On the Development of Material Constitutive Model for 45CrNiMoVA Ultra-High-Strength Steel

Abstract

:1. Introduction

2. Materials and Experimental Procedures

2.1. 45CrNiMoVA Steel

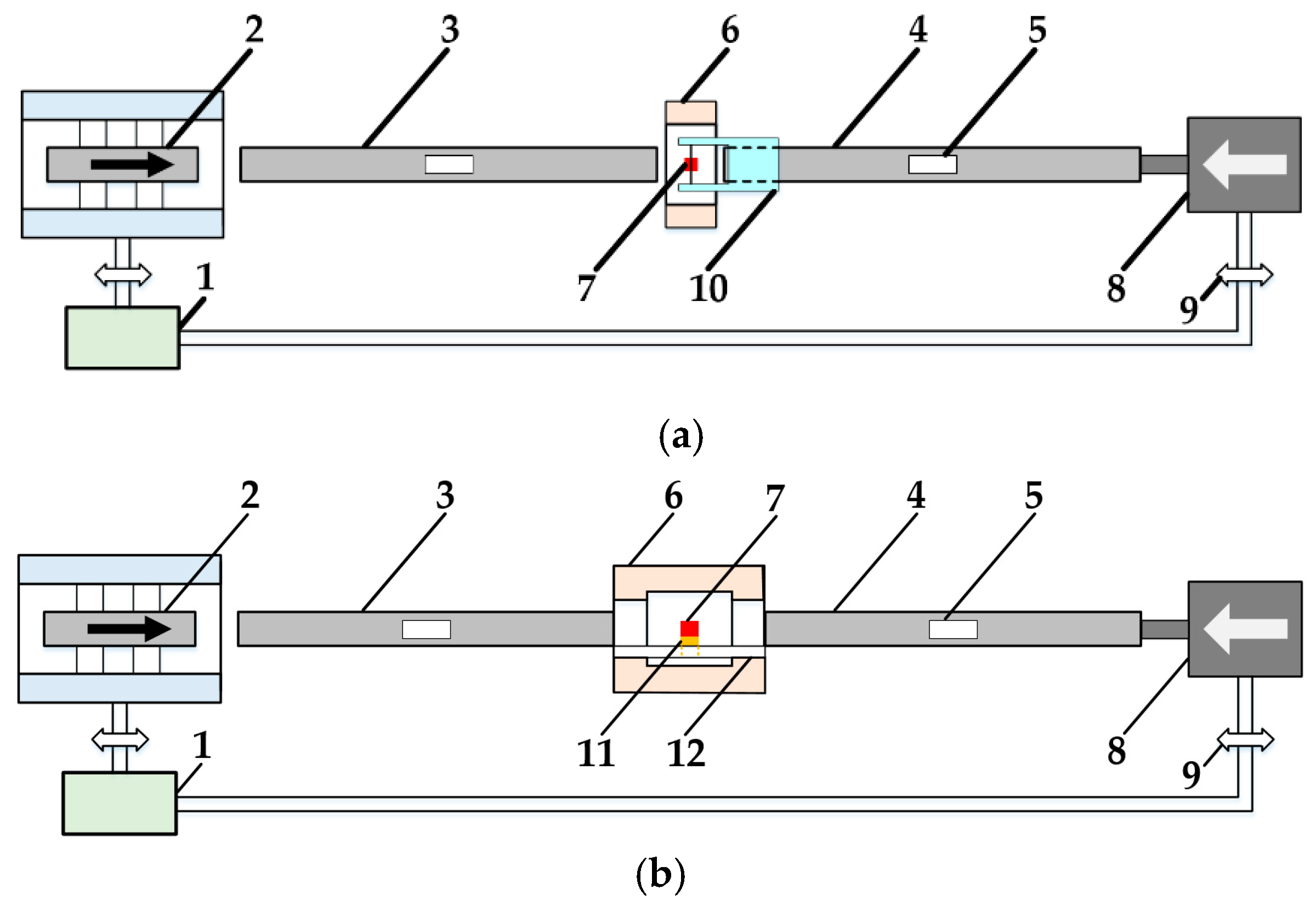

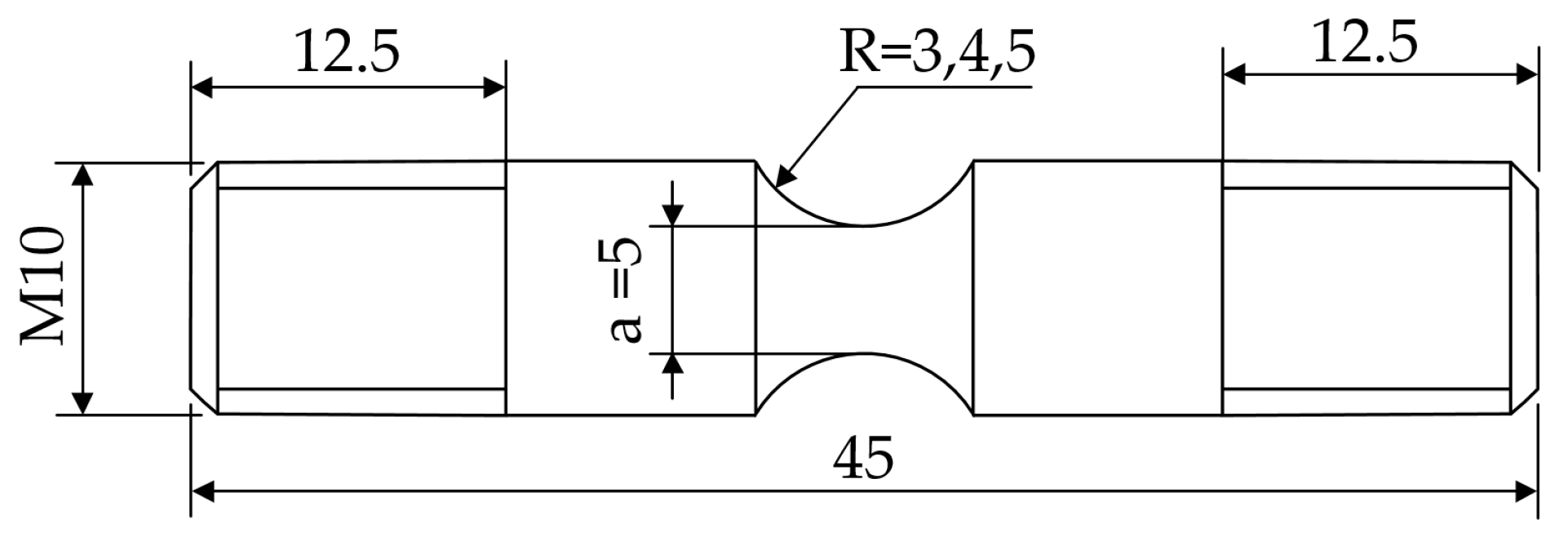

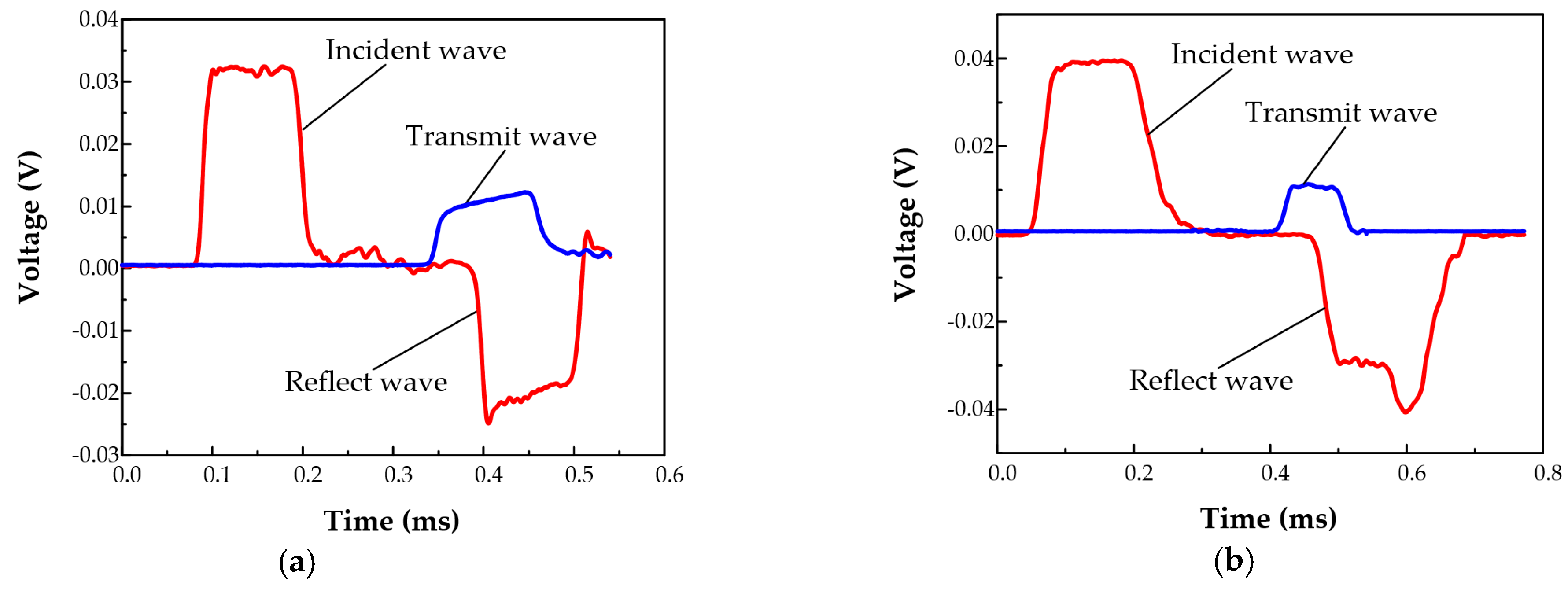

2.2. An Improved SHPB and SHTB Tests at High Temperature

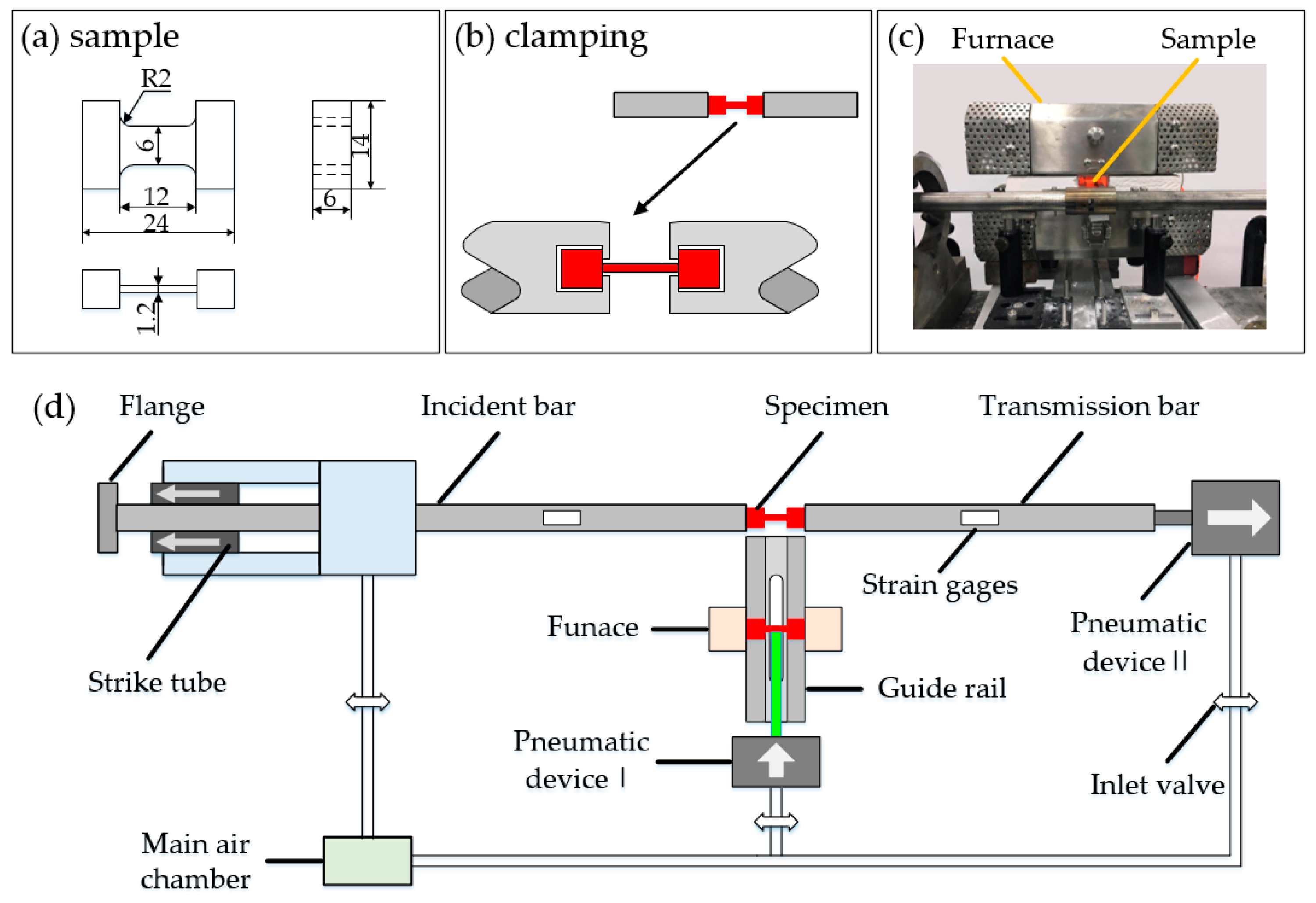

2.3. Quasi-Static Tensile Tests with Notched Sample

2.4. Test Scheme

3. Result and Analysis

3.1. Mechanical Behavior Analysis

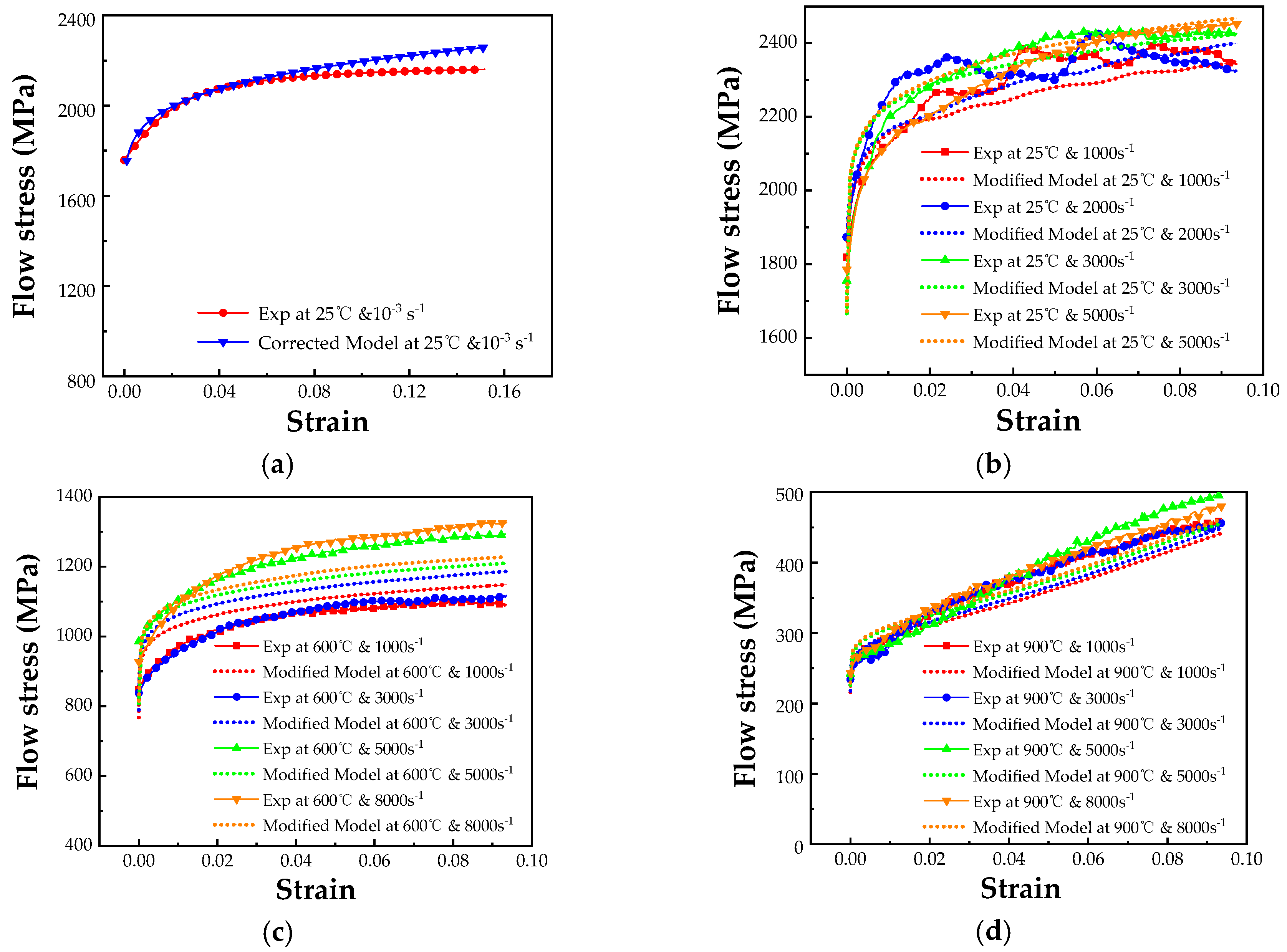

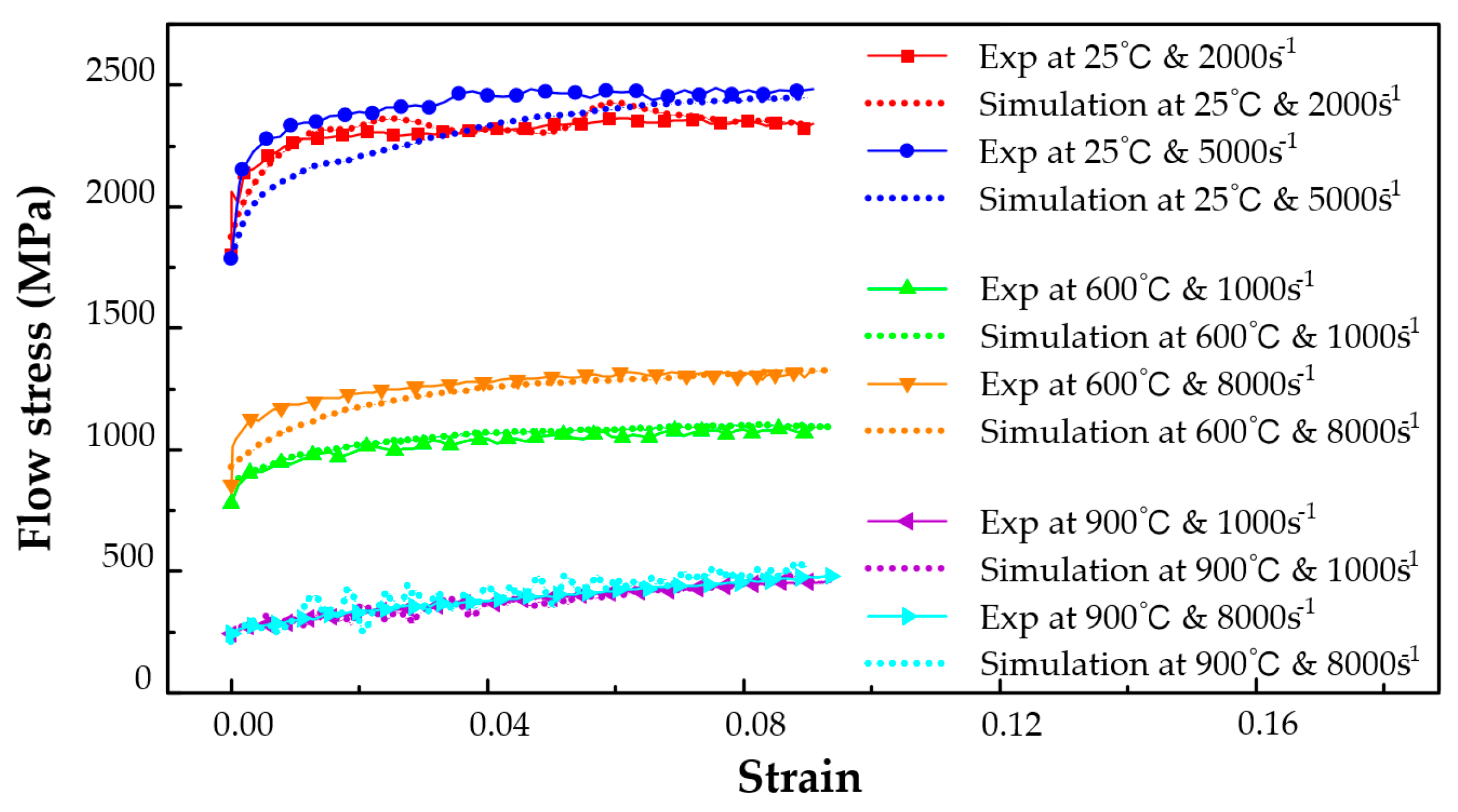

3.2. Plastic Constitutive Model Fitting

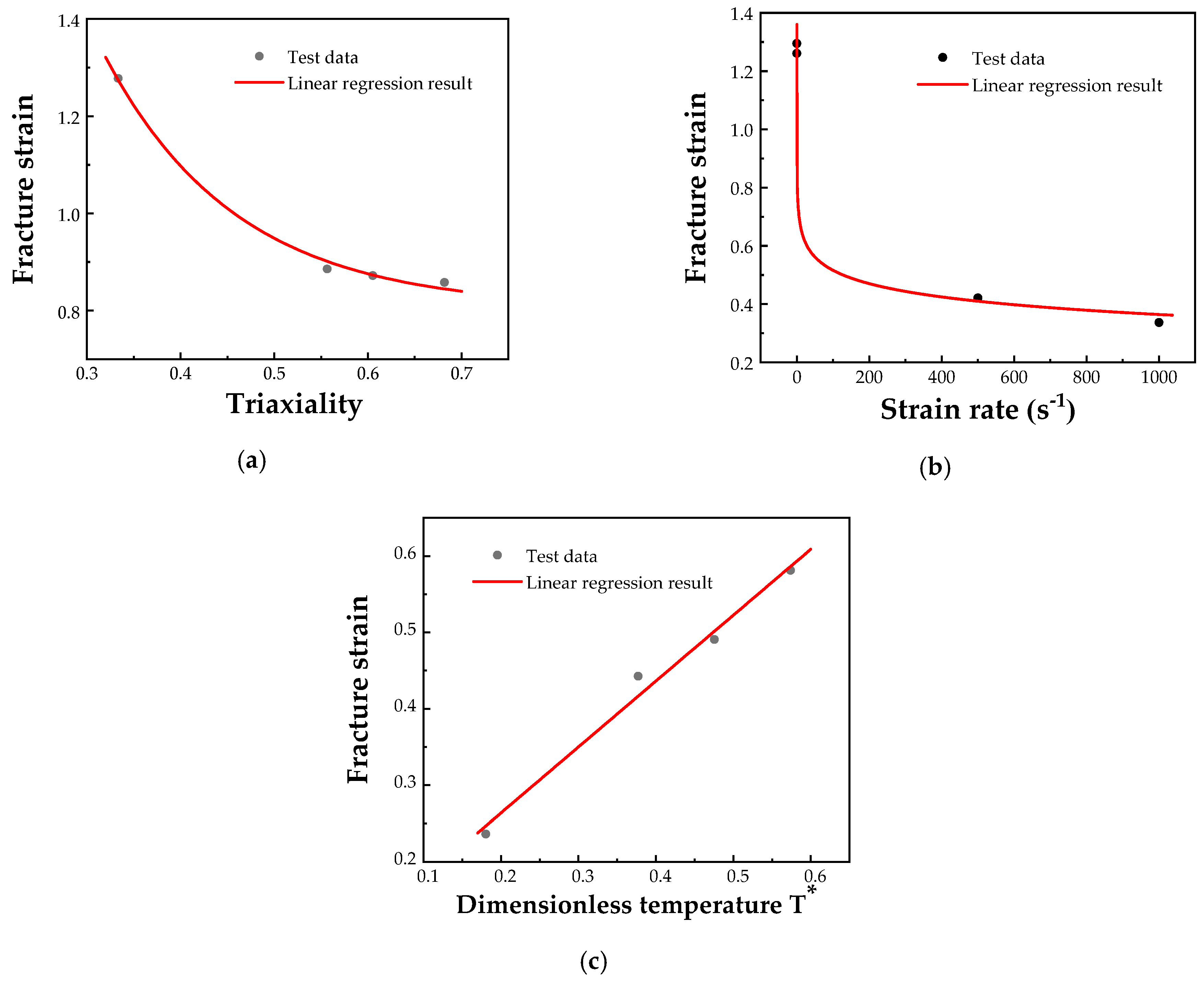

3.3. Johnson-Cook Damage Model Constants Fitting

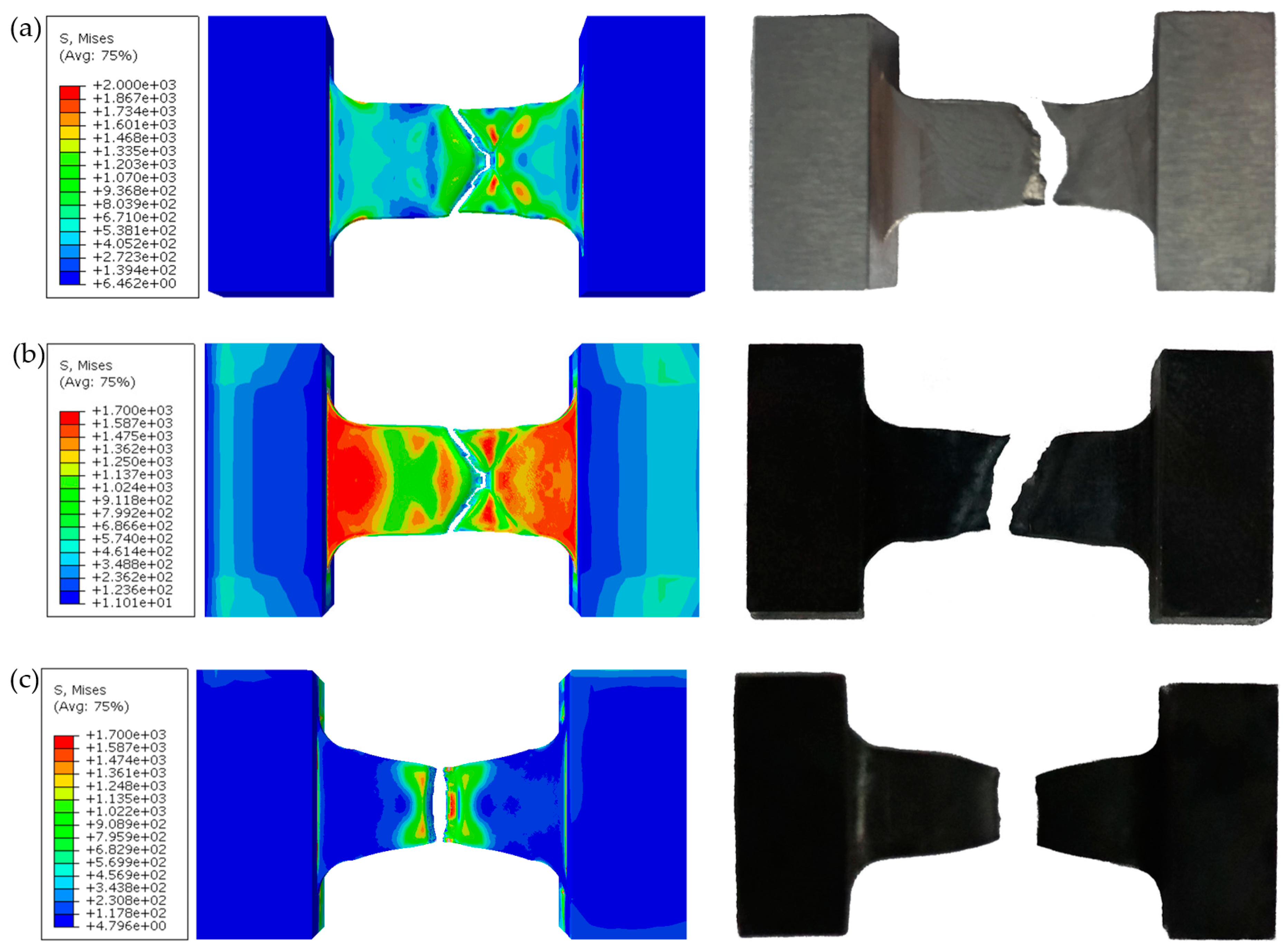

4. Finite Element Simulation Verification

5. Conclusions

- (1)

- According to the improved SHTB and SHPB tests, 45CrNiMoVA steel is characterized by obvious temperature softening effect, the yield strength and flow stress decreases significantly with increasing temperature. The obvious strain-rate hardening effect at 600 °C is considered to be related to the activated dislocations rephrase by temperature. And, the especially significant strain hardening effect at 900 °C is assumed to result from the phase transition from initial tempered martensite to austenite.

- (2)

- In order to describe the special temperature softening and strain-hardening effect at high temperature, a modified J-C model is established by incorporating a temperature-related term and a strain-temperature coupled term. Based on the multi-objective optimization fitting strategy, the model parameters are fitted with a fitting accuracy of 99.53% in R2. The constants of J-C damage model are fitted though a three-step fitting process based on the SHTB tests and quasi-static tensile tests with notched samples.

- (3)

- The stress-thermal coupled finite element simulations of SHPB and SHTB tests at different strain rates and temperature are conducted using ABAQUS. A user subroutine called VUHARD, based on the modified J-C constitutive model, is developed and incorporated into the simulations. The fracture morphology and flow stress-strain from the tests and the simulations are compared, and their good agreement means that the modified constitutive model and damage model constants are quite suitable for this material.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- List, G.; Sutter, G. Cutting temperature prediction in high speed machining by numerical modelling of chip formation and its dependence with crater wear. Int. J. Mach. Tools Manuf. 2012, 55, 1–9. [Google Scholar] [CrossRef]

- da Silva, R.B.; Machado, Á.R.; Ezugwu, E.O.; Bonney, J.; Sales, W.F. Tool life and wear mechanisms in high speed machining of Ti–6Al–4V alloy with PCD tools under various coolant pressures. J. Mater. Process. Technol. 2013, 213, 1459–1464. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Tounsi, N.; Vincenti, J.O.A.; Elbestawi, M.A. From the basic mechanics of orthogonal metal cutting toward the identification of the constitutive equation. Int. J. Mach. Tools Manuf. 2002, 42, 1373–1383. [Google Scholar] [CrossRef]

- Dabboussi, W.; Nemes, J.A. Modeling of ductile fracture using the dynamic punch test. Int. J. Mech. Sci. 2005, 47, 1282–1299. [Google Scholar] [CrossRef]

- Tan, J.Q.; Zhan, M.; Liu, S.; Huang, T.; Guo, J.; Yang, H. A modified Johnson–Cook model for tensile flow behaviors of 7050-T7451 aluminum alloy at high strain rates. Mat. Sci. Eng. A-Struct. 2015, 631, 214–219. [Google Scholar] [CrossRef]

- Zhang, D.N.; Shangguan, Q.Q.; Xie, C.J.; Liu, F. A modified Johnson–Cook model of dynamic tensile behaviors for 7075-T6 aluminum alloy. J. Alloy. Compd. 2015, 619, 186–194. [Google Scholar] [CrossRef]

- Zhou, T.F.; Wu, J.J.; Che, J.T.; Wang, Y.; Wang, X.B. Dynamic shear characteristics of titanium alloy Ti-6Al-4V at large strain rates by the Split-Hopkinson pressure bar test. Int. J. Impact Eng. 2017, 109, 167–177. [Google Scholar] [CrossRef]

- Xiang, J.F.; Xie, L.J.; Gao, F.N.; Zhang, Y.; Yi, J.; Wang, T. On multi-objective based plastic constitutive modelling methodology and numerical validation in small-hole drilling of Al6063/SiCp composites. Materials 2018, 11, 97. [Google Scholar] [CrossRef]

- Xiang, J.F.; Xie, L.J.; Gao, F.N.; Yi, J.; Pang, S.Q. Methodology for dependence-based integrated constitutive modelling: An illustrative application to SiCp/Al composites. Ceram. Int. 2018, 44, 11765–11777. [Google Scholar] [CrossRef]

- Brandon, D.G. The structure of high-angle grain boundaries. Acta Metall. Sin. 1966, 14, 1479–1484. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron. Steel Inst. 1953, 174, 25–28. [Google Scholar]

- He, Z.J.; Zhou, Z.X.; Huang, X.M. Study on the constitutive relation modeling technology of 45CrNiMoVA for high speed machining. Mater. Sci. Technol. 2016, 24, 33–39. [Google Scholar]

- Chiddister, J.L.; Malvern, L.E. Compression-impact testing of aluminum at elevated temperatures. Exp. Mech. 1963, 3, 81–90. [Google Scholar] [CrossRef]

- Gálvez, F.; Cendón, D.; Enfedaque, A.; Sánchez-Gálvez, V. High strain rate and high temperature behaviour of metallic materials for jet engine turbine containment. J. Phys. IV 2006, 134, 269–274. [Google Scholar] [CrossRef]

- Klepaczko, J.R.; Rusinek, A.; Rodríguez-Martínez, J.A.; Pęcherski, R.B.; Arias, A. Modelling of thermo-viscoplastic behaviour of DH-36 and Weldox 460-E structural steels at wide ranges of strain rates and temperatures, comparison of constitutive relations for impact problems. Mech. Mater. 2009, 41, 599–621. [Google Scholar] [CrossRef]

- Li, P.H.; Guo, W.G.; Yuan, K.B.; Su, Y.; Wang, J.J.; Lin, X. Effects of processing defects on the dynamic tensile mechanical behavior of laser-solid-formed Ti-6Al-4-V. Mater. Charact. 2018, 140, 15–29. [Google Scholar] [CrossRef]

- Hill, R. Studies in Large Plastic Flow and Fracture; Bridgman, P.W., Ed.; Mcgraw-Hill Book Company, Inc.: New York, NY, USA, 1952; p. 362. [Google Scholar]

- Yeddu, H.; Lookman, T.; Saxena, A. Reverse phase transformation of martensite to austenite in stainless steels: A 3D phase-field study. J. Mater. Sci. 2014, 49, 3642–3651. [Google Scholar] [CrossRef]

- Dryzek, E.; Sarnek, M. Reverse transformation of deformation induced martensite in austenitic stainless steel. J. Mater. Sci. 2014, 49, 8449–8458. [Google Scholar] [CrossRef]

- Morito, S.; Nishikawa, J.; Maki, T. Dislocation dnsity within lth mrtensite in Fe–C and Fe–Ni Alloys. ISIJ Int. 2003, 43, 1475–1477. [Google Scholar] [CrossRef]

- Garciamateo, C.; Caballero, F.G. Ultra-high-strength bainitic steels. ISIJ Int. 2005, 45, 1736–1740. [Google Scholar] [CrossRef]

- Trimble, D.; Shipley, H.; Lea, L.; Jardine, A.; O’Donnell, G.E. Constitutive analysis of biomedical grade Co-27Cr-5Mo alloy at high strain rates. Mater. Sci. Eng. A-Struct. 2017, 682, 466–474. [Google Scholar] [CrossRef]

- Gupta, N.K.; Iqbal, M.A.; Sekhon, G.S. Experimental and numerical studies on the behavior of thin aluminum plates subjected to impact by blunt- and hemispherical-nosed projectiles. Int. J. Impact Eng. 2006, 32, 1921–1944. [Google Scholar] [CrossRef]

| C | Cr | Ni | Mo | V | Si | Mn |

|---|---|---|---|---|---|---|

| 0.42–0.49 | 0.8–1.1 | 1.3–1.8 | 0.2–0.3 | 0.10–0.20 | 0.17–0.37 | 0.5–0.8 |

| Notation | Material Properties | Value |

|---|---|---|

| ρ | Density (kg/m3) | 7800 [13] |

| Tmelt | Melting point (°C) | 1550 |

| Troom | Room/reference temperature (°C) | 25 |

| E | Elastic modulus (GPa) | 212 |

| ν | Poisson’s ratio | 0.29 |

| Reference strain rate | 0.001 | |

| C | Specific heat (J/kg·K−1) | 460 [13] |

| α | Thermal expansion coefficient (10−6 K−1) | 11.7 [13] |

| к | Thermal conductivity (W/m·K−1) | 19 |

| Grain Diameter (μm) | Fraction (%) |

|---|---|

| 0–4 | 67.52 |

| 4–8 | 27.78 |

| 8–12 | 3.31 |

| >12 | 1.39 |

| Models | A | B | C | n | m | R2 |

|---|---|---|---|---|---|---|

| J-C model | 1404 | 1247 | 0.009101 | 0.1943 | 0.5724 | 96.67% |

| Modified J-C model | 1410 | 1124 | 0.008786 | 0.1954 | 0.5622 | 99.53% |

| Sample Numbers | A | B | C | D | E |

| Notch Radius (mm) | 3.0 | 4.0 | 5.0 | 0.0 | 0.0 |

| Initial Section Area A0 (mm2) | 19.6350 | 19.6350 | 19.6350 | 19.6350 | 19.6350 |

| Section Area after Fracture Af (mm2) | 8.3251 | 8.2091 | 8.0968 | 5.5641 | 5.3778 |

| Fracture Strain εf | 0.8580 | 0.8721 | 0.8858 | 1.2610 | 1.2950 |

| Triaxiality σ* | 0.6816 | 0.6053 | 0.5565 | 0.3333 | 0.3333 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Xie, L.; Gao, F.; Xiang, J. On the Development of Material Constitutive Model for 45CrNiMoVA Ultra-High-Strength Steel. Metals 2019, 9, 374. https://doi.org/10.3390/met9030374

Hu X, Xie L, Gao F, Xiang J. On the Development of Material Constitutive Model for 45CrNiMoVA Ultra-High-Strength Steel. Metals. 2019; 9(3):374. https://doi.org/10.3390/met9030374

Chicago/Turabian StyleHu, Xin, Lijing Xie, Feinong Gao, and Junfeng Xiang. 2019. "On the Development of Material Constitutive Model for 45CrNiMoVA Ultra-High-Strength Steel" Metals 9, no. 3: 374. https://doi.org/10.3390/met9030374

APA StyleHu, X., Xie, L., Gao, F., & Xiang, J. (2019). On the Development of Material Constitutive Model for 45CrNiMoVA Ultra-High-Strength Steel. Metals, 9(3), 374. https://doi.org/10.3390/met9030374