Effect of Cold Rolling on the Mechanical Properties and Formability of FSWed Sheets in AA5754-H114

Abstract

:1. Introduction

2. Material and Experimental Procedures

2.1. Material

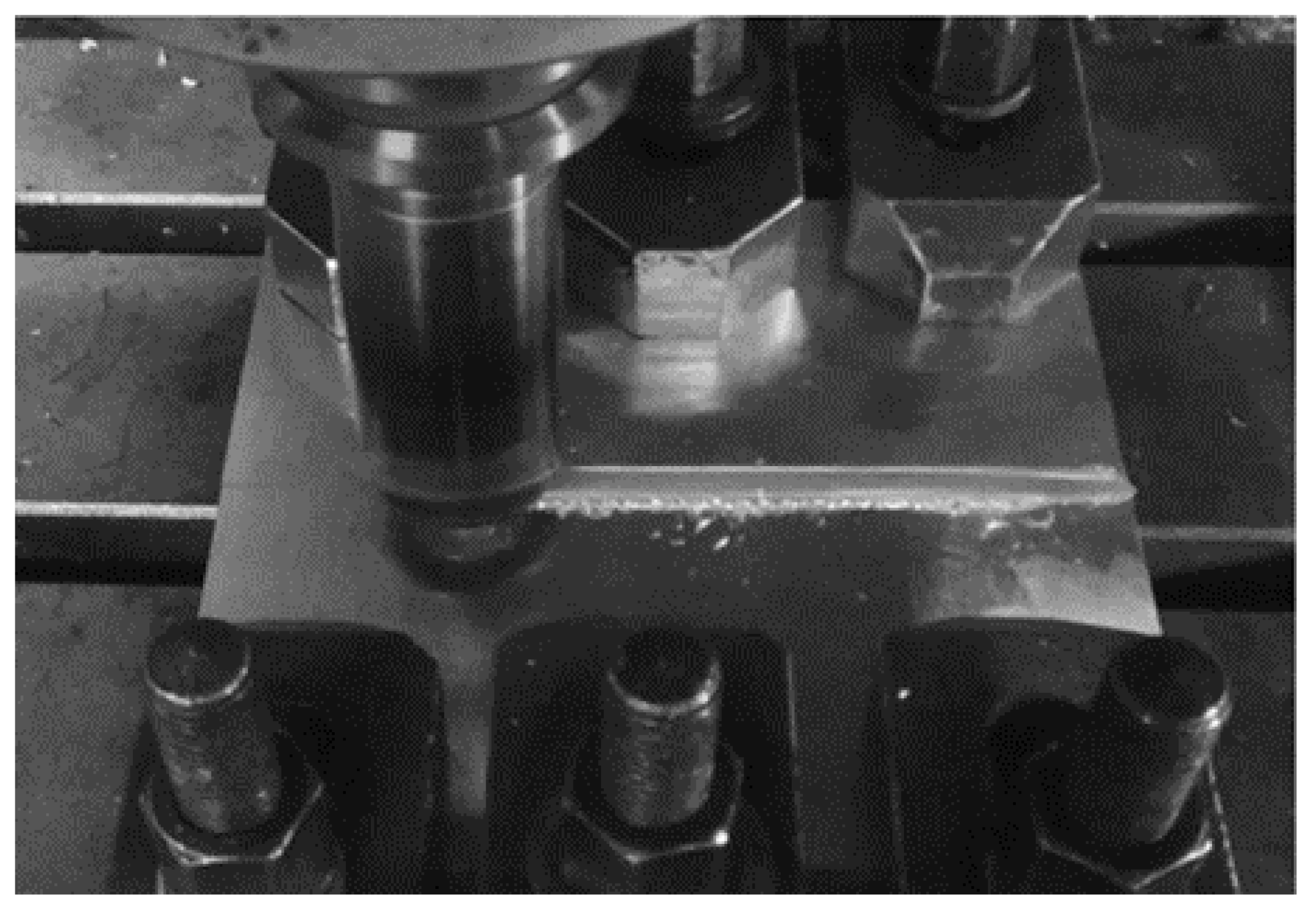

2.2. Friction Stir Welding

2.3. Cold Rolling

2.4. Uniaxial Tensile Tests

2.5. Formability Tests

2.6. Microstructural Analysis

3. Experimental Results

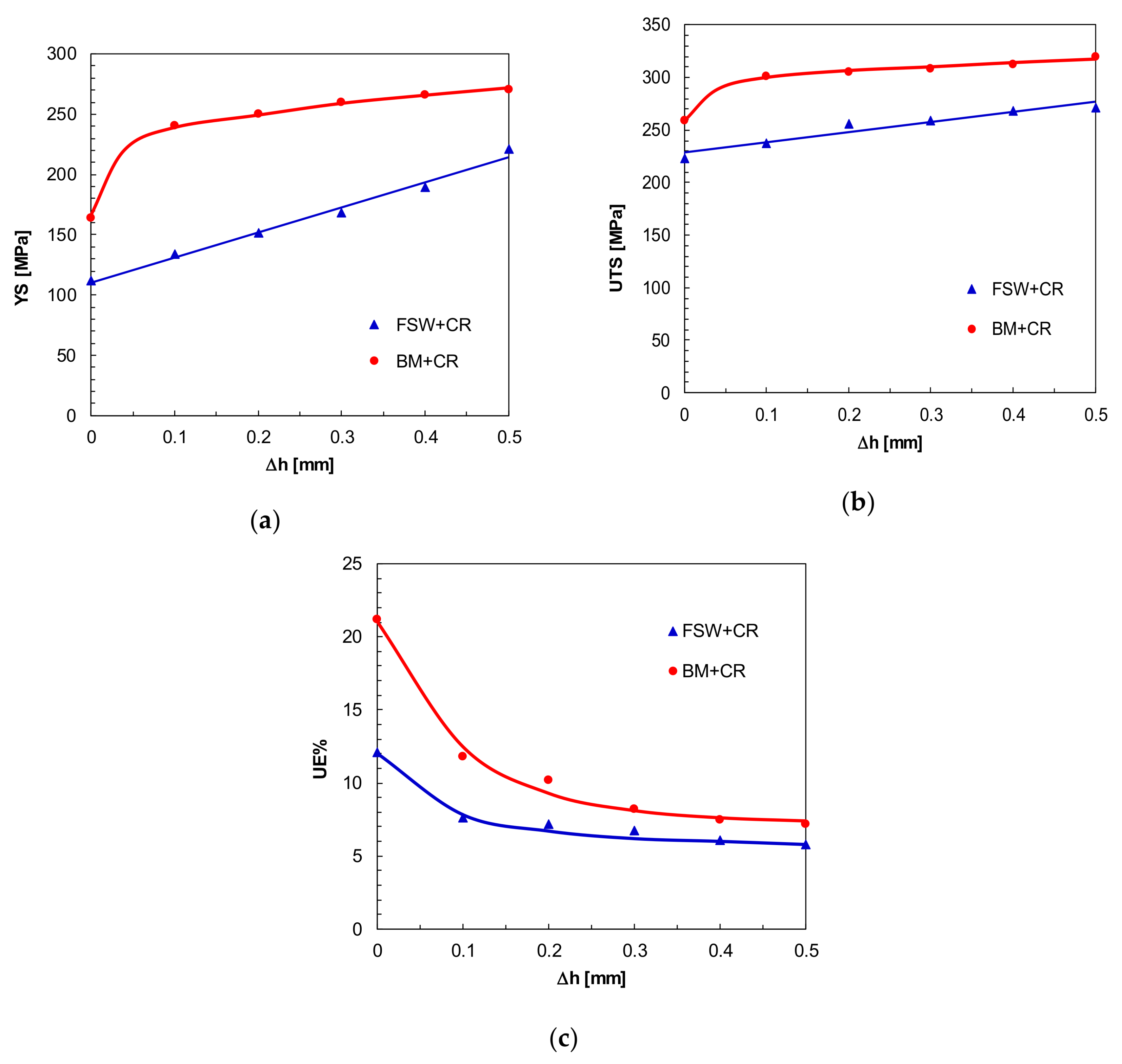

3.1. Effect of Cold Rolling on the Mechanical Properties of FSWed Workpieces

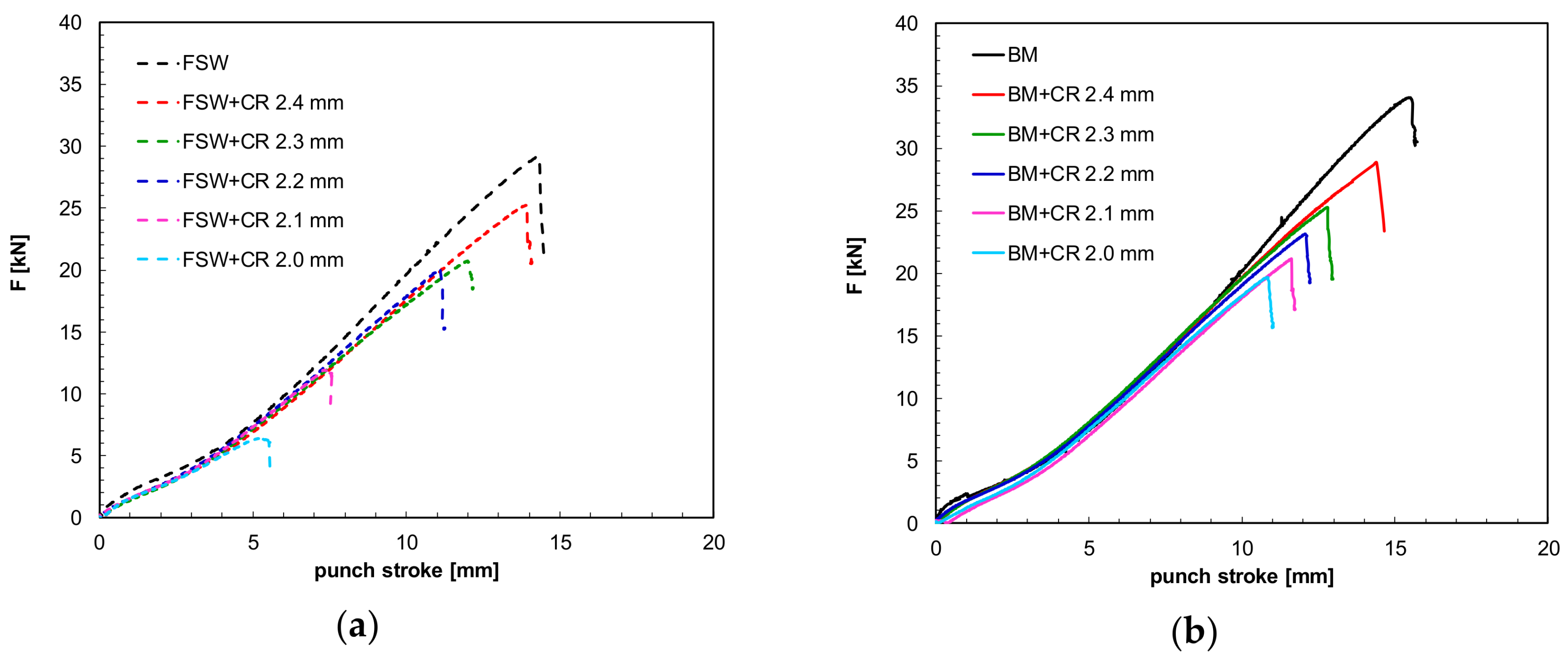

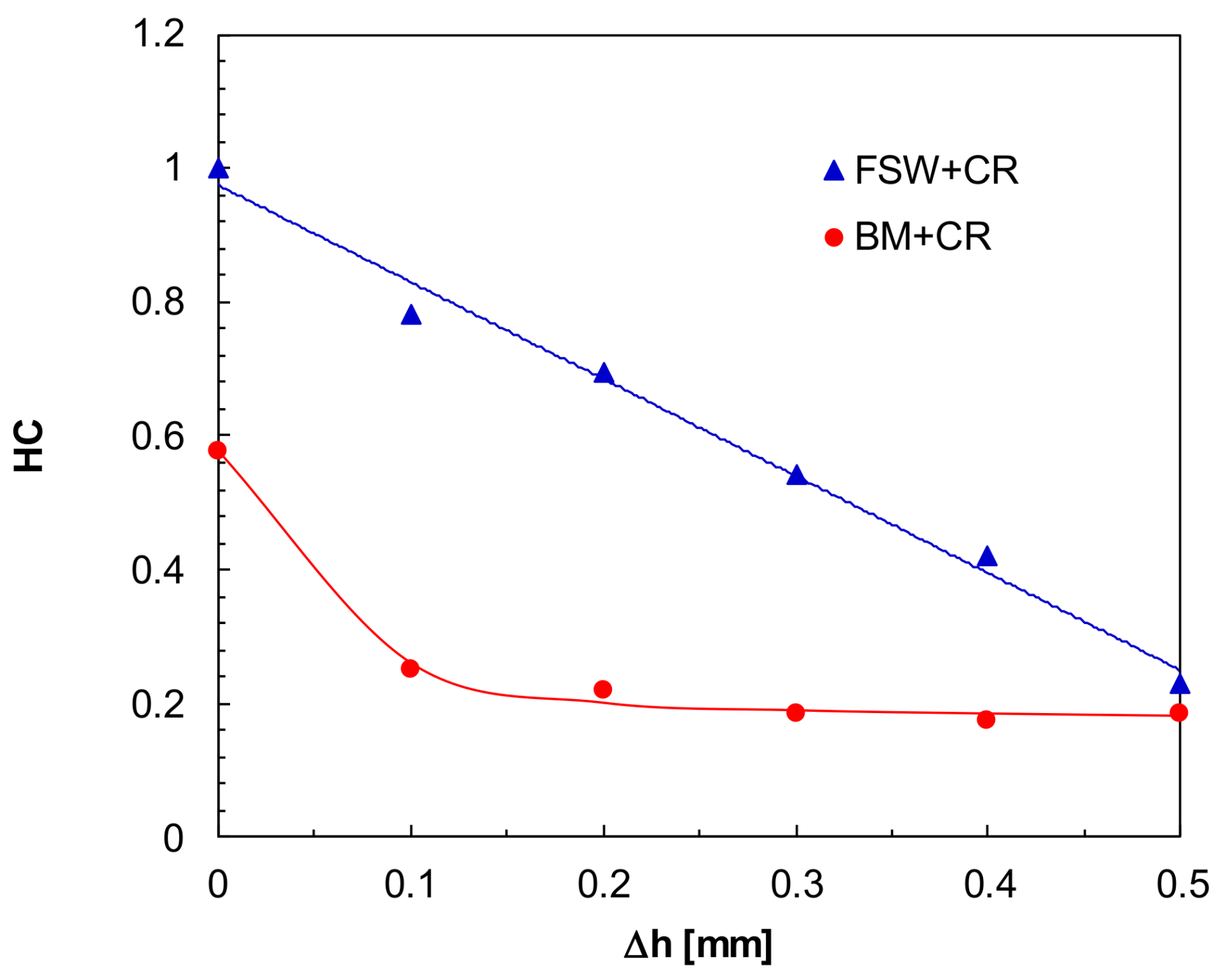

3.2. Effect of Cold Rolling on the Formability of FSWed Workpieces

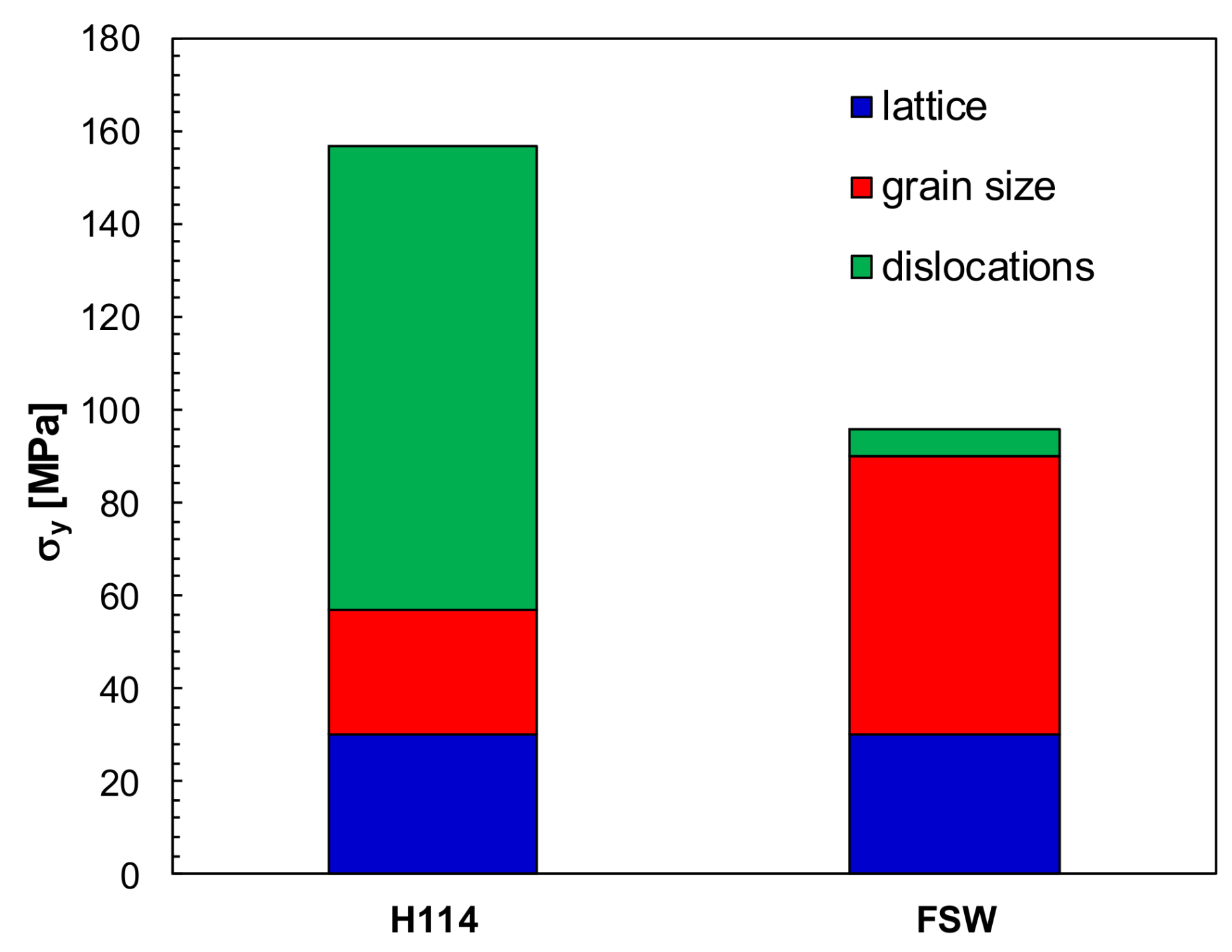

4. Discussion

5. Conclusions

- The yield strength and ultimate tensile strength in the FSWed+CRed condition are higher than those in the FSWed. Such discrepancy increases with the height reduction imposed by cold rolling. On the contrary, the ultimate elongation in the FSWed+CRed condition is lower than that in the FSWed, with a difference that grows with height reduction,

- The yield strength, ultimate tensile strength, and ultimate elongation in the FSWed+CRed condition are lower than those in BM+CRed one.

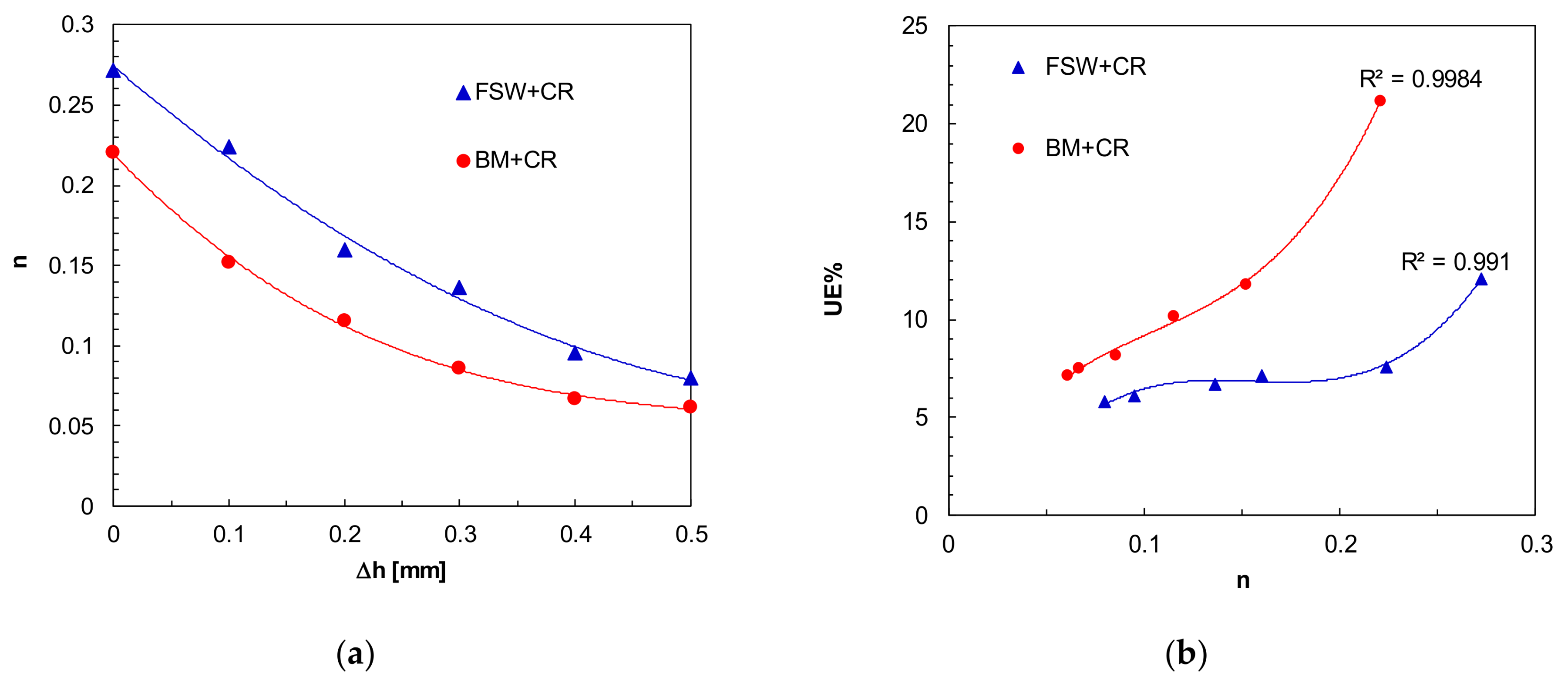

- The mechanical behaviour is strongly affected to by the strain hardening caused by cold rolling. In particular, the strain hardening exponent and hardening capacity decrease with increasing height reduction with the FSWed+CRed condition characterised.

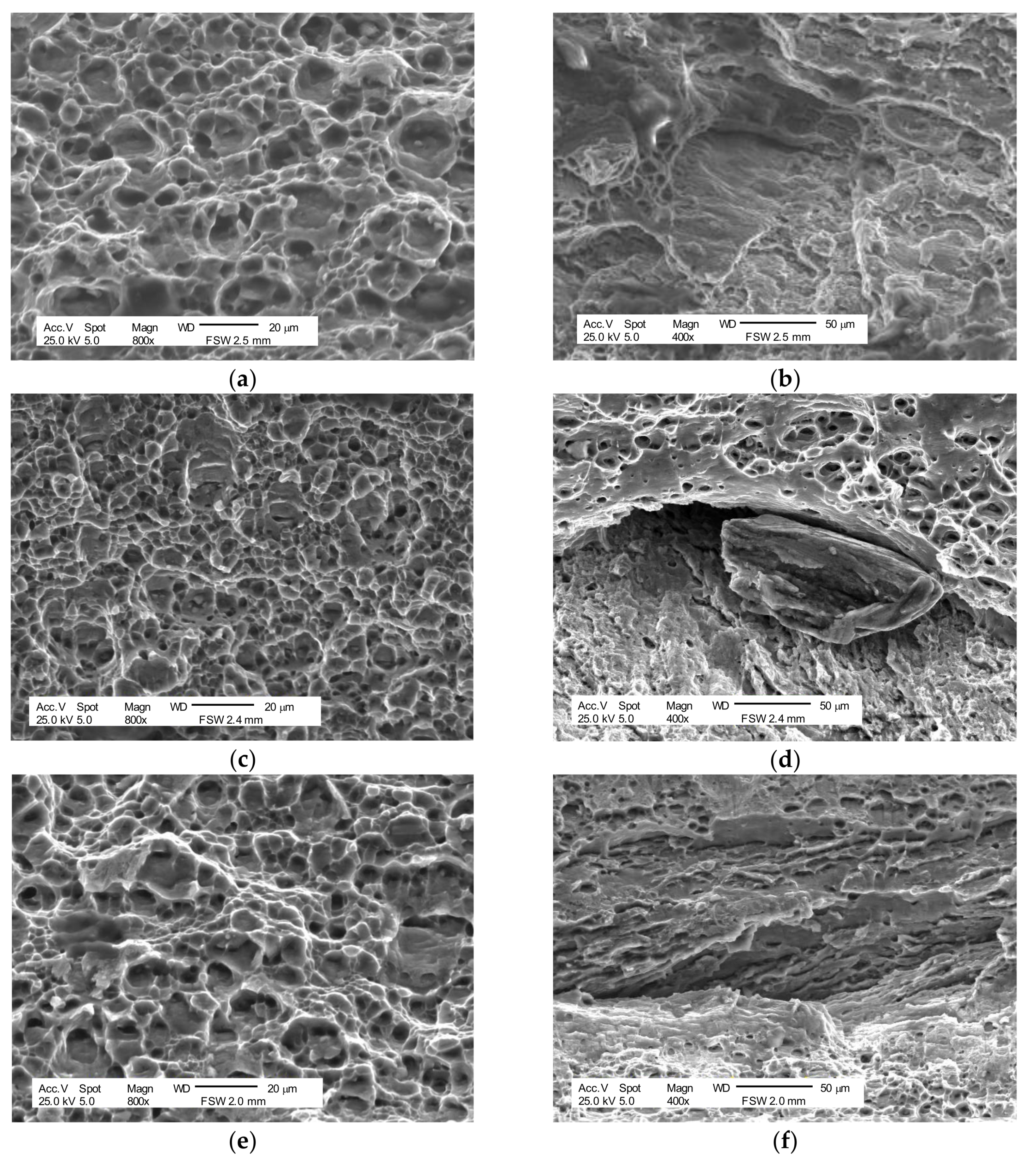

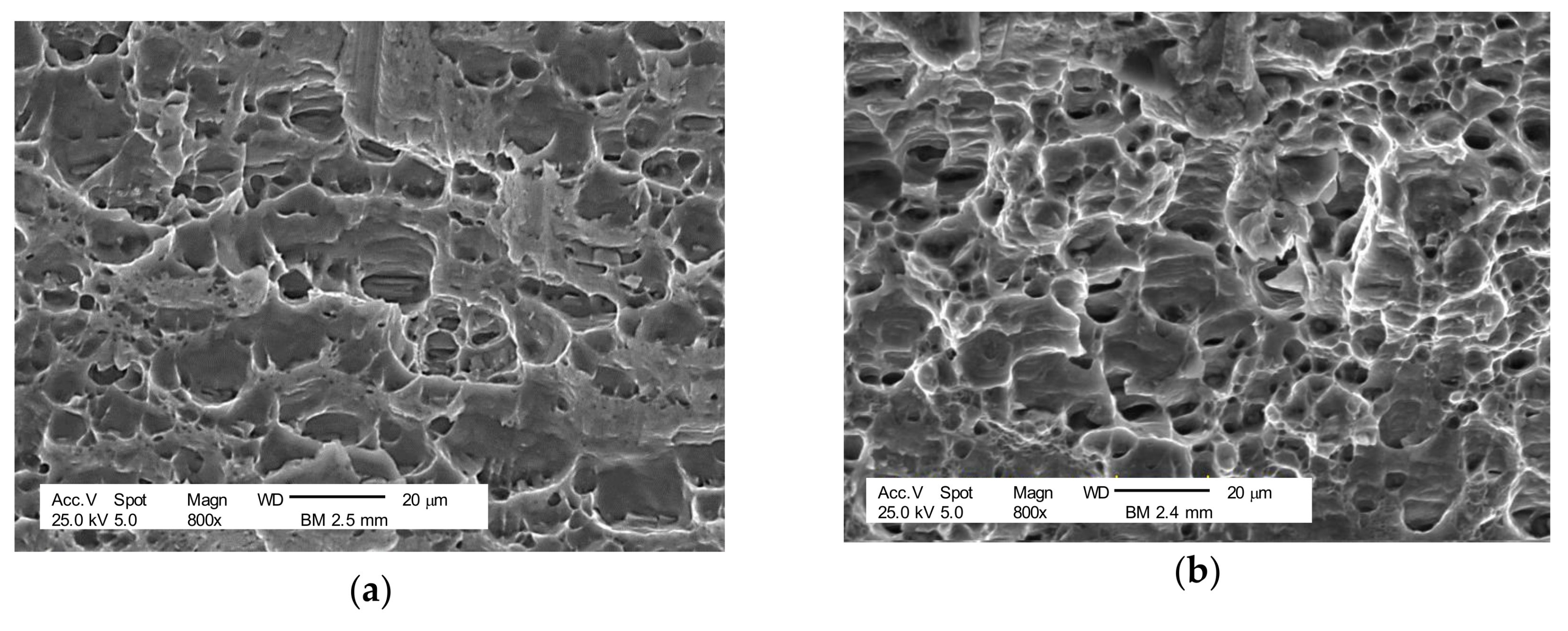

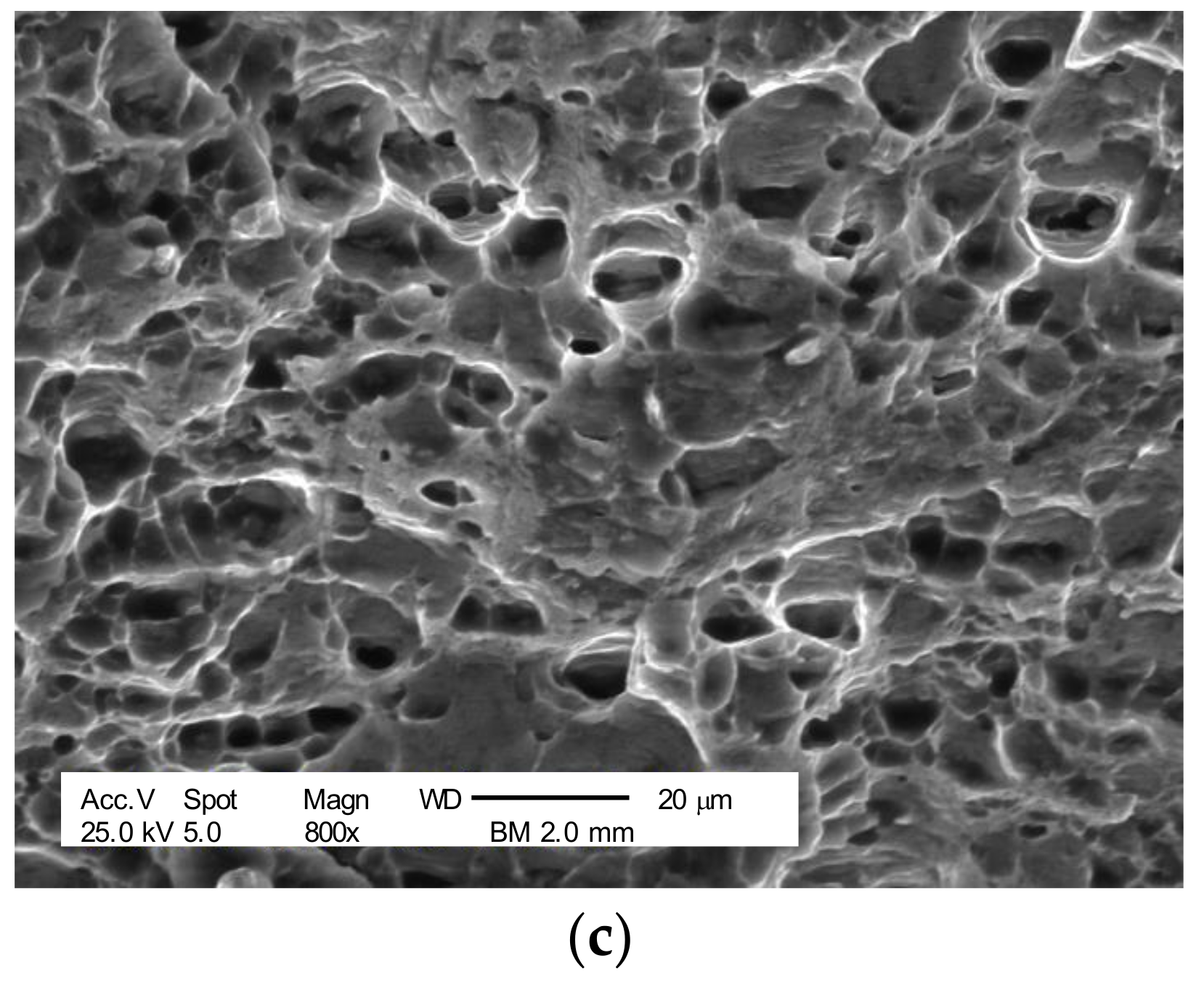

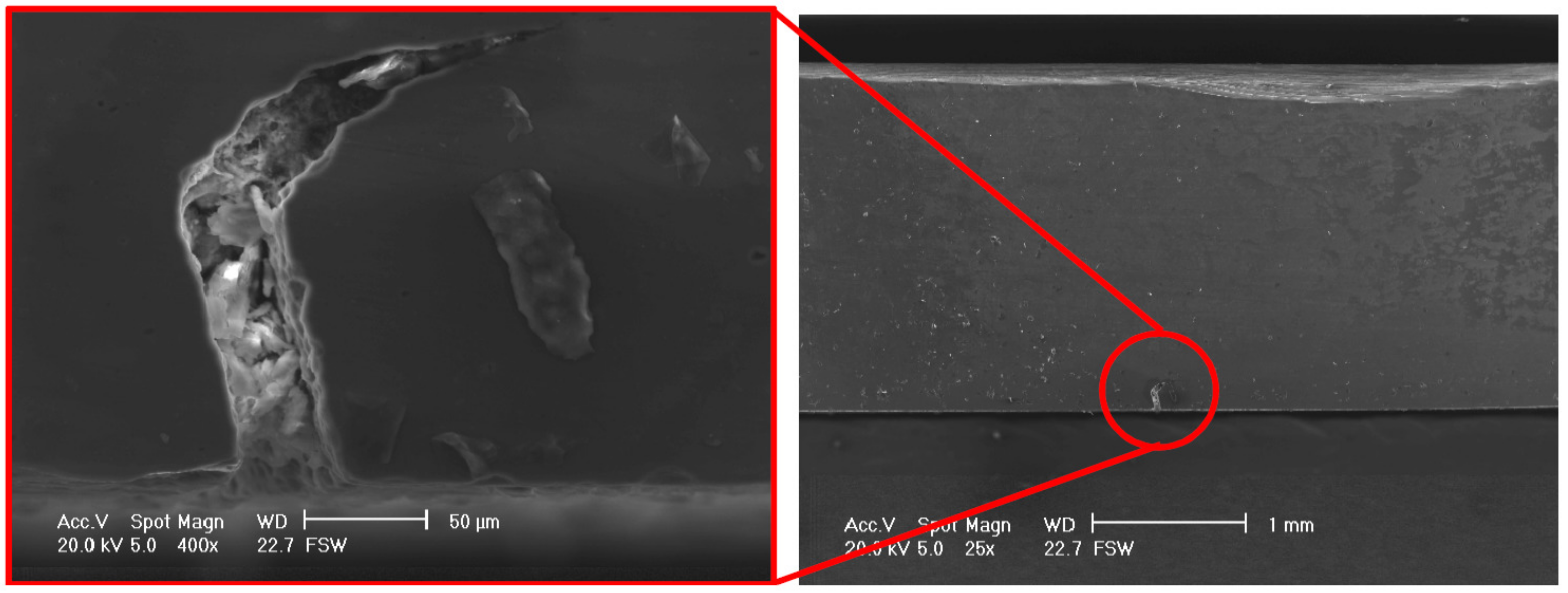

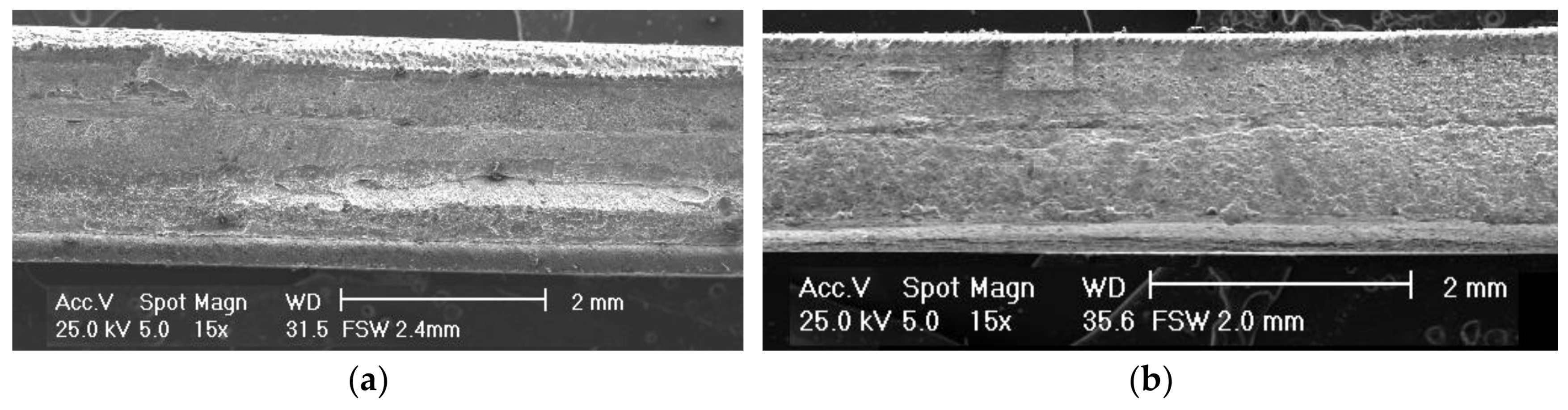

- The SEM images of FSWed+CRed samples show a ductile behaviour with the microvoid coalescence even though cracks propagating along the direction of welding motion appears. The BM+CRed samples exhibit a ductile fracture surface morphology.

- The limiting dome height decreases with increasing height reduction. In the FSWed+CRed condition the LDH values are slightly lower than those in the BM+CRed one until a height reduction of 0.2 mm; as Δh further increases, such discrepancy strongly grows.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Wonoh, L.; Kyung-Hwan, C.; Daeyong, K.; Junehyung, K.; Chongmin, K.; Kazutaka, O.; Wagoner, R.H.; Kwansoo, C. Experimental and numerical study on formability of friction stir welded TWB sheets based on hemispherical dome stretch tests. Int. J. Plast. 2009, 25, 1626–1654. [Google Scholar] [CrossRef]

- Padhy, G.K.; Wu, C.S.; Gao, S. Friction stir based welding and processing technologies—Processes, parameters, microstructures and applications: A review. J. Mater. Sci. Technol. 2018, 34, 1–38. [Google Scholar] [CrossRef]

- Mahdi Moradi, M.; Jamshidi Aval, H.; Jamaati, R.; Amirkhanlou, S.; Ji, S. Microstructure and texture evolution of friction stir welded dissimilar aluminum alloys: AA2024 and AA6061. J. Manuf. Process. 2018, 32, 1–10. [Google Scholar] [CrossRef]

- Contuzzi, N.; Campanelli, S.L.; Casalino, G.; Ludovico, A.D. On the role of the thermal contact conductance during the friction stir welding of an AA5754-H111 butt joint. Appl. Therm. Eng. 2016, 104, 263–273. [Google Scholar] [CrossRef]

- Forcellese, A.; Simoncini, M.; Casalino, G. Influence of process parameters on the vertical forces generated during friction stir welding of AA6082-T6 and on the mechanical properties of the joints. Metals 2017, 7, 350. [Google Scholar] [CrossRef]

- Bruni, C.; Forcellese, A.; Gabrielli, F.; Simoncini, M. Post-welding formability of AZ31 magnesium alloy. Mater. Des. 2011, 32, 2988–2991. [Google Scholar] [CrossRef]

- Forcellese, A.; Simoncini, M. Plastic flow behaviour and formability of FSWed joints in AZ31 thin sheets obtained using the “pinless” tool configuration. Mater. Des. 2012, 36, 123–129. [Google Scholar] [CrossRef]

- Simoncini, M.; Forcellese, A. Effect of the welding parameters and tool configuration on micro- and macro-mechanical properties of similar and dissimilar FSWed joints in AA5754 and AZ31 thin sheets. Mater. Des. 2012, 41, 50–60. [Google Scholar] [CrossRef]

- Kleiner, M.; Geiger, M.; Klaus, A. Manufacturing of lightweight components by metal forming. CIRP Ann. 2003, 52, 521–542. [Google Scholar] [CrossRef]

- Fratini, L.; Buffa, G.; Shivpuri, R. Improving friction stir welding of blanks of different thicknesses. Mater. Sci. Eng. A 2007, 459, 209–215. [Google Scholar] [CrossRef]

- Simoncini, M.; Ciccarelli, D.; Forcellese, A.; Pieralisi, M. Micro- and macro- mechanical properties of pinless friction stir welded joints in AA5754 aluminium thin sheets. Procedia CIRP 2014, 18, 9–14. [Google Scholar] [CrossRef]

- Lertora, E.; Gambaro, C.; Mandolfino, C.; Pedemonte, M. Friction stir welding between extrusions and laminates. Weld. Int. 2015, 29, 117–123. [Google Scholar] [CrossRef]

- Fratini, L.; Buffa, G.; Shivpuri, R. Finite element studies on friction stir welding processes of tailored blanks. Comput. Struct. 2008, 86, 181–189. [Google Scholar] [CrossRef]

- Guerra, M.; Schmidt, C.; McClure, J.C.; Murr, L.E.; Nunes, A.C. Flow patterns during friction stir welding. Mater. Charact. 2003, 49, 95–101. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.; Mortello, M. Influence of shoulder geometry and coating of the tool on the friction stir welding of aluminium alloy plates. Procedia Eng. 2014, 69, 1541–1548. [Google Scholar] [CrossRef]

- Hirata, T.; Oguri, T.; Hagino, H.; Tanaka, T.; Wook Chung, S.; Takigawa, Y.; Higashi, K. Influence of friction stir welding parameters on grain size and formability in 5083 aluminum alloy. Mater. Sci. Eng. A 2007, 456, 344–349. [Google Scholar] [CrossRef]

- Cabibbo, M.; Forcellese, A.; Simoncini, M. New approaches to the friction stir welding of aluminum alloys. In Joining Technologies; Mahadzir, Ishak, Ed.; InTech: Rijeka, Croatia, 2016; pp. 7–26. [Google Scholar]

- Lertora, E.; Mandolfino, C.; Gambaro, C. Effect of welding parameters on AA8090 Al-Li alloy FSW T-joints. Key Eng. Mater. 2013, 554–557, 985–995. [Google Scholar] [CrossRef]

- Rodrigues, D.M.; Loureiro, A.; Leitao, C.; Leal, R.M.; Chaparro, B.M.; Vilaça, P. Influence of friction stir welding parameters on the microstructural and mechanical properties of AA 6016-T4 thin welds. Mater. Des. 2009, 30, 1913–1921. [Google Scholar] [CrossRef]

- Forcellese, A.; Fratini, L.; Gabrielli, F.; Simoncini, M. Formability of friction stir welded AZ31 magnesium alloy sheets. Mater. Sci. Forum 2010, 638–642, 1249–1254. [Google Scholar] [CrossRef]

- Simoncini, M.; Cabibbo, M.; Forcellese, A. Development of double-side friction stir welding to improve post-welding formability of joints in AA6082 aluminium alloy. Proc. IMechE B: J. Eng. Manuf. 2016, 230, 807–817. [Google Scholar] [CrossRef]

- Gabrielli, F.; Forcellese, A.; El Mehtedi, M.; Simoncini, M. Mechanical properties and formability of cold rolled friction stir welded sheets in AA5754 for automotive applications. Procedia Eng. 2017, 183, 245–250. [Google Scholar] [CrossRef]

- Ciarapica, F.; D’Orazio, A.; Forcellese, A.; Simoncini, M. Sustainability analysis of friction stir welding of AA5754 sheets. Procedia CIRP 2017, 62, 529–534. [Google Scholar] [CrossRef]

- Liu, H.J.; Fujii, H.; Maeda, M.; Nogi, K. Tensile properties and fracture locations of friction-stir-welded joints of 2017-T351 aluminum alloy. J. Mater. Process. Technol. 2003, 142, 692–696. [Google Scholar] [CrossRef]

- Spigarelli, S.; Paoletti, C. A unified physical model for creep and hot working of Al-Mg solid solution alloys. Metals 2018, 8, 9. [Google Scholar] [CrossRef]

- Armstrong, R.W.; Douthwaite, R.M. Hall-Petch basis for assessing alloy strengthening. In Grain Size and Mechanical Properties—Fundamentals and Applications; Otooni, M.A., Armstrong, R.W., Grant, N.J., Ishizaki, K., Eds.; Materials Research Society: Pittsburgh, PA, USA, 1995; pp. 41–47. [Google Scholar]

- Wang, S.C.; Zhu, Z.; Starink, M.J. Estimation of dislocation densities in cold rolled Al-Mg-Cu-Mn alloys by combination of yield strength data, EBSD and strength models. J. Microsc. 2005, 217, 174–178. [Google Scholar] [CrossRef] [PubMed]

- Afrin, N.; Chen, D.L.; Cao, X.; Jahazi, M. Strain hardening behavior of a friction stir welded magnesium alloy. Scr. Mater. 2007, 57, 1004–1007. [Google Scholar] [CrossRef]

- Ni, D.R.; Chen, D.L.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Tensile properties and strain-hardening behavior of friction stir welded SiCp/AA2009 composite joints. Mater. Sci. Eng. A 2014, 608, 1–10. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding—Process, weldment structure and properties. Progress Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Budai, D.; Tisza, M.; Zoltán Kovács, P. Investigation of the formability of EN AW 5754 aluminium alloy sheets with different thickness. In International Multidisciplinary Scientific Conference; University of Miskolc: Miskolc, Hungary, 2016; ISBN 978-963-358-113-1. [Google Scholar]

- Simoncini, M.; Panaccio, L.; Forcellese, A. Bending and stamping processes of FSWed thin sheets in AA1050 alloy. Key Eng. Mater. 2014, 622–623, 459–466. [Google Scholar] [CrossRef]

| Zn | Cu | Mn | Si | Fe | Mg | Cr | Ti | Ni | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.1 | 0.5 | 0.4 | 0.4 | 2.6–3.6 | 0.3 | 0.15 | - | Bal. |

| Feature | Value |

|---|---|

| Shoulder diameter [mm] | 15 |

| Cone base diameter [mm] | 3.9 |

| Pin height [mm] | 2.3 |

| Pin angle [°] | 30 |

| Parameter | Value |

|---|---|

| Rotational speed [rpm] | 1200 |

| Welding speed [mm/min] | 100 |

| Tool sinking [mm] | 0.08 |

| Plunging angle [°] | 2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casalino, G.; El Mehtedi, M.; Forcellese, A.; Simoncini, M. Effect of Cold Rolling on the Mechanical Properties and Formability of FSWed Sheets in AA5754-H114. Metals 2018, 8, 223. https://doi.org/10.3390/met8040223

Casalino G, El Mehtedi M, Forcellese A, Simoncini M. Effect of Cold Rolling on the Mechanical Properties and Formability of FSWed Sheets in AA5754-H114. Metals. 2018; 8(4):223. https://doi.org/10.3390/met8040223

Chicago/Turabian StyleCasalino, Giuseppe, Mohamad El Mehtedi, Archimede Forcellese, and Michela Simoncini. 2018. "Effect of Cold Rolling on the Mechanical Properties and Formability of FSWed Sheets in AA5754-H114" Metals 8, no. 4: 223. https://doi.org/10.3390/met8040223

APA StyleCasalino, G., El Mehtedi, M., Forcellese, A., & Simoncini, M. (2018). Effect of Cold Rolling on the Mechanical Properties and Formability of FSWed Sheets in AA5754-H114. Metals, 8(4), 223. https://doi.org/10.3390/met8040223