Tribological Behavior of Nano-Sized SiCp/7075 Composite Parts Formed by Semisolid Processing

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of the Rheoformed and Thixoformed Nanocomposite Parts

2.2. Dry Sliding Wear Tests of the Rheoformed and Thixoformed Parts

3. Results and Discussion

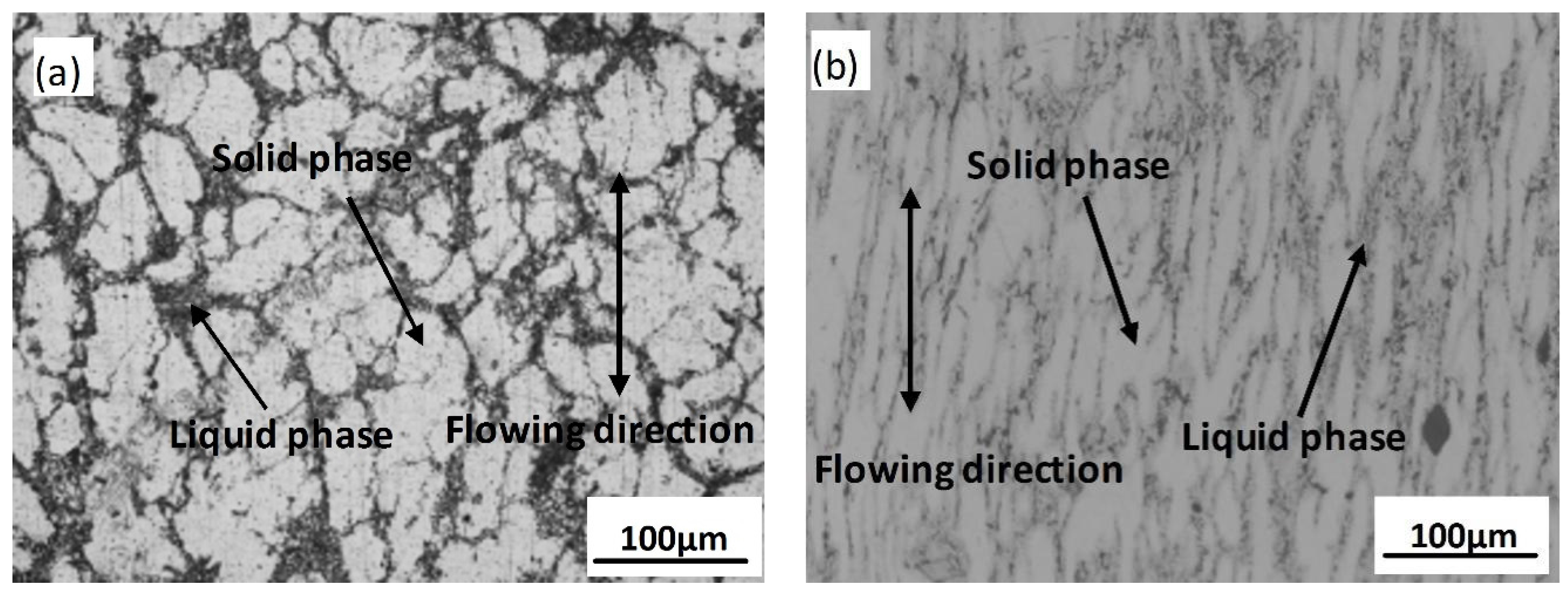

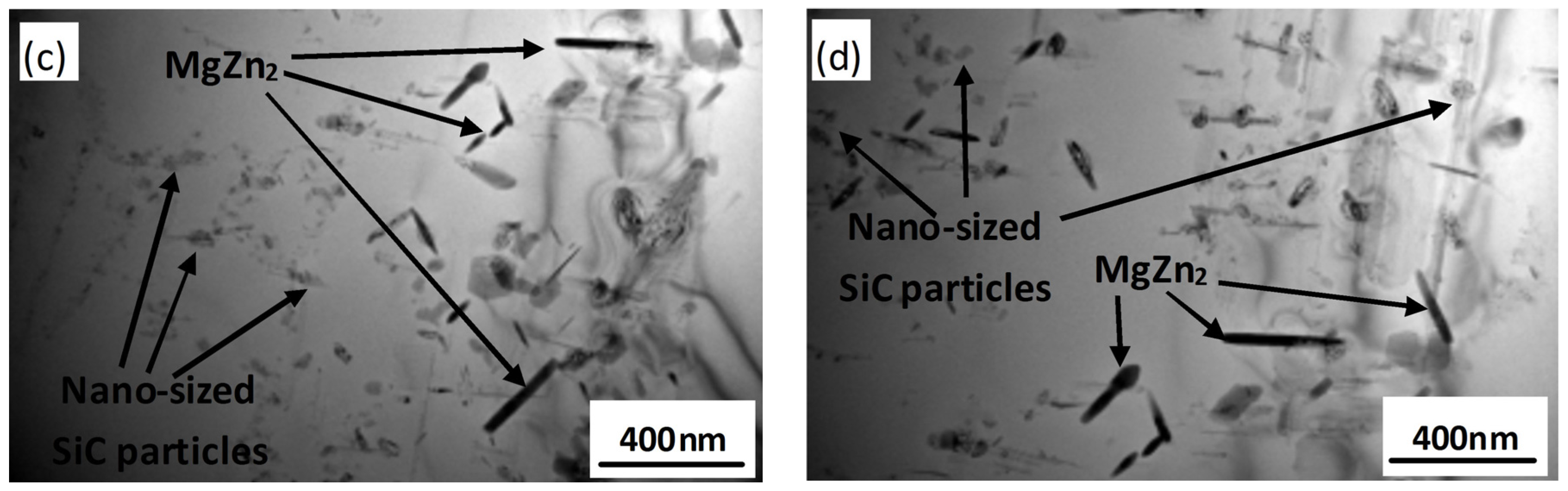

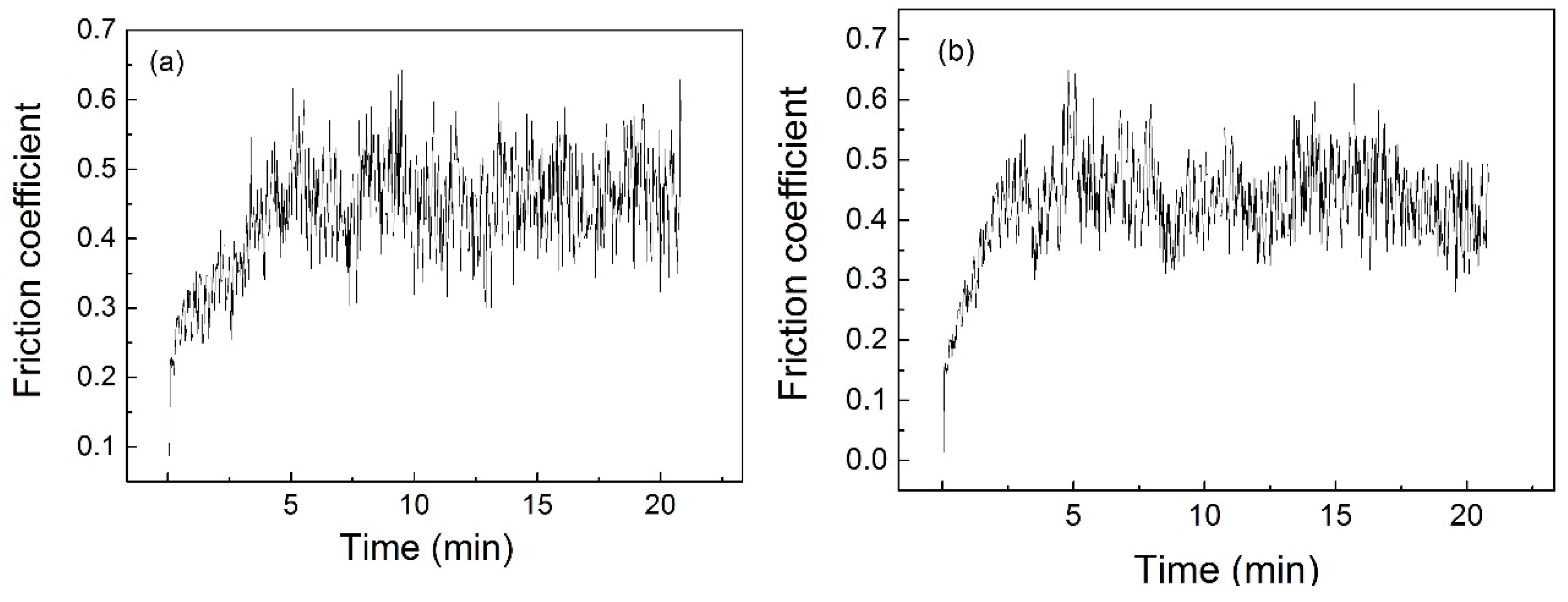

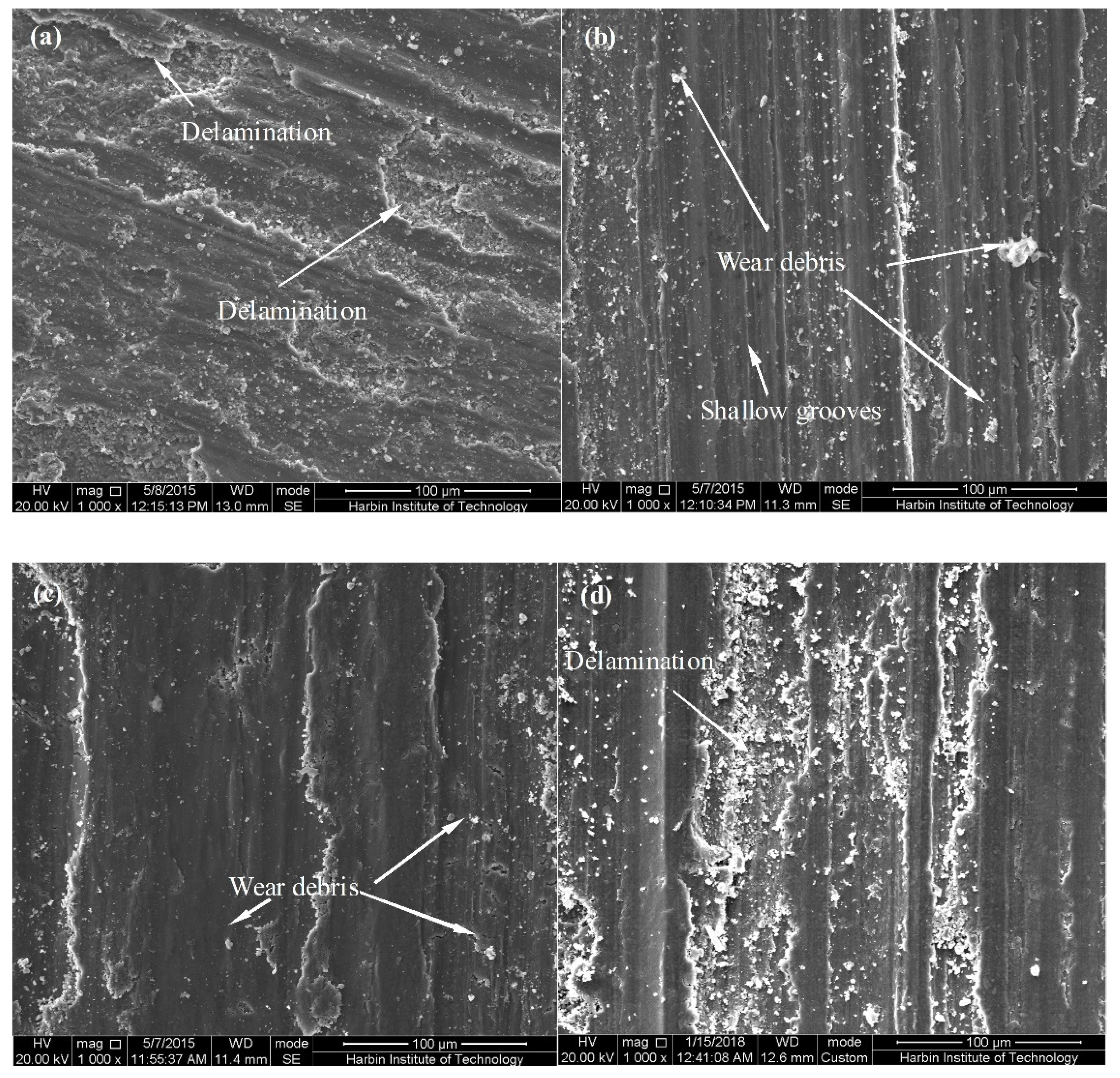

3.1. Influence of Semisolid Stirring Temperature on Tribological Behavior of Rheoformed Composite Parts

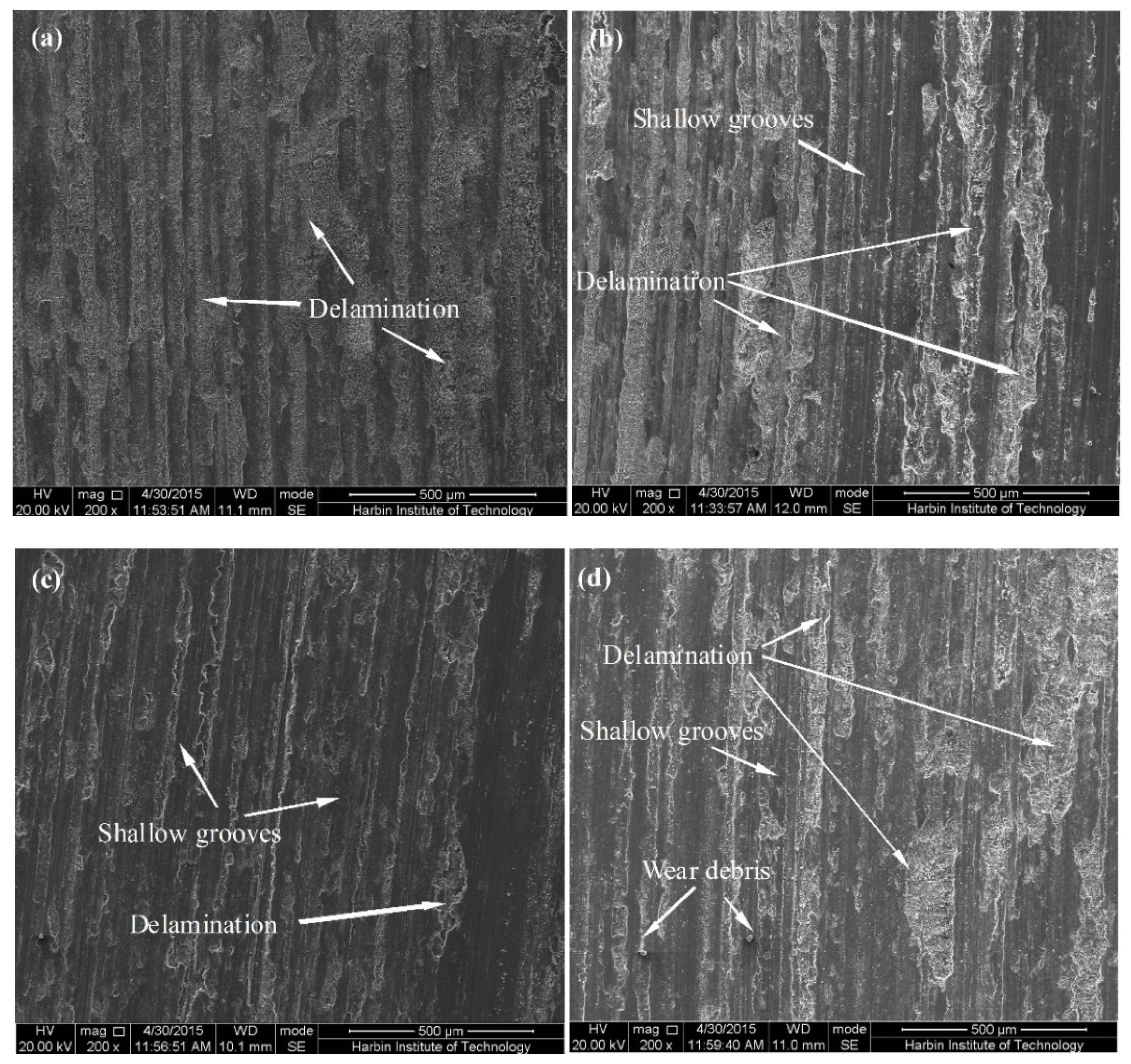

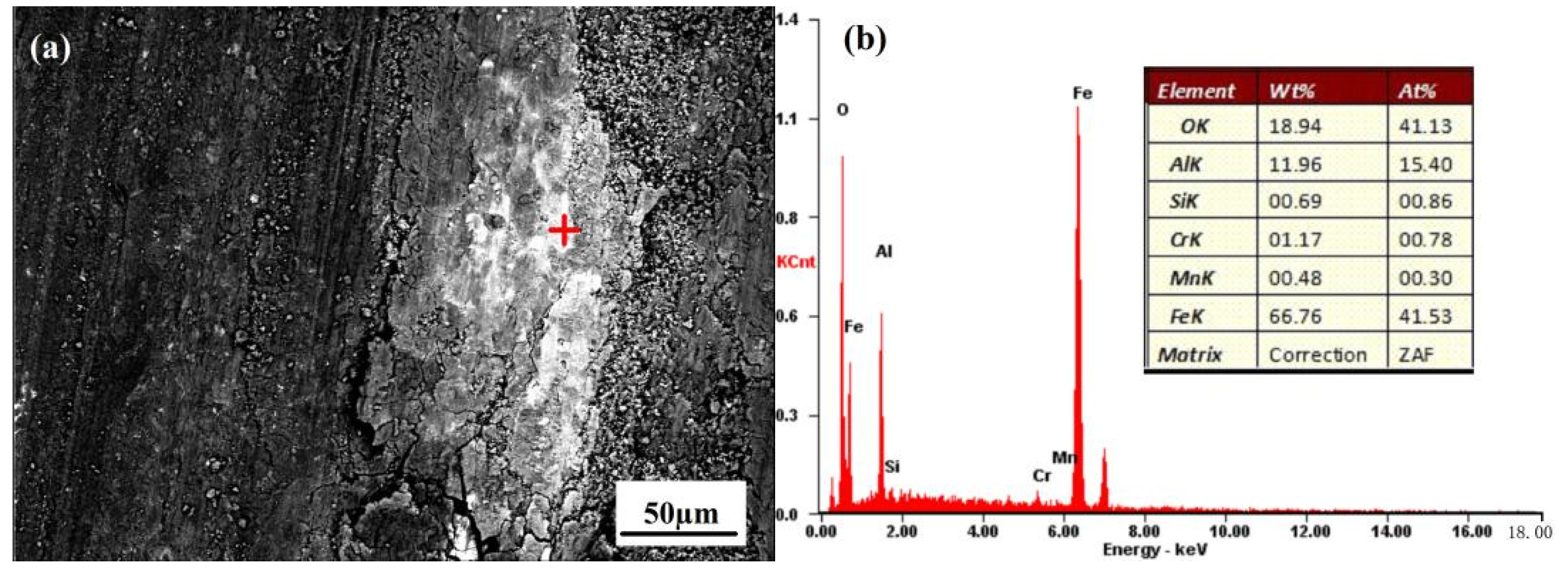

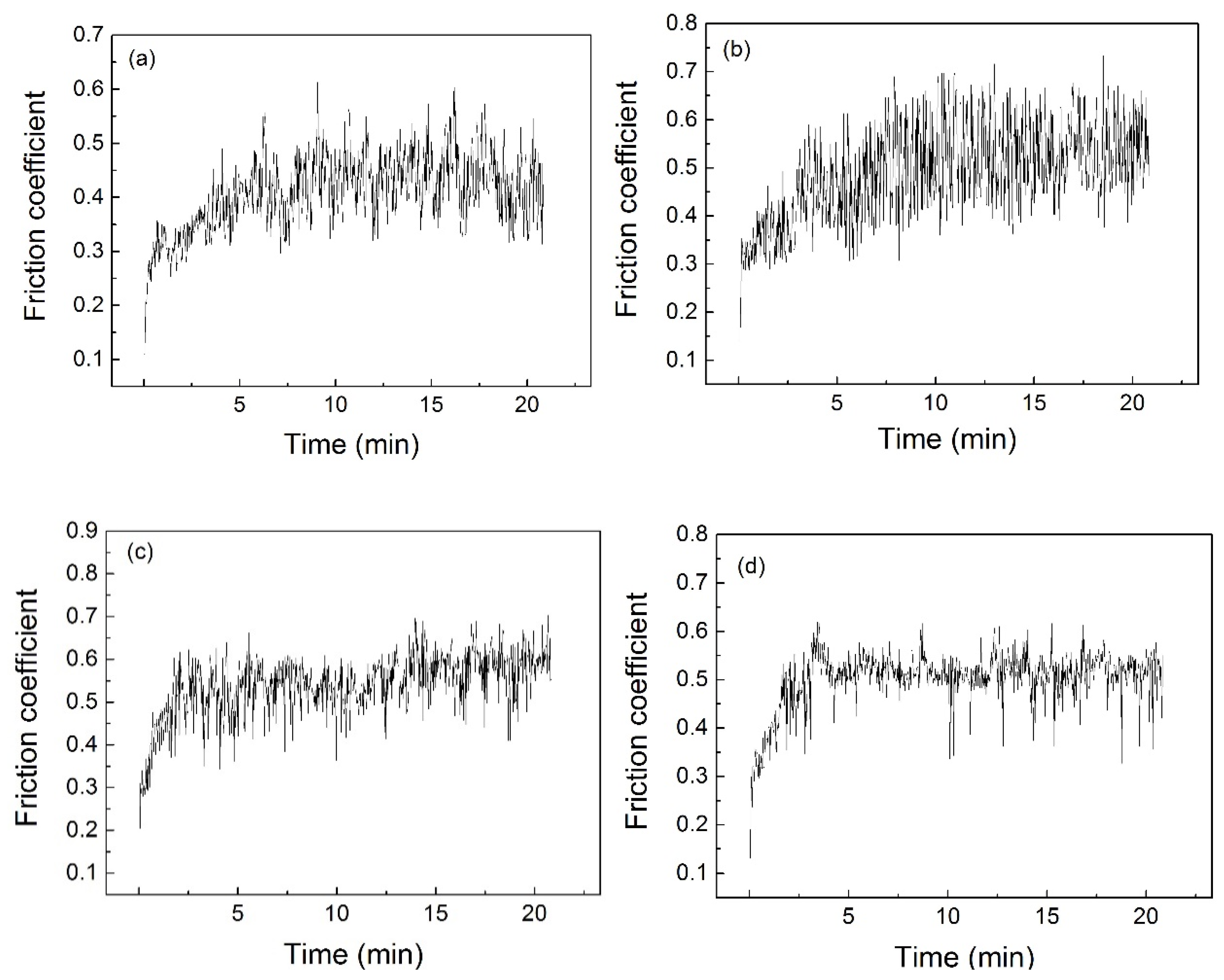

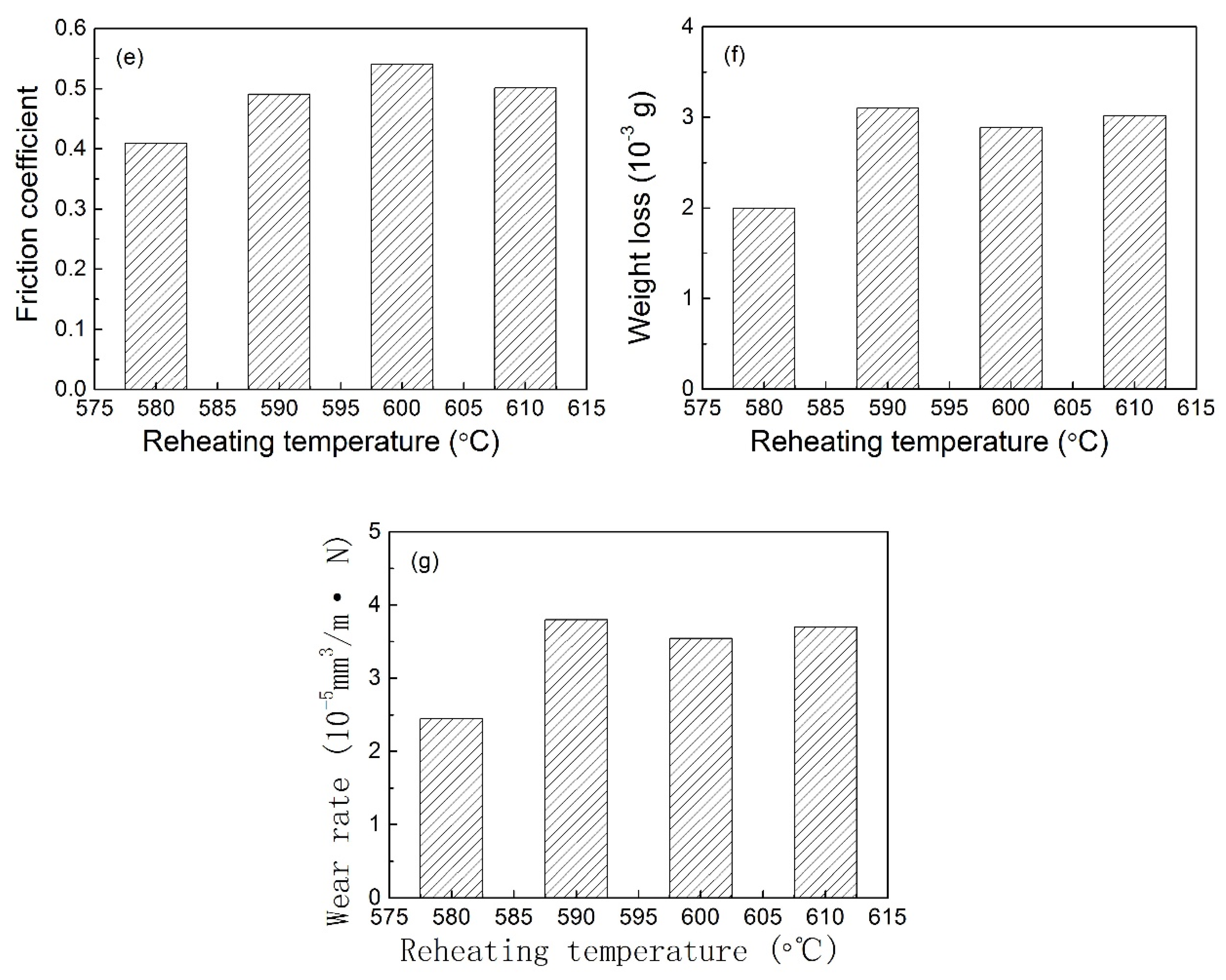

3.2. Influence of Reheating Temperature on Tribological Behavior of Thixoformed Composite parts

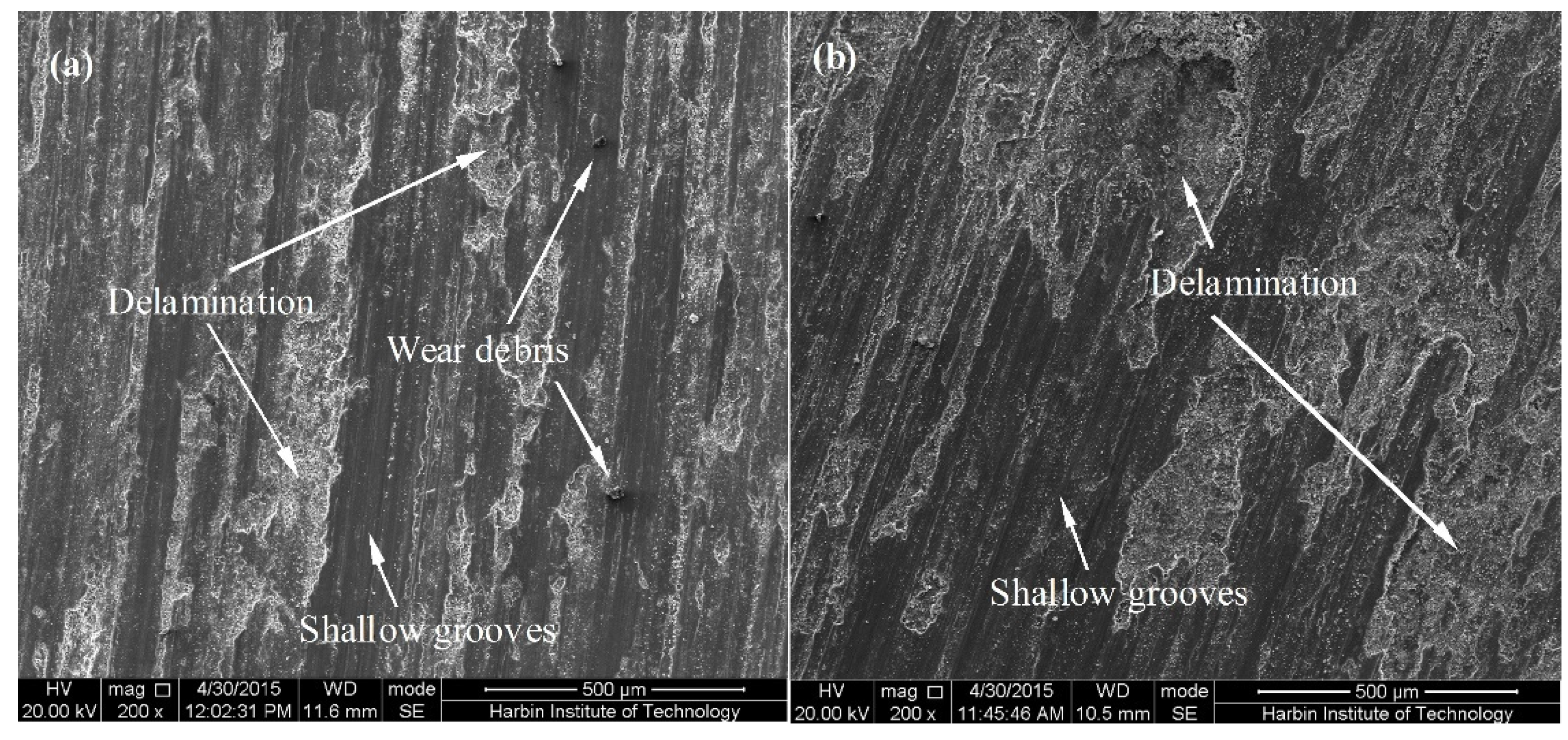

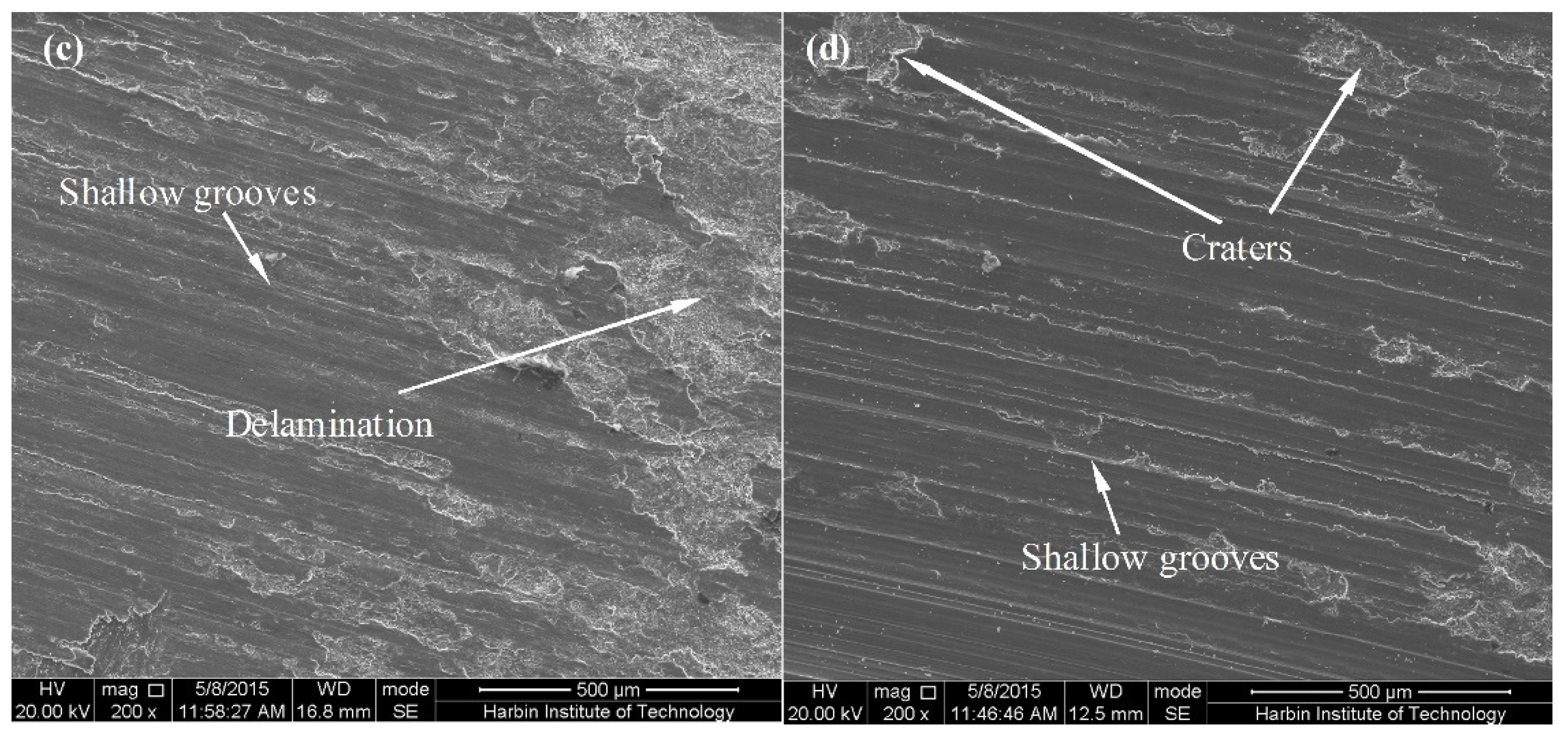

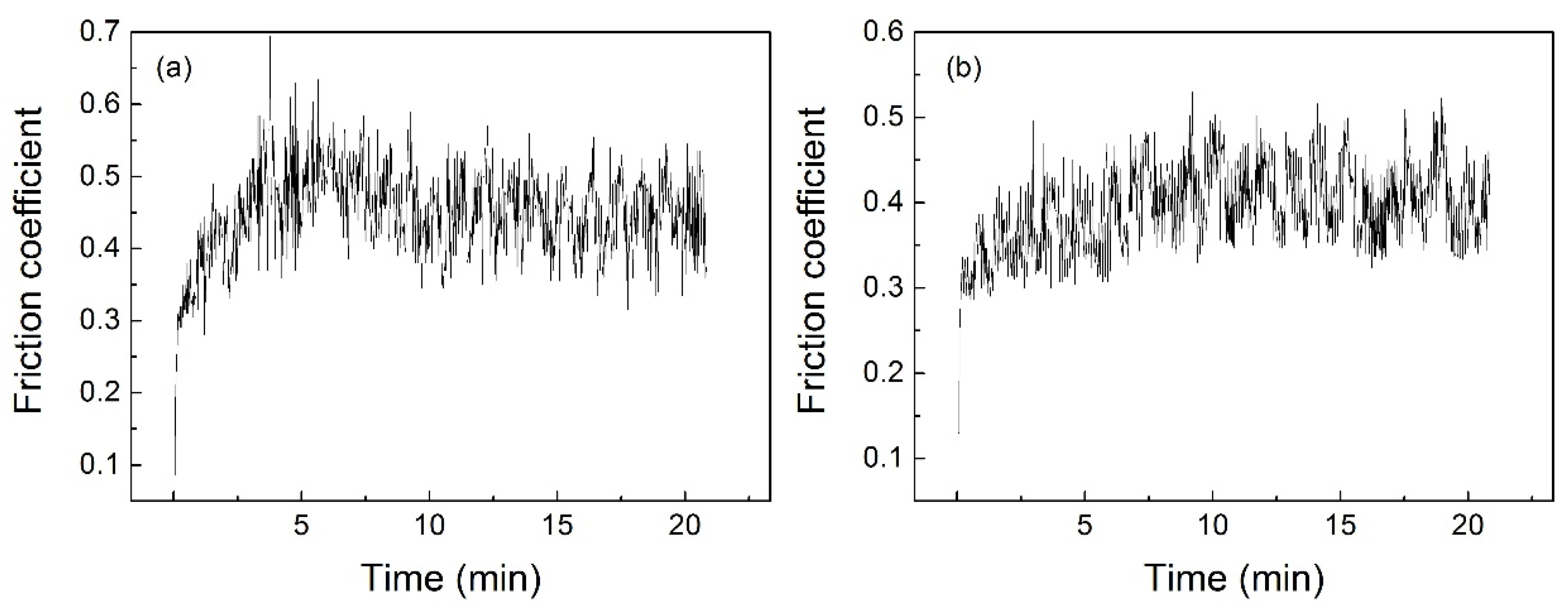

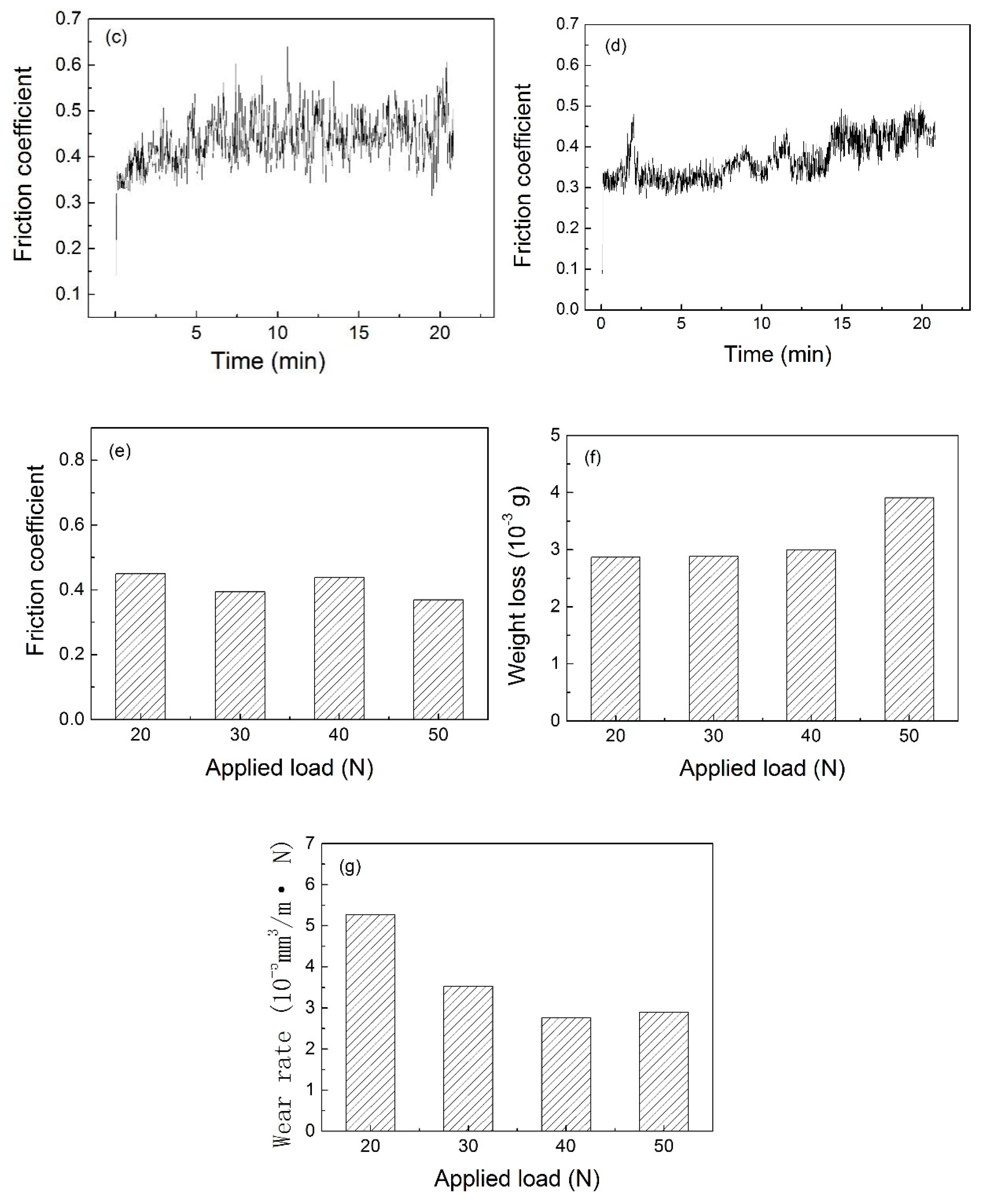

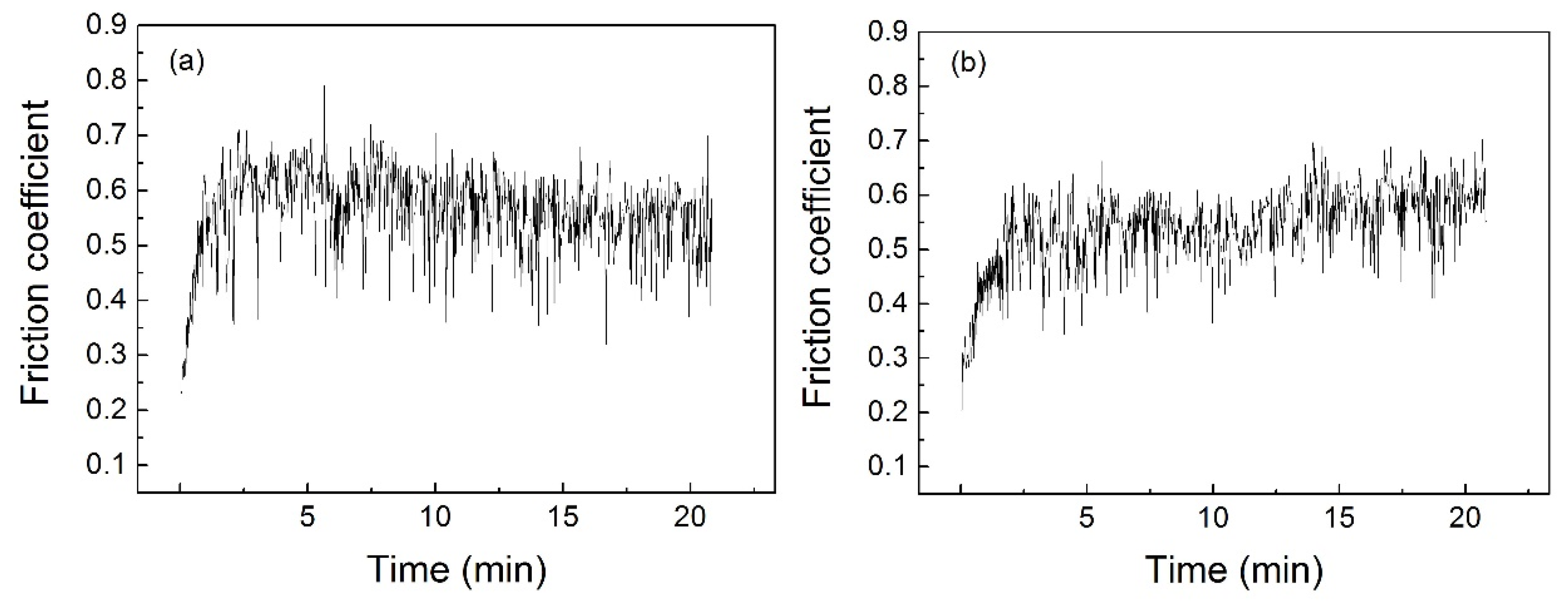

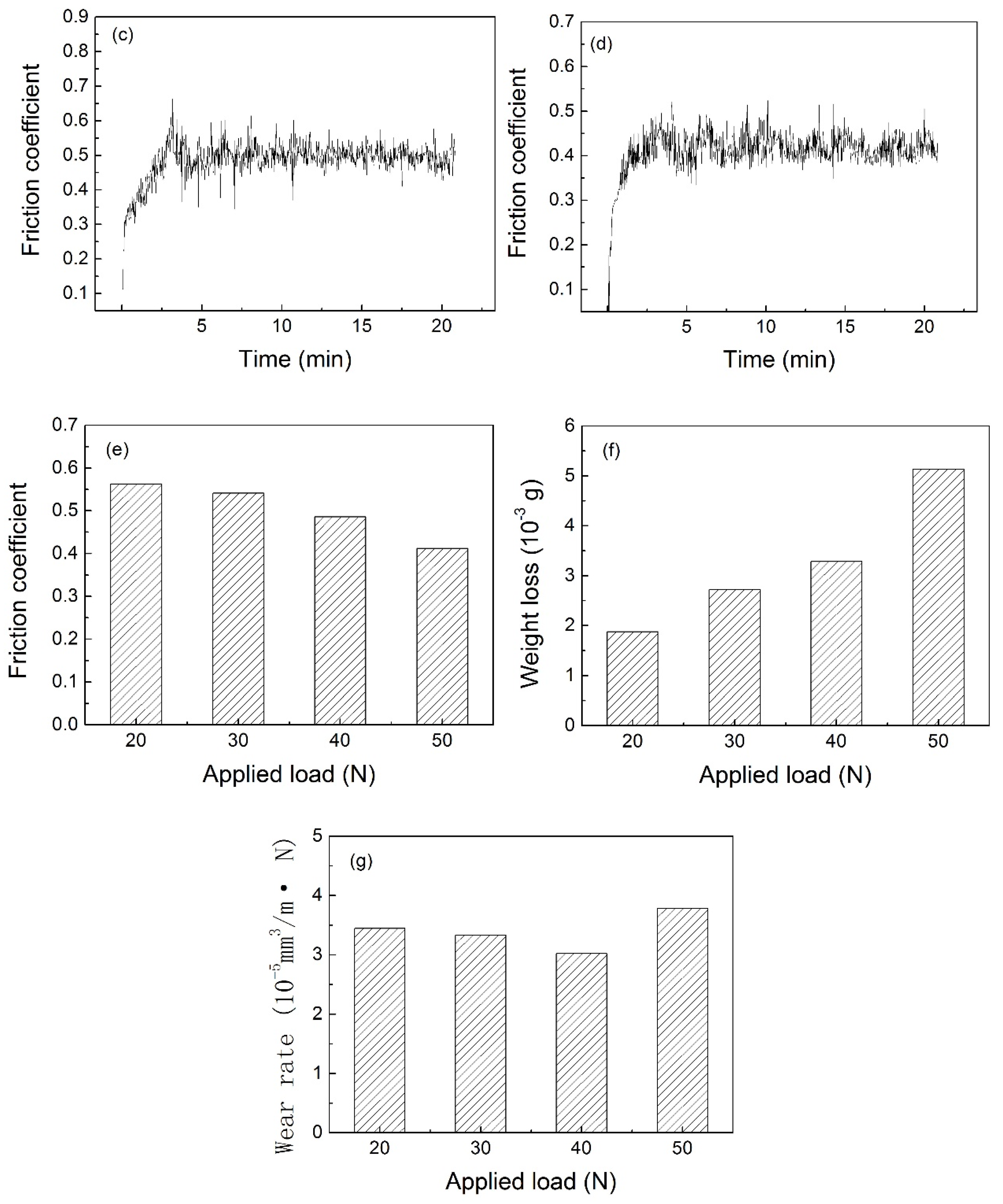

3.3. Influence of Applied Load on Tribological Behavior of the Rheoformed and Thixoformed Composite Parts

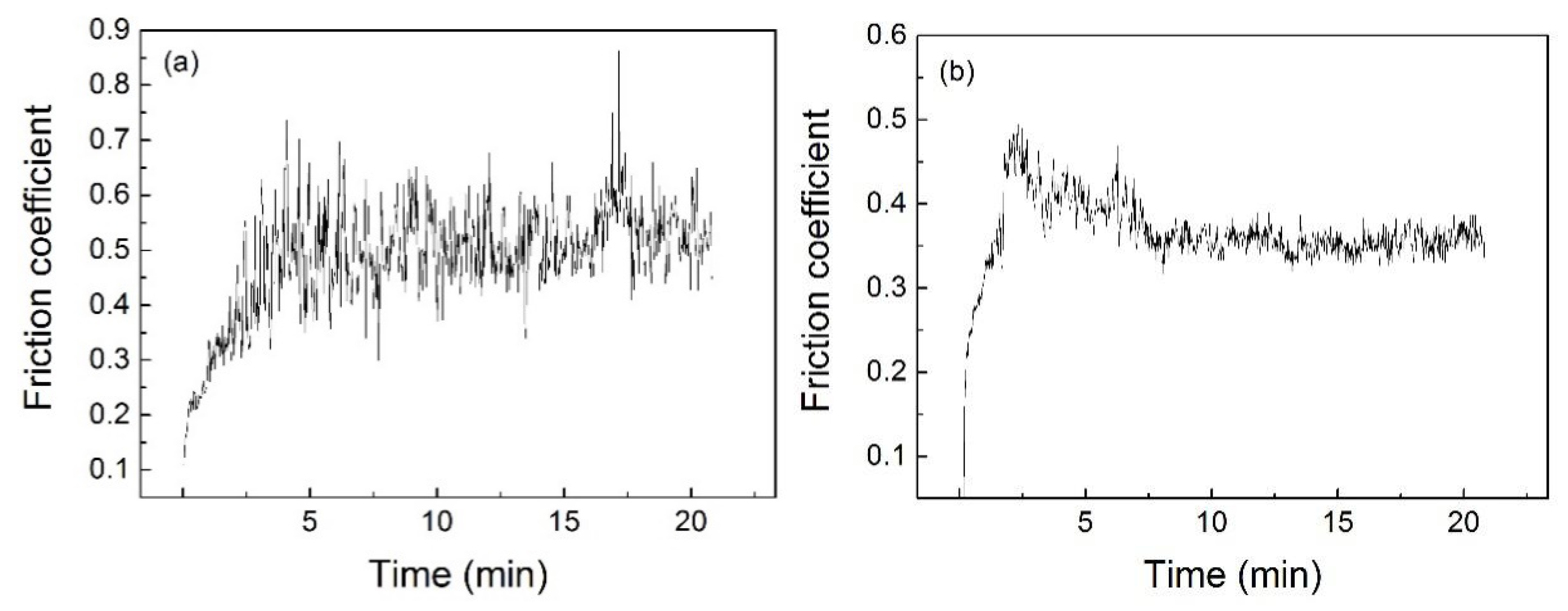

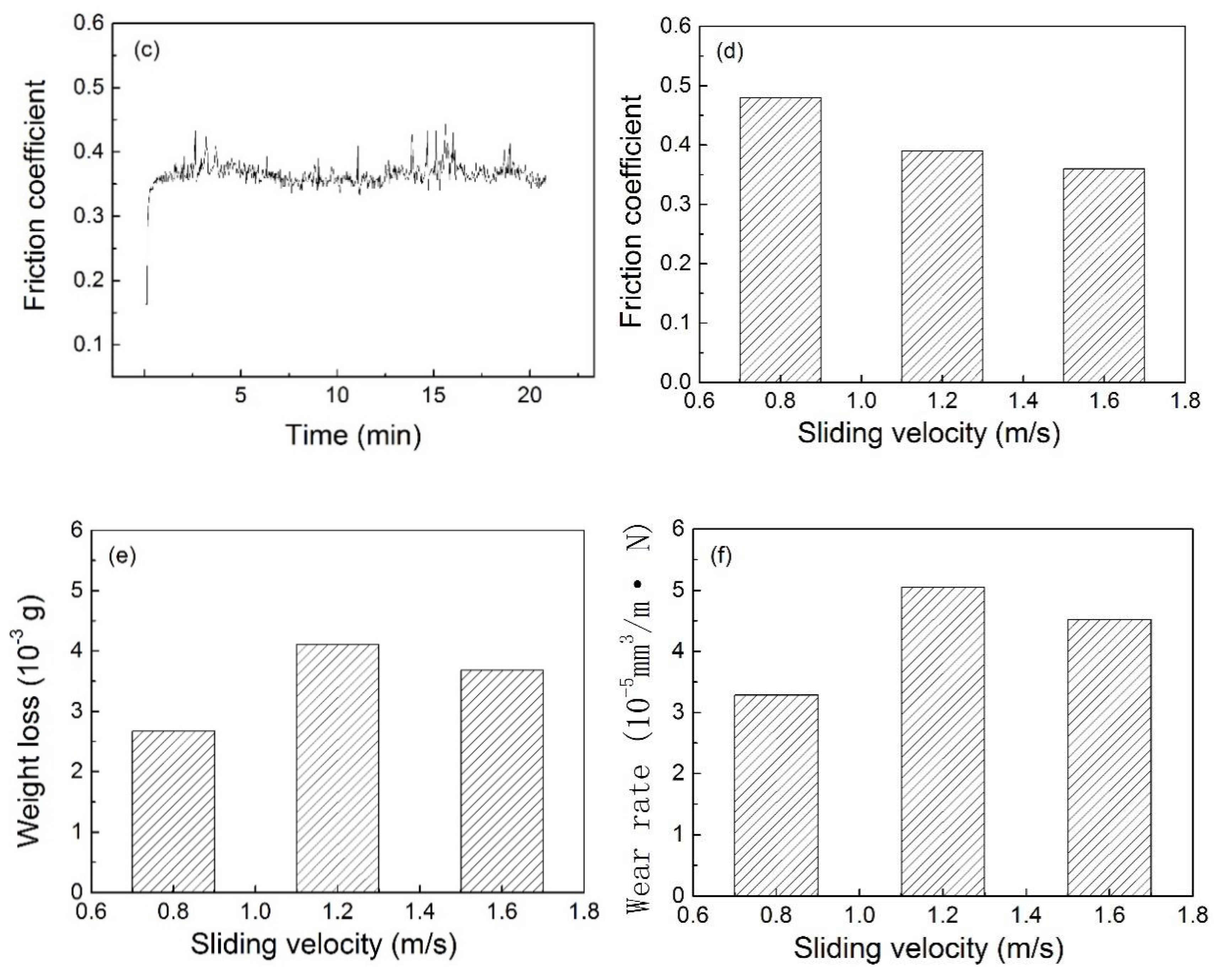

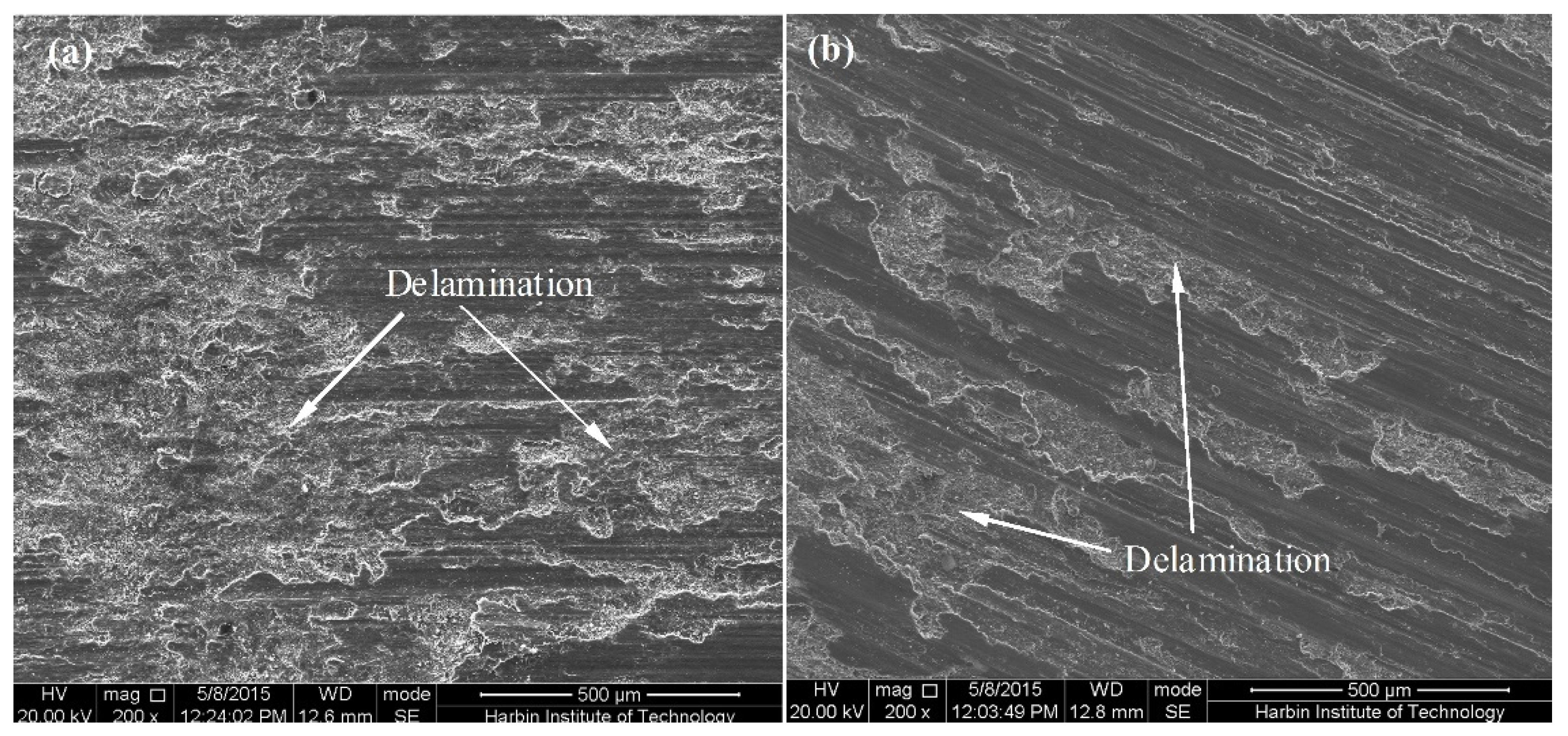

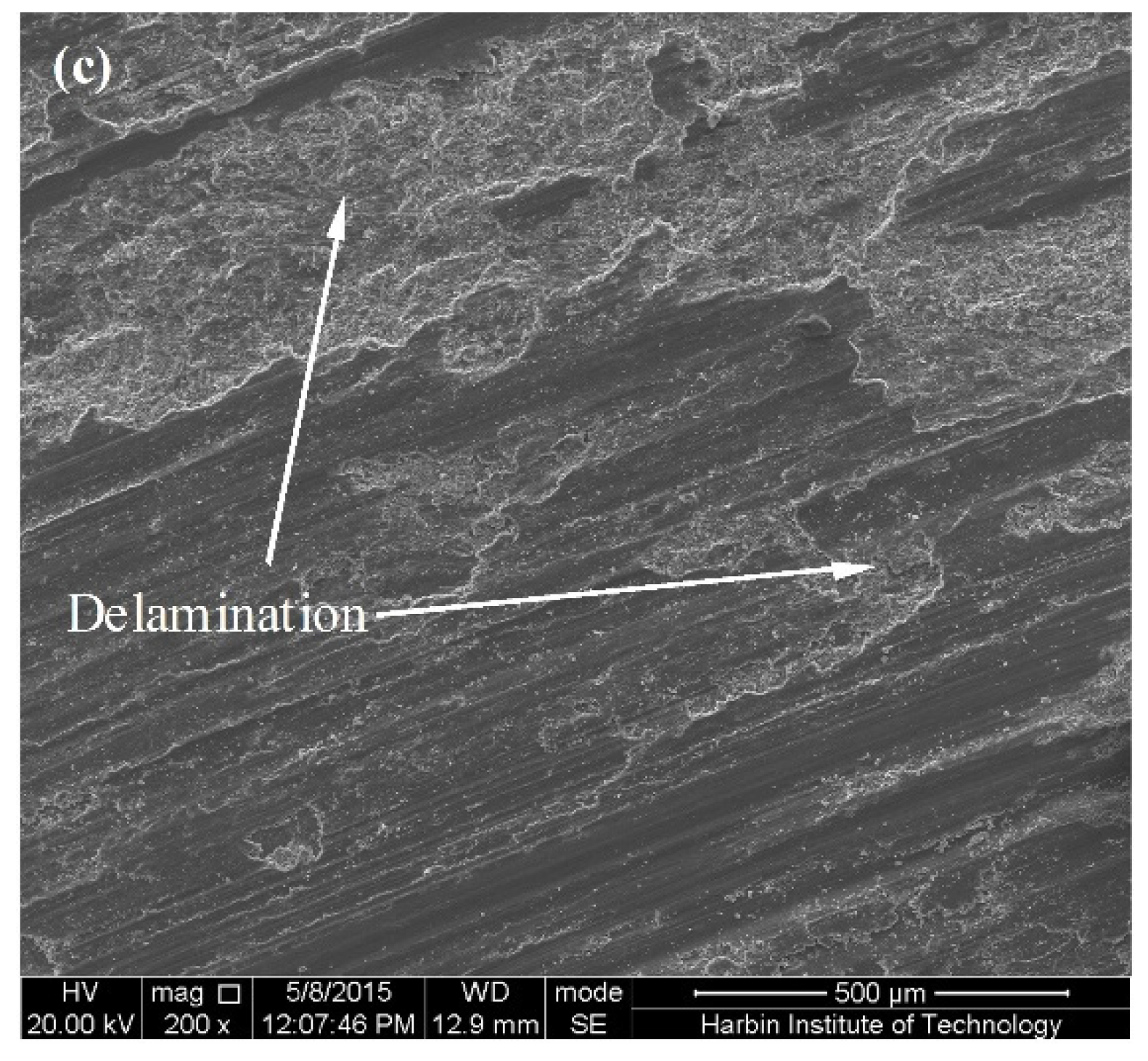

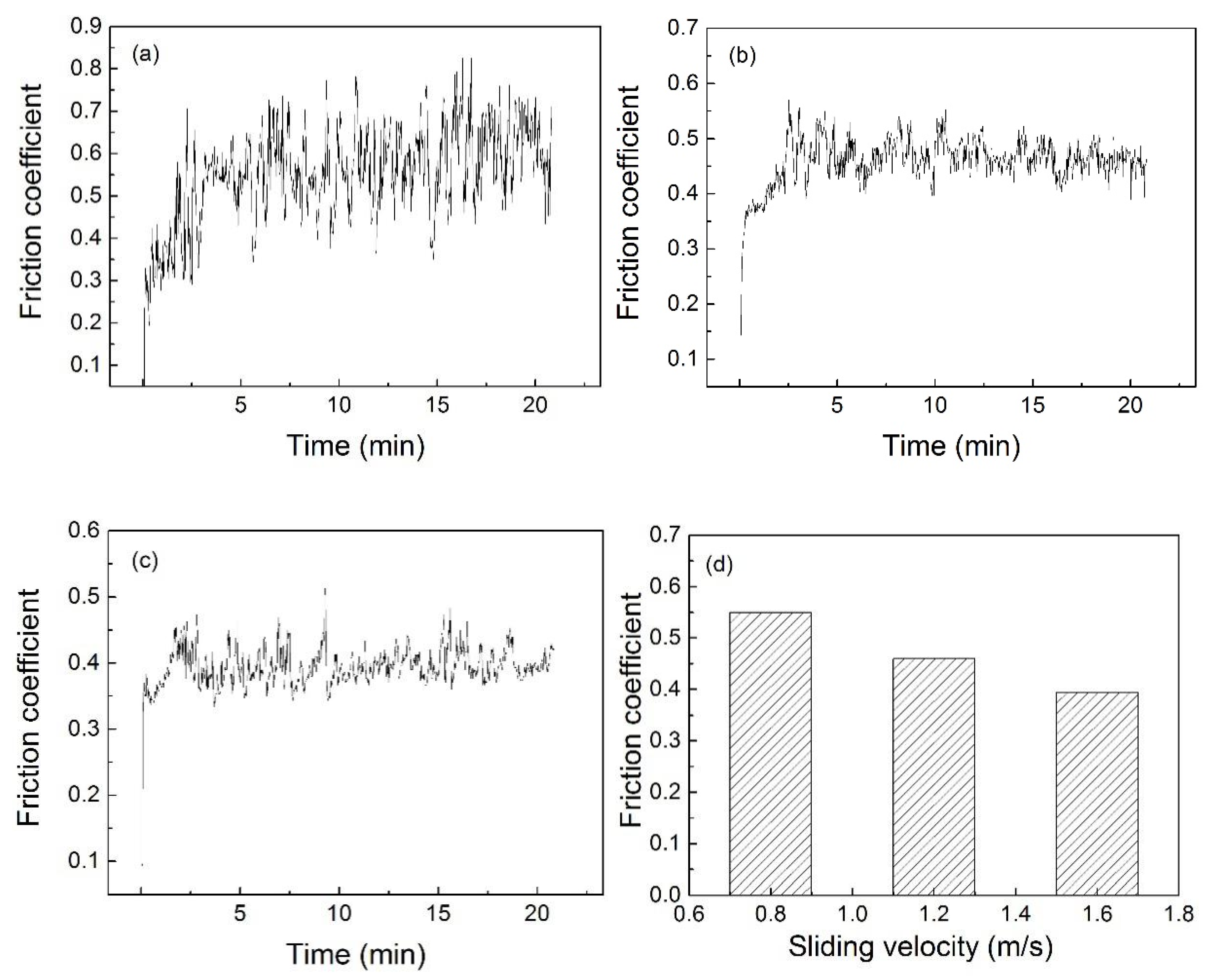

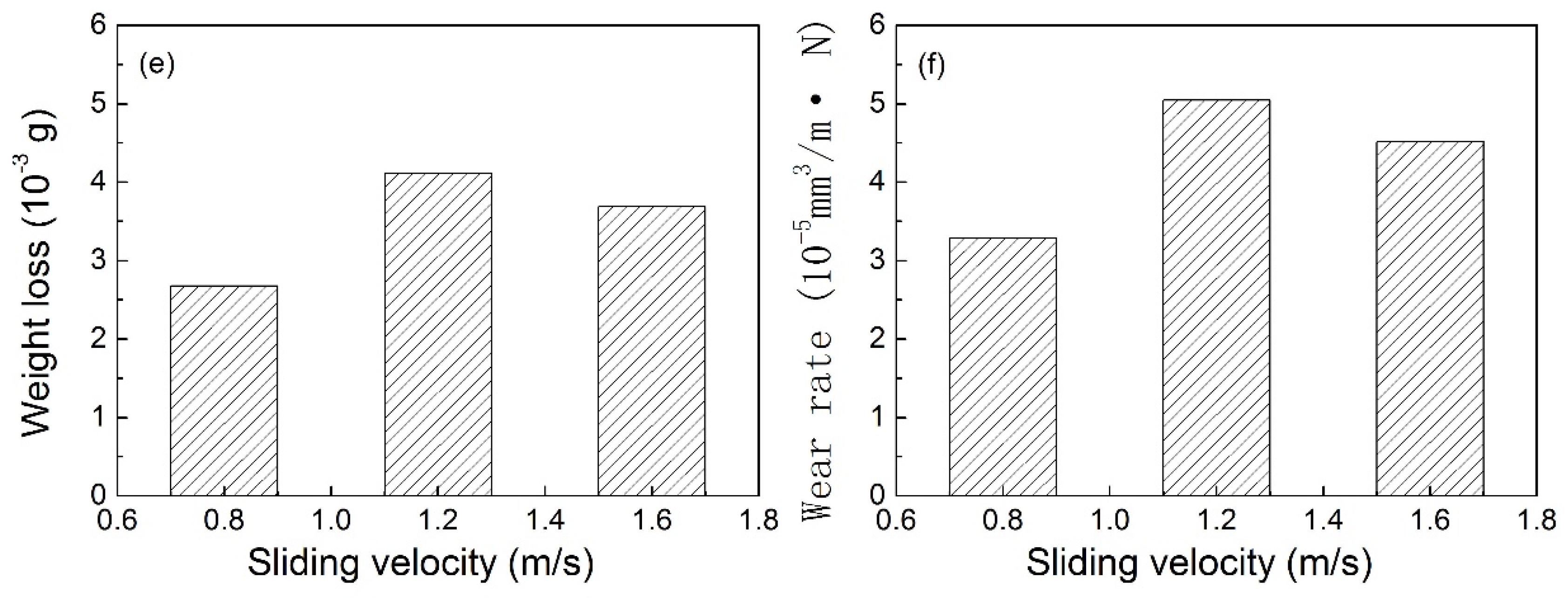

3.4. Influence of Sliding Velocity on Tribological Behavior of the Rheoformed and Thixoformed Composite Parts

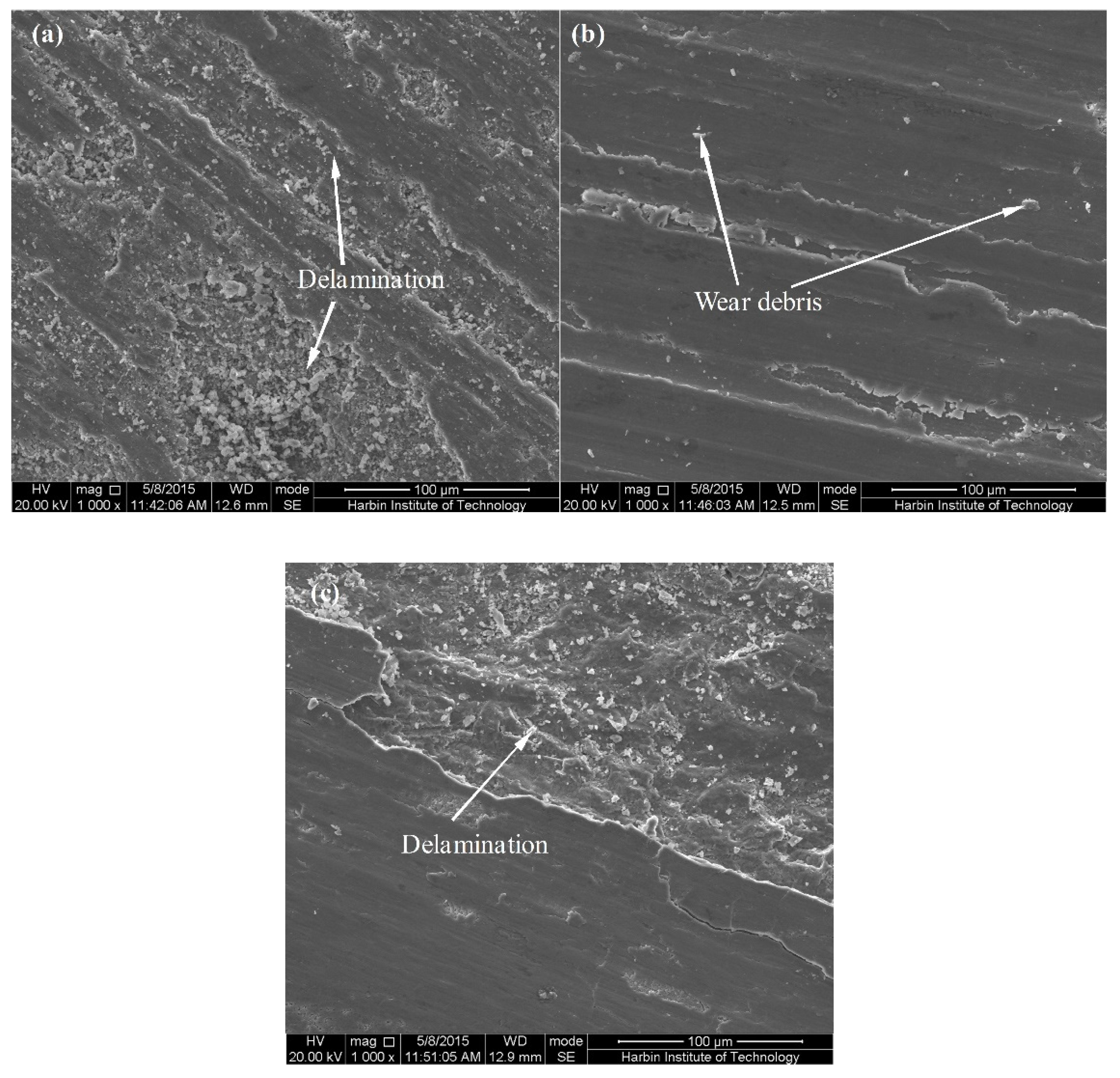

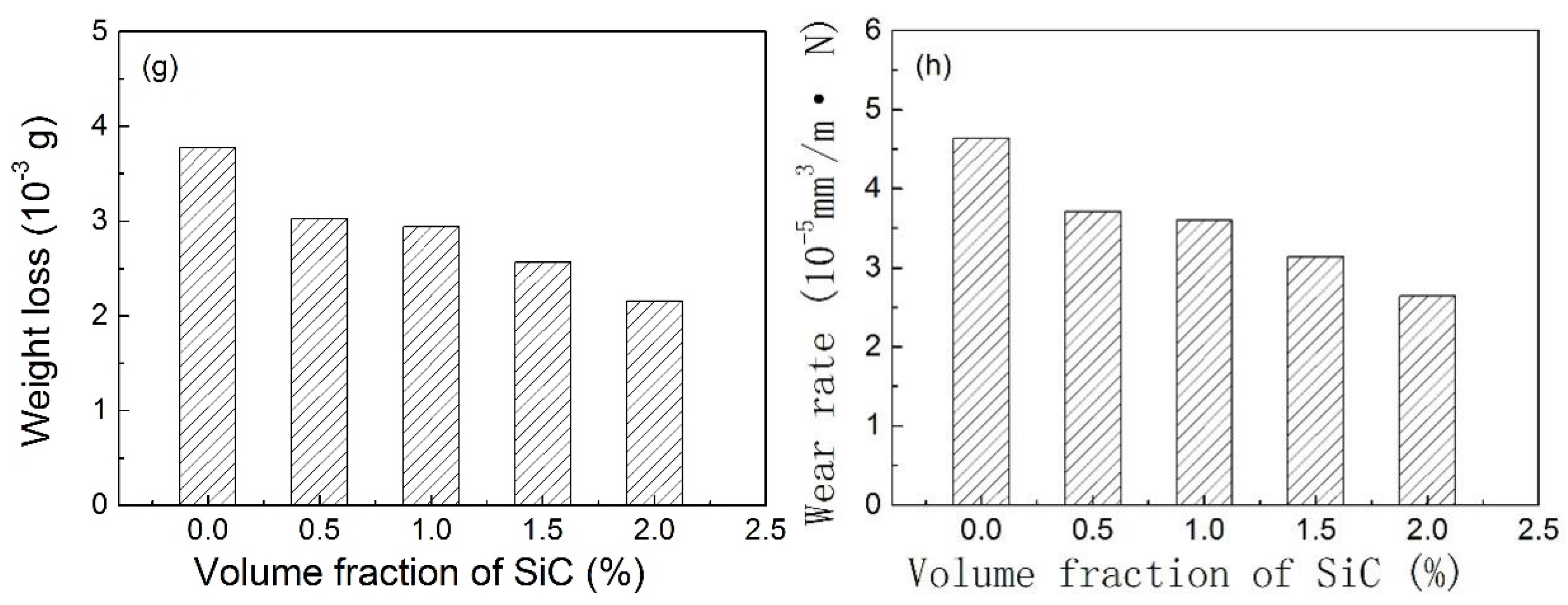

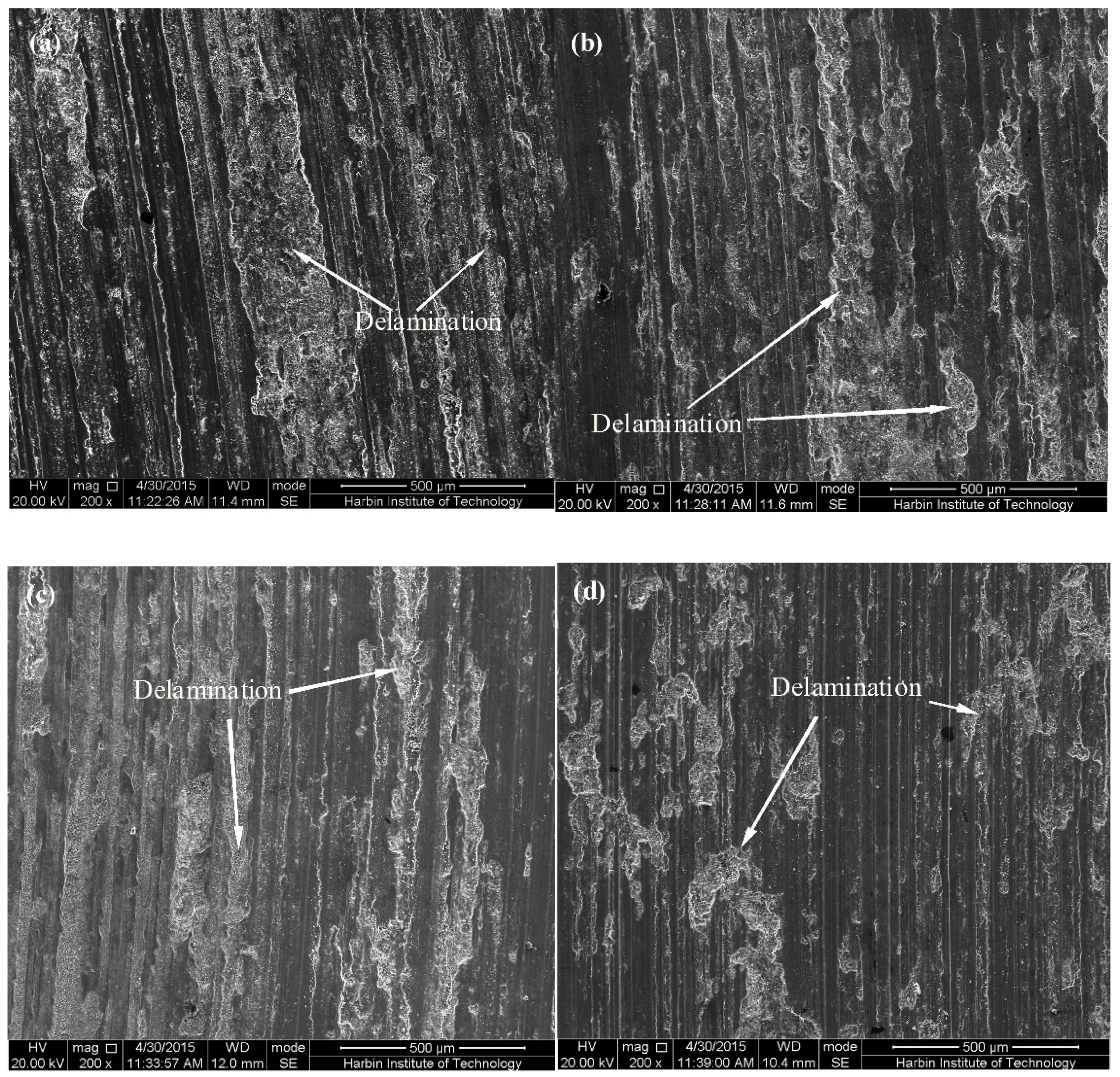

3.5. Influence of Volume Fraction of SiC Particle on Tribological Behavior of the Rheoformed and Thixoformed Composite Parts

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, S.S.; Yeo, J.S.; Hong, S.H.; Yoon, D.J.; Na, K.H. The fabrication process and mechanical properties of SiCp/Al-Si metal matrix composites for automobile air-conditioner compressor piston. J. Mater. Process. Technol. 2001, 113, 202–208. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. High-temperature creep behaviour of powder-metallurgy aluminium composites reinforced with SiC particles of various sizes. Compos. Sci. Technol. 1999, 59, 1117–1125. [Google Scholar] [CrossRef]

- Tatar, C.; Özdemir, N. Investigation of thermal conductivity and microstructure of the α-Al2O3 particulate reinforced aluminum composites (Al/Al2O3-MMC) by powder metallurgy method. Phys. B Condens. Matter 2010, 405, 896–899. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, G.H.; Chen, G.Q.; Jiang, L.T.; Luan, B.F. The thermal expansion and mechanical properties of high reinforcement content SiCp/Al composites fabricated by squeeze casting technology. Compos. Part A 2003, 34, 1023–1027. [Google Scholar] [CrossRef]

- Abdollahi, A.; Alizadeh, A.; Baharvandi, H.R. Dry sliding tribological behavior and mechanical properties of Al2024–5 wt. % B4C nanocomposite produced by mechanical milling and hot extrusion. Mater. Des. 2014, 55, 471–481. [Google Scholar] [CrossRef]

- Kumar, B.A.; Murugan, N.; Dinaharan, I. Dry sliding wear behavior of stir cast AA6061-T6/AlNp composite. Trans. Nonferr. Met. Soc. China 2014, 24, 2785–2795. [Google Scholar] [CrossRef]

- Onat, A. Mechanical and dry sliding wear properties of silicon carbide particulate reinforced aluminium-copper alloy matrix composites produced by direct squeeze casting method. J. Alloy. Compd. 2010, 489, 119–124. [Google Scholar] [CrossRef]

- Mazahery, A.; Shabani, M.O. Microstructural and abrasive wear properties of SiC reinforced aluminum-based composite produced by compocasting. Trans. Nonferr. Met. Soc. China 2013, 23, 1905–1914. [Google Scholar] [CrossRef]

- Mindivan, H.; Kayali, E.S.; Cimenoglu, H. Tribological behavior of squeeze cast aluminum matrix composites. Wear 2008, 265, 645–654. [Google Scholar] [CrossRef]

- Spencer, D.B. Rheology of liquid-solid mixtures of lead-tin. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1971. [Google Scholar]

- Spencer, D.B.; Mehrabian, R.; Flemings, M.C. Rheological behavior of Sn-15 pct Pb in the crystallization range. Metall. Trans. B 1972, 3, 1925–1932. [Google Scholar] [CrossRef]

- Flemings, M.C. Behavior of metal alloys in the semisolid state. J. Metall. Trans. B 1991, 22A, 957–981. [Google Scholar] [CrossRef]

- Guan, R.G.; Zhaom, Z.Y.; Zhang, H.; Lian, C.; Lee, C.S.; Liu, C.M. Microstructure evolution and properties of Mg-3Sn-1Mn (wt. %) alloy strip processed by semisolid rheo-rolling. J. Mater. Process. Technol. 2012, 212, 1430–1436. [Google Scholar] [CrossRef]

- Guan, R.G.; Zhao, Z.Y.; Lee, C.S.; Zhang, Q.S.; Liu, C.M. Effect of wavelike sloping plate rheocasting on microstructures of hypereutectic Al-18 pct Si-5 pct Fe alloys. Metall. Trans. B 2012, 43, 337–343. [Google Scholar] [CrossRef][Green Version]

- Bolouri, A.; Kang, C.G. Characteristics of thixoformed A356 aluminum thin plates with microchannels. Mater. Charact. 2013, 82, 86–96. [Google Scholar] [CrossRef]

- Chayong, S.; Atkinson, H.V.; Kapranos, P. Thixoforming 7075 aluminium alloys. Mater. Sci. Eng. A 2005, 390, 3–12. [Google Scholar] [CrossRef]

- Birol, Y. Comparison of thixoformability of AA6082 reheated from the as-cast and extruded states. J. Alloy. Compd. 2008, 461, 132–138. [Google Scholar] [CrossRef]

- Guan, L.N.; Geng, L.; Zhang, H.W.; Huang, L.J. Effects of stirring parameters on microstructure and tensile properties of (ABOw + SiCp)/6061Al composites fabricated by semi-solid stirring technique. Trans. Nonferr. Met. Soc. China 2011, 21, s274–s279. [Google Scholar] [CrossRef]

- Cheng, F.L.; Chen, T.J.; Qi, Y.S.; Zhang, S.Q.; Yao, P. Effects of solution treatment on microstructure and mechanical properties of thixoformed Mg2Sip/AM60B composite. J. Alloy. Compd. 2015, 636, 48–60. [Google Scholar] [CrossRef]

- Kang, C.G.; Youn, S.W. Mechanical properties of particulate reinforced metal matrix composites by electromagnetic and mechanical stirring and reheating process for thixoforming. J. Mater. Process. Technol. 2004, 147, 10–22. [Google Scholar] [CrossRef]

- Zhang, H.W.; Geng, L.; Guan, L.N.; Huang, L.J. Effects of SiC particle pretreatment and stirring parameters on the microstructure and mechanical properties of SiCp/Al-6.8Mg composites fabricated by semi-solid stirring technique. Mater. Sci. Eng. A 2010, 528, 513–518. [Google Scholar] [CrossRef]

- Mazahery, A.; Shabani, M.O. Tribological behaviour of semisolid–semisolid compocast Al-Si matrix composites reinforced with TiB2 coated B4C particulates. Ceram. Int. 2012, 38, 1887–1895. [Google Scholar] [CrossRef]

- Curle, U.A.; Ivanchev, L. Wear of semi-solid rheocast SiCp/Al metal matrix composites. Trans. Nonferr. Met. Soc. China 2010, 20, s852–s856. [Google Scholar] [CrossRef]

- Alhawari, K.S.; Omar, M.Z.; Ghazali, M.J.; Salleh, M.S.; Mohammed, M.N. Wear properties of A356/Al2O3 metal matrix composites produced by semisolid processing. Procedia Eng. 2013, 68, 186–192. [Google Scholar] [CrossRef]

- Sarajan, Z. Friction and wear of aluminum alloy reinforced by TiO2 particles. Strength Mater. 2013, 45, 221–230. [Google Scholar] [CrossRef]

- Koli, D.K.; Agnihotri, G.; Purohit, R. A review on properties, behaviour and processing methods for Al-nano Al2O3 composites. Procedia Mater. Sci. 2014, 6, 567–589. [Google Scholar] [CrossRef]

- Mazahery, A.; Shabani, M.O. Characterization of cast A356 alloy reinforced with nano SiC composites. Trans. Nonferr. Met. Soc. China 2012, 22, 275–280. [Google Scholar] [CrossRef]

- Mazahery, A.; Abdizadeh, H.; Baharvandi, H.R. Development of high-performance A356/nano-Al2O3 composites. Mater. Sci. Eng. A 2009, 518, 61–64. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Parizi, M.T.; Ezatpour, H.R.; Sedghi, A. Fabrication of A356 composite reinforced with micro and nano Al2O3 particles by a developed compocasting method and study of its properties. J. Alloy. Compd. 2012, 511, 226–231. [Google Scholar] [CrossRef]

- Jiang, J.F.; Wang, Y. Microstructure and mechanical properties of the semisolid slurries and rheoformed component of nano-sized SiC/7075 aluminum matrix composite prepared by ultrasonic-assisted semisolid stirring. Mater. Sci. Eng. A 2015, 639, 350–358. [Google Scholar] [CrossRef]

- Jiang, J.F.; Wang, Y. Microstructure and mechanical properties of the rheoformed cylindrical part of 7075 aluminum matrix composite reinforced with nano-sized SiC particles. Mater. Des. 2015, 79, 32–41. [Google Scholar] [CrossRef]

- Jiang, J.F.; Wang, Y.; Nie, X.; Xiao, G.F. Microstructure evolution of semisolid billet of nano-sized SiCp/7075 aluminum matrix composite during partial remelting process. Mater. Des. 2016, 96, 36–43. [Google Scholar] [CrossRef]

- Standarization Administration of the People’s Republic China. High-Carbon Chromium Bearing Steel; PRC National Standard GB/T18254-2016; Standarization Administration of the People’s Republic China: Beijing, China, 2016.

- Zhang, S.Y.; Wang, F.P. Comparison of friction and wear performances of brake material dry sliding against two aluminum matrix composites reinforced with different SiC particles. J. Mater. Process. Technol. 2007, 182, 122–127. [Google Scholar] [CrossRef]

- Natarajan, N.; Vijayarangan, S.; Rajendran, I. Wear behaviour of A356/25SiCp aluminium matrix composites sliding against automobile friction material. Wear 2006, 261, 812–822. [Google Scholar] [CrossRef]

- Zhong, X.L.; Wong, W.L.E.; Gupta, M. Enhancing strength and ductility of magnesium by integrating it with aluminum nanoparticles. Acta Mater. 2007, 55, 6338–6344. [Google Scholar] [CrossRef]

- Gutam, M.; Srivastant, T.S. Interrelationship between matrix microhardness and ultimate tensile strength of discontinuous particulate-reinforced aluminum alloy composites. Mater. Lett. 2001, 51, 255–261. [Google Scholar]

| Experimental Serial Number | Fraction of SiC Particles (%) | Wear Velocity (m/s) | Stirring Temperature (°C) | Remelting Temperature (°C) | Applied Load (N) | Status |

|---|---|---|---|---|---|---|

| 1 | 1 | 0.8 | 615 | - | 30 | Rheoformed |

| 2 | 1 | 0.8 | 620 | - | 30 | Rheoformed |

| 3 | 1 | 0.8 | 625 | - | 30 | Rheoformed |

| 4 | 1 | 0.8 | 628 | - | 30 | Rheoformed |

| 5 | 1 | 0.8 | 620 | 580 | 30 | Thixoformed |

| 6 | 1 | 0.8 | 620 | 590 | 30 | Thixoformed |

| 7 | 1 | 0.8 | 620 | 600 | 30 | Thixoformed |

| 8 | 1 | 0.8 | 620 | 610 | 30 | Thixoformed |

| 9 | 1 | 0.8 | 620 | - | 20 | Rheoformed |

| 10 | 1 | 0.8 | 620 | - | 40 | Rheoformed |

| 11 | 1 | 0.8 | 620 | - | 50 | Rheoformed |

| 12 | 1 | 0.8 | - | 600 | 20 | Thixoformed |

| 13 | 1 | 0.8 | - | 600 | 40 | Thixoformed |

| 14 | 1 | 0.8 | - | 600 | 50 | Thixoformed |

| 15 | 1 | 1.2 | 620 | - | 30 | Rheoformed |

| 16 | 1 | 1.6 | 620 | - | 30 | Rheoformed |

| 17 | 1 | 1.2 | 620 | 600 | 30 | Thixoformed |

| 18 | 1 | 1.6 | 620 | 600 | 30 | Thixoformed |

| 19 | 0 | 0.8 | 620 | 600 | 30 | Rheoformed |

| 20 | 0.5 | 0.8 | 620 | 600 | 30 | Rheoformed |

| 21 | 1.5 | 0.8 | 620 | 600 | 30 | Rheoformed |

| 22 | 2 | 0.8 | 620 | 600 | 30 | Rheoformed |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; Xiao, G.; Wang, Y.; Liu, Y. Tribological Behavior of Nano-Sized SiCp/7075 Composite Parts Formed by Semisolid Processing. Metals 2018, 8, 148. https://doi.org/10.3390/met8030148

Jiang J, Xiao G, Wang Y, Liu Y. Tribological Behavior of Nano-Sized SiCp/7075 Composite Parts Formed by Semisolid Processing. Metals. 2018; 8(3):148. https://doi.org/10.3390/met8030148

Chicago/Turabian StyleJiang, Jufu, Guanfei Xiao, Ying Wang, and Yingze Liu. 2018. "Tribological Behavior of Nano-Sized SiCp/7075 Composite Parts Formed by Semisolid Processing" Metals 8, no. 3: 148. https://doi.org/10.3390/met8030148

APA StyleJiang, J., Xiao, G., Wang, Y., & Liu, Y. (2018). Tribological Behavior of Nano-Sized SiCp/7075 Composite Parts Formed by Semisolid Processing. Metals, 8(3), 148. https://doi.org/10.3390/met8030148