Abstract

In the construction of asphalt pavement, poor quality is often the main reason for damage to the pavement, which necessitates the use of monitoring systems during the construction stage. Therefore, this study focuses on building an asphalt concrete pavement construction monitoring system to monitor the construction phase. Through a literature review and semi-structured interviews with industry experts, this paper provides an in-depth understanding of the goals and obstacles of asphalt pavement monitoring and discusses directions for improvement. Subsequently, based on the analysis of the interview results, a system framework for asphalt concrete pavement construction monitoring was constructed, and the system was successfully developed and applied to a highway construction project. The results show that the monitoring system significantly improves the construction quality of asphalt concrete pavement, improves the intelligent level of pavement construction management, and promotes the digital development of highway construction.

1. Introduction

With the rapid development of China’s society and economy, there are many road construction projects across the country [1]. In this context, asphalt concrete pavement, which is an important part of high-grade highways, is widely used in road construction [2]. Unfortunately, asphalt concrete pavements in highways can become damaged to varying degrees during the operational life of the infrastructure. There are two main reasons for the damage of asphalt pavement. Firstly, continuous development of the economy and corresponding acceleration of urbanization has increased sharply the number of overloaded vehicles and private cars on the road, thereby exacerbating geological and climatic conditions. Secondly, the design of the pavement is not effective and construction quality is poor. In addition and due to the complex construction procedures of asphalt pavement, there is a further need for more careful management of the mixing, transportation, spreading, and rolling stages of asphalt construction. However, in the construction of asphalt pavement, there is a lack of effective quality monitoring, which causes damage to the asphalt pavement. Therefore, when asphalt pavement is laid in highways, it is important to track and control the process and improve the quality of pavement construction [3]. Consequently, related literature was studied on improving the construction quality of asphalt pavement [4]. On this matter, Chen [5] identified measures and methods to improve the quality and uniformity of asphalt pavement construction quality from the perspectives of materials, machinery, and construction technology. Yu Jiang Miao [6] combined traditional construction technology with new construction quality control technology to improve anti-skid and noise-reducing asphalt pavement. Li tan [7] introduced mathematical statistics to establish more scientific quality control and management methods for asphalt pavement construction quality control. It can be observed that the above studies adopt the perspectives of materials, construction techniques, and related technologies to improve the construction quality of asphalt pavement and provide corresponding contributions to this area of engineering research. However, these methods do not result in overall improvements in the construction quality of asphalt pavement, since the process of mixing and paving of asphalt crucially needs to be included in the improvement process. Therefore, research needs to be carried out on the process of laying asphalt pavement. Furthermore, with the rapid development of digital technologies and computer networks, the use of remote monitoring technology to monitor the construction process has become an effective way to address the poor quality of pavement construction [8,9].

Many scholars have researched the aforementioned issues. Indeed, Cong, Lin, and others studied the use of a three-dimensional network visualization integrated model of monitoring information to monitor the quality of asphalt paving in real time, thereby improving the quality and safety of asphalt pavement [10]. Tan Yiqiu and other scholars studied the use of fiber-grating sensing technology to monitor the compaction of asphalt concrete pavement, which can effectively improve the compaction quality of the pavement [11]. Scholars such as Milad and Adwan studied the use of low-altitude UAV lidar remote sensing data and the random forest algorithm to build a remote sensing identification model for asphalt concrete pavement problems, which can meet the needs of large-scale road pavement fault monitoring [12]. However, despite the above research solutions for monitoring the construction quality of asphalt pavement, the following problems still exist: (1) Due to the limited monitoring methods available on construction sites, feedback from monitoring at the construction stage is not available in a timely manner, thereby resulting in an inability to effectively control the construction quality of asphalt concrete pavement [13]; (2) Although China previously deployed a pavement construction quality control system and automatic monitoring equipment, the system relies too much on manual data collection with low efficiency and inaccurate data, thus affecting the quality of asphalt concrete pavement [14]; (3) Construction of asphalt concrete pavement is complicated with many stages and there are various issues to be tackled in the construction processes. Further, if digital monitoring is only performed for one of the stages, such as paving or compaction, this is not enough to support the overall asphalt concrete pavement monitoring system [11].

Therefore, given the above problems that still need to be addressed, this study proposes to use a new generation of information technology (IT) to combine with the process of asphalt concrete pavement construction to establish a whole-life system (i.e., production, mixing, transportation, paving, and rolling of asphalt mixtures) for monitoring of asphalt concrete pavement construction. The study is focused on a number of key underpinning areas, namely implementing the concept of information transmission in the whole life cycle; combining with the management system of asphalt mixture production, mixing, transportation, paving, and rolling; and collecting data for each link of the production of pavement base and surface layer through the internet of things software and hardware system to improve the quality of asphalt. The data for the production and mixing, transportation, paving, and rolling process of production and mixture are dynamically monitored. This ensures the standardization of quality data in the whole life process of mixing, transportation, paving, and rolling, which fully conforms to the quality of construction management. The management concept of process visualization and responsibility traceability improves the intelligent level of pavement construction management and improves the quality and safety of asphalt concrete pavement. The innovations of this empirical study can be summarized according to the following themes: (1) Improvement of the quality of pavement construction through digital monitoring of asphalt mixture production, mixing, transportation, paving, and rolling; (2) Integration of BeiDou technology and 5G technology with pavement construction, where the combination of monitoring technologies improves positioning accuracy, data collection breadth, and transmission efficiency; (3) Achievement of real-time data traceability by linking the data of each system in real-time.

The purpose of this study is to enable efficient management of the whole process of asphalt concrete pavement construction. To achieve this goal, the research uses a combination of BeiDou satellite navigation, internet of things technology, and smart sensors to develop a full life-cycle digital monitoring system for asphalt concrete pavement, where data collection and transmission are enabled via 5G wireless networks. This study provides an innovative new method for the construction monitoring of asphalt concrete pavement.

The article is structured as follows: Section 2 describes the literature on asphalt pavement monitoring systems and related technologies. Section 3 describes the research methods and findings. The case studies in Section 4 validate the monitoring system framework proposed in this study. Finally, Section 5 summarizes the research results of the study and the direction of future research.

2. Background

2.1. Asphalt Concrete Pavement Monitoring System

The application of monitoring technology in asphalt concrete pavement construction can effectively improve the quality of asphalt pavement [15]. Indeed, scholars have studied the application from different perspectives. Ma, Z, and other scholars developed an asphalt mixture dynamic quality monitoring system to monitor the asphalt mixture production process [9]. Hu, Dongliang, and other scholars researched the compaction degree of asphalt pavement and proposed a real-time monitoring system to monitor and control the compaction degree of the pavement [16], thereby improving the quality of pavement compaction. Ravichandran, M et al. proposed a real-time monitoring system to monitor and control the compaction degree of the pavement and verified the theoretical feasibility of the system [17]. However, although the above studies designed a monitoring system to improve road quality, such monitoring systems still have certain problems, such as low information feedback efficiency and insufficient monitoring range. Emad Kassem and Wenting Liu researched this aspect and developed a CMS (content management system). The system uses the latest global positioning system (GPS) and various sensors to ensure that the monitored asphalt range is large enough. The new system can be quickly installed on the road roller and the system can display real-time displays. The compaction efficiency, compaction times, and compaction temperature provide fast and accurate information for the staff, and the collected data are stored in the database for post-processing analysis and evaluation [18]. Compared with the previous compaction monitoring system, this approach represents a significant improvement.

In other work, Chang et al. combined intelligent compaction technology, PMTP (paver mounted thermal profiling), and a global satellite navigation system to develop an asphalt pavement monitoring system to monitor the paving and compaction stages in real time, and make appropriate adjustments according to the actual situation [19]. Whereas Sicong Zhu and Xiangdi Li [14] developed an asphalt pavement monitoring system that is mainly responsible for monitoring the production, compaction, and paving operation stages of hot mix asphalt. The system can automatically collect and transmit data, and provide feedback to the construction site to monitor and control the construction quality of asphalt pavement in real time. This approach to monitoring systems has further improved the quality of asphalt pavement monitoring. Moreover, the number of monitoring stages has been increased from two or three, and the monitoring range is wider, which provides a reliable guarantee for the construction of asphalt pavement. However, the construction of asphalt pavement is complex, and all the stages of asphalt mixture from production, mixing, transportation, and paving to rolling are equally important.

In the production stage, problems with the proportion of mixtures directly affect the subsequent stages, and eventually impact the quality of asphalt pavement [20]. In the stages of mixture mixing and transportation, if certain factors such as asphalt weight, transportation route, and mixture temperature present problems or reach the threshold, such incidents will directly cause the construction quality to fail to meet the required standard and affect the overall pavement construction process [21]. Further, it has previously been identified that the application of monitoring technology in asphalt concrete pavement construction can effectively improve the quality of asphalt pavement [9].

2.2. Navigation and Positioning System and Network Transmission Technology

As early as 1996, scholars proposed that the GPS navigation system could be used in vehicle navigation. With its navigation and positioning functions, the system can help vehicles avoid traffic accidents and traffic jams, reduce economic losses, and ensure life safety [22]. With the deepening of research, the navigation and positioning system has also been applied to road monitoring. Wasle and Elmar’s research closely integrated Galileo’s navigation and positioning system with a machine control and monitoring system. The study designed a GNSS (global navigation satellite system) receiver and RTK (real-time kinematic positioning) solution for high-precision positioning, which is used to continuously monitor and control key parameters in the process of road construction. [23]. The Astarita V team developed an automatic sensing system to detect anomalies such as potholes and speed bumps. A GPS receiver and a three-axis accelerometer are used to collect the acceleration data generated by moving vehicles under abnormal road conditions, thereby identifying high-energy events [24].

To promote the construction of smart cities and change the manual monitoring of road conditions to intelligent monitoring, Wang Kan et al. proposed to build a real-time road monitoring system. This was achieved by installing gyroscopes and GPS sensors on a vehicle to collect road condition data, retrieve the data in the sensors, and accurately find the logical model of road anomalies [25]. In 2020, China’s BeiDou navigation and positioning system was completed. The BeiDou navigation system has been applied to road monitoring and construction to obtain accurate location information, such as driving route and time, and the data can be transmitted to other systems. In further work, Luo, Jian et al. developed a highway video surveillance system to monitor the traffic flow of special channels and transmit information through 4G communication [26]. However, with the development of 5G communication technology in China and construction of 5G base stations, 5G communication technology has been applied to the operation of monitoring systems and data transmission [27], which allows a higher transmission speed compared to 4G communication [28]. Therefore, this study proposes to apply the BeiDou navigation system and 5G communication technology to the construction of the asphalt pavement monitoring system framework.

3. Method and Materials

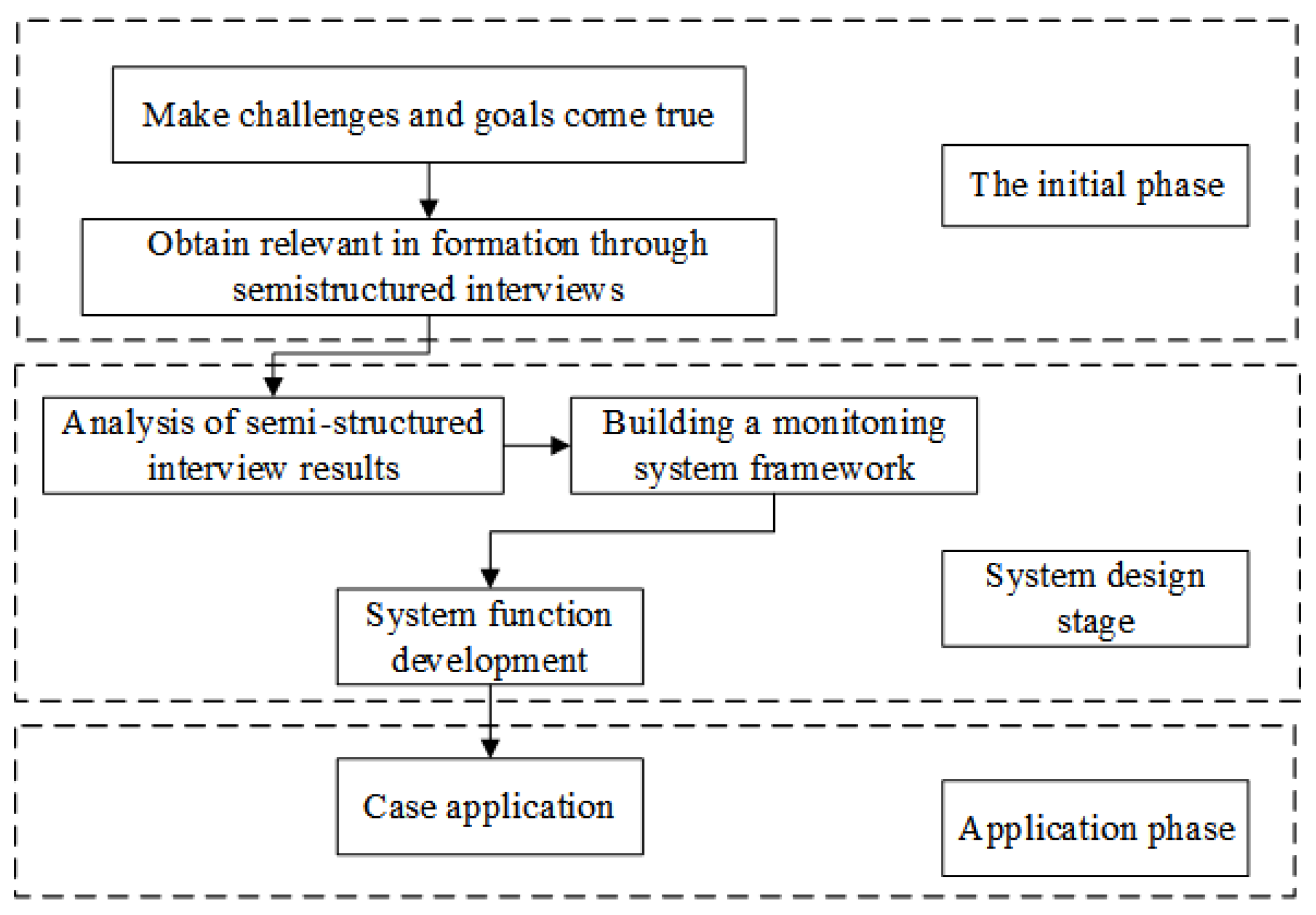

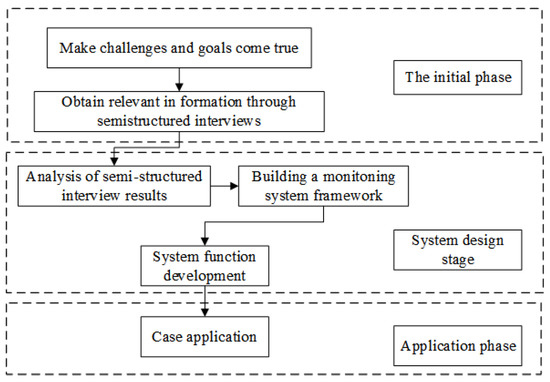

This section covers the research conducted, results, and conclusions, which are presented in the following subsections. The first aspect that will be presented in this section includes the methodology employed throughout the research process. After that, the development process of the monitoring system will be introduced. Finally, a case study will be presented where monitoring tests were performed using the monitoring system to verify its correct operation under real conditions. The flow chart in Figure 1 shows the methods and steps of this research, which consisted of four stages. In the initial stage, it was necessary to clarify what were the main goals and challenges of asphalt concrete pavement construction monitoring. This is a critical step that determined the direction of this study and the design of the system. Prior to this, it was necessary to review the current status of existing monitoring systems and key technologies adopted to promote the high quality of the study in this paper. The second phase was the system design and test phase. According to the results of the literature survey and semi-structured interviews, a digital monitoring framework suitable for asphalt concrete pavement construction was designed. The third stage was the analysis stage. There was a need to collect and analyze the information detected during system tests, feed back data on system defects, and make improvement according to these system defects. The final stage was application. The improved system was applied to a highway construction project, and the practicability of the system thereby verified.

Figure 1.

Flowchart of the methodology employed during the study.

3.1. Initial Stage

To successfully build a digital monitoring system for asphalt concrete pavement construction, it was necessary to determine the research objectives and the main challenges of current monitoring [9]. Therefore, this study used the semi-structured interview method to achieve this purpose.

Semi-structured interviews are suitable for qualitative research, with interviewer-to-respondent conversations, supplemented by follow-up evaluations and surveys, which are conducted within the framework of a pre-defined interview.

- (1)

- Research purpose

Through semi-structured interviews with relevant professionals, we can gain an in-depth understanding of the current goals and challenges of digital monitoring of asphalt concrete pavements, to promote follow-up high-quality research.

- (2)

- Planning the interview

A total of 25 interviews were conducted in this study, and employees or managers engaged in asphalt pavement construction, pavement quality monitoring, and monitoring system development were selected as interviewees with consideration of their education and working years. The specific selection criteria were as follows. A stratified sampling method was adopted to determine the source of the respondents, and ensure that the respondents came from different work departments. Table 1 contains the data of the respondents.

Table 1.

Respondent information.

- (1)

- Working in the same unit or the same job for more than 5 years;

- (2)

- Working in different types of units;

- (3)

- Different ages or gender;

- (4)

- From different professional backgrounds or fields of work;

- (5)

- Ranks of different positions.

- (3)

- Conduct interviews

After the researchers collected the descriptive data of the interviewees, the interview outline was prepared in advance, and the interview was conducted twice; 12 interviews were conducted for the first time, and 13 interviews were conducted for the second time. The entire interview process was recorded using mobile phones, and the transcripts were analyzed using NVivo 12pro software. Before conducting the formal interview, the research team conducted a pre-interview and revised and improved the interview outline through the pre-interview session. The interviews were conducted informally using open-ended questions. The interview questions could be changed according to the specific circumstances of the interviewees’ answers to the questions. See Table 2 for the interview questions.

Table 2.

Interview outline.

3.2. Interview Results and Discussion

This subsection presents the results of qualitative data analysis. The researchers used NVivo pro12 software to analyze the interview records to improve the efficiency and accuracy of the analysis. The interview process allowed a detailed understanding of the goals and obstacles of asphalt concrete pavement monitoring to be ascertained. It was also possible to discuss and analyze the benefits and improvement options enabled by implementation of monitoring systems in asphalt pavement.

- (1)

- Objective of the system

The interviewee (A1) said that the current asphalt pavement generally does not reach the designed service life, and major damages such as ruts, cracks, and oil flooding will occur within 3–4 years of use, which seriously affects the comfort and safety of daily use. Therefore, maintenance needs to be carried out, resulting in a waste of funds. Therefore, it is necessary to monitor the construction of asphalt pavement to improve the quality of the pavement and reduce losses. Respondents (A19) said that the early damage to asphalt pavement was also related to many external factors, such as overloaded vehicles, bad weather, and complex geology. However, in most cases, the road surface was damaged due to technical reasons. For example, in the production process, the proportion of asphalt mixture was unbalanced, the stirring speed was not up to standard, and the mechanical operation was not in place. There were problems with the quality of the road surfaces. Therefore, the primary goal of monitoring must be to improve the construction quality of asphalt pavement and build high-quality asphalt concrete pavement.

- (2)

- Obstacles for system implementation

Barriers are challenges or limitations that hinder asphalt pavement construction monitoring. For example, after the monitoring data are collected by the sensor, there is a delay in the data transmission and the feedback is not timely, which leads to the failure of the monitoring process [29,30]. During the interviews, technical issues were identified as the biggest hurdles, including “scope issues”, “data transfer”, and “data processing”. Respondents (A2, A5, A7, A11, A12, A13, and A14) indicated that the current asphalt pavement monitoring process needed to expand the scope of the monitoring system. However, if multiple systems were used for monitoring, the data would not be easily correlated. Respondents (A15, A23, A24, A25) believed that the monitoring data transmission was delayed with the signal often fluctuating due to weather and other reasons, and the data transmission was subsequently slow.

Furthermore, respondents (A1, A3, A4, A6, A8, A9, A10, A17, A18, A20) indicated that the processing of monitoring data remained challenging. For example, when asphalt concrete was being paved, there was a problem with the temperature of the mixture, which could not be traced back to whether the insulation measures were in place during transportation or the temperature of the mixture when it left the site. Consequently, the process has certain problems and consumes too much time and money. Another obstacle is the lack of technical skills and inexperience of employees. In this regard, respondents (A2, A5, A16, A21, A22) indicated that the current construction personnel lacked relevant professional knowledge and necessary operating skills, which made them unsuitable for the needs of modern construction projects.

- (3)

- Benefits for system implementation

The benefits of using monitoring systems were extensively discussed in the interviews with respondents. For example, the application of highway side slope automatic monitoring systems, highway electromechanical equipment intelligent monitoring systems, and asphalt pavement damage monitoring systems have improved highway construction and management [31,32,33]. During the interviews, respondents agreed that the main benefits of adopting a monitoring system were greater efficiency and accuracy as well as improved safety when compared to traditional manual monitoring.

Another advantage, according to five respondents, was the reduction of errors caused by human factors, such as reading data incorrectly. Six respondents believed that the monitoring system could effectively reduce the cost of the whole project, and the information management system could improve the management efficiency and convert the previously handwritten forms into electronic records to reduce the cost. Therefore, the application of monitoring systems could greatly improve the construction quality of asphalt pavement and make a great contribution to modernization.

- (4)

- Improvements for system implementation

Based on the respondents’ responses, the interviewers discussed how to improve the asphalt pavement construction monitoring system. Firstly, 15 respondents said that when implementing the monitoring system, it was necessary to ensure that the processing of monitoring data met the requirements of asphalt pavement construction. Therefore, the monitored data could be integrated to develop a monitoring system that was more suitable for on-site construction and management. Secondly, 20 interviewees agreed that there was a need to expand the scope of monitoring and use only one system for monitoring. It was necessary to conduct real-time monitoring of the mixture from production, mixing, transportation, paving to rolling, and monitor key parameters at each stage. Feedback to staff when the threshold was reached was also needed as part of the process. Finally, construction workers needed the appropriate training and professional knowledge and skills to meet the needs of modernization projects. The specific improvement measures are shown in the next two subsections.

3.2.1. Data Management System

Based on the results of the semi-structured interviews, this study designed a data management system to store and process key data in the production, mixing, transportation, paving, and rolling process of the mixture. The system links the production data of the mixture, the driving route of the vehicle, the paving and rolling, and other data to realize the integration of the process. The data management system must ensure efficient and rapid processing of monitoring data. The system must also enable feedback of the results to workers to ensure the standardization of quality data throughout production, mixing, transportation, paving, and rolling, and ensure it fully conforms to the quality, analyzability, and process of construction management. The management concept of visualization and traceable responsibility improves the intelligent level of road construction management and maintenance management.

3.2.2. Asphalt Mixture Construction Monitoring

According to the analysis of the results of the semi-structured interviews, the framework of the asphalt concrete pavement construction monitoring system proposed in this study should include the following aspects: an asphalt material production monitoring system; an asphalt mixture mixing monitoring system; an asphalt mixture transportation monitoring system; an asphalt mixture monitoring system; a paving monitoring system; and an asphalt mixture rolling monitoring system. Real-time monitoring and control of the mixture through five subsystems to improve the construction quality of asphalt pavement is needed. The process should be according to the concept of information transmission across the whole life cycle. There is also a requirement for combining with the monitoring system of mixture production, mixing, vehicle transportation, paving, and rolling; and collecting key data of the production process of the pavement base and surface layer through the internet of things software and hardware system. The key data of the production, mixing, transportation, paving, rolling process are dynamically monitored.

3.3. Construction of Digital Monitoring System for Asphalt Concrete Pavement Construction

3.3.1. Overall System Design

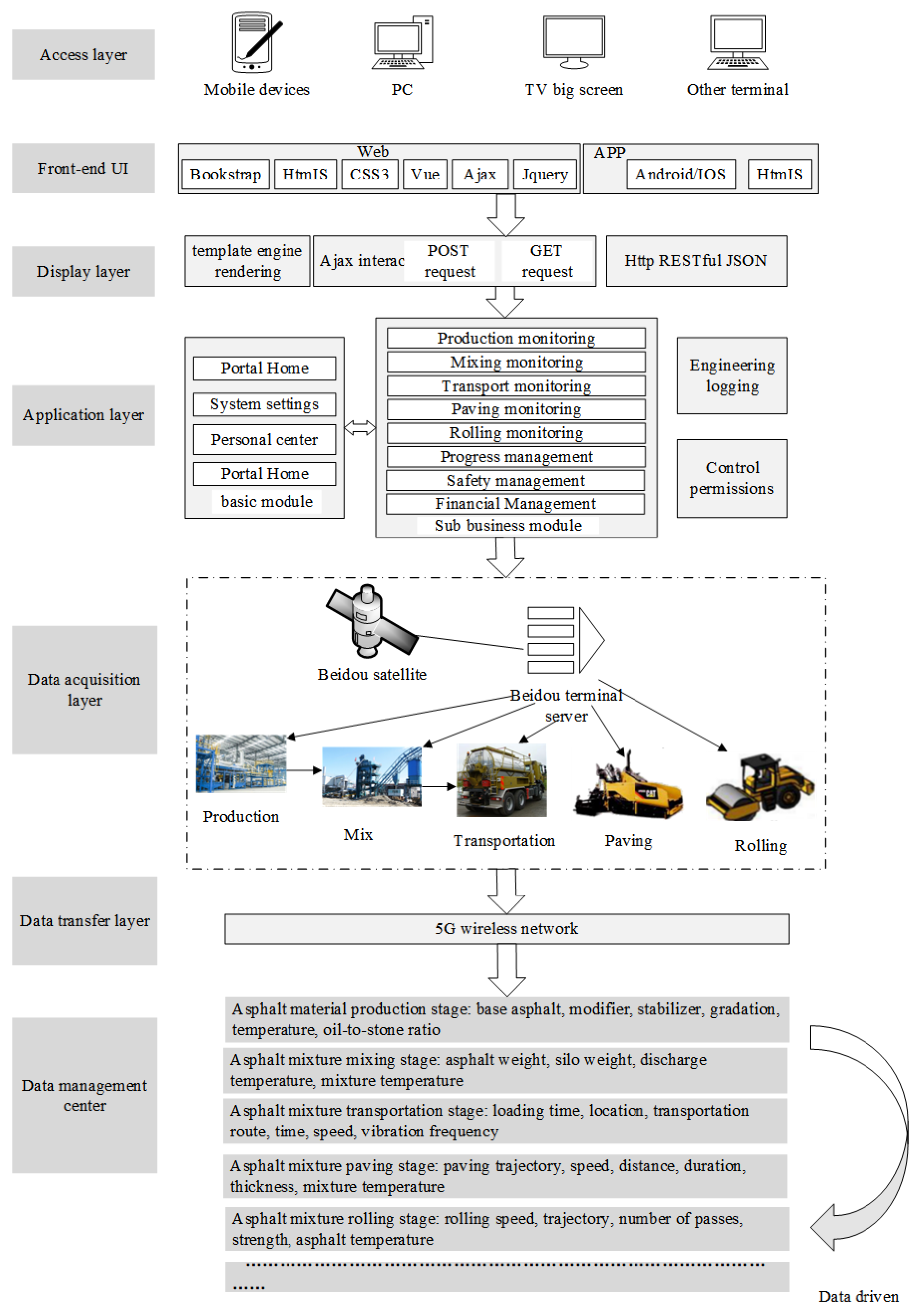

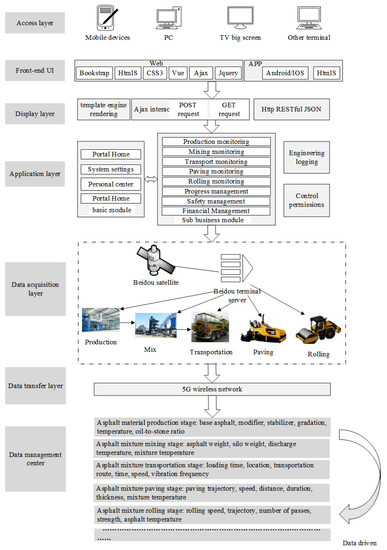

The construction of the digital monitoring system for the whole process of asphalt concrete pavement construction adopts the “1+5” mode. Specifically, it is composed of a data management system and an asphalt material production monitoring system; an asphalt mixture mixing monitoring system; an asphalt mixture transportation monitoring system; an asphalt mixture paving monitoring system; and an asphalt mixture rolling monitoring system; a total of 4 subsystems. The system architecture is shown in Figure 2.

Figure 2.

Architecture of the monitoring system for the whole process of asphalt concrete construction.

(1) Data acquisition layer. This includes monitoring and extraction of key parameters during asphalt mixture production, mixing, transportation, paving, and rolling through IoT, sensors, and the BeiDou navigation system. Compared with the GPS, the BeiDou system can realize two-way communication and has significant advantages [34].

(2) Data transmission layer. The whole lifecycle process monitoring system of asphalt concrete pavement construction adopts a 5G wireless communication network for data transmission. As a new generation of communication technology, the 5G network has the characteristics of low latency, wide connection, and high speed [35]. Compared with the 4G network, the transmission rate of the 5G network is increased by 10–100 times, and the delay can reach the millisecond level, which can meet the transmission efficiency of massive data during the construction process. The 4G network faces a major problem in the current construction stage. Mobile broadband and real-time indicators cannot meet the needs of application scenarios such as high-definition video surveillance and remote control [36,37]. The comparison between 5G and 4G is shown in the following Table 3 [38].

Table 3.

Comparison of key technical indicators between 5G and 4G.

(3) Application layer. The application of the monitoring system includes basic modules and subservice modules. Guided by the actual needs of asphalt concrete pavement construction, it provides construction parties and partners with application functions and technical services for project management and construction monitoring. Users can enter through the WEB terminal and APP terminal to obtain the data of the basic modules and sub-business modules. The sub-business modules mainly include production monitoring, mixing monitoring, transportation monitoring, paving monitoring, rolling monitoring, project progress management, project safety management, and project financial management.

3.3.2. Composition of the Digital Monitoring System

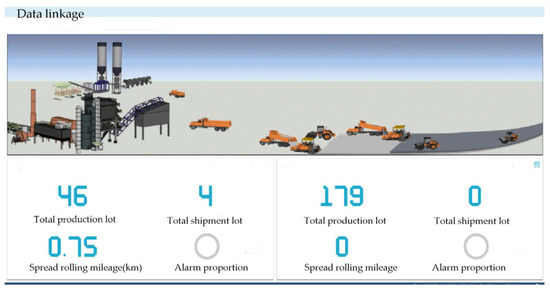

Data Management System

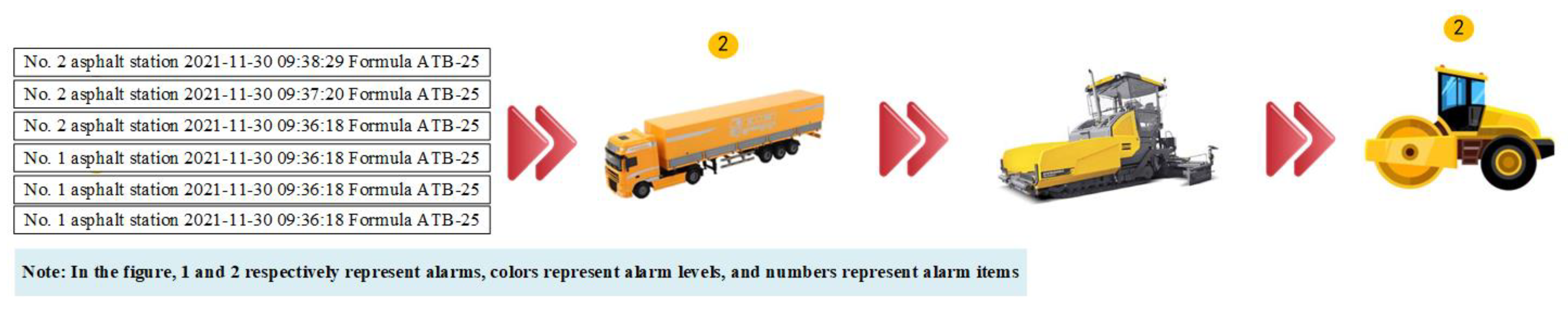

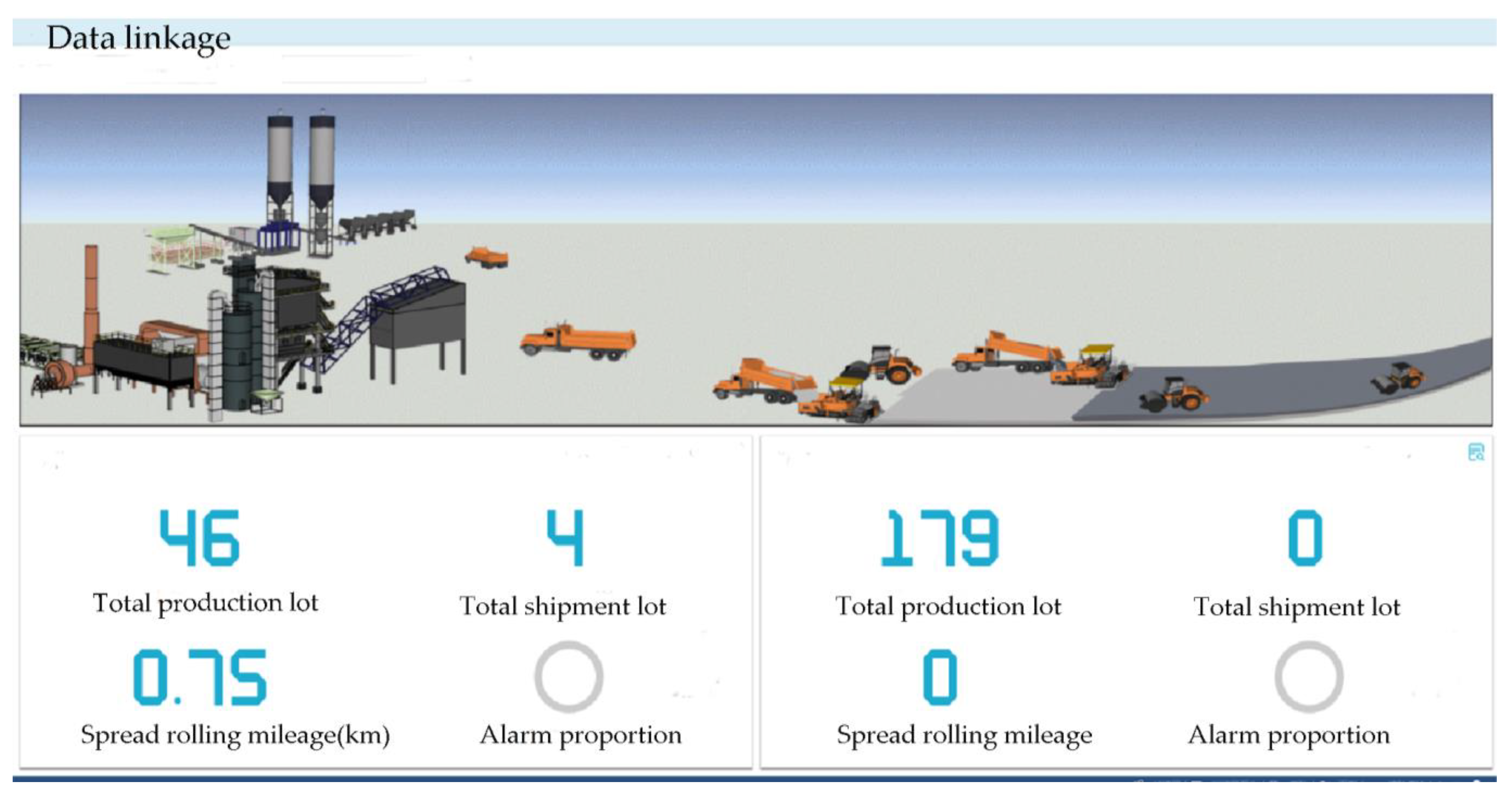

After the data management system acquires key data monitored during the production and construction of each subsystem (see Table 4 for monitoring indicators), the data are correlated with the indicators related to the production quality of the project, and the data of each system are linked in real time. For example, the data information linkage of the batches of mixed materials transported by each train is realized, and the position information of the pile number corresponding to the paving of the mixed materials transported by each train is also realized. The system links the data information of the mixed material transported by each transport vehicle, the loading and unloading time of the vehicle, the driving data information, the paving and compaction data information, and realizes the integration of various businesses. The system can also comprehensively and centrally monitor key data and has the characteristic function of a real-time alarm. It can view data and alarms in various ways, and realize the implementation quality control of the entire project. The schematic diagram of data linkage is shown in Figure 3.

Table 4.

Monitoring indicators.

Figure 3.

Data linkage display.

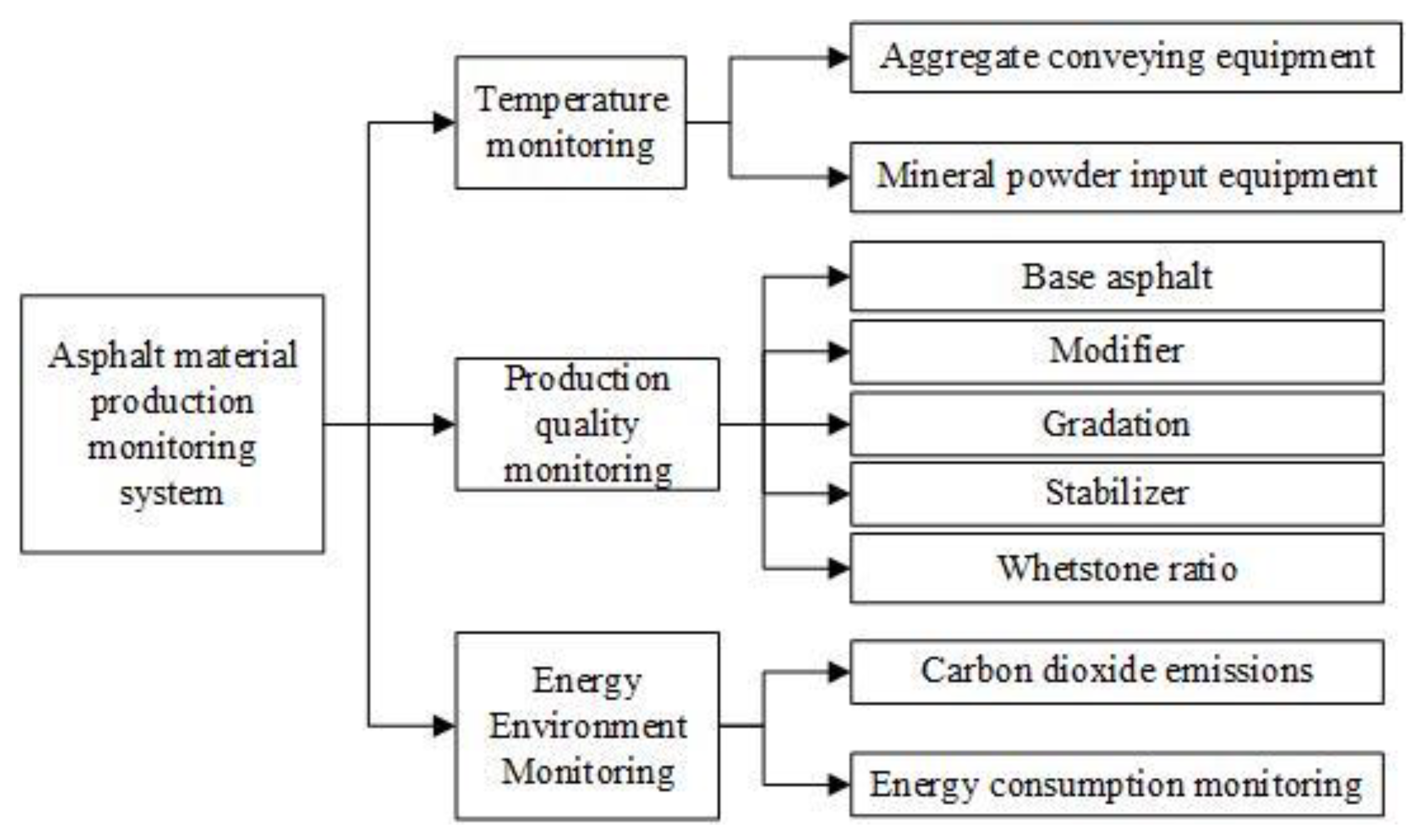

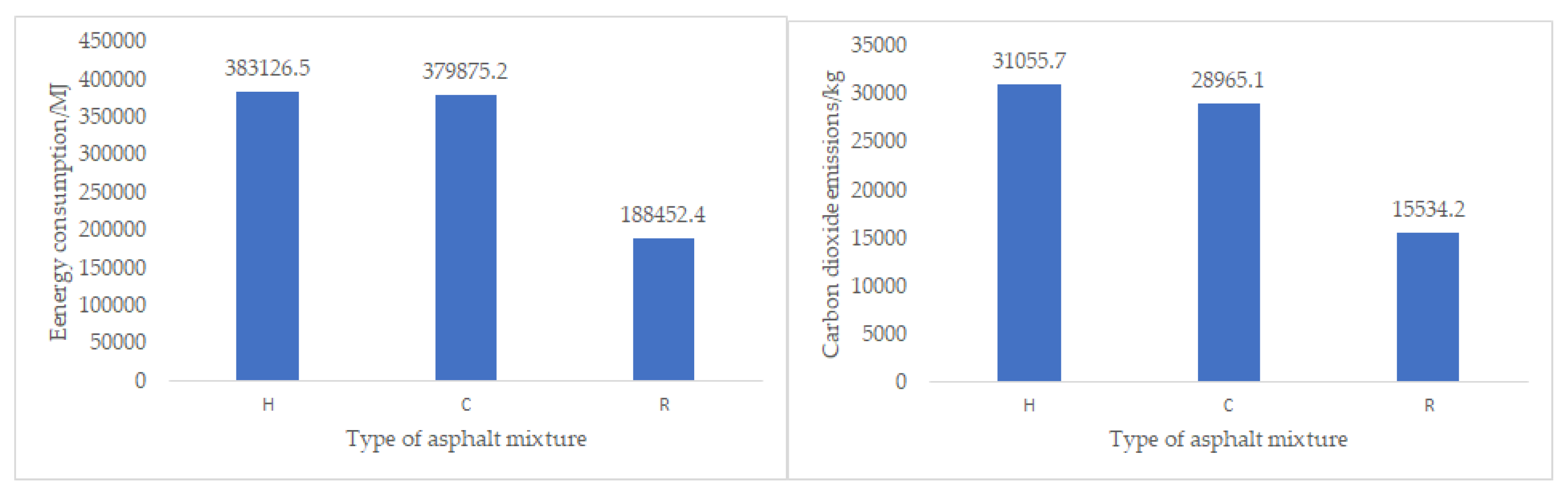

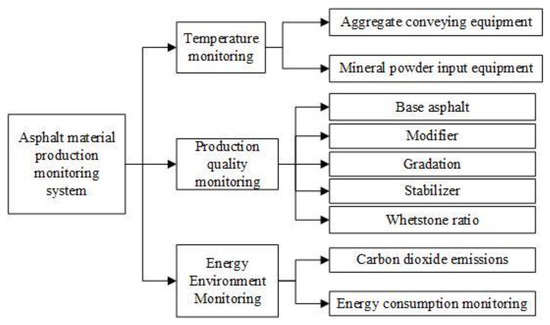

Asphalt Material Production Monitoring System

The quality state of the asphalt mixture in the production process directly determines the quality of the mixture [39]. Moreover, during the “13th Five-Year Plan” period, China attaches great importance to building a resource-saving and environment-friendly society, and it is necessary to significantly reduce energy consumption and carbon dioxide emissions. Carbon emissions and energy consumption in the production of asphalt mixtures have always been a concern [9,12]. Therefore, it is necessary to strengthen the monitoring of the production process of asphalt mixtures. The asphalt mixture production monitoring system consists of temperature monitoring, production quality monitoring, and energy environment monitoring systems. The system architecture is shown in Figure 4. The temperature monitoring module mainly monitors the aggregate conveying equipment and the mineral powder input equipment. The proportion of the aggregate and mineral powder is determined during the production process. The factors that can affect the quality of the asphalt mixture are mainly concentrated on the equipment. When the temperature of the equipment is too high, the system will send an alarm, and the necessary staff can take the required measures to reduce the temperature of the equipment. The production quality monitoring module mainly monitors graduation, base asphalt, modifier, stabilizer, and oil-to-stone ratios. The system sets the ratio of various material indicators in advance, automatically monitors the quantity ratio of raw materials when the material enters the production equipment, and ensures the quality of asphalt by controlling the processing cycle. The energy and environmental monitoring module is responsible for monitoring energy consumption and carbon emissions in the production of aggregates, asphalt, mineral powder, and cement [28,38].

Figure 4.

Subsystem architecture diagram.

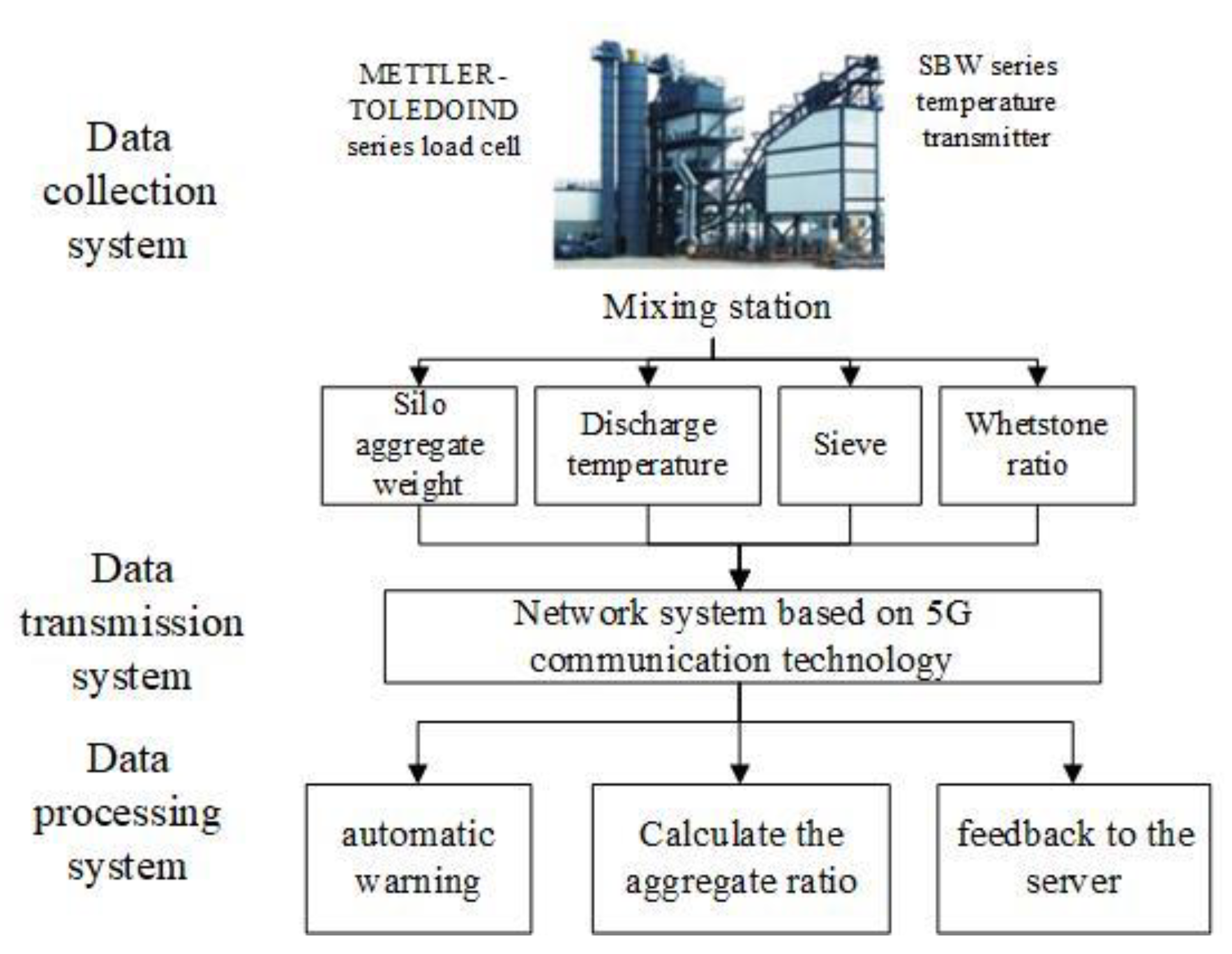

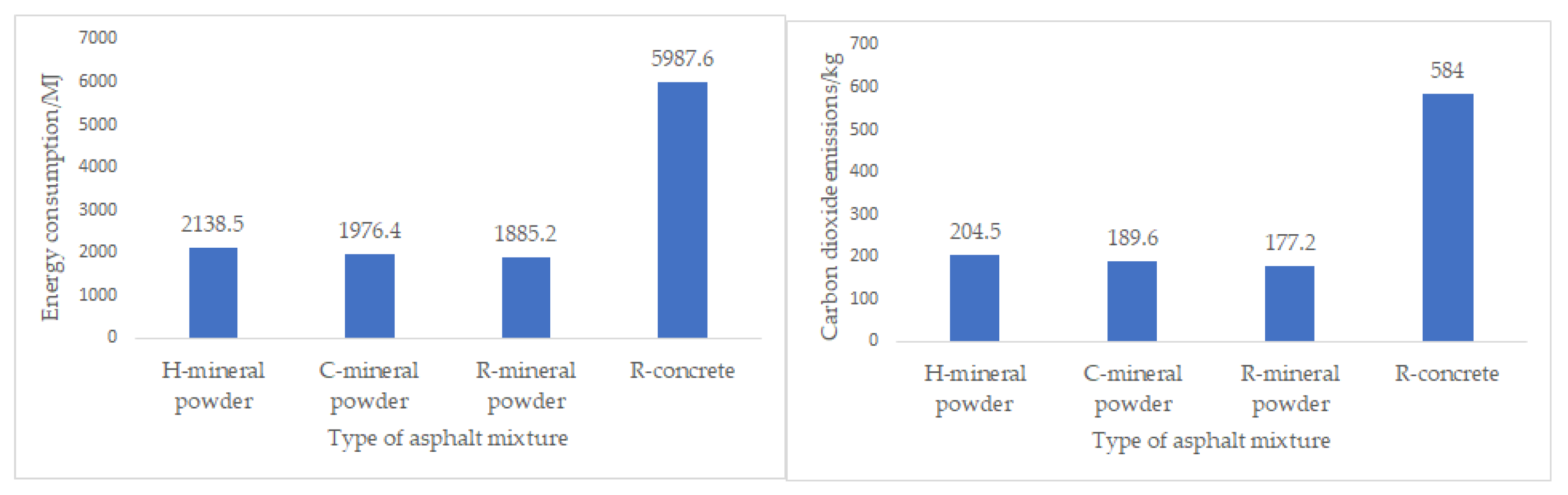

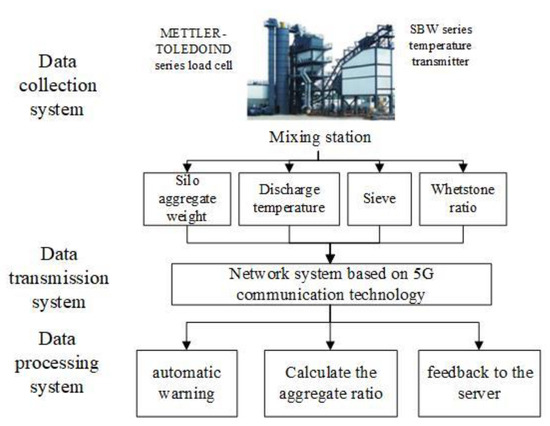

Asphalt Mixture Monitoring System

The asphalt mixture mixing monitoring system includes a data acquisition system, 5G network transmission system, and a data processing system. The mixing station data acquisition system is constructed by installing SBW series temperature transmitters next to the discharge bin and installing METTLER-TOLEDOIND series load cells and other sensing devices in the reduction bin screening system. The system automatically monitors the quality, weight, and discharge temperature of the silo aggregates in real time, and collects key data such as on sieve holes and mixture weight. The collected data are processed into an internal transmission format, and a data processing system is compiled through software engineering. The network system is constructed based on the 5G communication technology and transmitted to the data processing system through the 5G network. The data processing system analyzes the collected data. If a certain index reaches the specified threshold, the system automatically gives a warning and notifies the staff to rectify the problem through SMS or email and calculates the asphalt aggregate ratio and gradation. The system also transfers the data to a remote central server (as shown in Figure 5).

Figure 5.

Mixing monitoring system.

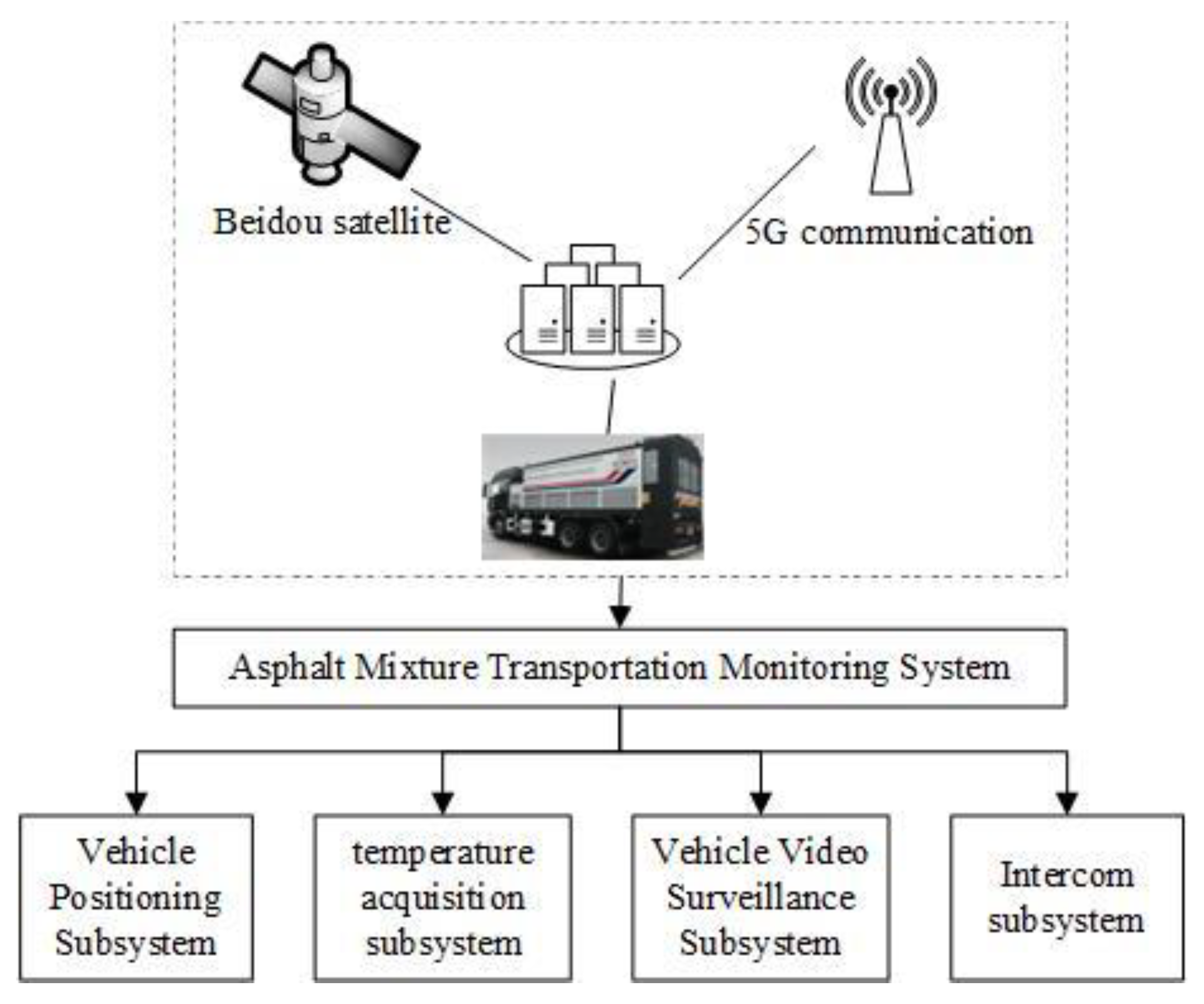

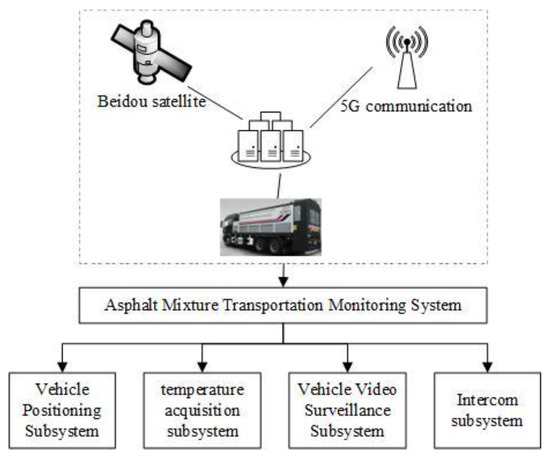

Asphalt Mixture Transportation Monitoring System

The asphalt mixture monitoring system consists of a vehicle positioning subsystem, temperature acquisition system, vehicle video monitoring subsystem, and intercom subsystem. Based on the BeiDou high-precision positioning technology [16], the BDS positioning module is installed on the asphalt mixture transport vehicle, and the transport vehicle is tracked in real time throughout the whole process. Radio frequency identification technology (RFID) [32] is used to install tags and card readers in the mixture transporter, the mixture mixing station, and the mixture paving site to collect the start time and end time of the transporter. In the transportation cycle, if the difference between the start and end of the paving is small, it means that the thickness of the structural layer is large, and the interval between the time when the mixture is discharged and the time when the mixture starts to be paved is relatively long, which means that the construction site is far from the mixing station. For long distances, asphalt mixture transportation will take a significant amount of time, and the transportation route should therefore be re-routed. In the process of asphalt concrete transportation, the temperature of the asphalt mixture is monitored by use of appropriate temperature sensors. Based on the 5G communication technology, a network transmission system is built to monitor and feed back the transportation time and other information for asphalt mixture transportation. The onboard video monitoring subsystem and the intercom subsystem assist the vehicle in safely transporting the mixture to the paving site. The architecture of the asphalt mixture transportation monitoring system is shown in Figure 6.

Figure 6.

Architecture of asphalt mixture transportation monitoring system.

Asphalt Mix Paving Monitoring System

The asphalt mixture paving monitoring system consists of a paving process monitoring subsystem, a temperature acquisition subsystem, a paver operation monitoring subsystem, and a vehicle-mounted video monitoring subsystem. At the paving site, the GNSS positioning board is installed on the paver and construction equipment to monitor the paving speed of the paver. The GNSS positioning board supports BeiDou satellites, and the recognition accuracy of the board reaches the centimeter level. Using the carrier phase differential RTK technology, the dynamic real-time monitoring of the paving process is realized, the geographic information of the paving operation process is monitored, and the monitoring and statistics of the mileage and speed of the paver are also realized. The infrared temperature sensor is installed on the paver, and with the help of this device, the temperature of the paving surface is monitored in real time to draw the temperature change map of the paving surface at each stage of paving, which can be analyzed by professionals and effectively control the temperature segregation of the asphalt concrete pavement. To improve the efficiency of information feedback during the paving stage, the LED screen can be used to dynamically display the construction information to realize the visualization of the construction of the paving operation, and the information is convenient for the relevant personnel to adjust the construction operation. The onboard video monitoring subsystem is responsible for recording the working environment and trajectory of the paving operation vehicle. The subsystem records the construction impact data of the paving operation in real time and transmits it back to the project department in real time through the 5G wireless network. During the entire paving process, a network transmission system is constructed based on the 5G communication technology, and the information on the paving status of the asphalt mixture is fed back in real time.

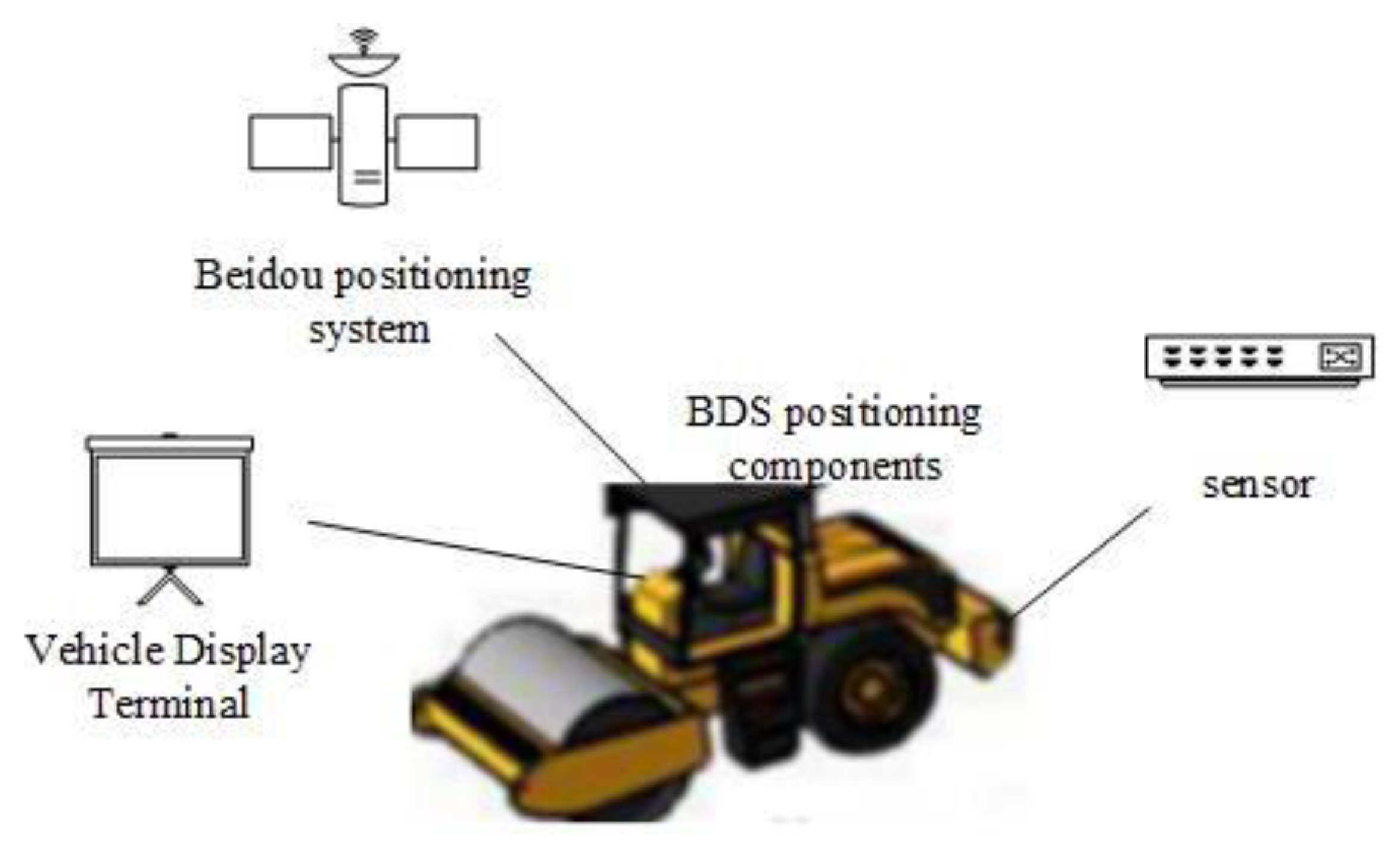

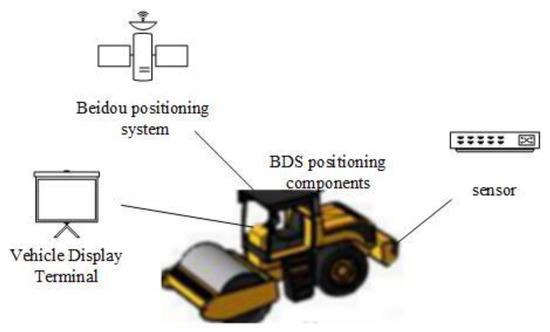

Asphalt Mixture Rolling Monitoring System

The asphalt mixture rolling real-time monitoring system is similar to the paving real-time monitoring system. The main equipment includes a mobile station, temperature sensor, and vibration sensor. The functions of each piece of equipment are shown in Table 5. There is a need to install the BDS positioning component on the compactor to monitor the location parameters of the compactor using RTK technology and a vehicle-mounted mobile station (through the temperature sensor and vibration sensor) to monitor the rolling speed, rolling times, and acceleration as well as other parameters during the rolling process. Data such as temperature and vibration frequency during the rolling process are collected in real time, and a data receiving device is installed in the compactor, which transmits the data collected by the system to the data management system. The onboard display terminal in the compactor guides the construction workers to carry out road rolling. Based on the 5G communication technology, a network transmission system is constructed to feed back the status information of the asphalt mixture rolling in real time. The composition of the compactor monitoring system is shown in Figure 7.

Table 5.

Main equipment functions of real-time monitoring of asphalt concrete pavement rolling.

Figure 7.

The framework of the compactor monitoring system.

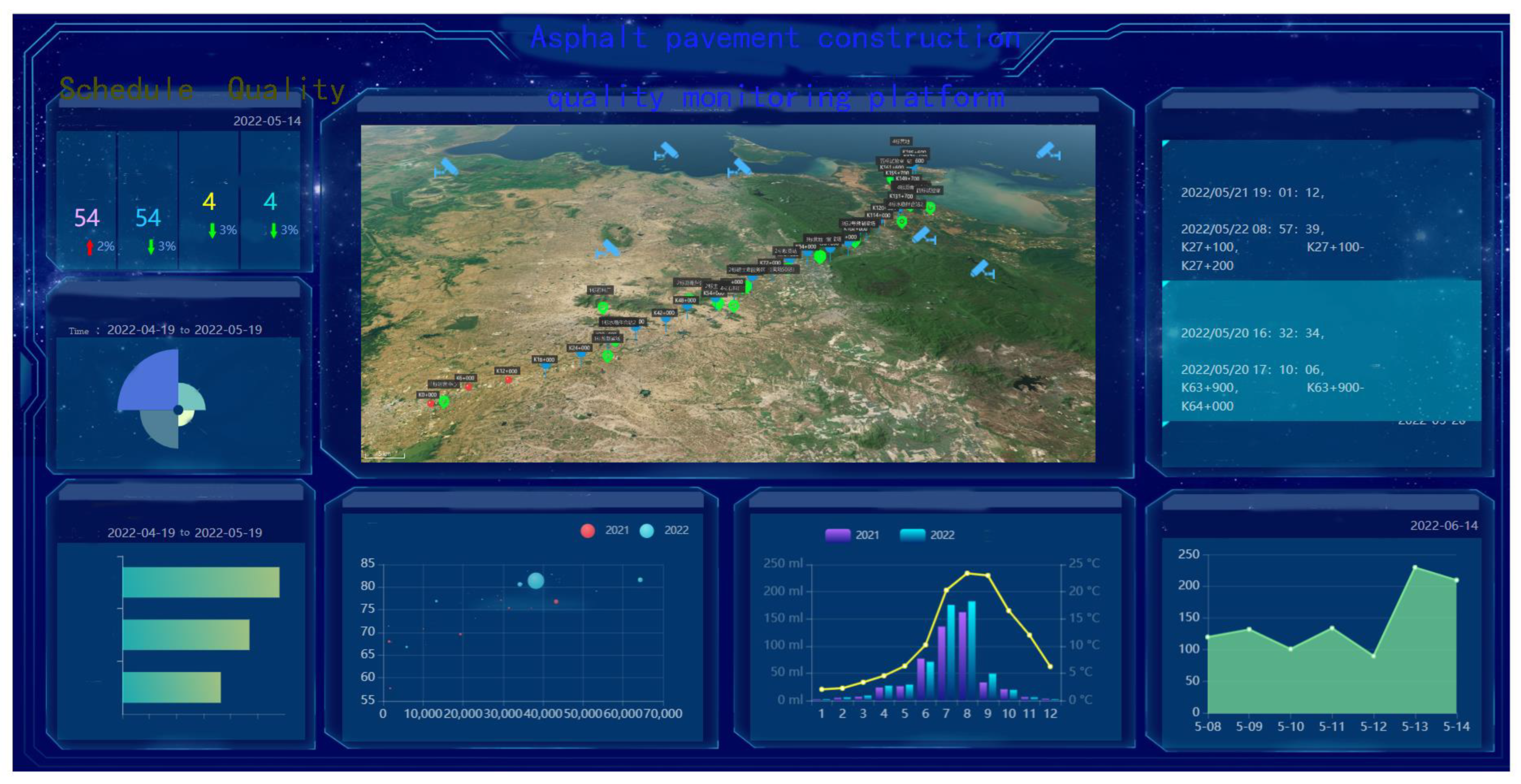

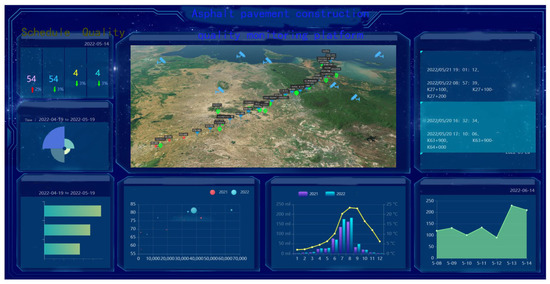

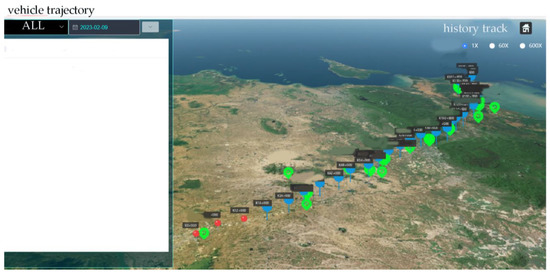

4. Case Study Investigation

Based on the semi-structured interview results, researchers constructed the framework of the asphalt concrete pavement construction monitoring system and collaborated with a domestic software company to develop an asphalt pavement construction intelligent monitoring platform. A digital highway construction project was taken as a typical example application, and the system platform interface is shown in Figure 8.

Figure 8.

Intelligent monitoring platform for asphalt pavement construction.

4.1. Data Management System

The system linked the monitored data in real time. The remote viewing of production data by internet-based mobile devices helped construction parties, owners, third-party supervisors, and other departments to conduct real-time production quality inspections. The data linkage module architecture and system display are shown in Figure 9.

Figure 9.

System display diagram.

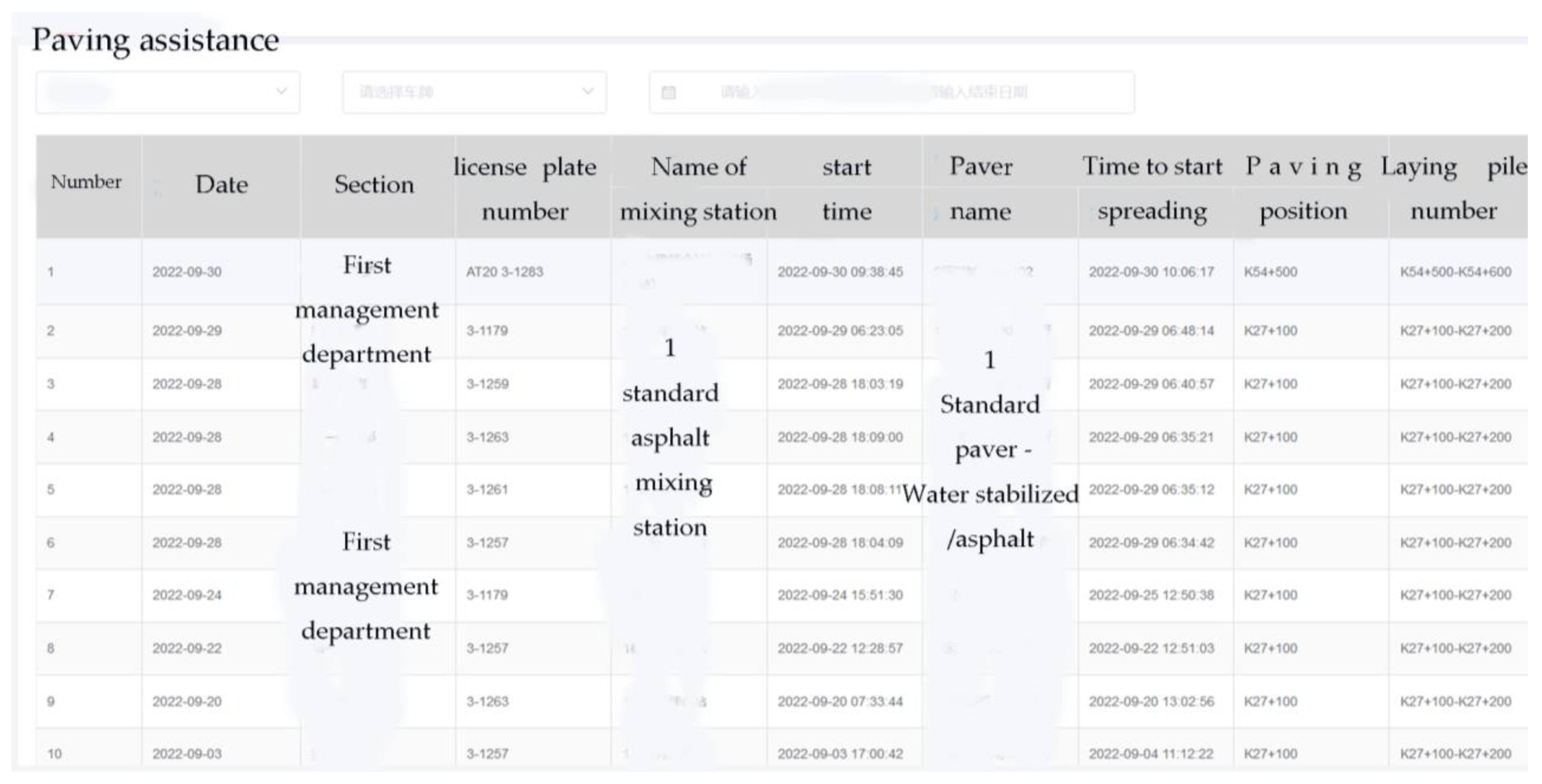

(1) The system automatically performed data sharing and data linkage with the production, mixing station, vehicle transportation, paving, and compaction systems, and links with the production data of the mixing station, the vehicle data, and the paving and compaction data in real time. It has the following main functions: Firstly, the system displays the current paving and compaction mileage in a graphic form. In the Figure 10, the paved mileage of each batch of transportation and the corresponding batch of the mixture used can be directly related to the paving and pressing data. Secondly, the display provides the quantity of the corresponding module, and the corresponding alarm data information can be associated with the actual quantity. Furthermore, it is possible to click on the total production batch to display the current number of production data batches, and at the same time display the data with a warning in color. Finally, users can click the transport data batch that displays the current number to view the details of the number of productions transported by each batch of transport vehicles, and color prompts for data with early warning are also provided.

Figure 10.

System function display.

(2) The paving pile number corresponds to each batch of transport materials and the corresponding batch of the mixing production material can be visually checked on the paving and compaction effect diagram(As shown in Figure 11). This can also be linked to the corresponding pile number section for paving, and the compaction can be videoed, as well as the driving track of the transport vehicle, and the production data information of the mixing material.

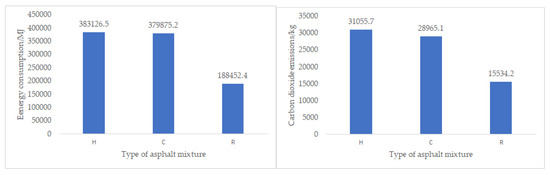

Figure 11.

Energy consumption and carbon emissions of equipment in the aggregate production stage.

(3) Historical traceability and playback can be performed on the corresponding data of each batch of truck paving stakes on the paving and compaction renderings.

(4) The platform provides system analysis and early warning to automatically link early warning data of various systems, and provides a centralized early warning prompt for each construction link.

(5) Finally, the platform supports the access of relevant data to the provincial management platform, and realizes the data connection and business integration with the existing project information management platform and the provincial integrated comprehensive management platform.

4.2. Asphalt Material Production Monitoring System

In the asphalt material production monitoring system, firstly, the quantity ratio of raw materials (such as base asphalt, stabilizers, and modifiers) was monitored, and the quantity was adjusted after an imbalance was found to ensure the quality of asphalt required for the K63 to K67 tenders. Secondly, by monitoring the temperature of the aggregate conveying equipment and the mineral powder input equipment, the production quality of the modified asphalt was ensured. During this period, the system sounded alarms and prompted staff to take cooling measures for the equipment. Finally, the energy consumption monitoring module monitored and collected aggregated data. The energy consumption and carbon emissions in the production of raw materials and slag cement production were calculated, and related graphs were drawn (as shown in Figure 11 and Figure 12).

Figure 12.

Energy consumption and carbon emissions in the production of mineral powder materials.

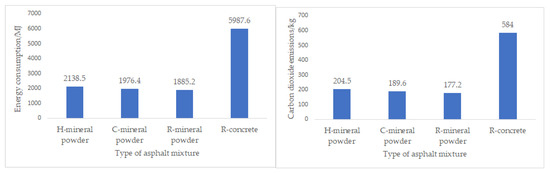

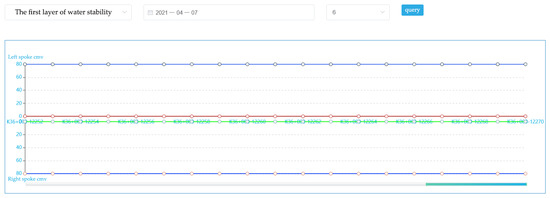

4.3. Asphalt Mixture Monitoring System

For the asphalt mixture mixing monitoring system, SBW series temperature transmitters were installed in the discharge bin of the mixing station and Mettler Toledo IND series load cells were installed in the silo screening system to monitor the quality and weight of the silo aggregates. The system recorded the monitored data and made a monitoring report (as shown in the Figure 13), and transmitted the monitoring data to the data management system through the 5G transmission channel. The construction site of the mixing station is shown in the Figure 14.

Figure 13.

Mixing monitoring report.

Figure 14.

Mixing construction site.

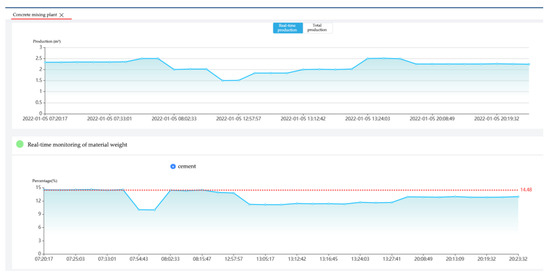

4.4. Asphalt Mixture Transportation Monitoring System

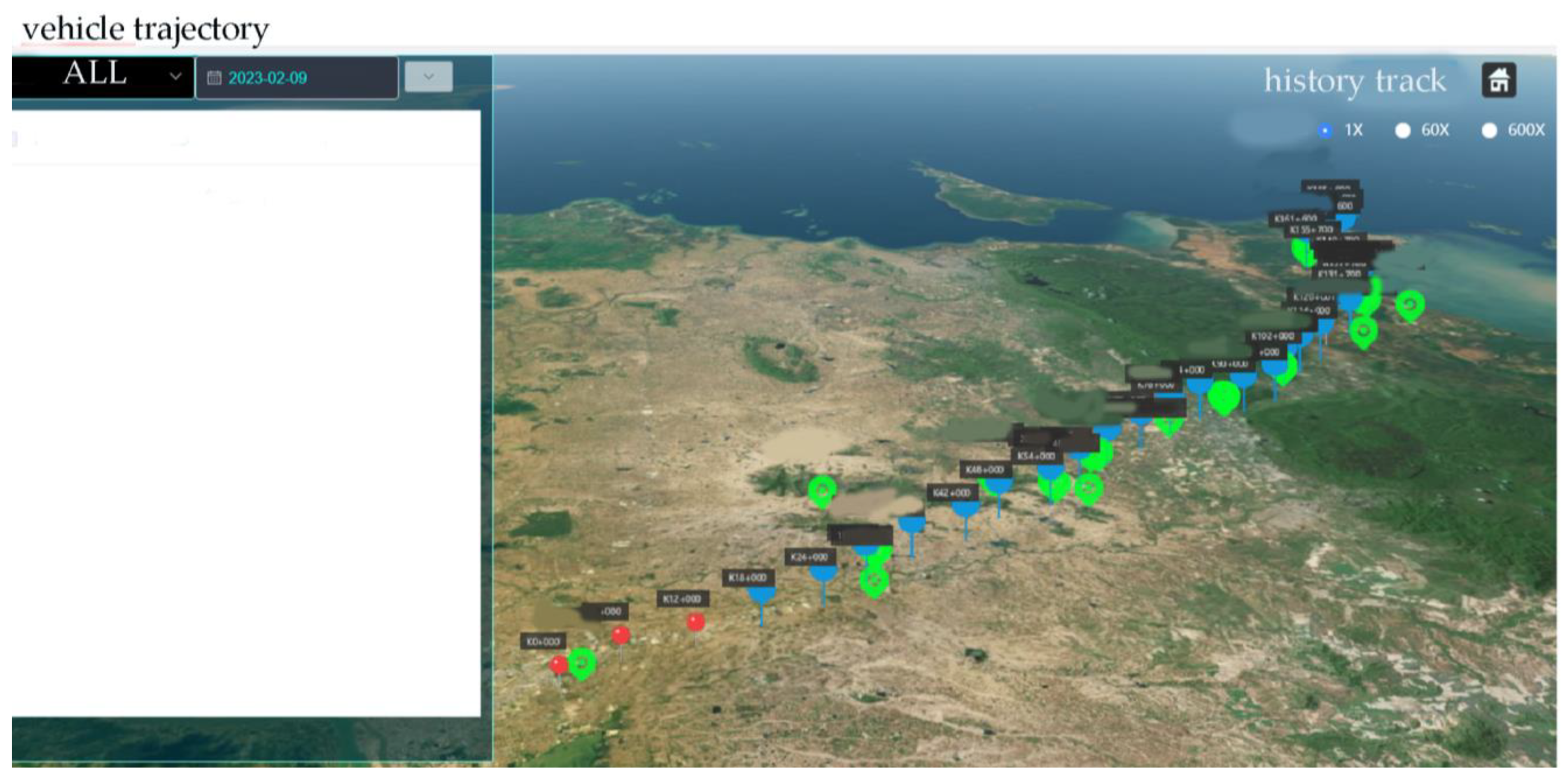

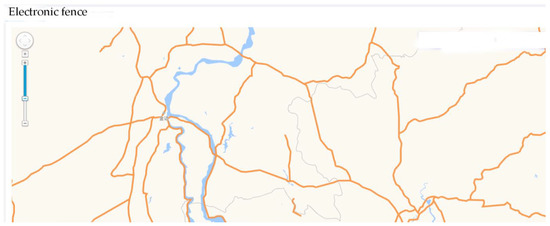

The asphalt mixture transportation monitoring system installed the BDS positioning module on the mixture vehicle, tracked the vehicle’s driving route, collected data such as transportation route and transportation time, and formed a historical track playback route map (as shown in Figure 15). Through radio frequency identification technology, the team collected the time when the mixture came out of the field and started to be transported, and the time when the transportation was finished and started to be paved. In addition, a range area (as shown in Figure 16) was set on the electronic map of the construction project. Once the transport vehicle went outside this area, the system automatically recorded the data and sounded an alarm for the operator to respond appropriately.

Figure 15.

Trajectory of transport vehicles.

Figure 16.

Transport vehicle electronic fence.

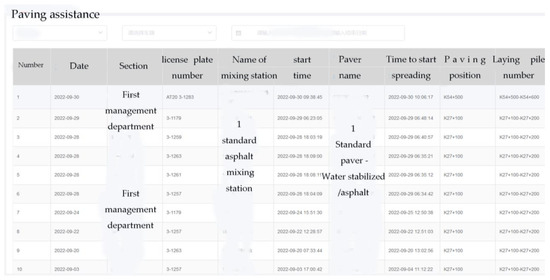

4.5. Asphalt Mixture Paving Monitoring System

In the asphalt mixture paving monitoring system, the GNSS board positioning and the carrier phase differential RTK technology were used to monitor the paving speed and paving mileage of the paving and collect the data, as well as the infrared temperature sensor to monitor the paving temperature in real time and draw a paving temperature change map for the staff to analyze. The monitored data, such as paving speed, paving temperature, paving mileage, and the working environment of the paver, were packaged and sent to the data management system through the 5G network transmission channels so that the real-time reception and storage of paving operation information could be completed. The construction work information could be dynamically displayed through the LED screen, which ensured the quality and efficiency of the paving. The on-site operation of the paver and the monitoring information of intelligent paving are shown in Figure 17 and Figure 18.

Figure 17.

Paving site.

Figure 18.

Paving monitoring information.

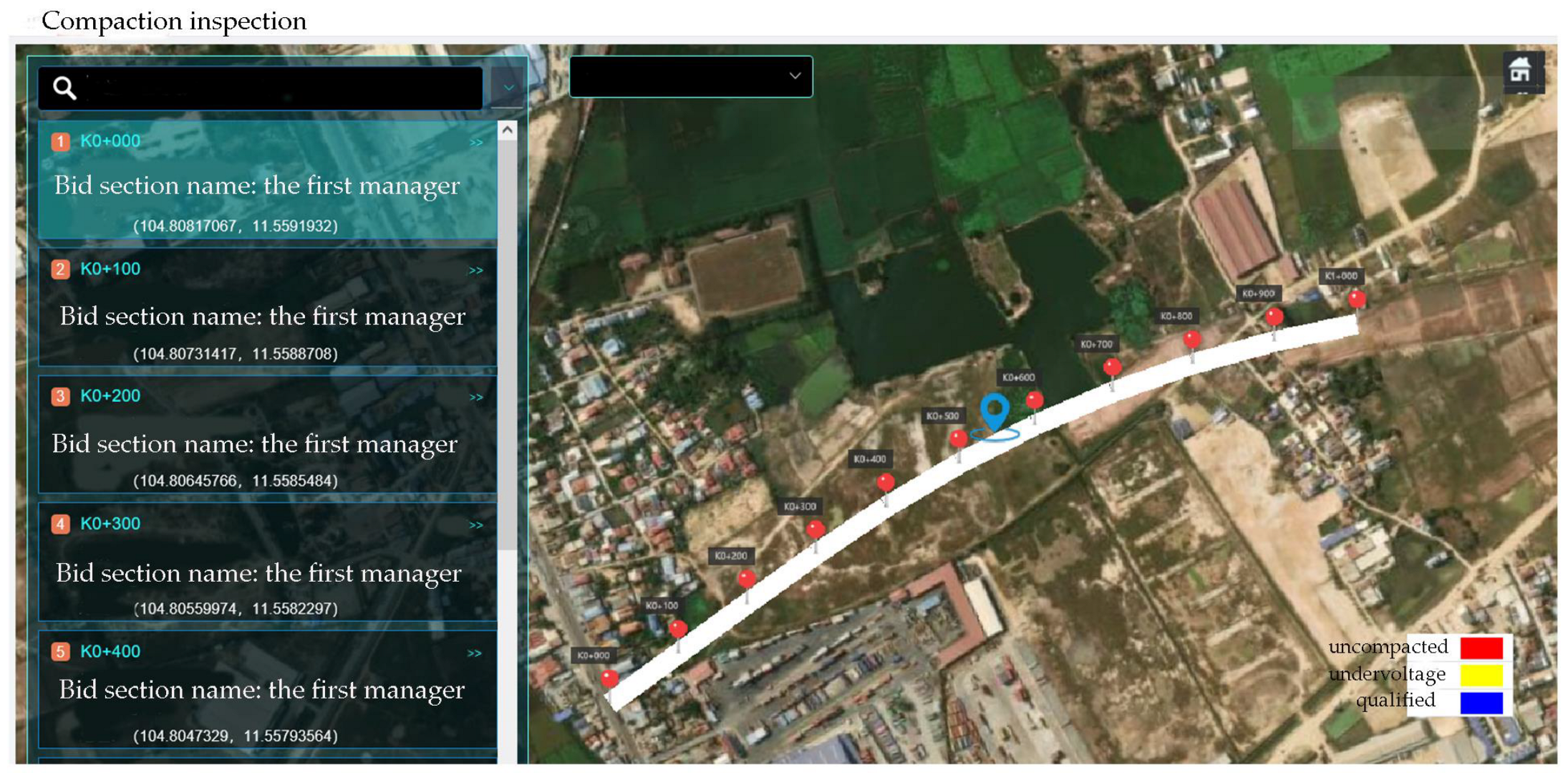

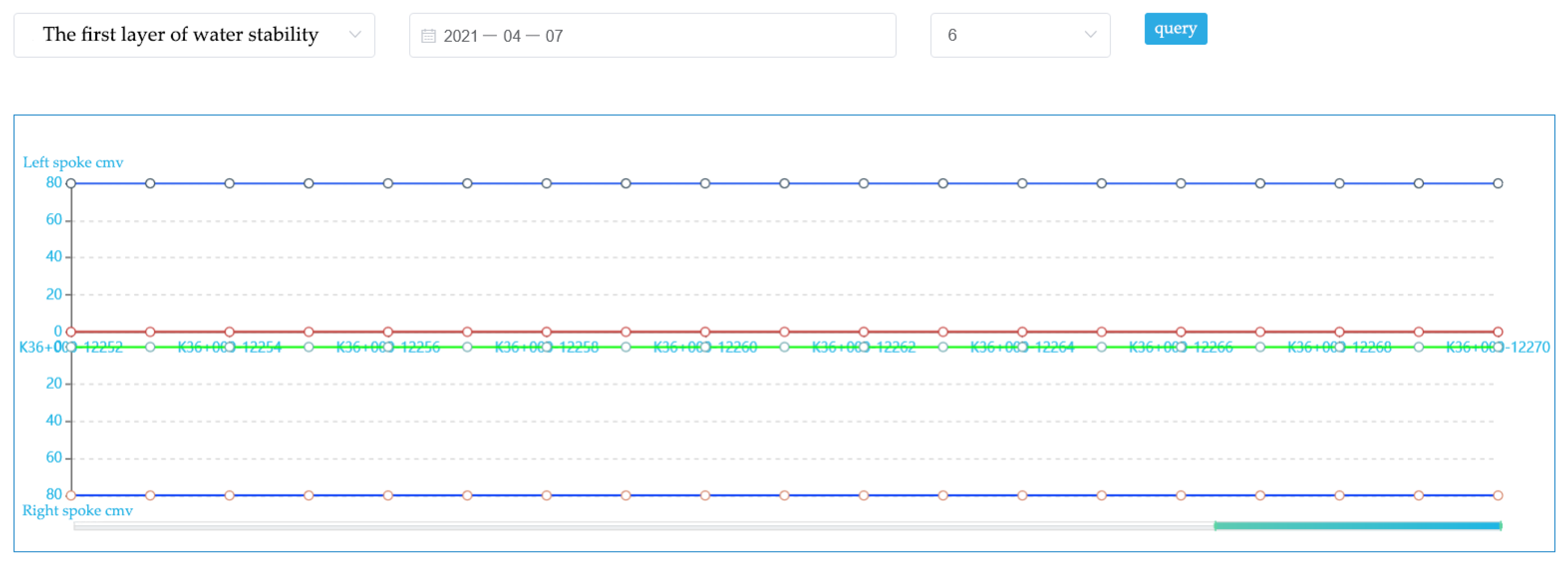

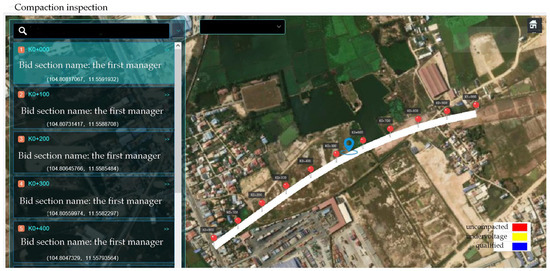

4.6. Asphalt Mixture Compaction Monitoring System

As part of the asphalt mixture compaction monitoring system, a real-time monitoring device was installed on the roller shaft of the road roller to monitor the main compaction indicators and collect parameters. The road roller was also equipped with BDS positioning components, temperature sensors, and vibration sensors, which collected key data such as the number of compaction passes, compaction speed, compaction trajectory, temperature, and vibration frequency. The system also transmitted all the collected data through the 5G transmission channel. The compaction monitoring date shown in Figure 19. In the data management system, the command center also directed staff to carry out a series of operations, such as compaction, through the vehicle-mounted display terminal. The asphalt concrete pavement construction quality monitoring platform monitored the data of the construction section, collected compaction degree and other data, and drew the compaction degree curve (as shown in the Figure 20). In addition, the relationship between the degree of compaction and the secondary resonance spectrum during vibration rolling was established, and the calculation parameters of vibration compaction degree were adjusted. The three colors of red, yellow and blue were used to calibrate the road compaction degree. The compaction monitoring system and compaction site are shown in Figure 21.

Figure 19.

Compaction monitoring information.

Figure 20.

Compaction curve.

Figure 21.

Compaction work site.

4.7. Platform Application Results

In this research study, an asphalt pavement construction quality monitoring platform was developed and applied to a highway construction project. The results are summarized as follows:

1. Centralized supervision of raw materials for construction projects was realized for the digital storage of 9380 pieces of data, thereby providing data support for the traceability of construction engineering quality.

2. The early warning management system for the asphalt concrete pavement construction process was developed based on real-time monitoring. The system accumulated early warning compaction substandard data (N = 954), unqualified asphalt parameter data (N = 102), and unqualified concrete parameter data (N = 39,896). Consequently, the digital monitoring system significantly improved the quality outcomes for asphalt pavement construction.

3. The asphalt pavement construction quality monitoring platform was used for centralized online supervision of the project. The system reduced the difficulty for engineers in checking whether the metrology procedures were complete, and the whole cycle was 30% shorter.

4. The asphalt pavement construction quality monitoring platform for asphalt mixture construction process provided real-time dynamic monitoring. The monitoring data feedback efficiency was high, which ensured that the construction quality was up to standard as well as 100% data compliant, directly saving labor and thereby reducing management costs by RMB 2.6 million. The use of electronic archiving to store a large amount of data also saved paper waste. The system integrated the four stages of mixing, transportation, paving, and rolling in asphalt pavement construction, unified personnel and machinery management, and allocated personnel according to real-time road construction status monitoring, thereby saving RMB 400,000 in material costs and RMB 800,000 in labor and machinery fees.

5. Discussion

At present, research on the construction monitoring of asphalt concrete pavement mainly focuses on the asphalt paving or rolling stage, and less consideration has been given to the entire construction stage of the asphalt mixture. In addition, due to the lack of whole-process tracking and monitoring of key processes by engineering construction management personnel, the quality of asphalt pavement is often substandard or even destroyed. Based on the results of semi-structured interviews, this research study developed a construction monitoring system framework for asphalt concrete pavement. A data management system to comprehensively improve the construction quality of asphalt pavement was developed. The system includes real-time monitoring of the asphalt production stage and pavement construction stage, accompanied by an early warning system, which promotes the effective and efficient process of digital highway construction. Although there are certain limitations, the results from this study have significant value for the construction monitoring of asphalt concrete pavement.

From a theoretical perspective, the study developed a digital monitoring system according to data linkage processing, which effectively solves the problem of unsatisfactory data application in engineering construction and realizes information transmission as well as sharing among construction enterprises at various stages. From a practitioner point of view, the asphalt pavement construction quality monitoring system provides a data-centric management system to assist in the design and delivery of construction engineering projects. In addition, the system monitoring of test batches is also associated with the real-time data, which ensures the accuracy of the data as well as reliable test results.

Previously there have been in-depth studies on the construction monitoring of asphalt pavement. Indeed, Liu Donghai [40] developed a cyber–physical system and proposed a multi-roller compaction monitoring system framework. The results showed that the proposed system effectively controlled the compaction process and ensures compaction quality. Ma, Xianyong [39] proposed an airport asphalt pavement health monitoring system framework to monitor asphalt pavement quality and help pavement maintenance. Chen and Shu-Yang [41] proposed a framework of a data-driven digital highway construction whole-process management platform, which plays a role in monitoring and management of asphalt mixture transportation, paving, and compaction. The above literature provides an important basis for the construction monitoring of asphalt concrete pavement, but established system frameworks are aimed at either one or three stages and do not cover the whole process.

Based on the results of semi-structured interviews, this study integrated BeiDou technology and 5G technology into the system framework to establish an asphalt pavement construction monitoring system framework to improve the quality of pavement construction across the whole process lifecycle. Ma Zi-yuan [9] proposed a dynamic quality monitoring system for asphalt concrete pavement, which integrates the BeiDou navigation system, intelligent sensing, internet of things, and 5G technology, but the difference is that the system framework proposed in this study, firstly, not only covers the five construction stages of asphalt mixtures but also includes a data management system, which links the data collected by monitoring in real time to realize the integration of various businesses and make the monitoring data more efficient. Secondly, in terms of research methods, this study conducted semi-structured interviews with practitioners to gain an in-depth understanding of the goals and challenges of asphalt pavement construction monitoring and discussed ideas for improvement. Other studies previously proposed the development of a performance monitoring system for asphalt pavement construction [8,42,43], which has been addressed by the study reported herein.

6. Conclusions and Future Work

Based on analysis of the results of semi-structured interviews, this study proposes a system framework that facilitates the digital monitoring of asphalt concrete pavement construction based on IoT, the BeiDou navigation system, and 5G technology. In this framework, a data management system and an asphalt mixture production, mixing, transportation, paving, and rolling monitoring system are defined to realize asphalt concrete pavement monitoring from six aspects. It is proposed that based on implementing the concept of information transmission across the whole life cycle, the key data in the production process of the production, mixing, transportation, paving, and rolling of the mixture system can be acquired, and real-time linkage between the data of each system carried out. Corresponding functions of each system were also developed, such as the query of total production batches, the query of total transportation batches, and the proportion of alarms issued to operators. Users can directly operate and view the corresponding data results through real-time interaction with the system and corresponding functions.

The study has demonstrated the system framework of a digital monitoring system for asphalt concrete pavement construction. The research team collaborated with a software company to develop an intelligent monitoring platform for asphalt pavement construction and successfully applied the platform to a digital highway construction project to validate the system framework. The results of the case study investigation highlight that the monitoring platform developed by the system framework enables monitoring of asphalt pavement construction. This led to an improved level of pavement construction and management, which is consistent with the development of the construction sector in China. The results of this empirical study support the design and development of a highway construction quality monitoring system. This system approach renders it easier and more efficient for engineering construction workers to handle, predict, and solve road construction problems, so that construction projects can be completed more efficiently.

It is suggested that future research includes the following directions: (1) The function of the system may potentially be enhanced through reducing the level of manual operations. For example, if the temperature of the equipment is too high, automatic operation of the system can be enabled to cool the equipment without requiring workers to operate the platform. (2) There is a need to monitor the performance of the system and suitable research studies should therefore be undertaken in this area.

Author Contributions

Methodology—J.Z. (Jingxiao Zhang); writing—original draft—Z.Z. (Zhe Zhu); validation—H.L.; formal analysis—J.Z. (Jian Zuo) and Y.K.; writing—review and editing—S.P.P.; funding acquisition—Z.Z. (Zhendong Zhou), Y.F. and Q.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Branch of China Road and Bridge Corporation (Cambodia) Technology Development Project (No. 2020-zlkj-04), National Social Science Fund projects (No. 20BJY010), National Social Science Fund Post-Financing Projects (No. 19FJYB017), Sichuan-Tibet Railway Major Fundamental Science Problems Special Fund (No. 71942006), List of Key Science and Technology Projects in China’s Transportation Industry in 2018-International Science and Technology Cooperation Project (No. 2018-GH-006 and No. 2019-MS5-100), Emerging Engineering Education Research and Practice Project of Ministry of Education of China (No. E-GKRWJC20202914), Shaanxi Social Science Fund (No. 2017S004), and Xi’an Construction Science and Technology Planning Project (Nos. SZJJ201915 and SZJJ201916).

Data Availability Statement

If you have any need, please contact us via email (zz18629440410@163.com).

Conflicts of Interest

The authors declare no competing financial or non-financial interest.

References

- Li, S.; Xu, W.; Zhang, F.; Wu, H.; Zhao, P. Effect of Graphene Oxide on the Low-Temperature Crack Resistance of Polyurethane-SBS-Modified Asphalt and Asphalt Mixtures. Polymers 2022, 14, 453. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Hou, K.; Jia, Y.; Wei, Z.; Wang, S.; Li, Z.; Ding, F.; Gong, X. Variability Evaluation of Gradation for Asphalt Mixture in Asphalt Pavement Construction. Autom. Constr. 2021, 128, 103742. [Google Scholar] [CrossRef]

- Hu, W.; Shu, X.; Jia, X.; Huang, B. Geostatistical Analysis of Intelligent Compaction Measurements for Asphalt Pavement Compaction. Autom. Constr. 2018, 89, 162–169. [Google Scholar] [CrossRef]

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R. Patterns and Trends in Internet of Things (IoT) Research: Future Applications in the Construction Industry. Eng. Constr. Archit. Manag. 2021, 28, 457–481. [Google Scholar] [CrossRef]

- Chen, B.; Yu, X.; Dong, F.; Zheng, C.; Ding, G.; Wu, W. Compaction Quality Evaluation of Asphalt Pavement Based on Intelligent Compaction Technology. J. Constr. Eng. Manag. 2021, 147, 04021099. [Google Scholar] [CrossRef]

- Yu, J.; Xiong, C.; Zhang, X.; Li, W. More Accurate Modulus Back-Calculation by Reducing Noise Information from in Situ-Measured Asphalt Pavement Deflection Basin Using Regression Model. Constr. Build. Mater. 2018, 158, 1026–1034. [Google Scholar] [CrossRef]

- Li, T.; Wen, Y.; Feng, H.X.; Wei, L. Analysis on the De-Noise Effect of Anti-Skid Noise Reduction Asphalt Pavement; Wang, H., Liu, Y., You, Z., Eds.; Destech Publications: Lancaster, PA, USA, 2016; pp. 297–303. [Google Scholar]

- Yuan, J.; Li, X.; Ke, Y.; Xu, W.; Xu, Z.; Skibnewski, M. Developing a Building Information Modeling-Based Performance Management System for Public-Private Partnerships. Eng. Constr. Archit. Manag. 2020, 27, 1727–1762. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, J.; Philbin, S.P.; Li, H.; Yang, J.; Feng, Y.; Ballesteros-Perez, P.; Skitmore, M. Dynamic Quality Monitoring System to Assess the Quality of Asphalt Concrete Pavement. Buildings 2021, 11, 577. [Google Scholar] [CrossRef]

- Cong, L.; Shi, J.; Wang, T.; Yang, F.; Zhu, T. A Method to Evaluate the Segregation of Compacted Asphalt Pavement by Processing the Images of Paved Asphalt Mixture. Constr. Build. Mater. 2019, 224, 622–629. [Google Scholar] [CrossRef]

- Yiqiu, T.; Haipeng, W.; Shaojun, M.; Huining, X. Quality Control of Asphalt Pavement Compaction Using Fibre Bragg Grating Sensing Technology. Constr. Build. Mater. 2014, 54, 53–59. [Google Scholar] [CrossRef]

- Milad, A.A.; Adwan, I.; Majeed, S.A.; Memon, Z.A.; Bilema, M.; Omar, H.A.; Abdolrasol, M.G.M.; Usman, A.; Yusoff, N.I.M. Development of a Hybrid Machine Learning Model for Asphalt Pavement Temperature Prediction. IEEE Access 2021, 9, 158041–158056. [Google Scholar] [CrossRef]

- Tan, Y.; Liang, Z.; Xu, H.; Xing, C. Research on Rutting Deformation Monitoring Method Based on Intelligent Aggregate. IEEE Trans. Intell. Transp. Syst. 2022, 23, 22116–22126. [Google Scholar] [CrossRef]

- Zhu, S.; Li, X.; Wang, H.; Yu, D. Development of an Automated Remote Asphalt Paving Quality Control System. Transp. Res. Rec. 2018, 2672, 28–39. [Google Scholar] [CrossRef]

- Liu, P.; Wang, C.; Lu, W.; Moharekpour, M.; Oeser, M.; Wang, D. Development of an FEM-DEM Model to Investigate Preliminary Compaction of Asphalt Pavements. Buildings 2022, 12, 932. [Google Scholar] [CrossRef]

- Hu, D.; Gu, X.; Yang, F.; Zhou, Z.; Bo, W.; Cui, B.; Pei, J. Atomic Mechanisms of Separation Failure at the Asphalt-Aggregate Interface and Its Dependence on Aging and Rejuvenation: Insights from Molecular Dynamics Simulations and DFT Calculations. Appl. Surf. Sci. 2022, 598, 153775. [Google Scholar] [CrossRef]

- Ravichandran, M.; Castorena, C. Critical Evaluation of Dynamic Shear Rheometer (DSR)-Based Methods to Measure Asphalt Binder Diffusion. J. Test. Eval. 2021, 49, 4014–4031. [Google Scholar] [CrossRef]

- Kassem, E.; Liu, W.; Scullion, T.; Masad, E.; Chowdhury, A. Development of Compaction Monitoring System for Asphalt Pavements. Constr. Build. Mater. 2015, 96, 334–345. [Google Scholar] [CrossRef]

- Chang, G.K.; Mohanraj, K.; Stone, W.A.; Oesch, D.J.; Gallivan, V. (Lee) Leveraging Intelligent Compaction and Thermal Profiling Technologies to Improve Asphalt Pavement Construction Quality: A Case Study. Transp. Res. Rec. 2018, 2672, 48–56. [Google Scholar] [CrossRef]

- Wan, Y.; Jia, J. Nonlinear Dynamics of Asphalt-Screed Interaction during Compaction: Application to Improving Paving Density. Constr. Build. Mater. 2019, 202, 363–373. [Google Scholar] [CrossRef]

- Howell, R.; Muench, S.; Feracor, J.; Ashtiani, M.; Weston, J. Field Performance of 9.5-Mm Nominal Maximum Aggregate Size Asphalt Pavement in Washington State. J. Transp. Eng. Part B-Pavements 2020, 146, 04020024. [Google Scholar] [CrossRef]

- Zuo, W.; Guo, C.; Liu, J.; Peng, X.; Yang, M. A Police and Insurance Joint Management System Based on High Precision BDS/GPS Positioning. Sensors 2018, 18, 169. [Google Scholar] [CrossRef] [PubMed]

- Wasle, E.; Seybold, J.; Urquijo, S.; Rohmer, G.; Seidel, C.; Ligier, A.; Euler, H.-J. IEEE Advanced Galileo Navigation System for Asphalt Fleet Machines ASPHALT. In Proceedings of the 2010 5th ESA Workshop on Satellite Navigation Technologies and European Workshop on GNSS Signals and Signal Processing (NAVITEC), Noordwijk, The Netherlands, 8–10 December 2010. [Google Scholar]

- Astarita, V.; Giofre, V.P.; Guido, G.; Vitale, A. The Use of Adaptive Traffic Signal Systems Based on Floating Car Data. Wirel. Commun. Mob. Comput. 2017, 2017, 4617451. [Google Scholar] [CrossRef]

- Wang, K.; El-Mowafy, A.; Wu, J. Inst Navigat Integrity Monitoring Using ARAIM for Bridging DFMC SBAS Outages in Road Transport; Inst Navigation: Washington, DC, USA, 2020; pp. 2430–2439. [Google Scholar]

- Luo, J.; Zhu, X.; Hou, X. Research about Monitoring Systems of Special Roads Based on 4G; Jiang, P., Liang, X., Eds.; Atlantis Press: Paris, France, 2016; Volume 80, pp. 726–730. [Google Scholar]

- You, K.; Ding, L.; Zhou, C.; Dou, Q.; Wang, X.; Hu, B. 5G-Based Earthwork Monitoring System for an Unmanned Bulldozer. Autom. Constr. 2021, 131, 103891. [Google Scholar] [CrossRef]

- Nguyen, K.; Nguyen, P.L.; Li, Z.; Sekiya, H. Empowering 5G Mobile Devices With Network Softwarization. IEEE Trans. Netw. Serv. Manag. 2021, 18, 2492–2501. [Google Scholar] [CrossRef]

- Lee, W.; Lin, K.-Y.; Johnson, P.W.; Seto, E.Y.W. Selection of Wearable Sensor Measurements for Monitoring and Managing Entry-Level Construction Worker Fatigue: A Logistic Regression Approach. Eng. Constr. Archit. Manag. 2022, 29, 2905–2923. [Google Scholar] [CrossRef]

- Ye, Z.; Yan, G.; Wei, Y.; Zhou, B.; Li, N.; Shen, S.; Wang, L. Real-Time and Efficient Traffic Information Acquisition via Pavement Vibration IoT Monitoring System. Sensors 2021, 21, 2679. [Google Scholar] [CrossRef]

- Li, Z.; Cui, Y.; Zhong, J. Recent Advances in Nanogenerators-Based Flexible Electronics for Electromechanical Biomonitoring. Biosens. Bioelectron. 2021, 186, 113290. [Google Scholar] [CrossRef]

- Segalini, A.; Carri, A.; Grignaffini, C.; Capparelli, G. Formulation of Landslide Risk Scenarios Using Underground Monitoring Data and Numerical Models: Conceptual Approach, Analysis, and Evolution of a Case Study in Southern Italy. Landslides 2019, 16, 1043–1053. [Google Scholar] [CrossRef]

- Wang, H.-P.; Xiang, P.; Jiang, L.-Z. Optical Fiber Sensing Technology for Full-Scale Condition Monitoring of Pavement Layers. Road Mater. Pavement Des. 2020, 21, 1258–1273. [Google Scholar] [CrossRef]

- Cao, Y.; Huang, G.; Xie, W.; Xie, S.; Wang, H. Assessment and Comparison of Satellite Clock Offset between BeiDou-3 and Other GNSSs. Acta Geod. Et. Geophys. 2021, 56, 303–319. [Google Scholar] [CrossRef]

- Kim, Y.-E.; Kim, Y.-S.; Kim, H. Effective Feature Selection Methods to Detect IoT DDoS Attack in 5G Core Network. Sensors 2022, 22, 3819. [Google Scholar] [CrossRef]

- Fu, H.; Zhu, H.; Xue, P.; Hu, X.; Guo, X.; Liu, B. Eye-Tracking Study of Public Acceptance of 5G Base Stations in the Context of the COVID-19 Pandemic. Eng. Constr. Archit. Manag. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Guo, Y.; Yang, F.; Jin, P.J.; Liu, H.; Ma, S.; Yao, Z. Vehicle Travel Path Recognition in Urban Dense Road Network Environments by Using Mobile Phone Data. Transp. A-Transp. Sci. 2022, 18, 1496–1516. [Google Scholar] [CrossRef]

- Mishra, L.; Vikash; Varma, S. Seamless Health Monitoring Using 5G NR for Internet of Medical Things. Wirel. Pers. Commun. 2021, 120, 2259–2289. [Google Scholar] [CrossRef]

- Ma, X.; Dong, Z.; Chen, F.; Xiang, H.; Cao, C.; Sun, J. Airport Asphalt Pavement Health Monitoring System for Mechanical Model Updating and Distress Evaluation under Realistic Random Aircraft Loads. Constr. Build. Mater. 2019, 226, 227–237. [Google Scholar] [CrossRef]

- Liu, D.; Chen, J.; Li, S. Collaborative Operation and Real-Time Control of Roller Fleet for Asphalt Pavement Compaction. Autom. Constr. 2019, 98, 16–29. [Google Scholar] [CrossRef]

- Chen, S.-Y.; Zhang, J.-X.; Ni, Q.-C.; Skitmore, M.; Ballesteros-Perez, P.; Ke, Y.-J.; Zuo, J.; Sun, H.-J. Data-Driven Platform Framework for Digital Whole-Process Expressway Construction Management. Front. Neurosci. 2022, 16, 891772. [Google Scholar] [CrossRef]

- Khan, S.; Nagabhushana, M.N.; Hossain, K.; Tiwari, D.; Guruvittal, U.K.; Bazan, C. Performance Evaluation of Fly Ash-Based Inverted Pavement System. J. Transp. Eng. Part B-Pavements 2022, 148, 04022028. [Google Scholar] [CrossRef]

- Shabbir Hossain, M.; Nair, H.; Celik Ozyildirim, H. Construction of a Composite Pavement (Asphalt over Concrete) in Virginia. Transp. Res. Rec. 2022, 2676, 251–264. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).