Abstract

The rapid development of the traditional ceramic industry contributes considerably to economic advancements; however, the ecological hazards caused by the large amount of sintered ceramic wastes generated during ceramic production and discarded at landfill sites are becoming increasingly severe. To realize the large-scale resource utilization of ceramic waste, sintered ceramic waste was used in this study to partially replace natural quartz sand, and new environmentally friendly artificial stones were fabricated by using vacuum vibration molding and inorganic/organic composite curing technology. The effects of ceramic waste addition and particle size on the mechanical strength, surface hardness, wear resistance, stain resistance, and microstructure of artificial stone materials were investigated. The results showed that the replacement of quartz sand with 40–55% ceramic waste significantly improved the mechanical strength of artificial stone and maintained sufficient surface hardness and wear resistance. When 45% of ceramic waste powder (particle size ≥ 120 mesh) was added, the bending strength of the artificial stone was 64.4 MPa, whereas when 55% of ceramic waste particles with different particle sizes were added, the maximum compressive strength was 158.7 MPa. Good wear resistance and sufficient Moh’s hardness of 5.5–6.5 was obtained for all the samples. The prepared ceramic waste artificial stone also had a dense microstructure and low water absorption and porosity, which are helpful for improving stain resistance.

1. Introduction

China is the largest ceramic producer and consumer in the world, and its output of traditional ceramics has ranked first in the world for more than 10 consecutive years. In 2021, the output of building ceramics was approximately 8.174 billion square meters, and the output of sanitary ceramics and daily ceramics reached approximately 220 million and 60 billion square meters, respectively. The rapid development of the traditional ceramic industry has made a significant contribution to China’s economic construction [1]. However, the massive ceramic output is also accompanied by substantial ceramic wastes. At present, the annual amount of solid waste generated from traditional ceramic production in China has reached nearly 20 million tons [1]. A large amount of sintered ceramic wastes are mainly discarded at landfill sites, occupying a large amount of land and causing severe environmental pollution [2], which has become a prominent problem to plague the ecological development of ceramic production areas.

The dominant ceramic producers from developed countries, such as Japan, Italy, the United States, the United Kingdom, Turkey, and Spain had pioneered the pollution control and resource utilization of ceramic waste in the mid-1990s [3]. Early research mainly focused on the application of non-sintered ceramic waste with certain hardening characteristics to the preparation of cement or concrete [4,5,6,7,8,9], but the cost accrued by the collection of solid waste and off-site transportation caused this technology to be rarely applied in practice. From the perspective of economics and technology, it is more feasible to consume ceramic waste in the local enterprise or use ceramic waste cooperatively in the ceramic industry park. After years of research and application practice, most of the non-sintered solid wastes (such as waste billets and waste sludge) have been recycled for the same type of ceramic products in many countries with a high level of ceramic production technology, such as China, Japan, Spain, and Italy [1,10,11,12,13,14,15,16,17]. In the past 10 years, rapid growth of the traditional ceramic industry led to the depletion of high-quality raw material resources and escalated ceramic waste pollution, causing increased attention from the government and industry on efforts to recycle ceramic waste. However, only a few large enterprises with complete process technology and equipment have the resources to realize the recycling of some solid wastes, which are mainly developed for the production of products such as light ceramic tiles, vitrified tiles, permeable tiles, etc. [11,12]. To ensure the stability of production process and quality, the consumption of ceramic waste is kept low. Therefore, a large number of ceramic wastes are still directly disposed of directly in landfill [13], and the problems of ecological environment pollution and land resource occupation cannot be ignored [18,19].

Artificial stone is a building material generally made of natural mineral materials such as quartz sand, marble, calcite, and binder of organic resin [20,21,22,23] or inorganic cementitious material [24,25,26,27,28]. In recent years, the resin-based artificial stone is becoming favored by the construction industry because of its excellent appearance, outstanding stain resistance, and mechanical properties [29,30]. The demand for artificial stone is growing rapidly [31], and it has become one of the good candidates to replace natural stone. Natural minerals are non-renewable resources, and their overexploitation will not only cause damage to the natural environment; it will also face the crisis of resource depletion. Therefore, nowadays, the recycling of various solid wastes in the preparation of artificial materials has been intensively concerned [19,22,32,33,34,35,36]. Ceramic waste (CW) sintered at high temperature is still composed of silicate phases. After reasonable crushing, the ceramic waste particles have high hardness and a smooth surface, so it has great potential to replace the use of natural mineral aggregates in the preparation of resin-based artificial stones [37,38]. This not only alleviates the concern of a shortage of natural mineral resources, it also opens up a new way for the large-scale resource utilization of ceramic waste [39], which is expected to bring substantial economic and social benefits. However, the composition of ceramic waste and the complexity of its appearance will have varying effects on the bonding strength of the inorganic/organic interface. For this reason, sintered ceramic waste was investigated to replace natural mineral quartz sand as the main raw material in preparing resin-based artificial stone. In this study, the effects of additional content and particle size of waste ceramic particles on the mechanical properties, stain resistance, and microstructure of the prepared artificial stone materials were studied.

2. Materials and Methods

2.1. Raw Materials and Reagents

The sintered ceramic waste used in the experiment was produced in the production of domestic and sanitary ceramics in Jingdezhen, Jiangxi Province, as shown in Figure 1. To investigate the effect of the particle size of sintered ceramic waste on the properties of artificial stone and the feasibility of simplifying the preparation process, two different methods were used to process the solid waste raw materials. (1) After the solid waste was processed by employing jaw crushing and sieving classification, different particle size levels, such as 8–26 mesh (0.710–2.36 mm) and 26–70 mesh (0.212–0.710 mm), were obtained (referred to as particle material). (2) After jaw crushing, the ceramic waste was further crushed by ball milling and sieved and graded to obtain the powders with a mesh size of ≥120 (≤0.125 mm) and a median diameter (D50) of approximately 45 μm (referred to as fine powder). The industrial grade quartz sand used included different particle size ranges of 8–26 mesh, 26–70 mesh, and ≥120 mesh. The resin used was o-phenyl unsaturated polyester resin. The coupling agent used was KH-570 (γ-methacryloxypropyltrimethoxysilane), the curing agent was methyl ethyl ketone peroxide, and the accelerator was cobalt naphthenate.

Figure 1.

Photo of the used ceramic waste.

2.2. Preparation of Artificial Stone Samples

In this experiment, based on the different particle sizes of ceramic waste and the raw materials used for preparing resin-based artificial stone samples, the samples were divided into two groups: A and B. The samples in Group A were fabricated by using different contents of fine ceramic waste powders with a mesh size of ≥120 (median diameter D50 of approximately 45 μm) to directly replace the finer quartz particles (see Table 1). The samples in Group B were prepared by using ceramic waste particle material with a size of 8–70 mesh and a certain amount of fine powders to replace the quartz particles in the corresponding gradation (see Table 2). The selected design of these mixtures aims to better investigate the effects of waste content and particle size on the properties of obtained artificial stones. To facilitate the comparison, the artificial stone samples without ceramic waste were prepared under the same conditions by mixing quartz particles of different sizes (8–26 mesh, 26–70 mesh, and ≥120 mesh; 23%, 37%, and 28%, respectively).

Table 1.

Batching of Group A samples with fine ceramic waste powder instead of quartz sand (in mass fraction).

Table 2.

Batching of Group B samples with ceramic waste particles instead of quartz sand of different sizes (in mass fraction).

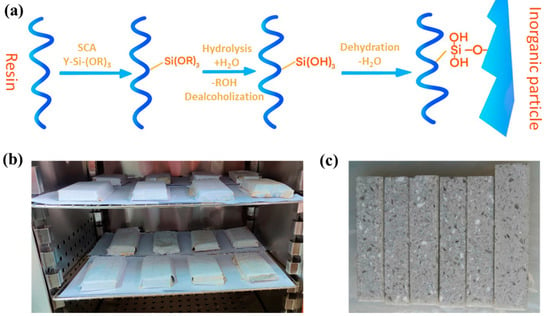

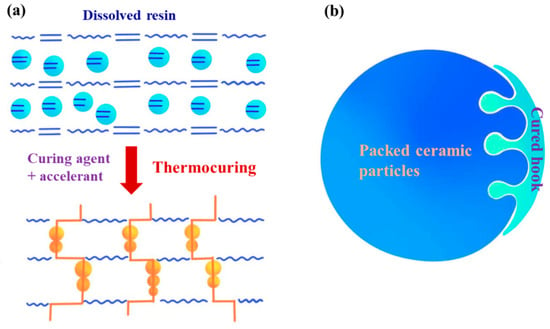

The specific preparation process of the sample was as follows. (1) According to the aggregate particle grading scheme shown in Table 1 and Table 2, the crushed and graded ceramic waste was mixed with the quartz sand particles for 30 min. Then, the coupling agent aqueous solution and resin solution was added and continued to stir for 5 min for granulation (the amount of coupling agent was 1 wt% of the amount of resin). After this step, the appropriate amount of curing agent and curing accelerator were added (the content of the resin was 0.5 wt%) and fully stirred for 5 min. The mixture was poured into the forming mold to distribute evenly. (2) High-frequency vibration compaction molding was performed by applying vacuum vibrating press. The vacuum degree was −0.1 MPa, molding pressure was 10 MPa, and pressure holding time was 5 min. (3) The samples were fully cured by holding at 90 °C for 2 h after pressing and molding. After being cured and molded, the samples were demolded and allowed to naturally cool to room temperature. The dimension of obtained samples was 140 mm × 75 mm × 20 mm. The performance tests were conducted after cutting and multi-stage polishing. Figure 2 shows the schematic diagram of the curing process for ceramic particles combined with resin and the ceramic waste artificial stone samples obtained after thermocuring, polishing, and cutting.

Figure 2.

(a) Schematic diagram of the curing process between ceramic particles and resin, and artificial stone samples subjected to (b) thermocuring and (c) polishing and cutting.

2.3. Analysis and Tests

The chemical composition of ceramic waste was analyzed by using X-ray fluorescence (XRF) spectroscopy (PANalytical B.V., Almelo, Netherlands). The phase composition of raw materials was analyzed by performing X-ray diffraction (XRD, Bruker, Karlsruhe, Germany). The surface structure of the ceramic waste before and after modification was analyzed by applying Fourier transform infrared (FTIR) spectroscopy (Thermo Electron Corporation, Waltham, the United States). The cross-section microstructure of artificial stone samples was observed by using field-emission scanning electron microscopy (SEM, Hitachi, Tokyo, Japan). The three-point bending strength test was conducted by using an electronic universal material testing machine (Xi’an Letry, Xi’an, China), and the bending strength of the rectangular sample with a dimension of 60 mm × 15 mm × 10 mm was calculated by applying Formula (1). The loading speed during the test was 0.5 mm/min. The same material testing machine was used to test the compression strength of the sample. First, the cube sample was prepared as per the method described in JC/T908-2013 to have a side length of 50 mm. Then, the sample was loaded at a constant speed of 2 mm/min until the sample was damaged, as per the method specified in GB/T9966.1-2020, and the maximum load was recorded. The compression strength was calculated as P = F/S, where P is the compression strength (MPa), F is the maximum load (N), and S is the area of the load-bearing surface (mm2). Seven specimens were tested under each experimental condition. The obtained results were averaged, and the standard deviation was also calculated. The test method specified in Appendix A of JC/T908-2013 was used to determine the Moh’s hardness of samples. A standard ore with known hardness was used to apply force, and Moh’s hardness was measured by manually scratching the surface of different parts of the sample evenly and vertically, taking the lowest value as the test result. Based on the methods specified in JC/T908-2013, GB/T12988-2009, and other standards, the wear resistance of the samples (100 mm × 70 mm × 15 mm) was measured by using a material abrasion tester (Xiangtan Xiangyi Instrument Limited, Xiangtan, China). The method characterizes the wear resistance of a corundum abrasive by measuring the volume of grooves (grinding pits) worn on the surface of artificial stones caused by the corundum abrasive under the action of a transmission friction wheel (see Formula (2) and Formula (3) for the calculation method). The water absorption and porosity of the sample were determined according to the Archimedes principle and the method in GB/T3810.3-2016.

where σ is the bending strength (MPa), F is the maximum load when the specimen breaks (N), L is the span of the specimen (mm), b is the width of the specimen (mm), and h is the height of the specimen (mm).

where V is the volume of the grinding pit (mm3), α is the value of the angle of the arc-shaped grinding pit chord to the center of the friction wheel (°), d is the diameter of the friction wheel (mm), h is the thickness of the friction wheel (mm), and L is the chord length of the groove (mm).

3. Results and Discussion

3.1. Analysis of Chemical Composition and Physical Structure of Ceramic Waste

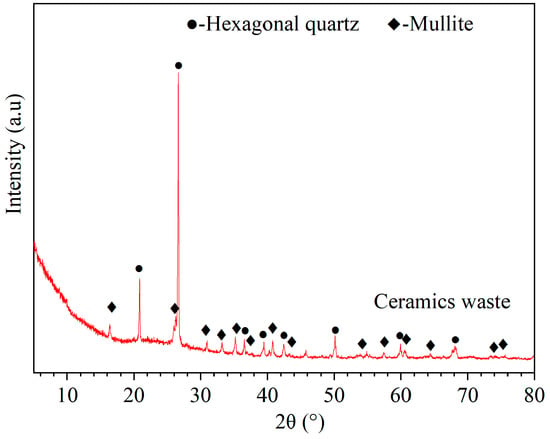

The chemical composition of the sintered ceramic waste raw materials used in the experiment is shown in Table 3. It can be seen that the solid waste has a high content of SiO2 and Al2O3, and the flux composition was mainly K2O. The sintering temperature of the original domestic and sanitary ceramics was relatively high (~1300 °C) in accordance with the chemical composition, which contributed to dense microstructure of the ceramic waste. Figure 3 shows the XRD spectrum of the ceramic waste. The main crystal phases are the quartz crystal phase and the mullite phase (3Al2O3·2SiO2). In addition, combined with the chemical composition of ceramic waste, the main phase in ceramic waste is the silicate glass phase, which accounts for approximately 65% of the phases present. Based on the chemical and phase composition results, it can be anticipated that the obtained ceramic waste particles would have good mechanical properties, such as hardness, wear resistance, and mechanical strength, as well as high density, which helps to reduce the water absorption rate and improve the stain resistance of artificial stone. Preparing an inorganic/organic resin-composite-cured artificial stone by replacing quartz sand with ceramic waste is likely possible because of the hydroxyl groups (–OH) present on the surface of inorganic oxides in the atmospheric environment, having the ability to combine with the polysiloxane produced from the hydrolysis of KH-570, a silane coupling agent.

Table 3.

Chemical composition of pretreated ceramic wastes (in mass fraction).

Figure 3.

XRD pattern of ceramic waste.

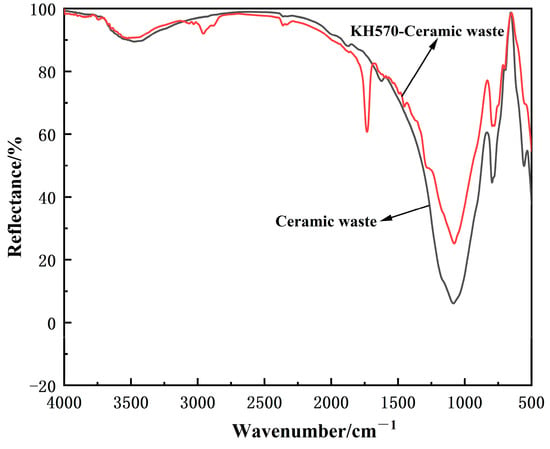

3.2. FTIR Analysis of Surface-Modified Ceramic Waste Raw Material Particles

Figure 4 shows the FTIR spectra of the ceramic waste raw materials before and after modification by silane coupling agent KH-570. The spectra before and after modification are consistent, indicating that the compositions are the same, but the structure of their surface groups changes significantly. The broad peak at 3526 cm−1 on the sample surface before modification is the antisymmetric stretching vibration peak of structural water OH; the strong and wide absorption band at 1078 cm−1 is the antisymmetric stretching vibration peak of SiO2 in the ceramic waste; the symmetric stretching vibration peak of the Si–O bond is at 793 cm−1; the bending vibration peak of the Si–O bond is at 462 cm−1. A comparison of the spectrograms before and after the modification of ceramic waste raw materials reveals that stretching vibration absorption peaks of CH3 and CH2 in KH-570 are present near 2956 cm−1 and 2877 cm−1 in the modified samples, and that of the C=O bond is at 1731 cm−1, indicating that organic substances exist on the surface of the modified ceramic waste particles. That is, after the hydrolysis of the three methoxy functional groups of the silane coupling agent, it reacted with –OH on the surface of waste ceramic particles for dehydration; therefore, the ceramic waste particles can be chemically grafted and bonded with KH-570. Thus, the modification of the silane coupling agent improves the bonding strength between inorganic particles and resin, which is helpful for improving the mechanical strength of the artificial stone.

Figure 4.

FTIR spectra of ceramic waste before and after modification by using the silane coupling agent.

3.3. Effect of Ceramic Waste Addition on Mechanical Properties of Artificial Stones

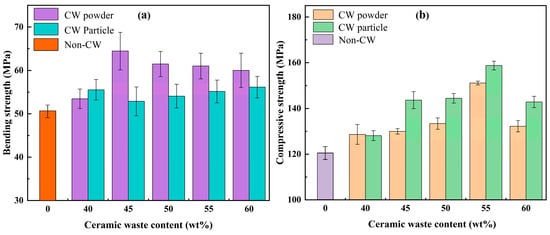

Figure 5a shows the bending strength of resin-based artificial stone samples prepared by partially replacing quartz particles with fine ceramic waste powders (Group A) and ceramic waste particle material (Group B). The bending strength of Group A artificial stone samples with 45–60% fine ceramic waste powders partially replacing quartz sand is significantly higher than that of the Group B sample of ceramic waste particle material and the sample prepared entirely with quartz sand as particle material (50.7 MPa). Among them, the bending strength of the Group A sample with 45% ceramic waste powders is the highest, reaching 64.4 MPa, which is far beyond the requirements of the industrial standard of artificial stone building materials (JC/T908-2013) (no less than 35 MPa). The bending strength of Group B samples with a different amount of waste ceramic particles is also improved to varying degrees compared with that of the samples prepared entirely with quartz sand. The porosity and microstructure analysis shown in Figures 7b and 8 reveals that this was due to the use of fine ceramic waste powders that replace the relatively large quartz particles in the artificial stone. The fine ceramic waste particles can play a role in filling the aggregate accumulation gap, which improves the aggregate accumulation density of the sample. At the same time, the complex composition and appearance of ceramic waste powders did not affect the interface bonding strength. The resin could completely wet the aggregate, and the inorganic/organic interface bonded well, a possible reason that Group A samples showed higher bending strength. The bending strength of Group A samples was still high although slightly reduced. There was no obvious phenomenon of lacking glue at the interface as the consumption of fine powders of ceramic waste was further increased to 60%, though the specific surface area of aggregate was increased. Figure 5b shows the compressive strength of corresponding samples with different compositions. The compressive strength of artificial stone samples can be significantly improved by replacing quartz sand with ceramic waste of different particle sizes. Among them, the maximum compressive strength of Group A samples was 151.1 MPa when 55% of the waste ceramic powders was added, and the maximum compressive strength of Group B samples was 158.7 MPa when 55% of the waste ceramic particles were added, which was much higher than the artificial stone samples (120.0 MPa) prepared entirely with quartz sand. This may be due to the fact that the shape of waste ceramic particles was more irregular than that of quartz sand. After vacuum vibration molding, the irregular particles were intermingled, which was helpful to improve the bonding strength of the green body. Compared to Group A samples, Group B used relatively large waste ceramic particles, which was conducive to improving the compression deformation resistance. The increased content of fine particles in the aggregate of Group A, the increase in specific surface area, and the decrease in the amount of resin bonded to the particles compared to Group B, also affected the bonding strength of green body to a certain extent. Therefore, Group B artificial stone samples prepared by replacing quartz sand with ceramic waste particles had higher compressive strength. Figure 5 displays that for the samples of both Group A and Group B, when the amount of ceramic waste further increases from 55% to 60%, the compressive strength decreases significantly; this may be related to the decrease in particle packing density caused by the increase in the content of irregular ceramic waste particles. The obtained values of bending and compressive strengths for the two group samples are much higher than those of most artificial stones fabricated from other industrial solid wastes, such as marble slabs, granite, and chamotte residues [22,29,31,40]. For instance, the artificial stone from marble waste only showed the bending strength and compressive strength of 26.6 and 100 MPa, respectively, fabricated by the similar method [31]. Nevertheless, better performance with bending and compressive strengths of 73.5 and 170.9 MPa was also reported for artificial stones based on SiO2 waste crucible and quartz sand aggregates, which was attributed to excellent interfacial bonding and very dense structure by carefully optimizing the content of coupling agent and binder, the compaction process parameters, and using finer waste particle aggregate (>200 mesh) [41].

Figure 5.

(a) Bending strength and (b) compressive strength of artificial stones with different particle content and particle size of ceramic wastes.

These results show that the use of a high content of fine ceramic waste powders (≥120 mesh) to partially replace quartz particles of different particle sizes can significantly improve both the bending and compressive strength of the artificial stone, which will facilitate the non-differential treatment of ceramic waste. The partial replacement of the corresponding quartz particles by ceramic waste particles of different particle sizes has little effect on the bending strength, but can significantly improve the compressive strength of the artificial stone. In conclusion, the use of high content ceramic waste instead of quartz sand raw materials can not only effectively improve the utilization rate of solid waste and reduce the amount of natural quartz raw materials, it can also improve the mechanical strength of artificial stone and reduce production costs to a certain extent.

In addition to the compactness of the aggregate particles mentioned above, the properties of the resin itself as a binding agent and its degree of curing have an important influence on the mechanical properties of the artificial stone. After mixing and pressing, the dissolved resin diffused and filled in the pores between accumulated particles. It then cross-linked and cured into a three-dimensional network structure (Figure 6a) by the action of the curing agent (or initiator) and accelerator, and sufficient bonding strength was obtained between the aggregate particles. In addition, as shown in Figure 6b, the resin binder penetrating into the pores of solid particles can also form a large number of “glue hooks” which can provide bonding force to the particles in addition to existing van der Waals forces and hydrogen bonding, and can also improve the mechanical strength of artificial stone samples to a certain extent. The mechanical strength of the artificial stone samples was also improved to some extent. The results of the performance analysis shown in Figure 5 and Table 4 indicate that the use of relatively inexpensive o-phenyl unsaturated resin as a binding agent was fully capable of producing high-performance ceramic waste artificial stones, which can be attributed to the good mechanical properties of the resin itself and the vacuum vibration and compaction effect to achieve close accumulation of aggregate particles.

Figure 6.

Schematic diagrams of (a) resin crosslinking and curing and (b) the interlocking effect between pores of packed particles and cured resin hooks.

Table 4.

Moh’s hardness and wear resistance of artificial stone with different ceramic waste additions.

Table 4 shows the Moh’s hardness values and wear resistance of the artificial stone samples from Group A and Group B. It is seen that the Moh’s hardness value of Group A samples prepared by using fine powders of ceramic waste reached above 6.0 only when the addition of ceramic waste was 40% and 45%, while the hardness value of Group B samples obtained by using a larger size of ceramic waste particles reached above 6.0 when the addition of ceramic waste was 45% to 55%. Among these, the Moh’s hardness value of Group B samples reached 6.5 when the amount of ceramic waste was ≤50%, which was the same as that of samples prepared entirely by using quartz sand. The hardness of artificial stone is not only related to the hardness of the resin after curing, it is also closely related to the hardness of its aggregate. As the main phase in the ceramic waste was the silicate glass phase, its hardness value was lower than the quartz crystal phase (>7). With the increase in the amount of ceramic waste in the sample and the reduction of quartz grain content, its hardness value slightly decreased, but was still higher than the artificial stone industry standard requirements (Moh’s hardness ≥ 5.0). The table also indicates that the wear resistance of the ceramic waste-based artificial stone has a greater correlation with its hardness, the change in the pattern of wear resistance of the samples is consistent with the trend of their Moh’s hardness, and the wear volume of all samples is considerable below the upper limit (300 mm3) specified in the aforementioned standard, showing good wear resistance. A comparison of the analysis results of samples from Group A and Group B revealed that the use of waste ceramic particle aggregate with larger particle size is helpful for improving the Moh’s hardness and wear resistance of artificial stones.

3.4. Effect of Ceramic Waste Addition on Porosity and Water Absorption of Artificial Stones

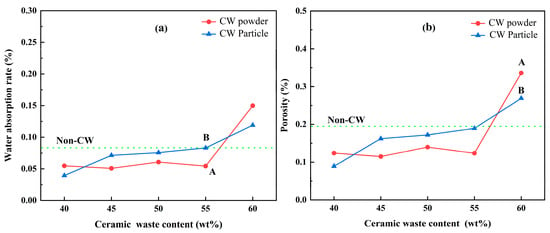

The water absorption and porosity of resin-based artificial stones are important indicators of its stain resistance. Therefore, they are often used to characterize the superiority or inferiority of the stain resistance of artificial stones. Figure 7 shows the water absorption and porosity curves of two groups of samples in relation to the amount of ceramic waste added. The water absorption rate and porosity of Group A and Group B samples with 40–55% ceramic waste additions were lower than those of artificial stone samples prepared entirely with quartz sand aggregate, and the water absorption of ceramic waste-based artificial stone samples increased significantly when the addition amount was increased to 60%. This still meets the aforementioned industry standard requirements (water absorption ≤0.2%). Figure 7a depicts that as the addition of ceramic waste fines increases from 40% to 55%, the water absorption of Group A samples remains very low (only approximately 0.05%) and the corresponding porosity is maintained at approximately 0.12% (Figure 7b), indicating that the ceramic waste particles are tightly bonded to the resin and the artificial stones obtained have high density. The water absorption and porosity of Group B samples prepared with different grades of ceramic waste particles are slightly higher than those of Group A samples prepared with fine ceramic waste powders at 45–55% of ceramic waste addition. Despite this, the obtained water absorption and porosity are still much lower than those of artificial stones made from other mineral wastes [22,31]. As the water absorption of dense ceramic particles and quartz grains sintered at high temperature is almost negligible, the water absorption and porosity of the artificial stone materials mainly depend on the packing density of aggregate particles and their interfacial bonding with resin after molding and curing. Therefore, the shape and gradation of aggregate particles and resin content are decisive factors affecting the water absorption and porosity of artificial stone. Using an appropriate amount (40–55%) of fine ceramic waste material to replace the coarser quartz particles can play a more effective role in filling the gap, thus ensuring that the prepared artificial stones have very low water absorption and porosity. However, when too high content of irregularly shaped waste particles is present (e.g., 60%), the fluidity of the particles is affected during the compaction process, thus reducing the particle stacking density. An increase in the specific surface area of fine particles makes the resin binding agent content relatively insufficient, thus affecting the particle/resin interfacial bonding tightness to a certain extent and causing a significant increase in the water absorption and porosity of the samples.

Figure 7.

(a) Water absorption rate and (b) porosity of artificial stones with different ceramic waste additions.

These results show that the resin-based artificial stones prepared by replacing quartz sand with ceramic waste exhibit better stain resistance. After the aggregate was wrapped and cured by the resin, the artificial stone possesses good impermeability and effectively reduced internal porosity. Therefore, the artificial stone has good stain resistance and strengthened internal structure. Compared with natural stones, the artificial stones prepared in this work do not easily erode and are not polluted by various liquids, dirt, etc.

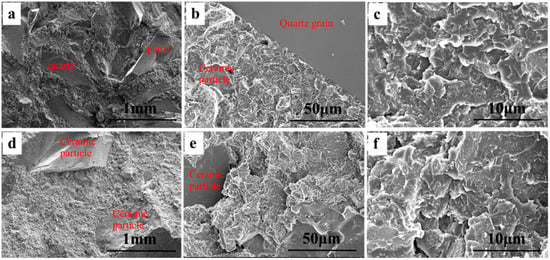

3.5. Microscopic Morphological Analysis of Artificial Stones

Figure 8 shows the cross-sectional SEM photographs of the samples from Group A and Group B with 45% addition of ceramic waste. It is seen that the ceramic waste artificial stones prepared by using o-phenyl unsaturated resin as the curing binding agent have a very dense microstructure in general. In Figure 8a, it is found that the fine particles of ceramic waste fully filled space between larger-sized quartz particles, forming a highly dense microstructure, and no obvious porosity is observed. This is consistent with the results of porosity analysis shown in Figure 7b. Figure 8b shows the tight interfacial bonding between the larger quartz particles and the smaller ceramic waste particle accumulations. The higher magnification SEM photograph shown in Figure 8c further reveals that the fine particles of ceramic waste distributed among the large quartz particles form a homogeneous and dense accumulation structure by themselves. It is this ideal microstructure that gives the highest bending strength to the A2 artificial stone samples prepared from the fine ceramic waste powders. It is observed in Figure 8d that B2 samples prepared from ceramic waste particles with relatively large particle sizes also have a relatively dense microstructure in general. However, by comparing Figure 8b,c,e,f, it is seen that the cross-section of B2 samples is relatively rough, the homogeneity of the microstructures is reduced, and a small number of small holes were generated between large irregular particles. Although high-strength vacuum vibration compression molding was adopted, these small holes were difficult to completely eliminate due to the irregular shape of large waste ceramic particles and the low fluidity of resin, which cause its bending strength to be lower than A2 samples.

Figure 8.

Cross-sectional SEM images of obtained (a–c) A3 and (d–f) B3 artificial stones with 45% ceramic waste at different magnifications.

4. Conclusions

The artificial stone materials with high mechanical strength and excellent stain resistance were successfully prepared in the laboratory by vacuum vibration molding and high temperature curing of o-phenyl unsaturated resin using high doping ratio sintered ceramic waste instead of natural quartz sand. Based on the present study, the following conclusions can be drawn:

- The ceramic waste used is composed of a high content of SiO2 and Al2O3 in chemical composition, as well as 65% silicate glass and other crystalline quartz and mullite in phase composition. These basic characteristics of high-temperature sintered ceramic waste endow the obtained aggregates with good mechanical properties and high density.

- The composite aggregate particles composed of ceramic waste and quartz sand can form a good interfacial bond with resin under the cross-linking effect of a coupling agent, and the artificial stone shows a very dense microstructure.

- The application of 40–60% ceramic waste instead of quartz sand can improve the bending strength and compressive strength of artificial stones to varying degrees. The highest bending strength of 64.4 MPa was achieved when 45% of ceramic waste powders (particle size ≥ 120 mesh) were added; the highest compressive strength of 158.7 MPa was attained when 55% of different graded ceramic waste particles were added; these values are 27% and 32% higher than when only quartz sand was used as aggregate particles.

- The dense artificial stones prepared by introducing ceramic waste exhibited very low water absorption and porosity with excellent stain resistance, particularly when 40–55% of fine ceramic waste powders was introduced. The water absorption and porosity were maintained at about 0.05% and 0.12%, respectively.

- As the hardness of ceramic particles is lower than that of quartz grains, the surface hardness and wear resistance of the prepared ceramic waste artificial stone are lower than that of quartz sand artificial stone, but they can still meet the requirements of the product standards of the artificial stone industry. Moreover, the use of ceramic waste particles with larger particle sizes to replace quartz sand is more conducive to improving the hardness and wear resistance than fine particles.

In conclusion, adding a high content of sintered ceramic waste instead of quartz sand to prepare artificial stone materials can not only improve the mechanical properties and pollution resistance of artificial stone but also realize the massive utilization of ceramic waste and save natural mineral raw materials; this is crucial for reducing solid waste pollution and ensuring environmental protection. The prepared ceramic waste artificial stones have broad application prospects in public building decoration and home decoration.

Author Contributions

Conceptualization, X.Z. and Y.C.; methodology, J.L. and J.F.; software, J.L. and Z.M.; validation, Y.W., S.W. and Y.C.; formal analysis, J.L. and X.Z.; investigation, J.L. and Z.M.; resources, X.Z., Y.C. and J.F.; data curation, S.W.; writing—original draft preparation, J.L.; writing—review and editing, X.Z. and J.F.; supervision, X.Z.; project administration, Y.C.; funding acquisition, X.Z. and Y.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China (2018YFC1903406), and Jiangxi Provincial Graduate Innovation Special Project (YC2021-S529).

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Wang, S.; Wang, C.; Wang, Y.; Zhang, X.; Chen, Y. Production and Reutilization of Ceramic Waste. J. Ceram. 2019, 40, 710–717. [Google Scholar]

- Turner, A. Lead pollution of coastal sediments by ceramic waste. Mar. Pollut. Bull. 2019, 138, 171–176. [Google Scholar] [CrossRef]

- Rambaldi, E.; Esposito, L.; Tucci, A.; Timellini, G. Recycling of polishing porcelain stoneware residues in ceramic tiles. J. Eur. Ceram. Soc. 2007, 27, 3509–3515. [Google Scholar] [CrossRef]

- Li, L.G.; Zhuo, Z.Y.; Zhu, J.; Kwan, A. Adding ceramic polishing waste as paste substitute to improve sulphate and shrinkage resistances of mortar. Powder Technol. 2019, 362, 149–156. [Google Scholar] [CrossRef]

- Gautam, L.; Jain, J.K.; Kalla, P.; Choudhary, S. A review on the utilization of ceramic waste in sustainable construction products. Mater. Today Proc. 2020, 43, 1884–1891. [Google Scholar] [CrossRef]

- Agrawal, A.; Saravanan, T.J.; Bisht, K.; Kabeer, K. Synthesis of Cement Composites Utilizing Ceramic Waste as a Partial Replacement for Portland Cement: Literature Review. J. Hazard. Toxic Radioact. Waste 2021, 25, 1–18. [Google Scholar] [CrossRef]

- Saxena, R.; Gupta, T. Assessment of mechanical, durability and microstructural properties of geopolymer concrete containing ceramic tile waste. J. Mater. Cycles Waste Manag. 2022, 24, 725–742. [Google Scholar] [CrossRef]

- El-Dieb, A.S.; Taha, M.R.; Kanaan, D.; Aly, S.T. Ceramic Waste Powder from Landfill to Sustainable Concretes. Constr. Mater. 2017, 171, 109–116. [Google Scholar] [CrossRef]

- Passos, L.; Junior, A.; Fernandes, B.; Costa, C.N. Bond between steel and concrete made with ceramic waste aggregate. REM-Int. Eng. J. 2019, 72, 31–37. [Google Scholar] [CrossRef]

- López, V.; Llamas, B.; Juan, A.; Morán, J.; Guerra, I. Eco-efficient Concretes: Impact of the Use of White Ceramic Powder on the Mechanical Properties of Concrete. Biosyst. Eng. 2007, 96, 559–564. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Z.; Liu, L.; Wang, X.; Ji, R. Synthesis of a foam ceramic based on ceramic tile polishing waste using SiC as foaming agent. Ceram. Int. 2018, 44, 10078–10086. [Google Scholar] [CrossRef]

- Liang, B.; Zhang, M.; Li, H.; Zhao, M.; Deng, L. Preparation of ceramic foams from ceramic tile polishing waste and fly ash without added foaming agent. Ceram. Int. 2021 47, 23338–23349. [CrossRef]

- Hoseny, N.A.; Amin, S.K.; Fouad, M.; Abadir, M.F. Reuse of ceramic sludge in the production of vitrified clay pipes. Ceram. Int. 2018, 44, 12420–12425. [Google Scholar] [CrossRef]

- Yi, H.; Luo, J.; Xia, B. Application of cleaner production as an important sustainable strategy in the ceramic tile plant-a case study in Guangzhou, China. J. Clean. Prod. 2013, 43, 113–121. [Google Scholar]

- Tarhan, B.; Tarhan, M.; Aydin, T. Reusing sanitaryware waste products in glazed porcelain tile production. Ceram. Int. 2016, 43, 3107–3112. [Google Scholar] [CrossRef]

- El-Fadaly, E.; Bakr, I.M.; Breka, M. Recycling of ceramic industry wastes in floor tiles recipes. J. Am. Sci. 2010, 6, 241–247. [Google Scholar]

- Wang, C.; Wang, S.; Li, X.; Liu, Y.; Zhang, X.; Chang, Q.; Wang, Y. Phase composition, microstructure and properties of ceramic tile prepared using ceramic polishing waste as raw material. Int. J. Appl. Ceram. Technol. 2021 18, 1052–1062. [CrossRef]

- Dabas, N.; Yadav, K.K.; Ganguli, A.K.; Jha, M. New process for conversion of hazardous industrial effluent of ceramic industry into nanostructured sodium carbonate and their application in textile industry. J. Environ. Manag. 2019, 240, 352–358. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, T.; Shen, X.; Zhai, Y.; Hong, J. Environmental footprint assessment of China’s ceramic tile production from energy-carbon-water nexus insight. J. Clean. Prod. 2022, 337, 130606. [Google Scholar] [CrossRef]

- Shieh, J.J.; Hsu, T.C.J. Curing of unsaturated polyester resins: Effect of surface treatment of particulates. Polym. Eng. Sci. 1992, 32, 335–343. [Google Scholar] [CrossRef]

- Bera, P.; Guptha, N.; Dasan, K.P.; Natarajan, R. Recent developments in synthetic marble processing. Rev. Adv. Mater. Sci. 2012, 32, 94–105. [Google Scholar]

- Gomes, M.; Carvalho, E.A.; Demartini, T.J.; Carvalho, E.; Colorado, H.A.; Vieira, C. Mechanical and physical investigation of an artificial stone produced with granite residue and epoxy resin. J. Compos. Mater. 2021, 55, 1247–1254. [Google Scholar] [CrossRef]

- Rusmirović, J.D.; Radoman, T.; Džunuzović, E.S.; Džunuzović, J.V.; Markovski, J.; Spasojević, P.; Marinković, A.D. Effect of the modified silica Nanofiller on the Mechanical Properties of Unsaturated Polyester Resins Based on Recycled Polyethylene Terephthalate. Polym. Compos. 2017, 38, 538–554. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.İ.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of replacing cement with waste glass on mechanical properties of concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef] [PubMed]

- Karalar, M.; Bilir, T.; Çavuşlu, M.; Özkiliç, Y.O.; Sabri, M.M.S. Use of recycled coal bottom ash in reinforced concrete beams as replacement for aggregate. Front. Mater. 2022, 9, 1064604. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete containing waste glass as an environmentally friendly aggregate: A review on fresh and mechanical characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical Behavior of Crushed Waste Glass as Replacement of Aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Aksoylu, C.; Sabri, M.M.S.; Alexey, N.; Sergey, A.; Evgenii, M. Flexural behavior of reinforced concrete beams using waste marble powder towards application of sustainable concrete. Front. Mater. 2022, 701, 1068791. [Google Scholar] [CrossRef]

- Ribeiro, C.; Rodriguez, R. Influence of Compaction Pressure and Particle Content on Thermal and Mechanical Behavior of Artificial Marbles with Marble Waste and Unsaturated Polyester. J. Med. Ethics 2015, 28, 277. [Google Scholar] [CrossRef]

- Morote-Martínez, V.; Torregrosa-Coque, R.; Martín-Martínez, J. Addition of unmodified nanoclay to improve the performance of unsaturated polyester resin coating on natural stone. Int. J. Adhes. Adhes. 2011, 31, 154–163. [Google Scholar] [CrossRef]

- Ribeiro, C.; Rodriguez, R.; Carvalho, E. Microstructure and mechanical properties of artificial marble. Constr. Build. Mater. 2017, 149, 149–155. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Deifalla, A.F.; Aksoylu, C.; Arslan, M.H.; Ahmad, M.; Sabri, M.M.S. Improvement in bending performance of reinforced concrete beams produced with waste lathe scraps. Sustainability 2022, 14, 12660. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Özdöner, N.; Tayeh, B.A. Performance assessment of fiber-reinforced concrete produced with waste lathe fibers. Sustainability 2022, 14, 11817. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Çelik, A.İ.; Deifalla, A.F.; Ahmad, M.; Sabri Sabri, M.M. Performance evaluation of fiber-reinforced concrete produced with steel fibers extracted from waste tire. Front. Mater. 2022, 9, 1057128. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Meskhi, B.; Shilov, A.A.; Varavka, V.; Evtushenko, A.; Özkılıç, Y.O.; Aksoylu, C.; Karalar, M. Composition Component Influence on Concrete Properties with the Additive of Rubber Tree Seed Shells. Appl. Sci. 2022, 12, 11744. [Google Scholar] [CrossRef]

- Shcherban′, E.M.; Stel′makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Chernil′nik, A.; Özkılıç, Y.O.; Aksoylu, C. Normal-Weight Concrete with Improved Stress–Strain Characteristics Reinforced with Dispersed Coconut Fibers. Appl. Sci. 2022, 12, 11734. [Google Scholar] [CrossRef]

- Senthamarai, R.; Manoharan, P.D. Concrete with ceramic waste aggregate. Cem. Concr. Compos. 2005, 27, 910–913. [Google Scholar] [CrossRef]

- Suzuki, M.; Meddah, M.S.; Sato, R. Use of porous ceramic waste aggregates for internal curing of high-performance concrete. Cem. Concr. Res. 2009, 39, 373–381. [Google Scholar] [CrossRef]

- Chen, H.; Xu, J.; Li, Y.; Zhang, T.; Huang, X. Trash to treasure: From construction waste to tellurium adsorbent materials. J. Clean. Prod. 2021, 312, 127752. [Google Scholar] [CrossRef]

- Gomes, M.L.P.; Carvalho, E.A.; Sobrinho, L.N.; Monteiro, S.N.; Rodriguez, R.J.; Vieira, C.M.F. Production and characterization of a novel artificial stone using brick residue and quarry dust in epoxy matrix. J. Mater. Res. Technol. 2018, 7, 492–498. [Google Scholar] [CrossRef]

- Peng, L.; Qin, S. Mechanical behaviour and microstructure of an artificial stone slab prepared using a SiO2 waste crucible and quartz sand. Constr. Build. Mater. 2018, 171, 273–280. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).