Abstract

Microalloying with Sn is a pivotal strategy for enhancing the strength and thermal stability of Al-Mg-Mn-Si alloys by enabling microstructural optimization. This study systematically investigates the influence of 0.1 wt.% Sn on an Al-4.0Mg-1.0Mn-0.2Si alloy through a comparative analysis with a Sn-free counterpart. The experimental methodology included isochronal aging and isothermal aging, room-temperature tensile testing, electrical conductivity measurements, and detailed microstructural characterization via transmission electron microscopy (TEM) and optical microscopy (OM). The results unequivocally demonstrate that Sn addition significantly enhances the alloy’s microhardness, tensile properties, and heat resistance. Specifically, the Sn-containing alloy (1#) achieved a peak hardness of 98.4 HV during a three-stage aging process, which is 14.1% higher than the 84.5 HV of the Sn-free alloy (2#). In the as-rolled state, alloy 1# exhibited ultimate tensile strength (UTS) and yield strength (YS) of 397 MPa and 344 MPa, representing increases of 20.2% and 15.7%, respectively, without compromising ductility. Microstructural analysis revealed that the enhancement is attributed to the Sn-promoted formation of finely dispersed α-AlMnSi precipitates. These precipitates effectively pin dislocations, strengthening the alloy, and simultaneously suppress recrystallization nucleation and growth, thereby elevating the recrystallization temperature and improving overall heat resistance. This work confirms that microalloying with Sn is an effective strategy for developing high-performance Al-Mg-Mn-Si alloys with superior mechanical properties and thermal stability.

1. Introduction

The 5XXX series aluminum alloy, as a non-heat-treatable strengthened aluminum alloy, features low density and exhibits excellent ductility, corrosion resistance, machinability, and weldability [,,]. It is widely used in fields such as shipbuilding, vehicle and aircraft welded components, and structural parts for subway vehicles [,]. However, traditional 5XXX series aluminum alloys possess moderate strength, making them unsuitable for structural components subjected to extremely high loads, and they exhibit poor high-temperature performance, rendering them inadequate for long-term use in high-temperature environments []. The enhancement in their properties primarily relies on work hardening (dislocation strengthening, grain refinement strengthening) and solid solution strengthening induced by magnesium [,,]. Therefore, through meticulous alloy composition design and optimized processing techniques, it is the core approach to tapping the performance potential of this series of alloys.

Microalloying, a core technical approach for optimizing material properties, regulates the microstructure by introducing trace alloying elements (typically with a mass fraction of <1%). This enables targeted strengthening without significantly compromising other properties of the material [,]. Microalloying can notably enhance the strength, toughness, and corrosion resistance of alloys. For instance, the addition of Sc to Al-Mg-Mn alloys not only strongly refines grains during solidification and hot working processes but also forms nanoscale Al3(Sc, Zr) precipitates with extremely high thermal stability when combined with Zr []. These uniformly dispersed coherent precipitates directly improve strength through a strong precipitation strengthening effect while also effectively pinning grain boundaries, inhibiting recrystallization, and stabilizing the microstructure [,]. However, the extremely high cost of Sc limits its large-scale industrial application, necessitating the search for economical alternatives. Some studies have found that an appropriate amount of Si can reduce the poor regions of the dispersed phase, but excessive Si will form Mg2Si phase and segregation, thus leading to failure. The composite addition of Si and Cr can achieve uniform distribution of precipitates throughout the material by complementing the element distribution coefficients []. During hot working (such as rolling, extrusion) or annealing processes, Sn tends to segregate at grain boundaries. It hinders grain boundary migration through the “grain boundary dragging effect,” thereby inhibiting the growth of recrystallized grains. Meanwhile, Sn can act as a heterogeneous nucleation site, promoting an increase in the dynamic recrystallization nucleation rate [,,,].

Mn is the most traditional and crucial microalloying element in 5xxx series alloys. Its primary role is not direct strengthening, but rather to promote the formation of fine, dispersed Al6(Mn, Fe) phases. These phases pin grain boundaries and dislocations, suppressing the material’s tendency for recrystallization during annealing and refining the grain structure. This stabilizes the worked microstructure and enhances both strength and toughness []. The Al6Mn phase is the main strengthening phase in Al-Mn alloys; however, coarse, skeletal Al6Mn phases can easily cause stress concentration at interfaces. Sn can inhibit the growth and agglomeration of Al6Mn phases, resulting in a more uniform phase distribution and reducing microstructural inhomogeneity caused by phase clustering [,,]. The low solid solubility, high diffusion rate of Sn in the aluminum matrix, and its strong binding capacity with vacancies enable trace additions of Sn to significantly influence the aging precipitation process in aluminum alloys, thereby profoundly affecting the microstructure and properties of the alloy []. The diffusion of Sn in aluminum exhibits significant anisotropy, characterized by preferential grain boundary diffusion and extremely slow lattice diffusion. This unique diffusion behavior can substantially alter the precipitation kinetics of aluminum and aluminum-based alloys by modulating the nucleation, growth, and distribution of precipitates []. Introducing Sn into Al-Mn-Si aluminum alloys promotes the formation of α-AlMnSi precipitates, refines them, and encourages their dispersed distribution. It also suppresses their coarsening behavior during high-temperature treatments, thereby improving the thermal stability and strength of Al-Mn-Si alloys []. Based on the role of Sn in Al-Mn-Si alloys, applying Sn to Al-Mg-Mn alloys can prevent the formation of harmful phases, resulting in alloys with higher strength and heat resistance. Furthermore, optimizing rolling processes can enhance material strength and control texture, while appropriate aging treatments can ensure strength after forming [,,]. The Al-Mg-Mn-Si-Sn alloy demonstrates excellent processability, superior machinability, and eco-friendly lead-free characteristics, making it suitable for applications in automotive lightweight components, precision electronic and electrical parts, architectural decoration hardware, non-load-bearing auxiliary structural components in aerospace, and medical device accessories [].

Therefore, investigating the effect of Sn microalloying on the microstructure and mechanical properties of Al-Mg-Mn-Si alloys is of significant importance. Adding Sn element helps to improve the microstructure of aluminum alloys and regulate the phase morphology [,]. In response to the demand for extended service life of Al-Mg-Mn-Si alloys in complex environments, this study utilizes microalloying technology to compare the microstructural and property changes before and after Sn addition. It focuses on examining the influence of Sn on the Al-Mg-Mn-Si alloy and the α-AlMnSi phase, aiming to develop an Al-Mg-Mn-Si alloy with comprehensive performance. This study aims to explore the mechanism of Sn in the Al-Mg-Mn-Si alloy regarding its effect on the α-AlMnSi phase, and to examine its impact on the alloy’s microstructure and properties.

2. Materials and Methods

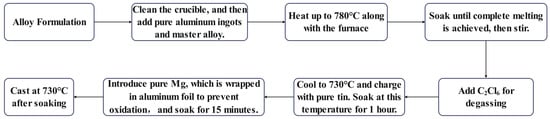

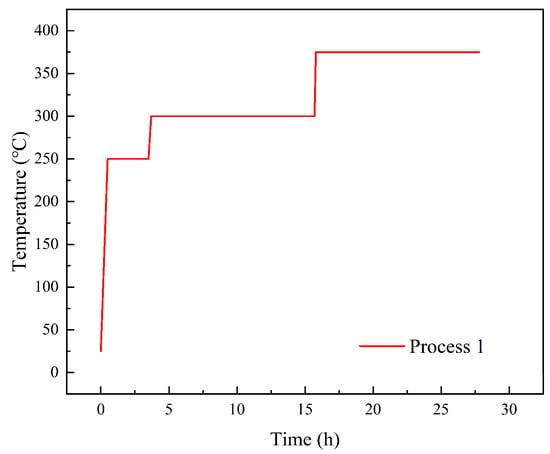

The experimental alloys in this study were fabricated using traditional casting methods with high-purity Al (99.9%), Sn (99.9%), Mg (99.9%), and Al-10Mn and Al-20Si master alloys. The materials were added in the following sequence: pure Al, master alloys, pure Sn, and finally pure Mg. The melting process was conducted at 780 °C, with pouring initiated at 730 °C. The total melting duration was 3.5 h. The melt was cast into a permanent iron mold and subsequently air-cooled. A detailed schematic of the melting process is presented in Figure 1. The chemical composition of the material, as determined by inductively coupled plasma optical emission spectrometry (ICP-OES), is shown in Table 1. The as-cast samples were treated with Isochronal aging and isothermal aging. The rolled material was divided into two groups: one group underwent a three-step homogenization heat treatment at 250 °C/3 h + 300 °C/12 h + 375 °C/12 h (Process 1), The heat treatment process is shown in Figure 2. The non-homogenized group (Process 2) was multi-pass rolled using a two-roll mill (0.3 m/min, 320 mm roll diameter). The alloys were then subjected to multi-pass rolling using a dual-roll mill. They were held at 450 °C and rolled from an initial thickness of 30 mm to 10 mm with a reduction of 1 mm per pass. After air cooling, the material was cold-rolled from 10 mm to 5.5 mm. This was achieved with a reduction of 1 mm per pass, and a final reduction of 0.5 mm in the last pass.

Figure 1.

Flowchart of the Melting Process.

Table 1.

The chemical compositions of experiment alloys (wt. %).

Figure 2.

Heat Treatment Temperature Profile.

The rolled plates were cut into 10 mm × 10 mm × 5 mm cubes. These cubes were wet-ground on a grinding and polishing machine using 800-mesh, 1200-mesh, and 2000-mesh sandpapers sequentially, followed by rinsing thoroughly with alcohol. Hardness testing in this experiment was conducted using an HXD-1000 microhardness tester (Shanghai Taiming Optical Instrument Co., Ltd., Shanghai, China). The tests were performed with a load of 100 gf and a dwell time of 10 s. For each sample, 8 to 10 random indentations were made, and the average value was taken as the final measured hardness.

The electrical conductivity was measured using a SIGMATEST 2.069 portable conductivity tester (FOERSTER, Reutlingen, Germany). The conductivity was measured in %IACS. To ensure accuracy and enable comparative analysis across multiple frequencies, the test frequencies were set at 60 Hz, 120 Hz, 240 Hz, 480 Hz, and 960 Hz. Prior to measurement, all samples were ground with 2000-grit sandpaper to remove surface oxides and impurities, thereby ensuring flat and smooth surfaces. Testing was conducted at room temperature, with five random measurement points selected on each sample to avoid localized anomalies. The average of these five readings was taken as the final conductivity value.

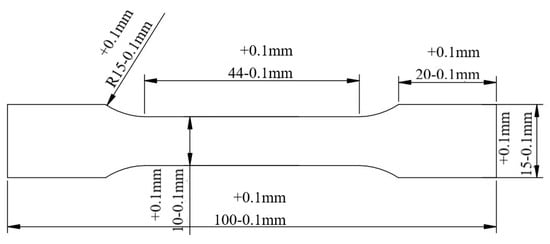

According to the GB/T 228-2002 standard [], the schematic diagram of the tensile specimen design is shown in Figure 3. The sample is cut to the size as shown in the figure by wire cutting. The alloy after rolling treatment was tested on the MTS810 electronic universal testing machine (MTS Systems, Eden Prairie, MN, USA). The orientation of the tensile specimens was kept parallel to the rolling direction, and two parallel specimens were taken for each alloy. Testing rates: A strain rate of 0.015/min was applied before yield, and a crosshead displacement rate of 4.8 mm/min was used after yield.

Figure 3.

Schematic diagram of stretching dimensions.

In this experiment, the metallographic structure was observed using polarized light metallography. The samples were mechanically ground and polished until the surface was bright and free of scratches. The samples were first subjected to electrolytic polishing using an electrolyte solution consisting of 15 mL perchloric acid, 35 mL deionized water, and 450 mL ethanol, applied at a voltage of 20 V and a current of 0.6 A for 15–17 s. Subsequently, anodic coating was performed using the same instrument, with a coating solution prepared by mixing 11 g boric acid, 10 mL hydrofluoric acid, and 980 mL deionized water, applied at a voltage of 15 V and a current of 0.6 A for 90 s.

The microstructure of the alloys, including precipitates and dislocations, was characterized using a JEM-F200 transmission electron microscope (TEM) operated at an accelerating voltage of 200 kV (JEOL Ltd., Tokyo, Japan). The TEM specimens were prepared by electrolytic twin-jet polishing. First, a 0.5 mm thick thin sheet was cut from the ND-RD surface of the sample. Then, it was mechanically ground to 60–70 µm with 800-mesh and 2000-mesh sandpaper. Next, a small circular sheet with a diameter of 3 mm was punched out from the thin sheet. The punched small circular sheet was slightly sanded with sandpaper to remove the burrs on the edges. The double-spray liquid is prepared by mixing 30% nitric acid and 70% methanol. The constant current method is adopted, with a double-spray current of 60 mA and a double-spray temperature of −30 °C.

3. Results and Discussions

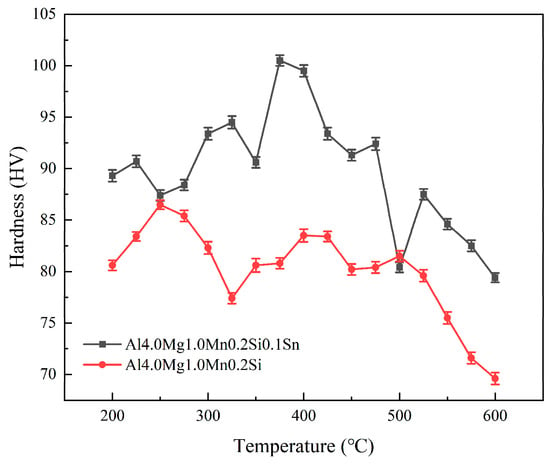

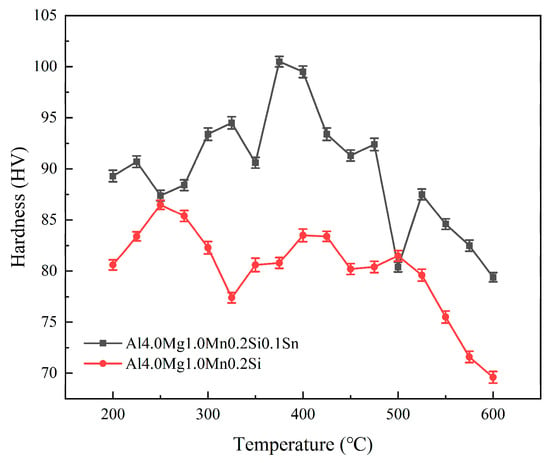

Figure 4 shows the isochronal hardness curves for Alloy 1# and Alloy 2#. Alloy 1# (Al-Mg-Mn-Si-Sn) exhibits significant hardness variation, with a peak hardness of 100 HV, which is 20 HV higher than its minimum hardness. In contrast, Alloy 2# (Al-Mg-Mn-Si) demonstrates relatively stable hardness below 500 °C. Compared to Alloy 2#, the addition of Sn in Alloy 1# likely promotes the precipitation of α-AlMnSi phases, thereby significantly enhancing the microhardness of the Al-Mg-Mn-Si alloy.

Figure 4.

Isochronous hardness curve.

Figure 5 shows the isothermal aging hardness curves of Alloys 1# and 2# at 375 °C following an initial annealing treatment at 250 °C/3 h + 300 °C/12 h. As can be seen from the figure, Alloy 2# exhibits relatively stable hardness, while Alloy 1# maintains a higher hardness level above 90 HV. The microhardness of Alloy 1# shows a significant increase with prolonged annealing time, and the decline in hardness occurs only after an extended duration. This demonstrates that the α-AlMnSi precipitates, whose formation is promoted by Sn, remain stably distributed even at high temperatures. In contrast, Alloy 2# lacks this precipitation strengthening effect from α-AlMnSi, resulting in no significant improvement in its hardness. The isothermal aging hardness curves of both Alloys 1# and 2# further confirm that the addition of Sn can significantly enhance the microhardness of the Al-Mg-Mn-Si alloy.

Figure 5.

Hardness curve after isothermal aging at 375 °C following pre-aging at 250 °C for 3 h and 300 °C for 12 h.

The homogenization treatment (250 °C/3 h + 300 °C/12 h + 375 °C/12 h) was designed based on the precipitation behavior of Sn and hardness data. Sn, with a melting point of 231.89 °C, precipitates at 250 °C. A 3 h hold promotes nucleation without significant coarsening. This is supported by Figure 2 (high hardness at 375 °C) and Figure 3 (stable high hardness after 12 h), validating the chosen parameters.

The Johnson–Mehl–Avrami–Komolgorov (JMAK) relationship is often used to describe the kinetics of isothermal phase transformations, whereby the fraction transformed, X(t), is expressed as:

where k is the rate constant, D is the diffusion coefficient of Sn in Al, and n is dependent on the nucleation mechanism.

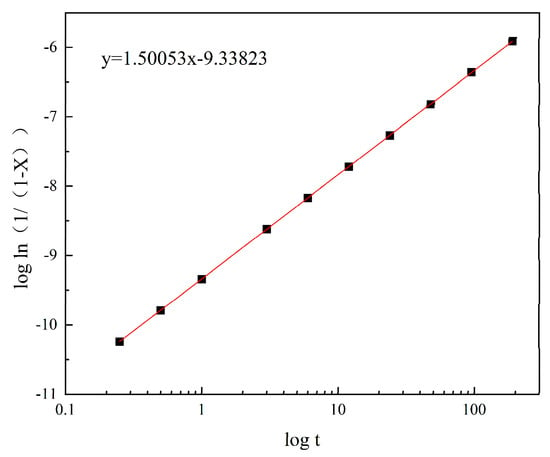

Figure 6 shows the Johnson-Mehl-Avrami-Kolmogorov (JMAK) transformation plot for the isothermal treatment at 375 °C following the 250 °C/3 h + 300 °C/12 h pre-treatment. The fitted line yields an Avrami exponent of n ≈ 1.5, indicating that the precipitation process is dominated by heterogeneous nucleation and one-dimensional growth (such as the directional growth of needle-shaped or rod-shaped precipitates).

Figure 6.

JMAK kinetics model fitting for Alloy 1#.

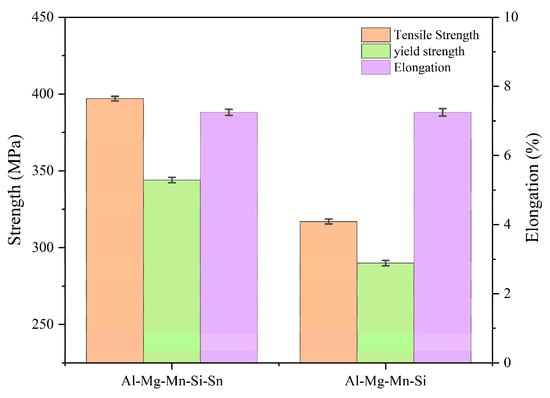

Figure 7 shows the room-temperature tensile properties of as-rolled Alloy 1# (Al-Mg-Mn-Si-Sn) and Alloy 2# (Al-Mg-Mn-Si). For the Sn-containing Alloy 1#, the measured ultimate tensile strength (UTS), yield strength (YS), and elongation (EL) are 397 MPa, 344 MPa, and 7.3%, respectively. For Alloy 2#, the measured tensile strength, yield strength and elongation were 317 MPa, 290 MPa and 7.3%, respectively. Compared with Alloy 2#, Alloy 1# exhibits increases of 20.2% in UTS and 15.7% in YS, while the elongation remains comparable. The comparison of mechanical properties between the Al-Mg-Mn-Si-Sn and Al-Mg-Mn-Si alloys indicates that the addition of Sn significantly enhances the strength (UTS and YS) of the Al-Mg-Mn-Si-Sn alloy without compromising ductility. This demonstrates that Sn addition enables a synergistic optimization of strength and plasticity in the alloy.

Figure 7.

Tensile properties at room temperature in the rolled state.

The yield strength to ultimate tensile strength ratio (YS/UTS) of Alloy 1# is 0.866, while that of Alloy 2# is 0.915. The addition of Sn reduces the YS/UTS ratio by 5.7%, indicating that the alloy maintains its ductility while achieving enhanced strength, demonstrating favorable deformation safety. Conventional 5XXX series aluminum alloys (e.g., 5052, 5083, 5A06) typically exhibit YS/UTS ratios in the range of 0.88–0.93. Alloy 1# (with Sn), with an YS/UTS ratio of approximately 0.866, falls below this conventional range, demonstrating its superior suitability for applications requiring both strength and deformation safety (such as automotive structural components and rail transit parts), effectively balancing load-bearing capacity and resistance to failure.

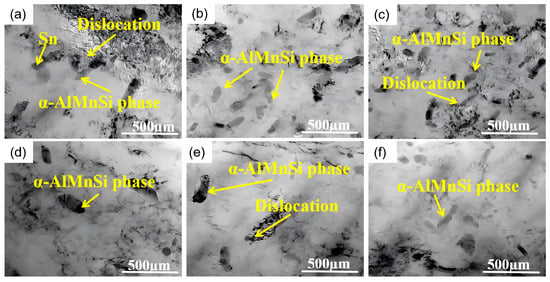

Figure 8 shows the microstructure of the alloys after rolling treatment. Figure 8a–f show the TEM microstructures of the rolled 1# (Sn-containing) and 2# (Sn-free) alloys, respectively. In Figure 8a, the α-AlMnSi phase is observed to precipitate in the vicinity of Sn, indicating that Sn particles act as nucleation sites, thereby promoting the precipitation of the α-AlMnSi phase. As observed in Figure 8b,c, Alloy 1# contains a high density of α-AlMnSi precipitates with a relatively uniform distribution. Numerous dislocations are accumulated around these α-AlMnSi particles. Figure 8d shows the presence of notably coarse α-AlMnSi phases. Figure 8e,f reveals that Alloy 2# exhibits fewer α-AlMnSi precipitates with an inhomogeneous distribution. Dislocations in this alloy do not accumulate near the precipitates but mostly exist as dispersed individual dislocation lines. Overall, the precipitates in Alloy 1# are finer and more densely distributed. The α-AlMnSi phases have an average size of 193 nm in length and 48.1 nm in width, with a number density of 4.8 × 1011 m−3. In contrast, the precipitates in Alloy 2# are coarser and sparser, with the α-AlMnSi phases exhibiting an average size of 263.7 nm by 56.9 nm and a number density of 2.4 × 1011 m−3. Compared with Alloy 2#, the α-AlMnSi precipitates in Alloy 1# are finer and more uniformly distributed, resulting in more effective dislocation pinning.

Figure 8.

TEM micrographs of the as-rolled (a–c) Alloy 1#; (d–f) Alloy 2#.

As evidenced by the TEM micrographs, Alloy 1# demonstrates a higher number density, finer size, and more homogeneous distribution of α-AlMnSi precipitates compared to Alloy 2#. The Al-Mg-Mn-Si alloy containing Sn can promote the precipitation of the α-AlMnSi phase and at the same time cause dislocations to be pinned near the α-AlMnSi precipitated phase. Dislocations being nailed by the precipitated phase can enhance their strength by hindering their movement []. These results confirm that the addition of Sn enhances both the strength and hardness of the Al-Mg-Mn-Si alloy.

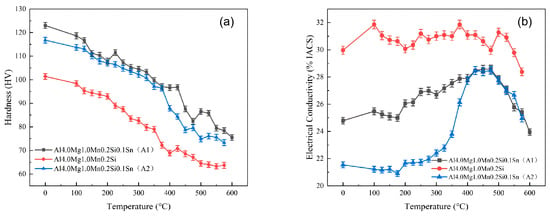

All specimens subjected to recrystallization were in the as-rolled condition, having undergone a three-stage homogenization treatment prior to testing. Figure 9a shows the recrystallization hardness curves of 1# and 2# alloys (after three-stage homogenization). Process 1 (A1) represents the recrystallization curve of the homogenized Alloy 1# (Al-Mg-Mn-Si-Sn) after rolling, while Process 2 (A2) corresponds to the recrystallization curve of non-homogenized Alloy 1#. Comparing processes A1 and A2, the homogenized Al-Mg-Mn-Si-Sn alloy exhibits higher microhardness and a higher recrystallization onset temperature. Homogenization treatment promotes the diffusion of solute atoms, enabling their uniform distribution in the aluminum matrix. These uniformly dispersed solute atoms can more effectively impede dislocation motion, thereby enhancing the material’s microhardness. The comparison between Alloy 1# (with Sn) and Alloy 2# (without Sn) reveals that Alloy 1# has significantly higher microhardness, increasing from 101.4 HV to 123 HV, along with an elevated recrystallization onset temperature from 350 °C to 425 °C. In the recrystallization curves of Figure 6, it can be observed that the microhardness of Alloy 2# decreases from 79 HV to 68.9 HV after 350 °C. For Alloy 1#, the microhardness drops sharply from 96.8 HV to 82.4 HV at 425 °C, indicating the onset of recrystallization. This increase in recrystallization onset temperature indicates that Sn enhances the heat resistance of the alloy, which is attributed to the pinning of dislocations and inhibition of subgrain boundary migration by the Sn-promoted α-AlMnSi precipitates [].

Figure 9.

(a) Recrystallization hardness curve; (b) Recrystallization conductivity curve.

Figure 9b shows the recrystallization conductivity curves of alloys 1# and 2# (after three-stage homogenization). The results demonstrate that homogenization treatment promotes the precipitation of α-AlMnSi phase, enabling its formation at lower temperatures in the Al-Mg-Mn-Si alloy, thereby improving electrical conductivity. However, comparison between Alloy 1# and Alloy 2# shows that Alloy 2# exhibits higher conductivity, indicating that the solid solution of Sn atoms increases electron scattering, resulting in reduced electrical conductivity [].

In the recrystallization curves of Figure 9, it can be observed that the microhardness of Alloy 2# decreases from 79 HV to 68.9 HV after 350 °C. For Alloy 1#, the microhardness drops sharply from 96.8 HV to 82.4 HV at 425 °C, indicating the onset of recrystallization.

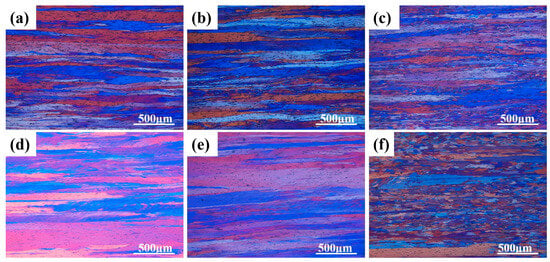

Figure 10a shows the metallographic structure of Alloy 1# (Sn-containing) in the as-rolled state. Figure 10b shows the microstructure of the as-rolled Alloy 1# following a 400 °C/1 h thermal treatment. Figure 10c shows the microstructure of the as-rolled Alloy 1# following a 425 °C/1 h thermal treatment. Figure 10d shows the microstructure of Alloy 2# (without Sn) in the as-rolled condition. Figure 10e shows the microstructure of the as-rolled Alloy 2# following a 325 °C/1 h thermal treatment. Figure 10f shows the microstructure of the as-rolled Alloy 2# following a 350 °C/1 h thermal treatment. After plastic deformation, grains become elongated, forming a fibrous microstructure. During recrystallization, new equiaxed grains (characterized by the absence of deformation features and clearly defined grain boundaries) nucleate and grow. Under polarized light, deformed grains appear as multi-colored “bands” due to their different crystallographic orientations, whereas recrystallized grains exhibit more uniform coloration and an equiaxed morphology []. As observed in Figure 10a,b, the grains along the rolling direction present a fine and disordered elongated fibrous structure, without significant presence of new equiaxed grains. The overall microstructure remains deformed, indicating that recrystallization has not yet occurred. According to Figure 10c, it can be observed that in addition to the existence of slender fibrous deformed grains, there are also some equiaxed regions with relatively uniform coloration and clearly defined grain boundaries. These areas represent newly formed grains generated by recrystallization, indicating that the microstructure has entered the initial stage of recrystallization and the recrystallization process has commenced. Figure 10d,e exhibit coarse, randomly oriented, and elongated grains along the rolling direction. The absence of equiaxed new grains indicates a predominantly deformed microstructure without the onset of recrystallization. Figure 10f shows the metallographic structure of Alloy 2# after treatment at 350 °C/1 h. Observation of the microstructure reveals that the grains still retain a distinct elongated deformation pattern. In addition to the presence of coarse fibrous deformed grains, newly formed equiaxed grains are also visible. This further confirms that the recrystallization start temperature is 425 °C for Alloy 1# and 350 °C for Alloy 2#. The fibrous structure in Alloy 2#, resulting from processing deformation, exhibits greater width compared to that in Alloy 1#. This difference can be attributed to the influence of Sn addition on stress distribution during deformation of the alloy. The presence of Sn enhances grain elongation along the processing direction, resulting in more slender grains [].

Figure 10.

Microstructure of metallographic structure. (a) as-rolled Alloy 1#; (b) 1#heat-treated at 400 °C/1 h; (c) 1#heat-treated at 425 °C/1 h; (d) as-rolled 2#; (e) 2# heat-treated at 325 °C/1 h; (f) 2# heat-treated at 350 °C/1 h.

Based on observations of polarized light metallographic microstructure and grain size, at 425 °C, the original fibrous deformed structure of Alloy 1# begins to exhibit small, uniformly colored equiaxed grains. These equiaxed grains represent newly nucleated recrystallized grains, marking the onset of recrystallization. In contrast, Alloy 2# already begins to recrystallize at 350 °C. Comparing the metallographic microstructures of Alloys 1# and 2#, the addition of Sn promotes the formation of α-AlMnSi phase, which segregates at grain boundaries and dislocation sites, hindering grain boundary migration and dislocation movement. This effect increases the resistance to recrystallization nucleation and growth, thereby raising the recrystallization onset temperature. These findings demonstrate that Sn addition enhances the thermal resistance of Al-Mg-Mn-Si alloys.

4. Conclusions

This study demonstrates that the application of Sn in Al-Mg-Mn-Si alloys effectively enhances their strength and thermal resistance. Based on the experimental results, the main conclusions can be summarized as follows:

- (1)

- In Al-Mg-Mn-Si alloys, the addition of Sn element can significantly promote the formation of uniformly distributed α-AlMnSi precipitates. Sn facilitates the heterogeneous nucleation of α-AlMnSi precipitates, favoring the formation of fine, dispersed, and high-volume-fraction precipitates, which markedly enhances the precipitation strengthening effect. During the three-stage aging homogenization process, the peak hardness of the Sn-containing Alloy 1# increased by 14.1% compared to the Sn-free Alloy 2#, fully demonstrating that the Sn element can enhance the microhardness of the Al-Mg-Mn-Si alloy.

- (2)

- The addition of Sn significantly enhances the mechanical properties of the Al-Mg-Mn-Si alloy, achieving a synergistic improvement in both strength and ductility. In the as-rolled state, the microhardness of Alloy 1# increased by 17.6% compared to Alloy 2#, while the ultimate tensile strength (UTS) and yield strength (YS) increased by 20.2% and 15.7%, respectively, with no reduction in elongation. This demonstrates that Sn not only improves the strength of the alloy but also maintains good ductility, providing a superior performance foundation for broader engineering applications of the alloy.

- (3)

- The addition of Sn enhances the heat resistance of the Al-Mg-Mn-Si alloy by promoting the precipitation of α-AlMnSi phase. Simultaneously, these precipitates can also effectively hinder the slip of dislocations when the alloy undergoes plastic deformation. These precipitates pin dislocations and hinder the migration of subgrain boundaries, thereby increasing the recrystallization onset temperature of the alloy from 350 °C to 425 °C. This improvement enables the alloy to maintain stable microstructural characteristics and mechanical properties at elevated temperatures, expanding its potential for high-temperature applications.

Based on the above findings, the addition of Sn to the Al-Mg-Mn-Si alloy actively and significantly enhances hardness, mechanical properties, and heat resistance by promoting the formation of α-AlMnSi precipitates. This provides an important theoretical basis and practical guidance for the development of high-performance Al-Mg-Mn-Si alloy materials. In future research, further exploration into the optimal Sn content and its synergistic effects with other alloying elements (such as Cr) should be conducted to achieve further performance optimization, meeting the growing demand for high-performance aluminum alloy materials across various industrial sectors.

Author Contributions

Y.C.: Methodology, Conceptualization, Validation, Formal analysis, Writing—original draft, Writing review and editing. S.W.: Methodology, Conceptualization, Formal analysis, Writing review and editing, Resources. X.W.: Formal analysis, Methodology, Conceptualization. K.G.: Formal analysis, Methodology, Conceptualization. L.R.: Formal analysis, Methodology, Conceptualization. W.W.: Formal analysis, Conceptualization, Resource. H.H.: Formal analysis, Resource, Conceptualization. Z.N.: Formal analysis, Resource, Conceptualization. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Advanced Materials-National Science and Technology Major Project (No. 2025ZD0611900); the National Natural Science Foundation of China (52494943); the Beijing Lab Project for Modern Transportation Metallic Materials and Processing Technology.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ran, J.; Zhao, J.; Liu, Z.; Zhao, P.; Shi, X.; Dong, X.; Yu, K.; Chen, K.; Liu, M.; Wang, R.; et al. Effect of processing path on microstructure and uniform deformation of Al-Mg-Si alloy sheet. J. Mater. Eng. Perform. 2025, prepublish, 1–13. [Google Scholar] [CrossRef]

- Hu, S.; Dong, Q.; Yao, Z.; Liu, F.; Li, Z.; Zeng, L.; Nagaumi, H. On the role of Zn addition in dispersoid precipitation and associated mechanical properties of Al-Mg-Mn alloy. Mater. Sci. Eng. A 2025, 944, 148864. [Google Scholar] [CrossRef]

- Rao, M.S.; Ramanjaneyulu, S. Influence of FSW and MIG on the mechanical properties of Al-Mg-Mn alloy with minor additions of 0.4% Sc and 0.1% Zr. Stroj. Časopis—J. Mech. Eng. 2024, 74, 135–140. [Google Scholar] [CrossRef]

- Olaf, E. Microchemistry evolution during industrial DC casting and subsequent homogenization of aluminum alloy AlMn0.5Mg0.5 (AA 3105). Mater. Today Commun. 2023, 36, 106724. [Google Scholar] [CrossRef]

- Aravindh, G.; Preetham Kumar, G.V.; Udayabhat, K. Enhancement of mechanical and tribological properties of Sm-modified Al5083 alloy through multiaxial forging. Results Eng. 2025, 27, 105954. [Google Scholar] [CrossRef]

- Algendy, A.Y.; Liu, K.; Chen, X.G. Formation of intermetallic phases during solidification in Al-Mg-Mn 5xxx alloys with various mg levels. MATEC Web Conf. 2020, 326, 2002. [Google Scholar] [CrossRef]

- Liu, Q.; Jin, Y.; Bian, Q.; Yang, H.; Zhang, T.; Li, J.; Wang, J. Influence of the solidification rate on the microstructure and mechanical properties of rapidly solidified Al-Mg-Si alloy. J. Mater. Res. Technol. 2025, 39, 692–702. [Google Scholar] [CrossRef]

- Mofarrehi, M.; Javidani, M.; Chen, X.G. Effect of Mn on hot workability and processing maps of Al-Mg-Mn 5xxx alloys. J. Mater. Eng. Perform. 2023, 33, 11265–11277. [Google Scholar] [CrossRef]

- Engler, O.; Kuhnke, K.; Hasenclever, J. Development of intermetallic particles during solidification and homogenization of two AA 5xxx series Al-Mg alloys with different Mg contents. J. Alloys Compd. 2017, 728, 669–681. [Google Scholar] [CrossRef]

- Ding, Y.; Gao, K.; Guo, S.; Wen, S.; Huang, H.; Wu, X.; Nie, Z.; Zhou, D. The recrystallization behavior of Al-6Mg-0.4Mn-0.15Zr-xSc (x = 0.04–0.10 wt%) alloys. Mater. Charact. 2018, 147, 262–270. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, H.; Nagaumi, H.; Wang, D.; Luo, S.; Dong, X.; Zou, J.; Yang, D.; Cui, J. Effect of microstructure evolution on the discharge characteristics of Al-Mg-Sn-based anodes for Al-air batteries. J. Power Sources 2022, 521, 230928. [Google Scholar] [CrossRef]

- Puybras, M.; Massardier, V.; Barnett, M.; Perez, M.; Dorin, T. Grain structure evolution in Al-Mg(-Sc-Zr) alloys during additive friction stir deposition. Mater. Charact. 2025, 229, 115566. [Google Scholar] [CrossRef]

- Kawahara, Y.; Marioara, C.D.; Hell, C.M.; Thrane, E.S.; Mørtsell, E.A.; Røyset, J.; Holmestad, R.; Kaneko, K. Effect of Cu addition on atomic clusters and its influence on the dispersion of precipitates in Si-rich Al-Mg-Si alloys. Mater. Sci. Eng. A 2025, 946, 149121. [Google Scholar] [CrossRef]

- Liu, C.; Liu, Y.; Huang, Y.; Sheng, Z.; Fan, X.; Wu, Z.; Feng, W.; Liu, P. Investigation of hot deformation behavior and optimization of hot workability for a novel Zr, Sc alloyed Al-Mg-Mn alloy. J. Alloys Compd. 2025, 1017, 178943. [Google Scholar] [CrossRef]

- Lyu, W.; Shen, Y.; Tang, Y.; Yang, K.; Zhou, Z.; Zhao, C.; Lu, Y.; Guo, X. Particle-based friction stir additive manufacturing of an Al-Mg-Mn alloy. Addit. Manuf. 2025, 103, 104768. [Google Scholar] [CrossRef]

- Chen, L.; Liu, K.; Su, R.; Li, G. Effect of Sn element on microstructure and mechanical properties of Al-Cu-Mg alloy. Mater. Today Commun. 2025, 45, 112383. [Google Scholar] [CrossRef]

- Yu, T.; Chen, Y.; Zhang, Y.; Zhang, P.; Zhang, J. Correlated impacts of deformation-induced precipitation and precipitates dissolution on mechanical properties in Al-Mg-Si alloys. J. Alloys Compd. 2025, 1041, 183737. [Google Scholar] [CrossRef]

- Gao, J.; Wei, W.; Shi, W.; Zhou, X.; Wen, S.; Huang, H.; Gao, K.; Wu, X.; Rong, L.; Nie, Z. Enhanced homogeneous dispersoid precipitation by adding Si and Cr in an Al-Mg-Mn alloy. J. Alloys Compd. 2025, 1041, 183857. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; Chen, X.G. Microstructure, elevated-temperature mechanical properties and creep resistance of dispersoid-strengthened Al-Mn-Mg 3xxx alloys with varying Mg and Si contents. Mater. Sci. Eng. A 2017, 708, 383–394. [Google Scholar] [CrossRef]

- Liu, X.; Ma, Y.-L.; Wang, X.; Zhang, S.-Y.; Zhang, M.-X.; Wang, H.-Y. Enhanced long-term thermal stability and mechanical properties of twin-roll cast Al-Mg-Si alloys with Mn and Cu additions. Mater. Sci. Eng. A 2023, 872, 144945. [Google Scholar] [CrossRef]

- Liu, K.; Chen, X.G. Influence of heat treatment and its sequence on elevated-temperature properties of Al-Mn-Mg 3004 alloy. Mater. Sci. Eng. A 2017, 697, 141–148. [Google Scholar] [CrossRef]

- Tong, M.; Yang, J.; Xia, P.; Li, R.; Jiang, F. Influences of trace additions of Sc/Zr elements on high-temperature tensile behaviors of the Al-Mg-Mn alloys. J. Alloys Compd. 2025, 1040, 183681. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, X.; Wang, X.; Liu, Y.; Hu, W.; Guo, Y.; Wu, G. Effect of cerium on electrical conductivity and mechanical properties of Al-Mg-Si alloy. JOM 2025, prepublish, 1–12. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Song, R.; Harada, Y.; Muraishi, S.; Kumai, S.; Maruno, S.; Yoshino, M.; Iwao, S. Microstructure and mechanical properties of high-manganese-containing high-speed twin-roll cast Al-Mn-Si alloy strips and their cold-rolled sheets. MATEC Web Conf. 2020, 326, 6004. [Google Scholar] [CrossRef]

- Akopyan, T.K.; Milovich, F.O.; Lukyanchuk, A.A.; Sviridova, T.A.; Fortuna, A.S.; Letyagin, N.V.; Solovev, I.S. New mechanisms and approaches in design and heat treatment of Al-Cu-Mn-Zr(-Sn, Si) based casting alloys aiming to increase heat resistance via formation of α(almnsi) phase dispersoids assisted by θʹ precipitates. Mater. Sci. Eng. A 2025, 947, 149217. [Google Scholar] [CrossRef]

- Lu, G.; Xu, C.; Wang, X.; Guan, S. Composition optimization of Al-Mg-Mn alloys for continuous casting-direct rolling and influence of Er and Zr on their microstructure and mechanical properties. J. Mater. Eng. Perform. 2023, 33, 10589–10602. [Google Scholar] [CrossRef]

- Pan, S.; Wang, Z.; Li, C.; Wan, D.; Chen, X.; Chen, K.; Li, Y. Achieving superior dispersion-strengthening effect in an aa5xxx Al-Mg-Mn alloy by mico-alloying. Mater. Des. 2023, 226, 111647. [Google Scholar] [CrossRef]

- Li, M.-J.; Liu, S.; Wang, X.-D.; Shi, Y.-J.; Pan, Q.-L.; Zhou, X.-J.; Zhang, R.-F.; Birbilis, N. Improved intergranular corrosion resistance of Al-Mg-Mn alloys with Sc and Zr additions. Micron 2021, 154, 103202. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Li, M.; Lu, G.; Guan, S.; Zhang, E.; Xu, C. Effect of trace elements on the crystallization temperature interval and properties of 5xxx series aluminum alloys. Metals 2020, 10, 483. [Google Scholar] [CrossRef]

- Hu, S.; Dong, Q.; Yao, Z.; Chen, Y.; Yu, B.; Wei, Z.; Nagaumi, H. Sn microalloying-induced enhancement of dispersoid precipitation and mechanical properties in 5083 aluminum alloy. Mater. Lett. 2025, 403, 139457. [Google Scholar] [CrossRef]

- Wang, Y.; Fu, Y.; Yang, B.; Gao, M.; Guan, R. Deformation behavior and microstructure evolution induced by nano-sized Al6Mn phase particles in a homogenized Al–6Mg–0.8Mn alloy during hot compression. Mater. Sci. Eng. A 2023, 882, 145461. [Google Scholar] [CrossRef]

- Sun, Y.C.; Jin, Y.H.; Xu, Z.; Zhao, T.; Li, Q.; Zhu, L.H.; Wang, N. Effect of Mn and Zr microalloy on the recrystallization and solidification behavior of cast-rolled Al-Mg-Si alloy. J. Mater. Eng. Perform. 2024, 34, 17333–17343. [Google Scholar] [CrossRef]

- GB/T 228-2002; Metallic Materials—Tensile Testing at Ambient Temperature. Standards Press of China: Beijing, China, 2002.

- Xing, J.; Lei, G.; Wang, Y.; Bhatta, L.; Kong, C.; Yu, H. Effect of room-temperature pre-rolling and pre-cryorolling on natural aging and bake hardening response of an Al-Mg-Si alloy. Metall. Mater. Trans. A 2023, 54, 3709–3732. [Google Scholar] [CrossRef]

- Algendy, A.Y.; Liu, K.; Rometsch, P.; Parson, N.; Chen, X.G. Effects of almn dispersoids and Al3(Sc,Zr) precipitates on the microstructure and ambient/elevated-temperature mechanical properties of hot-rolled AA5083 alloys. Mater. Sci. Eng. A 2022, 855, 143950. [Google Scholar] [CrossRef]

- Meier, J.; Shin, D.; Poplawsky, J.D.; Allard, L.F.; Cheng, H.; Ohnishi, I.; Bahl, S.; Haynes, J.A.; Vo, N.Q.; Shyam, A. Effect of sn microalloying on the nucleation of l12 Al3Zr precipitates in a dilute aluminum-zirconium alloy. J. Alloys Compd. 2025, 1027, 180433. [Google Scholar] [CrossRef]

- Zerouki, M.; Khouas, A.; Ouali, M.O.; Ben Chabane, N. Experimental and numerical study of the behavior of an almgmn aluminum alloy under different strain rates and temperatures. Procedia Struct. Integr. 2023, 47, 915–918. [Google Scholar] [CrossRef]

- Zheng, D.; Li, J.; Wei, B.; Liang, T.; Yang, Z.; Wang, Z.; Wang, S. Sn–Sc microalloying-induced property improvement and micromechanisms of an Al-Mg-Si alloy. J. Mater. Res. Technol. 2023, 27, 472–489. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).