef]

- Wang, S.; He, C.; Nie, L.; Zhang, G. Study on the long-term performance of cement-sodium silicate grout and its impact on segment lining structure in synchronous backfill grouting of shield tunnels. Tunn. Undergr. Space Technol. 2019, 92, 103015. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, M.; Liu, R.; Zhang, H.; Zhang, C.; Liu, Y.; Bai, J.; Zhang, L. Study of the viscosity-temperature characteristics of cement-sodium silicate grout considering the time-varying behaviour of viscosity. Constr. Build. Mater. 2021, 306, 124818. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, J.; Fu, J.; Wang, S.; Yin, J.; Ou, X.F.; Xie, Y. Optimal formulation design of polymer-modified cement based grouting material for loose deposits. Constr. Build. Mater. 2020, 261, 120513. [Google Scholar] [CrossRef]

- JC/T 2536; Cement Sodium Silicate Grout. China Building Materials Press: Beijing, China, 2019. (In Chinese)

- GB/T 17671-2020; Standard for Method of Testing Cements-Determination of Strength. People’s Republic of China National Standard. The State Bureau of Quality and Technical Supervision of the People’s Republic of China: Beijing, China, 2020. (In Chinese)

- Kumar, S.; Suman, S.K. Investigating the properties of cement grouted bituminous mix with alternative grout compositions. Mater. Today Proc. 2022, 65, 831–838. [Google Scholar] [CrossRef]

- Song, B.; Liu, S.; Hu, X.; Ouyang, K.; Li, G.; Shi, C. Compressive strength, water and chloride transport properties of early CO2-cured Portland cement-fly ash-slag ternary mortars. Cem. Concr. Compos. 2022, 134, 104786. [Google Scholar] [CrossRef]

- Li, L.; Wei, Y.-J.; Li, Z.; Farooqi, M.U. Rheological and viscoelastic characterizations of fly ash/slag/silica fume-based geopolymer. J. Clean. Prod. 2022, 354, 131629. [Google Scholar] [CrossRef]

- Li, L.; Yang, J.; Li, H.; Du, Y. Insights into the microstructure evolution of slag, fly ash and condensed silica fume in blended cement paste. Constr. Build. Mater. 2021, 309, 125044. [Google Scholar] [CrossRef]

- Chang, J.J. A study on the setting characteristics of sodium silicate-activated slag pastes. Cem. Concr. Res. 2003, 33, 1005–1011. [Google Scholar] [CrossRef]

- Lin, R.; Yang, L.; Pan, G.; Sun, Z.; Li, J. Properties of composite cement-sodium silicate grout mixed with sulphoaluminate cement and slag powder in flowing water. Constr. Build. Mater. 2021, 308, 125040. [Google Scholar] [CrossRef]

- Chen, K.; Lin, W.-T.; Liu, W. Microstructures and mechanical properties of sodium-silicate-activated slag/co-fired fly ash cementless composites. J. Clean. Prod. 2020, 277, 124025. [Google Scholar] [CrossRef]

- Chen, W.; Li, B.; Wang, J.; Thom, N. Effects of alkali dosage and silicate modulus on autogenous shrinkage of alkali-activated slag cement paste. Cem. Concr. Res. 2021, 141, 106322. [Google Scholar] [CrossRef]

- Li, X.; Bizzozero, J.; Hesse, C. Impact of C-S-H seeding on hydration and strength of slag blended cement. Cem. Concr. Res. 2022, 161, 106935. [Google Scholar] [CrossRef]

- Bellmann, F.; Stark, J. Activation of blast furnace slag by a new method. Cem. Concr. Res. 2009, 39, 644–650. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, G.; Wang, C.; Zhang, Y.; Wang, P.; Yan, N. Activation effects and micro quantitative characterization of high-volume ground granulated blast furnace slag in cement-based composites. Cem. Concr. Compos. 2020, 109, 103556. [Google Scholar] [CrossRef]

- Gu, L.; Lv, Q.; Wang, S.; Xiang, J.; Guo, L.; Jiang, J. Effect of sodium silicate on the properties of loess stabilized with alkali-activated fly ash-based. Constr. Build. Mater. 2021, 280, 122515. [Google Scholar] [CrossRef]

- Cristelo, N.; Soares, E.; Rosa, I.; Miranda, T.; Oliveira, D.V.; Silva, R.A.; Chaves, A. Rheological properties of alkaline activated fly ash used in jet grouting applications. Constr. Build. Mater. 2013, 48, 925–933. [Google Scholar] [CrossRef]

- Li, H.; Xu, F.; Li, B.; Sun, T.; Huang, X.; Zhu, J.; Peng, C.; Lin, J.; Chen, Z. Investigation on mechanical properties of excess-sulfate phosphogypsum slag cement: From experiments to molecular dynamics simulation. Constr. Build. Mater. 2022, 315, 125685. [Google Scholar] [CrossRef]

- Kamseu, E.; Alzari, V.; Rosa, R.; Nuvoli, D.; Sanna, D.; Mariani, A.; Leonelli, C. Marble wastes recycling: Design and synthesis of low-temperature calcium silicate hydrate under various CaO:SiO2 ratio and alkalinity. Materialia 2021, 20, 101224. [Google Scholar] [CrossRef]

| Raw Materials | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | SO3 | TiO2 | MnO | P2O5 | LOI a |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FA | 52.45 | 29.35 | 5.93 | 6.69 | 0.83 | 1.07 | 0.89 | 0.74 | 1.24 | - | 0.24 | 0.17 |

| SG | 30.64 | 15.28 | 0.33 | 36.88 | 5.84 | 0.20 | 0.35 | 0.04 | 0.56 | 0.24 | - | 0.06 |

| CM | 29.34 | 13.10 | 3.28 | 48.67 | 1.09 | 0.54 | - | 3.29 | 0.27 | - | - | 0.12 |

| Series | CM | FA | SG | H2O |

|---|---|---|---|---|

| C30F70S0 | 30 | 70 | 0 | 100 |

| C22.5F70S7.5 | 22.5 | 70 | 7.5 | 100 |

| C15F70S15 | 15 | 70 | 15 | 100 |

| C7.5F70S22.5 | 7.5 | 70 | 22.5 | 100 |

| C0F70S30 | 0 | 70 | 30 | 100 |

| C2.5F70S27.5 | 2.5 | 70 | 27.5 | 100 |

| C2.5F48.75S48.75 | 2.5 | 48.75 | 48.75 | 100 |

| C2.5F27.5S70 | 2.5 | 27.5 | 70 | 100 |

| C7.5F70S22.5 | 7.5 | 70 | 22.5 | 100 |

| C7.5F46.25S46.25 | 7.5 | 46.25 | 46.25 | 100 |

| C7.5F22.5S70 | 7.5 | 22.5 | 70 | 100 |

| C22.5F70S7.5 | 22.5 | 70 | 7.5 | 100 |

| C22.5F38.75S38.75 | 22.5 | 38.75 | 38.75 | 100 |

| C22.5F7.5S70 | 22.5 | 7.5 | 70 | 100 |

| Series | Slurry A/kg | Slurry B/kg | |||

|---|---|---|---|---|---|

| CM | FA | SG | H2O | ||

| C30F70S0-ZX | 30 | 70 | 0 | 100 | 66.67 |

| C22.5F70S7.5-ZX | 22.50 | 70 | 7.50 | 100 | 66.67 |

| C15F70S15-ZX | 15 | 70 | 15 | 100 | 66.67 |

| C7.5F70S22.5-ZX | 7.50 | 70 | 22.50 | 100 | 66.67 |

| C0F70S30-ZX | 0 | 70 | 30 | 100 | 66.67 |

| Factor | Lever | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| X | 70 | 80 | 90 |

| Y | 10 | 17.5 | 25 |

| Z | 2.3 | 2.8 | 3.3 |

| Group | X | Y | Z | Group | X | Y | Z |

|---|---|---|---|---|---|---|---|

| R1 | 80 | 17.5 | 2.8 | R10 | 90 | 10 | 2.8 |

| R2 | 90 | 17.5 | 3.3 | R11 | 80 | 10 | 3.3 |

| R3 | 80 | 25 | 2.3 | R12 | 80 | 17.5 | 2.8 |

| R4 | 70 | 10 | 2.8 | R13 | 80 | 17.5 | 2.8 |

| R5 | 70 | 17.5 | 2.3 | R14 | 90 | 25 | 2.8 |

| R6 | 80 | 17.5 | 2.8 | R15 | 80 | 10 | 2.3 |

| R7 | 80 | 17.5 | 2.8 | R16 | 90 | 17.5 | 2.3 |

| R8 | 80 | 25 | 3.3 | R17 | 70 | 17.5 | 3.3 |

| R9 | 70 | 25 | 2.8 |

| No. | 28-day Compressive Strength (MPa) | No. | 28-day Compressive Strength (MPa) |

|---|---|---|---|

| R1 | 7.2 | R10 | 3.8 |

| R2 | 0.9 | R11 | 6.2 |

| R3 | 4.0 | R12 | 6.8 |

| R4 | 11.3 | R13 | 6.5 |

| R5 | 10.8 | R14 | 1.6 |

| R6 | 6.9 | R15 | 8.0 |

| R7 | 6.5 | R16 | 1.5 |

| R8 | 1.3 | R17 | 6.1 |

| R9 | 8.2 |

| Source | F-Value | p-Value |

|---|---|---|

| Model | 58.96 | <0.0001 |

| X | 346.09 | <0.0001 |

| Y | 85.32 | <0.0001 |

| Z | 40.64 | 0.0004 |

| XY | 0.6854 | 0.4350 |

| XZ | 14.23 | 0.0070 |

| YZ | 0.6854 | 0.4350 |

| X2 | 1.30 | 0.2910 |

| Y2 | 0.9087 | 0.3722 |

| Z2 | 38.92 | 0.0004 |

| Lack of Fit | 6.59 | 0.0500 |

| R2 | 0.9870 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, A.; Li, Z.; Liu, P.; Liu, K.; Yu, G.; Zheng, Q.; Han, Y.; Xu, H.; Sun, D. Preparation and Properties of Double Liquid Grouting Materials (DLGMs) Used for the Regenerated Roof of a Coal Mine. Buildings 2023, 13, 584. https://doi.org/10.3390/buildings13030584

Wang A, Li Z, Liu P, Liu K, Yu G, Zheng Q, Han Y, Xu H, Sun D. Preparation and Properties of Double Liquid Grouting Materials (DLGMs) Used for the Regenerated Roof of a Coal Mine. Buildings. 2023; 13(3):584. https://doi.org/10.3390/buildings13030584

Chicago/Turabian StyleWang, Aiguo, Zheng Li, Peng Liu, Kaiwei Liu, Guofeng Yu, Qun Zheng, Yunchun Han, Haiyan Xu, and Daosheng Sun. 2023. "Preparation and Properties of Double Liquid Grouting Materials (DLGMs) Used for the Regenerated Roof of a Coal Mine" Buildings 13, no. 3: 584. https://doi.org/10.3390/buildings13030584

APA StyleWang, A., Li, Z., Liu, P., Liu, K., Yu, G., Zheng, Q., Han, Y., Xu, H., & Sun, D. (2023). Preparation and Properties of Double Liquid Grouting Materials (DLGMs) Used for the Regenerated Roof of a Coal Mine. Buildings, 13(3), 584. https://doi.org/10.3390/buildings13030584