Fracture Toughness Prediction under Compressive Residual Stress by Using a Stress-Distribution T-Scaling Method

Abstract

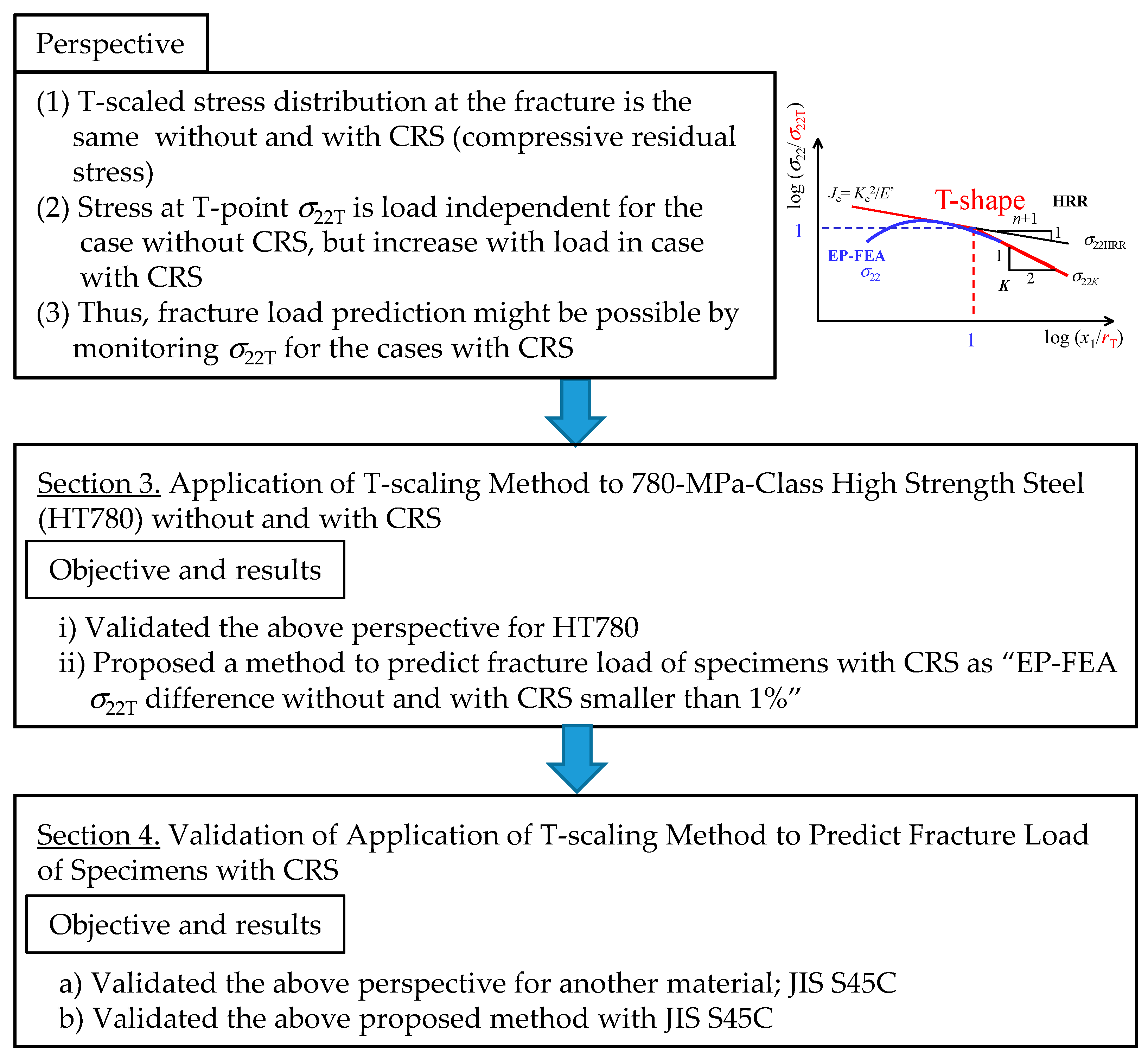

:1. Introduction

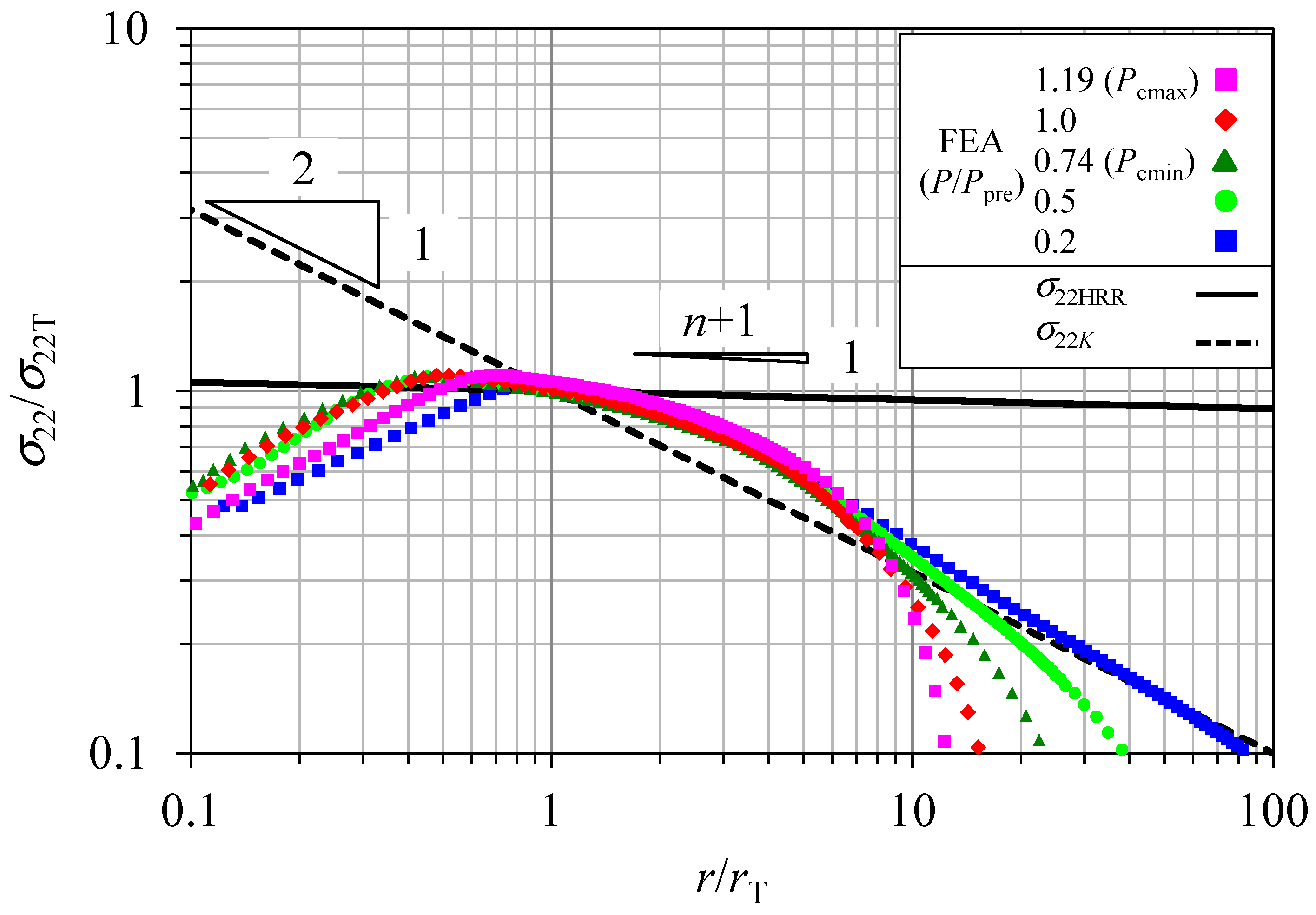

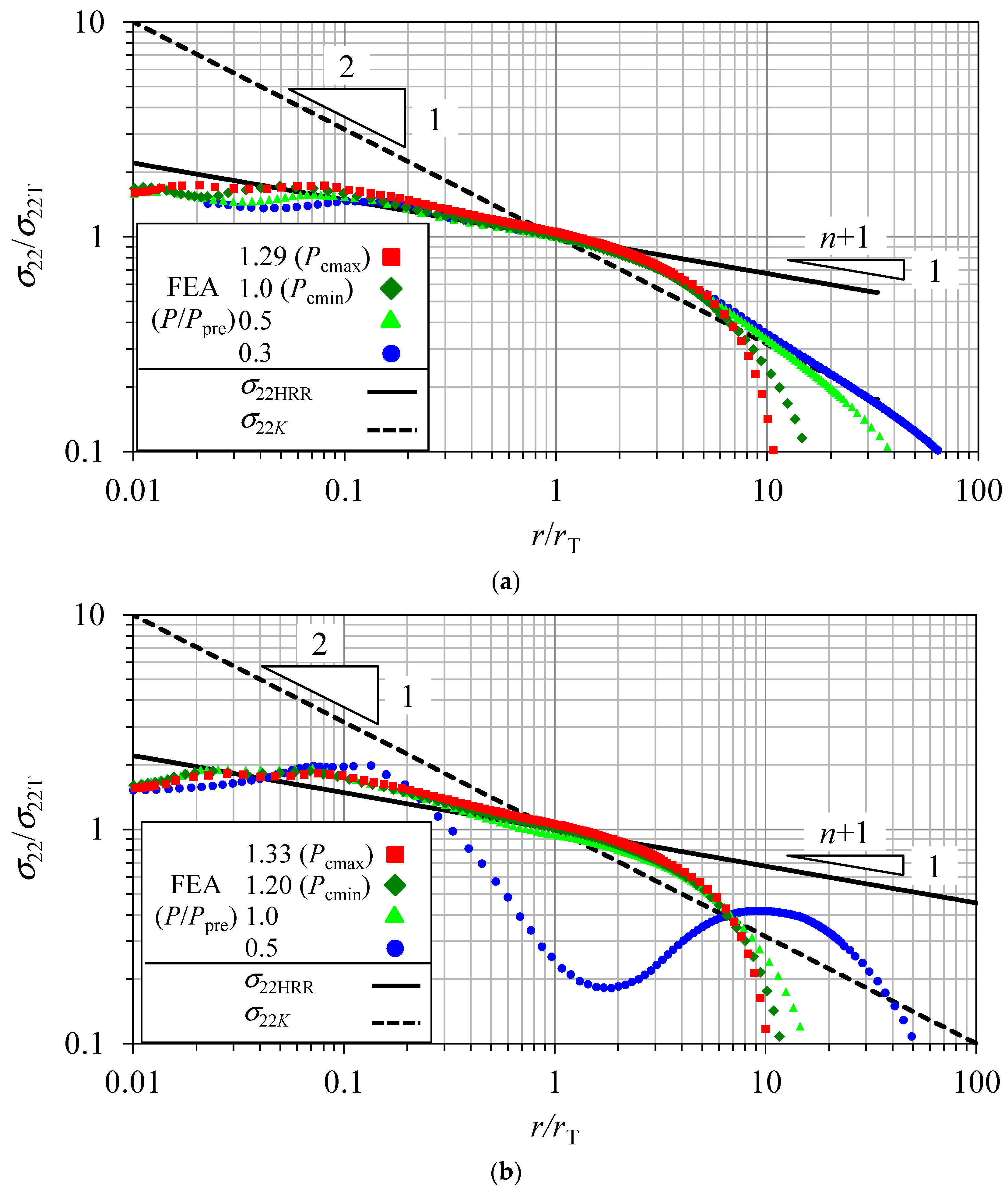

2. T-Scaling Method

3. Application of T-Scaling Method to 780-MPa-Class High-Strength Steel without and with CRS

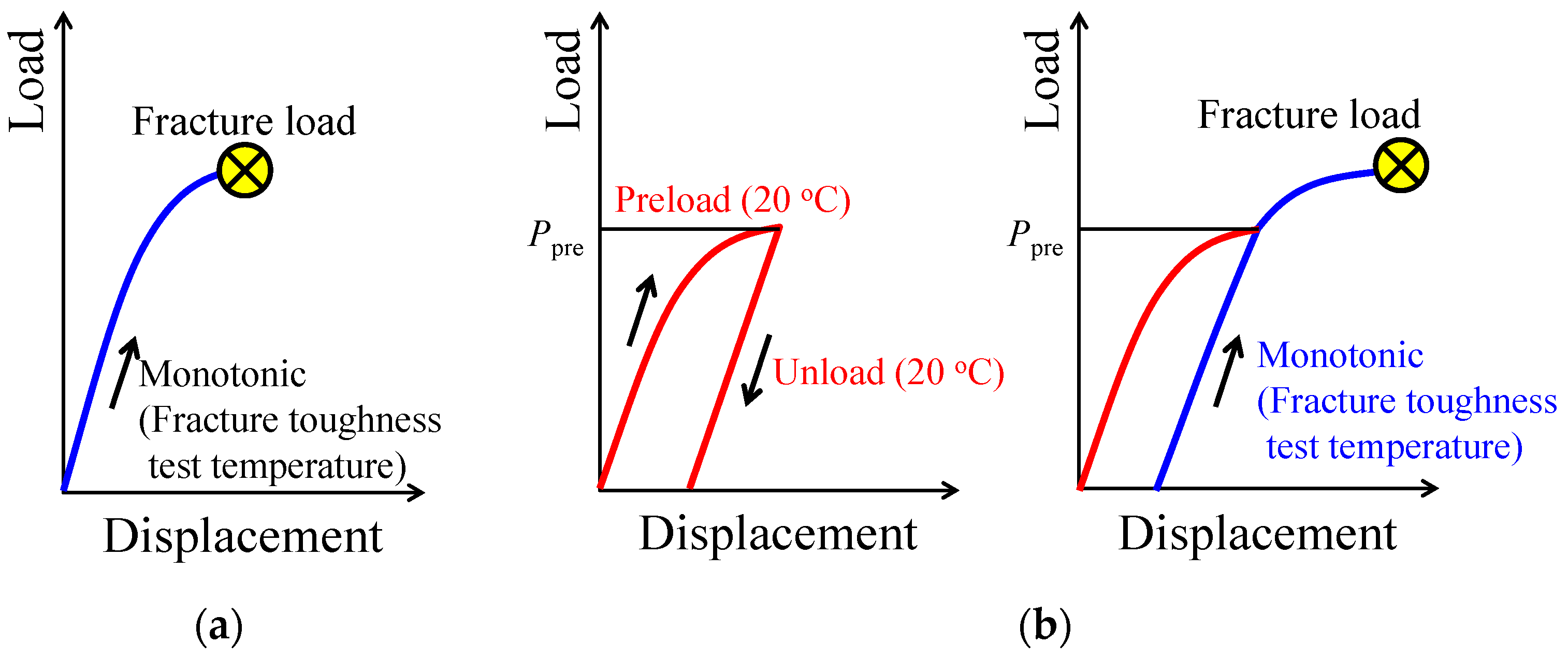

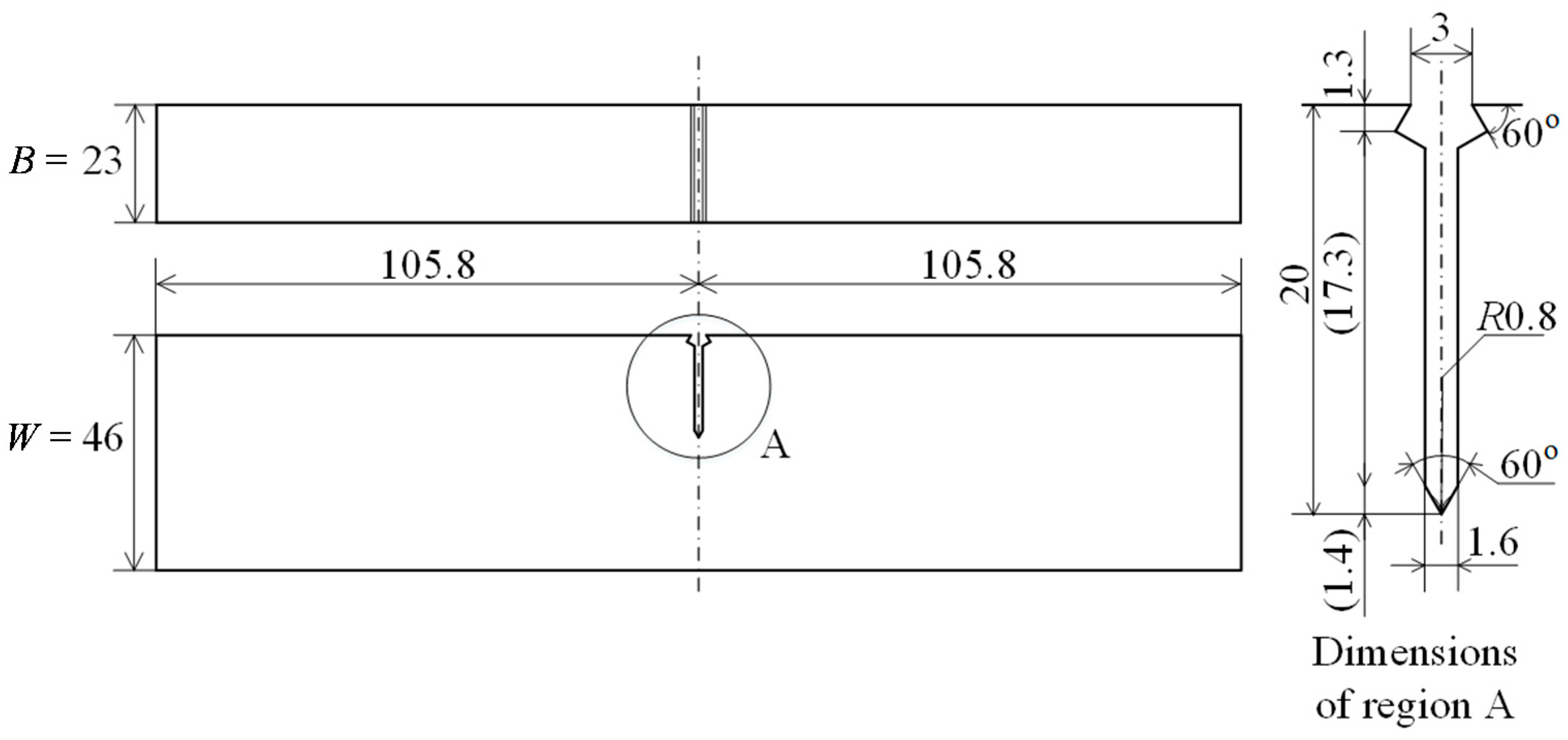

3.1. Outline of Tests to Be Reproduced

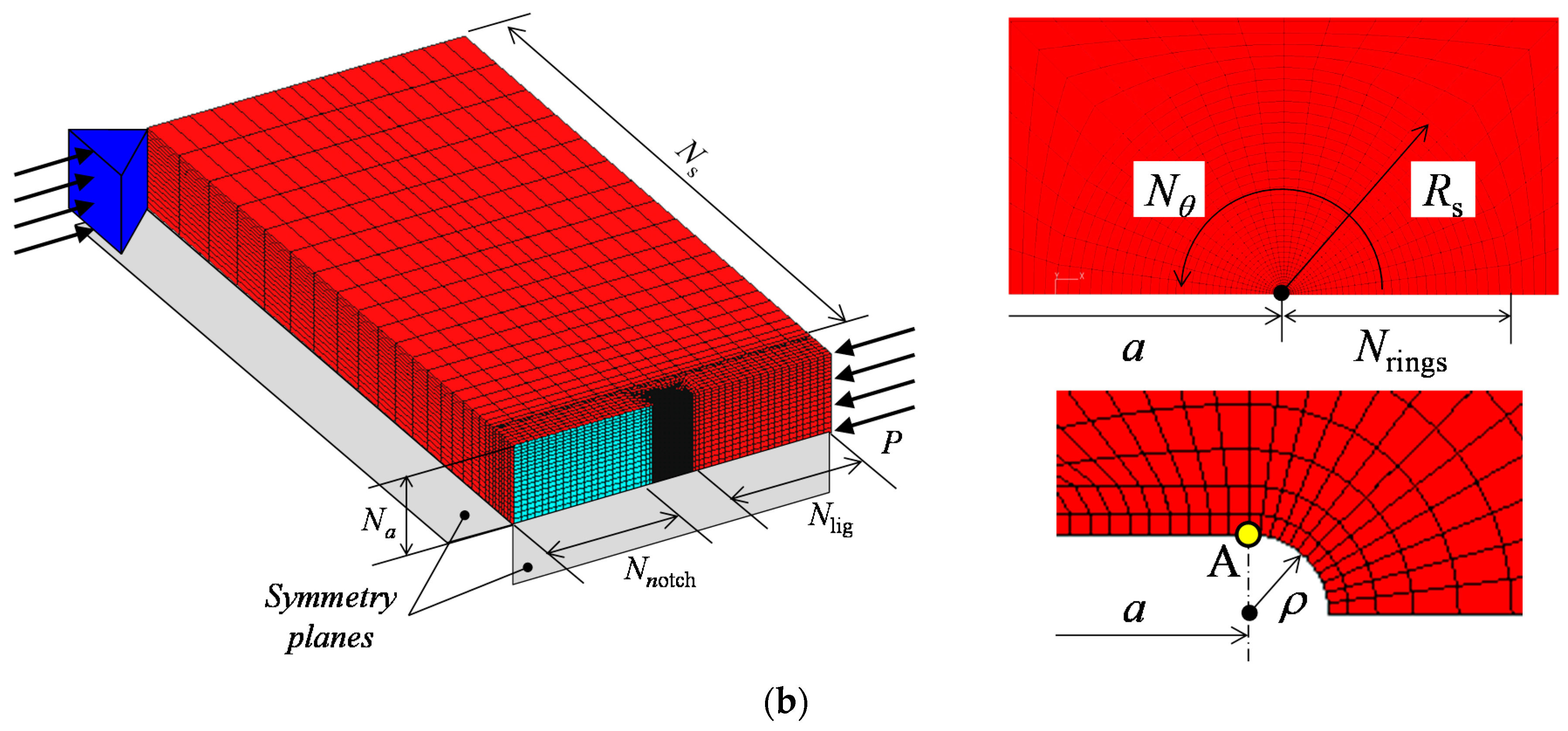

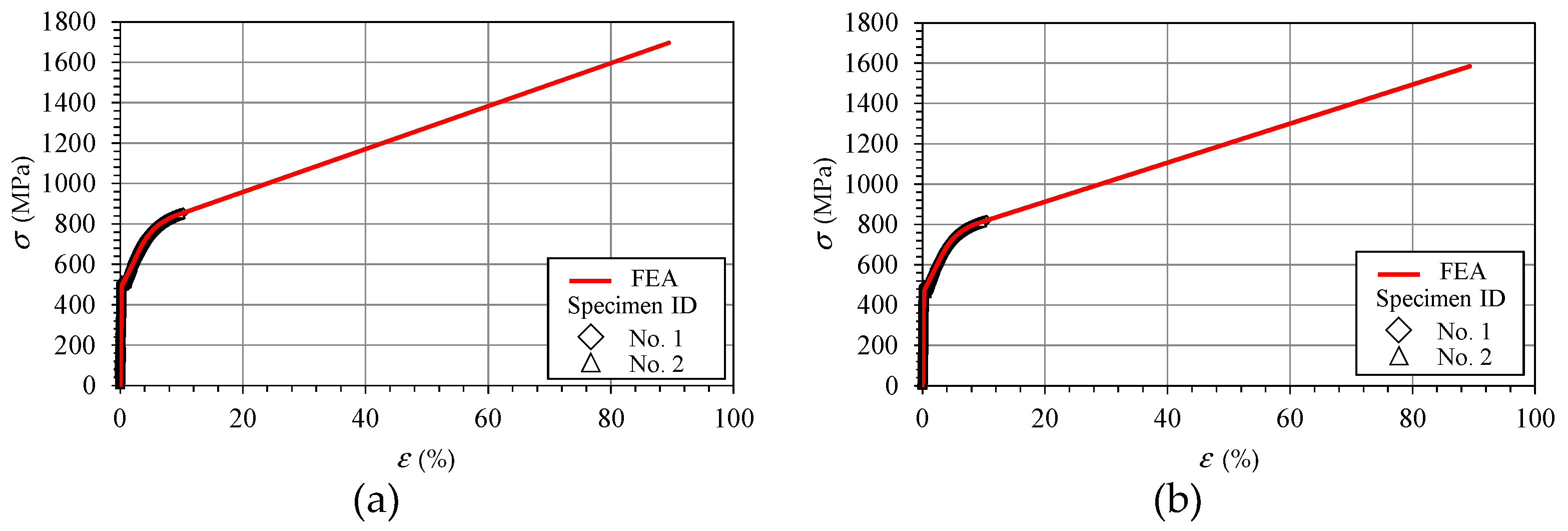

3.2. EP-FEA to Reproduce Test Results for HT780

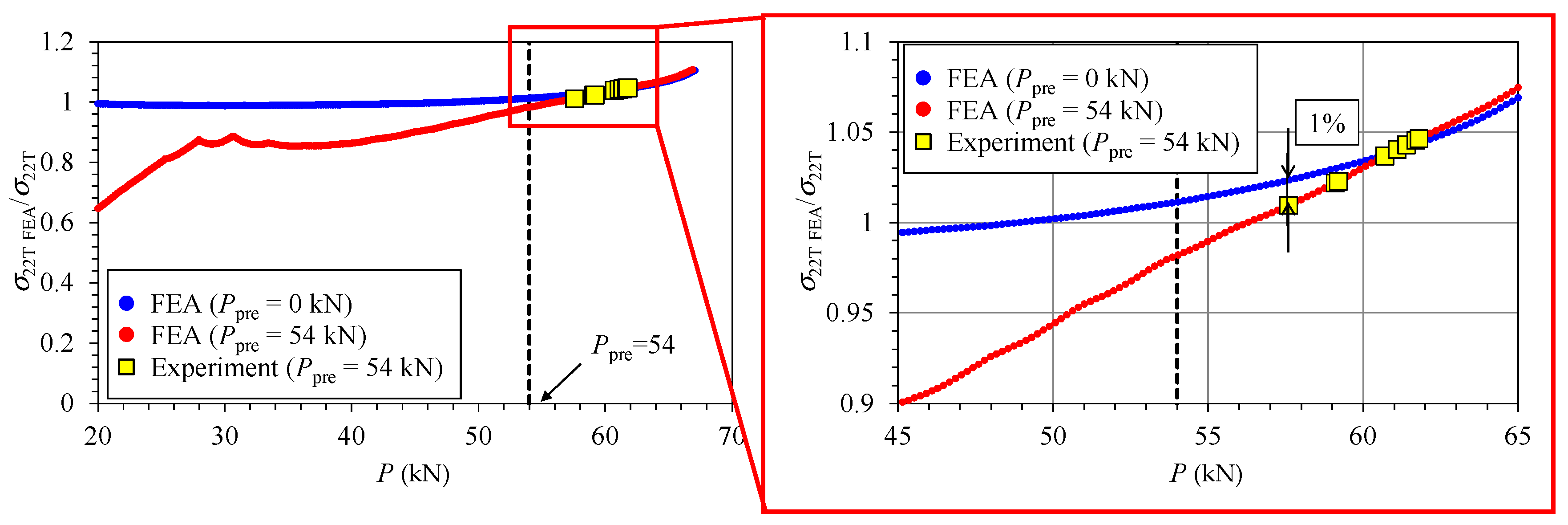

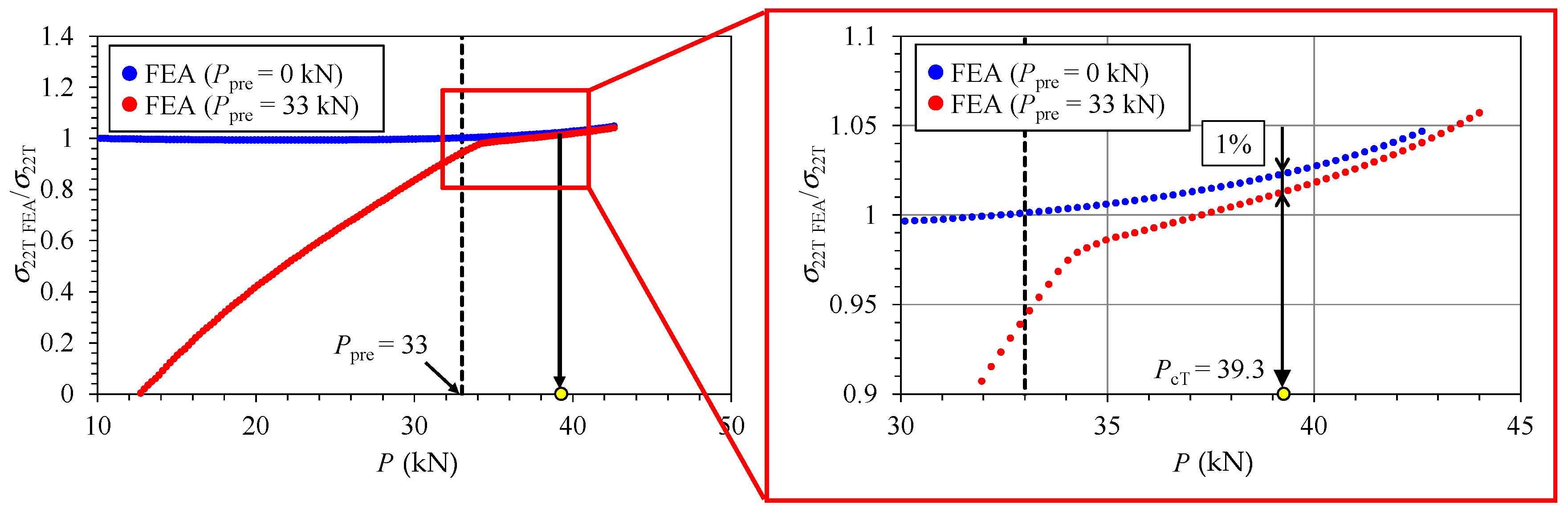

3.3. Proposed Method to Predict Fracture Load for Cases with CRS

4. Validation of Application of T-Scaling Method to Predict Fracture Load of Specimens with CRS

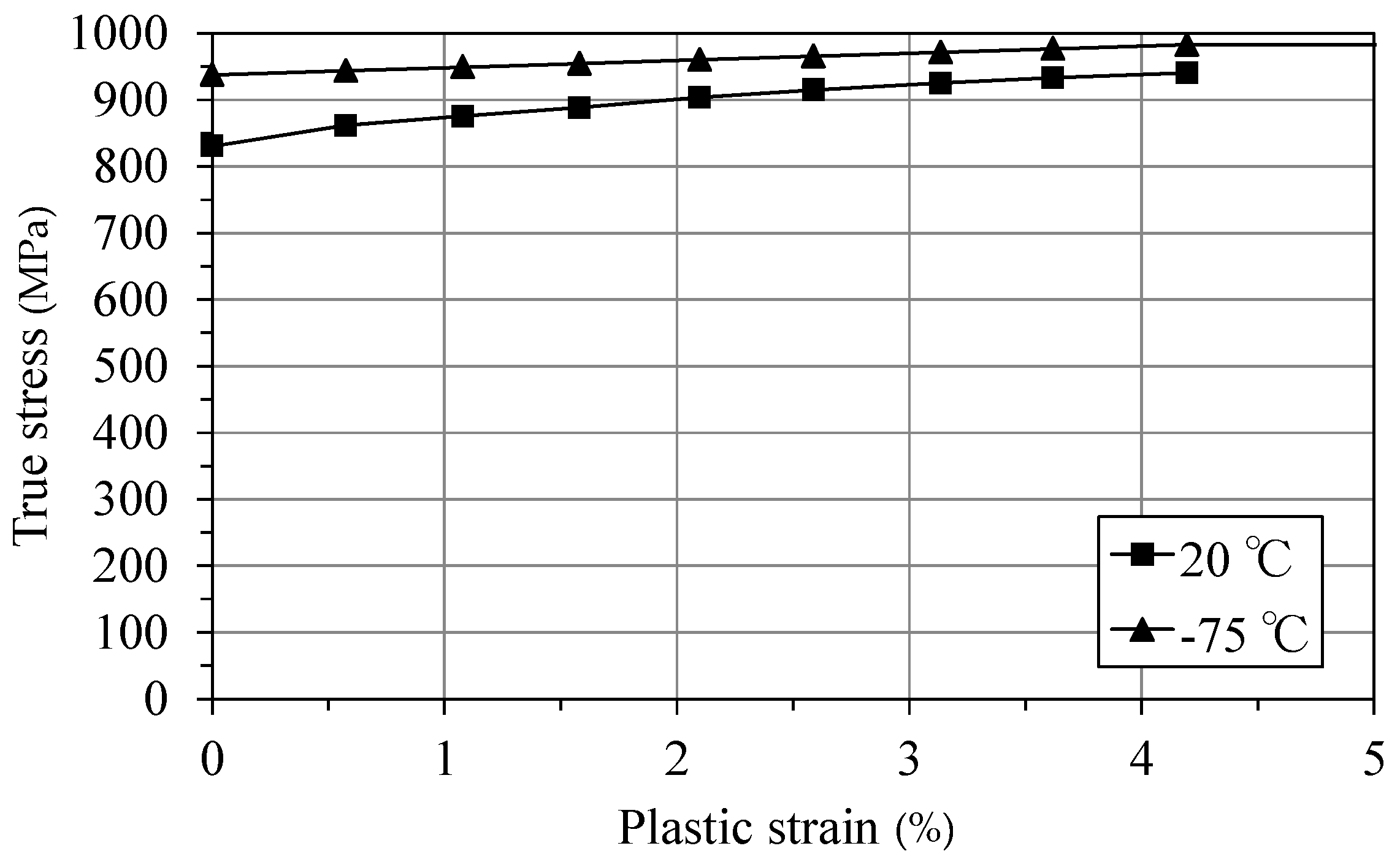

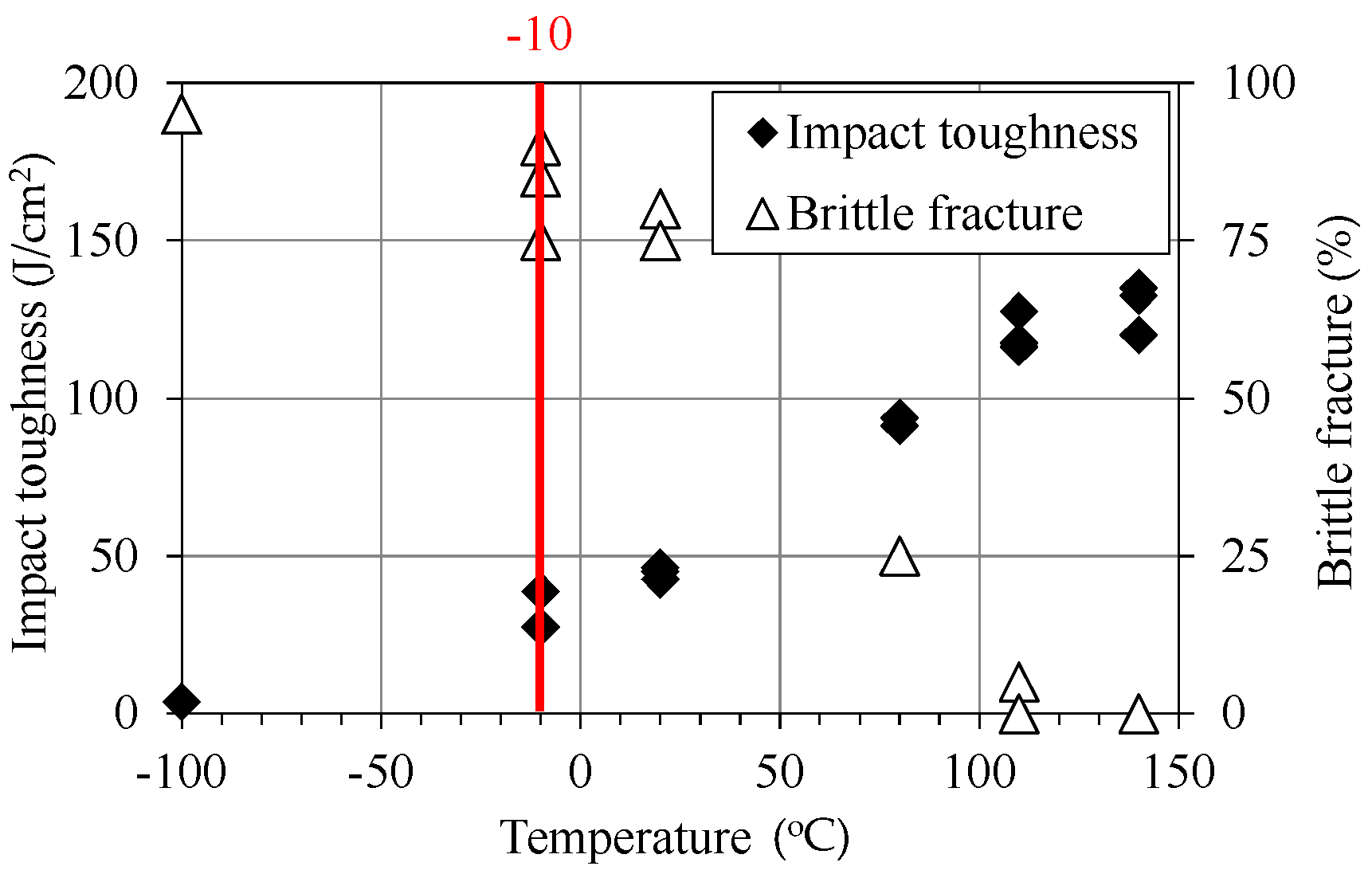

4.1. Material Selection

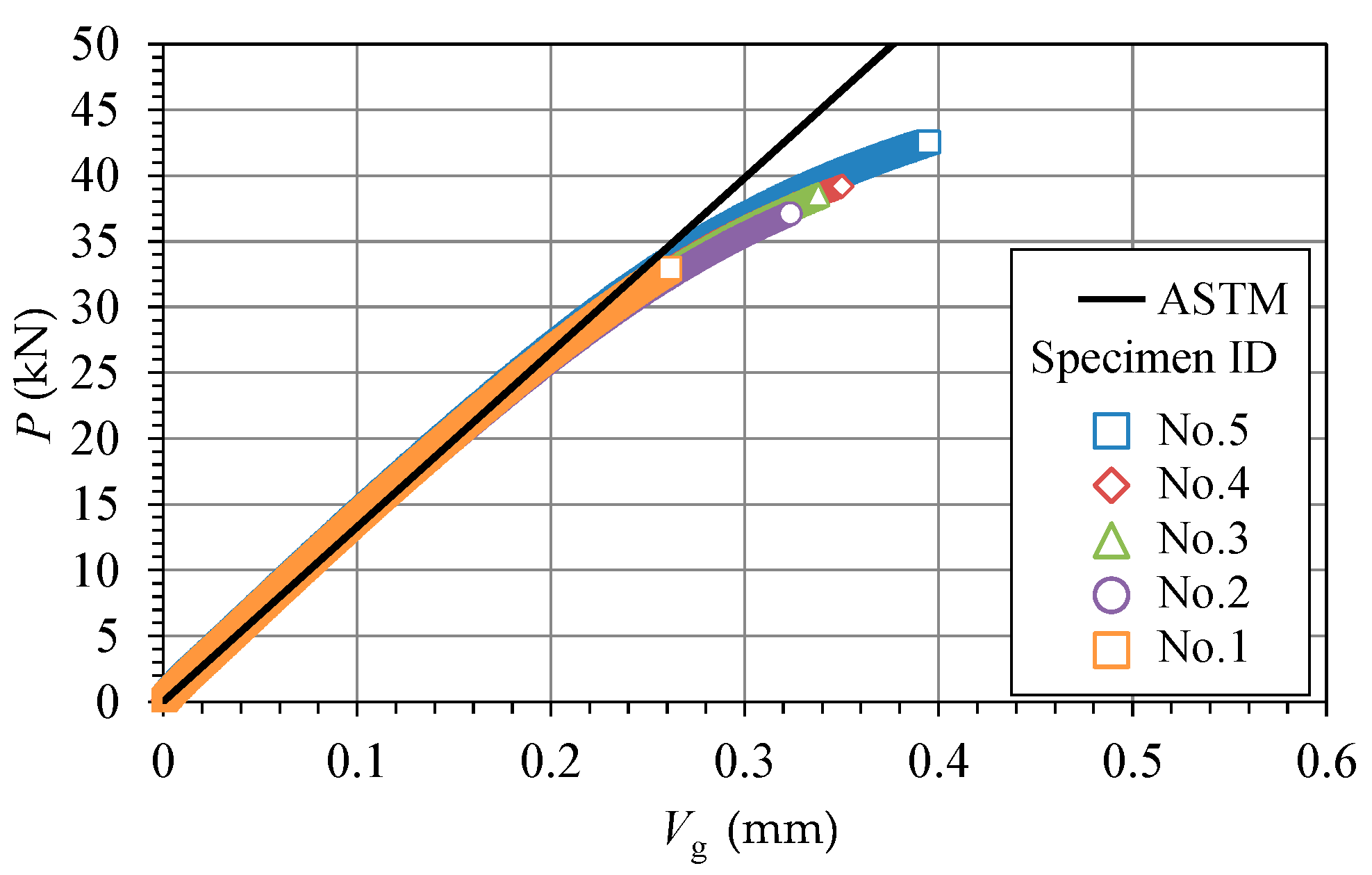

4.2. Fracture Toughness Tests for S45C without CRS

4.3. Selection of Load Ppre to Apply CRS

4.4. Prediction of Fracture Load with CRS

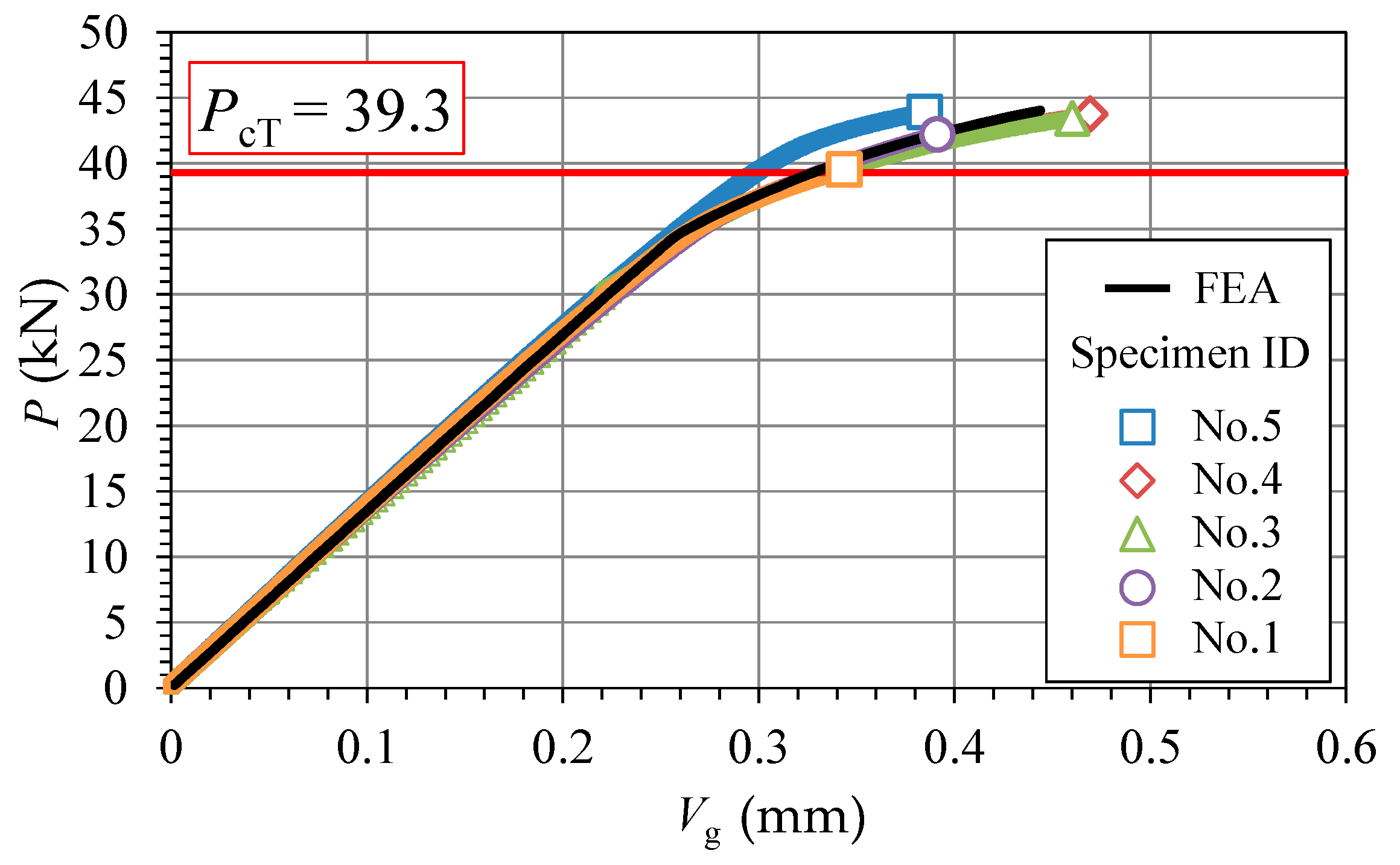

4.5. Validation of Predicted Fracture Load for Specimens with CRS

5. Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| B | Test specimen thickness |

| E | Young’s modulus |

| J | J-integral |

| Jc | Fracture toughness obtained from experimental results |

| Kc | Stress intensity factor corresponding to fracture load Pc |

| Ke | Elastic stress intensity factor |

| KJc | Fracture toughness expressed in terms of K (=(EJc/(1 − ν2))1/2) |

| Pc | Fracture load |

| Ppre | Preload for applying compressive residual stress |

| Vg | Crack-mouth opening displacement |

| W | Specimen width |

| α, n | Parameters of Ramberg–Osgood power law |

| a | Crack depth |

| ε0 | Reference strain for Ramberg–Osgood power law |

| In, | Parameters depending on n and θ for HRR stress solution |

| ν | Poisson’s ratio |

| rT | Intersection point between K and HRR stress distributions (T-point) |

| δt | Crack-tip opening displacement |

| σij | Stress components (i, j = 1, 2, 3) |

| σ0 | Reference stress for Ramberg–Osgood power law |

| σ22HRR | Stress of J-dominated region described as HRR stress distribution |

| σ22K | Stress of K-dominated region described as K stress distribution |

| σ22T | Crack-opening stress σ22 at r = rT |

Abbreviations

| ASTM | American Society for Testing and Materials |

| BS | British Standard |

| CRS | Compressive residual stress |

| CTOD | Crack-tip opening displacement |

| DBTT | Ductile-to-brittle transition temperature |

| EP-FEA | Elastic–plastic finite element analysis |

| HRR | Hutchinson–Rice–Rosengren |

| HT780 | 780-MPa-class high-strength steel |

| JIS | Japan Industrial Standard |

| SE(B) | Single-edge notched bend bar |

| SIF | Stress-intensity factor |

| SSY | Small-scale yielding |

| T-point | Location where σ22HRR and σ22K intersect on x1-axis |

Appendix A

References

- Chell, G.G.; Haigh, J.R.; Vitek, V. A theory of warm prestressing: Experimental validation and the implications for elastic plastic failure criteria. Int. J. Fract. 1981, 17, 61–81. [Google Scholar] [CrossRef]

- Curry, D.A. A micromechanistic approach to the warm pre-stressing of ferritic steels. Int. J. Fract. 1981, 17, 335–343. [Google Scholar] [CrossRef]

- Reed, P.A.S.; Knott, J.F. Investigation of the role of residual stresses in the warm prestress (WPS) effect. Part I—Experimental. Fatigue Fract. Eng. Mater. Struct. 1996, 19, 485–500. [Google Scholar] [CrossRef]

- Pokrovsky, V.V.; Troshchenko, V.T.; Kopcmsky, G.A.; Kaplunenko, V.G.; Fiodorov, V.G.; Dragunov, Y.G. The influence of plastic prestraining on brittle fracture resistance of metallic materials with cracks. Fatigue Fract. Eng. Mater. Struct. 1995, 18, 731–746. [Google Scholar] [CrossRef]

- Okamura, H.; Yagawa, G.; Hidaka, T.; Urabe, Y.; Satoh, M.; Tomimatsu, M.; Koyama, K.; Iida, M. Further experimental verification of warm prestressing effect under pressurized thermal shock (PTS). J. Press. Vessel Technol. 1996, 118, 174–180. [Google Scholar] [CrossRef]

- Cheng, J.; Noble, F.W. The warm prestressing effect in steels undergoing intergranular fracture. Fatigue Fract. Eng. Mater. Struct. 1997, 20, 1399–1411. [Google Scholar] [CrossRef]

- Smith, D.J.; Hadidimoud, S.; Fowler, H. The effects of warm pre-stressing on cleavage fracture. Part 1: Evaluation of experiments. Eng. Fract. Mech. 2004, 71, 2015–2032. [Google Scholar] [CrossRef]

- Jacquemoud, C.; Marie, S.; Nédélec, M. Evaluation of the active plasticity hypothesis as a relevant justification of the warm pre stressing effect. Eng. Fract. Mech. 2013, 104, 16–28. [Google Scholar] [CrossRef]

- Yuritzinn, T.; Ferry, L.; Chapuliot, S.; Moinereau, D.; Dahl, A.; Gilles, P. Warm pre-stressing tests on specimens with semi-elliptical cracks and analysis of the results. Eng. Fract. Mech. 2010, 77, 71–83. [Google Scholar] [CrossRef]

- Van Gelderen, D.G.A.; Rosahl, K.; Booker, J.D.; Smith, D.J. Monte Carlo simulations of the effects of warm pre-stress on the scatter in fracture toughness. Eng. Fract. Mech. 2015, 134, 124–147. [Google Scholar] [CrossRef]

- Rubio-González, C.; Ocaña, J.L.; Gomez-Rosas, G.; Molpeceres, C.; Paredes, M.; Banderas, A.; Porro, J.; Morales, M. Effect of laser shock processing on fatigue crack growth and fracture toughness of 6061-T6 aluminum alloy. Mater. Sci. Eng. A 2004, 386, 291–295. [Google Scholar] [CrossRef]

- Kalentics, N.; Boillat, E.; Peyre, P.; Ćirić-Kostić, S.; Bogojević, N.; Logé, R.E. Tailoring residual stress profile of selective laser melted parts by laser shock peening. Addit. Manuf. 2017, 16, 90–97. [Google Scholar] [CrossRef]

- Huang, S.; Wang, Z.; Sheng, J.; Agyenim-Boateng, E.; Liu, M.; Yang, X.; Zhou, J. Residual stress distribution and microstructure evolution of AA 6061-T6 treated by warm laser peening. Metals 2016, 6, 292. [Google Scholar] [CrossRef]

- Yamashita, Y.; Sakano, K.; Minami, F.; Onozuka, M. Local approach to brittle fracture under residual stress field-Evaluation of effect of compressive residual stress caused by pre-loading. J. Soc. Nav. Archit. Jpn. 1999, 186, 455–463. [Google Scholar] [CrossRef]

- Beremin, F.M.; Pineau, A.; Mudry, F.; Devaux, J.C.; D’Escatha, Y.; Ledermann, P. A local criterion for cleavage fracture of a nuclear pressure vessel steel. Metall. Mater. Trans. A 1983, 14, 2277–2287. [Google Scholar] [CrossRef]

- Mudry, F. A local approach to cleavage fracture. Nucl. Eng. Des. 1987, 105, 65–76. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM). E1921-10 standard test method for determination of reference temperature, To, for ferritic steels in the transition range. In Annual Book of ASTM Standards; American Society for Testing and Materials: Philadelphia, PA, USA, 2010; Volume 3.01. [Google Scholar] [CrossRef]

- Wallin, K. Master Curve Analysis of Ductile to Brittle Transition Region Fracture Toughness Round Robin Data. The “EURO” Fracture Toughness Curve; Technical Research Centre of Finland: Espoo, Finland, 1998; p. 58. ISBN 951-38-5345-4. [Google Scholar]

- Wallin, K. Irradiation damage effects on the fracture toughness transition curve shape for reactor pressure vessel steels. Int. J. Press. Vessel. Pip. 1993, 55, 61–79. [Google Scholar] [CrossRef]

- Wallin, K. Master curve analysis of the “Euro” fracture toughness dataset. Eng. Fract. Mech. 2002, 69, 451–481. [Google Scholar] [CrossRef]

- Wallin, K. The size effect in KIC results. Eng. Fract. Mech. 1985, 22, 149–163. [Google Scholar] [CrossRef]

- Dodds, R.H.; Anderson, T.L.; Kirk, M.T. A framework to correlate a/W ratio effects on elastic-plastic fracture toughness (Jc). Int. J. Fract. 1991, 48, 1–22. [Google Scholar] [CrossRef]

- Kirk, M.T.; Dodds, R.H.; Anderson, T.L. An approximate technique for predicting size effects on cleavage fracture toughness (Jc) using the elastic T stress. In STP 1207, Fracture Mechanics: 24th Volume; Landes, J.D., McCabe, D.E., Boulet, J.A.M., Eds.; American Society for Testing and Materials: Philadelphia, PA, USA, 1994; Volume STP 1207, pp. 62–86. [Google Scholar] [CrossRef]

- Matvienko, Y.G.; Nikishkov, G.P. Two-parameter J-A concept in connection with crack-tip constraint. Theor. Appl. Fract. Mech. 2017, 92, 306–317. [Google Scholar] [CrossRef]

- Nevalainen, M.; Dodds, R.H. Numerical investigation of 3-D constraint effects on brittle fracture in SE(B) and C(T) specimens. Int. J. Fract. 1995, 74, 131–161. [Google Scholar] [CrossRef]

- Theiss, T.J.; Bryson, J.W. Influence of crack depth on the fracture toughness of reactor pressure vessel steel. In STP 1171, Constraint Effects in Fracture; Hackett, E.M., Ed.; American Society for Testing and Materials: Philadelphia, PA, USA, 1993; Volume STP 1171, pp. 104–119. [Google Scholar] [CrossRef]

- Sumpter, J.D.G. An experimental investigation of the T stress approach. In STP 1171, Constraint Effects in Fracture; Hackett, E.M., Schwalbe, K.-H., Dodds, R.H., Eds.; American Society for Testing and Materials: Philadelphia, PA, USA, 1993; Volume STP 1171, pp. 495–502. [Google Scholar] [CrossRef]

- Rathbun, H.J.; Odette, G.R.; He, M.Y.; Yamamoto, T. Influence of statistical and constraint loss size effects on cleavage fracture toughness in the transition—A model based analysis. Eng. Fract. Mech. 2006, 73, 2723–2747. [Google Scholar] [CrossRef]

- Meshii, T.; Tanaka, T. Experimental T33-stress formulation of test specimen thickness effect on fracture toughness in the transition temperature region. Eng. Fract. Mech. 2010, 77, 867–877. [Google Scholar] [CrossRef]

- Meshii, T.; Tanaka, T.; Lu, K. T-stress solutions for a semi-elliptical axial surface crack in a cylinder subjected to mode-I non-uniform stress distributions. Eng. Fract. Mech. 2010, 77, 2467–2478. [Google Scholar] [CrossRef]

- Meshii, T.; Yamaguchi, T. Applicability of the modified Ritchie–Knott–Rice failure criterion to transfer fracture toughness Jc of reactor pressure vessel steel using specimens of different thicknesses—Possibility of deterministic approach to transfer the minimum Jc for specified specimen thicknesses. Theor. Appl. Fract. Mech. 2016, 85, 328–344. [Google Scholar] [CrossRef]

- Lu, K.; Meshii, T. A systematic investigation of T-stresses for a variety of center-cracked tension specimens. Theor. Appl. Fract. Mech. 2015, 77, 74–81. [Google Scholar] [CrossRef]

- Lu, K.; Meshii, T. Application of T33-stress to predict the lower bound fracture toughness for increasing the test specimen thickness in the transition temperature region. Adv. Mater. Sci. Eng. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Lu, K.; Meshii, T. Three-dimensional T-stresses for three-point-bend specimens with large thickness variation. Eng. Fract. Mech. 2014, 116, 197–203. [Google Scholar] [CrossRef]

- Meshii, T.; Lu, K.; Takamura, R. A failure criterion to explain the test specimen thickness effect on fracture toughness in the transition temperature region. Eng. Fract. Mech. 2013, 104, 184–197. [Google Scholar] [CrossRef]

- Meshii, T.; Yamaguchi, T.; Higashino, Y. Applicability of the modified Ritchie-Knott-Rice failure criterion to examine the feasibility of miniaturized Charpy type SE(B) specimens. Adv. Mater. Sci. Eng. 2016, 2016, 3728035. [Google Scholar] [CrossRef]

- Khalili, A.; Kromp, K. Statistical properties of Weibull estimators. J. Mater. Sci. 1991, 26, 6741–6752. [Google Scholar] [CrossRef]

- Sherry, A.H.; Lidbury, D.P.G.; Bass, B.R.; Williams, P.T. Developments in local approach methodology with application to the analysis/re-analysis of the NESC-1 PTS benchmark experiment. Int. J. Press. Vessel. Pip. 2001, 78, 237–249. [Google Scholar] [CrossRef]

- Petti, J.P.; Dodds, R.H. Calibration of the Weibull stress scale parameter, σu, using the master curve. Eng. Fract. Mech. 2005, 72, 91–120. [Google Scholar] [CrossRef]

- Wasiluk, B.; Petti, J.P.; Dodds, J.R.H. Temperature dependence of Weibull stress parameters: Studies using the Euro-material. Eng. Fract. Mech. 2006, 73, 1046–1069. [Google Scholar] [CrossRef]

- Burstow, M.C.; Beardsmore, D.W.; Howard, I.C.; Lidbury, D.P.G. The prediction of constraint-dependent R6 failure assessment lines for a pressure vessel steel via micro-mechanical modelling of fracture. Int. J. Press. Vessel. Pip. 2003, 80, 775–785. [Google Scholar] [CrossRef]

- Qian, G.; González-Albuixech, V.F.; Niffenegger, M. Calibration of Beremin model with the master curve. Eng. Fract. Mech. 2015, 136, 15–25. [Google Scholar] [CrossRef]

- Minami, F.; Brückner-Foit, A.; Munz, D.; Trolldenier, B. Estimation procedure for the Weibull parameters used in the local approach. Int. J. Fract. 1992, 54, 197–210. [Google Scholar] [CrossRef]

- Dodds, R.H.; Shih, C.F.; Anderson, T.L. Continuum and micromechanics treatment of constraint in fracture. Int. J. Fract. 1993, 64, 101–133. [Google Scholar] [CrossRef]

- Ishihara, K.; Hamada, T.; Meshii, T. T-scaling method for stress distribution scaling under small-scale yielding and its application to the prediction of fracture toughness temperature dependence. Theor. Appl. Fract. Mech. 2017, 90, 182–192. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2005; ISBN 9781420058215. [Google Scholar]

- BS 7448-1:1991 Fracture Mechanics Toughness Tests. Method for Determination of KIc, Critical CTOD and Critical J Values of Metallic Materials; BSI Group: London, UK, 1991; Volume BS7448, ISBN 0-580-20037-X.

- McMeeking, R.M. Finite deformation analysis of crack-tip opening in elastic-plastic materials and implications for fracture. J. Mech. Phys. Solids 1977, 25, 357–381. [Google Scholar] [CrossRef]

- Healy, B.; Gullerud, A.; Koppenhoefer, A.R.; RoyChowdhury, S.; Petti, J.; Walters, M.; Bichon, B.; Cochran, K.; Carlyle, A.; Sobotka, J.; et al. WARP3D—Release 17.5.9 Manual; University of Illinois at Urbana-Champaign: Champaign, IL, USA, 2015. [Google Scholar]

- Hutchinson, J.W. Singular behaviour at the end of a tensile crack in a hardening material. J. Mech. Phys. Solids 1968, 16, 13–31. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM). E1820-06a Standard test method for measurement of fracture toughness. In Annual Book of ASTM Standards; ASTM: Philadelphia, PA, USA, 2006; Volume 3.01. [Google Scholar] [CrossRef]

- Ritchie, R.O.; Knott, J.F.; Rice, J.R. On the relationship between critical tensile stress and fracture toughness in mild steel. J. Mech. Phys. Solids 1973, 21, 395–410. [Google Scholar] [CrossRef]

- Pook, L.P. A 50-year retrospective review of three-dimensional effects at cracks and sharp notches. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 699–723. [Google Scholar] [CrossRef]

| Model | ρ (μm) | Rs (mm) | Na | Nnotch | Nlig | Ns | Nθ | Nrings |

|---|---|---|---|---|---|---|---|---|

| Without CRS | 2.5 | 2.56 | 18 | 18 | 18 | 20 | 24 | 50 |

| With CRS | 3.5 | 2.56 | 18 | 18 | 18 | 20 | 24 | 50 |

| T (°C) | σ0 (MPa) | α | n | In | |

|---|---|---|---|---|---|

| 20 | 838 | 2.56 | 19.5 | 4.40 | 2.62 |

| −75 | 938 | 2.56 | 39.8 | 4.40 | 2.62 |

| JIS S45C | C | Si | Mn | P | S | Cu | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Specified | 0.42–0.48 | 0.15–0.35 | 0.60–0.90 | ≤0.030 | ≤0.035 | ≤0.30 | ≤0.20 | ≤0.20 |

| Check analysis | 0.47 | 0.17 | 0.64 | 0.009 | 0.004 | 0.02 | 0.02 | 0.02 |

| T (°C) | σYS0 (MPa) | σB0 (MPa) | Elongation (%) | σ0 (MPa) | α | n | In | |

|---|---|---|---|---|---|---|---|---|

| 20 | 467 | 738 | 22 | 468 | 2.71 | 4.73 | 5.07 | 2.21 |

| −10 | 492 | 770 | 22 | 493 | 2.59 | 4.83 | 5.04 | 2.22 |

| Specimen ID | 1 | 2 | 3 | 4 | 5 | μ | ∑ |

|---|---|---|---|---|---|---|---|

| a/W | 0.50 | 0.51 | 0.50 | 0.50 | 0.50 | 0.50 | 0.00 |

| Pc (kN) | 32.9 | 37.1 | 38.5 | 39.1 | 42.6 | 38.0 | 3.50 |

| Kc (MPam1/2) | 71.9 | 81.9 | 83.3 | 85.0 | 91.6 | 82.7 | 7.09 |

| Jc (N/mm) | 24.8 | 36.0 | 39.3 | 42.0 | 52.1 | 38.8 | 9.87 |

| KJc (MPam1/2) | 77.4 | 92.8 | 97.0 | 101 | 111 | 95.8 | 12.3 |

| M | 453 | 310 | 287 | 269 | 218 | 307 | 88.1 |

| Model | ρ (μm) | Rs (mm) | Na | Nnotch | Nlig | Ns | Nθ | Nrings |

|---|---|---|---|---|---|---|---|---|

| Without CRS | 1.0 | 2.3 | 18 | 18 | 18 | 20 | 24 | 50 |

| With CRS | 1.0 | 2.3 | 18 | 18 | 18 | 20 | 24 | 50 |

| Specimen ID | Predicted | 1 | 2 | 3 | 4 | 5 | μ | ∑ |

|---|---|---|---|---|---|---|---|---|

| a/W | 0.50 | 0.51 | 0.50 | 0.50 | 0.50 | 0.50 | 0.00 | |

| Pc (kN) | 39.3 | 39.5 | 42.2 | 43.9 | 43.4 | 43.8 | 42.6 | 1.83 |

| Kc (MPam1/2) | 84.8 | 85.6 | 93.1 | 94.3 | 94.9 | 95.1 | 92.6 | 3.97 |

| Jc (N/mm) | 38.1 | 41.5 | 51.6 | 52.1 | 66.6 | 69.3 | 56.2 | 11.6 |

| KJc (MPam1/2) | 93.6 | 98.2 | 110 | 110 | 125 | 127 | 114 | 12.0 |

| M | 272 | 217 | 218 | 169 | 163 | 208 | 44.5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meshii, T.; Ishihara, K. Fracture Toughness Prediction under Compressive Residual Stress by Using a Stress-Distribution T-Scaling Method. Metals 2018, 8, 6. https://doi.org/10.3390/met8010006

Meshii T, Ishihara K. Fracture Toughness Prediction under Compressive Residual Stress by Using a Stress-Distribution T-Scaling Method. Metals. 2018; 8(1):6. https://doi.org/10.3390/met8010006

Chicago/Turabian StyleMeshii, Toshiyuki, and Kenichi Ishihara. 2018. "Fracture Toughness Prediction under Compressive Residual Stress by Using a Stress-Distribution T-Scaling Method" Metals 8, no. 1: 6. https://doi.org/10.3390/met8010006

APA StyleMeshii, T., & Ishihara, K. (2018). Fracture Toughness Prediction under Compressive Residual Stress by Using a Stress-Distribution T-Scaling Method. Metals, 8(1), 6. https://doi.org/10.3390/met8010006